to Propel Meat Sector Growth CMIT Keeping Ontario’s Meat and Poultry Industry Informed Spring 2023 • Vol. 29, Issue 2 ALSO INSIDE: 24 Finest Butcher Competition Celebrating 10 Years 26 Artisnal Chicken: Committed to Craftsmanship 28 Member Profile: Stemmler’s Meats

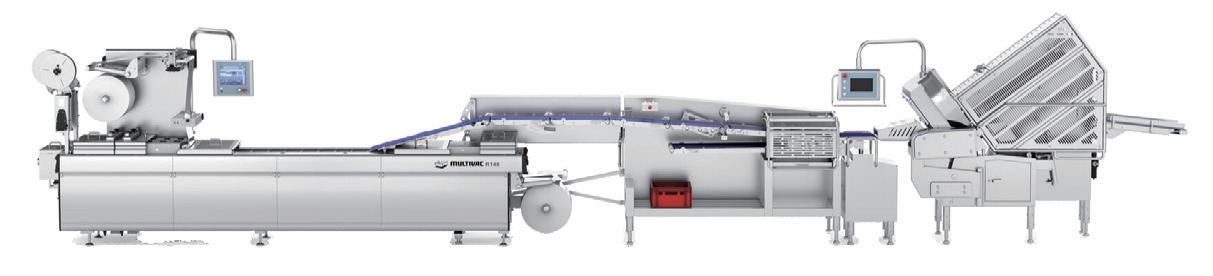

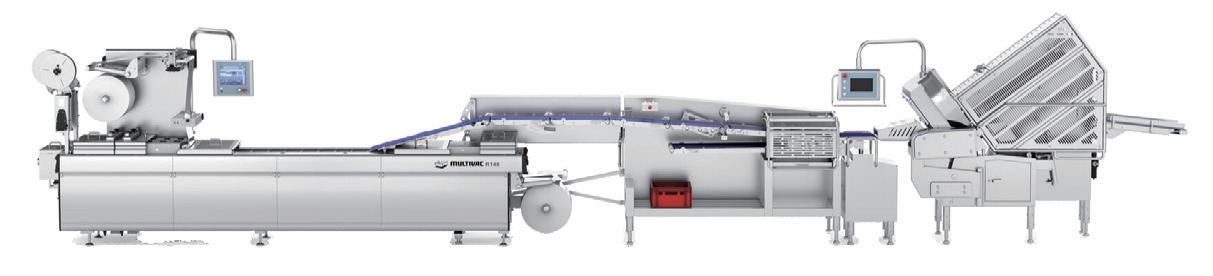

EVOLUTION LEADS TO REVOLUTION MEET THE R-SERIES FROM VC999! Let VC999 help you create the perfect packaging solution! - www.VC999.com The R-Series runs Flexible, Rigid, Skin, Shrink, & Easy Peel Films ALL ON ONE MACHINE! www.vc999.com · 877-435-4555 · Sales.Canada@VC999.com • Durable • Customizable • Increased Speed Certifications Pending

BlockTalk - Summer 2023 3 President’s Message ......................................................... 4 Welcome to the Association ............................................. 5 Why it’s Time to Shift Thinking About Food Processing Sustainability .................................................. 8 Innovative HR Solutions from the Ontario Agri-Food Careers Support Initiative ............................. 12 Centre for Meat Innovation and Technology (CMIT) Designed to Help Meat Sector in Ontario Advance and Grow 18 Ontario’s Ultimate Burger Competition 22 Promoting Butchery as a Trade: Celebrating 10 Years of Ontario’s Finest Butcher Competition 24 Artisanal Chicken ............................................................. 26 Jerk Chicken and Pepper Kebabs ................................... 27 Stemmler’s Meats: From Artisan Family Business to Large Scale Manufacturer .......................................... 28 Big or Small: CSB Builds Unique System for Each Customer ........................................................... 32 How Food Businesses Can Utilize SR&ED Tax Credits ........................................................... 34 Industry Leaders Identify Top Health & Safety Risks in Food Manufacturing 38 Revolutionizing Ontario’s Meat Industry: Top 5 Innovations Driving Efficiency, Quality, and Sustainability 42 Advertiser Index 46 8 24 28

Celebrating 10 Years of Ontario’s Finest Butcher Competition Stemmler’s Meats Index BlockTalk - Summer 2023 Vol. 29, Issue 2

Why it’s Time to Shift Thinking About Food Processing Sustainability

Iwant to take a moment to reflect on the remarkable 10-year anniversary of the Butcher Competition, an event that has become a pinnacle of excellence within our community. For a decade, the Butcher Competition has gathered the finest artisans, showcasing their extraordinary skills, dedication, and passion for the craft. As we celebrate this milestone, let us pay tribute to the butchers who have elevated our industry through their unwavering commitment to craftsmanship and innovation. While we commemorate this significant achievement, it is important to recognize the state of the meat industry and the challenges we face. In recent years, we have witnessed a growing consumer demand for sustainably sourced and ethically produced meats. Consumers are increasingly seeking transparency, traceability, and high-quality products that align with their values. As an association, it is our responsibility to adapt and embrace these changing consumer preferences, promoting sustainable practices and supporting our members in their journey towards a more conscious and responsible industry. We cannot ignore the impact of technology and digital transformation on our sector. From precision farming to blockchain-based supply chain management, technological advancements are revolutionizing the way we produce, process, and distribute meat products. Embracing these innovations will not only enhance efficiency and productivity but also provide us with new opportunities to meet the evolving needs of our consumers. As an association, we are committed to equipping our members with the necessary tools, knowledge, and resources to navigate this digital landscape and seize these exciting prospects. In conclusion, as we celebrate the 10-year anniversary of the Butcher Competition, let us pay homage to the exceptional talent within our association and their tireless dedication to craftsmanship. At the same time, let us remain vigilant of the challenges and opportunities presented by a changing industry. Together, we will continue to adapt, innovate, and shape the future of the meat industry, ensuring its resilience, sustainability, and success for years to come.

Kevin Schinkel President

VISION

A sustainable, respectful and diverse food system that celebrates the nutritional and economic value of meat and poultry.

MISSION

We strengthen the meat and poultry industry in Ontario by connecting people, influencing change and empowering our members.

MPO LIFETIME MEMBERS

• Richard Halenda (2021)

• Doris Valade (2019)

• Laurie Nicol (2018)

• Joe Abate (2017)

• Brian Quinn (2016)

• Graham Dalziel (2015)

• Tony Facciolo (2011)

• Pat Johnson (2005)

• Gerry Houtzager (2003)

• Leo Rocheleau (2001)

• Jim Vidoczy (2000)

• Nancy Ackert (1997)

• Dr. Ron Usborne (1996)

• Ron Deeth (1995)

MPO LONG TIME MEMBERS

Thank you to our long time members who have been helping move the industry forward for over 25 years.

Ontario Pork - 1980

Gord’s Abattoir Inc. - 1982

L’Orignal Packing Ltd. - 1986

Walnut Hill Farm - 1986

MMIS / Mondo Inc. - 1986

VG Meats - 1987

Stemmler Meats - 1988

Darling International

Canada Inc. - 1988

Schinkels’ Gourmet

Meats - 1989

Springer’s Meats Inc. - 1989

Chicken Farmers of

Ontario - 1989

Jetnet Norstar Corp. - 1989

Brenner Packers Ltd. - 1991

Norwich Packers Ltd. - 1991

Weston Abattoir Ltd. - 1991

This April, Meat & Poultry Ontario proudly introduced the Centre for Meat Innovation and Technology (CMIT), the leading hub for the meat industry in Canada. CMIT is all about collaboration and innovation, which is Ontario’s secret sauce for standing out. And guess what? It can be your secret weapon too, setting you apart from the competition. In this edition of BlockTalk, we’re exploring how Innovation and Technology can give your business a serious boost. Innovation goes beyond your product lineup—it touches every aspect of your business, from sourcing to marketing, operations, and talent. As you read through these pages, ask yourself: How can I shake things up? What can I do differently to leave the competition behind? Innovation is the key to growth in an ever-changing world. If you’re not growing, you’re fading away. So where do you start? It begins with a simple thought or question. What can you do tomorrow to make your business even better? Embrace change—it’s the driving force behind innovation. Change doesn’t have to be daunting; it starts with you. Each one of us has a responsibility to make innovation happen. It’s not something that magically occurs or can be bought—it’s a process that can be learned, practiced, and improved upon.

Take the time to explore and discover what innovation can do for your business. Trust me, it’s a game-changer.

