STATE OF THE INDUSTRY 2022

NOVEMBER/DECEMBER 2022 oemoffhighway.com 2022 PRODUCTS

PAGE 12

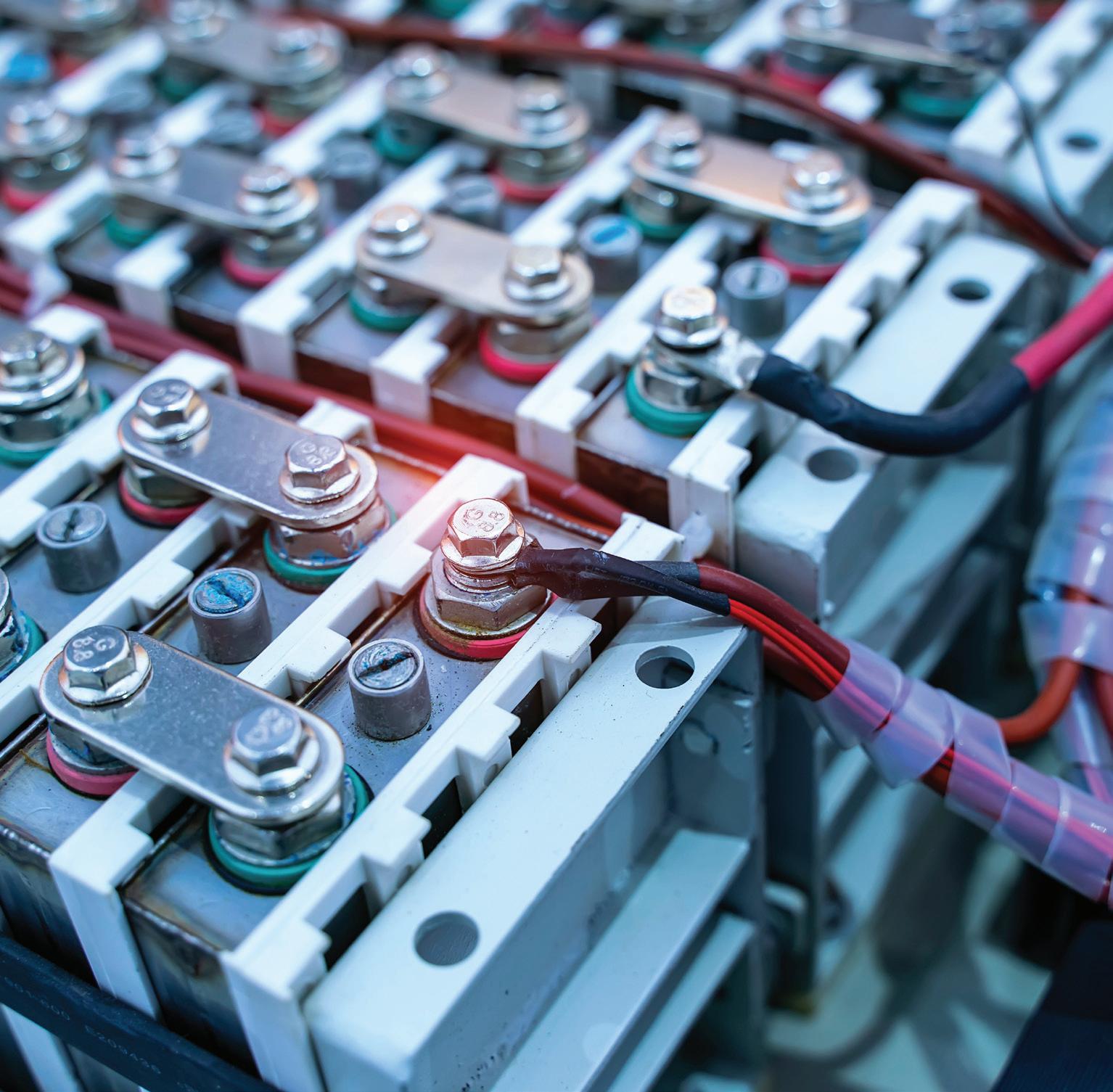

RELIABLE POWER DISTRIBUTION MODULES from Littelfuse Littelfuse has the right power distribution modules for the OEM market. Featuring • Maximum load capabilities of up to 300 Amps • Working voltage ranging from 12-24V DC • Available in a variety of circuit sizes and adaptable configurations • Rugged and sealed for use in high moisture/dirt environments For stocking information visit www.waytekwire.com/littelfuse or call 800-328-2724 Developed for the heavy-duty commercial vehicle industry, these configurable PDMs can host a dense concentration of high-power circuits in a centralized location, resulting in less wire to power and less hardware to assemble. They provide reliability in locating a blown fuse or failed relay, reducing service and repair downtime.

CONTENTS VOLUME 40, NO. 4 | NOVEMBER/DECEMBER 2022 OEM Off-Highway | NOVEMBER/DECEMBER 2022 3 COVER STORY 16 State of the Industry 2022 Challenges and hurdles often trigger innovation driven by disruption. 4 EDITOR’S NOTE 40 WHAT’S NEW ON OEM.COM EQUIPMENT MARKET OUTLOOK 6 US Construction Machinery Orders Higher than 2021 Levels OFF-HIGHWAY HEROES 42 HCEA Convention Illustrates Equipment Evolution WEB EXCLUSIVES Video Network www.oemoffhighway.com/videos OEM Industry Update www.oemoffhighway.com/podcasts Premium Content www.oemoffhighway.com/premium-content TRADE SHOW PREVIEW 10 Inside World of Concrete 2023 The world’s prominent heavy equipment manufacturers will be at the show.. AWARDS 12 Top New Products of 2022 Check out the winners and honorable mentions in each of our technology categories. FLUID POWER 26 The Future of Mobile Hydraulics Is Digital Digital technology reduces mechanical complexity and improve functionality. ELECTRIFICATION 32 The 3 Cs That Mining Must Consider Before Going Electric Electrifying mines requires smart thinking around these key factors. 16 32 26 10 40 42

Our team closed out the 2022 trade show season with a wonderful trip to bauma in Munich, Germany. My first trip to Europe was inspir ing. We especially enjoyed talking with all the passion ate exhibitors about the new technology on display.

Our website is filled with great articles, images and videos from the event. If you’ve missed any of it, make sure you check it out. Much of it is still featured on our home page.

Speaking of closing out seasons, this is our last print issue of 2022, and we may have saved the best for last! We are excited to include the winners of our 2022 Top New Products of the Year on page 12. Congrats to all our winners.

We also asked 10 industry thought leaders about the trends and challenges of 2022 and predict what may affect the off-highway sector next year. When sharing what challenged their organizations as well as the industry this year, most indicated that the supply chain remains an issue but will hopefully abate in 2023.

Another trend that was no surprise is the move to alternative power sources, includ ing electrification, hybrid configurations and alternative fuels. This trend was indicated as both a positive transition and a challenge for original equipment manufacturers and the companies that supply them. Check out the article on page 16 for more details.

We look forward to the New Year and more great issues. Let us know what you’d like to see in our 2023 magazines!

EDITORIAL ADVISORY BOARD

Craig Callewaert, PE, Chief Project Manager, Volvo Construction Equipment

Roy Chidgey, Business Segment Head, Minerals Projects and Global Mobile Mining, Siemens Large Drives US

Andrew Halonen , President, Mayflower Consulting, LLC

Terry Hershberger, Director, Sales Product Management, Mobile Hydraulics, Bosch Rexroth Corp.

Steven Nendick, Marketing Communications Director, Cummins Inc.

John Madsen, Director Engineering & Product Management, GKN Wheels & Structures

Doug Meyer, Global Director of Construction Engineering, John Deere

Andy Noble, Head of Heavy Duty Engines, Ricardo

Daniel Reibscheid, Business Development Manager, MNP Corporation

Matt Rushing, Vice President, Product Line, Global Crop Care, AGCO Corp.

Allen Schaeffer, Executive Director, Diesel Technology Forum

Keith T. Simons, President – Controls Products, OEM Controls, Inc.

Alexandra Nolde , Senior Communication & Media Specialist, Liebherr-Components AG

Bob Straka, General Manager, Transportation SBU, Southco, Inc.

Luka Korzeniowski, Global Market Segment Leader, Mobile Hydraulics, MTS Sensors

Chris Williamson, PhD, Senior Systems Engineer Global Research & Development, Danfoss Power Solutions Company

EDITORIAL

Editor Lori Ditoro lditoro@acbusinessmedia.com

Managing Editor Gigi Wood gwood@acbusinessmedia.com

Technology Editor Charles Rathmann crathmann@acbusinessmedia.com

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manger Cindy Rusch crusch@acbusinessmedia.com

Art Director Dave Haglund

ADVERTISING/SALES

Brand Director Sean Dunphy sdunphy@acbusinessmedia.com

Sales Representative Greg Schulz gschulz@acbusinessmedia.com

Sales Representative Nikki Lawson nlawson@acbusinessmedia.com

Sales Representative Kris Flitcroft kflitcroft@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Chief Digital Officer Kris Heineman

VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director Marina Mayer

GM, Online & Marketing Services Bethany Chambers

Content Director, Marketing Services Jess Lombardo Director, Demand Generation & Education Jim Bagan Director, Enterprise Sales Kay Ross-Baker

CIRCULATION & SUBSCRIPTIONS

PO Box 3605 Northbrook, IL 60065-3605, Phone: 877-201-3915 Fax: 847-291-4816

circ.OEMOff-Highway@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo, Data Axle 402-836-2768 | bart.piccirillo@data-axle.com

REPRINTS & LICENSING

Sales Representative Greg Schulz 920-542-1239 | gschulz@acbusinessmedia.com

Published and copyrighted 2022 by AC Business Media. All rights reserved. No part of this publication shall be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher.

SUBSCRIPTION POLICY: Individual print subscriptions are available without charge in the United States to original equipment manufacturers. Digital subscriptions are available without charge to all geographic locations.

Publisher reserves the right to reject nonqualified subscribers. Subscription Prices: U.S. $35 One Year, $70 Two Years; Canada and Mexico $60 One Year, $105 Two Years; all other countries, payable in U.S. funds, drawn on U.S. bank, $85 One Year, $160 Two Years.

OEMOff-Highway (USPS 752-770, ISSN 1048-3039 (print); ISSN 2158-7094 (online) is published 6 times a year: January/February, March/April, May/June, July/August, September/October and November/December by AC Business Media, 201 N. Main Street, 5th Fl., Fort Atkinson, WI 53538. Periodicals Postage paid at Fort Atkinson, WI and additional entry offices. POSTMASTER: Send address changes to: OEMOff-Highway, PO Box 3605 Northbrook, IL 600653605. Printed in the U.S.A.

EDITOR’S NOTE OEM Off-Highway | NOVEMBER/DECEMBER 2022 4

LDITORO@ACBUSINESSMEDIA.COM

E @OEMOffHighway D @OEMOffHighway C @oem-off-highway Published by AC Business Media 201 N. Main Street, Fort Atkinson, WI 53538 800-538-5544 www.ACBusinessMedia.com www.OEMOffHighway.com

www.IronPros.com

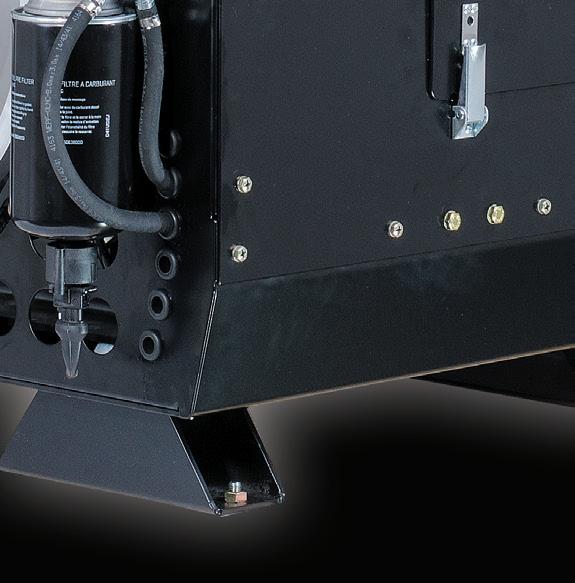

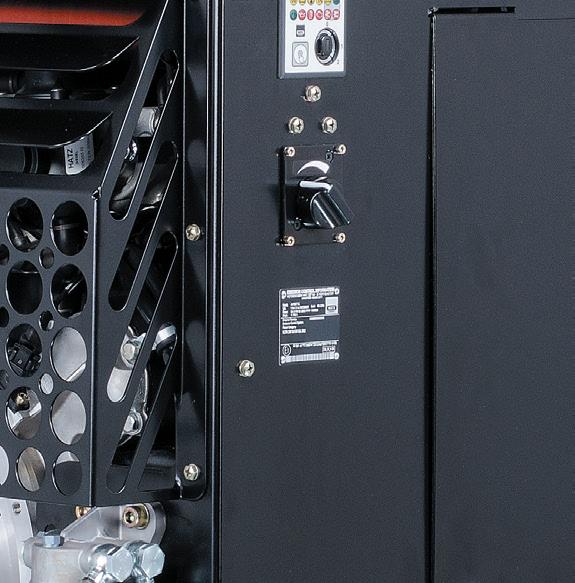

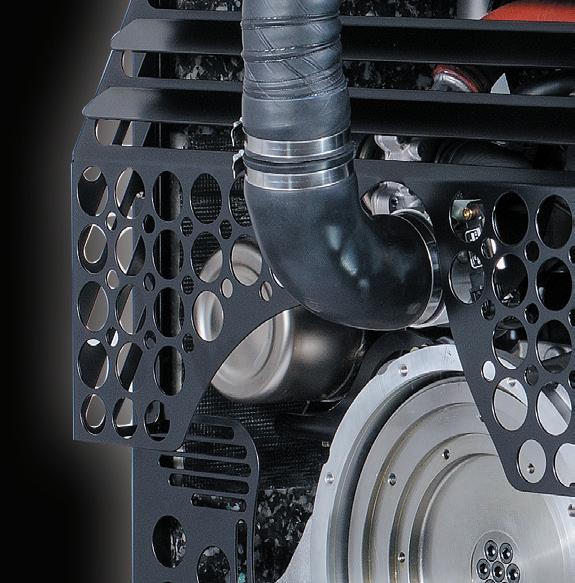

We created solutions that deliver more power, reliability, and fuel savings. Leveraging the R&D resources and proven experiences of the Volvo Group to bring our customers to the forefront of sustainable driveline technologies.

Together, let’s rethink the possibilities and take your operations – and bottom line – to the next level with Volvo Penta´s industry-leading Tier 4 Final solutions.

Everything

Challenge

Lower Total Cost of Ownership Better Value In The Long Run Fuel Efficiency Reduce Your Operational Cost Service and Support Global Dealer Network With Local Expertise

Scan the QR code to learn more.

US Construction Machinery, New Orders

• U.S. construction machinery in the 12 months through August was 13.9% above the year-ago level. The pace of rise is slowing.

• Rising interest rates may hinder investment in construction and related machinery, putting downside pressure on demand fo r new orders.

US CONSTRUCTION MACHINERY ORDERS HIGHER THAN 2021 LEVELS

In the 12 months through August, construction machinery orders were 13.9% above the year-ago level. However, the pace of rise is slowing. With interest rates increasing, this number may decline. In addition, several U.S. indicators increased.

• Both the monthly value and the monthly rateof-change for the U.S. OECD leading indicator moved lower in September.

• Decline in the indicator monthly rate-of-change suggests downward cyclical movement in industri-al production will persist through at least the first half of 2023.

US Defense Industry, New Orders

• The U.S. defense capital goods new orders annual growth rate was at 3.8% in August.

