This is the last issue of Hammer before the kick-off of SEMA Show events, including the Collision Industry Conference (CIC), SCRS’ Repairer Driven Education (RDE) with OEM Summit, and much more. So, I’m going to beat the horse, but it’s not dead yet! By horse, I mean YOU. Not that I’d beat you up for any other reason than I’d love to see you take advantage of one of the biggest “all-in-one” opportunities existing for our industry.

You can attend your regional show,

PRESIDENT Kris Burton kris@rosslynautobody.com - 703-820-1800

VICE PRESIDENT Phil Rice phil@ricewoods.com - 540-846-6617

TREASURER John Shoemaker john.a.shoemaker@basf.com - 248-763-4375

which I’m a huge fan of, and get a load of benefits. At our local tradeshow, you are also participating in your local community and making local connections. If you only had one choice, I may say that’s your best bet. But if you want to take initiative in your business to another level, and garner innovative ideas, then adding the trip to Vegas every year is a no-brainer!

When it comes to the Vegas industry events, it’s another horse race completely. The tradeshow itself is a spectacular reason to make the trek, with booths featuring the latest in tools and equipment, as well as business management products. Kick off the week attending the Collision Industry Conference, where you can actively participate in discussions about the issues and trends our industry faces daily, and into the future. Hear presentations and panel discussions on topics ranging from estimating and repair planning to industry relations, and a variety of topics in between, while networking with the best-in-class folks from every segment of collision repair.

Get smarter – so you don’t have to work harder – by attending classes in the

SECRETARY Barry Dorn bdorn@dornsbodyandpaint.com - 804-746-3928

IMMEDIATE PAST PRESIDENT Steven Krieps steve@gregclineauto.com 304-755-1146

Rodney Bolton (boltonconsulting61@gmail.com) 443-386-0086

Tom Brown (thbrown@ppg.com) 703-624-5819

Torchy Chandler (torchy.chandler@gmail.com) 410-309-2242

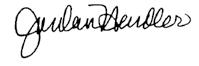

EXECUTIVE DIRECTOR

Jordan Hendler (jordanhendler@wmaba.com) 804-789-9649

WMABA CORPORATE OFFICE

P.O. Box 3157 • Mechanicsville, VA 23116

SCRS RDE series, offering a variety of engaging and informative sessions, which you can see by the coverage in this issue and the September issue. The OEM Summit is part of SCRS’ RDE sessions (page 26), where you hear directly from manufacturers and counterparts, which complement the education series.

Bonus: You can be in Vegas for the election, with much more fun to be had than sitting around the house worrying about the results!

Saddle up, brothers and sisters; it is only a matter of a couple weeks away. There’s still a chance to ride off into the sunset for 2024 with a big win in the city known for going “all in”.

I’ll end on my last pun: Be the horse in the race you place your bet on, and go win! H&D

HAMMER & DOLLY STAFF

PUBLISHER Thomas Greco thomas@grecopublishing.com

SALES DIRECTOR Alicia Figurelli alicia@grecopublishing.com

EDITORIAL DIRECTOR Alana Quartuccio alana@grecopublishing.com

SENIOR CONTRIBUTING Chasidy Rae Sisk EDITOR chasidy@grecopublishing.com

Tracy Dombrowski (tracy@collisionadvice.com) 571-458-0648 Bill Hawkins (hawkinswilliamjr@gmail.com) 510-915-2283

OFFICE MANAGER Donna Greco donna@grecopublishing.com

PRODUCTION Joe Greco

COORDINATOR joe@grecopublishing.com

www.grecopublishing.com @grecopublishing

Benjamin Kimbark has SKILLS!

Kimbark, a 2024 graduate from the Frederick County Career and Tech Center (FCPS CTC) in Frederick, MD, showcased his talents as a collision repair technician when he took first place in the collision repair competition during the Maryland SkillsUSA State Leadership and Skills Conference, held last April. FCPS CTC Collision Instructor Philip Allen acknowledges, “One of my students won the collision repair competition at States in 2023, so I did apply a little fun pressure to Ben to make it two years in a row for us.”

Kimbark has always been interested in the automotive world. “Cars, trucks, tractors…if it had an engine, it had my attention,” he shares. “I’ve been working on engines since before I can remember, and that’s not an exaggeration. I’ve always had a desire to learn more and do more when it comes to hands-on trades. This really started to flourish during the final years of middle school. At that time, I was working on a vast majority of small engines and lawn equipment and would help my father work on their vehicles. Once I heard about CTC and the programs they offered, I knew it was for me. Upon digging into it, the hardest part was picking the class that would benefit me the most and allow further growth of my skills, company and vast network of people.”

Kimbark credits his school and instructor for preparing him for the competition. “Let’s just say I couldn’t have done it without Mr. Allen and FCPS CTC. Mr. Allen has been a great mentor; he deserves more credit than he gets. It’s hard putting up with the same 18 students day to

day for two years, but he never ceases to find a way to keep those who want to learn engaged and learning in a way they enjoy, including giving us the chance to work on students’ vehicles – from my service truck to my buddy’s Mustang. There’s really no way to prepare without hands-on experience.”

Most people experience some anxiety before a competition, and Kimbark is no different, so he acknowledges that he “felt a big wave of relief” after winning the state competition. “I can be pretty arrogant when it comes to things, but I was really just anxious on what the outcome would be, even though I had an idea as to what it would be. Once they called my name, it was a big mix of emotions, like a weight was taken off my shoulders and I had done what everyone expected me to do.”

“Ben’s attention to detail when completing any task is never in question,” Allen adds regarding Kimbark’s performance during the state competition. “His biggest obstacle – like so many of my

past students – has been knowing when to stop or transition. For example, when removing a dent from a damaged panel, knowing when to stop working the metal to avoid stretching or work-hardening it in excess, then knowing when to stop sanding the filler to avoid creating a low spot. I knew if Ben could keep from overdoing it, that he would excel in competition.”

He certainly did excel at the state level, but Kimbark took things a step further when he headed to Atlanta in June to compete against the winners from other states as the Old Line State’s gold medal champion; he placed third among the national competitors, heading home with a coveted bronze medal. But Allen wasn’t surprised by his student’s success.

