3 minute read

Aluminium perfect solution for offshore upgrades Middle East

The future of Walk to Work in the Middle East

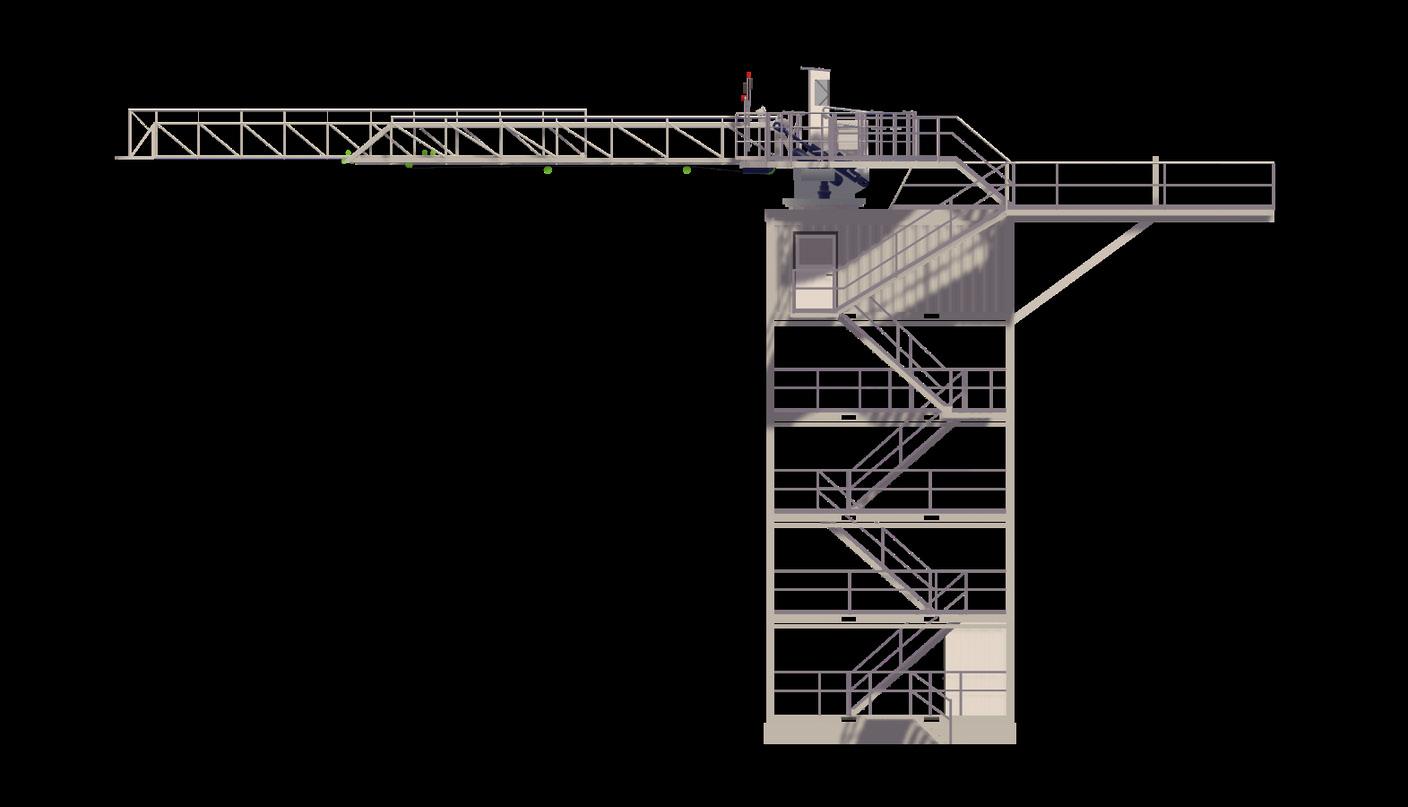

Ampelmann A-type.

Advertisement

The introduction of Walk to Work (W2W) has permanently changed the face of the global offshore energy sector. In a rapidly changing energy infrastructure, it has become crucial to maximise efficiencies, maintain the highest safety standards and reduce the environmental impact of offshore operations. Ampelmann designs and builds motion compensated gangways that extend weather windows, increase workability and provide safe access to offshore installations. As W2W offers significant advantages over traditional offshore access solutions, it has become a key area of innovation in the modern offshore service industry.

Globally, W2W has made its mark on the offshore energy sector and is becoming increasingly well-known in the Middle East. Cost-effective and efficient, motion compensated systems increase year-round productivity and increase the safety of offshore operations. Reduction of carbon emissions and improved energy efficiencies will be achieved through the electrification of these systems, clever use of digitised services and by designing new systems that suit regional needs and make W2W an appealing offshore access solution.

Flagship system

Since Ampelmann’s first operations in the Arabian Gulf over twelve years ago, the company has already transferred more than 1,200,000 people and has opened two offices in Qatar and Dubai. With eight projects running concurrently in Qatar, Oman, Azerbaijan, Abu Dhabi and Saudi Arabia, there clearly is a growing market for Ampelmann’s W2W solutions. Ampelmann’s flagship system, the A-type, already sees frequent use in the Middle East and has become a testament to the type of efficiencies that motion compensated systems can bring to the global offshore energy sector.

Electrification

The coming years will see the full electrification of the A-type fleet. By reusing the hydraulic pressure on the hexapod, 90 percent of the total energy consumption is fed back into the system. The result is an energy efficient gangway with a very low carbon footprint. The first electric A-types have already been commissioned, and a variation of this system, the S-type, currently sees use on the Aqua Helix, a prizewinning fast crew change vessel that supplies on demand offshore access in the North Sea. As the S-type is fully integrated, it is lighter than the regular A-type, making it ideally suited to be fixed on smaller DP vessels that are prevalent in the Arabian Gulf.

F-type

Together with the electrification of its older systems, Ampelmann has introduced new gangway designs that address specific shortcomings in the regional access market. One example is the newly designed F-type, a cost-effective modular gangway that is height-adjustable, easy to mobilise and enables the continuous transfer of personnel in sea states up to 2.5m Hs. Like the electric A- and S-type, the system uses electric recuperation to store and reuse energy from the vessels motions. Its modular containerised design allows for greater operational flexibility as t can be transported much more cost effectively and adjusted in between projects. Designed specifically for a large variety of vessels, the system has a 21m gangway that is perfect for a variety of work scopes in maritime conditions like those in the Arabian Gulf and Asia Pacific.

Alongside the electrification of its systems and the introduction of specialised fully electric gangways,

the company has created robust product service alignments. All its customers can benefit from the advantages of 24/7 support through the Operation Control Center (OCC) and Ampelmann Insights - a data tracking tool that provides workability forecasts and enables the company to track carbon emissions during offshore operations. This allows Ampelmann, as well as its clients, to be extremely focused on the potential energy savings that can be made and leads to the identification of new ways to reduce environmental footprints further down the line.

Future

Through the introduction of electric regenerative technology, modularity, and strong product-service alignments, Ampelmann retains its focus on the future. In 2020 the company cut almost half of its carbon emissions. By measuring all emissions throughout the entire value chain and offsetting those that currently cannot be accounted for through the electrification of its systems and the improvement of onshore and offshore ecological footprints, Ampelmann became 100 percent carbon neutral in 2020.

Continuous innovation lies at the heart of Ampelmann and the company believes it is imperative to lay the foundation for the future. The last two decades have seen a tremendous growth of W2W in the Middle East as an important alternative mode of offshore access. By focusing on what is important to regional markets, Ampelmann has gained significant traction throughout the world and continues to have a marked impact on the safety and efficiency of offshore operations.