• Dollar-denominated new orders are rising but will be subject to some downside pressure via declining commodity prices, such as steel and copper.

oemoffhighway.com/economics OEM Off-Highway | NOVEMBER/DECEMBER 2022 6 EQUIPMENT MARKET OUTLOOK US Leading Indicator ITR Economics is an independent economic research and consulting firm with 60+ years of experience. QUESTIONS? economics@oemoffhighway.com Editor’s Note: Please note that this chart has been modified on the Y-axis to show the trend more easily. Go to www.oemoffhighway.com to sign up for our monthly ECONOMIC NEWSLETTER! 0 9 98.5 98.7 98.8 98.9 99.1 99.2 99.3 99.5 99.6 99.7 99.9 100.0 100.1 100.3 Sep Aug Jul Jun May Apr Mar Feb Actual index (2010=100) 100.3% 100% 99.1% 99.4% 99.8% 98.9% 98.5% 98.6% Sponsored by Eberspächer -4.0 -3.5 -3.0 -2.5 -2.0 -1.5 -1.0 -0.5 0.0 Jun May Apr Mar Feb Jan ’22 Dec Nov ’21 Annual % change in 12 month moving totals -0.5% -2.7% -3.7% -1.9% -2.6% -3.1% -1.4% -1.1%

@GUI YONG NIAN – STOCK.ADOBE.COM 0 5 10 15 20 25 Jun May Apr Mar Feb Jan ’22 Dec Nov ’21 Annual % change in 12 month moving totals 24.3% 23.7% 24.0% 22.0% 19.9% 15.9% 14.2% 15.6%

US Industrial Production US Private Nonresidential New Construction

• U.S. industrial production in the third quarter was 4.2% above the third quarter of 2021. Growth is generally slowing.

• The 10-year to three-month treasury yield spread inverted briefly in October; a sustained inversion (two or more months) would signal an increased risk of recession this cycle.

• In the three months through August, U.S. private nonresidential new construction totaled $132.9 billion, up 6% from the same period one year ago.

• Note that when adjusted for inflation, quarterly construction is still below year-ago levels, but it is rising.

US Total Public New Construction

• U.S. total public construction is rising. In the 12 months through August, Construction totaled $346.9 billion, just 2.3% below the same period one year ago.

• Robust growth in U.S. state and local tax revenue signals business cycle rise in construction in the year ahead. Construction is likely to break above year-ago levels in the near term.

OEM Off-Highway | NOVEMBER/DECEMBER 2022 7 0 1 2 3 4 5 6 Sep Aug Jul Jun May Apr Mar Feb Annual % change in 3 month moving totals 5.0% 4.6% 4.7% 5.5% 4.3% 4.2% 3.7% 4.0% 0 1 2 3 4 5 6 Aug Jul Jun May Apr Mar Feb Jan Annual % change in 12 month moving totals 6.0% 5.5% 3.5% 4.1% 3.9% 3.8% 4.9% 3.6% -8 -7 -6 -5 -4 -3 -2 -1 0 Aug Jul Jun May Apr Mar Feb Jan Annual % change in 12 month moving totals -5.6% -5.9% -6.0% -6.2% -5.3% -2.3% -3.3% -4.3%

US Farm Machinery Production Europe Ag & Forestry Machinery Production

• U.S. farm machinery and equipment shipments in the 12 months through August were 2.9% above the same period one year ago, marking a second month of accelerating growth.

• Ongoing improvement in supply chains, as indicated by the global supply chain index, are likely improving producers’ ability to fulfill backlogged demand.

• The European agricultural and forestry machinery production annual growth rate ticked up to 2.9% in August. More data is necessary to see if an accelerating growth trend will hold, but the quarterly trend suggests it is likely.

• Weather and tight fertilizer supplies are headwinds for Europe’s farmers.

US HeavyDuty Truck Production

• U.S. heavy-duty truck production in the 12 months through September was 11.9% above the same period one year ago.

• Class 8 truck orders were at a record high in September as producers reopened order boards. This bodes well for growth in production next year, even as the economy at large broadly trends on the back side of the business cycle.

Europe Leading Indicator

• The Europe leading indicator declined for the twelfth consecutive month in September.

• Movement in the leading indicator signals cyclical decline in European industrial production will persist into at least mid-2023. Production growth is currently slowing, and year-over-year contraction is probable in the coming quarters.

China Diesel Bus Production Germany Industrial Production

• In the 12 months through August, China large diesel bus production totaled 16.2 thousand units, 26.2% below the year-ago level.

• The China leading indicator is exhibiting budding upward momentum, but this may not translate to much upward movement in bus production given the adoption of electric buses.

• Quarterly Germany industrial production is generally declining, as of August down 0.9% from the year-ago level.

• Leading indicator evidence and a cooling global macroeconomy suggest that further business cycle decline is in store for industrial production. Nascent recovery in the automotive sector will likely contribute upward pressure in the near term.

EQUIPMENT MARKET OUTLOOK oemoffhighway.com/economics OEM Off-Highway | NOVEMBER/DECEMBER 2022 8 -2 -1 0 1 2 3 4 5 Aug Jul Jun May Apr Mar Feb Jan Annual % change in 12 month moving totals 4.5% 1.9% -0.3% -1.1% -0.5% 2.9% 0.3% 3.1% 0 3 6 9 12 15 Aug Jul Jun May Apr Mar Feb Jan Annual % change 2.9% 13.8% 13.0% 4.7% 9.0% 3.4% 2.8% 2.4% 0 5 10 15 20 25 Sep Aug Jul Jun May Apr Mar Feb Annual % change in 12 month moving totals 18.3% 11.1% 4.7% 5.8% 7.1% 8.8% 11.9% 22.2% -30 -25 -20 -15 -10 -5 0 5 10 Aug Jul Jun May Apr Mar Feb Jan Annual % change -26.2% -25.1% -25.9% -0.9% 4.3% 5.1% 4.6% 9.0% -3.5 -3.0 -2.5 -2.0 -1.5 -1.0 -0.5 0.0 0.5 1.0 1.5 2.0 2.5 Aug Jul Jun May Apr Mar Feb Jan Annual % change in 3 month moving totals 1.2% -0.2% -3.2% -0.7% -1.3% -2% -0.9% 2.2% 0 98.0 98.1 98.3 98.5 98.8 99.0 99.2 99.4 99.7 99.9 100.1 100.3 100.6 Sep Aug Jul Jun May Apr Mar Feb Monthly index 98.6 98.9 98.0 98.3 99.3 101.0 100.1 99.7 Editor’s Note: Please note that this chart has been modified on

the Y-axis to show the trend more easily.

Sponsored by Eberspächer

A LONG WAY TOGETHER

WHEREVER YOU ARE, BKT IS WITH YOU

No matter how challenging your needs, BKT is with you offering a wide range of OTR tires specifically designed for the toughest operating conditions: from mining to construction sites.

Sturdy and resistant, reliable and safe, able to combine comfort and high performance. BKT is with you, even when work gets tough.

BKT USA Inc.

202 Montrose West Ave. Suite 240 Copley, Ohio 44321

Toll free: (+1) 888-660-0662 - Office: (+1) 330-836-1090 Fax: (+1) 330-836-1091

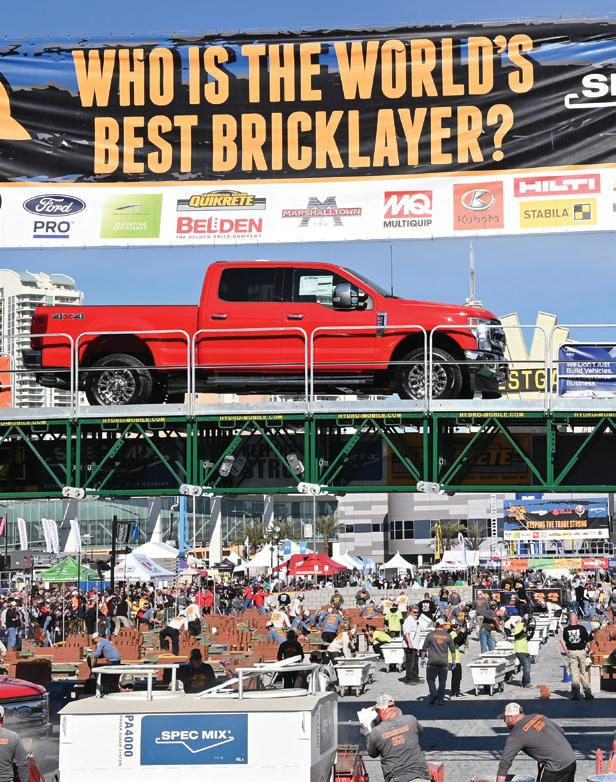

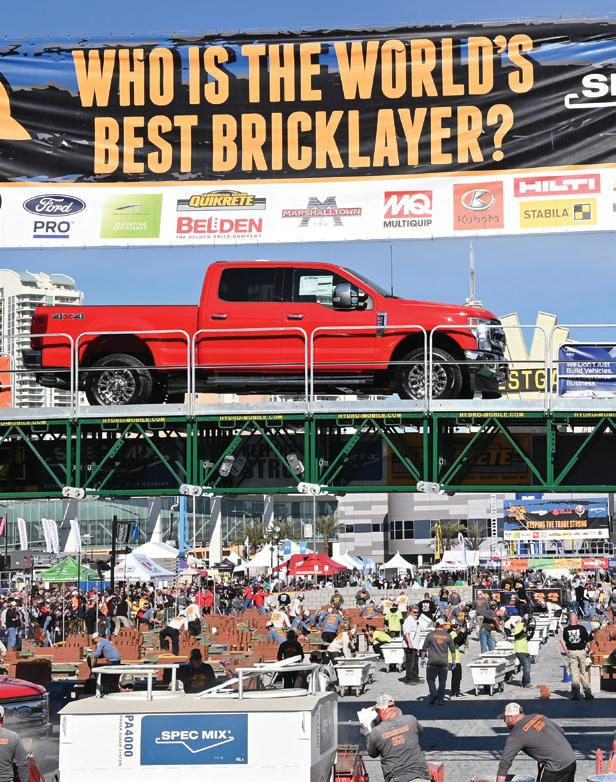

INSIDE WORLD OF CONCRETE 2023

The world’s prominent heavy equipment manufacturers will be at the show.

by Gigi Wood

by Gigi Wood

The only international event dedicated to the commercial concrete and masonry con struction industries, World of Concrete will take place from January 16-19 in Las Vegas. With more than 1,300 exhibitors and 50,000 attend ees, World of Concrete is one of the construction industry’s largest trade shows, connecting buyers with sellers, creating networking opportunities and showcasing new technologies and products across 500,000 square feet of the Las Vegas Convention Center.

The event includes more than 160 educational sessions, as well, offering industry certifications and hard-to-find instruction on new technologies and technical topics.

As those in the concrete industry know, it can be difficult to find expert training in topics such as petrography, mass concrete, fiber reinforcing, 3D

printing and even business issues, like defect litigations.

In 2023, eight educational sessions will be presented in Spanish. There will also be a three-hour seminar on concrete repair, as well as workshops on business issues such as hiring and decorative concrete techniques, such as staining and stamped concrete.

"Year after year, industry profession als flock to World of Concrete for its highly-regarded education and the unique opportunity to garner techni cal certifications to help professionals navigate this complex industry,” said Jackie James, group director, World of Concrete.

Visit the Outdoor Space

World of Concrete is much more than a classroom, however. Nothing beats the indoor and outdoor demonstration spaces, where attendees can watch,

and sometimes try out, the latest construction equipment designed for the concrete industry. The world’s prominent heavy equipment manu facturers will be at the show—as will several new, entrepreneurial compa nies—putting their newest screeds, vibratory plates, breakers and more on display. Many of those will be powered by traditional means, although there will also be many battery-powered models at the event.

Focus on Work Trucks

New for 2023 is a focus on work trucks. Work Truck Live will highlight innova tions in the design and configuration of work trucks and accessories that will help contractors increase safety and productivity. Work Truck Live is designed to bring attention to com panies that manufacture chassis and supply up-fitting accessories, as well as develop technologies with which con tractors can customize their vehicles to the job.

In addition to Work Truck Live, World of Concrete is debuting a Ride and Drive experience that provides attend ees the opportunity to test-drive select Class 1- Class 7 vehicles. Approved drivers and passengers experience the feel of the vehicle in a closed, short loop. Ride and Drive will take place on Tuesday and Wednesday during World of Concrete.

TRADE SHOW PREVIEW OEM Off-Highway | NOVEMBER/DECEMBER 2022 10

WORLD

CONCRETE

OF

Reduced Noise

A tradition of silence

142 years of experience built into every engine

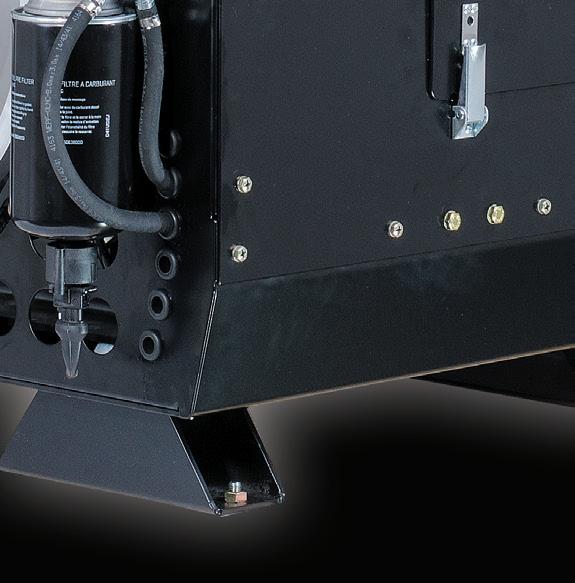

From the very beginning Hatz has been known for smooth and quiet running engines. Starting in the 1960s the effort to reduce noise emissions became an important area of focus for the engineers at Hatz. These efforts led to noise reduction that made Hatz engines the quietest in their class and led to the introduction of the Hatz Silent Pack. Which offered a 10-fold reduction in noise.

This legacy is brought forward to today in the Hatz H-Series engines which are engineered not only to be light and fuel efficient, but also for reduced noise emissions. The H-Series engines are available directly from Hatz in F2F, OPU, and Silent Pack versions. The Hatz Silent Pack is sound attenuated enclosure, designed and assembled by Hatz, which provide a 60% reduction in noise emissions.

Visit us at Hatznorthamerica.com Booth

#S-85429 Booth #N2423 Booth #5533

Top New Products of 2022

by Lori Ditoro

by Lori Ditoro

Drivetrains

The winner is Eaton Cummins Automated Transmission Technologies for its Endurant XD Pro Automated Transmission

This product was chosen because of its mix of hardware and intelligence that give drivers confidence in challenging applica tions such as construction, heavy haul, towing and recovery, and logging. It has an unlimited gross combined weight rating and long maintenance intervals.

For long reversing distances and deep axle ratios, the Endurant XD Pro can be configured with up to six reverse gears and it can be paired with the powerful engines with torque ratings from 1,650 pound-feet to 2,050 pound-feet.

The Endurant XD Pro utilizes Eaton’s Extreme Duty clutches, which feature components designed for increased durability, reduced noise and vibration, and high thermal capacity for enhanced low-speed maneuverability.