“With Ben’s abilities and skill level, and after his win at States, I was confident that he would perform well at the national level. Ben’s personality, high level of comprehension and problem-solving

Audi Silver Spring

Direct: 301-890-3015

Fax: 240-471-6103

Email: wholesaless@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Mercedes-Benz Silver Spring

Direct: 301-890-3060

Fax: 301-890-5473

Email: mbsilverspring@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Porsche Silver Spring

Direct: 301-890-3015

Fax: 240-471-6103

Email: wholesaless@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Sprinter Silver Spring

Direct: 301-890-3060

Fax: 301-890-5473

Email: mbsilverspring@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Free delivery on our fleet of 15 GPS-equipped delivery trucks - delivering all Silver Spring brands on the same truck throughout Maryland, D.C. and Virginia

We use IRF automotive systems including CCC, CollisionLink, OPSTrax, partslink24, PartsTrader & RepairLink

Highly knowledgeable, experienced and dedicated wholesale specialist team

Large inventory of OEM parts and tires

Contact our dealers for all your Genuine Parts needs!

BMW of Silver Spring

Direct: 301-890-3015

Fax: 240-471-6103

Email: wholesaless@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Herb Gordon Subaru

Direct: 301-890-3065

Fax: 301-847-2239

Email: herbgordonsubaruwholesaleparts@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Volvo Cars Silver Spring

Direct: 301-890-5456

Fax: 301-847-2239

Email: herbgordonvolvowholesaleparts@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Collision repair professionals often bemoan the scarcity of young people interested in pursuing a career in this industry, but Matt Ingram, auto body instructor for Northern Neck Technical Center (Warsaw, VA), believes this field continues to hold the same appeal it always has, as evidenced by his program’s complete enrollment year after year.

“We run a two-year, ASE-accredited program at a regional technical center serving six school districts, so students get bussed in from up to 40 minutes away,” he says, noting that first-year students attend the morning session, while the afternoon session is reserved for second-year students. “We spark interest in our program by doing a lot of promotion and recruitment directed toward 10th graders in our region. Each school is allotted a day to bring their students, who attend 50-minute sessions in their first and second choice programs. We set up workstations where current students give these prospective students a glimpse of what the class actually entails.

“Each year, we have to turn students away,” Ingram adds, explaining that due to Virginia’s student-to-teacher ratio requirements, each class is capped at 20 students. “We typically have 15 students return the following year and graduate from the auto body program.”

The school also participates in the state’s co-op opportunities, helping students find jobs in various shops, and that has been the most rewarding part of the job for Ingram over the past 18 years. “Seeing my students get hired in the field they studied means we’re doing something right. I can walk into collision shops

in Fredericksburg, MD to Richmond, VA and plenty of places in between and find one of our graduates. Many students who graduated from Northern Neck’s auto body program are now doing great for themselves in this industry, and that’s awesome to see.”

So, why has the industry suffered such a technician shortage if young people remain interested in collision repair? According to Ingram, the issue relates more to retention than attraction. “While we’ve had a lot of success in getting students placed – we’ve established some great partnerships with local MSOs as well as some mom-and-pop shops – a lot of shops that struggle to find new talent just don’t understand how to work with young people.

Recent graduates require guidance, so it’s vital that shops are willing to partner with them and really grow that person into a true technician by helping them develop their skills. Too often, young people get pigeonholed into certain roles, so they become aggravated and end up leaving not just the shop but the entire industry.”

Ingram blames the old-school “caveman mentality” for how many shops treat young workers, and he notes that it’s even worse for a certain demographic. “A lot of young ladies do really well in the auto body program, but in some areas, it’s a challenge to convince shop owners to view them as technicians instead of ‘just a girl.’ I refuse to deal with shops that are so close-minded, but it’s very upsetting to see young collision professionals with so much potential being rejected simply because of their gender.”

Pay is another factor. “A lot of shops want to pay $12-$13 an hour for an entry-level technician, but Walmart and fast food establishments are offering over $17 for unskilled labor jobs. Shop owners and managers need to recognize that these young

technicians are valuable and can be grown into highly skilled technicians if you’re willing to exert the effort. The industry needs to treat them well and pay them properly. Because if you don’t, they are going to accept that job at Walmart.”

Of course, Ingram fully understands how expensive it is to run a collision repair shop; funding the auto body program at Northern Neck presents its own challenges. “We have a high amount of consumables needed to train these students, so we have to beg, borrow and do customerbased work to make up the difference,” he acknowledges. “If our budgetary needs aren’t met, it’s difficult to do the job of training students effectively, but I’ve been very lucky to partner with the local industry – paint companies, jobbers and body shops donate products and materials for students to learn on, plus the Collision Repair Education Foundation does a great job of providing collision programs with funds and resources to stay afloat. WMABA has also donated funds raised at their annual golf outing to support our program. We’re always looking for new ways to overcome our budgetary constraints and finance the program.”

Ingram is grateful that he has a supportive administration that encourages creativity. Last spring, the school hosted a car show as a fundraiser to subsidize costs for Northern Neck students who won their local SkillsUSA competition and went on to compete at the national level. In fact, Ingram’s students have advanced

to the national stage in 17 of the 18 years he’s been teaching. “I’m very proud of that achievement,” he boasts. “That’s quite an accomplishment for a small rural school.”

The program’s success would not be possible without the support of the industry professionals who encourage students in their pursuit of a collision career by participating in the school’s annual career fair, hosting tours of their shops and visiting the program as guest speakers. “We’ve had a lot of WMABA members come in to help connect the dots. We love it when collision repairers come in and talk to the students about the different aspects of this industry. You don’t have to turn wrenches in this field; there are career opportunities in management, parts and on the adjuster side. It’s not always the dirty job it once was, especially with the ADAS on modern vehicles. Tech-savvy students can show up to work in a polo shirt and slacks to run scans and perform calibrations. It’s still a labor-intensive field, but there’s so many different aspects and opportunities for young people to pursue.”

