A Deep Dive with CP Industries on Sanitation Solutions Safeguarding Food Safety Keeping Ontario’s Meat and Poultry Industry Informed Fall 2023 • Vol. 29, Issue 3 ALSO INSIDE: 24 Newmarket Meat Packers 30 Government Funding for Food Safety Projects 38 Unraveling Best Before Dates

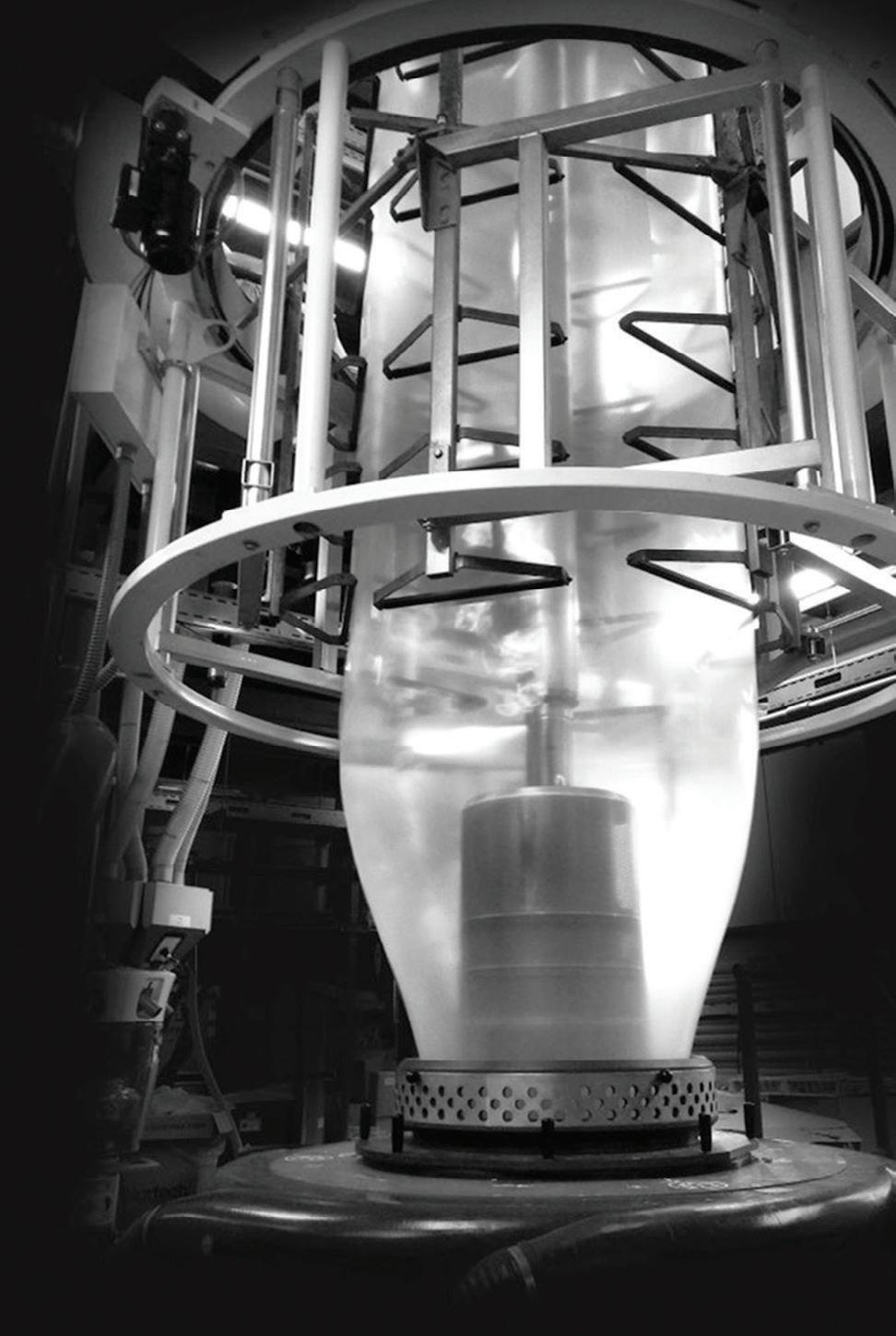

SMALL BUT MIGHTY OUR NEW COMPACT ROLLSTOCK THERMOFORMER Let VC999 help you create the perfect packaging solution! - www.VC999.com WE’VE PACKED THE FUNCTIONALITY OF A MUCH LARGER THERMOFORMING MACHINE INTO A COMPACT MACHINE ONLY 12 FOOT LONG. • Durable • Efficient • Small Footprint Call 877-435-4555 · Sales.Canada@VC999.com

BlockTalk - Fall 2023 3 REVIVE & THRIVE OCTOBER 20-21, 2023 JW MARRIOTT THE ROSSEAU MUSKOKA RESORT & SPA Place Meating YOU’RE INVITED!! JOIN MEAT & POULTRY ONTARIO, OCTOBER 20-21 FOR THE MEATING PLACE CONFERENCE IN MUSKOKA Join us at the beautiful JW Marriott Muskoka for a one-of-a-kind event dedicated to inspiring and bringing together leaders in the meat industry. The Meating Place Conference in is back, and this year, we are taking our theme to new heights with

you ready to harness the power of leadership and drive your organization towards unparalleled success? Then mark your calendars for October 20 – 21 and secure your spot at

premier

of industry professionals,

leaders, and visionaries. ACCOMODATIONS A block of rooms are being held at the beautiful JW Marriott Muskoka at the The rate will be available until September 22 or until the room block is sold out. AGENDA AT A GLANCE FRIDAY An Evening with Handtmann Ontario’s Ultimate Burger Competition - People’s Choice

AM Speaker Program

PM TableTALK 2023

Tiller People’s Choice Competition Ontario’s Finest Butcher Competition

NIGHT

Carpet Gala - Dinner and Awards Silent Auction President’s Message 4 Welcome to the Association ............................................. 5 Ways to Reduce the Risk of Food Contamination in Your Plant ....................................................................... 8 Risk Assessment Method for Determining the Risk to Food Safety and Product Quality Within Your Food Production Processes....................... 12 Meating Place 18 Increasing the Appeal of Ontario Veal .......................... 20 Warm Bistro Salad with Grilled Veal Chops .................. 23 Newmarket Meat Packers ............................................... 24 Safeguarding Food Safety ............................................... 26 Government Funding for Food Safety Projects 30 Reduce Injuries with Safe Food Handling Practices..... 34 Unraveling Best Before Dates 38 Advertiser Index ............................................................... 42 18 20 24 Meating Place Increasing the Appeal of Ontario Veal Newmarket Meat Packers Index BlockTalk - Fall 2023 Vol. 29, Issue 3

Are

this

gathering

thought

SATURDAY

SATURDAY

Dave

SATURDAY

Red

As we continue to navigate the ever-evolving landscape of the meat and poultry industry, I want to emphasize the critical importance of upholding the highest standards of food safety. Our commitment to this fundamental aspect of our industry not only safeguards public health but also maintains consumer trust and confidence in the products we provide.

At Meat & Poultry Ontario, we prioritize safety across the supply chain. Every step in production and distribution ensures food safety. I urge all members to stay vigilant and follow established safety protocols. Here are some key reminders to keep in mind:

1. Employee Training: Train staff in hygiene and safety procedures.

2. Sanitation: Keep production areas clean to prevent contamination.

3. Temperature Control: Maintain a consistent cold chain.

4. Traceability: Implement tracking for transparency.

5. Collaboration: Share knowledge and address emerging risks together.

As we move forward, let’s remain united in our dedication to food safety. By maintaining the highest standards and continuously improving our practices, we can continue to provide safe and high-quality meat and poultry products to consumers across Ontario.

VISION

A sustainable, respectful and diverse food system that celebrates the nutritional and economic value of meat and poultry.

MISSION

We strengthen the meat and poultry industry in Ontario by connecting people, influencing change and empowering our members.

MPO LIFETIME MEMBERS

• Richard Halenda (2021)

• Doris Valade (2019)

• Laurie Nicol (2018)

• Joe Abate (2017)

• Brian Quinn (2016)

• Graham Dalziel (2015)

• Tony Facciolo (2011)

• Pat Johnson (2005)

• Gerry Houtzager (2003)

• Leo Rocheleau (2001)

• Jim Vidoczy (2000)

• Nancy Ackert (1997)

• Dr. Ron Usborne (1996)

• Ron Deeth (1995)

MPO LONG TIME MEMBERS

Thank you to our long time members who have been helping move the industry forward for over 25 years.

Ontario Pork - 1980

Gord’s Abattoir Inc. - 1982

L’Orignal Packing Ltd. - 1986

Sprucedale Meats - 1992

Handtmann

Canada Ltd. - 1992

Kevin Schinkel President

Thank you for your ongoing commitment to excellence in food safety. Together, we can ensure the well-being of our customers and the continued success of our industry.

Embracing Food Safety: Beyond Regulations

Food safety is at the heart of everything that MPO does. Providing technical support, templates and forms to help you better manage your programs are all things we help with. Distributing information and providing training on different food safety topics is what we do routinely. We are there to help you with meeting regulatory requirements.

Food safety isn’t solely for regulators; it’s a shared societal duty, not just a checklist. It should be integral to your ethos. Operators must elevate standards and foster a strong food safety culture.

Merely striving for regulatory compliance falls short in today’s world. While essential, it should not be our sole aim. Our ultimate objective is to instill a culture and systems that cultivate safe food practices throughout the entire manufacturing process, from ingredient sourcing to packaging and distribution. As leaders, champion food safety as a core value, setting the tone for enthusiastic employee adherence.A robust food safety culture protects consumers’ health and fosters brand trust through quality control, transparency, and contamination prevention.

This edition of Block Talk serves as a reminder that food safety isn’t a mere formality. It demands continual dedication, leadership, and a robust organizational culture. By surpassing regulatory requirements, manufacturers and consumers can collaborate to establish a safer food environment. Let’s collectively prioritize food safety as a shared responsibility in all aspects of our lives because, in matters of food safety, there’s no such thing as being “too safe.”

Franco Naccarato, Executive Director

Walnut Hill Farm - 1986

MMIS / Mondo Inc. - 1986

VG Meats - 1987

Stemmler Meats - 1988

Darling International

Canada Inc. - 1988

Schinkels’ Gourmet

Meats - 1989

Springer’s Meats Inc. - 1989

Chicken Farmers of

Ontario - 1989

Jetnet Norstar Corp. - 1989

Brenner Packers Ltd. - 1991

Norwich Packers Ltd. - 1991

Weston Abattoir Ltd. - 1991

Hay’s Custom Cutting - 1992

Hoffman’s Meats & European Deli - 1992

Newmarket Meat Packers Ltd. - 1992

Metzger

Meat Products - 1993

Schinkel’s Legacy - 1993

Yes Group Inc. - 1993

Windcrest

Meat Packers - 1994

Malabar Ingredients - 1994

R Denninger’s Ltd. - 1995

Abate Packers Ltd. - 1996

Domingos Meat Packers Ltd. - 1996

Sargent Farms Ltd. - 1996

Townsend Butchers Inc. - 1996

Conestoga Meat Packers Ltd. - 1997

Pemberton & Associates Inc. - 1998

UniPac Packaging Products Ltd. - 1998

MEAT INDUSTRY ACHIEVEMENT (MIA)

AWARD RECIPIENTS

• King Cole Duck (2021)

• Hayter’s Farm, Dashwood (2016)

• Schinkel’s Legacy, Chatham (2014)

• Conestoga Meat Packers, Breslau (2013)

• In Memory of Dave Tiller (2012)

• Halenda’s Fine Foods, Oshawa (2011)

• Springer’s Meats, Hamilton (2010)

• VG Meats, Simcoe (2009)

• Stemmler’s Meat & Cheese, Heidelberg (2008)

• Leo Rocheleau, Maidstone (2007)

ASSOCIATE MEMBER RECOGNITION AWARD (AMRA) RECIPIENTS

• Farm Credit Canada (2022)

• Viscofan (2021)

• Multivac Canada Inc., Brampton (2020)

• Reiser Canada, Burlington (2019)

PAT JOHNSON AWARD

• Natasha Barlett, OMAFRA (2022)

• VC999, Saint-Germainde-Grantham (2018)

• Handtmann Canada, Waterloo (2017)

• Malabar Super Spice, Burlington (2016)

• Kelly McAslan, OMAFRA (2022)

www.meatpoultryon.ca 4 BlockTalk - Fall 2023

Welcome to the Association

Building an informed and engaged membership representing a diverse Ontario meat and poultry industry.