Franco Naccarato, Executive Director

Hay’s Custom Cutting - 1992

Hoffman’s Meats & European Deli - 1992

Newmarket Meat Packers Ltd. - 1992

Sprucedale Meats - 1992

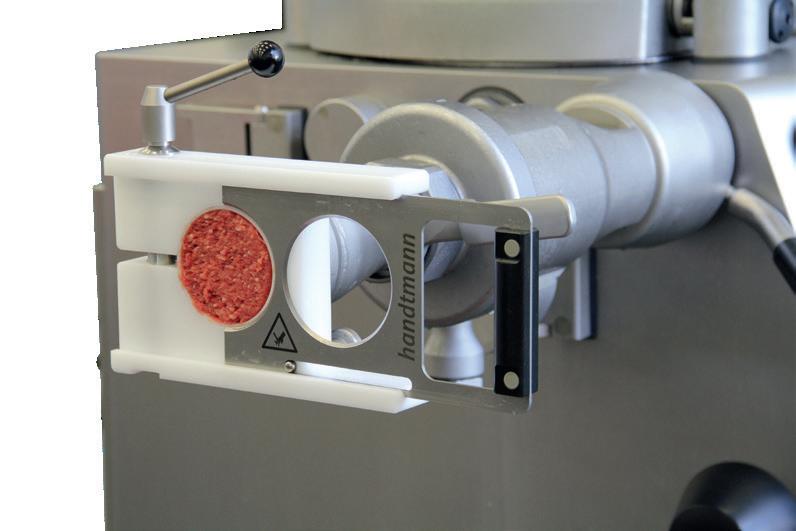

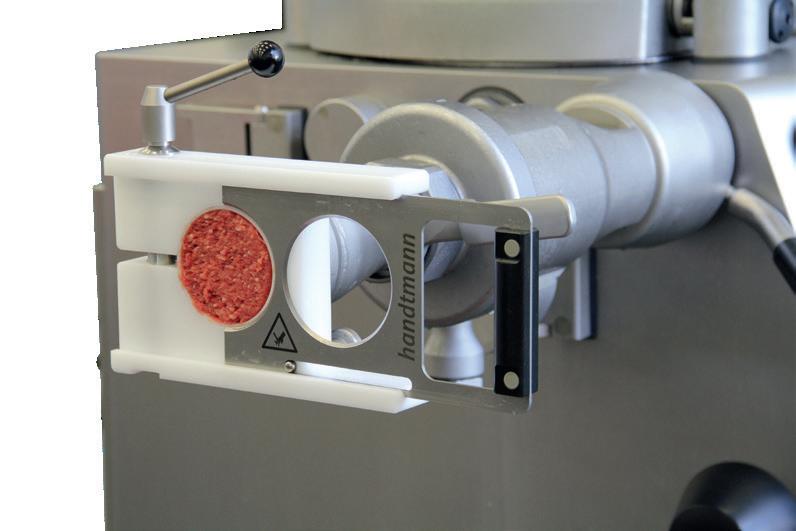

Handtmann

Canada Ltd. - 1992

Metzger

Meat Products - 1993

Schinkel’s Legacy - 1993

Yes Group Inc. - 1993

Windcrest

Meat Packers - 1994

Malabar Ingredients - 1994

R Denninger’s Ltd. - 1995

Abate Packers Ltd. - 1996

Domingos Meat Packers Ltd. - 1996

Sargent Farms Ltd. - 1996

Townsend Butchers Inc. - 1996

Conestoga Meat Packers Ltd. - 1997

Pemberton & Associates Inc. - 1998

UniPac Packaging Products Ltd. - 1998

MEAT INDUSTRY ACHIEVEMENT (MIA)

AWARD RECIPIENTS

• King Cole Duck (2021)

• Hayter’s Farm, Dashwood (2016)

• Schinkel’s Legacy, Chatham (2014)

• Conestoga Meat Packers, Breslau (2013)

• In Memory of Dave Tiller (2012)

• Halenda’s Fine Foods, Oshawa (2011)

• Springer’s Meats, Hamilton (2010)

• VG Meats, Simcoe (2009)

• Stemmler’s Meat & Cheese, Heidelberg (2008)

• Leo Rocheleau, Maidstone (2007)

ASSOCIATE MEMBER RECOGNITION AWARD (AMRA) RECIPIENTS

• Farm Credit Canada (2022)

• Viscofan (2021)

• Multivac Canada Inc., Brampton (2020)

• Reiser Canada, Burlington (2019)

PAT JOHNSON AWARD

• Natasha Barlett, OMAFRA (2022)

• VC999, Saint-Germainde-Grantham (2018)

• Handtmann Canada, Waterloo (2017)

• Malabar Super Spice, Burlington (2016)

www.meatpoultryon.ca 4 BlockTalk - Summer 2023

• Kelly McAslan, OMAFRA (2022)

Welcome to the Association

Building an informed and engaged membership representing a diverse Ontario meat and poultry industry.

Bonar Plastics

Susan Burns sales@bonarplastics.com

(402) 467-5221

6940 0 Street

Suite 100

Lincoln, NE 68510

Grasselli SSI Canada

Geraint Paul

geraintp@grassellicanada.com

2530 Speers Road

Oakville, ON L6L 5K8 Canada

(289) 291-5263

Marel

Alex Feld

(514) 638-3939

1100 225 - 6th Avenue S.W. Brookfield Place, AB T2P 1N2

MPO

ADMINISTRATION BOARD LISTING

EXECUTIVE DIRECTOR

Franco Naccarato franco@MeatPoultryON.ca

TECHNICAL DIRECTOR

Daphne Nuys-Hall technical@MeatPoultryON.ca

EVENTS, MARKETING & COMMUNICATIONS MANAGER

April Jackman april@MeatPoultryON.ca

OFFICE MANAGER

Meghan Schmuck meghan@meatpoultryon.ca

MEMBERSHIP COORDINATOR

Tina Begin member@meatpoultryon.ca

MARKET DEVELOPMENT

COORDINATOR

Derek Boudreau derek@MeatPoultryON.ca

DIRECTOR, CENTRE FOR MEAT

INNOVATION & TECHNOLOGY

Luis Garcia luis@meatpoultryon.ca

PRESIDENT | Kevin Schinkel

Schinkel’s Legacy, Chatham

PAST PRESIDENT | Carol Goriup

Florence Meats

SECRETARY/TREASURER

Adam Hayward

Nesbitt’s Meat Market, Lindsay

DIRECTOR | Gerhard Metzger

Metzger Meats, Hensall

DIRECTOR | Peter Baarda

J&G Quality Meats, Burlington

DIRECTOR | Doris Valade

The Malabar Group Inc., Campbellville

DIRECTOR | Jeff Miedema

Townsend Butchers Inc., Simcoe

DIRECTOR | Dale Schefter

Schefter Poultry Processing Ltd., Gorrie

DIRECTOR | Doug Alexander

Leadbetter Foods Inc., Orillia

DIRECTOR | Yaser Alqayem

Parkhill Meats, Parkhill

DIRECTOR | Christine BonneauO’Neill

L’Orignal Packing, L’Orignal

DIRECTOR | Shannon Desborough

Finest Sausage & Meats, Kitchener

DIRECTOR | Rafal Rusiniak

Handtmann Canada

Limited, Waterloo

BLOCKtalk is the official publication of the MPO, distributed to over 250 MPO members, commodity groups, and others throughout the industry, providing excellent advertising opportunities for suppliers of the meat and poultry industry to promote their newest, most innovative, supplies, equipment, and technology.

BLOCKtalk encourages Associate Members and supporters of the industry to submit articles which would be beneficial to our members.

ADVERTISING DEADLINES 2023

Fall July 27

Winter October 26

Spice & Seasoning Blends

Rubs & Decor Seasonings

Brine Injection Units

Curing Salt

The information published in BLOCKtalk is compiled from a variety of sources, which we believe to be reliable; however, MPO does not guarantee, and assumes no responsibility for the correctness of the information.

Sausage Seasonings

Sausage Binder Units

Functional Food Ingredients

Custom Blending

BlockTalk - Summer 2023 5

&

Pouch

Chamber Machinese

Inspection Checkweighers X-ray Inspection

Detectors

Bowl Cutters Injectors Massagers/Defrosters

Simplify your life. Choose Grinders Vacuum

Labellers Visual

Metal

Mixers

Shrinking/Drying Thermoformers

Loaders

Portioners Slicers

Traysealers

Line Solutions

Whether you are a small family-run business or a multinational corporation, we are your one-stop shop for preparation, portioning and packaging solutions. We've been helping our customers for over 60 years.

Preparation & Processing

Portioning & Slicing

Packaging Equipment

Packaging Materials

Automation & Integration

Inspection & Verification

Labelling & Coding

Isn’t it time we helped you?

Project Management

a single solution provider. MULTIVAC.COM | 877-264-1170

Why it’s Time to Shift Thinking About Food Processing Sustainability

By Chris Powell, Farm Credit Canada

It’s time to flip the script on food processing sustainability. While going green is the new reality in all sectors, including food and beverage processing, the reality for many processors is concern about increased costs that may come from increased sustainability.

But Peter Chapman of SKUFoods says it’s time for a shift in thinking. He works with food companies to help them differentiate their products and grow their business. Chapman says while there is certainly an investment needed for increased sustainability, there are also opportunities. Instead of being held back by worry, consider how creating a sustainable product may ultimately benefit your business – and the environment.

With sustainability practices in place, doors to major retailers with similar philosophies may be easier to open.