Industry professionals can make an even bigger difference for the Northern Neck auto body program by participating on its advisory board. “It’s a lot of work to maintain our ASE accreditation, and our advisory board helps a lot with that. They participate in curriculum reviews to ensure we stay up-to-date on industry trends and expectations because they are our boots on the ground, so to speak. They also help

with placing students, but joining an advisory board to cherry-pick students is not the right reason to get involved; our committee members understand that the goal is to help the program grow and get stronger. The stronger our advisory board is, the stronger our program will be.” Northern Neck will be seeking new advisory board members beginning in October.

For more information on the program, visit northernnecktech.org/programs/ auto_body. Industry professionals interested in joining the advisory board, presenting to the students or hosting shop tours, contact Ingram via email at mingram@ northernnecktech.org H&D Shaping

This year, as Albert Kemperle Inc. celebrates its 83rd anniversary, BASF also celebrates its 158th anniversary. We are proud of our decades of partnership with BASF and years of serving the auto paint and body industry together. Kemperle’s founders would be proud of this relationship and the growth their company has experienced because of it.

Today, as we look forward to many more decades of service to our customers, we find ourselves filled with gratitude. The creativity, hard work, and sense of responsibility of the people working for our two companies have made us what we are today.

Thank you for your many years of loyalty.

626 E. Elizabeth Ave., Linden, NJ 07036 Phone: (908) 925-6133

(908) 925-4344 414-416 Madison Ave., Paterson, NJ 07524 Phone: (973) 279-8300

631 Clifton Ave., Toms River, NJ 08753 Phone: (732) 797-3942

(973) 279-9030

(732) 797-0774 100 Melrich Road, Cranbury, NJ 08512 Phone: (609) 860-2800

(609) 860-2801 4 Emery Ave., Randolph, NJ 07869 Phone: (862) 244-4818

(862) 244-4822 www.kemperle.com

Quality repairers need quality tools to ensure precision in every job, every time. The RAE – Wieländer+Schill XPress 800 Riveting System provides a variety of options for all riveting needs, offering excellent accessibility and effortless maneuverability regardless of the nature of repairs needed.

Vans. Born to run.

Get your customers back on the road faster with Genuine Sprinter Parts.

Call our Sprinter Certified Parts Advisors today to get started.

Sprinter Silver Spring 3301 Briggs Chaney Rd. Silver Spring, MD 20904

The XPress 800 is made even more user-friendly with easily interchangeable adaptors, while being lightweight and effortlessly maneuverable. Its power control system includes a convenient STOP key, allowing you to halt tool advancement for adjustments without releasing pump pressure.

301-890-3060 Fax: 301-890-5473

mbsilverspring@mileone.com

The XPress riveting system provides versatility by accommodating various tools for diverse functions and applications, with several customizations available to accommodate any repair needs. Thanks to its modular design, this device seamlessly integrates with a range of hydraulic cylinders and designated C-arms, enabling pressure control for self-piercing rivets, flow form rivets, blind rivets, punching and blind rivet nuts (when appropriately configured). The basic, standard and full set options offer versatility and portability, enabling repairers to locate the system wherever the job requires. Additional kits are available for specific manufacturers, allowing facilities to adhere to OEM requirements and repair procedures wherever necessary.

At RAE, we recognize that the right tools are only half of the

The XPress 800 Riveting System offers options and customizations to handle a wide variety of repairs.

Give your customers the reliability and quality of Genuine Parts.

Hours: M-F 7:30am-5pm, S 8am-3pm For your Volvo parts needs, please

get started.

301-890-3060 Fax: 301-890-5473 mbsilverspring@mileone.com Hours: M-F 7:30am-5pm, S 8am-3pm

equation. That’s why we provide comprehensive training with the purchase of tools like the XPress 800, ensuring technicians can confidently master the equipment and perform repairs with precision. This commitment to training helps facilities not only meet, but exceed, OEM standards.

To learn more about the XPress 800 system and our full product offering, visit raeservice.com, and visit RAE at SEMA 2024 in the South Upper Hall, Booth #32135.

Contact our team of Mercedes-Benz Certified Parts Advisors today to get started.

Mercedes-Benz Silver Spring 3301 Briggs Chaney Rd. Silver Spring, MD 20904

301-890-3060 Fax: 301-890-5473

mbsilverspring@mileone.com

Hours: M-F 7:30am-5pm, S 8am-3pm

Exceptional service and expert assistance to surpass your expectations

The competition skips procedures like alignments, test drives and checking all ADAS systems. At ADAS Elite, we run all processes and check all systems to ensure your customers are back on the road quickly and safely, with a focus on transparency and warmth. Our dedicated team offers honest guidance and unwavering support - including free pick-up and delivery.

Services including:

• Electrical diagnostics & repair

• Wiring harness replacement & repair

• Installing, programming & reprogramming computer modules

• Problem car diagnostics & repair

• AND MORE!

At ADAS Elite, we offer more than services; we offer a partnership built on trust, quality, and a commitment to excellence.

ADAS calibration is the precise adjustment of your vehicle’s sensors and cameras, essential for the optimal functioning of advanced safety systems. This process is especially critical following significant repairs, part replacements, collisions, or windshield replacements, as these events can disrupt sensor alignment.

It’s important to avoid driving without proper sensor calibration. Uncalibrated ADAS sensors can compromise your vehicle’s safety features, leading to potential malfunctions and driving hazards.

The calibration of ADAS can be performed in two main ways: static and dynamic. Static calibration takes place in a controlled environment, ensuring accuracy and consistency. Dynamic calibration, on the other hand, involves driving the vehicle under specific conditions to fine-tune the sensors in real-world scenarios. This comprehensive approach ensures that your vehicle’s safety systems are reliable and effective, providing peace of mind on the road.

Just like drivers purchase auto insurance policies to cover them in the event of a loss, shop owners invest in business insurance that will protect their assets if the unthinkable happens…but is it enough?

According to Peter Kelyman of Wheaton Body Shop (Wheaton, MD), it probably isn’t, especially if your policy was written years ago and simply renewed without being thoroughly reviewed! Unfortunately, Kelyman learned this lesson the hard way when his shop went up in flames – literally! He agreed to share his story with Hammer & Dolly in hopes of preventing other shop owners from suffering a similar scenario.

