5 minute read

Notes from the Field: How AI helps energy storage operators increase revenues

Notes from the Field

How AI helps energy storage operators increase revenues

by Ted James

As more battery energy storage systems (BESS) are deployed worldwide, leading operators are turning to predictive battery analytics software to improve battery system safety, performance, and lifetimes.

BESS assets already achieving performance optimization today clearly showcase how innovations in predictive analytics support operations teams. One key area of focus is asset availability, which ties directly to revenue opportunities. Operators using predictive capabilities are increasing system availability by minimizing unplanned maintenance and mitigating safety issues.

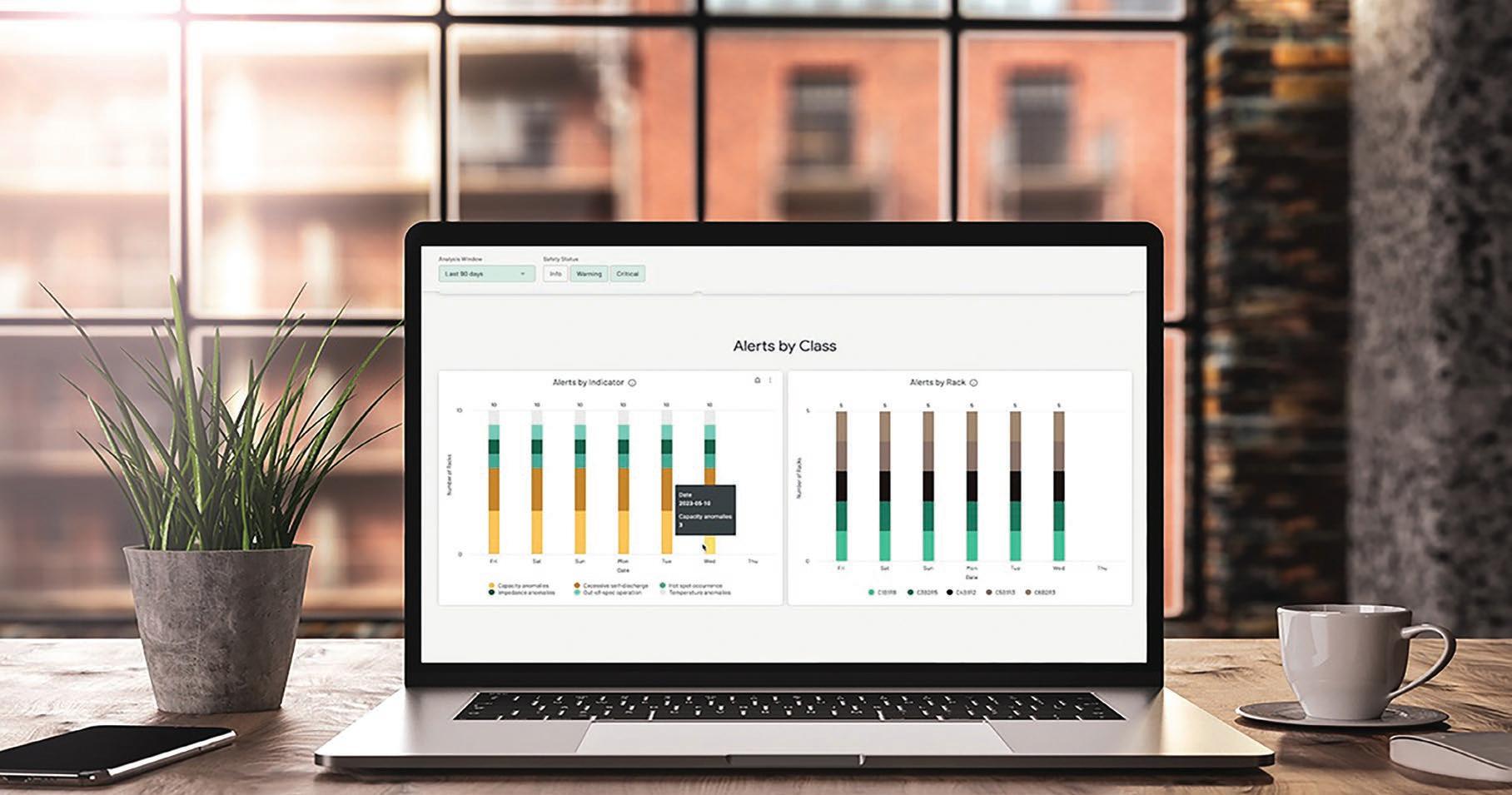

Cloud-based analytics software rapidly processes large quantities of field data with approaches based on software engineering, data science, and physics-based battery modeling, including AI. Together, these areas represent the foundation for a new category of software solutions delivering value to BESS owners and operators.