Major Canadian grocery retailers, including Loblaw, Metro, Sobeys and Walmart, for example, have all committed to a 50% reduction in food waste within their organization by 2025 and are looking to their suppliers to institute similar policies, Chapman says. With sustainability practices in place, doors to major retailers with similar philosophies may be easier to open.

That’s not to say that sustainability comes cheaply or easily.

“For small to mediumprocessors, it’s usually a higher percentage of costs because their volume is lower,” he says. “And they don’t always have the expertise because they have six balls in the air, and they’re adding another layer of complexity.

“If you’re a Maple Leaf, you’ve got a sustainability department; if you’re a small or medium-sized processor, you’ve got a sustainability hour in each week.”

www.meatpoultryon.ca 8 BlockTalk - Summer 2023

Continued on page 10 Pember ton & Associates Inc TECHNOLOGY FOR THE FOOD INDUSTRY w w w.pemcom.com 1-800-668-6111

Excellence in Clipping | polyclip.com WORKS OVERTIME. EXCEEDS EXPECTATIONS. FCA 80 AUTOMATIC DOUBLE CLIPPER + Increased throughput and versatility for midsize processors + Reduced labor and production times + Enhanced presentation with cleaner tails

Isabelle Lam and Jamie Lee at Remix Snacks decided to bake sustainability into their food from the very beginning. To make their snacks, they use imperfect fruit - the stuff grocery stores can’t sell because it is misshapen or not the right colour.

“At the end of the day, you don’t really notice the difference when it’s dried and cut up into pieces,” says Lam, who adds that Remix has saved more than 9,500 pounds of fruit from being wasted since launching in April 2018.

According to a report from Second Harvest, 58% of the food produced in Canada each year is wasted, and imperfect fruit represents a large portion of that total. In the early days of Remix, Lam and Lee deliberately sought out fruit they suspected finicky customers would never buy to make their snack product.

Remix also uses a black bean blend rather than nuts to make their snacks. The beans are grown in Canada, so don’t need to be shipped long distances and require up to 50% less water than nuts to grow.

Key areas

Chapman says companies need to address three key areas when it comes to incorporating sustainability into their operation:

1. Environmental impact of producing and transporting their products

2. Food waste

3. Packaging

When it comes to waste, Chapman advises processors to shift their perspective to look at it not as reducing waste, but instead potentially boosting their marketable yield.

“If last week you made 100 units, but only 85 met the right standard, your shrink [product purchased but not sold] was 15,” he explains. “If you can change that to 90, you’ve not only reduced your food waste, but you’ve made more money because now you have 90 units to sell instead of 85. That to me is a big opportunity.”

Sustainability can be a giant topic for food processors. But as consumer demand for more environmentally sustainable products continues to grow, it’s important to change processing methods, whether it’s upcycling food or switching to more environmentally friendly packaging.

Food processing sustainability resources

• Second Harvest Guide to Food Waste Audit

• Anthesis Provision Coalition has an extensive library of resources, covering everything from greenhouse gas management and energy management to responsible sourcing of ingredients and water management

• Second Harvest resource library. Click “food businesses” in the column on the left for industry-specific information.

www.meatpoultryon.ca 10 BlockTalk - Summer 2023

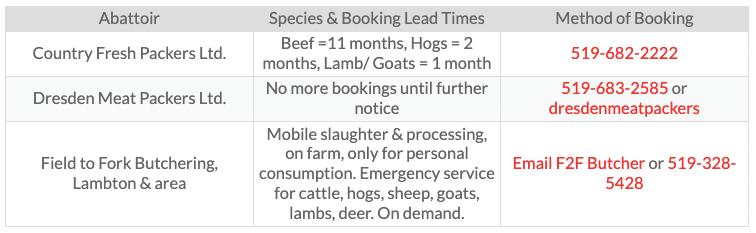

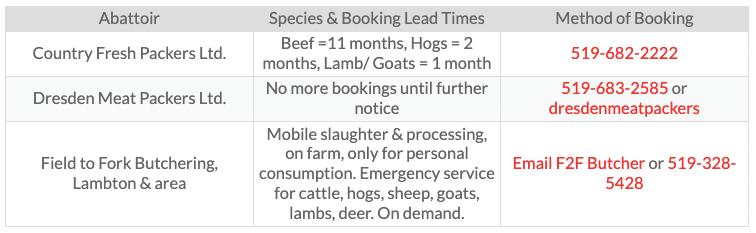

This article is reprinted by permission of FCC. It was originally published in the FCC Food & Beverage Newsletter. For subscription information about FCC newsletters, click: https://www.fcc-fac.ca/en/knowledge/fcc-knowledge-newsletter.html Improve business efficiency. Reduce labour. Anytime. Anywhere Connecting farmers and processors Processor Links Join today and share your availability and contact information Booking support & Space availability Last minute cancellations shared daily with the support of Beef Farmers of Ontario Continued from page 8 – WHY IT’S TIME TO SHIFT THINKING ABOUT FOOD PROCESSING

SUSTAINABILITY

- Summer 2023 11 Phone: +1 (647) -269-0398 Toll Free: +1 (888) -777-1672 Email: info@kungfubutchers.ca Website: www.kungfubutchers.ca Meat & Poultry Ontario Food Processing Skills Canada Need Workers? • A Dedicated Training Centre • Capacity of Supplying 200 Workers/Year • 2-Year Guarantee • In-House Legal Team (LMIA & Work Permit) • Worker Arrival Support (Flight & Housing) WE PROVIDE Strategic Partners Contact Us Your A-Z Recruitment Service

Innovative HR Solutions from the Ontario Agri-Food Careers Support Initiative

By Isabel Dopta, Food Processing Skills Canada

By Isabel Dopta, Food Processing Skills Canada

The Ontario Agri-Careers Support Initiative (OACSI) was designed to grow the labour market for food and beverage processing businesses by either enticing people to become employed in the sector or to remain employed.

Given the significant challenges faced by Ontario’s 4,000+ food and beverage processors in recruiting and retaining top talent, the timing of OACSI was important. By 2025, it is estimated that the Ontario industry will experience up to 25,000 job vacancies representing approximately 20% of the current workforce. The looming gap is a result of an ageing workforce demographic but also the lacklustre attraction of younger generations to the huge variety of jobs and career opportunities in the industry.

As with any complex issue, the labour challenges in this sector demand a comprehensive strategy that includes both industrydriven and facility-level solutions. The OACSI program provided support to eight innovative companies to develop unique pilot solutions that offered value to not just the applicant, but the entire Ontario food and beverage processing industry.

The following project summaries offer insights, best practices, and practical resources that can be shared across the industry.

3 Ways Food and Beverage Processors are Developing Skills Training & Mentorship

The skills gap and worker shortage for Ontario’s food and beverage processing industry is serious.

Food Processing Skills Canada tells us that the national industry is short about 50,000 people or 16% of the overall workforce, and every vacancy costs a business approximately $190 per day. Given there are, on average, six vacancies per business, the cost to an employer is significant at $1,100 per day in lost production.

Employee skills training and a workplace culture of continuous learning have long been proven to support jobseeker recruitment and employee retention, and COVID-19 certainly emphasized it. Even prior to the pandemic, LinkedIn’s 2018 Workplace Learning Trends reported that 94% of employees would stay longer in companies that are willing to invest in their professional development.

As part of the Ontario Agri-Careers Support Initiative (OACSI), three food and beverage processing companies had the opportunity to develop training and mentorship strategies to support their workforce in unique ways.

Continued on page 14

www.meatpoultryon.ca 12 BlockTalk - Summer 2023

WHAT’S O N YO UR GRILL THIS S UMMER?

Creating a Blended Approach to Employee Upskilling

With over 700 full-time employees and an impressive growth plan, Highbury Canco recognized they needed a comprehensive approach to upskilling employees that was customized to their facility in Leamington, Ontario, otherwise known as the heart of Canada’s tomato capital.

“We decided to use an Alchemy Learning Management System and Playbook for our online skills training to ensure a consistent approach for all levels of employees. We also implemented packer training and seamer training onsite for a blended approach of hands-on and online learning,” said Brittany Gurney, Training Coordinator. “A survey we conducted confirmed that employees appreciate the training and use it daily in their jobs. Next we would like to add training in multiple languages and more video-based learning.”

Adapting Employee Training & Upskilling for the Virtual World

For Village Juicery, their new training strategy started with a 100% commitment to digital learning from paper-based. The Toronto maker of fresh, organic, plant-based beverages, meals, and cleanses has 90 full-time and 75 part-time employees. During the COVID-19 pandemic, the company knew it needed a new approach to training.

“We implemented a semi-custom system to provide training on policies and procedures, health and safety, and to make it easier for our employees to access a training library and onboarding

tools,” Tanu Kapoor, Director of Human Resources. “With this new system, managers can also spend more time on team building and operational efficiencies. We are always thinking about how we can improve the life journey of our employees and we are already seeing improvements in the quality of products.”

Mentoring Women & Newcomers Entering the Food and Beverage Processing Industry

For Centennial Foods, recognizing an underrepresented demographic — women — in the food and beverage processing industry and providing mentorship was a priority. As an international distributor of fresh and frozen protein products, their workforce is also diverse with many new Canadians and landed immigrants employed.