Kelyman first met the previous owner of Wheaton Body Shop in 1995 when he worked as a delivery driver, and two years later, he sought a part-time job there while attending school. He started out washing cars and sweeping floors before moving up to receiving parts, writing estimates and eventually being promoted to assistant manager. In 2002, Kelyman became the shop manager; he bought the shop in 2007 and continued to build on the business’s reputation for quality repairs and customer service.

As the owner of a successful business, Kelyman made sure that his bills were paid, his equipment was updated as needed and his shop was insured, of course. “You never think something horrible is going to happen to you, but we were prepared if something did. Or at least, that’s what I thought,” Kelyman laments, stressing, “I want everyone to know what happened to me so they can learn from my situation and protect themselves.”

When tragedy struck on April 26, 2023 via an accidental fire that raged through the building, Kelyman’s initial thought was relief that no one was hurt. “Our employees were safe. None of the firefighters were injured. The fire didn’t even spread to the other buildings.

“But the damage to our facility was extensive,” he adds. “The whole building was completely burned inside; it was a total loss. Half the cars in the shop burned completely before the fire could be extinguished, and the other cars were so damaged by smoke that cleaning them was impossible and they also got totaled. All of our equipment in the shop and the office were either directly destroyed by the fire or damaged beyond repair by the smoke. Although our roof initially survived the fire, the shell of a building beneath did not provide enough support, so it ultimately collapsed from the weight of water from putting out the fire and subsequent rains.”

Over $2 million in damages – $1 million for the building and another $1 million to cover the shop’s contents and customers’ cars – was the final loss tally, but the actual cost would turn out to be higher as the process of filing a claim and learning how much the shop was underinsured would cause a lot of undue stress on Kelyman.

How exactly did the shop come to be underinsured? “There were a couple different factors,” Kelyman explains. “First, we had our policy set up 10 years ago based on an estimate of the building set to account for an annual inflation increase of five percent.

PHOTOS: An accidental fire at Wheaton Body Shop resulted in a final tally of over $2 million in damages to the shop’s contents and customers’ cars, a total loss on the building and months of stress following the claims filing process.

Each year, we renewed without considering the fact that, over the past five years, inflation has been substantially higher than what was stipulated in the policy, so when it came time to make a claim, we realized that inflation had outpaced our policy increases and found ourselves in a situation where our insurance was not enough to cover the cost of repairs to the building and the cost of the building’s contents.”

It’s important to Kelyman that other shops learn what happened to Wheaton Body Shop so they can protect themselves from suffering a similar fate. “Contact your insurance provider to review your policy, understand what’s covered and determine if you need to increase coverage,” he advises. “It may be worth the time to inventory your equipment, tools and supplies to ensure you truly know what it would cost to replace it. Don’t forget to account for your employees’ toolboxes, which are considered personal property but can be quite expensive to replace.”

Shop owners who lease the land where their business is located should also examine whose policy covers the building and its contents, according to Kelyman. “It works differently if you don’t own the land, so just do your research to make sure you’re covered adequately. Just like the cost of everything in our industry, the cost of building materials has skyrocketed over the past few years, so your policy probably needs to be increased to account for those changes if you haven’t updated it lately.

“It’s like the story of the boiling frog; throw it in hot water, and it will jump out, but if you boil it slowly, it will boil to death,” Kelyman analyzes the situation. “We get so used to these small increases that we don’t pay attention. Sometimes, we have to slow down from the daily grind to tend to these types of business needs.”

Kelyman also suggests making sure that any contingencies on the policy are up-to-date. In his situation, the initial policy included a lien by an equipment leasing company, and although the lease was paid off years ago, the company was never removed from the policy. “We just never thought of it, but the insurer couldn’t give us the money without proof that we had paid them off. Meanwhile, that company had gone bankrupt, so we had to track down the company that bought them to verify they had no claim against our policy. And even after we resolved the issue, the insurer still wrote the check out to the wrong party and took months to reissue a check.”

Shops should also keep in mind: an insurer is an insurer is an insurer, as Kelyman was repeatedly reminded during the claims process. “The insurance company’s goal is minimizing losses, not helping us get back in business. It took three times longer for them to provide reports than it took for our public adjusting company (and I highly recommend hiring someone who will make sure you’re properly indemnified if you have a loss). Then, they would use reports contrary to our agreements. It basically took six months for them to provide the money for the building and its contents, so we were stuck at a standstill for half a year. So, even if you do have adequate coverage, don’t expect that money to be readily available!

“Additionally, the policy calls for continuing business coverage,” he points out. “They gave us a very small amount two months after

Catastrophes may strike without warning, but being proactive can help shop owners avoid becoming the next tragedy.

Unfortunately, a lot of collision repair facility owners do not have enough coverage through their business insurance, according to David Willett of Spark Underwriters. “From a risk management standpoint, it’s just as important to make sure your insurance policy reflects today’s needs as it is to send your technicians to training or to invest in current tools; it’s an aspect of running a fine-tuned, efficient business,” he insists, recommending an annual review of one’s policy at a bare minimum, though his company monitors their policyholders’ companies on an ongoing basis.

“We’re unique because this is our only industry,” Willett points out, acknowledging that a handful of carriers specialize in offering coverage to collision shops. “When dealing with customers’ insurance policies, shops are apt to complain about how little insurance companies know about the collision business, yet those are the same companies they insure their businesses with. It’s easy to put a picture of a car at the top of your paperwork, but that’s meaningless if you don’t know what it takes to repair today’s vehicles. This is such a unique industry; choosing a provider that understands this field goes a long way toward ensuring your shop has adequate coverage.”

It’s imperative that shops consider possible exposures that may necessitate additional coverage, such as cybersecurity risks and employment practices liability insurance (EPLI), while also identifying irrelevant and outdated coverages that should be removed from the policy. Willett also believes it’s a good idea for insurers to run building appraisals on a regular basis, rather than just increase coverage by a certain percentage, so that building costs and new zoning laws are taken into consideration.

