6 minute read

Terzo Power Systems, LLC: Michael Terzo, CEO

Electrifi cation Will Continue to Advance the Off -Highway Industry

responses submitted by Michael Terzo, CEO, Terzo Power Systems, LLC

Electrifi cation is permeating every aspect of the industry, and will an be an integral part of the continued advancement of IoT, connectivity and automation.

Global Markets, Government & Trade What are the key global markets your company sees as growth opportunities and why?

Medium- and Heavy-duty trucking: Electrifi cation is taking hold of all aspects of transportation. While it might seem to be coming out of nowhere, all the recent activity in the MD/HD space has been going on behind the scenes for quite a few years; we are just seeing the acceleration as OEMs get closer to their start of production dates over the next 2-5 years. Of course, the recent announcement by California of their Advanced Clean Truck rule has brought this activity into the spotlight. This rule by the California Air Resources Board (CARB) requires OEMs to increase their ZEV (zero-emission vehicle) truck sales beginning in 2024 to 40-70% by 2035. The impact of this rule will have long-lasting impacts on the trucking industry.

Diesel, Electric & Other Power Alternatives What opportunities for technology and effi ciency advancements still exist with diesel engines?

The major opportunities we see for diesel engines is in hybrid systems where the duty cycle of the application still is a diffi cult proposition for pure electric. Hybrid systems for off -highway equipment provides some incredible advantages for OEMs in terms of performance, fuel effi ciency, controllability, and fl exibility. What this means to the engine manufacturers is a growth in smaller engine platforms, specifi cally those engine platforms that work well with a hybrid architecture. A fully decoupled hybrid system utilizes constant speed engines with the best effi ciency band while still providing fl exibility in integration. We have already seen about a 50% engine size reduction across the board in every hybrid design we have done.

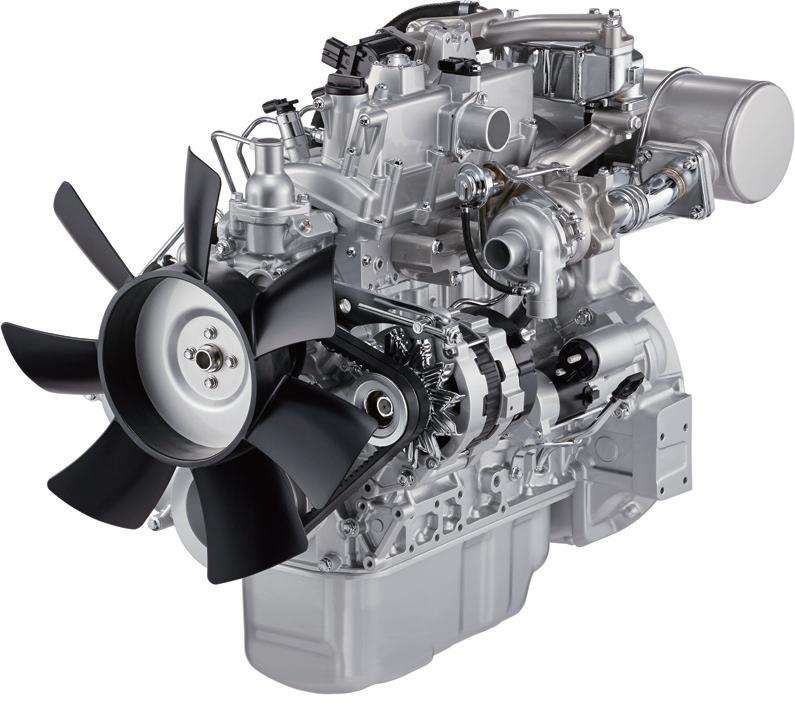

Isuzu. Caring people providing The power behind it all.

Their legacy of strength and kindness became essential for Global business life, supporting countries around the world with the power to meet their needs. Today, with over 190 countries experiencing worldwide uncertainty with pandemic proportions, they are here to support a company’s power requirements by providing environmentally responsible products for numerous applications.