“Providing leadership training and mentorship to women, and skills training to our workforce is how we intend to retain and support employees,” Atoosa Shahrooz, Centennial Food Group “For our company, mentorship is closely connected to the local community and is customized to our predominantly Asian, female workforce.”

Practical Industry Solutions to the Employment Challenge in Food and Beverage Processing

The shortage of workers in the food and beverage processing industry is similar to what is being experienced across other manufacturing sectors in Canada.

14 BlockTalk - Summer 2023

Continued from page 12 – INNOVATIVE HR SOLUTIONS FROM THE ONTARIO AGRI-FOOD CAREERS SUPPORT INITIATIVE

Continued on page 16

Travaglini Contact us: info@goklever.com +1 905 532 0330 www.goklever.com Meat, poultry, and fish Cheese Plant-based and fungi-based foods Pet food Vegetables, nuts, fruits, salt and spices Why us? Because we represent the best in class with a wide range of applications: Our brand: Our partners:

In 2022, Canadian Manufacturers and Exporters surveyed 563 manufacturers from across the country on their labour shortage and the impact to the Canadian economy. For the second consecutive year, more than 80% of manufacturers reported facing labour and skills shortages, up sharply from 60% in 2020 and 39% in 2016. And in the last year alone, labour and skills shortages in the manufacturing sector cost the Canadian economy almost $13 billion, a consequence of lost sales, penalties for late delivery, and postponed or cancelled investment projects.

As companies are dealing with broader societal and industrybased challenges related to labour shortages, they are also recognizing their own unique situations and possible solutions. As part the Ontario Agri-Careers Support Initiative (OACSI), Maple Leaf Foods, Burnac Produce and Bimbo Canada developed solutions that are shareable and applicable to other businesses.

Helping Jobseekers Explore Opportunities in Food and Beverage Processing

Jobs That Feed was the brainchild of Burnac Produce to address their immediate job vacancies. The initiative was not just a job board available to other businesses, but a place for jobseekers to explore the industry and the types of careers available through video and information also shared via social media and radio. An impressive 519 people applied for jobs during the initial four week period.

In addition to the job board functionality, Jobs That Feed offers a behavioural assessment tool to help jobseekers and employers understand the best job fit based on personal traits and aptitudes.

Looking to enhance your recruitment efforts? Check out Jobs That Feed

Perfecting In-Person Job Fairs

Perfecting the in-person job fair was the focus for Maple Leaf Foods. The company found that job fairs organized in partnership with communities, external providers (i.e., Indeed) or organized onsite or locally all proved successful. In fact, Maple Leaf Foods experienced a significant and sustained increase in hiring across the company due to a series of tactics including career fairs from 98 individuals to 146 during the project timeline.

Ready to undertake your own company job fair? Check out the Employer Guide to Hosting a Job Fair — Everything You Need To Know

Engaging Temporary Foreign Workers to Address Immediate Labour Needs

Understanding the details of engaging temporary foreign workers and the approach to collaborating with the local community was the priority for Bimbo Canada. While other solutions to the current labour crisis can require large amounts of capital and research, temporary foreign workers provide, in some cases, quicker and substantial relief. While there is a cost to hiring a temporary foreign worker, the analysis suggests that the benefit outweighs the cost. Are you thinking about hiring temporary foreign workers but aren’t sure how the program

works? Check out the TFW Employer Guide developed by Food and Beverage Ontario in conjunction with Bimbo Canada.

Rural Processors Finding Community-Based Solutions for Transportation and Housing

Farm Fresh Poultry, a leading chicken processor located in Harriston, Ontario, has experienced several of its own challenges with affordable housing and transportation for employees. In this region, there is no public transit, but there are local rideshare programs and a network of community partners interested in supporting a strategy for the region. That said, without a personal vehicle, individuals may find it too cumbersome and time consuming to take a job that is outside of a rural town.

“There are 1,800 people living in Harriston which is a small pool to recruit workers from,” said Ryan Lemire, Chief Operating Officer, Farm Fresh Poultry. “We knew implementing transportation solutions and identifying housing options would be key to resolving our labour challenges.”

The company found a rideshare service that significantly reduced the cost of transportation to the plant. Previously, an employee who was unable to get transportation would likely commute via taxi at a variable cost that could be as high as $50.00 one way. With a local ride sharing company called Ride Well it was possible to reduce transportation costs to roughly $8.00 one way. Farm Fresh Poultry also found housing initiatives local to Harriston with new housing available at reduced prices. This list is shared with employees and affordable housing programs –Rent Geared to Income and Below Market Rent — are highlighted for them.

VG Meats is another rural processor with similar challenges. A family-owned company located in Simcoe, Ontario, VG Meats has proudly been serving Ontario families high quality meat since the 1970s.

“We partnered with local interests to implement a rideshare program and assessed the potential of offering our own daycare options for families,” said Kevin VanGronigen, Owner, VG Meats. “My advice for any rural processor is to connect with the community supports already in place and work together in finding solutions.”

About the Agricultural Adaptation Council

The Agricultural Adaptation Council (AAC) is an industryled organization that stimulates growth and opportunity for Ontario’s agriculture and food industry through the delivery of funding programs, facilitating connections, and developing partnerships.

To access the resources listed in this article please visit: https://adaptcouncil.org/program/oacsi

www.meatpoultryon.ca 16 BlockTalk - Summer 2023

The Ontario Agri-Careers Support Initiative program was funded in part through the Canadian Agricultural Partnership (the Partnership), a five-year, federal-provincialterritorial initiative. This program is being delivered by the Agricultural Adaptation Council on behalf of the Ontario Ministry of Agriculture, Food and Rural Affairs.

Continued from page 14 – INNOVATIVE HR SOLUTIONS FROM THE ONTARIO AGRI-FOOD CAREERS SUPPORT INITIATIVE

Centre for Meat Innovation and Technology (CMIT) Designed to Help Meat Sector in Ontario Advance and Grow

By Karen Sample and Janet Morley

By Karen Sample and Janet Morley

In April, Ontario’s meat industry witnessed a significant event with the official launch of the Centre for Meat Innovation and Technology (CMIT) in Guelph. This launch, attended by Ontario Minister of Agriculture and Food and Rural Affairs (OMAFRA), Lisa Thompson, industry leaders, as well as dignitaries including Rene VanAcker, Dean of the Ontario Agricultural College, represents a major advancement in Ontario’s agri-food sector and has the potential to shape the future of the meat industry in Canada.

The President for Meat and Poultry Ontario, Kevin Schinkel, recognized the valuable contributions from the public and private sectors to make the CMIT a reality, including over $250,000 worth of donated equipment and products. Highlighting the pivotal contributions of the University of Guelph and OMAFRA,, he remarked, “We’ve made significant progress since the inception of CMIT, and these partnerships have made our journey possible.”

Schinkel also emphasized the immense potential of Ontario’s meat industry, which generates an astonishing $11.2 billion annually. His words underscored CMIT’s vital role in fostering further growth and revenue generation in the industry. Schinkel affirmed, “CMIT represents a beacon of promise for our industry, paving the way for innovation and prosperity.”

The Honourable Lisa Thompson, Minister of Agriculture, Food, and Rural Affairs shared an impassioned perspective on CMIT’s transformative potential. “We’re here because we’re celebrating all of you who believe in what we can accomplish together at the Centre for Meat Innovation and Technology,” she acknowledged.

From L-R: Kevin Schinkel (MPO President), Franco Naccarato (MPO Executive Director), Lisa Thompson (Minister of Food, Agriculture & Rural Affairs), Luis Garcia (CMIT Director)

Thompson highlighted the fact that the centre’s initiative’s are in sync with Ontario’s overarching strategy, “Grow Ontario.” This strategy ensures a secure supply chain, promotes research and innovation, and attracts top-tier talent to Ontario, all areas where CMIT’s influence is expected to be significant. “CMIT is not merely a centre; it exemplifies Ontario’s leadership, adaptability, and commitment to quality meat production,” Thompson said.

“It is genuinely a pleasure to be here with all of you this evening to participate in the launch of something that I believe with all my heart will separate Ontario from the rest of the pack when it comes to excellence in our meat industry,” she told attendees.

Thompson highlighted the importance of promoting Ontario’s sustainable and professional value chain during the launch. She underscored the significance of shaping a narrative that resonates with consumers both locally and globally. With CMIT in place, Ontario is well-positioned to strengthen its supply chain, attract and nurture talent, and further advance its meat industry through research and innovation, she noted.

“Let’s be loud and proud about our sustainable story and how much professionalism is involved in every link of our value chain,” she said.

“I thank you for your investment. I thank you for your passion and belief in what we’re doing here in Ontario. And please shout it from the rooftops. Let people know what we’re doing right here at Guelph because it’s good, and it can make a difference around the world. So don’t stop doing what you’re doing. Thompson concluded her remarks by saying, “Let’s maintain open lines of communication and continue to spread the word about the innovative work happening at CMIT.”