Tayybain Cooperatives

Mohammad Rahaman Maks@rogers.com

647-070-7314

8794 Indian Line

Hagersville,ON N0A 1H0

Laplante Poultry

Robert Laplante

613-835-4440

robertlaplante@rogers.com

17141 Rombough Rd

Monkland,ON K0C 1V0

Fortinos Meat Productions

Steve Mayburry

Steve.mayburry@loblaws.ca

1275 Rymal rd East

Hamilton,ON L8W 3N1

905-383-5445 ext 624546

Craigmore Farms

Wayne Kreklewich info@craigmorefarms.com

P.O BOX 700 Nobleton,ON L0G 1N0 416-892-0664

Claritas Marketing

Sakiko Honda

Sakiko.honda@claritasmarketing.com

6 Aztec Row

1 Berners rd London, United Kingdom

N10PW 440-795-074-4970

MPO

ADMINISTRATION BOARD LISTING

EXECUTIVE DIRECTOR

Franco Naccarato franco@MeatPoultryON.ca

TECHNICAL DIRECTOR

Daphne Nuys-Hall technical@MeatPoultryON.ca

EIO Solutions

John Trainor john@eiosolutions.com

9131 Keele Street Suite A4 Vaughan, ON L4K0G7 Canada

1-885-440-3993

Oliffe Meats

Sam Gundy reginab@pemcom.com

1097A Yonge St Toronto, ON M4W 2L7 Phone 416-928-0296 info@olliffe.ca

Rowe Farms

Jamie Cooney jamie.cooney@rowefarms.ca

1027 Gordon Street Guelph, ON N1G 4X1 Canada

519-822-2171

BLOCKtalk is the official publication of the MPO, distributed to over 250 MPO members, commodity groups, and others throughout the industry, providing excellent advertising opportunities for suppliers of the meat and poultry industry to promote their newest, most innovative, supplies, equipment, and technology.

EVENTS, MARKETING & COMMUNICATIONS MANAGER

April Jackman april@MeatPoultryON.ca

OFFICE MANAGER

Meghan Schmuck meghan@meatpoultryon.ca

MARKET DEVELOPMENT

COORDINATOR

Derek Boudreau derek@MeatPoultryON.ca

DIRECTOR, CENTRE FOR MEAT INNOVATION & TECHNOLOGY

Luis Garcia luis@meatpoultryon.ca

PRESIDENT | Kevin Schinkel

Schinkel’s Legacy, Chatham

PAST PRESIDENT | Carol Goriup

Florence Meats

SECRETARY/TREASURER

Adam Hayward

Nesbitt’s Meat Market, Lindsay

VICE PRESIDENT | Gerhard Metzger

Metzger Meats, Hensall

DIRECTOR | Peter Baarda

J&G Quality Meats, Burlington

DIRECTOR | Doris Valade

The Malabar Group Inc., Campbellville

DIRECTOR | Jeff Miedema

Townsend Butchers Inc., Simcoe

DIRECTOR | Dale Schefter

Schefter Poultry Processing Ltd., Gorrie

DIRECTOR | Doug Alexander

Leadbetter Foods Inc., Orillia

DIRECTOR | Yaser Alqayem

Parkhill Meats, Parkhill

DIRECTOR | Christine BonneauO’Neill

L’Orignal Packing, L’Orignal

DIRECTOR | Shannon Desborough

Finest Sausage & Meats, Kitchener

DIRECTOR | Rafal Rusiniak

Handtmann Canada

Limited, Waterloo

BLOCKtalk encourages Associate Members and supporters of the industry to submit articles which would be beneficial to our members.

ADVERTISING DEADLINES 2023

Winter October 26

Spice & Seasoning Blends

Rubs & Decor Seasonings

Brine Injection Units

Curing Salt

The information published in BLOCKtalk is compiled from a variety of sources, which we believe to be reliable; however, MPO does not guarantee, and assumes no responsibility for the correctness of the information.

Sausage Seasonings

Sausage Binder Units

Functional Food Ingredients

Custom Blending

BlockTalk - Fall 2023 5

&

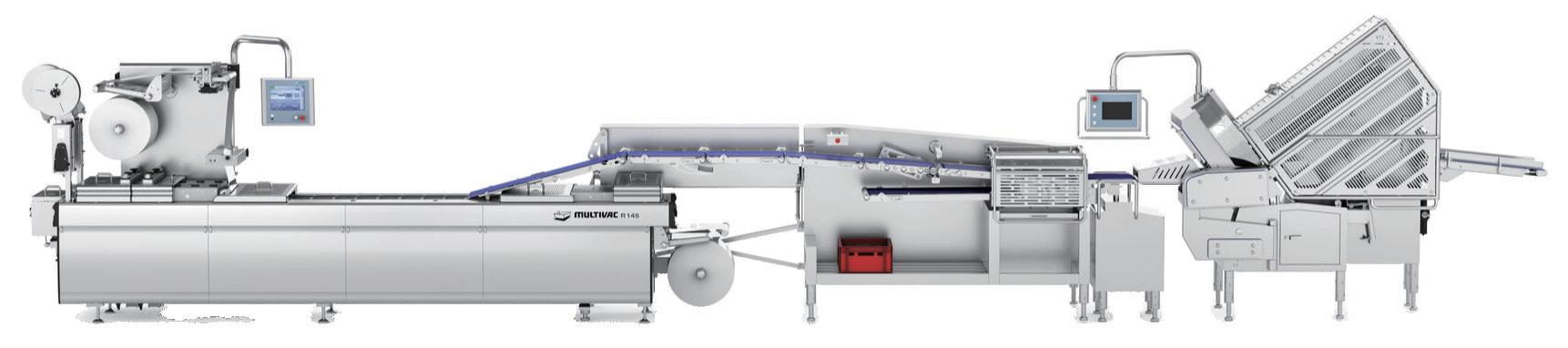

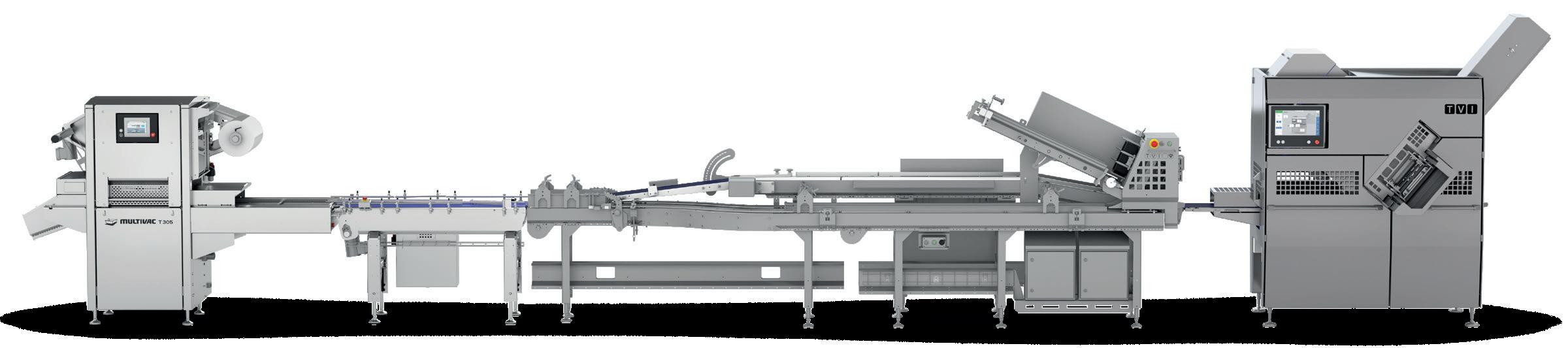

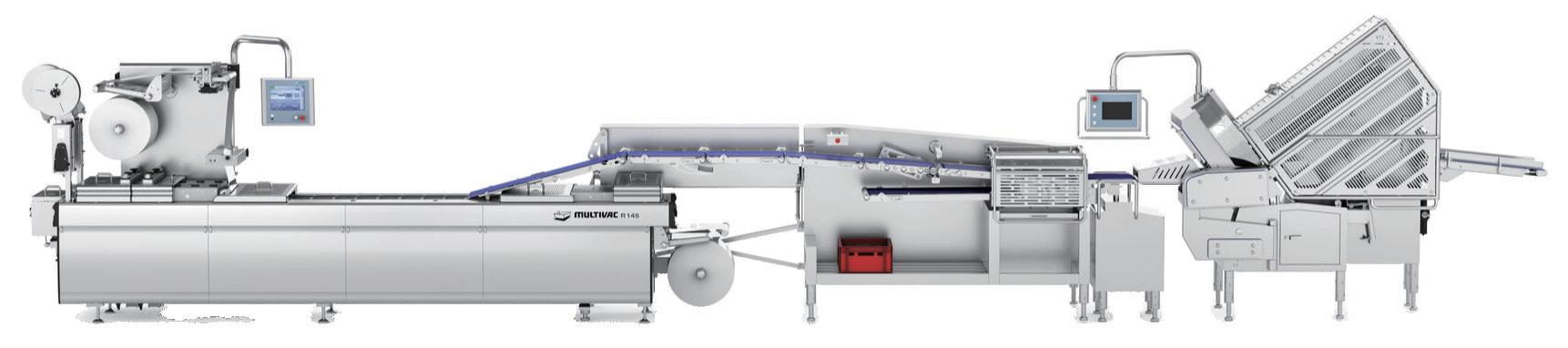

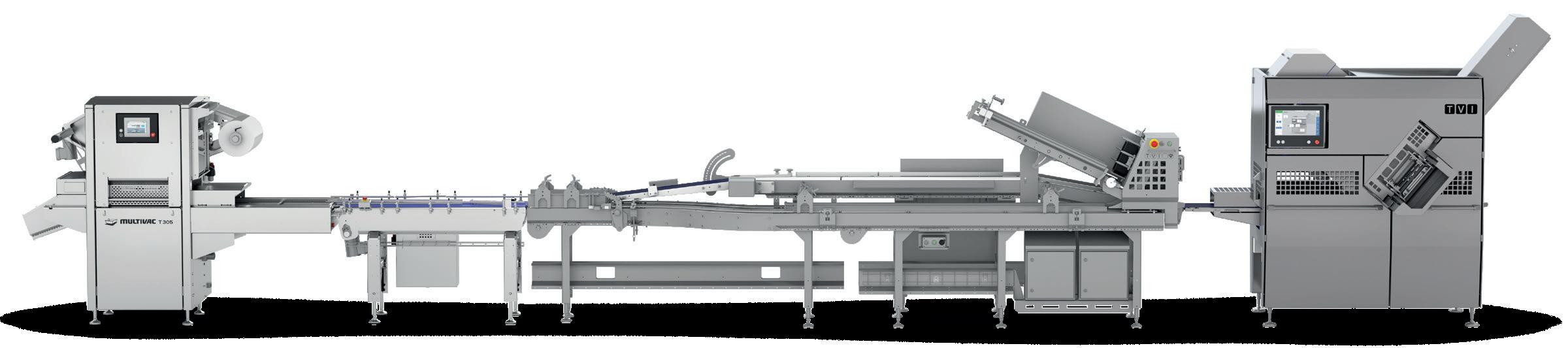

Compact slicing and packing line for deli. Get Your......

Compact portioning and packing line for fresh meat.

Game On!

Ready to play in the major league?

Don’t let your size limit your ambition!

At MULTIVAC, we understand the unique challenges faced by smaller meat processors when it comes to competing with the big names in today’s market.

Our compact line solutions help to level the playing field by removing labour, increasing output, and delivering the highest quality product.

Don’t let your products sit on the bench, call us today and together we’ll turn them into all-star performers!

Preparation & Processing

Portioning & Slicing

Packaging Equipment

Packaging Materials

Automation & Integration

Inspection & Verification

Labelling & Coding

Project Management

MULTIVAC.COM | 877-264-1170

Ways to Reduce the Risk of Food Contamination in Your Plant

By: Sani-Marc

Food and beverage processing plants play a key role in keeping our food supply safe. This requires adherence to strict protocols, one of which is implementing a system for managing food safety based on the HACCP system.

The Three Main Categories of Food Contamination

When something gets into food that shouldn’t be there, and makes it unsafe to eat, the food is contaminated. This can lead to food-borne illness, and food-borne illness outbreaks, which can negatively impact your business. We can help you identify potential risks and take steps to avoid them. There are three main categories of food safety hazards; biological, physical, and cross-contamination or chemical.

Biological contamination

Biological contamination is when food becomes contaminated by living organisms or the substances they produce. It is a common cause of food-borne illness, food poisoning, and food spoilage and waste.