Global leader of innovative power

As a producer of on-road commercial vehicles, off-road Diesel and Alternative Fuel

Engines and Power Units for the needs of their customers. They have been building and maintaining a world class organization to provide power solutions that work in every environment. Isuzu manufacturing operations and expanded products are in over 100 countries and they now have over 28,000,000 engines produced globally. Isuzu ensures the most advanced performance and services, with a goal to become one of the new international standards of excellence in product development, quality, manufacturing and customer support.

So, while there will still be a signifi cant market for diesel engines over the next decade, the types and sizes of these engines will change. Unfortunately, a hybrid system does not necessarily need the torque (one of the biggest advantages of a diesel versus gas) since we can match the output of an engine to the permanent magnet motor generator. This opens the door for other fuel types; so diesel manufacturers who also provide multiple fuel engines will see increasing growth.

What role is electrifi cation—or other alternative energy/power systems— playing in your company’s design initiatives?

Well, since our entire mission is to develop and manufacture the best electrohydraulic solutions for OEMs it’s a pretty big role! While we believe the entire power system for every off -highway vehicle will be fully electric (either via battery, fuel cell, hybridization or a combo of these) over the coming decades, electrifi cation has already permeated every aspect of the off -highway industry and in many instances, it is not for the reasons that many people believe. We can electrify parts of a system that provide early return on fuel savings or maintenance such as operating a clutch with an electrohydraulic pump versus pulling that circuit off the main hydraulic system. This provides a power-on-demand aspect that would have robbed a lot of effi ciency and provided wear and tear issues in a conventional system.

Data, IoT & Connectivity How will the role of the Internet of Things (IoT) and data continue to progress in the coming years?

While these are big areas of interest and growth in the off -highway industry, I see that we might not see the true impacts of these areas until we are further down the electrifi cation path. Once you electrify your system, IOT, data and connectivity become much more interesting and powerful for a whole number of reasons. Big Data can allow improved motion control, effi ciency, and performance but those benefi ts are diffi cult to pencil out with a traditional ICE (internal combustion engine) system. A hybrid or electric system is a diff erent story. I see that electrifi cation will truly enable an explosion in the data, IOT, and connectivity fi elds, but that might not be started quite yet.

What challenges remain for the continued adoption of data, IoT and connectivity?

As I mention above, the true growth of these sectors is just beginning. The largest challenge (which is also the opportunity for those who harness the technology) will be to understand how our industry can easily digest and absorb these new technologies without requiring signifi cant education and/or inconvenience. We all hear how “old school” and “resistant to change” our industry is, but I don’t believe that is the case when you present the technology the correct way to off -highway stakeholders such as OEMs, designers, and executives. |

Watch the Video

Watch our video interview with Michael Terzo to learn more about electrifi cation trends and the work his company is doing to electrify off -highway equipment at oemoff highway.com/21172916.

Isuzu products, built to last

Isuzu has proven to be Reliable, Eco-friendly, Durable, and Technologically Advanced since 1916. Their Tier 4 and Stage V Engines and Power Units, branded under Isuzu REDTech™️, provide quiet, low maintenance and fuel efficient solutions for existing and new applications. From 6.7kW to 397kW these Engines and Power Units use the latest proven after treatment DOC or DOC+SCR, with vertical or horizontal SCR for design flexibility. Including Alternative Fuel Engines and Power Units using natural gas or propane can now be equipped with a new Dual-Fuel System to simply reconfigure the fuel source and eliminate location downtime. Every Isuzu Engine or Power Unit is precision tuned for its highest efficiency, while reducing oil and fuel consumption. A long-lasting and robust fuel injection system incorporates excellent fuel economy and extended service life. Stringent criteria to lower NVH (noise, vibration, harshness) are engineered into every Isuzu product. Each application is designed to meet customer specifications and is engineering validated for each environment. Isuzu REDTech™️ Engines and Power Units with reliable performance, durability, and high thermal efficiency help increase productivity. All of their products are supported by Genuine Isuzu Parts, a Distributor and Dealer network along with dedicated professionals disciplined in engineering, manufacturing, and management to ensure the right customer solutions every time.

ADVERTORIAL