Shop owners commonly question whether their technicians’ tools are covered under the business’ policy or if each employee is required to insure their own toolbox. “While your employees’ homeowners or renters policy can include coverage for their tools, they shouldn’t have to. It’s much cheaper for the shop to insure than for the individuals to add tools to their policies; it typically costs them as much as eight times what it would cost the shop.”

In fact, Spark Underwriters recommends it so strongly that they built it into their standard policy with far fewer restrictions than many others offering the coverage, Willett explains, advising shops to include it in their employee handbook as an employee benefit. “Encourage employees to submit pictures and/or receipts of their tools each year to capitalize on this unique offering. Think about it – technicians are not exactly in abundant supply, so covering their tools as an employee benefit is just another way to demonstrate that you’ve got their back.”

Reliable Automotive Equipment (RAE) is the premier OEM Collision Repair equipment supplier, o ering tailored solutions to the automotive aftermarket. With a focus on innovation and customer satisfaction, RAE provides quality products and expert support globally, serving as a trusted advisor to vehicle manufacturers and collision repair facilities. In addition to selling equipment, RAE o ers comprehensive repair and maintenance servicing for all our products. We also provide specialized training services, ensuring technicians possess the skills necessary to e ectively understand and utilize our equipment.

After purchasing our equipment, RAE will reach out to you annually or semi-annually to perform routine maintenance services. Should any issues arise or if something isn't functioning correctly, we also provide repair services to promptly restore your equipment to optimal certified operation.

RAE provides extensive training services focused on essential equipment. We understand the importance of keeping your technicians well-educated and informed, which is crucial for both OEMs and our commitment to your operational success. For added convenience, we provide detailed training videos on YouTube, accessible whenever you need them!

continued from pg. 18

the fire, but for six months, we were paying our employees and the shop’s bills with next to nothing from the policy. We had to use our business savings to stay afloat. From dealing with them on auto policies, we already know that insurers take their sweet time responding and don’t care, but it’s even worse on this side of the business. There’s absolutely no sense of urgency. Their primary purpose is to save money; we’ve had to retain a lawyer to sue for some of the losses that still haven’t been covered.”

In addition to the lack of money, Kelyman has faced a number of issues with the rebuild. He warns that there are permitting

challenges, a lack of materials and a labor shortage. “There’s a matter of scheduling and getting things organized. It’s very complicated, and we’re only halfway there. Getting the permits to start construction presented challenges, and then there’s weather delays and all manner of nonsense to contend with.”

Kelyman is grateful to the support he has received from his friends and members of his community who have made donations to help sustain the shop and its employees. “It’s very touching and rewarding to see all the work you’ve done to help people being acknowledged through their support in these difficult times. What we do isn’t just about earning a living; it’s also about helping people get their lives back together after an accident, and for our community to recognize that service and return that aid to help us rebuild so we’ll be able to serve them again – well, it’s very motivating and helps me push through some of the challenges we’ve faced during this rebuilding process.”

Wheaton Body Shop is still under construction with quite a road ahead before the facility can be reopened, and Kelyman reminds shop owners to take steps to avoid dealing with this type of situation. “When you’re running a small business and constantly dealing with the rigors day in and day out, it’s easy to forget to pay attention to all the details. But these things need an additional look on a regular basis. God forbid something bad happens, but once it does, it’s too late. I hope this story inspires other shop owners to review their policies and take actions to protect themselves.” H&D

I N S T A L L A T I O N & S E R V I C E

There’s only one place to go to get the latest information on innovative automotive technology, and those looking to take their level of knowledge to new heights are securing their spots to attend the the Society of Collision Repair Specialists’ (SCRS) OEM Technology Summit on November 7 during SEMA 2024 in Las Vegas.

With just one month to go, details are rolling in about what one can expect to take away from this year’s anticipated sessions. Because collision repair centers have an increasing responsibility around proper repairs that follow prescribed repair processes, the OEM Summit sets out to offer attendees the opportunity to learn how vehicles, materials, technologies and trends are evolving in ways that will impact repair processes and repair businesses.

Information will feature members of the Rivian Research, Engineering, Service and Collision teams, who will present on the process an automaker undertakes to research, develop, validate and publish new repair procedures for the industry. Expected presenters include David Sosa (manager, Collision Research & Development Workshop for Rivian), Dan Black (senior manager, Service Engineering - Collision for Rivian) and Kelly Logan (director, 3P Service and Collision Repair Program for Rivian).

“I’m personally really excited for this Summit delivery,” expresses SCRS Executive Director Aaron Schulenburg. “I think the topics are a direct reflection of the complex conversations taking place in the industry today and fit perfectly with the intention behind why the Summit was created in the first place. Having worked with the Rivian team on the overview of this segment, there is a lot of really fascinating material they intend to share with the industry surrounding the exhaustive efforts that go into procedure development to make sure it is a safe and validated approach to repair. I think seeing behind the scenes is going to place added emphasis on the need to adhere to the documented and prescribed steps.”

This discussion will dive into the developmental life cycle of the front frame rail section concept. Field data has shown that the front frame rail could incur damage even in low-speed impact, and the market would benefit

Taking things further with telematics. BY

ALANA QUARTUCCIO

from a safe and cost-effective alternative to a complete “skateboard” replacement. Those in attendance will receive a unique overview with visual examples of the testing methods involved, which mirrors the protocol used in the manufacturing process in many cases. They will also walk away with an understanding of the consequences of improper repairs and learn the process for validating the outcome of misplaced welds, incorrect cut or section locations and the effect on non-visible structural aspects on the vehicle.

“This session is really the epitome of what the OEM Summit was designed to accomplish for the industry,” shares SCRS Chair Amber Alley. “We’ve always worked hard to bring presenters and content that provide the repair industry with insight into leading-edge developments in repair. This team and the case study they have to share with the industry are testaments to the dedication and responsiveness OEMs have to real-world demands and the complexity that goes into developing the available information used to result in safe and proper repairs. I’m personally very excited to learn from this session and bring it home to my team.”

Want to learn more from this cutting-edge electric vehicle manufacturer? SCRS is inviting SEMA Show attendees to join the Rivian Collision Network and Engineering teams in their booth (31147) on the Upper South Hall of the Las Vegas Convention Center to explore and discuss a speciality-built Rivian R1S body in white (BIW) which highlights the Rivian material matrix.