Tips for reducing the risk of biological contamination:

• Safe temperature – Keep high-risk foods such as meat, poultry, dairy, and eggs out of the Temperature Danger Zone* In Manitoba, the Temperature Danger Zone is 5°C –60°C (41°F – 140°F). In all other provinces and territories in Canada, it is 4°C – 60°C (40°F – 140°F)

• Safe surfaces – Clean and sanitize all food contact surfaces and equipment regularly

• Safe surroundings – Maintain good overall hygiene and sanitation of the premises

Physical contamination

Physical contamination occurs when a physical object enters food during production or processing. Physical objects in food are not only distressing for the consumer, they can be a choking hazard, and can also introduce biological contaminants.

www.meatpoultryon.ca 8 BlockTalk - Fall 2023

Pember ton & Associates Inc TECHNOLOGY FOR THE FOOD INDUSTRY w w w.pemcom.com 1-800-668-6111

Continued on page 10

Excellence in Clipping | polyclip.com WORKS OVERTIME. EXCEEDS EXPECTATIONS. FCA 80 AUTOMATIC DOUBLE CLIPPER + Increased throughput and versatility for midsize processors + Reduced labor and production times + Enhanced presentation with cleaner tails

Tips for reducing the risk of physical contamination:

• Wear hair neatly tied back or wear a hair/beard net

• No nail polish, fake nails, mascara, or anything that can become detached and end up in the packaging

• Employees must have specific footwear to wear exclusively inside the plant, and when passing from one department to another, they must make sure their footwear undergoes the established sanitization process.

Cross-contamination

In a food processing environment, cross-contamination is the transfer of contaminants from a surface, object, or person to food, and is usually the result of improper handling procedures. Cross-contamination can be physical or chemical. It can also pose a risk to customers with food allergies, as trace amounts of an allergen can be transferred in the same way as microorganisms, and cause a serious, and in some cases, lethal allergic reactions.

Tips for reducing the risk of cross contamination:

• Use colour coding – Colour coding is a way of differentiating between different stages, parts, tools or areas of a food production process, such as using red for raw and blue for cooked items.

• Sanitize footwear – Footwear is an often-overlooked source of cross-contamination. Pathogens such as salmonella and listeria, which are the most frequent cause of food recalls, can enter a facility on a worker’s boots and spread throughout an entire plant.

• Make allergen management procedures part of your food safety plan

• Maintain high standards of personal hygiene

The food safety tips, and best practices listed above are by no means an exhaustive list what you need to do to prevent food contamination. The best way to keep your practices up to date and ensure food safety is through continuous education and training.

A good place to begin is with a thorough evaluation of your current practices and facility. Why not let Sani Marc provide you with an in-depth OPTIsafe® evaluation? Our team of experts, including food safety professionals, engineering system specialists and microbiologists, will thoroughly assess your current sanitation operations and provide you with a customized action plan for optimizing food safety.

www.meatpoultryon.ca 10 BlockTalk - Fall 2023

Improve business efficiency. Reduce labour. Anytime. Anywhere Connecting farmers and processors Processor Links Join today and share your availability and contact information Booking support & Space availability Last minute cancellations shared daily with the support of Beef Farmers of Ontario Continued from page 8 – WAYS TO REDUCE THE RISK OF FOOD CONTAMINATION IN YOUR PLANT

- Fall 2023 11 Phone: +1 (647) -269-0398 Toll Free: +1 (888) -777-1672 Email: info@kungfubutchers.ca Website: www.kungfubutchers.ca Meat & Poultry Ontario Food Processing Skills Canada Need Workers? • A Dedicated Training Centre • Capacity of Supplying 200 Workers/Year • 2-Year Guarantee • In-House Legal Team (LMIA & Work Permit) • Worker Arrival Support (Flight & Housing) WE PROVIDE Strategic Partners Contact Us Your A-Z Recruitment Service

Risk Assessment Method for Determining the Risk to Food Safety and Product Quality Within Your Food Production Processes

By: Lauren Cole, Mallot Creek Group

The onset of the Safe Food for Canadians Regulations as well as the increasing popularity of GFSI scheme certifications have placed responsibility on the operator to determine pre-emptive measures to control and minimize product contamination. As an operator, having the ability to accurately assess risks associated with hazards in your process will allow you to create an effective food safety plan and help to satisfy regulatory and/or GFSI requirements.

The following tables will illustrate an example of how to take a risk-assessment approach to food safety and ensure the approach is used appropriately.

One of the most common causes of food recalls, CARs, NCFs etc. is due to a lack of an accurate risk- assessment of the hazards to food safety and/or quality.

Using a simple risk-assessment tool, we can assess the risk of a particular hazard within your production process based on two factors: probability and severity.

Risk = Probability (A Hazard Will Occur) X Severity (Of the Outcome if The Hazard Occurs)

General criteria to establish probability are:

1 Improbable

2 Remote

3 Occasional

4 Probable

5 Frequent

The criteria for establishing the severity are:

1 Negligible

An incident that results in instantly reversible disturbances (same day); chronic exposure resulting in near instantly reversible disturbances (same day).

2 Minor

An incident that results in rapidly reversible disturbances (a few days); chronic exposure resulting in rapidly reversible disturbances (a few days).

3 Serious

An incident giving rise to reversible disturbances (months); chronic exposure resulting in reversible disturbances (months).

4 Critical

5 Catastrophic

Accident with effects of partial or irreversible permanent disability; chronic exposure with effects of partial or irreversible permanent disability.

Accident with total or fatal disability effects; chronic exposure with lethal or totally disabling effects.

The occurrence of the damage is subject to a chain of independent events; the occurrence of the damage is believed impossible by the employees; nothing similar has ever happened.

The occurrence of the damage depends on “unfortunate” conditions; the occurrence of damage would provoke reactions of great astonishment among the employees; similar events have very rarely occurred.

The occurrence of the damage depends on conditions not directly related to the situation but possible; the occurrence of the damage would provoke reactions of moderate astonishment; similar events are already documented.

The occurrence of the damage depends on conditions directly related to the situation; the occurrence of the damage would not provoke any reaction of astonishment; similar events have already occurred in the company or similar companies.

The occurrence of the damage depends on conditions directly related to the situation; the occurrence of the damage is expected given conditions; similar events have already occurred more than once in the company or similar companies.

www.meatpoultryon.ca 12 BlockTalk - Fall 2023

Continued

14 PROBABILITY PROBABILITY MEANING OF VALUE SELECTION CRITERION

on page

SEVERITY MEANING OF VALUE SELECTION CRITERION

SEVERITY

Continued from page 12 – RISK ASSESSMENT METHOD FOR DETERMINING THE RISK TO FOOD SAFETY AND PRODUCT QUALITY WITHIN YOUR FOOD PRODUCTION PROCESSES

Using an understanding of both probability of a hazard and the severity of the hazard, the numerical values (scale of values from 5 to 25 – the calculated risk) are shown and described in the table to the right.

The risk assessment, in order to be true and accurate, should be performed including key personnel familiar with your operation. No one would know better, for example, the likelihood of / frequency of occurrence, of a particular hazard within your operations. Using these accurate risks, we determine, based on the matrix example above, what controls are required (e.g., If a CCP is necessary, if a prerequisite program is sufficient to control the hazard, or if no control is necessary at all).

There are many different ways for the risk assessment to be presented but using this tool can help address the specific food safety challenges and agreed priorities in your operations to ensure consumer protection and to meet your regulatory or other requirements.

Very High (12-15)

The presence of the hazard will automatically result in unsafe food. Death or major injury can occur along with widespread hospitalization. There are multiple consumer or customer complaints made. There will be extensive media reporting with product recall required. Our business will suffer extensive financial loss leading to bankruptcy or cease of trade. An insurance claim is required.

The presence of the hazard will cause hospitalization of those affected. Prolonged medical treatment will be required. There may be multiple consumer or customer complaints made. There will be extensive media reporting with product recall required. Our trading partners / wholesale customers will lose confidence in our ability to supply safe food leading to loss of business. An insurance claim may be required.

Medium (6-10)

The presence of the hazard may result in a customer complaint. Consumers do not suffer any long-term effects and do not require hospitalization although acute medical treatment may occur. There is minimal long-term impact on the consumer. Affected stock may be returned to our business or financial compensation required. Consumers may use social media to communicate concerns.

The presence of the hazard results in no customer injury sustained. There is minimal customer inconvenience and minimal financial loss. Complaints may relate to service or quality issues. There is minimal media impact. Insignificant

The presence of the hazard does not and will not result in unsafe food. There is no injury, illness or hospitalization if the hazard is consumed. There is no adverse financial effect on our business or that of our trading partners. There is no media impact.

www.meatpoultryon.ca 14 BlockTalk - Fall 2023

Negligible (1) Minor (2) Serious (3) Critical (4) Catastrophic (5) Frequent (5) 5 10 15 20 25 Probable (4) 4 8 12 16 20 Occasional (3) 3 6 9 12 15 Remote (2) 2 4 6 8 10 Improbable (1) 1 2 3 4 5

SEVERITY PROBABILITY

CALCULATION DESCRIPTION Extreme (20-25)

Low (3-5)

(1-2)

This

Contact Troy McCartan at tmccartan@polytarp.com or 647.402.0036 for more details.

event will be held after the Gala at MEATING SPACE presented by Meat & Poultry Ontario.

Best in Class Smoking Cooking Chilling Fermenting Drying Defrosting Clean room Automation Warehouse management systems Work safety Environmental protection Travaglini Visit the Klever Equipped Walk-In Equipment Clinic at booth 5042 Contact us: info@goklever.com | +1 905 532 0330 | www.goklever.com McCormick Place | Chicago. IL October 23 - 25, 2023

www.meatpoultryon.ca 16 BlockTalk - Fall 2023

BlockTalk - Fall 2023 17 to our 2023/2024

CORPORATE SUPPORTERS Thank you DIAMOND PLATINUM GOLD SILVER

Meating

Place

REVIVE & THRIVE

OCTOBER 20-21, 2023

JW MARRIOTT THE ROSSEAU MUSKOKA RESORT & SPA

YOU’RE INVITED!!

JOIN MEAT & POULTRY ONTARIO, OCTOBER 20-21 FOR THE MEATING PLACE CONFERENCE IN MUSKOKA

Join us at the beautiful JW Marriott Muskoka for a one-of-a-kind event dedicated to inspiring and bringing together leaders in the meat industry. The Meating Place Conference in is back, and this year, we are taking our theme to new heights with “Revive and Thrive.”

Are you ready to harness the power of leadership and drive your organization towards unparalleled success? Then mark your calendars for October 20 – 21 and secure your spot at this premier gathering of industry professionals, thought leaders, and visionaries.

ACCOMODATIONS

A block of rooms are being held at the beautiful JW Marriott Muskoka at the special rate of $229/night The rate will be available until September 22 or until the room block is sold out.

AGENDA AT A GLANCE

FRIDAY

An Evening with Handtmann

Ontario’s Ultimate Burger Competition

- People’s Choice

SATURDAY AM Speaker Program

SATURDAY PM

TableTALK 2023

Dave Tiller People’s Choice Competition

Ontario’s Finest Butcher Competition

SATURDAY NIGHT

Red Carpet Gala - Dinner and Awards Silent Auction

Polytarp Products Power Play Pub

For more information or to register please visit www.meatpoultryon.ca

www.meatpoultryon.ca 18 BlockTalk - Fall 2023

SERVICES:

Preventative

Repairs

BlockTalk - Fall 2023 19 WWW.QMSINTL.COM TEL: 905-820-7225 EMAIL: INFO@QMSINTL.COM SUPERIOR EQUIPMENT FOR THE MEAT INDUSTRY New & Refurbished Equipment for the Food Processing Industry

We service, provide parts and sell equipment for the food processing industry.