Tour of the University of Guelph Meat Lab

The launch of CMIT marks a leap towards creating a more competitive and resilient meat industry in Ontario. The centre is ready to drive innovation, support research, deliver skillenhancing courses, and forge new partnerships.

The tour of the University of Guelph’s Meat Lab, which will be used by CMIT for project work for MPO members and others, provided a clearer vision of how CMIT can actually work with processors to help them advance products, processes and demonstrate equipment they may want to have in their own plants.

During the facility tour, hands-on processing and the potential for collaborations to drive innovation were discussed. The tour showcased advanced processing techniques, highlighted the importance of collaboration and innovation, and demonstrated CMIT’s commitment to addressing industry challenges

The right ERP system for the Meat Industry

Manage

Connects data, processes and departments. Quality management, production planning & control, identification, and labelling Continued

www.csb.com

BlockTalk - Summer 2023 19

all aspects of your business in a single solution

on page 20

and leveraging opportunities. CMIT aims to establish close relationships with local farmers, processors and those supplying the industry while contributing to research and innovation.

The Path to the Launch

Meat & Poultry Ontario Executive Director, Franco Naccarato, outlined the research and background that led to the formation of CMIT. The narrative underscored the need to embrace technology and the sector’s growth potential, with a recognition that strategic investments could potentially double the capacity of small abattoirs. Research showed that an investment of $50 million would result in a 7:1 return, ultimately a huge win for MPO members as well as the Ontario economy. The centre’s dedication to attracting the next generation of workers by showcasing industry technological advancements was also emphasized.

What makes CMIT different and unique?

Luis Garcia, the Director of CMIT reviewed CMIT’s mandate, core objectives and operational strategies, and launched a fundraising campaign to help the Centre cover operations costs for three to five years while it builds identified revenue streams. “Collaboration and innovation form the bedrock of CMIT,” he noted, emphasizing that the centre serves as a hub for showcasing and accessing globally sourced cutting-edge technologies.

With the launch of CMIT, Ontario’s meat industry is entering a new era of collaboration and shared progress. CMIT is determined to enhance the efficiency and competitiveness of the meat processing industry, catering not only to large-scale processors but also to smaller-volume operations. The centre’s focus on identifying research opportunities and assisting meat processors of all sizes in adopting new technologies levels the playing field and fosters healthy competition within the industry, Garcia explained.

Hadley Carpenter, Regional Director, Agriculture and Agri-Food Canada, praised the ambition, passion, and industry expertise behind the establishment of CMIT. On behalf of the Federal Minister of Agriculture and Agri-Food, Carpenter expressed gratitude and extended congratulations to everyone involved, emphasizing that partnerships like these are crucial for problem solving and bolstering the success of Canadian agriculture.

The launch of CMIT has sparked anticipation across Ontario’s meat industry, as it represents a game-changer for the sector. By providing a platform for knowledge exchange, skill development, technology adoption, and innovation, CMIT is steering the industry towards increased productivity, profitability, and resilience.

CMIT’s vision aligns with a brighter future for Ontario’s meat industry, driven by harnessing the power of technology, fostering collaboration, and nurturing talent. With a renewed focus on sustainability, skill development, and technology, the industry is poised for success. As Kevin Schinkel aptly stated, “CMIT stands as a testament to collective ambition and vision, ready to propel Ontario’s meat industry into a new era of innovation, growth, and success.”

www.meatpoultryon.ca 20 BlockTalk - Summer 2023

Continued from page 19 – CENTRE FOR MEAT INNOVATION

MEAT SECTOR IN

ADVANCE AND

AND TECHNOLOGY (CMIT) DESIGNED TO HELP

ONTARIO

GROW

Minister Thompson touring the Centre for Meat Innovation & Technology with MPO.

L-R: Carol Goriup (MPO Past-President) & Minister Thompson

BlockTalk - Summer 2023 21 to our 2023/2024

CORPORATE SUPPORTERS Thank you DIAMOND PLATINUM GOLD SILVER

ULTIMATE BURGER

COMPETITION

Attention Ontario Burger Processors!

Showcase your talent and expertise at Ontario's Ultimate Burger Competition! We're searching for the best burgers in six categories: beef, veal, poultry, lamb, pork, and other.

Our panel of expert judges will rigorously evaluate each patty based on taste, texture, and quality. Don't miss out on this unique experience that celebrates your skill and creativity as a processor.

Judging will be held on July 19th at Fanshawe College in London, and the winners will be announced at our Red-Carpet Gala on October 21st in Muskoka.

Submit your entries today at https://www.meatpoultryon.ca/finestmeat/ and show us what you've got!

Proudly sponsored by:

Ontario's ENTRY DEADLINE: June 30

W-5600SRX

NEW Solution Meets New Demand

DIGI’s W-5600SRX in-line stretch wrapping system, paired with the HI-700 high speed weigh price labeller, meets the growing demand for high-mix low-volume production output required in today’s food retail.

sales@ca.digi-group.com |

www.digisystem.com

FIRM & SECURE WRAPPING

DYNAMIC WEIGHING AND LABELLING

HIGHER PRODUCTIVITY

HI-SPEED LABELLING

FLEXIBLE LABEL HANDLING

EASY MAINTENANCE

BlockTalk - Summer 2023 23

HI-700

Meat & Poultry ad -MAY-JUNE 2023 ISSUE.indd 1 5/3/2023 9:01:56 AM

LEARN MORE

Promoting Butchery as a Trade

Celebrating 10 Years of Ontario’s Finest Butcher Competition

Ontario’s Finest Butcher Competition reaches a remarkable milestone as it celebrates its 10th year. This extraordinary competition has not only brought recognition to skilled artisans but also raised the art of butchery to new heights. Over the past decade, this competition has become a vibrant celebration of craftsmanship, innovation, and the local food culture in Ontario.

From its humble beginnings, the competition’s goal was to showcase the exceptional talent of Ontario’s butchers while promoting the trade of butchery and the exciting career pathways available within the industry. Today, it has grown into a significant annual event that captivates industry professionals and enthusiasts alike.

The competition itself is a thrilling display of skill and precision, with talented butchers competing from across the province. Esteemed judges, comprised of industry experts, evaluate contestants based on knife skills, product quality, and craftsmanship. Witnessing the expertise demonstrated by participants is both inspiring and a testament to the dedication and passion that drives Ontario’s butcher community.

As we celebrate the 10th anniversary of Ontario’s Finest Butcher Competition, it is essential to extend special recognition to Halenda’s for their generous support in hosting the competition’s elimination round over the years. Their contribution has been invaluable in creating a successful and memorable experience for the competitors and audience alike.

Looking ahead, Ontario’s Finest Butcher Competition will continue to flourish, nurture talent, and promote the trade. It will serve as an essential platform for showcasing the skills, creativity, and artistry that define the world of butchery in Ontario, inspiring a new generation of butcher.

The 10th anniversary marks a turning point for the competition, with some exciting changes on the horizon for the competition in 2023. Stay tuned for upcoming announcements and don’t miss out on being a part of this thrilling journey!

L-R: Peter Baarda, Troy Spicer, Damian Goriup, John Baker and Stephan Seher

L-R: Peter Baarda, Troy Spicer, Damian Goriup, John Baker and Stephan Seher

Winners over the Years

2017 Ontario’s Finest Butcher Damian Goriup, Florence Meats, Oakville

2018 Ontario’s Finest Butcher Nicholas Matusiak, Halenda’s, Oshawa

2019 Ontario’s Finest Butcher Brett Herrington, Herrington’s Quality Butchers, Port Perry

2014 Ontario’s Finest Butcher

Peter Baarda, Lococo’s, Stoney Creek

2015 Ontario’s Finest Butcher

Peter Baarda, Lococo’s, Stoney Creek

2016 Ontario’s Finest Butcher

Peter Baarda, J & G Quality Meats, Burlington

2020 Ontario’s Finest Butcher Steve Toms, Fortinos, Toronto

2022 Ontario’s Finest Butcher Doug Easterbrook, Townsend Butchers, Simcoe

2017 Ontario’s Finest Butcher Damian Goriup, Florence Meats, Oakville

2018 Ontario’s Finest Butcher Nicholas Matusiak, Halenda’s, Oshawa

2019 Ontario’s Finest Butcher Brett Herrington, Herrington’s Quality Butchers, Port Perry

2014 Ontario’s Finest Butcher

Peter Baarda, Lococo’s, Stoney Creek

2015 Ontario’s Finest Butcher

Peter Baarda, Lococo’s, Stoney Creek

2016 Ontario’s Finest Butcher

Peter Baarda, J & G Quality Meats, Burlington

2020 Ontario’s Finest Butcher Steve Toms, Fortinos, Toronto

2022 Ontario’s Finest Butcher Doug Easterbrook, Townsend Butchers, Simcoe

2014 2015 2016

2021 Ontario’s Finest Butcher Paul Gentile, Metro, Toronto

2018 2017 2019 2020 2021 2022

ARTISANAL CHICKEN: COMMITTED TO CRAFTSMANSHIP

MEETING LOCAL DEMAND

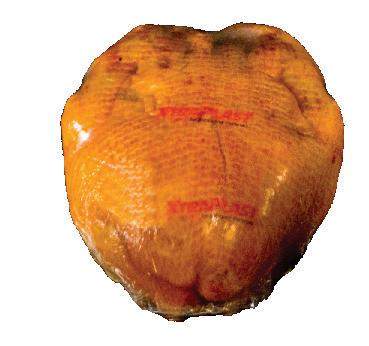

Chicken Farmers of Ontario’s (CFO) Artisanal Chicken Program provides opportunities for small, independent farmers to meet local demands for safe, high-quality chicken. CFO is continually looking to meet the changing needs of Ontario chicken consumers and markets. The Artisanal Chicken program helps farmers fill local food and seasonal markets and gives Ontario consumers more choice and options in how and where they buy locally-grown chicken.