The honorable mentions (listed in alphabetical order) in this category are:

• AVL HD Truck E-Axle

• Meritor ProTec Independent Front Suspension

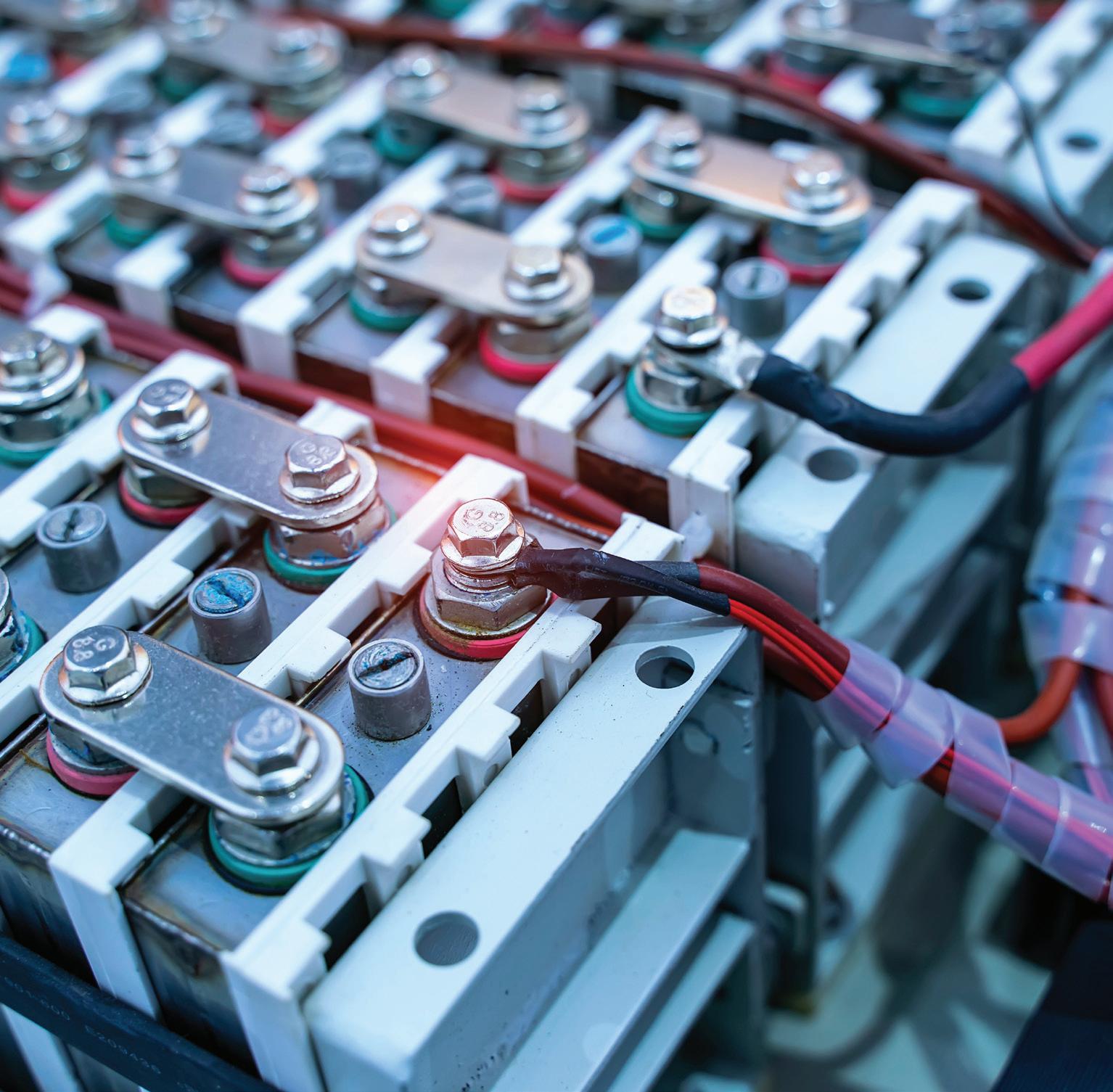

Electronics & Electrification

The winner is the ACEINNA INS401 Inertial Navigation System (INS). It has a real-time-kinematic-enabled, dual-frequency global navigation satellite system receiver, tripleredundant inertial sensors, and a positioning engine. It is designed for use in L2+ and higher autonomous vehicle applications requiring precise position information.

The new INS401 INS provides precise positioning for a wide range of autonomous vehicles, especially for vehicles in the agriculture and construction spaces. It enables these self-guided vehicles to operate (without a human in control) at a high level of operational accuracy, regardless of the type of terrain being worked upon. This includes at night, during heavy rain or snow, and in dusty and dirty environments. The inertial measurement unit technology used inside the INS responds to gravity, acceleration inertia and the laws of physics. It is immune to the challenges faced by other sensors.

The honorable mentions for this category are:

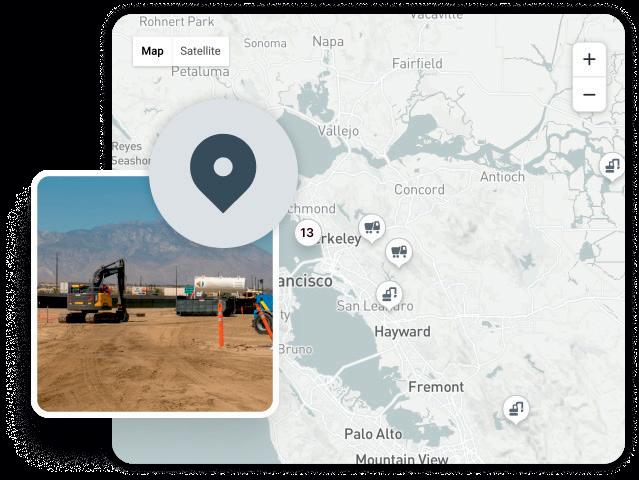

• Trackunit Kin Asset Utilization Capability, Extending Visibility of Device and Use

• Vanguard 48V 10kWh Commercial Battery

Engineering & Manufacturing

This category’s winner is the Syncron new Dealer to Dealer Solution Package with a new Backorder Recovery feature. The new Dealer to Dealer (D2D) is a solution package that improves manufacturers’ horizontal interaction across the supply chains to facilitate transactions between independent dealers and support the optimization of inventory beyond the OEM and PDC network.

An expansion on an existing product, the new capabilities added further reduce downtime and improve customer satisfaction, decrease the overall network inventory, reduce future part returns and reduce expediting cost.

A new Backorder Recovery feature was the focus for the newest version of the D2D solution package. Along with a user-friendly portal, Syncron’s new SmartBlox, D2D parts distribution center (PDC) Backorder, and D2D Mobile App were also introduced. PDC Backorder Recovery identifies potential selling dealers in the network and notifies them about the request. When the first dealer confirms, the order is executed. Other new features include automatic triggers for the dealer-to-dealer process and shipment management.

OEM Off-Highway | NOVEMBER/DECEMBER 2022 12 AWARDS

ACEINNA

EATON CUMMINS AUTOMATED TRANSMISSION TECHNOLOGIES

Check out the winners and honorable mentions in each of our technology categories.

We are thrilled to announce the Top New Products of 2022. Congratulations to each category winner and the honorable mentions!

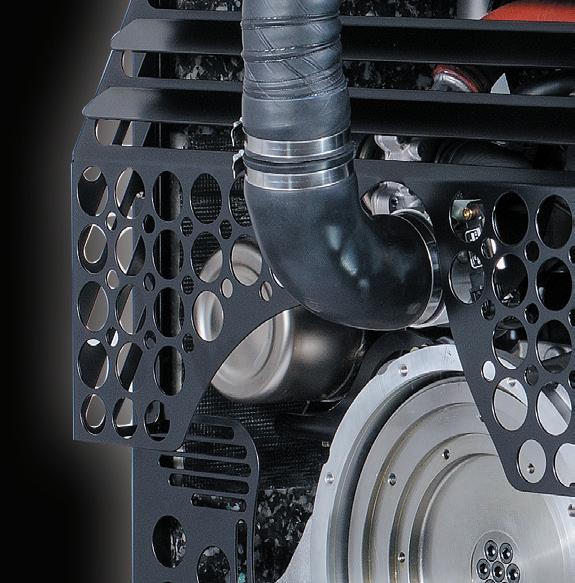

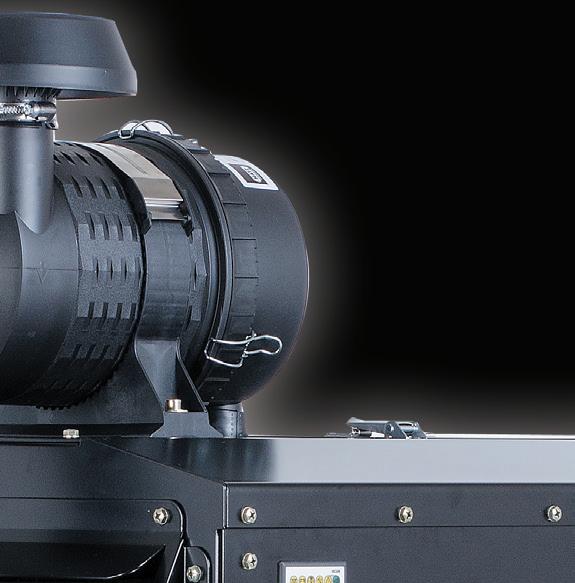

Complete Custom & HighPerformance Exhaust System Components

Grand Bending, a division of Morris Coupling, fabricates short and long radius bends for custom and high-performance exhaust systems for off-highway, asphalt paving, rail-mounted and airport service equipment, as well as on-highway buses and work trucks. An extensive product offering is available in aluminized carbon steel and stainless steel thin-wall tubing. Capabilities include compound bends, welded fabrications, expansion, swaging and beading. ISO9001: 2008 Certified.

Grand Bending 1092 West Atlanta Street, SE Bldg. 1200 Marietta, Georgia 30060 770-426-0734 grandbending.com sales@grandbending.com

Grand Bending is the proven choice for custom and high-performance asphalt paving, rail-mounted, and airport service equipment

Available in aluminized carbon steel

Get complete information at GrandBending.com

Marietta, Georgia 30060 Ph: 770-426-0734 sales@grandbending.com ISO9001:2008 CERTIFIED

OEM Off-Highway | MAY/JUNE 2022 65 Advertisement

or call 770-426-0734.

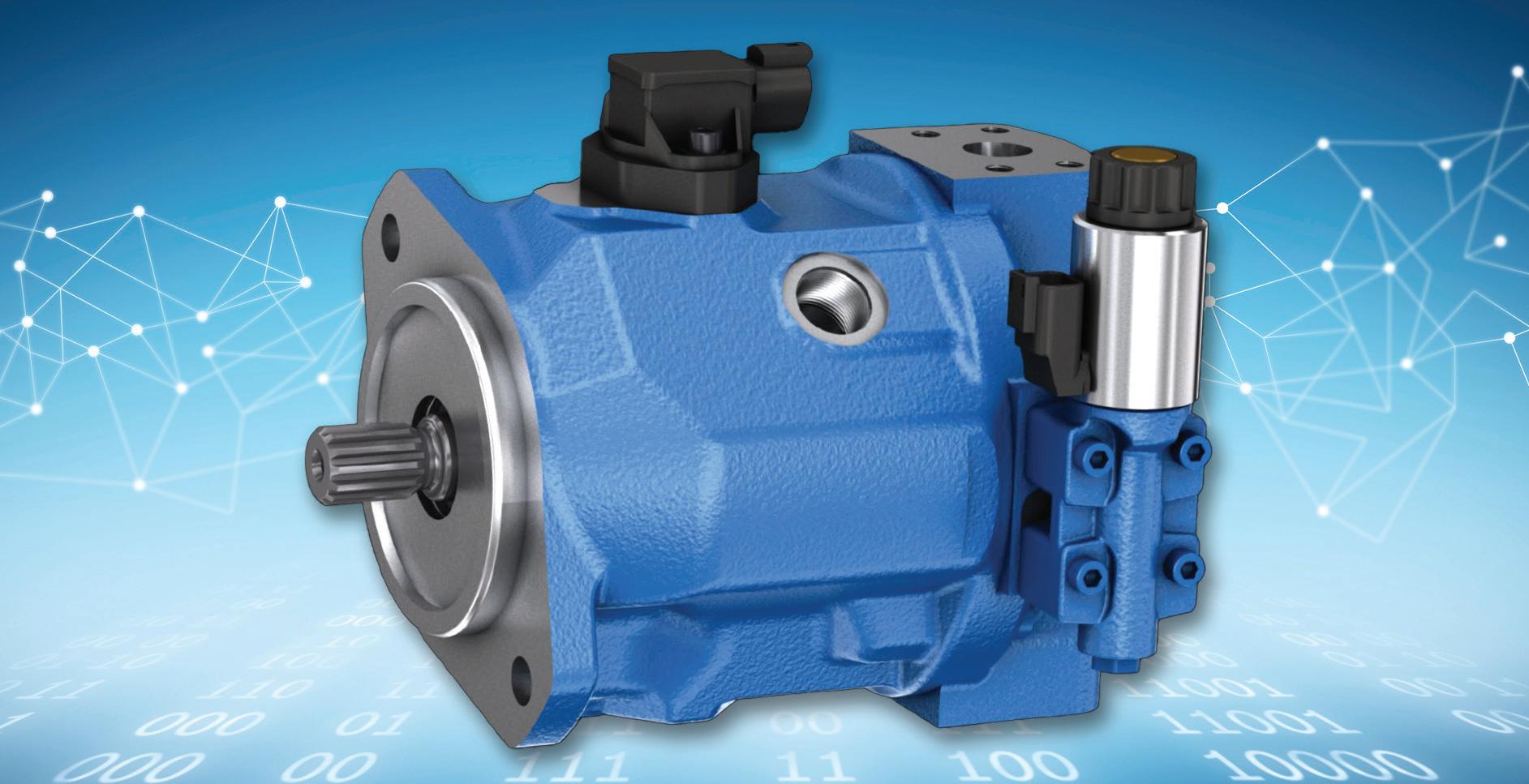

Fluid Power

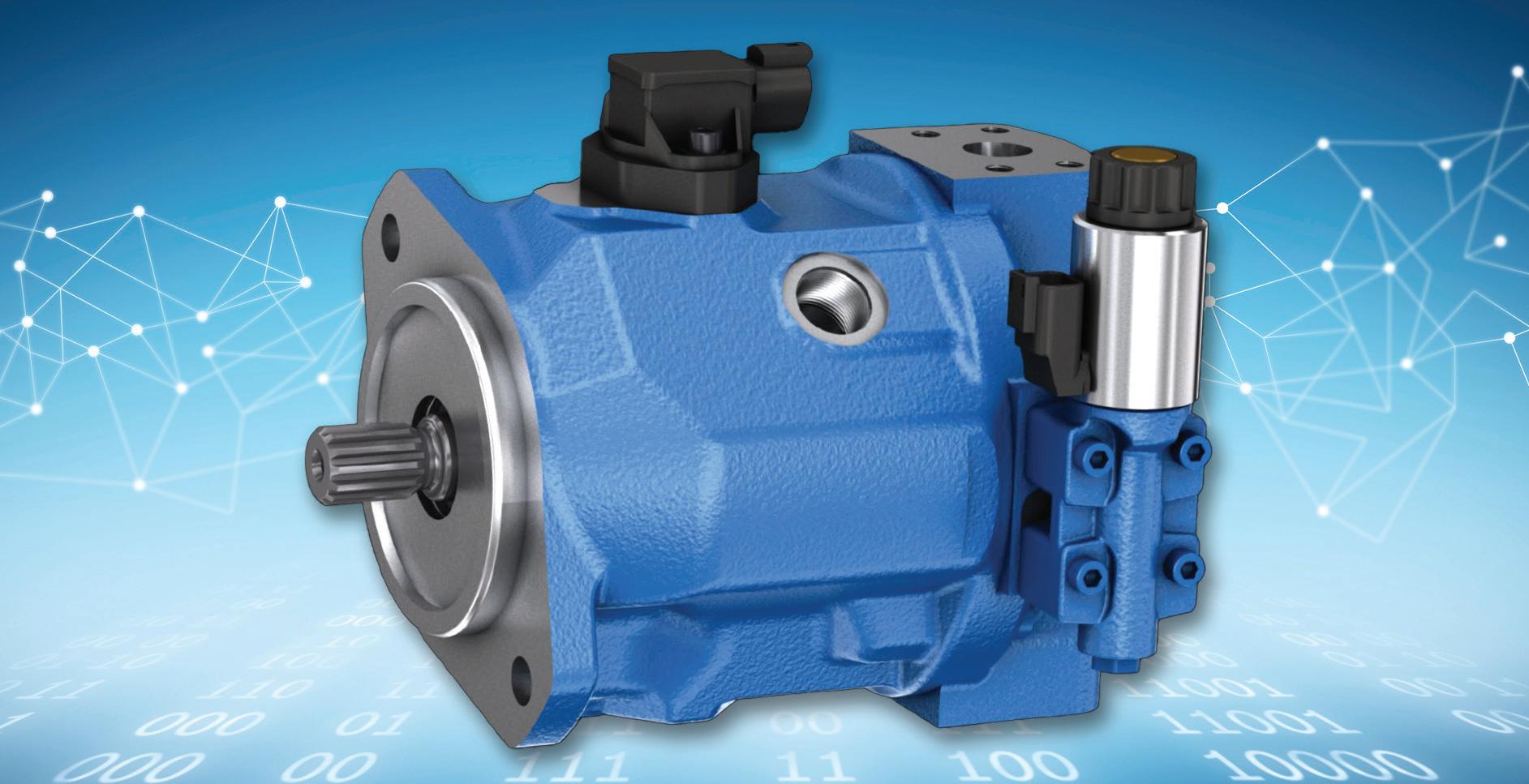

The winner in the fluid power technology category is the Bosch Rexroth Electronic Open Circuit for Pumps. Electronically controlling hydraulic pumps in open circuits with Rexroth eOC provides new possibilities in working hydraulics. The electrohydraulic eOC pump with swivel angle sensor and pressure sensors is the central component in the eOC architecture. It ensures that the proper control of the necessary setpoint values for torque, pressure or flow.