INCLUDE:

& training

SERVICES

Troubleshooting

maintenance

for electrical, hydraulic and mechanical issues

STUFFERS BUTCHER

VACUUM

MIX GRINDERS TUMBLERS SAWS

TWINE TYING MACHINES

PACKAGING

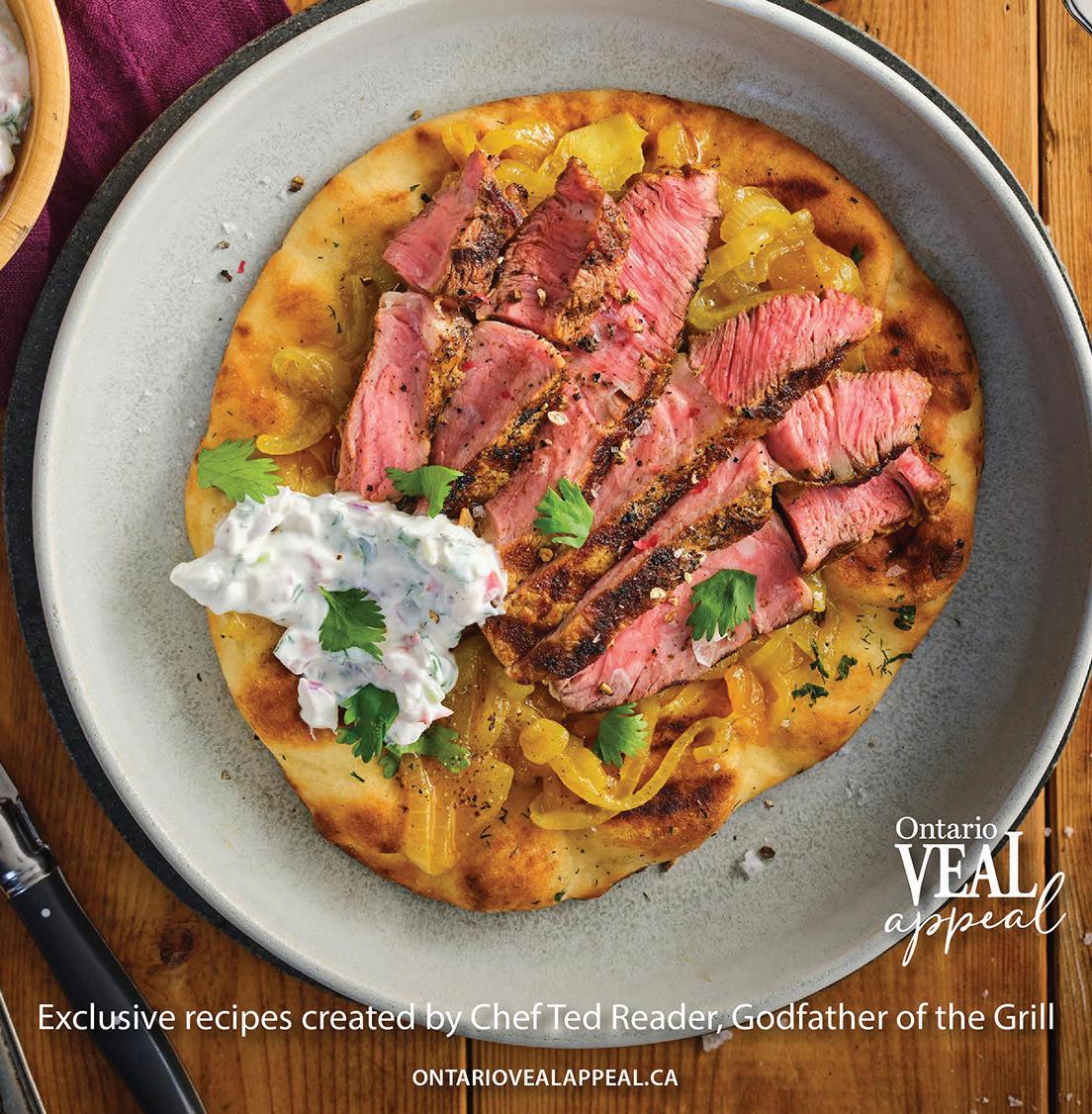

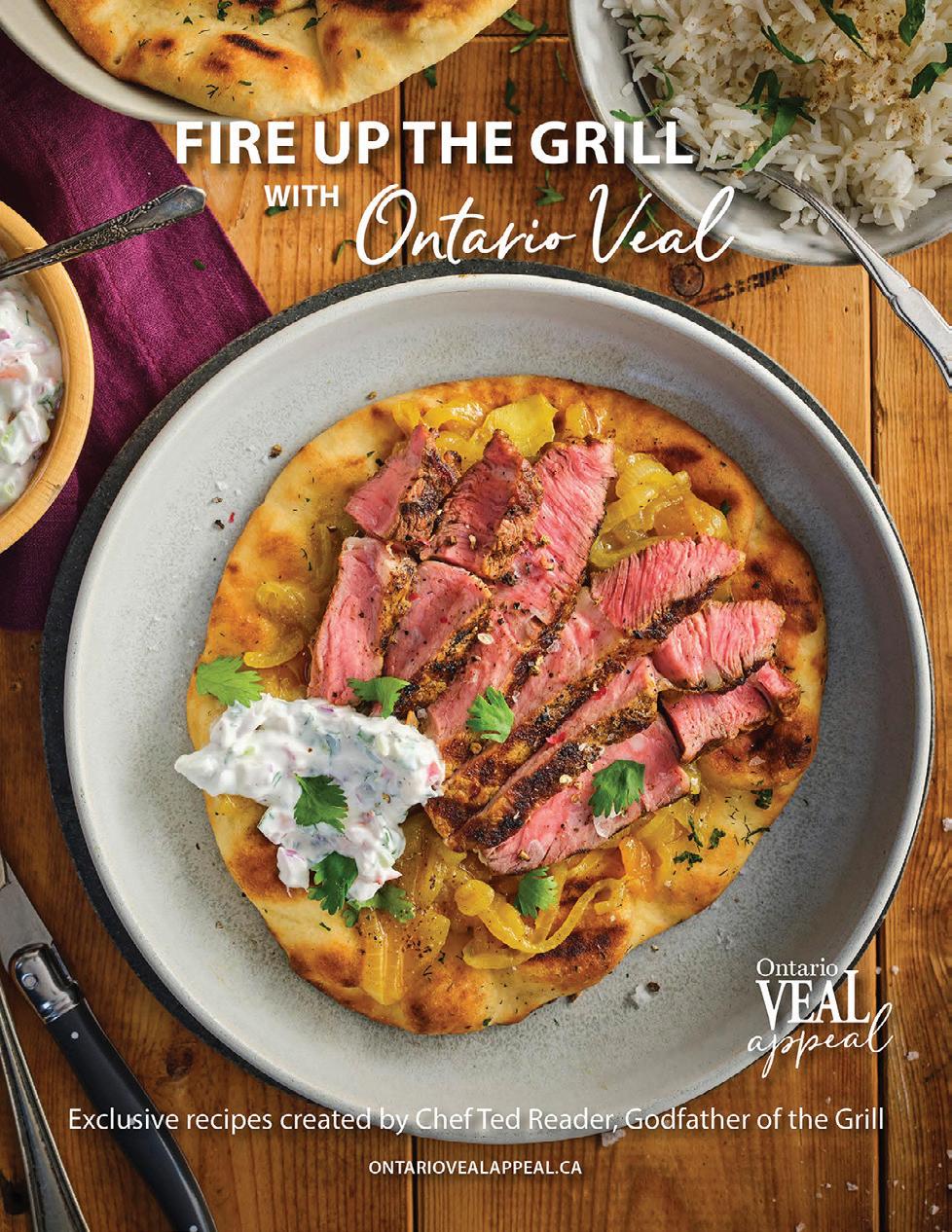

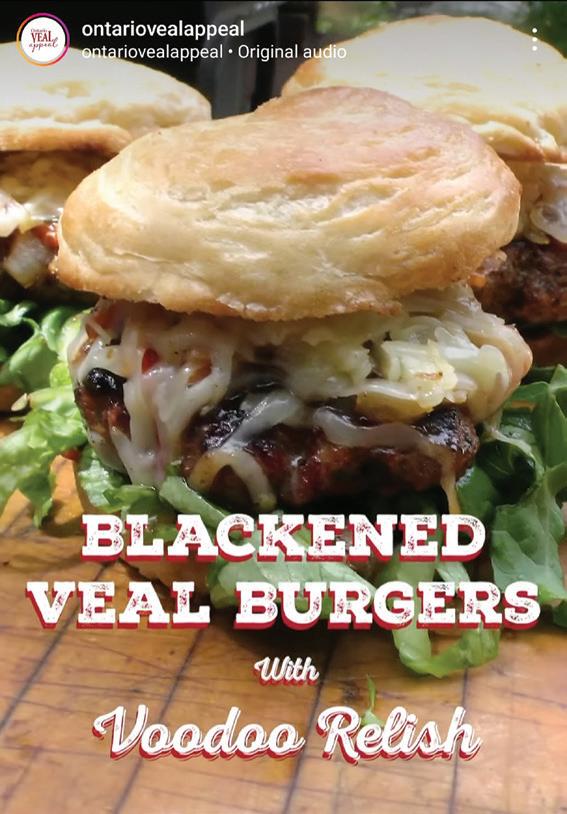

Increasing the Appeal of Ontario Veal

By Jennifer Haley, Executive Director

By Jennifer Haley, Executive Director

Veal Farmers of Ontario (VFO) has had a busy year which included a move to our new home at 130 Malcolm Road (Unit 2) in Guelph. This move makes us official neighbours of Meat & Poultry Ontario, Ontario Sheep Farmers, and Beef Farmers of Ontario. It’s wonderful to be in proximity to like-minded organizations that share a desire to grow a strong Ontario livestock industry.

At VFO, our mission is to provide leadership to promote industry growth and viability through collaboration, innovation, marketing, and education. While we have many irons in the fire, our consumer marketing initiatives are geared to maximize our limited budget while promoting the purchase and consumption of Ontario veal year-round. For VFO, we recognize that our marketing and promotion initiatives will also support those processors who also offer veal to their customers with the notion that all boats will float with rising tides.

To the consumer, veal has always been known for its premium quality, taste, and price. With meat prices increasing at the retail and foodservice sectors, it is important to maintain market share with the consumer and ensure veal remains center of the plate for the veal eating occasions our consumer is looking for. We know that with the escalating impacts of inflation and market supply, prices continue to rise, and consumers are looking for ways to lower their spending and preparing meals at home is on the rise. Beyond saving money, research shows that ease, health, and time are all factors in what consumers are making, and eating, at home*.

However, for many veal consumers, cooking veal at home seems to come with a fear factor and consumers tell us that they are not sure how to cook

veal to get that same restaurant quality experience. VFO’s consumer messaging approach addresses these concerns by educating consumers on available cuts and easy to understand how-to cooking tips. For meal inspiration, we’ve added a variety of new recipes with professional photography to our recipe library, along with videos with simple step-by-step cooking instructions. And of course, we include the message that Ontario veal is a delicious, lean, nutrient-packed protein.

You’ll find Ontario veal promoted on all the mainstream social media channels –Facebook, Instagram, YouTube, Pinterest, X (formerly known as Twitter) and now on TikTok! Inspiring veal eating occasions, sharing recipes from influencers, and providing recipe instruction – our reels have proven very popular. For Ramadan and Eid, VFO collaborated with Fariha Ekra (@lifewithfarihaa). Fariha is a micro influencer with a large South Asian following. Her content reaches and encourages veal consumption, especially within the Halal market. Working with Fariha offered us the opportunity to increase and add diverse content to our recipe library for usage in our consumer eNewsletters and our social channels.