The Artisanal Chicken program is an annual, applicationbased program, beginning in the fall of each year. Once accepted into the program, farmers are issued a license and provided access to a wealth of on and offline resources which are designed to orient farmers into the program. Online resources focus on quality and safe farming practices, production, and marketing; offline, there are multiple training and coaching resources available to further support learning.

FARMING ARTISANAL CHICKEN

Under the Artisanal Chicken program, non-quota holding farmers who wish to grow between 600 and 3000 chickens each year can partner with independent processors to provide Artisanal Chicken for select identified markets. Prior to the development of this program, smaller-scale farmers in Ontario were limited to only growing up to 300 chickens per year for home consumption or farm-gate sales under the CFO Family Food Program.

Prospective applicants who want to grow chicken are required to complete an application form with details of their production, intended markets and pricing. Participation in the Raised by a Canadian Farmer On-Farm Food Safety Assurance Program (OFFSP) and the Animal Care Program is required to maintain biosecurity and industry standards which support the long-term sustainability of the chicken industry in Ontario.

With just under a decade in the market, the Artisanal Chicken program continues to attract a variety of farmers who are looking for a unique farming experience that offers

additional income with flexibility to traditional farming. CFO continues to work alongside, and support, Artisanal Chicken farmers in their efforts to grow safe, healthy, locally-grown Ontario chicken.

To learn more about the Artisanal Chicken program and where to purchase Artisanal Chicken visit artisanalchicken.ca

www.meatpoultryon.ca 26 BlockTalk - Summer 2023

Jerk Chicken and Pepper Kebabs

“Jerk”

Caribbean method of cooking in which marinated chicken or pork is smoked in a charcoal pit. Serve these zesty kebabs with saffron rice (add a pinch of saffron when cooking the rice) and creamy coleslaw.

Jerk Chicken and Pepper Kebabs

Preparation Time: 10 minutes

INSTRUCTIONS

• Cooking Time: 12 minutes

Cut chicken into 1-1/2 inch (4 cm) chunks; place in bowl or sturdy plastic bag.

In food processor or blender, process onion, garlic, Scotch bonnet peppers, lime juice, oil, vinegar, allspice, thyme, sugar, salt, pepper, cinnamon and nutmeg; until fairly smooth. Pour over chicken, stirring to coat; cover and refrigerate for at least 4 hours or for up to 24 hours.

Alternately thread chicken, peppers and onion onto 8 metal or soaked wooden skewers, leaving space between pieces. Brush well with vegetable oil. Place on greased preheated grill over medium heat; close lid and cook for 10 to 12 minutes, turning over and brushing with oil partway, until chicken is no longer pink inside.

Nutritional Information

• Protein: 38 grams

• Carbohydrate: 22 grams

• Fat: 14 grams

• Calories: 368

• Source of fibre

INGREDIENTS

Makes 4 servings.

• 1-1/4 lb (625 g) boneless skinless Ontario Chicken Breasts

• 1 small Ontario Onion, coarsely chopped

• 2 cloves Ontario Garlic, coarsely chopped

• 2 Scotch bonnet peppers, halved and seeded

• 2 tbsp (25 mL) each fresh lime juice, vegetable oil and white wine vinegar

• 1 tsp (5 mL) each ground allspice, dried thyme, granulated sugar, salt and pepper

• 1/4 tsp (1 mL) each cinnamon and grated nutmeg

• 2 each Ontario Greenhouse Sweet Red and Yellow Peppers, cut into 1-1/2 inch (4 cm) chunks

• 2 Ontario Red Onions, cut lengthwise into 8 wedges each

• 2 tbsp (25 mL) vegetable oil for kebabs

is a

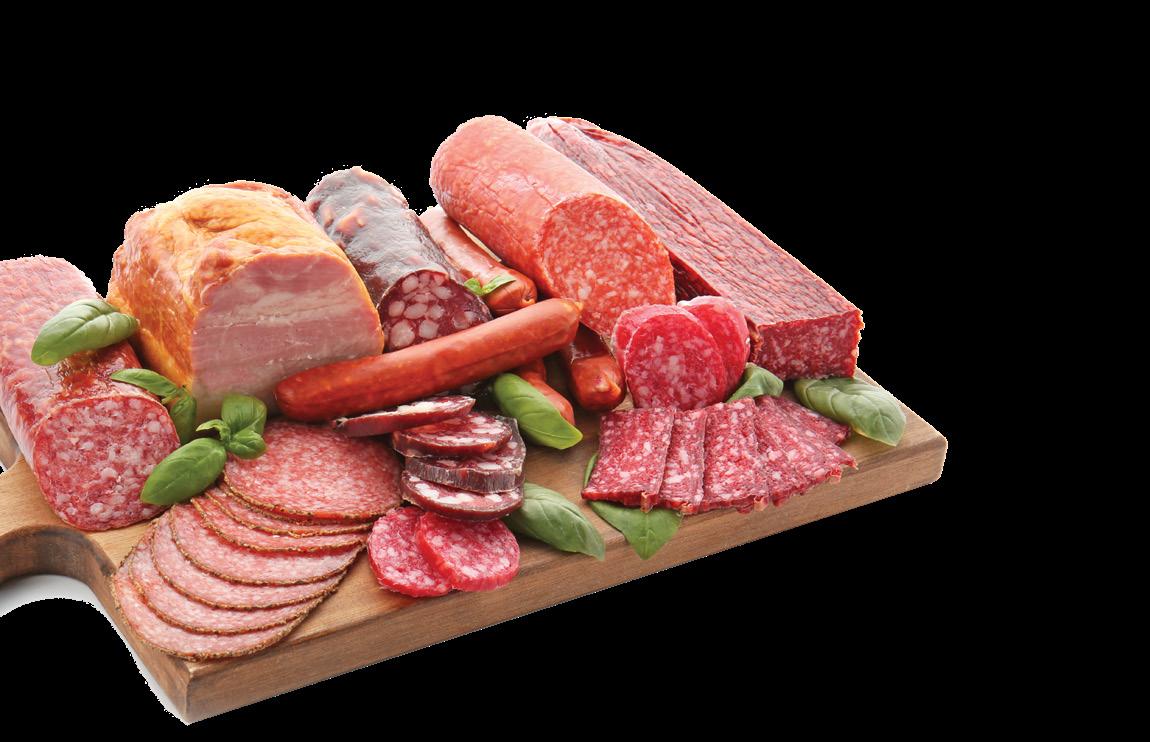

Stemmler’s Meats

From Artisan Family Business to Large Scale Manufacturer

By Karen Sample and Janet Morley

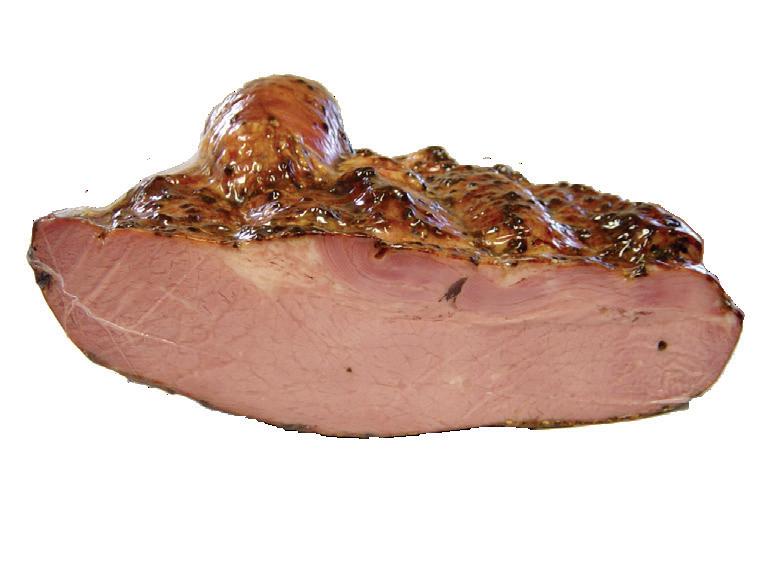

Founded in 1985, by Gerard and MaryAnn Stemmler, Stemmler Meats & Cheese is committed to delivering artisan-quality products. Originally located at a small retail outlet in the St. Jacobs Farmers’ Market, Stemmler’s products gained popularity quickly, which allowed them to open their first bricks and mortar store in Heidelberg. Soon after they built a larger facility next door to meet the needs of their growing clientele.

the family business growing while operating a large scale manufacturing facility.