The following case studies frame industry challenges and offer perspective into how leaders are putting solutions into practice, unlocking the value from BESS field data.

1. Battery Management Systems (BMS) have limited data analytics capabilities, which can result in lost revenues and safety risks.

At a BESS site in the United States this year, predictive analytics software found a weak battery cell in a 90+ MWh asset that was reducing system performance, and could have led to a safety incident if left unchecked. The BMS never flagged the issue. A key challenge for batteries is that the performance of the system is often determined by the weakest cell, which was certainly the case with this asset. After the issue was identified with independent cloud-based analytics, the asset owner notified the system’s hardware integrator, and the module containing the faulty cell was quickly replaced. By replacing the defective cell, the asset returned to full performance.

In a similar instance in the United States, a portion of a 200+ MWh BESS asset was consistently experiencing low availability. Yet, the on-site BMS could not detect or communicate the core problems. To manage this, the operator placed the malfunctioning part of the system into standby mode; after more than four months of evaluation, the operator still had no solution. By implementing predictive analytics software, however, the operator was able to use the systems’ existing data to discover that a single string of batteries within the system was the root cause. The string was reporting thousands of erroneous measurements of voltage, current, and temperature. Once identified, the issue was immediately addressed. While the resolution using cloud-based analytics was successful in this case, the scenario highlights the opportunity costs associated with delays and downtimes. Had the asset owners partnered with the predictive battery analytics provider earlier, including it as an essential part of operations, the asset would have generated revenues for an additional four months of the company’s fiscal year.

2. Errors in the state of charge (SOC) affect operators’ abilities to achieve revenue targets.

A 100+ MWh BESS site experienced an outage after the system mistakenly believed it had reached its discharge cut-off voltage. Leading up to this, the system had issued a faulty SOC reading of 100 percent, when the asset’s actual SOC was closer to 50 percent. As a result of cascading errors, the operator was unable to dispatch the energy committed by this asset, incurring a penalty in addition to losing revenues. In this situation, predictive analytics software was used to attain high-fidelity insights about the system’s actual SOC. The operator then took actions recommended by the cloudbased software to resolve the issues that were causing such severe SOC reporting errors. Given the common issue of SOC reporting errors with some battery technologies, the asset owner also implemented continuous monitoring using the predictive battery analytics software.

3. Undetected equipment malfunctions create problems for batteries if left unresolved.

It’s not just faulty battery cells that can threaten the health of a BESS asset. Problems with other system components, such as HVAC equipment, can degrade or even damage batteries if problems are not identified and addressed promptly. For example, predictive analytics software supporting a 100+ MWh system detected very high temperatures within a portion of the asset. The problem occurred due to malfunctioning chillers designed to keep the equipment cool. The operator was unaware of the broken chillers because the BMS had neither detected the problems nor issued any alerts. With the cloud-based analytics software enabled, the operator received notifications and placed the affected portion offline until the chillers could be repaired. If the problem had not been caught, the operator could have lost a share of their batteries at a significant cost, because the damage would have been excluded under the manufacturer’s warranty. In this case, predictive insights generated immediate savings.

These case studies highlight common battery quality issues, onsite BMS failures, SOC errors, and other system issues, and speak to how predictive battery analytics software is unlocking value and reducing risks for leading BESS owners and operators. In the fast-growing battery industry, operations teams have limited hands — predictive analytics are becoming essential to simplify the complexity of managing batteries. Cloud-based analytics and continuous monitoring supplement other tools in the field, giving operators the required insights to achieve key results.

Ted James is President, North America at ACCURE Battery Intelligence, where they work to make batteries safer, more reliable, and sustainable using analytics.