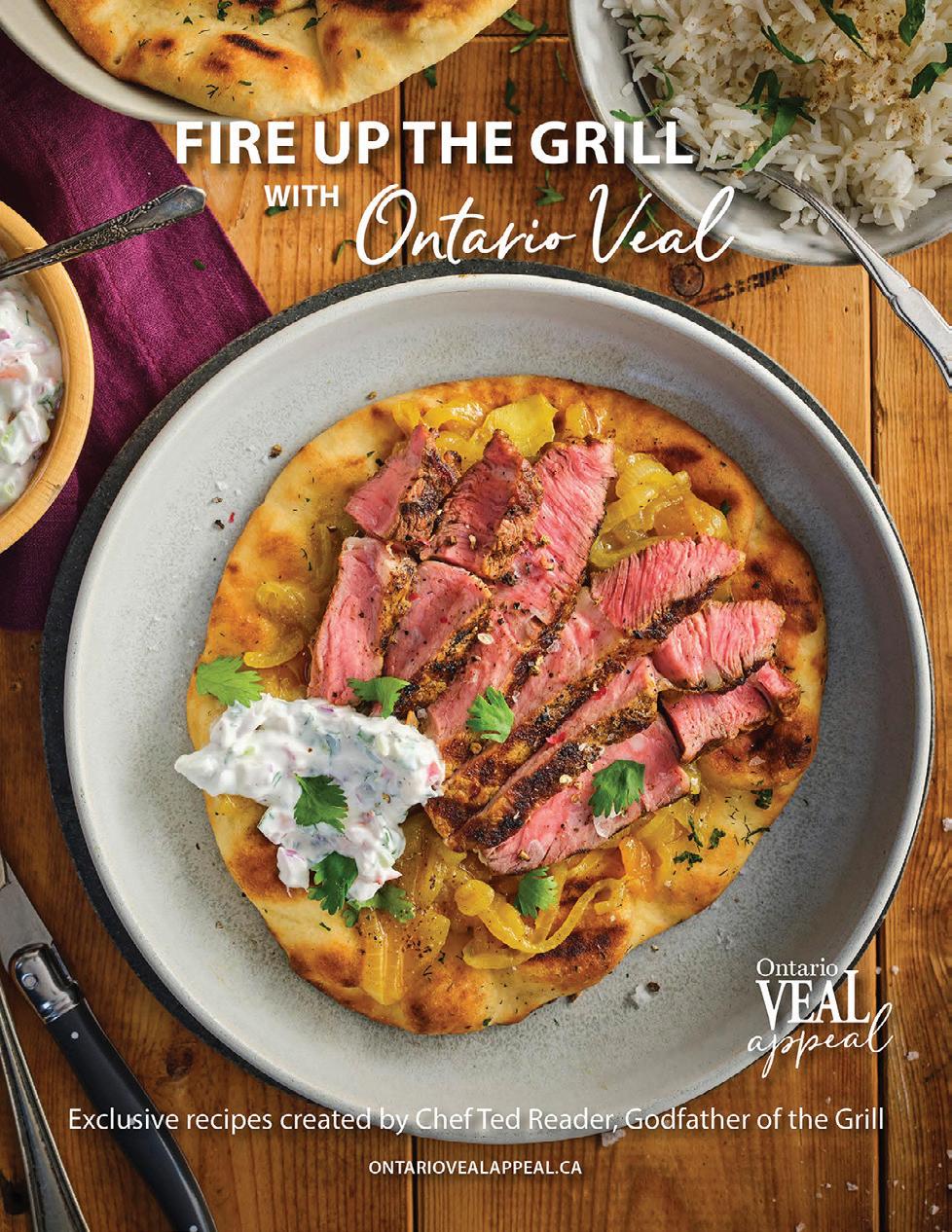

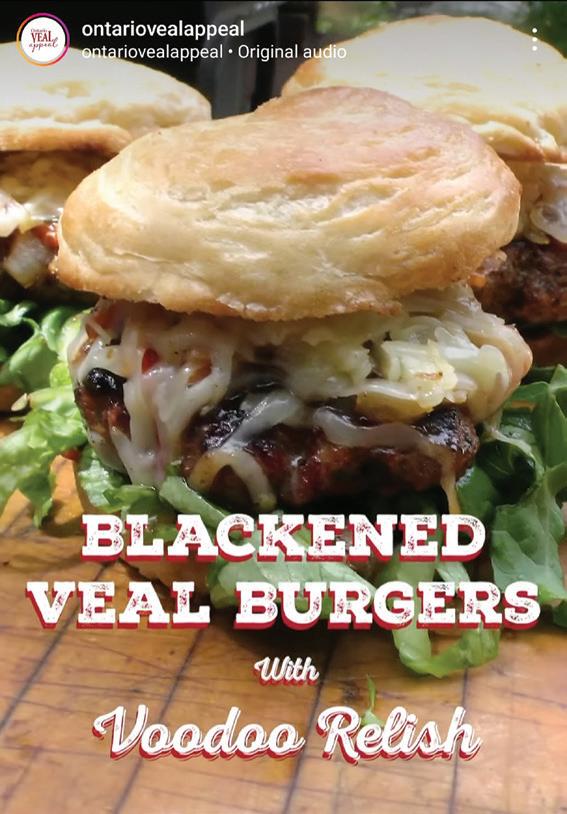

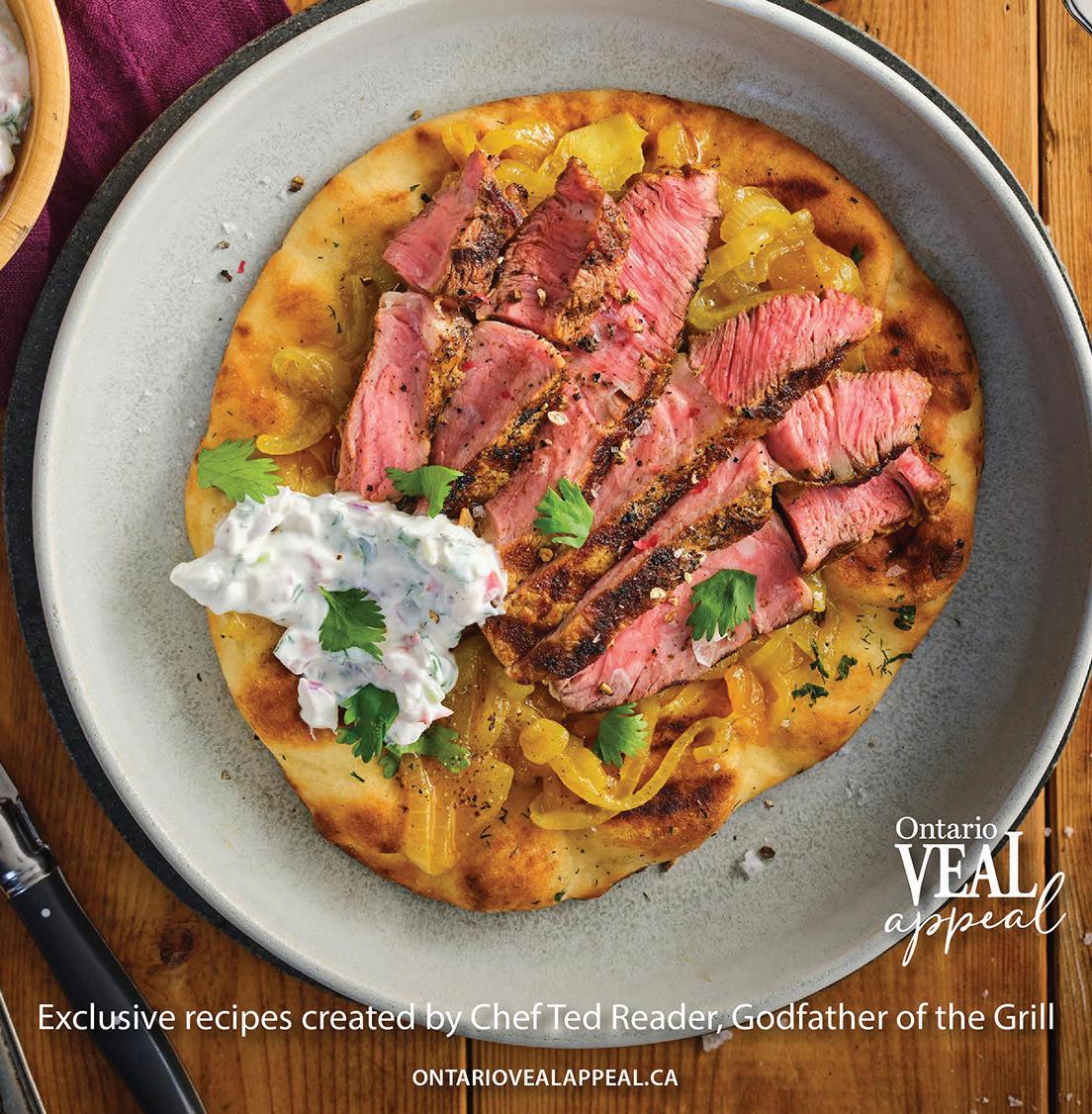

In the summer, consumers often forget to put veal on the BBQ as they gravitate to the more traditional meats. As a result, our veal sales are often impacted during the summer months. A key strategic direction for VFO has been to build awareness for Ontario veal on the grill and in the smoker! VFO expanded its longstanding partnership with Chef Ted Reader, the Godfather of the Grill.

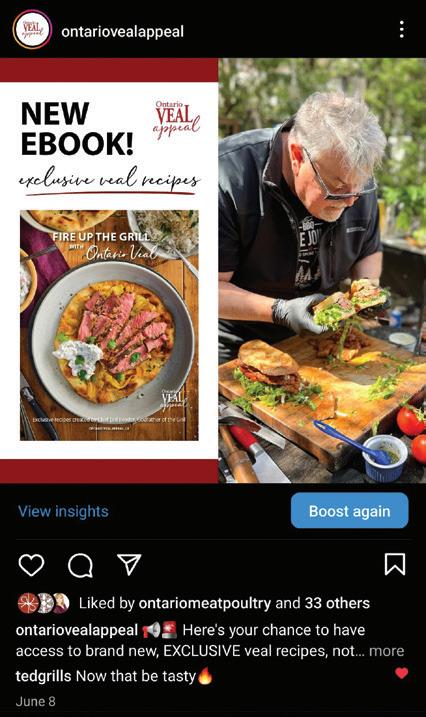

Chef Reader’s core audience consists of unapologetic and enthusiastic carnivores who engage with his content, try his recipes, and follow him like fan girls follow boy bands. Charged with producing a series of recipes that appeal to both novice and intermediate grillers while featuring a variety of readily available cuts, Chef Reader produced eight of his trademark “tasty” recipes. VFO also worked with Chef Reader to create several Veal 101 cooking tips video that have been shared across all our social channels as well as Chef Reader’s. VFO also showcased Chef Reader’s newly created recipes in a free eBook that was launched in

early June and promoted throughout the summer months on VFO’s consumer channels @OntarioVealAppeal.

Print ads in LCBO’s Food & Drink magazine continues to provide a strong return on investment. The magazine reaches a desirable consumer demographic and suits veal’s profile as a premium addition to special eating occasions. Visits to the ad’s featured recipe on the website spike after the magazine appears in store. For 2023, VFO secured a full page in the early summer issue, at the launch of grilling season, and another full page in the highly anticipated holiday edition which reaches LCBO stores November 8.

This coming holiday season, Ontario Veal Appeal will be launching a campaign that will once again put veal at the heart of this year’s celebrations. However you celebrate the holidays, food is always a part of new and old traditions, and Ontario veal fits perfectly on everyone’s menu! Make sure to watch for this campaign and leverage it with your own veal promotions.

*https://www.mintel.com/press-centre/nearly-all-canadians-91-identifycooking-from-scratch-as-a-way-to-save-on-groceries/

This fall and winter our goal is to connect with veal processors and retailers to discuss opportunities for collaboration. If there are specific marketing and promotion opportunities that you would like to discuss further, please reach out- we are here to help us all achieve increased veal sales. VFO also has some exciting plans in the works for 2024, and I invite you to contact me at the VFO office 519-824-2942 or jhaley@vealfarmers.ca to learn more.

Please follow and share our Ontario veal with your followers and tag us when you do!

@ontariovealappeal

@ontariovealappeal

@ontariovealappeal

@ontariovealappeal

@ontvealappeal (consumer)

@ontarioveal (trade)

Veal Farmers of Ontario: vealfarmers.ca

Ontario Veal Appeal: ontariovealappeal.ca (consumer website)

www.meatpoultryon.ca 22 BlockTalk - Fall 2023

Warm Bistro Salad with Grilled Veal Chops

Impress your family and friends and serve this delicious bistro salad.

Jerk Chicken and Pepper Kebabs

Preparation Time: 20 minutes • Baking Time: 60 minutes

• Grilling Time: 18 minutes

INSTRUCTIONS

In small bowl, whisk together butter, 3 tbsp (45 mL) of the oil, vinegar, thyme, mustard, honey and garlic. Remove 2 tbsp (25 mL) of the herb mixture into another small bowl; stir in sour cream. Refrigerate.

In 9 x 13-inch (3.5 L) baking dish, toss potatoes and onion with 3 tbsp (45 mL) of the herb mixture; season with salt and pepper and arrange in even layer. In small baking dish, toss beets with 1 tbsp (15 mL) of the herb mixture; cover with foil. Place baking dishes, side-by-side in 425°F (220°C) oven. Bake until tender, about 50 minutes, tossing potatoes occasionally. Keep warm. In medium bowl, toss mushrooms with 2 tbsp (25 mL) of the herb mixture; thread onto metal skewers. Season chops with salt and pepper. Place skewers and chops on greased grill over medium-high heat. Grill, covered, turning twice, for 12 minutes or until chops reach internal temperature of 145°F (73°C) for medium-rare. Brush chops with remaining herb mixture during the last 2 minutes of grilling. Rest for 5 minutes.

Cut lettuce into quarters, keeping base intact. Brush cut sides of lettuce with remaining oil. Turn off heat, grill lettuce over remaining heat just until grill marked, 1 to 2 minutes. Arrange lettuce, chops and skewers on large board. Sprinkle with cheese and parsley. Serve potatoes, onions and beets on the side with sour cream sauce.

Makes 4-6 servings.

INGREDIENTS

• 1/4 cup (50 mL) each melted butter and vegetable oil

• 2 tbsp (25 mL) red wine vinegar

• 1 tbsp (15 mL) each dried thyme leaves and Dijon mustard

• 2 tsp (10 mL) Ontario Honey

• 4 cloves Ontario Garlic, minced

• 1/2 cup (125 mL) Ontario Sour Cream

• 4 Ontario Yellow Fleshed Potatoes, cut into chunks

• 1 Ontario Onion, cut into wedges

• Salt and freshly ground black pepper

• 3 Ontario Beets, peeled and cut into wedges

• 12 oz (375 g) Ontario Crimini Mushrooms

• 4 Ontario Veal Rib Chops (about 250 g each)

• 1 head Ontario Romaine Lettuce

• 2 oz (60 g) Ontario Chévre, crumbled

• 2 tbsp (25 mL) chopped fresh Ontario Parsley

Newmarket Meat Packers

Evolving to Fill a Growing Niche in the Ontario Meat Industry

By Karen Sample

This fall, Newmarket Meat Packers will celebrate 55 years since Nick D’Elia Sr. and Gino Plastino founded the company. Over those five decades, the company has grown and changed by capitalizing on opportunities they recognized to become a leading provincial processor of domestic lamb, goat and veal.