Taking the Business to the Next Level

Enter Atul Gupta to help grow the Stemmler’s brand to a new level of success. The Stemmler brothers reached out to Gupta in 2018 requesting assistance with driving sales and welcomed him as their Chief Revenue & Operating Officer in January 2019.

Next came a manufacturing location in Waterloo, with the family leasing half of a large facility, which presented a whole new set of challenges. Gerard and MaryAnn’s sons, Kevin, Shawn and Terry, were now running the company with a focus on Stemmler branded products regulated to sell only in Ontario. They soon realized they needed experienced business guidance to keep

With over 35 years of experience, primarily in consumer-packaged goods with a Fortune 500 Company, Gupta knew what needed to be done and how to do it. Says Gupta, “I’m the guy that comes on board to assess the landscape, prepare and execute a strategy that will scale a business and result in substantial profitable growth.”

Gupta says of the three brothers, “They’re not afraid of change, they just don’t know how. It’s a totally different business and business model than their parents ever imagined it could be. The challenges are very different.”

Growth and the Pandemic

When Gupta joined Stemmler Meats, the company had already been running their Waterloo manufacturing facility for three years. At that point they were easily keeping up with customer demand both for retail and for wholesale customers. Gupta saw that the facility had tremendous potential, right up to the global level, but was only running at a small fraction of its total capacity.

www.meatpoultryon.ca 28 BlockTalk - Summer 2023 BUSINESS

MEMBER PROFILE

Atul Gupta

Significant expansion requires careful planning. Gupta hired Heather Nahatchewitz, an experienced Senior Marketing Manager who previously worked for Meat & Poultry Ontario, to help him craft the strategy. One of their goals was to use digital marketing and introduce real sales acumen to help drive potential sales leads.

Gupta and Nahatchewitz got the wheels turning by achieving federal status and then persuaded the Stemmler brothers to consider co-packing. Stemmler’s had space, capacity, an excellent reputation and top-quality artisan products. They needed a broader customer base to make the most of that capacity and expertise.

COVID-19 however, put those plans on hold temporarily. Due to the change in retail purchasing habits, the Heidelberg store saw extraordinary growth over the two years of the pandemic.

Sales Build Expansion and Modernization

Stemmler’s started looking for co-packing opportunities that focussed on the company’s core competencies including bacon, sausages and protein snacks (jerky and meat sticks). The company decided to expand their flavour profile options with additions like Dill Pickle, Sweet Heat and Korean BBQ to complement their excellent quality, but traditionally flavoured, jerky and meat sticks. The increased flavour profile showcases Stemmler’s ability to design unique, flavourful recipes and appeals to co-packers looking for something to help them gain market share.

The business is now delivering double digit month-over-month and quarter-over-quarter growth, to the point where Stemmler’s leased the remaining half of the building that houses their Waterloo manufacturing facility. Gupta expects that they will more fully expand into that space within the next 24 months.

BlockTalk - Summer 2023 29

Continued on page 30

What’s next?

Currently, they are considering automation and implementing true digital systems. “It’s critical for us to be cost competitive. That requires a different type of employee base. It’s not just production workers. Now the manager level becomes very critical,” Gupta says.

As one example, the company now has a team responsible for regulatory compliance and quality assurance led by an exceptional Director. “Our regulatory compliance has got to be bang on. We’re dealing with co-packers that are building their brands for North American exposure, and some even looking at international. The quality is absolutely critical. The stakes are higher,” Gupta explains.

Future of Stemmler Meats

Higher stakes mean that along with automating manufacturing in the Waterloo plant, marketing for both locations also needs to be up to date. Gupta has put a sales team in place and under Nahatchewitz’s savvy guidance, they are using Search Engine Optimization (SEO) and digital marketing campaigns with geo fencing to target geographically pertinent markets and drive leads. It is working. They have also initiated Enterprise Resource Planning (ERP) systems to allow them to use real time data to manage the business.

Gupta has devised robust business and financial plans that forecast manageable, steady growth over the next three to five years. Gupta says, “This is not a company that has to be built on hierarchy.” As the business grows, he will continue to hire for key management positions as needed and also ensure we have the right operational talent on the floor to drive the cases out the door effectively and efficiently.

Advice for others looking to scale their business

Gupta says you really need to understand what you’re getting yourself into when you’re looking to make an investment or expansion. The firm commitment to product quality stays the same, but everything else changes when scaling. To avoid

www.meatpoultryon.ca 30 BlockTalk - Summer 2023

Continued from page 29 – STEMMLER’S MEATS

financial pitfalls, it’s important to acquire qualified financial, human resources, and operational management when you’re looking at moving from a local to a national or international level. The earlier an expanding business can put great people in place to supplement existing areas of expertise, the smoother the transition to national and international markets will be

The Stemmler Family

While Stemmler’s grows, they will never lose sight of where they came from. Their original Heidelberg location will remain. The brothers will follow in their parents’ footsteps, continuing to be hands on in the plant knowing they can trust Gupta and the team to give them the data and information they need to make business and financial decisions that continue to drive success.

If you are driving through Heidelberg one day, be sure to stop in. Don’t be surprised if you see MaryAnn in the store, continuing to set an example for the next generations. With the Stemmler family at the helm, there are three things that won’t change as they grow: quality product, hands-on, hardworking owners and excellent customer service.

Meat and Poultry Ontario

Gupta says membership in MPO is important to Stemmler Meats. Having an association with regulatory expertise just a phone call away avoids unnecessary delays in production and the confidence we are meeting all requirements.

The camaraderie, idea sharing and knowledge transfer that takes place during MPO events cannot be matched by any webinar or breakfast networking group. “These are our peers with the same challenges and questions we have – its nice to know we are not alone,” concludes Gupta.

Kevin Stemmler

3031 Lobsinger Line

Heidelberg, ON N0B 2M1 Canada

info@stemmlermeats.ca

more sanimarc.com/shed-a-light

Learn

Enterprise Resource Management (ERP): More Than Inventory Control

Big or Small: CSB Builds Unique System for Each Customer

By Karen Sample and Janet Morley

By Karen Sample and Janet Morley

AAnyone who has worked in a plant or managed sales, procurement, production planning, production execution, inventory and distribution knows there are a lot of balls to juggle, especially when running a business that depends on perishables like meat.

Dr. Peter Schimitzek, a German Master Butcher and a man ahead of his time in many ways, realized 50 years ago that there had to be a better way to keep all those balls in the air for his family business. Dr. Schimitzek returned to school and obtained a degree in computer science - yes, 46 years ago. Using that expertise, he then built the first Enterprise Resource Planning (ERP) system specialized and focused on the meat industry for the meat industry. This was the start of the company that is now known as CSB-System today.

CSB-System has more than 40 years of experience developing and evolving Enterprise Resource Management (ERP) systems to help their customers manage the complexities of their businesses. The result is a specialized system focused on the meat industry that truly understands the needs of meat processors.

www.meatpoultryon.ca 32 BlockTalk - Summer 2023

ASSOCIATE MEMBER PROFILE

We are the only ERP company that is so entrenched and dedicated to the meat industry.

From Left, Nestor Plawiuk, CEO, Erin Scanlan, Marketing Manager and Bogdan Onaca Business Architect & New Business Development Manager attending the IPPE show in Atlanta

CSB-System remains family-managed, employing approximately 600 people globally with a service portfolio comprised of software, industry hardware for automation, support, training, process consulting and cloud services.

Nestor Plawiuk, CEO of CSB-System North America points out “the meat industry is the core business for CSB globally. That is our DNA. In North America the meat industry is about 90 per cent plus of all our customer base. We are the only ERP company that is so entrenched and dedicated to the meat industry.”

You might think that the secret to the company’s success is its programmers, but Plawiuk will be quick to tell you that the secret of their success is in the company’s consultants. They are experienced business analysts who fully understand the uniqueness and nuances of this demanding industry and can decipher how each company runs and how to best support that.

What is an ERP system?

ERPs are systems that collect data and enable the collection of information which provides businesses insights into their performance, results and areas for improvement. Though change can be intimidating, Plawiuk emphasizes that ERPs are about modifying how people operate, not what they produce. “It doesn’t matter what size of company, we work with them to develop a right-sized and effective ERP,” Plawiuk says.

“A good ERP system is one that’s integrated from beginning to end. We configure our system to the specific needs of each customer in each area.” Plawiuk explains there are basic modules such as Sales, Inventory, Production, Finance and Quality Management. Depending on the specific needs of the customer and the complexity of their operations, there may be numerous sub modules supporting those basic components. CSB-System builds all of their ERPs on a similar platform whether you’re a corner butcher or a multi-facility operation.

Traceability and Transparency

A robust ERP system, like CSB’s, offers inherent traceability by documenting and tracking the movement of all raw materials to the production procedure. This safeguards the supply chain, customers, and a company’s brand. In the event of a recall or audit, CSB’s ERP can provide results within minutes, letting you know where that product is now. It also facilitates job performance by ensuring knowledge transfer between generations or employees.