Session II: How Telematics Technologies are Evolving the Consumer Experience will feature panelists Ryan McMahon (senior vice president of Strategy & Corporate Development at Cambridge Mobile Telematics [CMT]), Hilary Cain (senior vice president of Policy, Alliance for Automotive Innovation) and John Eck (head of product - Collision Assistance, Global Strategy & Innovation at General Motors) who will dive into how these technologies are changing the consumer experience. Telematics continues to redefine the relationships between the driver, the vehicle, collision repair businesses and auto insurance providers because information continued on pg. 28

continued from pg. 27

is delivered differently, more accurately and timely thanks to the ability to share real-time data from crash scenes. Enhanced crash detection, accident reconstruction and consumer communication have all evolved as a result.

These revolutionary changes will be explored in this session as panelists explore the impact of these changes and weigh in on new industry standards for safety, satisfaction and technology integration.

Schulenburg is “excited that we get to bring new voices to the stage. I’ve worked very closely with Hilary Cain over the past several years and am glad that we get to welcome her to the Summit stage for the first time. I’m just grateful we have platforms such as this to showcase the impressive perspectives she and the rest of our panelists have on the way that technology intersects with the consumer experience.”

Details on the third session were still in the works at the time of this writing, so be sure to check out scrs.com/rde as it gets closer to November!

Although it is one of the most well-attended events SCRS presents, one would be doing themselves a disservice if they were to miss any of the other stellar presentations the Repairer

Driven Education series has in store on Tuesday, November 5 and Wednesday, November 6. For a refresh on what’s to come, check out our feature in last month’s Hammer & Dolly at grecopublishing.com/hammer-and-dolly-september-2024.

Also, be sure to make time for the IDEAS Collide showcase taking place on Wednesday from 2:30pm to 4pm.

Registration is open for automotive and collision repair professionals to attend SEMA at semashow.com. Sign up for SCRS’ RDE series at scrs.com/rde and don’t miss out on your chance to learn from the best of the best! Make your plans to attend SEMA 2024 today. H&D

The OEM Summit is a great example of one of the many opportunities collision repairers have to hear directly from the “top” levels of companies about repair. Besides OEs, repairers can hear directly from the horses’ mouths in many of the Repairer Driven Education classes. It matters who we get our information from, and SCRS goes straight to the source! - Jordan Hendler

THEY’RE CALLED “ORIGINAL BMW PARTS” FOR GOOD REASON. FOR UNCOMPROMISING PRECISION AND INCOMPARABLE QUALITY, YOUR BMW CENTER IS YOUR ONE-STOP SHOP FOR EVERYTHING

For Original BMW Parts, contact one of these authorized BMW centers:

BMW of Silver Spring 3211 Automobile Blvd

Silver Spring, MD 20904 866-737-8937

Direct: 301-890-3015

Fax: 301-890-3748

Email: wholesaless@mileone.com bmwofsilverspring.com

Passport BMW 5000 Auth Way Marlow Heights, MD 20746

301-423-0733

Fax: 301-423-2717 passportbmw.com

Richmond BMW 8710 West Broad Street Richmond, VA 23294

800-237-0130

Direct: 804-527-6860

Fax: 804-965-6254

Email: tdailey@crownauto.com richmond-bmw.com

BMW of Catonsville 6700 Baltimore National Pike Baltimore, MD 21228

855-996-2906

410-744-2000

Fax: 410-818-2600

bmwofcatonsville.com

You’ve got the right tools, staff, technology and procedures to give your customers the best repair possible. The missing piece of the puzzle? Genuine Volkswagen Collision Parts. Contact an authorized dealer today and find your perfect fit.

Alexandria Volkswagen 107 West Glebe Rd. Alexandria, VA 22305

703-684-7007

Fax: 703-684-4138

e-mail: parts@alexandriavw.com

Karen Radley Volkswagen 14700 Jefferson Davis Hwy. Woodbridge, VA 22191

703-550-0205

Fax: 703-643-0081

Ourisman Volkswagen of Bethesda 5415 Butler Road

Bethesda,MD 20816

301-652-2452

Fax: 301-652-2589

e-mail: vwwholesale@ourisman.com

Fitzgerald Volkswagen 114 Baughmans Lane

Frederick, MD 21702

Toll Free: 800-545-4745

Fax: 877-696-1841

e-mail: parts@fitzmall.com www.fitzparts.com

Fitzgerald Volkswagen of Annapolis 34 Hudson Street Annapolis, MD 21401

Phone: 410-224-4636

Fax: 410-224-4264 www.fitzmall.com

Ourisman Volkswagen of Laurel 3371 Ft. Meade Rd. Laurel, MD 20724

Phone: 301-498-6050

Fax: 301-498-0157 www.laurelvolkswagen.com

Ourisman Volkswagen of Rockville

801 Rockville Pike

Rockville, MD 20852

Parts Direct: 301-340-7668

Toll Free: 855-417-4511

Fax: 240-499-2488

e-mail: rockvilleparts@ourismanautomotive.com www.ourismanvolkswagenofrockville.com

“Volkswagen“ and the Volkswagen logo are registered trademarks of Volkswagen AG. ©2024 Volkswagen of America, Inc.

Wholesale Parts

continued from pg. 6

skills make him a pretty formative competitor. He had a good week in Atlanta. He didn’t let any of the distractions of working in a big environment affect his performance at all. We are all really proud of what Ben accomplished.”