The pump provides dynamic control with millisecond accuracy to modulate the pressure. In combination with the eOC software, characteristics such as dynamics and power control can be set, changed and combined. Controlled via a CAN interface, the eOC software makes it possible to set control parameters flexibly during operation. With hydromechanical control functions and interfaces moved to the software, control modes can be individually changed and combined during operation and the pump dynamics can be set variably.

Pressure, torque, flow and the swivel angle are controlled independently of each other in an electronically closed control circuit. The pump behaves optimally as part of the hydraulic system regardless of function. The eOC software can be installed on a Rexroth BODAS controller or a controller from a third-party manufacturer. It constantly adapts the hydraulic power to the available engine torque and allows dynamic, precise work functions, which ultimately increase the overall productivity of the working machine. The honorable mentions are:

• Ace Pump Corporation PRO 5 Series Pumps

• Danfoss Power Solutions DDP096 Digital Displacement Pump

Engines

The engine category winner is Hatz Diesel Business Digitalization for Light and Compact Equipment with an IoT Dashboard. This addition to an existing product closed the gap between engines of light equipment and digital business.

Users can manage their core business more easily, efficiently, competitively and commercially attractively. The vision of making all drive information available and creating new economic opportunities is provided as Hatz combines electronically controlled engines with digital solutions.

The plug-and-play hardware—electronic control unit and Internet of Things (IoT) module —combined with data analytics provide standardized or customized information that is seamlessly integrated into the fleet management, ERP system or the Hatz IoT dashboard. Digital information is immediately available, ensuring innovative processes, simple usage and optimized management.

The key to connecting to the IoT is the Hatz IoT module. This forms the central hub for the Hatz Digital Solutions and is in use now. Information from engines and digital add-on modules is merged to form an information stream that is made available via the Hatz analytics server, securely and encrypted.

Integration with an end user’s ERP or fleet management system as well as the Hatz IoT Dashboard, offers the user with the option of equipment management within their preferred software solution. This helps bringing operational efficiency and productivity to a higher level.

The honorable mentions are:

• Caterpillar C2.8 and C3.6 industrial power units

• Sy-Klone International Vortex MAX

Operator Cab

For the operator cab technology category, the winner is Sure Grip Controls Endurance Series Joystick. Developed with an ergonomic-first approach, the Endurance Series joystick is specifically engineered for durability in demanding, high-use vehicle applications, including equipment for construction, forestry, agriculture and mining.

With an advanced ergonomic design that matches biomechanical motion and high lumen, titanium oxide LEDs, the Endurance Series joystick simplifies operation.

The fully sealed and impact resistant Endurance Series is CE certified and up to SIL2 compatible. Rated for -40°C (-40°F) to 85°C (185°F) operation, the Endurance Series joystick is designed to withstand extreme cab conditions. The series is rated for up to 5 million cycles (20 million operations).

The honorable mentions are:

• EAO Corporation Series 09 Universal Switch

• Otto Engineering HJLG3-CK Joystick

OEM Off-Highway | NOVEMBER/DECEMBER 2022 14 AWARDS

SURE GRIP CONTROLS, INC.

BOSCH REXROTH CORPORATION

HATZ DIESEL

Maximizing Machine E ciency Integrating Electric and Hydraulics Connecting Off-Road Machinery Smart Electrification

unsurpassed people, technology and expertise that work

to develop electrification solutions with maximized

work

traction applications

Parker enables its partners in the off-road machinery industry access to

together

system efficiency in

and

for a quieter, cleaner parker.com/electrification

STATE OF THE INDUSTRY 2022

Challenges and hurdles often trigger innovation driven by disruption.

by Lori Ditoro

We saw several positives during 2022. Trade shows came back in earnest after nearly two years of cancellations and virtual events.

Nearly 500,000 people attended bauma in October 2022. This trend will continue into 2023 as our team prepares to attend several events, including CONEXPO-CON/ AGG in March 2023.

In addition, the huge push industry-wide to adopt electrification, alternative fuels and digital/internet of things (IoT) is another positive according to Wilfried Aulbur, senior partner, Roland Berger.

“Electrification has become increasingly more important, along with digitalization and a continuous shift in customer channels,” said Aulbur.

We spoke with 10 industry experts (see page 22) to get their insights about the challenges that they, their companies and the industry faced in 2022. We also asked them about their expectations for 2023.

This article examines some of these challenges and successes and looks toward 2023 for what the industry can anticipate in the New Year.

OEM Off-Highway | NOVEMBER/DECEMBER 2022 16

@METAMORWORKS.STOCK.ADOBE.COM COVER STORY

The Biggest Challenges of 2022

According to our experts, without question, supply chain problems topped the challenges globally and for OEMs in the off-highway industry. Working with teams and partners are critical to managing problems arising from delays in the supply chain.

“Behind the scenes, our team has done a great job maintaining our production lines with increasing demands,” said Tasker. “Maintaining a close relationship with our partners is key to resolving this challenge. Understanding their needs and having open communication allows us to collaborate quickly when issues arise.”

For others, adding to their internal team and shoring up engineering talent helped mitigate issues and improve delivery to customers. According to Hazelton, increasing talent on his team was paramount.

“To address this supply chain challenge, we have expanded and upgraded our internal team and invested in engineering and manufacturing experts to help navigate this complicated climate,” Hazelton said. “To better meet demand, we have focused on expanding our labor force at each of our five manufacturing and distribution centers throughout the U.S.”

Regionalizing suppliers has been a priority for Alström. “We’re working hard to localize our supply chains, ensuring our supply is closer to our customers. This is a significant change,” Alström said.

“Although container availability is easing, we are still going full force on regionalization. This can generate time and cost savings while freeing up working capital that we can put to better use.”

According to Harsin, the supply chain has improved but continues to affect the industry.

“Supply chain continues to be among the biggest challenge across the industry,” Harsin said. “We believe things are slightly better than they were in the earlier part of the year

and last year. However, this industry constraint isn’t going anywhere.”

Another challenge is also a positive for the industry and the environment: the transition from diesel internal combustion engines (ICEs) to electric and alternative fuels (including biofuels and hydrogen). However, these generational changes and disruptions are bringing innovation as well as trials.

Past “technological changes pale in comparison to the generational shift that our industry is beginning to navigate with advanced combustion technologies, battery and fuel cell electrification, autonomous vehicle deployment and the connected vehicle,” Harbin said.

Innovative Off-Highway Moves Next Year

When looking to 2023, what do our thought leaders expect to continue to innovate? The move to electrification, a focus on the operator and a bridge to zero emission are all trends that will continue into 2023.

For most respondents, innovation

and activity around alternative power sources will continue. These include:

• Biofuels, such as hydrotreated vegetable oil (HVO) and ethanol

• Electrification

• Hydrogen

• Hybrid configurations

“Alternative power sources are a strong focus in passenger vehicles; that is carrying over to the offhighway industry,” Ludwig said. “We anticipate that in 2023 alternative power will continue to be developed as companies like Volvo are already rolling out battery operated electric vehicles.”

Braden anticipates a continued focus on improvements for the operator’s environment.

Emphasis will continue “on better ergonomic solutions, efficiency and enhanced technology to reduce operator fatigue, increase safety, and lower emissions,” Braden said.

Allen anticipates more ways to utilize sensors.

“We expect to see more automation with sensors—not for just driving— but also to manage work zones and

OEM Off-Highway | NOVEMBER/DECEMBER 2022 17

@XIAOLIANGGE.STOCK.ADOBE

specific job applications.”

Equipment as a service (EaaS), like software as a service in the industrial sector, and intentional design for electrification and hybrid operation are likely to expand further next year.

According to Aulbur, “Movement towards leveraging technology to enable new service models at the dealer level is something that will continue to accelerate. Some lessons learned from recent innovation in the on-road and even passenger car space can potentially be successfully transferred to off-highway.

“Longer term, we are likely to move towards using the EaaS model for parts of our sales, similar to what we see in some industrial companies,” Aulbur said.

Hazelton predicts that designing equipment for electrification and

hybrid configuration will grow.

“As we see more OEMs pursuing electrification and integrating battery power into their equipment offerings, I think we’ll see a greater emphasis on intentional design of a battery system versus simply replacing an engine with a battery,” Hazelton said.

Tasker agrees with the electrification trend and anticipates connectivity advancements as well. “Innovation in renewable fuels and electromobility will continue to advance in 2023,” Tasker said. “We will also see an increase in connectivity and telematics that allow companies to enhance efficiency within their operations.”

Hurdles in Moving Toward Electrification & Automation

Progress has been made in 2022 to advance the use of electric power and

automation. However, challenges to adoption remain moving into 2023.

While passenger vehicles are rapidly moving toward electrification, Aulbur indicates, challenges exist for commercial and off-highway assets.

“Electrification is feasible for a number of commercial vehicle use cases,” Aulbur said. “Others may require hydrogen. For off-highway, we see electrification potential up to about 56 kW. Yet we need to solve some issues as charging availability at construction sites as well as fast charging mechanisms that are adequate for high-energy density off-highway applications.”

Most thought leaders brought up charging infrastructure as a major inhibitor moving forward.

“Electric or hybrid powertrains can improve the efficiency, productivity,

OEM Off-Highway | NOVEMBER/DECEMBER 2022 18

@KRUNJA.STOCK.ADOBE.COM COVER STORY

CARLINGTECH.COM/ON-OFF-HIGHWAY Electronic Switching, Controls, Power Distribution & Protection Concrete Solutions Visit Us at Las Vegas, NV South Hall 4 - Booth S85107

and fuel economy of any machine or application,” Alström said.

“Hybrid solutions improve machine performance while battery-powered machines enable zero-emission operation. The challenge is charging infrastructure. Charging stations aren’t typically available in remote areas, which is an obstacle in electrifying

forestry machines and some agricultural machines. Fortunately, fuel cells can provide an alternative to batteries for zero-emission operation. We believe in hydrogen technologies for many of the market segments in which we do business, even if the technology readiness for mass implementation is some years out.”

Several industries are likely to face challenges making this transition, including all heavy-duty industries.

“The industries that will face the most hurdles in the move toward electrification will be heavy-duty construction, forestry and agriculture,” Block said.

OEMs Embrace ESG Goals and Move Toward Cleaner Power Sources

Most off-highway OEMs are adopting or have adopted the global environment, social and governance (ESG) goals. With these, protecting the environment is a priority.

This goal goes together with decreased emissions, the use of alternative fuels and the move to electrification in the industry.

As OEMs embrace sustainability, their suppliers are answering the call as well. Tasker said, “We understand that we have a role to play in empowering OEMs to be climate stewards. It’s a commitment that must be evaluated strategically across the value chain from economic, social, and environmental points of view. By collectively embracing this mindset, we can drive advancement in stateof-the-art technology solutions while moving toward a sustainable future.”

Government benefits may also help OEMs move toward sustainable power sources. The government is funding many [diesel-hydrogen-hybrid] projects with grants and subsidies to

OEM Off-Highway | NOVEMBER/DECEMBER 2022 20

@THEEVENING.STOCK.ADOBE.COM COVER STORY

push progress in this area,” Ludwig said. “Off-highway OEMs are reevaluating their product development to build these alternative power sources into vehicle designs.”

The social component of the ESG goals includes diversity and inclusion. This is a target for Danfoss Power Solutions.

“We are focusing on becoming a more diverse, inclusive workplace where everyone—no matter their background, skin color, age or sexual orientation—feels that they belong,” Alström said. “Diversity for us is the key to leading our organization into the future. Diverse teams deliver better results, and they have much better innovation track records. Diversity of thought is a superpower.”

Biggest Challenges in the New Year

Geopolitical uncertainty with the Ukraine war, supply chain issues, infrastructure needs and workforce challenges will influence the industry into 2023. While the supply chain problems will continue to improve, lessons learned during 2022 should be used to try to avoid similar problems in the future.

“We need to take the learnings from the semiconductor crisis, the Russia/ Ukraine war and the supply chain crisis and ensure that they become part of our organizational fabric,” Aulbur said. “We need to develop a robust organization that can react to unexpected disruptions in an agile way while keeping its eye on its original mission.”

Because of the supply chain crisis, sourcing and pricing raw materials are a priority looking into 2023.

“Stabilization of raw materials and component pricing needs to occur, as current demand will not wait for new or alternative solutions,” Braden said. “Insourcing and innovation will also require investment on top of this, which will require companies to balance meeting production demands and being custom solutions providers.”

Workforce and talent retention will continue to challenge the industry into the New Year as well.

“Recruiting and retaining talent will continue to be a challenge as the industry faces a tight labor market in certain regions,” Hazelton said.

“We are placing a heavy emphasis on recruiting top talent for our electrification business as we build a world class team to lead the evolution

and growth of our electrified power solutions.”

MOBILE MACHINES SENSORS

The need to shore up the power grid to support the electrification of more mobile assets is also an obstacle moving into the New Year. According to Hazelton, “…One area of concern is the demand for electricity and the stress it will place on existing power grids. There is a pressing need to address infrastructure so we can safely SIKO Products Inc., www.siko-global.com

OEM Off-Highway | NOVEMBER/DECEMBER 2022 21

Stroke measurement in hydraulic cylinders – no piston-rod rifle boring required! Robust rotary encoders for safe angle and speed measurement! Up to PLd! Draw Wire-actuated rotary encoders for position measurement utilizing proven technology! Inclinometers for non-contact measurement of vehicle orientation!

FOR

and consistently meet the demands of an electrified customer base.”

In addition, ensuring that OEMs understand the correct battery sizes needed for their equipment is required. This optimizes the operation of the equipment and makes sure that equipment only charges a battery of the correct size for the applications.

“As we continue to see advancements in electrification over the next year, I believe the industry

will have to navigate the challenges of managing customer expectations when it comes to battery power,” Block said.