Today, Ontario Lamb Company, a product brand created under Newmarket Meat Packers, is the largest lamb processor in Canada and has been recognized by the provincial government with the 2013 Premier’s Award for Agri-Food Innovation Excellence.

This product brand proved a savvy move, growing the company’s niche sales with chain stores because they want to stock and sell items clearly branded as local Ontario meat.

Nick D’Elia Jr. is now President of Operations and Management and has been actively involved in the company since 1997. Although his father, Nick D’Elia Sr. has retired, Plastino, who is now 83, is still involved. D’Elia says Plastino remains “our inspiration.” He adds, “He is, honestly, the hardest working man in the building, the first in and the last out.” The second generation of both families fills in the ranks. Plastino’s son Mario is an active partner and D’Elia’s brother Phil is a third partner and the company now employs about 50 people.

D’Elia proudly points out the company is quality driven, “We’re not the type to be banging down doors. We like to focus on our quality; our quality customers and quality product,” he explains. “It is not about how many you do, it is about how well you do it,” he adds.

“We have great relationships with our producers. Without our producers, we wouldn’t have a business. If you’re growing and doing well, it’s always more fun when you do it with others. It’s more fun when everyone’s doing well.”

Products and Purchasers

Originally founded on beef and pork processing, Newmarket Meat Packers shifted towards small stock to take advantage of the growing ethnic market in Ontario that relies on lamb as one

of their staple meats. The Muslim community, for example, buys mainly shoulders and legs.

The company has added mini-kebabs called spiedini to their offering to help efficiently use more of the animal and develop lamb sales from seasonal to year round.

Their best-selling products are French-style Ontario Lamb racks and the spiedini mini skewers. “There are not enough racks of lamb in the world,” D’Elia jokes, speaking to the year-round demand for consumer-ready “grab and go” meat products.

Small independent grocers make up a large part of Ontario Lamb’s clientele partly because the packaging is branded Ontario Lamb and can be brought in and put on the shelf without any additional work in store. “The consumer can grab their lamb rack and not have to do a lot with it before they cook. It’s easier for the retailer and their customers. We’re also now doing a value add on our lamb chops, so we’re doing a retail pack of seasoned or unseasoned lamb chops. This makes it convenient for the consumer to just grab their four pack and convenient for the retailer to just put it out there,” says D’Elia, “We’re gearing our line more towards retail-ready or case-ready product.”

The company is considering expanding beyond the provincial market to become national and possibly international since some of their existing customers are asking for this. “It’s barbecue season all year long in Florida,” he explains, reiterating they will not compromise on quality if they decide to supply some of the larger demand in other parts of the country or across North America.

Two-way Street to Success

Success is only possible with the right customers and the means to retain them, D’Elia emphasizes. Describing his customer base he says, “We have the best customers in the world. They’re loyal. They are long standing.” While Newmarket Meat Packers does not have a dedicated sales team to push their product the company knows what their customers want and are sure to accommodate them. In return, D’Elia says, “They never let us down.”

www.meatpoultryon.ca 24 BlockTalk - Fall 2023 BUSINESS MEMBER PROFILE

Meat & Poultry Ontario: An Advocate for Members of All Sizes

When asked about Newmarket Meat Packers’ membership in MPO D’Elia says, “They have become an important part of the industry because they’re a voice for us. They’re a voice for the members, to advocate for us, to support us.” D’Elia feels the role that MPO plays in the industry has grown and become more important over the past few years, “They’re fighters. They’ll go to bat and they’re smart and they’re advocates and we need that. Processors [as individual entities] have no voice. When united through MPO, we have a voice.”

MPO is more than a voice for the meat industry, it’s an organization that is in place to help members navigate government regulation and policies. “Sometimes people want to do the right thing, they just don’t know how and they’re intimidated.” MPO is there to work with and advocate for members.

Part of the GSFI is Hazard Analysis Critical Control Point (HACCP) which has seven principles:

Principle 1: Conduct a hazard analysis.

Principle 2: Determine the critical control points (CCPs).

Principle 3: Establish critical limits.

Principle 4: Establish monitoring procedures.

Principle 5: Establish corrective actions.

Principle 6: Establish verification procedures.

Principle 7: Establish record-keeping and documentation procedures.

Fifty-Five Years and Counting

Always moving forward, keeping up with ever-changing regulations and changing to meet evolving market demands are all key to Newmarket Meat Packers’ success and longevity as well as to their future.

D’Elia says they will be celebrating that longevity and success with the company’s official 55th-year anniversary in November. Now that’s something worth celebrating!

Newmarket Meat Packers Ltd.

15452 Warden Avenue Newmarket, ON L3Y 4W1 Canada Nick D’Elia info@ontariolamb.ca (905) 836-7001 www.ontariolamb.ca

“ALL” the Acronyms for Product Safety and Reliability

D’Elia says the company has been able to take advantage of government funding for traceability, plant expansion, upgrading and improved automated equipment as well as food safety tools. Newmarket Meat Packers does a lot of in-house adenosine triphosphate (ATP) swabbing to keep their products safe and is a pilot plant for a colour-coded traceability system that uses the Julian calendar to be able to identify one step back and one step forward. Mock recalls are, of course, a mandatory part of maintaining the plant’s Safe Quality Food (SQF) Certification which is part of the Global Safe Food Initiative (GSFI).

BlockTalk - Fall 2023 25

Nick D’Elia Sr, Mario Plastino, Gino Plastino, Nick D’Elia Jr and Phil D’Elia, pictured at their 50th Anniversary Celebration five years ago.

“...the company knows what their customers want and are sure to accommodate them.”

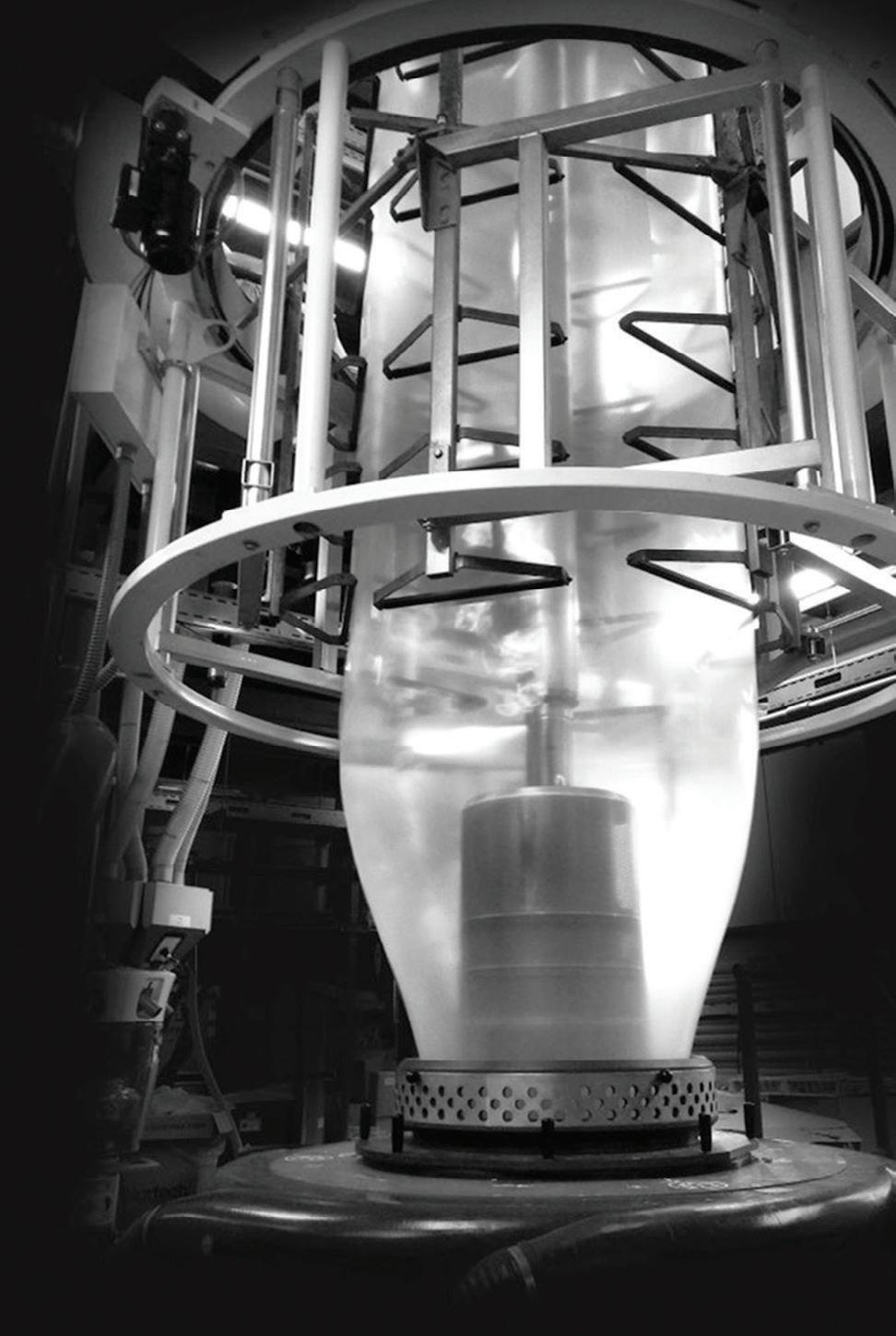

Safeguarding Food Safety A Deep Dive with CP Industries on Sanitation Solutions

By Karen Sample and Sandeep Parmar

In today’s world, with a booming population and the need for efficient food production, the emphasis on food safety has never been more crucial. We recently sat down with Keith Lucas, owner of CP Industries, to discuss the pressing concerns in food sanitation and how his company is tackling them.

Established in 1982 by Lucas’s parents, CP Industries, the food safety and sanitation company remains in Fergus to this day. In 2008, Lucas purchased the company from his parents and brought in his then CPA as partner.

Balancing Research and Execution

From the beginning Lucas took a hands-on approach ensuring safety protocols are not just theoretical but are rigorously implemented. He is deeply involved in the company’s operations, serving as the bridge between research, development, and onfloor execution. “I see myself as a firefighter,” he quipped, always ready to address any unexpected issues that arise in the business.

Company Structure and Distribution

With a dedicated team of around 50 individuals working across multiple enterprises from manufacturing to distribution arms, there is an undeniable sense of unity. The genesis of their ancillary companies is rooted in a simple yet powerful idea: listening to customers. Lucas explains, “Our clients expressed a desire for more. They wanted products that complemented CP’s core offerings. We responded, by either establishing new enterprises or making strategic acquisitions. At the end of the day, we’re here to serve, and our company structure echoes that sentiment.”

Diverse Applications and Training

The diversity of customer companies that CP Industries covers is broad, encompassing sectors from food and beverage to agriculture, healthcare, janitorial, laundry and municipal applications to vehicles. In order to service the full range of clientele, Lucas and his team conduct rigorous training sessions, focusing on chemical safety and usage both in house and in the field. This not only ensures the optimal performance of their products but guarantees their safety in varied applications.

Customization and Adaptation

Whether it’s designing custom equipment for specific sanitation applications or tweaking machinery for the poultry industry, the company is continually innovating to help its customers use CP products quickly and efficiently and to best advantage for their individual needs. Lucas highlighted instances where the company had to consider factors like line speeds, tank lengths, and unique sanitizing methods. This, however, is where Keith and his team excel. They thrive on a challenge and are at their best when helping a customer with a unique situation or need.

Green Solutions for a Sustainable Future

In a world growing ever more conscious of its environmental footprint, the pivot towards “green” solutions in the industry is both inevitable and welcome. Lucas, with his finger always on the pulse, spoke about this evolution. It is clear he believes green isn’t just a color – it’s a commitment.

“Major players in the industry are reimagining their product lines,” he says, “focusing on substances that not only serve their primary purpose but also degrade seamlessly, leaving minimal impact on our planet.”

www.meatpoultryon.ca 26 BlockTalk - Summer 2023

ASSOCIATE MEMBER PROFILE

He highlights peracetic acid as an excellent example of this shift in the industry. As it breaks down, peracetic acid sheds only environmentally benign residuals: hydrogen, oxygen, water and acetic acid – commonly known as vinegar. Lucas adds that peracetic acid is even increasingly being used to purify drinking water. “There’s a palpable move away from bleach,” he says.