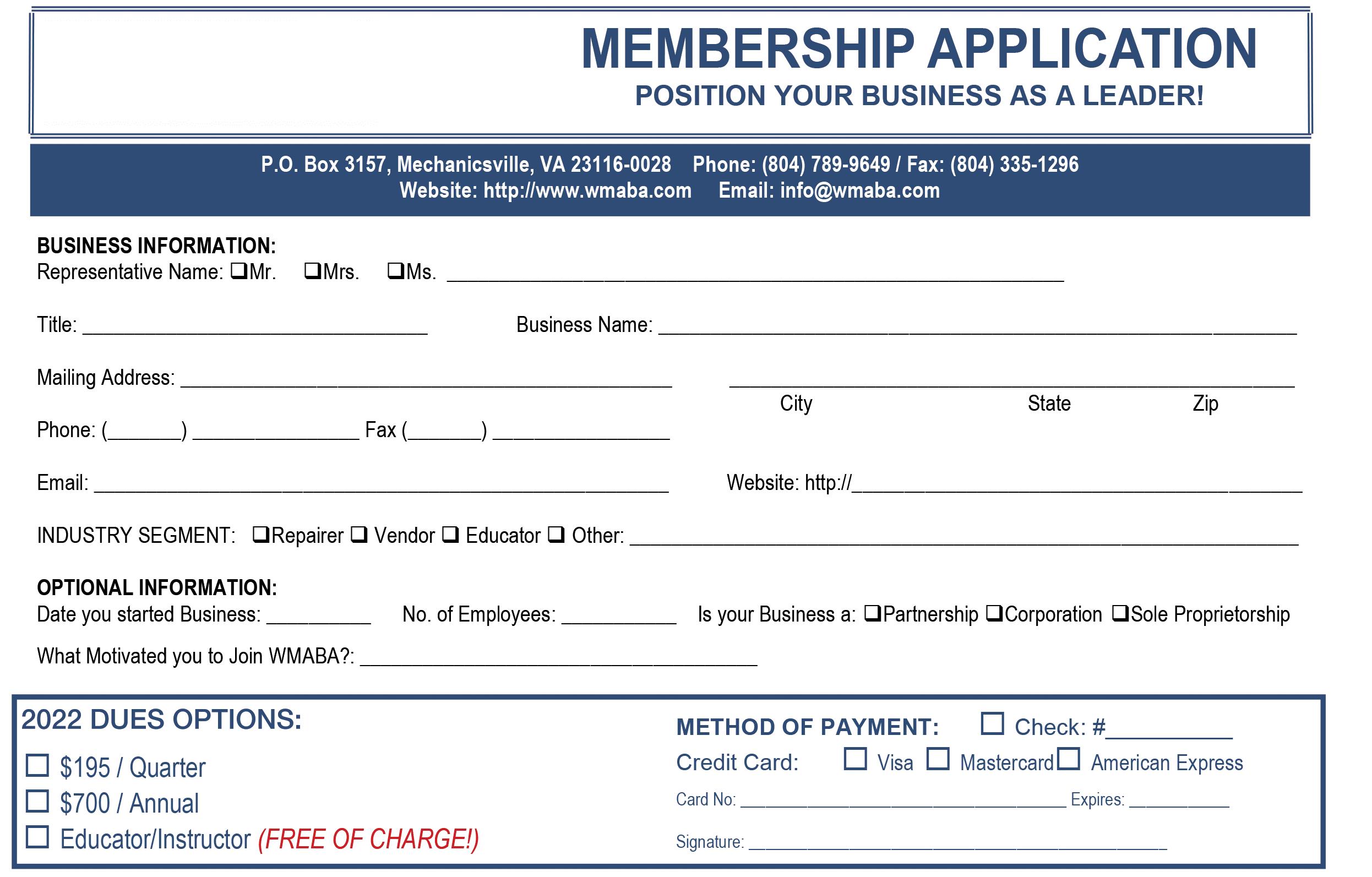

For Kimbark, “The feeling when I won third was indescribable. I was up against the best of the best and had a nervous start to the competition. With that thought in my mind, I worried about where I would place. When the day came, I had to sit there for three hours while waiting for my competition to be called, worried the whole time that I wouldn’t place. Once we got closer to the top three being called, I could hardly sit still. When my name was called, I could hardly believe it – everything I had worked for had paid off! Walking backstage and seeing the contestants who sat left and right of me during the competition was even better. Once we got up on stage, a wave of accomplishment flowed over me, and before we got too far apart, I made sure to congratulate them on first and second place.”

Kimbark has always shown great potential, according to Allen. “Ben came into our two-year program with a wealth of knowledge and skills, and he was eager to learn more. Ben has the natural ability to absorb and retain what he was taught very quickly. For some students, this can lead to becoming bored in class or feeling like they’re not being challenged, but this was not the case with Ben. When he completed a task, he would either take it upon himself to

help his fellow students in mastering their skills or come directly to me to ask what he could do next.

“During his senior year, Ben attended my class during the morning hours and then went to his work study job at a local heavy-duty collision repair shop,” Allen adds. “During his evenings and weekends, Ben worked to grow his own small engine repair business. Ben is a determined and focused young man, and it was a true pleasure to have him as a student.”

Kimbark is leaving some pretty big shoes to fill, but his instructor has high hopes for an incoming student: “Ben’s younger brother, William, started my program this fall. I’m hoping he can follow in his brother’s footsteps!”

William’s big brother takes his hopes one step further. “I’m hoping he can eventually be better than me. I plan on training him throughout the years on a few vehicles my company does some work on.”

Congratulations on your victory at SkillsUSA Nationals, Benjamin Kimbark! Hammer & Dolly wishes you the best of luck as you pursue your collision career! H&D

OURISMAN CHEVROLET OF ROCKVILLE

807 Rockville Pike

Rockville, MD 20852

Toll Free: 800-345-4640

Direct: 301-424-5332

Fax: 301-294-6381

www.rockvillechevrolet.com

OURISMAN CHEVROLET 4400 Branch Avenue

Temple Hills, MD 20748

Phone: 301-899-6990

Fax: 301-899-9375

www.ourismanchevrolet.com

Mitsubishi now offers Genuine OEM parts through our new “Opt-OE” parts program at discounted prices. See Mitsubishi’s Ultra-Conquest parts and prices in the Optional OEM Suppliers category of popular collision estimating systems.

Ultra-Conquest Collision Parts Program Highlights:

• Discounted prices on quality new and unblemished OEM parts

• Automated price and part selection in collision estimating systems

• High parts availability

• Delivery to most major U.S. cities within 24 hours

To find out more about Ultra-Conquest pricing contact your local Mitsubishi dealer. For Genuine Mitsubishi parts, contact these authorized Mitsubishi Dealers.