“Since the introduction of battery technology to the off-highway market, range and run time have been concerns. As more OEMs look to integrate battery power into their equipment, proper

and

packaging will be critical.”

OEM Off-Highway | NOVEMBER/DECEMBER 2022 22

sizing

power density

These are the off-highway industry thought leaders who provided great insights into how we faired in 2022 and what they expect entering 2023. Check out the QR codes to read each expert’s full responses to our questions.

Brian Hazelton Senior VP & President, Power Business Unit, Briggs & Stratton Read more

Jim Braden Vice President Sales & Marketing, PACCAR

Paul Ludwig President and CEO, HED Intelligent Controls Read more

Darren Tasker Vice President of Industrial Sales, Volvo Penta Read more

Nick Block Director, Global Marketing and Sales, John Deere Power Systems Read more

Branden Harbin Executive Director, Global Marketing, Allison Transmission Read more

Jeremy Harsin Global Construction Market Director, Cummins Read more

Jace Allen, Technical Evangelist, dSPACE, Inc. Read more

Eric Alström, President, Danfoss Power Solutions Read more

COVER STORY

Wilfried Aulbur, Senior Partner, Roland Berger Read more

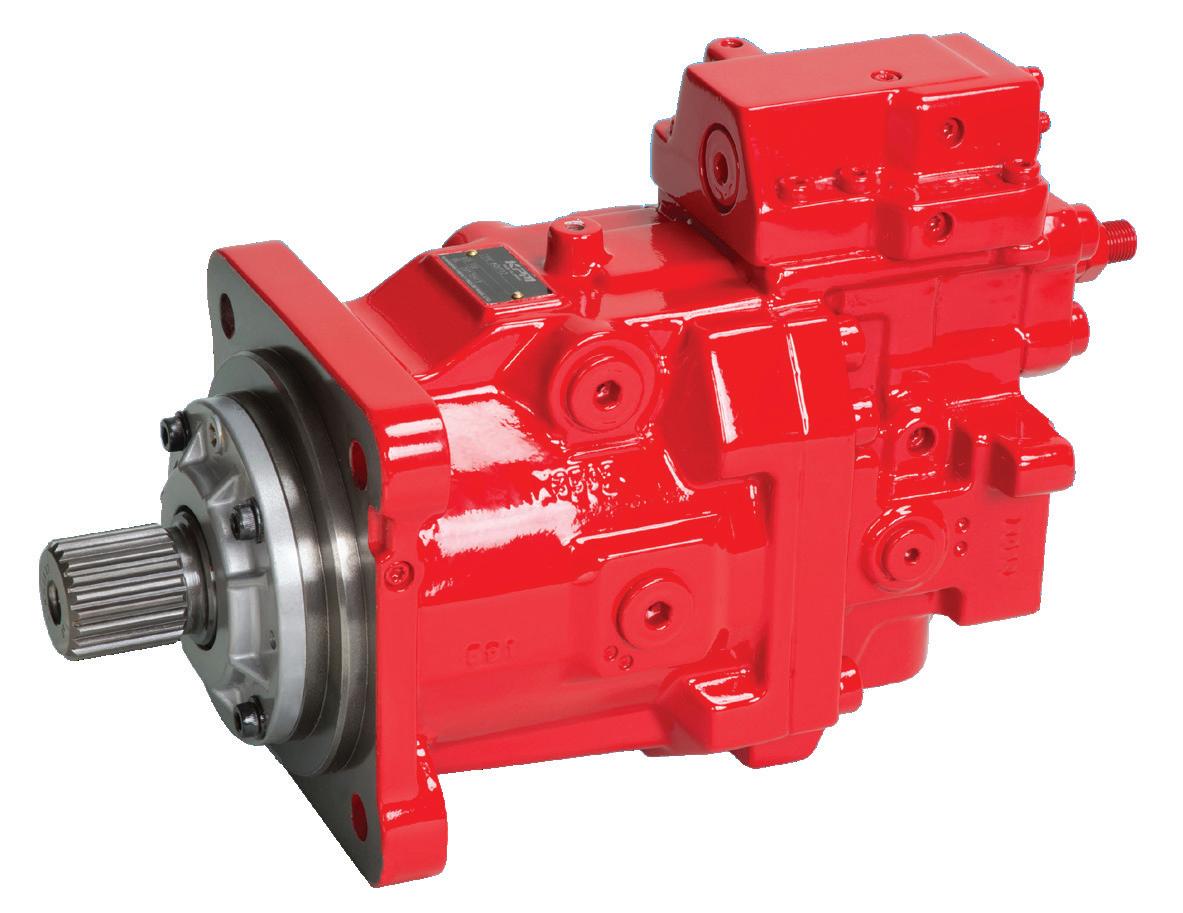

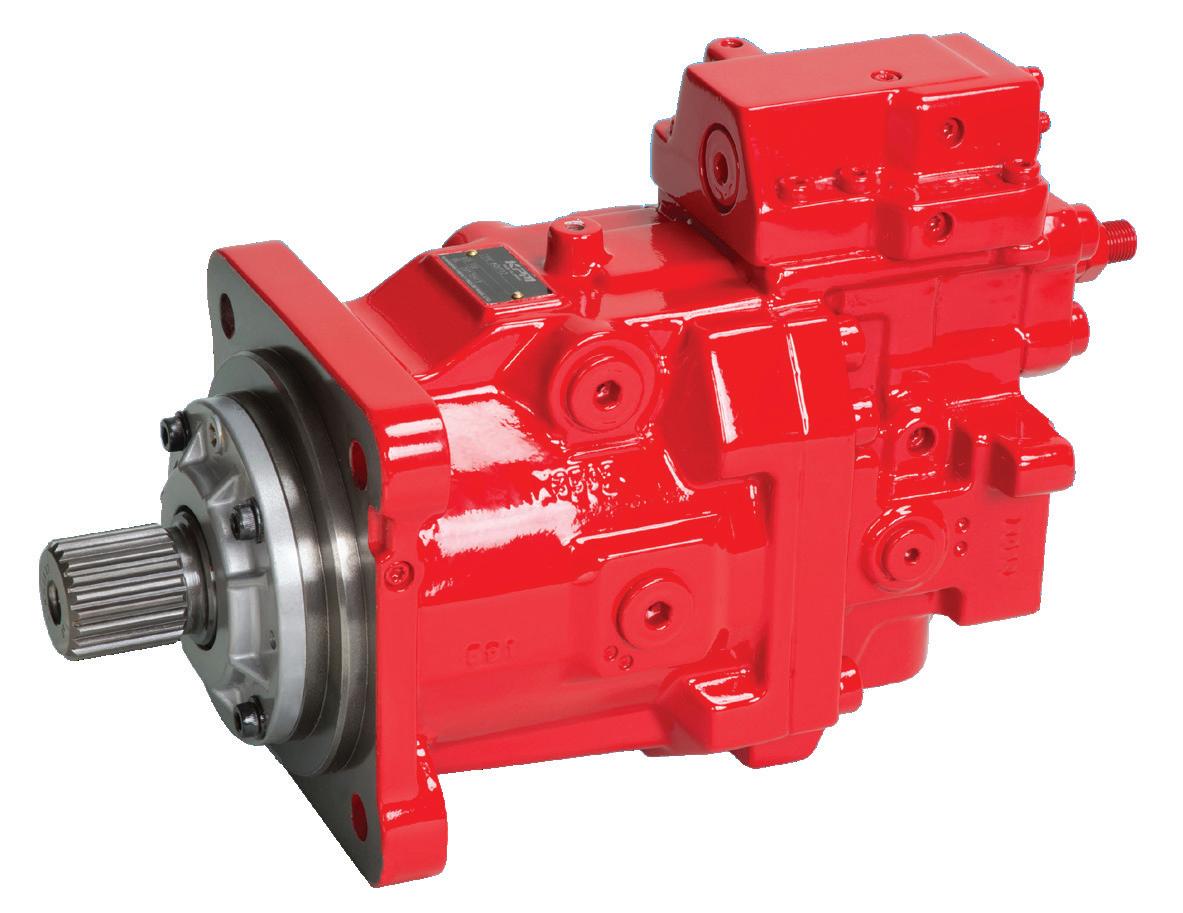

Kawasaki Precision Machinery (U.S.A.) Inc. • Grand Rapids, MI • www.kpm-usa.com • 616.975.3100

Axial Piston Motor • 85, 112, and 160cc displacements • 420 bar continuous pressure rating • Electric, hydraulic, two-position displacement and pressure related displacement controls • 85 & 112cc fixed displacement versions available • Optional Speed Sensor / X Quality Precision Performance Reliability

Kawasaki is a world-leader in motor efficiency and performance. Inside our range of products you’ll find some of the most efficient axial piston motors available on the market today. Our engineers understand our customers’ needs, each motor has been designed to deliver high performance across a diverse range of applications.