Ensuring Product Safety Through Traceability and Mock Recalls

The importance of traceability in the food industry cannot be overstated. Lucas’s company has taken this to heart, ensuring a meticulous tracking system that traces every product right back to its raw materials and packaging. Several times a year Lucas initiates mock recalls. “It’s a test of our preparedness,” he shares. “The objective is clear: If there’s a problematic batch, we should be able to identify and notify all relevant customers within two hours. It’s a tall order, but we’ve consistently risen to the challenge,” he says.

As industries evolve and consumers become increasingly conscious of what they consume, companies like CP Industries will play an increasingly pivotal role. The company’s unwavering commitment to safety, innovation, and customer satisfaction ensures that the food on our tables is not just delicious but safe when this team and their products are involved.

Meat and Poultry Membership

Even though he has been so busy in recent years he has not been able to be as involved as he would like, Lucas says, “I think it is still very important to be a member of Meat and Poultry. The industry needs someone to lobby for it and get in front of politicians.”

He takes time to read BlockTalk magazine regularly. “It’s interesting, it’s a great magazine and I enjoy it,” he says. He especially likes the member profiles and learning what is new in the industry. “The demand for food is just going to grow and grow,” he says, “and it is fun to see everything happening in the industry.”

CP Industries Ltd.

535 Dickson Drive Unit 300 Fergus, ON N1M 2W8 Canada

Keith Lucas (519) 843-6300

info@cpindustries.ca www.cpindustries.ca

Building Trust Nationwide

The level of trust CP Industries has earned with its customers is evident in Lucas’s nationwide distribution, spanning from Newfoundland to Vancouver Island. What stands out even more, however, is the technical service that goes along with the product offering. With technicians available on-call 24/7, the company ensures that clients, irrespective of time zones, have access to immediate assistance when they need it.

Interaction and Learning

It is safe to say that one of Lucas’s favourite parts of the job is interacting with customers and testing in the field. Training sessions offer CP Industries a chance to share their sanitation knowledge while they learn from varied customer experiences, plants and situations to make their products even better.

Consolidating for the Future: Expansion with a Vision

With the acquisition of a 12,000-foot warehouse in Guelph, Lucas says, “We’re looking to centralize our operations, bringing everything under one primary roof,” he says. The ambitious expansion will double their current operational space, We’re always looking ahead, always ready for the next leap.”

Challenges and the Road Ahead

As the world of food safety and the mechanisms in place to ensure it become ever more complex and challenging for the food industry, CP Industries is ready to help customers and meet their evolving needs head on.

BlockTalk - Spring 2023 27

www.csb.com The right ERP system for the Meat Industry Manage all aspects of your business in a single solution Connects data, processes and departments. Quality management, production planning & control, identification, and labelling

“At the end of the day, we’re here to serve, and our company structure echoes that sentiment.”

Learn more sanimarc.com/shed-a-light FCC.CA DREAM. GROW. THRIVE. If you produce it, process it, pack it or move it, we finance it. Partner with the only lender 100% invested in Canadian agriculture and food. And that includes businesses like yours. 1-800-387-3232 Financing your food and beverage business

Government Funding for Food Safety Projects

By Alena Barreca, Mentor Works

Grants, Loans, and Tax Credits for Canadian Food Safety Projects

Your business may know that Canadian government funding programs are available for your projects – maybe your business has even applied for grants, loans, and/or tax credits in the past – but the funding landscape is vast and often complicated, with hundreds of programs that each have their own unique deadlines, expectations, applications, and allocations.

Funding programs are available federally, provincially, and territorially, and maintaining an in-depth understanding of these incentives (including their purpose, timing, and what they look for in applications) can be incredibly difficult for most businesses. Based in Guelph, Ontario, Mentor Works, a Ryan company is a group of government funding specialists that aim to educate businesses on the funding available to them, as well as supporting them through the application process when they need assistance.

Let us streamline the process of finding funding for food safety projects and highlight three currently available programs that your business may want to take advantage of.

Up to $150K in Grants from the Meat Processors Capacity Improvement (MPCI) Program

Through the $3.5 billion Sustainable Canadian Agricultural Partnership (SCAP), federal, provincial, and territorial governments offer numerous funding opportunities intended to strengthen the competitiveness, innovation, and resiliency of Canada’s flourishing agriculture sector.

Via SCAP, the Meat Processors Capacity Improvement (MPCI) Program provides up to $150,000 per eligible Ontario applicant for short-term investments that improve meat handling and processing such as equipment, technologies, and practices. The MPCI program is open as of August 31, 2023.

About the MPCI Program:

• A maximum of $150,000 in non-repayable grant funding;

• Eligible applicants include free-standing meat processing plants and/or abattoirs located in Ontario;

• Eligible projects include short-term investments in meat handling and processing equipment, technologies, practices

Continued on page 32

www.meatpoultryon.ca 30 BlockTalk - Fall 2023

Learn how your business can access Canadian government grants, loans, and tax credits to offset food safety projects for equipment, technology, and practices.

November 15-16 Cambridge, Ontario 2023 Food Handler Training Workshops Register at meatpoultryon.ca

BlockTalk - Fall 2023 31 Australia-Brazil-Canada-CzechRepublic-China-CostaRica-Germany-Mexico-Russia-Serbia-Spain-Thailand-UnitedKingdom-Uruguay-USA Coffinet ShrinkBags Forming/Non-formingFilms ElasticNetting FibrousCasings PlasticCasings CelluloseSkinlessCasings NonEdibleCollagenCasings Formoreinformationcontact: ScottMcQuay SeniorTechnicalSalesManager mcquays@canada.viscofan.com 519-574-3969 Ourwidevarietyofediblecollagencasingshas enjoyedgreatpopularityworld-widefor decades.Whetheritbeforprocessedsausages, freshsausages,pre-cookedfriedsausagesor dry-curedsnacks–everyediblecollagencasing fromViscofanisaclassic. 800-465-8201www.viscofan.cominfo@canada.viscofan.com YourFIRSTCHOICEforallyourediblecollagenneeds Theworldwideleader inartificial casings VISCOFANEDIBLECOLLAGENCASINGFORCOOKED SMOKEDSAUSAGESORDRYSAUSAGESWHERE NATURALAPPEARANCEISIMPORTANT

that improve efficiency, productivity, and food safety, and/or consulting and engineering planning costs related to this project may also be covered;

• The application is open as of August 31, 2023; and

• The application deadline is January 31, 2024.

Up to $10M in Loans for Technology Adoption from the FedDev Ontario Business Scale-up and Productivity (BSP) Program

The FedDev Ontario Business Scale-up and Productivity (BSP) program offsets upfront project costs and helps southern Ontario businesses grow faster. The program provides no-interest repayable contributions in the form of government loans with repayment beginning within a year of project completion.

In support of Ontario’s food safety projects, the BSP program can provide loans of up to $10 million for the adoption and/or adaption of innovative technologies that can be implemented for the purpose of regulating and optimizing food safety processes.

The BSP program supports Ontario businesses as they adopt new, innovative technologies with the goal of ultimately scaling up productivity and the development of and entry into new markets to become globally competitive.

About the FedDev Ontario BSP Program:

• No-interest repayable contributions (government loans) of up to 35% of project costs to a maximum $10 million;

• Eligible applicants include southern Ontario businesses and organizations;

• Labour, consulting, capital, and non-capital costs associated with adopting, adapting, and commercializing innovative technologies; and

• Applications are accepted on an ongoing basis with no submission deadlines.

Tax Credits from the Scientific Research and Experimental Development (SR&ED) Program

Perhaps your business is looking to invest in food safety projects but you’re not sure where to begin or you’re tackling a specific issue that doesn’t have a set solution yet. If so, then tax credit programs for research and development activities may be right for you.

The Scientific Research and Experimental Development (SR&ED) tax credit is the largest single source of Canadian federal government support that incentivizes business-led research and development projects. The program provides more than $3 billion in tax incentives to over 20,000 claimants annually.

By accessing SR&ED funding, businesses can receive tax credits of up to 69% of labour and overhead costs, 36% of contractor costs, and/or 45% of material costs for basic research, applied research, or experimental development in Canada. These projects must have the purpose of developing new products, processes, or making incremental improvements to them, such as for food safety purposes.

About the SR&ED program:

• Up to 69% of eligible project costs depending on expense type and funding;

• Open to all Canadian businesses as Canada’s largest federal tax incentive program;

• Eligible SR&ED projects must be conducting experimental development and/or research activities exhibiting some level of uncertainty and risk as evidenced by the availability of solutions to overcome this uncertainty; and

• Applications are open year-round, but SR&ED claims are due within 18 months of the fiscal year end of the corporation.

Need Help Accessing Government Grants and Loans?

The Mentor Works team works directly with clients to design and implement tailored solutions to support business growth. They work with Canadian businesses to develop a dynamic government funding plan that supports all areas of business investment, which gives a significant competitive advantage when used properly. Their clients are awarded an average of $180,000 in grants per year. Get in touch by visiting mentorworks. ca or by calling 1-888-599-3111.

Alena Barreca is a Marketing Specialist at Mentor Works in Guelph, Ontario. She focuses on helping businesses learn about government funding opportunities and connecting her team with those in need of application assistance.

www.meatpoultryon.ca 32 BlockTalk - Fall 2023

Continued from page 30 – GOVERNMENT FUNDING FOR FOOD SAFETY PROJECTS DISCOVER OUR HOME DELIVERY SOLUTIONS Stay ahead of the competition! Get started today! 1-800-665-COLD | erbgroup.com sales@erbgroup.com https://erbgroup.com/ blocktalk_23-07/

BlockTalk - Fall 2023 33 Norstar Corporation 6 Vansco Road, Toronto, ON M8Z 5J4 Ph 416.253.6666 Fx 416.253.6647 www.norstarcorp.ca The Top Food Processors have trusted Norstar for all their food packaging needs for over 40 years. THE best in the business . . . use Norstar ORDER RESPONSE 24/ 7/360 EMERGENCY

Reduce Injuries with Safe Food Handling Practices

By Workplace Safety & Prevention Services

From all of us who enjoyed barbecuing with friends and family this summer, thank you. Without the farmers, butchers, and manufacturers that make up Ontario’s meat and poultry industry, we may not have had such a broad selection of delicious meats to choose from for our backyard or lakeside get-togethers. As you know, Ontario’s meat and poultry sector employs 25% of the province’s food and beverage processing industry. What you may not know is that between 2020 and 2022, the meat and poultry manufacturing sector experienced more than 2000 lost-time injuries, which means the injury was serious enough that the employee needed time away from work. We recently spoke with David Smith, WSPS Partnerships Account Manager for the manufacturing sector, about the main factors that contribute to injuries in the meat and poultry sector and tips to help you and your employees work safely when handling food.

What types of injuries are happening?

Many of the lost-time injuries experienced in this sector were related to contact with equipment or hand tools causing lacerations. “When it comes to handling meat, cold temperatures can impact hand dexterity,” says David. “When your hands are cold, blood flow becomes restricted, which can impede your

Nobody wants to pay for insurance.

ability to handle tools.” Gloves that fit properly will also help reduce these types if injuries.

According to David, another common factor that likely contributes to lost-time injuries is stationary work surfaces. “Stationary work surfaces or tables can lead to musculoskeletal disorders or MSDs,” says David. “If a taller person is working next to a shorter person at the same table, one or both of them may be in an awkward position because of their difference in height, arm length, etc. in relation to the height of the table,” he says. Given how common this scenario is, it’s not surprising that 26% of the lost-time injuries between 2020 and 2022 in this sector were from overexertion and repetitive motion related to lifting, bending, and reaching. “One way to reduce the risk of MSDs in these situations is job rotation,” says David. “Organize the work so that employees have an opportunity to move around and break up stationary tasks.”

Proper PPE, the right tools, and a clean shop make the difference

When you are cutting meat, hand protection is critical. Obviously, you need to protect yourself and your workers

If something were to happen, that would not be the right time to find out you bought ground beef when you were sure you purchased a rib eye. Not all things are equal and not all things cost the same.

Reasonably painless reviews of your insurance policies is always best done before a claim occurs.