Fitzgerald Mitsubishi

1930 West Street

Annapolis, MD 21401

Direct: 410-224-4636

Fax: 410-224-4264

E-mail: adamsf@fitzmall.com

Younger Mitsubishi 1945 Dual Highway Hagerstown, MD 21740

Direct: 800-296-1190

Fax: 301-733-5465 www.youngermitsubishi.com

Buy Genuine Mitsubishi Parts and get the perfect fit at the perfect price.

10% off on all parts orders when you mention this ad.

specifically for Mazda vehicles We’re an accurate, trusted resource as close as your

Safford Brown Mazda Fairfax 10570 Fairfax Boulevard

Fairfax, VA 22030

Toll Free: 800-234-8642

Phone: 703-385-3994

Fax: 703-591-5348

Fitzgerald Mazda 114 Baughmans Lane Frederick, MD 21702

Toll Free: 800-545-4745

Fax 877-696-1841

Email: parts@fitzmall.com www.fitzparts.com

Ourisman Mazda of Rockville 801 Rockville Pike

Rockville, MD 20852

Parts Direct: 301-340-7668

Phone: 855-417-4511

Fax: 240-499-2488

Email: rockvilleparts@ourismanautomotive.com www.ourismanmazdaofrockville.com

Fitzgerald Mazda of Annapolis 1930 West Street

Annapolis, MD 21401

Toll Free: 866-280-8022

Phone: 410-224-4636

Fax: 410-224-4264

www.fitzmall.com

This month, we “ASK MIKE” to share some of his personal experiences and perspectives on the value of trade shows and industry education. We at Hammer & Dolly hope you find the following exchange useful, and we encourage you to reach out to us if you have a question for Mike on this or any industryrelated matter that he can answer in a future issue.

Hammer & Dolly: We’ve talked a lot over the years about the value of trade shows and automotive industry education, and you’ve spent your career heavily involved in both. With SEMA 2024 right around the corner, let’s talk about why attending shows and seminars is still so important to you. How did you get your start with these things? What keeps you coming back?

Mike Anderson: NACE was the first trade show I ever went to back in the day. Once I went, I caught the fever. I walked the aisles and saw things I had never seen before. It was very eyeopening and educational. The show had the latest and greatest in equipment, management systems – you name it.

Closer to home, the first seminar I ever went to was through Mark Canby of Canby Motors, who was a WMABA member way back when. I went to his seminar and thought, ‘Man, this is the smartest guy in the world!’ I felt like he was saying everything I was thinking, and I could relate to what he was doing. I networked with some of the other people in the class and learned they were having the same challenges that I was having at the time. I found kindred spirits. My first seminar and my first trade show were different experiences, but they both created a fire and passion within me. I realized there were other people out there who thought the same way I did.

If you go to an amusement park, there’s something there for everyone – all ages, all everything. It’s the same thing when you go to SEMA. You have the Collision Industry Conference [CIC], the awards banquet, the Society of Collision Repair Specialists’ [SCRS] training sessions and National Auto Body Council [NABC] events, just to name a few things. There are all these other activities held in conjunction with SEMA. Being there always gives you a chance to connect with people from across the country. There’s always value in meeting up with vendors and seeing what’s new, but there’s also value in learning what other shops and members in the industry in other markets are doing. Going to SEMA and other shows and following their educational tracks is invaluable. SCRS does a great job of mixing it up at SEMA – it’s not just the same presenters every year. There are always new, up-and-coming speakers participating there.

H&D: One thing we’ve noticed over the past couple of years is the high number of first-time attendees at many of these shows. It seems that the newer people in this industry really embrace trade shows and seminars.

MA: Absolutely. Just today, I got a text from a younger member of our industry – whose family has already been in the business for two generations – who said, ‘Hi, Mike. I’m starting to research the SEMA Show. I saw that you followed SEMA on Facebook. I was just wondering if you’ve been there or know somebody who has.’ He’s in his twenties, has never been to SEMA before and wants to know what’s going on. That literally happened this afternoon.

H&D: That’s fantastic! Of course, we don’t want to leave out the fact that WMABA produces great educational content locally.

MA: WMABA was one of the first associations of its kind, and it was also one of the first to have a publication like Hammer &

Dolly. I’ve always loved the magazine because it talks about the national stuff in addition to things happening in my area. Back then, we didn’t have social media – or even the internet. When I was in my late twenties or early thirties, WMABA and Hammer & Dolly were where I went to find out what was going on. Obviously, past WMABA leaders like Sheila Loftus, Jerry Dalton, Les Pomeroy and Hans Martinsen were going to CIC on the national level and bringing that information back to us. That really helped me to stay current with what mattered to my business. It was my lifeline.

H&D: When you look back on your years as a shop owner, what was the biggest thing you took away from a trade show that helped your business that you wouldn’t have learned any other way?

MA: I taught myself how to write an estimate. I would read the Mitchell manual and learn about not-included items and ask for them. But at the earliest trade shows I attended, I learned about even more not-included items. I realized I didn’t fully understand some of the things I had been reading on my own, and being at those shows taught me how to make more money through

Exploring the quest for knowledge.

WITH MIKE ANDERSON

estimating. I also took advantage of classes on blueprinting and leadership back then. My quest for knowledge continues to this day, and that knowledge only comes by attending trade shows and seminars.

Mike Anderson is an Accredited Automotive Manager (AAM) and the former owner of Wagonwork Collision Centers, two highly acclaimed shops located in Alexandria, VA. He has served as a member of many industry organizations throughout his career, including the WMABA Board of Directors, the Mitchell Advisory Board, the MOTOR Advisory Board, the ASE Test Review Committee, the National Auto Body Council, the Collision Industry Conference and the Society of Collision Repair Specialists. Additionally, he is a past Virginia SkillsUSA chairman, serves as a facilitator for Axalta Coating Systems’ highly recognized Business Council 20 Groups in both the US and Canada and facilitates numerous courses for Axalta Coating Systems’ Educational Series. He currently offers expert industry consulting via his latest venture, Collision Advice (collisionadvice.com). H&D

$19,900