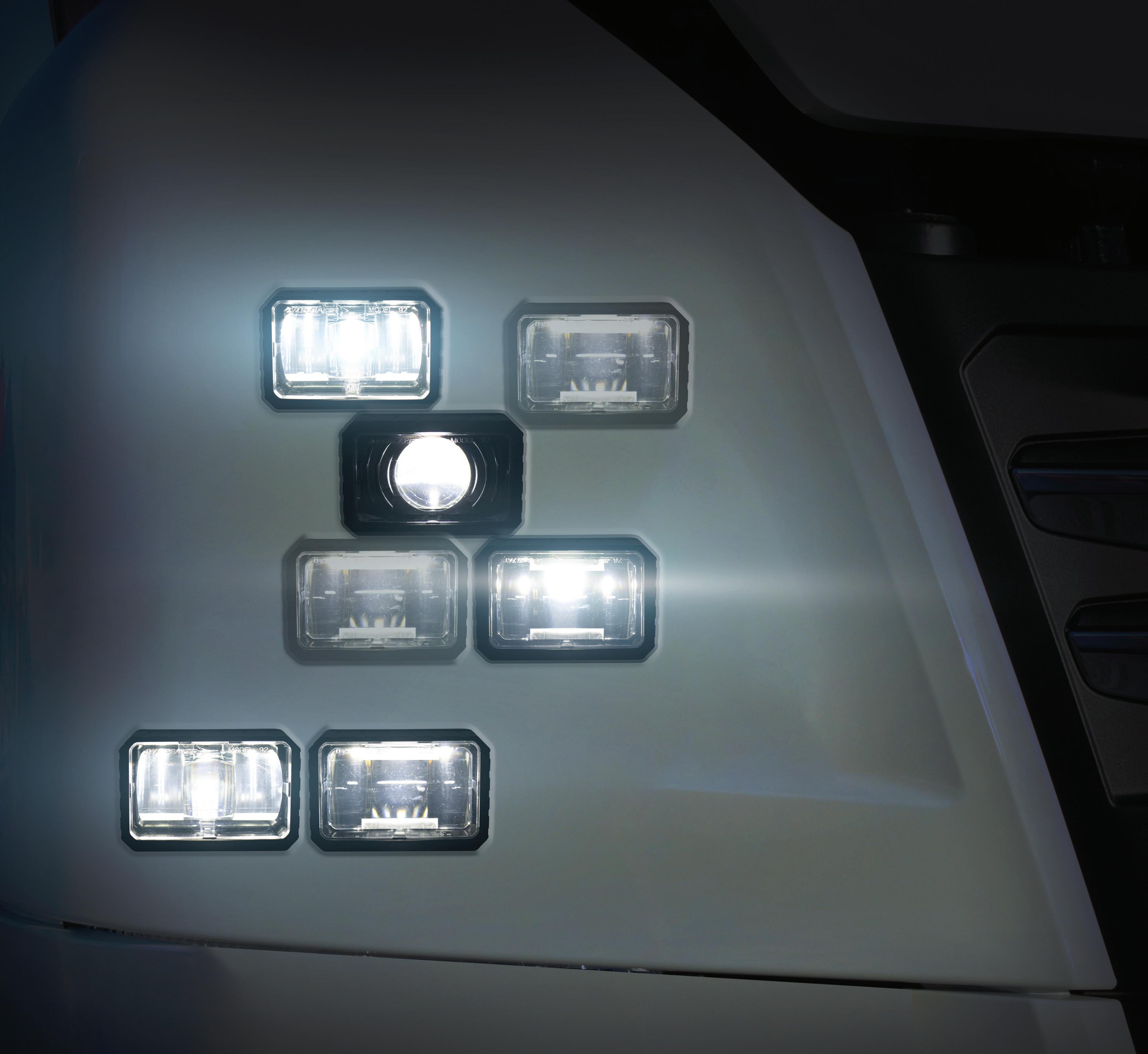

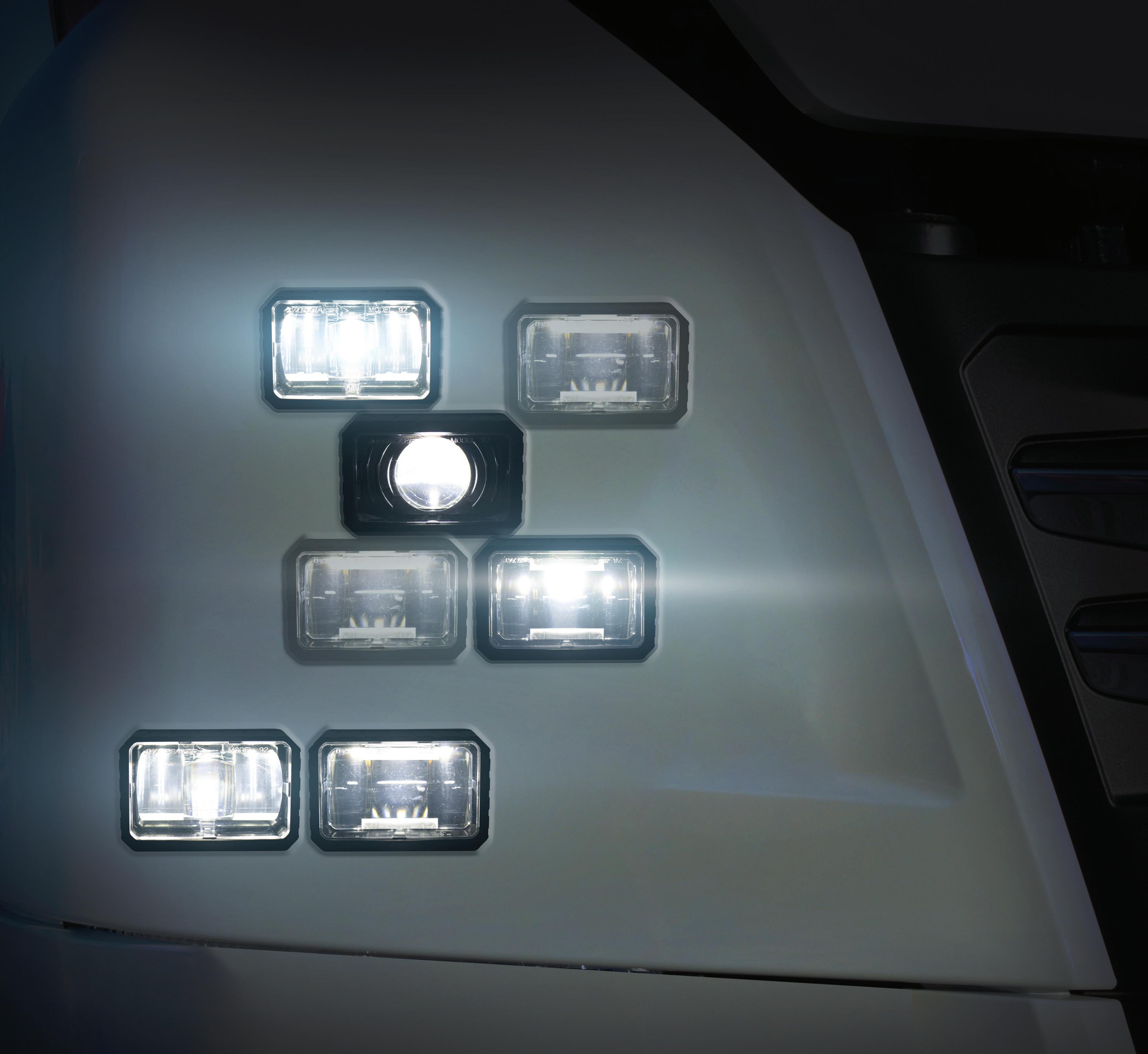

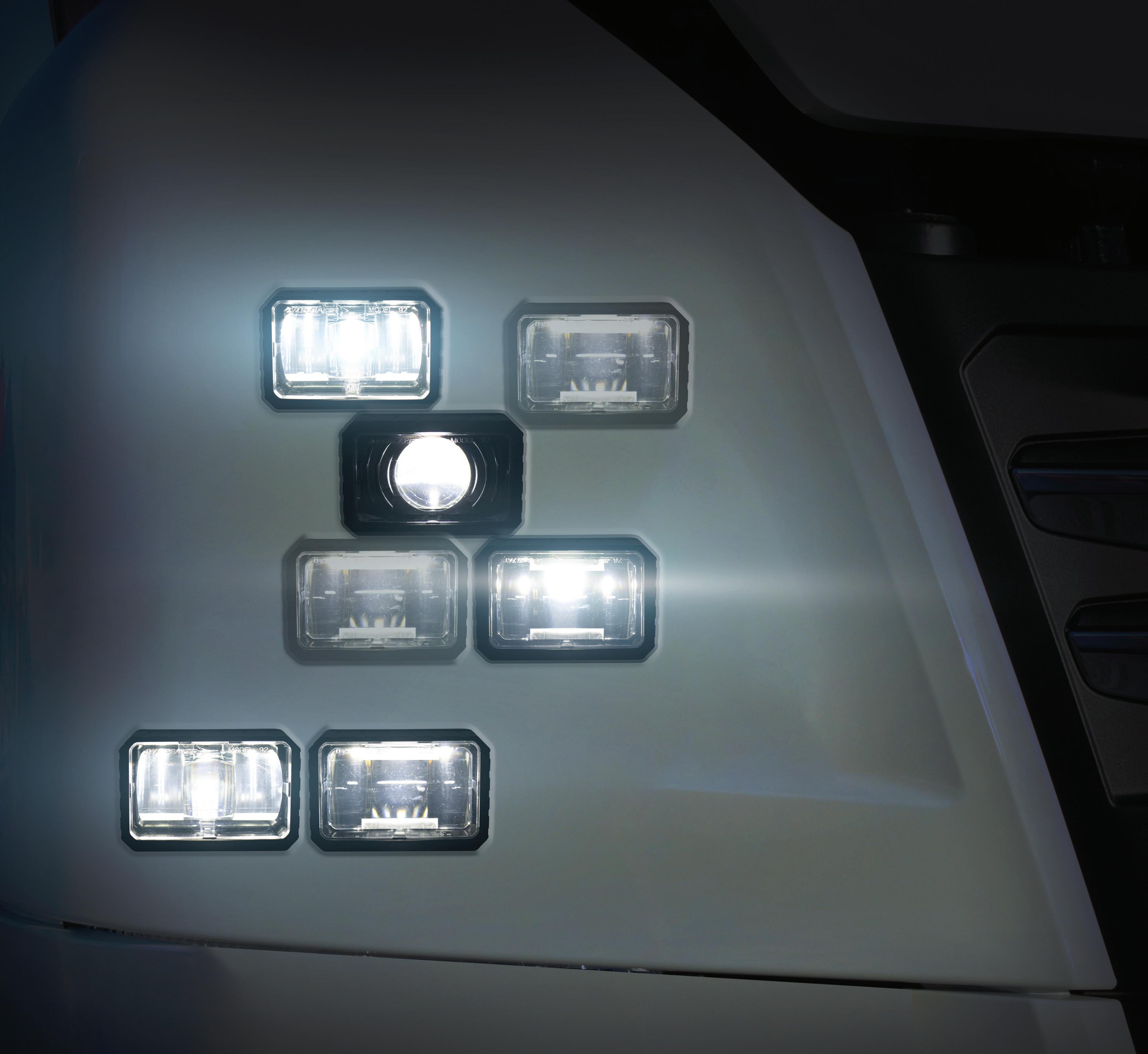

INTRODUCING THE MOSAIC LIGHTING SYSTEM

Design Flexibility

Create a wider range of unique, compelling and affordable lighting designs to accommodate more styles and applications.

Custom Lighting Endless Applications

OEM designers can incorporate a wide range of multifunctional DOT and ECE standard LED’s into custom bezels to reduce cost and expedite time-to-market.

Introducing the Mosaic Lighting System designed by J.W. Speaker: the new standard for custom lighting design. The Mosaic Lighting System includes pre-assembled lighting functions, including Low Beam, High Beam, Fog, Turn Signal, and DRL to mix and match to fit your design specifications.

The Mosaic Lighting System is compatible with a wide range of vehicle applications including but not limited to: agriculture, powersport, bus, construction, RV, and Truck.

Lower Development

Add pre-configured standard lights to custom housing to simplify the design process and eliminate unnecessary development hurdles

Our modular designs paired with your concept, make for endless possibilities. Select the function of lights desired and place them in a configuration that works best for your vehicle application — and avoid optical tooling and homologation costs of individual lamp functions without compromising quality or compelling design.

Reduce delays, avoid regulation hassles, and cut costs during the design process with the Mosaic Lighting System. Bring your designs to market faster.

Learn more: www.jwspeaker.com/mosaic/

Or scan:

Punch

High Beam

Spread

Punch

Spread DRL/Turn Punch

Punch

High Beam

Spread

Punch

Spread DRL/Turn Punch

The Future of Mobile Hydraulics Is Digital

Digital technology reduces mechanical complexity and improves functionality.

by Enrique Busquets, Bosch Rexroth Corporation

When building mobile machines, original equipment manu facturers (OEMs) face conflicting pressures and demands that impact hydraulic system design. Often, they must make difficult choices between streamlined architecture or more functionality, types of controls, or whether to provide maximum perfor mance over smooth operation.

With traditional hydraulics, the only way out of this dilemma is to make ei ther-or decisions—compromising one benefit for another. Once the choice is solidified in the hardware, those fea tures are set to stay the same through out a mobile machine’s service life.

The emergence of digitaliza tion—the movement to complement hydraulics with electronic systems and controls—in the mobile machine mar ket may help overcome some of these

challenges in certain applications, as hydraulic systems will continue to play a crucial role in mobile machines well into the future. Hydraulics deliver the power density, reliability and controlla bility that many operators need in the field. As hydraulic technology evolves alongside other technologies, OEMs are finding new ways to maximize the advantages with fewer drawbacks.

In fact, advancements in software and digital technology are opening a new world of possibilities for mobile hydraulic systems. Digitalized hydrau lic solutions are solving the either-or dilemmas by transferring hydraulic and mechanical control functions and interfaces into software. As a result, machine builders and end users alike are realizing a new range of operation al and business benefits that will shape the future of mobile hydraulics.

Advanced Software Simplifies Hydraulic Hardware

In standard implement hydraulics today, a pump has a specific config uration of control devices to deliver a desired functionality, along with a hose that is connected to a main control valve that delivers load-sensing pressure to control the pump dis placement. The digitalization of these hydraulic systems allows manufactur ers to simplify machines and eliminate complex mechanical devices, hoses, fittings and even external manifolds.

These parts are replaced with standardized components, electronic devices and advanced physics-based software that allow engineers to tune physical parameters digitally. This also allows OEMs to make fundamental changes to controls, completely trans forming the human-machine interface in the machine’s cab.

FLUID POWER OEM Off-Highway | NOVEMBER/DECEMBER 2022 26

BOSCH REXROTH CORPORATION

This digital application solution provides an ecosystem of software and hardware for the digital transformation of the off-highway market.

ENHANCE

THE LIFESPAN

YOUR

• SFEX

• RFEX

• LFEX

Available

OF

MACHINES PASSION TO PERFORM ELIXIR® guarantees easy maintenance by replacing only the cartridge style filter element FEX with a lower environmental impact than previous models Spin-on range

SERIES - Suction

SERIES - Return

SERIES - Low pressure

in 4 sizes: 060, 080, 110, and 160

New low pressure filter series designed for applications to 232 PSI and enhanced performance compared to spin-on filters. Interchangeable to MPS050/070 and 100/150 size spin-on series with increased working pressure and flow capacity.

Robust bowl to head sealing system to prevent external leakage as compared to traditional spin-on filters. Fast, simple bowl removal via hex nut wrench connection to service the patented cartridge style element providing guaranteed original fit service element over machine life. Zero leak bypass valve www.mpfiltriusa.com (215) 529-1300 sales@mpfiltriusa.com

By streamlining the mechanical architecture, manufacturers can save considerable costs not just in compo nents but also in logistics, production, assembly and service. These adjust ments can help end users reduce their costs as well. Having fewer mechanical components reduces maintenance. This also improves performance and leads to reductions in hysteresis and improvement of dynamic behavior. The advanced software additionally offers performance benefits, like more pre cise control and the ability to manip ulate the system behavior, ultimately leading to higher machine perfor mance and higher energy efficiency.

More Flexible, More Functional Mobile Hydraulics

The versatility of digitalized hydraulic systems also adds functionality. Wheth er a machine is used for construction, agriculture or material handling, OEMs can implement digital controls for the entire vehicle. This allows OEMs to standardize and consolidate compo nents for a streamlined way to achieve different functions.

Take for instance an OEM whose implement applications require either power control, electronic proportional control or other pressure-limited con trols. With a standard hydraulic system, each control would require different pumps with unique part numbers and configurations. More interestingly, even in pumps with the same control devices, an application could require

different configuration settings, leading to additional part numbers. In contrast, a digitalized electrohydrau lic solution uses digital controls that achieve the same functions through a single pump with a single standardized control device and advanced parame trized software.

The ability to replace mechanical hardware with software does not just create more flexibility for the OEM. It also gives end users improved versa tility. Standard hydraulic systems lock end users into limited characteristics and do not typically offer the ability to switch modes for different applica tions. With digital controls, everything is changeable through software. This gives end users the ability to switch between different operating modes at the flip of the switch.

New algorithms for additional ma chine functions can even be enabled or downloaded to the machine via the cloud. This opens a wide range of opportunities for new applications and new business models. Enabled or downloaded functions can be offered as a one-time purchase for a single job, or they could be provided as a premi um service via a subscription, similar to business models used in today’s consumer vehicles.

This hydraulic architecture lets machine manufacturers digitalize machine functions through software to reduce hardware components, improve flexibility and dynamically control drives and applications.

FLUID POWER OEM Off-Highway | NOVEMBER/DECEMBER 2022 28

BOSCH REXROTH CORPORATION

Digitalized mobile hydraulics combine hydraulic hardware, electronic components and network solutions to help machine manufacturers create the next generation of mobile machines.

BOSCH REXROTH CORPORATION

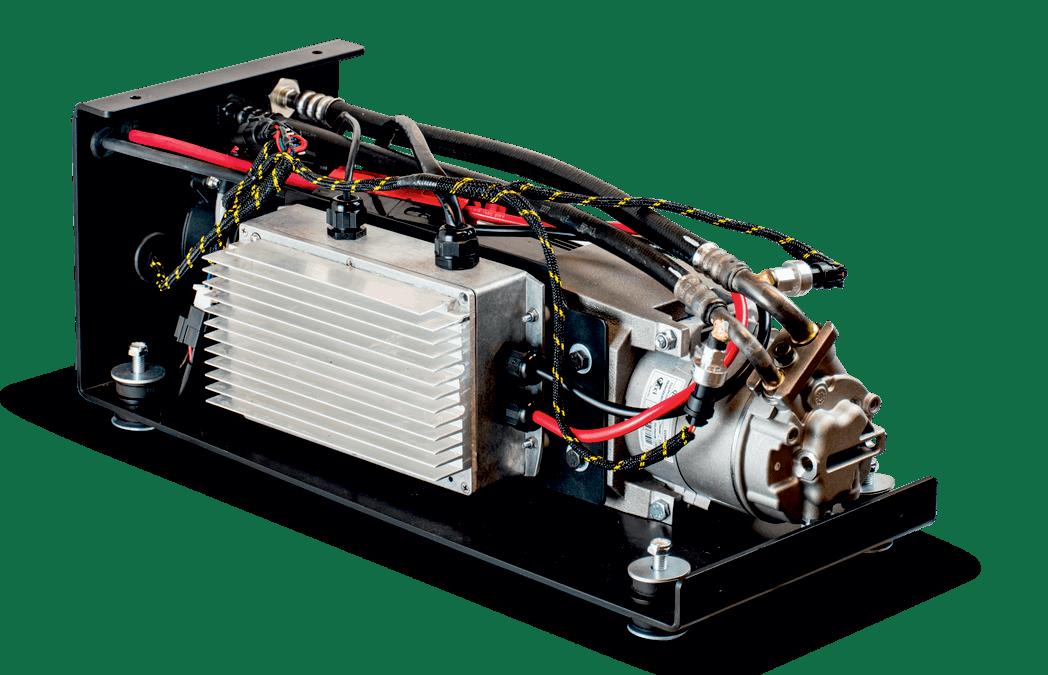

Accelerate Vehicle Electrification with Solutions from Molex

Electrification is revolutionizing commercial vehicle performance and efficiency. Manufacturers are better able to amplify electric capabilities and reduce maintenance costs as vehicle architecture and driver experiences shift.

Wesgarde, a provider of interconnect solutions for the ConAg, industrial, and transportation industries, is engineered to deliver Molex solutions for commercial vehicle electrification.

TM ISO 9001 Talk to us today!

representative. Squba Sealed Wireto-Wire Connector Carries up to 14.0A of current to deliver reliable power in space-constrained applications, like LCD displays inside buses MX150 Sealed and Unsealed Connector System Offers superior operating temperatures and current ratings up to 22.0A, with sealed versions for exterior lighting modules Terminal Blocks Distribute power from source to various elements in high-power equipment like charging stations Triton Busbar Braid

RA Straight Move power from point A to B safely in battery management systems

Wesgarde has many locations across the country. Call 1-800.554.8866 or email us at info@wegarde.com to connect with a sales

Tin

This digitalized electrohydraulic solution uses digital controls that achieve the same functions through a single pump with a single standardized control device and advanced parametrized software.

New Mobile Machines Will Be Easier to Scale

With simplified hydraulic components and a much broader range of func tionality, machine manufacturers have far greater abilities to develop new machines and scale them for market. From design and development to assembly and deployment, OEMs can reduce complexity and costs to get to market faster.

The next generation of digitalized hydraulics makes machine function ality dependent on software, not on hardware. This makes it far easier to apply functions with a single program across the entire range of vehicles and parametrized values that allow the same functionality to be used for different machine weight classes.

In turn, manufacturers can take a much more modular approach to building new machines, using fewer parts that are more standardized across their product portfolio. It also streamlines logistics, with less hardware variance in purchases and inventory.

This scalable approach to machine building could set in motion a new wave of innovation in the mobile machine market. With digitally driven functionalities, it takes less engineering and design effort to implement a new vehicle feature or create entirely new machines.

Where Mobile Hydraulics Are Going Next

As more OEMs adopt a software-driven approach to mobile machine design, they will find new ways to use digital technology to reduce mechanical complexity and improve functionality. They will also discover new ways to use the abundance of data produced by these systems.