We are committed to your livelihood, your association and the community we live in. Please give us a call.

www.meatpoultryon.ca 34 BlockTalk - Fall 2023 SAFETY FIRST

Business, Home and Auto Insurance | Employee Benefits We Care. (905) 319-2252 | (877) 338-2252 | peterd@donnellins.com

on page 36

Continued

BlockTalk - Fall 2023 35 CANADA COMPOUND Your food industry specialists since 1927 CCC Custom Blending Solutions Looking to create a new blend, rework an existing blend or match a recipe or product? Our BRC certified blending facility provides complete solutions for flavours, functional blends and complete custom units. Our in-house services ensure that you are speaking directly with our experts and getting the value and consistency in your products that we are trusted for. Contact us today to find the perfect solution for you. www.canadacompound.com Canada Compound Corporation 391 Rowntree Dairy Rd., Woodbridge, Ontario L4L 8H1 Canada P. 905-856-5005 E. info@canadacompound.com

against cuts and punctures, but you also need protection against biological hazards. David recommends wearing a chainmail glove on your holding hand and a cut-resistant glove on your cutting hand. Kevlar is a good example of a common cutresistant material. “For sanitary purposes, wear a nitrile glove over the chainmail and cut-resistant gloves to protect against bacteria and other biological hazards,” says David. “If you can’t find a nitrile glove large enough to fit over the other gloves, then wear one underneath. Either way, always ensure gloves fit properly and protect your wrists and lower arms as well as your hands.”

In addition to hand protection, an apron is an important piece of personal protective equipment (PPE). It can do a lot more than protect your clothes from getting dirty. A durable apron made of leather or Kevlar can protect your body from a cut or puncture. “Safety glasses are also a good idea,” says David. When there is a possibility of blood or bone flying through the air, eye protection becomes necessary. Keeping the shop floor free of slip and trip hazards also helps to prevent injuries. “Safety shoes with good grips help prevent slips, trips, and falls,” reminds David, “And they protect your feet if sharp items fall.”

Training, observation, and safe work procedures protect everyone

Training is one of the most effective steps you can take to ensure everyone’s safety. Before operating equipment or using a new tool, read the operator’s manual and follow manufacturer’s instructions. “The information in the operator’s manual is a good

start for developing safe work procedures,” says David. Once you have a procedure, train your employees and then observe them doing the work. “Look for coaching opportunities. If you see something being done incorrectly, provide corrective instruction,” he says.

Your training and procedures should include information not only on how to use tools and equipment, but also on what to wear at work. Make sure your employees are clear about the PPE they are expected to wear and how to inspect it for defects. Loose clothing should not be permitted. If it gets caught in a slicer or grinder, the outcome could be dire. Hair nets and beard nets keep stray strands of hair in place, which is important for cleanliness, but also for operator safety.

When it comes to establishing safe food handling practices, lead by example. When you wear proper PPE, use the right tools, and follow safe work procedures, others will know that health and safety is a priority in your workplace. Working together to reduce injuries, retain employees, and grow your business, benefits everyone—and keeps summer barbecues going strong.

This article was prepared by Workplace Safety and Prevention Services (WSPS). For more information visit Food Manufacturing & Root Cause Analysis | WSPS

www.meatpoultryon.ca 36 BlockTalk - Fall 2023

Continued from page 34 – INDUSTRY LEADERS IDENTIFY TOP HEALTH & SAFETY RISKS IN FOOD MANUFACTURING Call us and find out how you can start saving money AKR CONSULTING CANADA INC. 151 Courtneypark Drive West, Suite #100 Mississauga, ON L5W 1Y5 T: (905) 678-6368 | F: (905) 677-1700 info@akrconsulting.com www.akrconsulting.com • Vacuum Bags • VFFS & HFFS Film • Hot-Fill • Thermoforming Film • Combo Liners • Custom Bags ISO 9001 and FSSC 22000 Certified 350 Wildcat Road, Toronto, Ontario 1-800-606-2231 • info@polytarp.com CANADIAN MADE YOUR FOOD GRADE PLASTIC PACKAGING SUPPLIER

BlockTalk - Fall 2023 37 Grow your business. Automate your sausage production with a Lucky Linker by Vemag from Reiser. The Reiser Advantage: Sausage Specialists available to help you with your process and your product. Reiser Customer Center available to test your recipes on our equipment. No-hassle financing. Industry leading spare parts, service, and support. Watch video 2023 www.reiser.com Reiser Canada • Burlington, ON • (905) 631- 6 6 11 Reiser • Canton, MA • (781) 821-1290 Reiser UK • Milton Keynes, Bucks • ( 019 08) 585300

Unraveling Best Before Dates Navigating Consumer Perceptions of Food Safety and Best Before Dates

By Daphne Nuys-Hall, Technical Director, Meat & Poultry Ontario

One of the significant challenges in the food industry is food waste. According to a study conducted by Second Harvest, an organization focused on reducing food waste, Canada wastes approximately 11.2 million metric tons of food annually. Best Before dates play a role in contributing to this issue, as consumers often discard products once they pass the “Best Before” date even if they are still safe to consume. A 2022 report from the Agri-Food Analytics Lab at Dalhousie University and the Angus Reid Institute found that 25 per cent of respondents rely on “best before” dates as an indicator of food safety, while 65 per cent report throwing out unopened food because its “best before” date had passed.

In the recent Report of the Standing Committee on Agriculture and Agri-Food – Grocery Affordability: Examining Rising Food Costs in Canada, the committee recommended that the Government of Canada, in cooperation with the provinces

and territories, address food waste by investigating how the elimination of the best-before dates on foods would impact Canadians. However, until that investigation is complete, “It is the responsibility of the regulated party to determine if the product has a durable life of 90 days or less and the specific durable life information for the products they sell. What that durable life of a product is not prescribed in regulation and is the responsibility of the manufacturer to determine.

Manufacturers determine best before dates, also known as durable life or shelf life, based on their product testing and quality assurance measures, considering factors like ingredient stability, packaging, and storage conditions by conducting a shelf-life study. Shelf-life studies can be conducted either inhouse using Organoleptic Analysis or externally at a laboratory using Microbiological Analysis, or in some cases both.

38 BlockTalk - Fall

2023

TECH

Contact Us info@gtastrategies.com (416) 499-4588 GTA STRATEGIES GTA Strategies is your premier Government Relations and Strategic Planning services firm. Helping organizations in the Meat & Poultry Industry with all aspects of strategic services, including: • Securing government grants and financing • Navigating complex government policy issues • Strategic business planning and development • Rezoning for capacity expansion

Strategies

TALK

GTA

worked with us to define a winning strategy that helped break down interprovincial trade barriers for the meat and poultry industry. GTA Strategies helped us secure over $500,000 in funds to help modernize our plants Franco Naccarato Executive Director Meat and Poultry Ontario

Betty Dikeos VP Marketing D&D Poultry

Organoleptic Analysis: pertaining to the sensory properties of a particular food such as colour, odour, flavour, texture and the integrity of the package. Indicators of product deterioration include milkiness or cloudiness, ropiness characterized by a sticky slime build up, or a watery purge in the package caused by improper processing or microbial action.

Microbiological Analysis: indicates the quality and safety of the product by determining the number of microorganisms present. The following microorganisms are tested for: Generic E. coli, Total Coliforms and Total Plate Count.

Products for shelf life should be produced as intended for regular production (i.e., same equipment, finished product packaging materials). Products are to be stored at a minimum of 4ºC for the duration of the shelf life. If possible, the product should be evaluated / tested the day it is produced to determine the baseline of the parameters. The following tests should be completed: a visual analysis, an odour analysis of the product and microbiological analysis.

The product should be evaluated on a schedule determined by the expected shelf life of the product. For a shorter shelf-life product, the product may be evaluated daily or every other day.

For a longer shelf-life product, the product could be evaluated at intervals determined by the Q.A. personnel.

In some cases, the shelf-life timeline may be hypothesized by existing products (e.g., ground products generally are given 8 -10 days of shelf life), scientific literature, supplier specifications/industry best practices, etc. In the case of a pre-existing product, it may be sufficient to only test the end of product shelf life. A visual analysis, an odour analysis, and microbiological analysis may be performed.

Best before dates in Canada serve as guidelines for consumers to make informed decisions about product freshness and quality. Therefore, it is important for manufacturers to ensure that the best before dates that are applied to the products accurately reflect the shelf life of the product while minimizing the risk of consumers tossing away good food.

As the Ontario food industry continues to evolve, educating consumers and retailers about best before dates will be instrumental in fostering responsible food consumption practices and reducing environmental impact. Through collective efforts, Ontarians can move towards a more sustainable and mindful approach to food consumption.

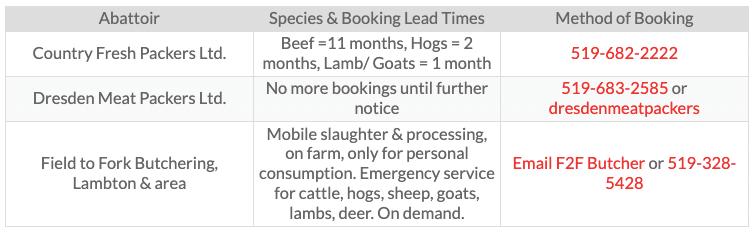

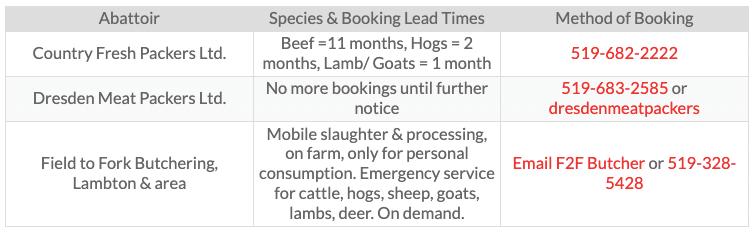

Processor Links Attention Abattoirs!

Important Update

Connecting farmers and processors

Don’t miss out on free availability promotion and managing requests. AgSights and MPO have partnered with Beef Farmers of Ontario to share availability with farmers and help ll open spots e ciently. Awareness of how you manage wait lists is also valuable feedback to demonstrate the daily challenges you experience.

If you need to sign-up to take advantage of this free support, please contact AgSights today. This service is here to nd e ciency in managing wait lists and lling space, while you have the skilled team ready.

www.meatpoultryon.ca 40 BlockTalk - Fall 2023

Continued from page 38 – UNRAVELING BEST BEFORE DATES: NAVIGATING CONSUMER PERCEPTIONS OF FOOD SAFETY AND BEST BEFORE DATES

Over delivers under budget.

• Maximum versatility and dependability

• Simple mechanics for less downtime

• Easier cleaning and maintenance

• Surprisingly affordable

Precisely what you need

BlockTalk - Fall 2023 41 precipak.com A member of the Poly-clip System family.

Brine Injectors for Multiple Applications

PI 26 Brine Injector >

Advertiser Index

MEMBERS, Are you receiving MPO electronic communications?

Word on the BLOCK, our bi-weekly email delivered Monday morning, highlights the latest events and opportunities within the industry. Technical eBulletins are distributed as needed with information such as regulatory challenges and animal rights activist events.

This important industry information is often time sensitive. Please make sure your spam list includes news@meatpoultryon.ca , technical@meatpoultryon.ca and member@meatpoultryon.ca.

If there are other people within your company that should be receiving information contact April at (519) 763-4558 or april@meatpoultryon.ca to have them added to our lists.

42 BlockTalk - Fall 2023

Abate pg. 22 abatepackers.com Agsights pg. 10 agsights.com AKR pg. 36 akrconsulting.com Canada Compound pg. 35 canadacompound.com CSB Systems pg. 27 csb.com Darling (Rothsay) pg. 25 darlingii.ca David Food Processing Equipment Inc. pg. 19 davidfoodprocessing.com Donnell pg. 34 digisystems.com DPEC Food Solutions pg. 13, 39 dpecfoodsolutions.ca Duropac pg. 22 Duropac.com Erb Transport pg. 32 Erbgroup.com FCC pg. 28 fcc.ca Grasselli SSI Canada pg. 19 grasselli.com GTA Stategies pg. 38 gtastrategies.com Handtmann pg. 43 handtmann.ca Klever Equipped pg. 15 goklever.com Kungfu Butchers pg. 11 kungfubutchers.ca Malabar Super Spice pg. 5 Malabarsuperspice.com Multivac pg. 6-7 ca.multivac.com Norstar Corporation 33 norstarcorp.ca Ontario Beef 16 ontariobeef.com Pack 3000 pg. 29 pack3000.com Pemberton pg. 8 pemcom.com Poly-clip pg. 9, 41 polyclip.com Polytarp pg. 14, 36 polytarp.com Reiser pg. 37 reiser.com Sani Marc pg. 28 sanimarc.com Viscofan pg. 31 viscofan.com VC999 pg. 2, 44 Vc999.com

Call 877-435-4555 · Sales.Canada@VC999.com Let VC999 Deliver A Customized Packaging Solution For You! - www.VC999.com The Series by VC999 • Skin, MAP, & Vacuum on ONE machine • All Stainless Design • Easy-Access, Low-Cost Maintenance • Rigid & Flexible Materials • Made in North America Stands for PERFORMANCE.

By Jennifer Haley, Executive Director

By Jennifer Haley, Executive Director