The digitalization of hydraulic components requires built-in sensors that gather important data like load sensing pressure, implement speeds and temperature, which can be used to unlock new capabilities via connected devices. That data can be used to:

• Gather important predictive mainte nance insights

• Optimize machine performance and precision

• Improve energy efficiency

These capabilities will unlock new business opportunities for OEMs as well. Machines can be upgraded with premium functions at any time via new software, or they can come packaged with subscription services.

Where mobile hydraulics go next will be up to the OEMs who take advantage of these digital solutions. With more flexibility and functionality that’s easier to scale, machine builders have the power to decide the future of mobile machines.

Enrique Busquets is director, product area mobile electronics and electrification, with Bosch Rexroth Corporation.

Read more: https://oemoh.co/wmxybj

FLUID POWER OEM Off-Highway | NOVEMBER/DECEMBER 2022 30

BOSCH REXROTH CORPORATION

The 3 Cs That Mining Must Consider Before Going Electric

by Mark Hannan, Shell Mining

Electrifying mines requires smart thinking around these key factors.

The World Economic Forum suggests that the production of minerals like graphite, cobalt and lithium could increase by nearly 500% by 2050 to meet the growing demand for clean energy technologies.1 The role of the mining industry—and by association, its equipment—in the energy transition is only likely to grow during the coming decades.

Though this output will help other industries achieve a lower-carbon future, it means mining itself faces somewhat of a paradox. Accounting for between 4% to 7% of global greenhouse gas (GHG) across Scope 1 and 2 emissions alone, the industry is facing increased scrutiny over decarbonizing itself.2 And given that

40% to 50% of mining’s carbon dioxide (CO2) emissions come from the diesel used in mobile equipment, these assets should arguably be a top priority for the sector.3

Mining’s reliance on diesel is well documented, with the sector using almost $7 billion worth of dieselpowered equipment globally.4 Because much of this ends up powering on-site vehicles, estimates suggest that the decarbonization of haulage trucks alone could reduce a mine’s emissions by up to 25%.5

With industry output likely to be even more energy intensive in the coming years, electrification is set to become more of a necessity for businesses. Though, as a hard-toabate, industrial sector, mining is

ELECTRIFICATION OEM Off-Highway | NOVEMBER/DECEMBER 2022 32

@BBANDSIR.STOCK.ADOBE.COM PHOTOGRAPIC SERVICES, SHELL INTERNATIONAL LIMITED

likely to face several complexities in its electrification transition. As an industry that affects all sectors, it is important that original equipment manufacturers (OEMs) and mining operators are aware of the considerations involved in making electrification a success environmentally, operationally and financially.

1. Cost: Look Beyond Upfront Investment for Electrification’s True Value

Like any operational transformation, one of the most important considerations when it comes to electrification is cost. Although electric equipment can be cheaper to operate and maintain when compared to its diesel counterparts, the initial, upfront investment in the technology and equipment can be significant.

To prevent the dissuading of companies from exploring electrification, a total cost of ownership (TCO) approach can be useful. TCO is the total amount spent on industrial equipment, including cost acquisition and operation over its entire life, as well as the costs of lost production

during periods of unplanned downtime.

The numbers back this up, too. Despite higher upfront vehicle and infrastructure costs, McKinsey estimates that by 2030, TCO for a battery electric vehicle (BEV) or fuel cell electric vehicle haulage truck will be approximately 20% and 10% lower, respectively, than existing diesel trucks.3

This is largely due to 20% to 30% lower maintenance costs and 40% to 60% lower fuel costs.3 Figures which underpin the potential that electrification holds for improved operational efficiency. Meanwhile, the projection that battery pack costs are set to decline 50% by 2030, points to a much more accessible and affordable entry point down the road.5

Other positive consequences center on environmental factors. For one, the cost of capital can be 20% to 25% higher for those miners with the lowest environmental, social and corporate governance scores, meaning an investment today is likely to pay dividends for years to come.3

Tied in with this is the importance of ensuring renewable energy sources for any electrified equipment being used. While 30% to 35% of mining’s current CO2 emissions come from non-renewable electricity, switching to a green source of electricity could address between 30% to 50% of the industry’s current emissions output.6

2. Conditions: Making Electric Work Across the Value Chain

To ensure a reliable and renewable electricity supply, and therefore allow electric equipment to thrive, a mine site must also consider the conditions in play. This includes both the logistical conditions above-ground that will help provide the necessary power for BEVs to run and the physical conditions below, which any electric equipment will have to operate in.

Starting with the former, power supply presents challenges. One of the first the decision over which comes first: guarantees of an adequate electricity supply or investment in the equipment itself. The fact that mining companies do not always have visibility into power grids makes this an even trickier puzzle to solve. To make things harder still, 42 of the top 50 mining-dependent countries are currently underdeveloping their renewable capacity, making a consistent, efficient energy supply difficult to come by.7

To remove these logistical barriers, mine operators have a couple of different options. They can either identify several partners that each bring their own expertise to the table, from energy supply to infrastructure to equipment. Or they can identify a partner that provides an integrated offering by combining mining experience, technology and equipment with energy-related expertise.

A partner that is involved at almost every stage of the power supply system while also providing a range of digital solutions and services is ideal. The digital solutions should target

ELECTRIFICATION OEM Off-Highway | NOVEMBER/DECEMBER 2022 34

@SASHAGRUNGE.STOCK.ADOBE.COM

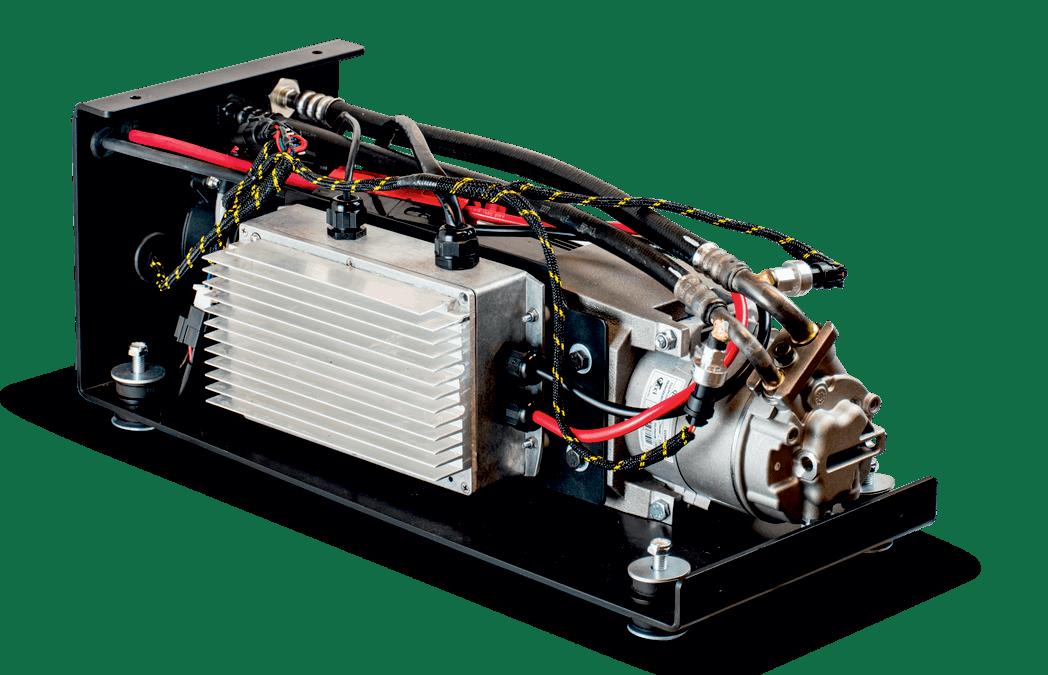

Innovation for the future, built on decades of expertise

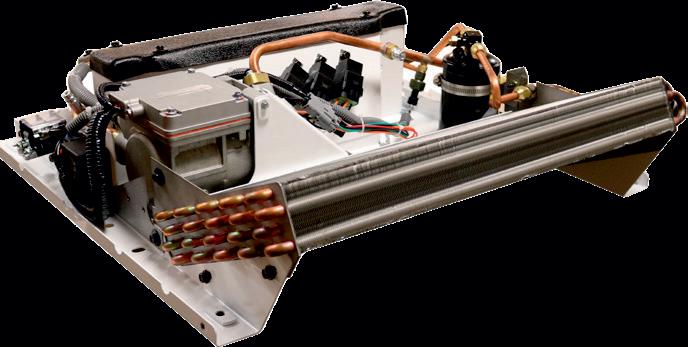

At Red Dot, we know that battery electric vehicles (BEVs) are the future. That’s why we are hard at work, partnering with OE companies to design and create HVAC systems that work symbiotically with on- and off-road BEVs.

From designing custom solutions for specific end-user needs, to creating a suite of electric products that endure the harshest environments, Red Dot has the capabilities to create a myriad of systems that support electric vehicles including in-cab climate control, battery climate control, HVAC system electrification and more.

Visit www.RedDotCorp.com to contact our sales team for more information.

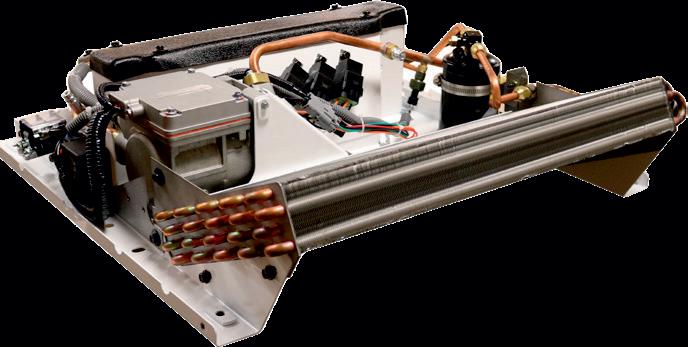

Electric Rooftop A/C

Electric Condenser R-9925: Electric Compressor

Electric Compressor with

E-6100:

E-9725:

R-9926

Condenser

important areas like:

• Fuel efficiency: Through data transparency and advanced analytics that can improve fuel efficiency while reducing costs.

• Tailings storage facility management: Providing a onestop shop that can help manage performance and risk by improving communication across the entire tailings process.

• Emissions management: Helping to manage a mine site’s emissions through live, dynamic reporting that supports proactive, strategic and data-driven decision making. Together, digitally enabled tools can help connect operational silos across the value chain, helping to forge a more integrated and effective ecosystem. The centralized insights that some platforms offer can help with demand and supply-

side management too, by providing the visibility needed to balance the equation.

Because of the specific, physical conditions presented by a mine site, there is also an increasingly important role for equipment manufacturers when it comes to electric solutions. After

all, mine sites have traditionally been designed with diesel-driven assets—not intricate, electric-powered equipment in mind. Dust, dirt, heat and humidity are all challenges that new, electric equipment must be able to withstand daily.

Prioritizing BEV haulage over

ELECTRIFICATION OEM Off-Highway | NOVEMBER/DECEMBER 2022 36

UFLYPRO.STOCK.ADOBE.COM

stationary or even trolley electrification systems could be beneficial, since interoperable, in-cycle, charging infrastructure can be implemented onsite without the significant investment required by off-truck trolley assist infrastructure.

Over time, this more advanced, cleaner, electrified equipment will help reduce the heat, dust and noise usually associated with diesel-powered vehicles—creating safer operating conditions that are more conducive to a zero-emission mine.

3. Collaboration: How to Connect the Entire Value Chain

Ultimately, there will be a period of adaptation when it comes to electrifying mobile assets and, in turn, mine sites themselves. Over time, costs will likely lower, and conditions will improve. The speed at which these two things happen, however,

will largely depend on how effective the surrounding collaboration is. In fact, collaboration is one of the three most important factors in achieving decarbonization, according to mining professionals.7

Since electrification is a relatively new entrant to the mining space, companies must be particularly strategic when deciding who partner with. Fortunately, there are several ways mine operators can collaborate, plus a growing number of companies they can choose to collaborate with –between customers, competitors and cross-sector players like technology companies. OEMs are obviously a large part of this equation too, with their specialist equipment knowledge an invaluable resource to mining operators.

For electrification needs specifically, it may make most sense to explore multilateral power agreements that

can help support shared power interests, while de-risking the investment required

Meanwhile, industry-wide alliances can help companies push through technology advancements more quickly.

Expertise Is a Valuable Commodity

Mining is the start of key supply chains globally. If the sector can get a decarbonization pathway like electrification right, then its impact will reverberate throughout the industrial world. But doing so will require smart thinking around these key considerations of costs, condition, and collaboration, on the part of OEMs and operators.

And with nine out of 10 mining leaders saying that a lack of skills and in-house expertise are barriers to their decarbonization efforts, there has

OEM Off-Highway | NOVEMBER/DECEMBER 2022 37

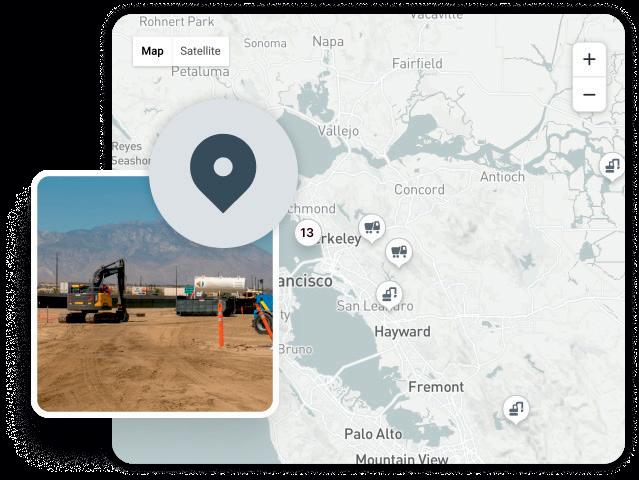

Your Big Picture in Real Time

your mixed fleet data connected, collected, and presented to you on one platform in real time. Trackunit Manager is the fleet management solution purpose-built for construction.

All

Book a demo trackunit.com

References

1. Sean Fleming. “This is why the energy transition will be reliant on the mining industry.” World Economic Forum. May 19, 2021.

2. Kimberly Henderson and Jukka Maksimainen. “Here’s how the mining industry can respond to climate change.” McKinsey & Company. August 27, 2020.

3. Henry Legge, Clemens MüllerFalcke, Tomas Nauclér, and Erik Östgren. “Creating the zero-carbon mine.” McKinsey & Company. June 29, 2021.

4. Diesel Technology Forum. “Mining.” DieselForum.org.

5. Lindsay Delevingne, Will Glazener, Liesbet Grégoir, and Kimberly Henderson. “Climate risk and decarbonization: What every mining CEO needs to know.” McKinsey & Company. January 28, 2020.

6. Deloitte analysis based on: ICMM, “Role of Mining in National Economies: Mining Contribution Index (5th edition).” 2022; IRENA, “Renewable Capacity Statistics.” 2022; World Bank national accounts data and OECD National Accounts data files, 2022.

7. Shell and Deloitte. “Emerging Sectors: Mining Decarbonization Study.” 2022.

8. S&P Global. “Path to net zero: More mining companies setting targets to reduce emissions.” SPGlobal.com. 2020.

Mark Hannan is vice president, mining decarbonization, at Shell. Read more https://oemoh.co/3yyevs

ELECTRIFICATION OEM Off-Highway | NOVEMBER/DECEMBER 2022 38 www.masterbond.com Hackensack NJ, 07601 USA ∙ +1.201.343.8983 ∙ main@masterbond.com Protection from many aggressive chemicals Acids, bases and many solvents Good flow properties Mixed viscosity, 75°F 15,000-25,000 cps Service temperature range -60°F to +450°F [-51°C to +232°C] Two Part Epoxy Supreme 62-1 SUPER TOUGHENED EPOXY SUPER TOUGHENED EPOXY RESISTS High Temperatures & Chemicals MADE IN THE USA E-MAIL: customerservice@enmco.com TOLL FREE: 888-372-0465 www. enmco.com LCD BATTERY INDICATOR PT33 SERIES This compact meter with various functions and alert systems is ideal for customers to get the most relevant information from their battery system. The unit has a built in hour meter and service timer, a battery level monitor, and a voltage monitor all designed to gather relevant information about your battery in an intuitive manner. arguably never been a more important time for the industry to lead the charge by investing in collaborative partnerships and projects.8

@BURANATRAKUL.STOCK.ADOBE.COM

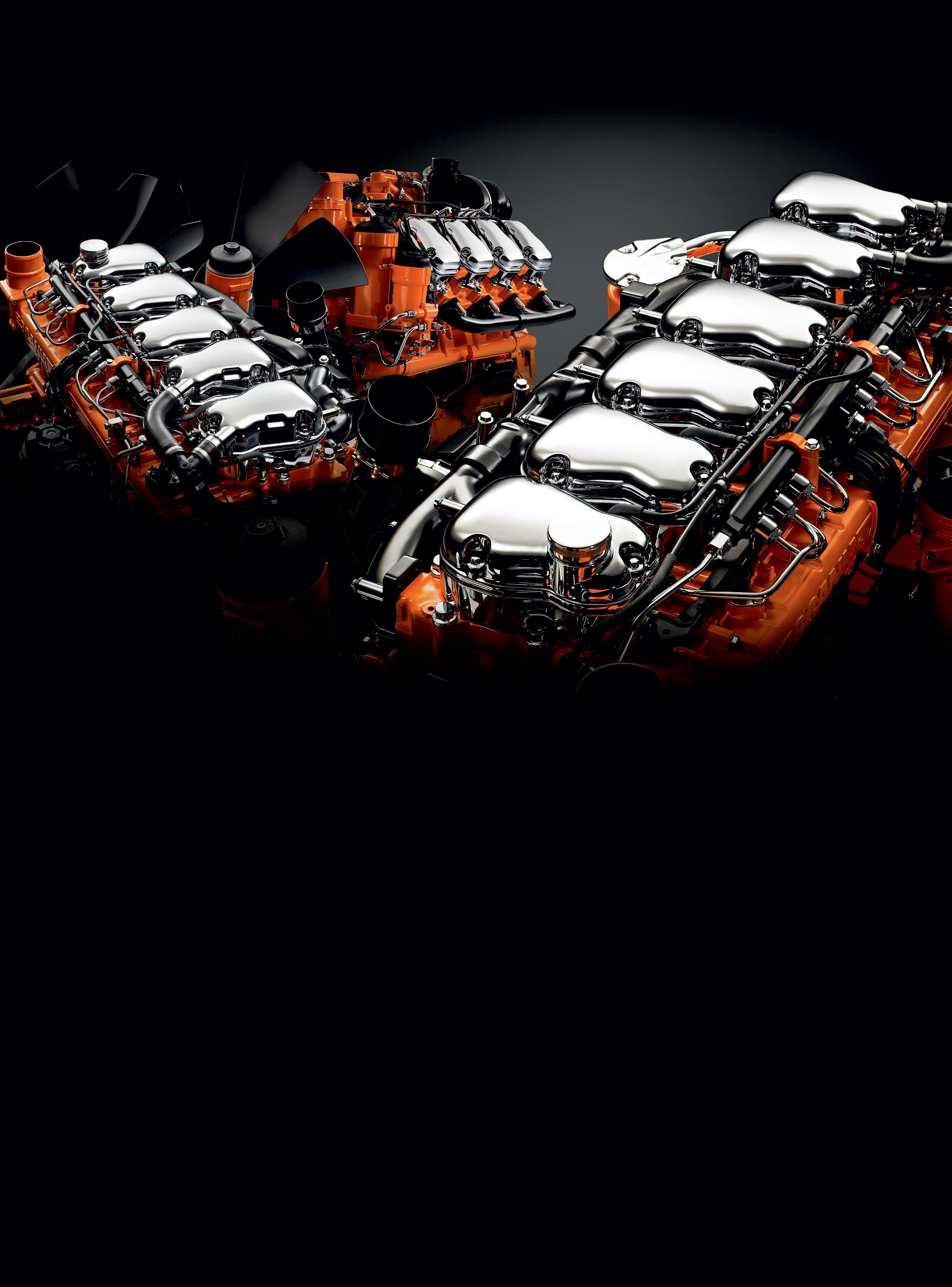

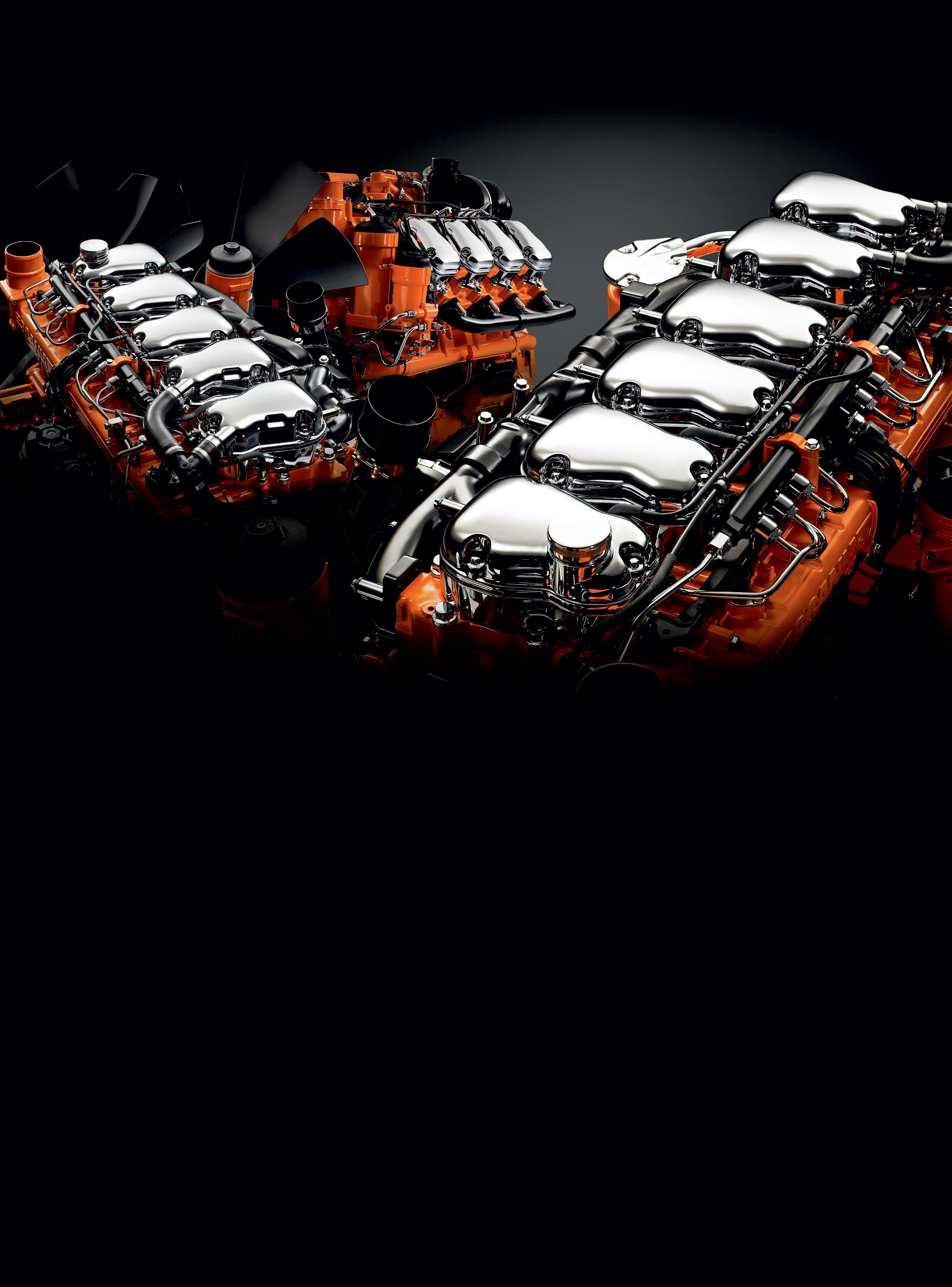

Sustainable power

years ahead of tomorrow’s standards

The Scania engine platform features compact dimensions and a common footprint which enhances flexibility, simplifies installation and shortens time-to-market. Last but not least: Proven reliability, outstanding operating economy and industry-leading fuel efficiency vouches for long-term profitability and satisfied customers.

www.scaniausa.com

Podcast: New Battery Technology

Check out the latest Industry Update podcast featuring battery technology information after the company’s exhibition during bauma 2022. Read more https://oemoh.co/ri0qi4

Video: 5 Questions from bauma

Check out this fun recap of bauma and the technology at the show from Caterpillar experts on Day 5.

Read more https://oemoh.co/v35v2r

Power Providers Respond to Off-Highway Industry’s Needs

Some manufacturers place emphasis on electrification. Others pursue alternative fuels and hybrid solutions to meet original equipment manufacturer applications. Pursuing these sustainable technologies while optimizing the power sources that have helped our world run for centuries is important. Learn more from this John Deere Power Systems article.

Read more https://oemoh.co/98e77e

New Power Tube System Presented During The Battery Show

During The Battery Show and the Electric & Hybrid Vehicle Technology Expo, TE Connectivity expert Bob Kill talked with us about the Power Tube system. Learn more about this high-vibration-resistant connector with this video.

Read more https://oemoh.co/hgwaoj

OEM Off-Highway | NOVEMBER/DECEMBER 2022 40 WHAT’S NEW ON THE WEBSITE

n New commercial vehicles, equipment and products n OEM chassis updates n Green Truck Summit n Ride & Drive n Advanced fuels and vehicle technology trends March 7–10 | Indiana Convention Center | Indianapolis, IN Brought to you by Register at worktruckweek.com North America’s Largest Work Truck Event

HCEA Convention Illustrates Equipment Evolution

The HCEA Museum will host the show again next year, September 22 to September 24.

by Thomas Berry, HCEA

The mission of the Historical Construction Equipment Association (HCEA) is to pre serve for public education the history of the construction, dredging and surface mining industries. One way this is accomplished is its annual inter national conventions and old equip ment exhibitions, in which attendees can see ancestors of today’s equipment in operation. The 2022 convention was held at the HCEA’s National Construc tion Equipment Museum in Bowling Green, Ohio.

Equipment Examples

Two great examples of machine evolu tion involved museum equipment. The show featured major reassembly of the Terex 33-15 Titan 170-ton capacity end dump. The work was carried out with donated labor and loaned equipment. Two local contractors provided crane and operator services. The museum’s collection also includes four older end dumps: a 1964 30-ton Mack; an 18-ton Euclid; a 10-ton Koehring Dumptor from the 1950s; and a 1928 HughesKeenan Iron Mule, a two-yard end dump built around a McCormick-Deer ing tractor chassis and power train.

The other example was the debut of the museum’s Manitowoc 3500 dragline and the first use of its new late 1960s Cat dirt spread—a D9G push loader, two 631B motor scrapers, and a 631B water wagon—all re stored, donated and transported from

Who needs diesel engines and hydraulics, anyway? A 1918 Russell & Company 30/90 traction engine owned by Jim Lashaway of Bowling Green, Ohio, pulls two 1920 Baker Maney D wheeled scrapers and a 1929 Galion Leaning Wheel E-Z Lift No. 10 pull grader from the museum’s collection.

HCEA ARCHIVES

New Jersey by the Mahan Collection Foundation. The spread was joined by tractor-drawn pull scrapers from the 1950s and two 1.5-yard Baker Maney D wheeled scrapers (see Image 1) from the late 1920s, examples of the earliest mechanized scrapers.

Restored Crawler Tractor

A third example, compared to the D9G’s hydraulic dozer, was a restored

One of the earliest bulldozer attach ments known to exist is this restored LaPlant-Choate dozer, installed on a 1929 Caterpillar Sixty crawler tractor. The outfit is owned by Will Wingo of Titusville, Pennsylvania.

HCEA ARCHIVES

1929 Caterpillar Sixty crawler tractor with one of the earliest dozer attach ments in existence, a LaPlant-Cho ate blade that flips over and back blades when the tractor is reversed (see Image 2). Many other rare and unusual construction and agricultural machines, trucks, cars, engines and military vehicles were exhibited. Next year’s conference is September 22 to September 24.

The Historical Construction Equipment Association (HCEA) is a 501(c )3 non-profit organization dedicated to preserving the history of the construction, dredging and surface mining equipment industries. With over 3,500 members in a dozen countries, our activities include operation of National Construction Equipment Museum and archives in Bowling Green, Ohio; publication of a quarterly magazine, Equipment Echoes, from which this text is adapted, and hosting an annual working exhibi tion of restored construction equipment. Individual memberships are $35.00 within the USA and Canada, and $55.00 US elsewhere. Our next International Convention and Old Equipment Exposition will be September 22-24, 2023, in Bowling Green, Ohio. We seek to develop relationships in the equipment manufacturing industry, and we offer a college scholarship for engineering students. Information is available at www.hcea.net, or by calling 419-352-5616 or e-mailing info@hcea.net.

OEM Off-Highway | NOVEMBER/DECEMBER 2022 42 OFF-HIGHWAY HEROES

Read more https://oemoh.co/6paqam INTERNATIONAL FLUID POWER EXPO MARCH 14-18, 2023 LAS VEGAS, NV, USA The International Fluid Power Exposition (IFPE) is the place where engineers meet to: “ There’s no other show in the world I think that brings the OEM machine manufacturers and the suppliers as close together as this show. It’s a good place to meet and learn about what’s going on. In the Americas, in the Western Hemisphere, this is the show for fluid power.” KEN ROSENBECKER SALES MANAGER NORTH AMERICA | WIPRO INFRASTRUCTURE ENGINEERING IFPE only happens once every three years! SAVE 20% OFF REGISTRATION Register now at IFPE.com and type AD20 in the Promo Code box Discover solutions current suppliers can offer to your unique challenges. Find new partners among suppliers pushing the envelope on what fluid power can do. CONNECT WITH TOP MANUFACTURERS CO-LOCATED WITH CONEXPO-CON/AGG (two shows, one price) Including Bosch Rexroth , Danfoss Power Solutions , Parker Hannifin , Poclain , IFM Efector , Hawe Hydraulik , Husco , and 375+ more! Join your peers from these OEMs: Caterpillar Inc Volvo Construction Equipment ∙ Liebherr ∙ CASE Construction Equipment Komatsu John Deere Construction Doosan Bobcat KOBELCO Construction Machinery USA ∙ LBX Company Spark new ideas with in-depth technical conversations with other engineers. The #1 Trade Show & Conference for Fluid Power, Power Transmission, and Motion Control

CONSTRUCTION EQUIPMENT

APEM’S NEW XP JOYSTICK

The new XP Series joystick offers the flexibility and customization of a full size controller, in a smaller palm-size configuration. The XP includes an all metal mechanism for exceptional performance and new wrap-around gaiter for panel sealing up to IP67, making it a reliable solution in outdoor applications.

The new XP series multifunction handle is large enough to integrate multiple APEM components, including proportional rockers, pushbuttons and miniature thumbsticks, while still remaining small enough to mount into panels and arm wrests where space is limited.

Find out more about this new multifunction compact solution at www.apem.com

an IDEC company

JOYSTICKS

by Gigi Wood

by Gigi Wood

by Lori Ditoro

by Lori Ditoro

Punch

High Beam

Spread

Punch

Spread DRL/Turn Punch

Punch

High Beam

Spread

Punch

Spread DRL/Turn Punch