In addition to these quality and assurance facets, CSB’s ERP will give performance analysis on financials. It will let you know how well you are doing by providing good financial information in real time.

Right Sizing

“It doesn’t matter what size of company, we work with them to develop a right-sized ERP,” Plawiuk says. CSB-System treats everyone equally whether the company is large or small. “It’s important that we understand how our customers produce because their customers come for their unique product.”

CSB’s ERP system is configured for the business today but is designed to continue to grow as a business expands. Customers can choose whether they use a server or cloud service for all software. Production floor hardware (i.e., scan guns) can be purchased from CSB or existing Mobile ERP (MERP) can be integrated.

Erin Scanlan, Marketing Manager of North America says, “No family business is too small for us to talk to. Even if they’re not ready yet, we will be there when they are ready. We really want to understand our customers’ problems and perspectives rather than us telling a customer what their problems are. We’re laser focused on the meat and poultry industry. We are definitely unique in that sense. We’ve all been to the warehouses, to the factories, to the slaughter houses. We really understand it. And we live and breathe it.”

Implementation

To implement an ERP, the first step involves ensuring an understanding between the business and CSB-System, a process managed by CSB’s consultants. The entire process is customercentric, with each system tailored to the customer’s specific needs. In addition, CSB-System provides 24/7 global customer support.

“Everybody knows CSB-System in Europe. We’re working hard trying to bring that same recognition over to Canada and North America. We want to grow in meat and poultry,” says Scanlan. She feels it’s important for MPO members, many who may have small and growing family businesses, to know that CSB started as a family business and continues to be run by that family today. “That is CSB-System’s strength. We are able to grow with our customers,” she says.

MPO Membership

CSB-Systems enjoys being a member of Meat and Poultry Ontario. “We truly value connecting with the M&P community, it’s important for us to understand issues that are directly impacting the members and this gives us that additional point of connection,” Scanlan says.

Erin Scanlan

10 Duke Street West Suite 103

Kitchener, ON N2H 3W4, Canada contactus@csb.com

BlockTalk - Spring 2023 33

...the meat industry is the core business for CSB globally. That is our DNA.

We’ve all been to the warehouses, to the factories, to the slaughter houses. We really understand it. And we live and breathe it.

How Food Businesses Can Utilize SR&ED Tax Credits

By Alena Barreca, Mentor Works

According to poll results provided by Global News, 90 per cent of Canadians surveyed stated it’s important to know what’s in the food they eat and 83 per cent stated importance about knowing where their food comes from.

As Canadian consumers seek more information about the food they eat, health and wellness experts suggest supporting consumers by updating the standards of commercially processed foods and ensuring consumers understand what ingredients are in their food and how the ingredients are grown, sourced, and processed.

The Scientific Research and Experimental Development (SR&ED) tax credit program can assist in food science research that must occur in relation to how foods are grown, genetically modified, sourced, processed, and/or integrated into new or existing products. For example, SR&ED tax credits may apply to businesses with the goal of providing consumers with more

research and development projects. The program provides more than $3 billion in tax incentives to over 20,000 claimants annually.

In addition to the federal SR&ED program, there are also provincial and territorial variations of tax credits that a Canadian business can apply for on top of the federal program. Most provinces and territories have one or more funding streams with specific eligibility criteria, funding amounts, eligible expenses, and deadlines to apply.

Unlike other government funding programs, however, SR&ED has no limit on financial reimbursement. This means that if a food business’ projects meet program eligibility, they are entitled to receive the full financial benefit in the form of an investment tax credit (ITC) and/or a cash refund. This is a significant advantage for businesses looking to improve their products, processes, and systemizations. Many projects can qualify for SR&ED support.

ober 20-21, 2023 J W M a r r i o t t T h e R o s s e a u M u s k o k a R e s o r t & S p a SAVE THE DATE

BlockTalk - Summer 2023 35 Excellentbarrieragainstmoisture,gas,oxygenandaroma SuperiorForminganddeep-drawproperties Higherpunctureresistanceandremarkablemechanicalproperties Completeline: flexible semi-rigid pouches 800-465-8201 www.viscofan.com info@canada.viscofan.com Makeusyour FIRST CHOICE forallyourcasingandpackagingneeds ExcellentFulllineofBonelessandBoneguardshrinkbags Straightorcurvedbottomseal,sidesealavailable Customsizingandfastservice Highshrinkwithexcellentclarity ProudlyconvertedinCanada COFFINET CELLULOSE ELASTICNETTING FIBROUS PLASTIC COLLAGEN PACKAGINGFILMS SPICETRANSFER FLAVOURTRANSFER SHRINKBAGS PackagingFilms PackagingFilms ShrinkBags ShrinkBags

why and how of their purpose and intent: why was a project undertaken and how was the work performed? Moreover, what benefits will the results provide for the organization’s practices and deliverables?

For SR&ED to occur and for a business project to be eligible, the work must be conducted to achieve a scientific or technological advancement and must be conducted in a systematic manner. This means that many food business projects looking for innovative ways to create food might be eligible.

For example, scientific and technological advancements may be required: to understand how products need to get reformulated to include natural and/or organic ingredients, to maintain or improve the existing organoleptic/sensory properties, and/or to overcome processing challenges related to natural and/or organic ingredients.

But what exactly is a natural and/or organic ingredient? “Natural” regarding food claims has three specific criteria as defined by the Canadian Food Inspection Agency (CFIA):

• Not to contain, or to ever have contained, an added vitamin, mineral nutrient, artificial flavouring agent, or food additive; and

• Not to have any part removed or significantly changed, except the removal of water (for example, the removal of caffeine); and

• Not to have been submitted to processes that have significantly altered their original physical, chemical, or biological state (i.e., maximum processes, such as chemical additions).

It is important to note that “natural” is not an indication of the quality or nutritional value of food.

As opposed to “natural,” the term “organic” refers to a specific, regulated way in which food products must be grown and processed.

Just like “natural”, “organic” food does not indicate the health or nutrition of a given food. Specifically, “organic” foods must be grown on fields where no prohibited substances have been applied to soils for the past three years, and then certified through an approved regulatory body. This does not mean that fertilizer or processing aids have not been used.

Similarly, for meat specifically to be “organic” in Canada, the animals the meat derives from must be free from any reproductive hormones or synthetic growth that would make them grow faster, as well as free from all antibiotics and preservatives.

There is a list of approved substances from the Standards Council of Canada that are approved for organic foods. To label a product under the term “organic”, it must contain 95% organic ingredients. To contain “organic ingredients,” a product must list the percentage of ingredients that are organic.

As such, there are many projects that a Canadian food business may undertake to help their processes and products meet “natural” and/or “organic” requirements.

Applying for SR&ED Tax Credits for Canadian Food Business Projects

As mentioned, technological and scientific uncertainties required for SR&ED can often arise when trying to remove the processed preservatives from foods without affecting shelf life, as the preservatives can also act as conditioning or processing aids.

Similarly, natural preservatives impart different taste profiles and dough conditioning. When investigation and experimentation is taken into how the preservatives behave in each food matrix or how to change the processing to match an existing product, SR&ED may occur.

There are many crucial factors that impact the SR&ED application such as eligibility of activities and timelines. It’s also important to note that once accepted, the government does not dictate the direction of any given project, which is why the approval process is so heavily reviewed.

The Mentor Works, a Ryan Company team of Government Funding Planners™ work directly with clients to design and implement tailored solutions to support business growth. They work with Canadian businesses to develop a dynamic government funding plan that supports all areas of business investment and gives a significant competitive advantage when fully leveraged. Their clients are awarded an average of $180,000 in grants per year. Get in touch by visiting mentorworks.ca or by calling 1-888-599-3111.

Alena Barreca is a marketing specialist at Mentor Works, a Ryan Company in Guelph, Ontario. She focuses on helping businesses learn about government funding opportunities and connecting her team with those in need of application assistance.

www.meatpoultryon.ca 36 BlockTalk - Summer 2023

Continued from page 34 – HOW FOOD BUSINESSES CAN UTILIZE SR&ED TAX CREDITS

For all your refrigerated logistic needs Transportation • Truckload • Less-than-truckload • Dual temperature trailers • Direct Store Delivery Expedite Services • Home delivery • Dedicated services Cold Storage • HACCP certified • Sorting & labelling • Multiple locations with cross-docking 1-800-665-COLD | erbgroup.com sales@erbgroup.com

YOUR ONE-STOP SOLUTION

NEW RULES

MORE PRIZES

Elimination: Sept. 11, Waterloo

Finale: Oct. 21, Muskoka

Join us as we celebrate the 10th Anniversary of Ontario's Finest Butcher Competition. This year, we're shaking things up with a new elimination round home at Handtmann Canada in Waterloo, new competition rules, and an extended finale time of 45 minutes, and more

Don't miss out on the chance to be a part of this thrilling new chapter, filled with butchery excellence, thrilling challenges, and unforgettable moments.

REGISTER BY AUG 11 MEATPOULTRYON.CA

ANNIV E R SARY th

PROUD PARTNERS

Industry Leaders Identify Top Health & Safety Risks in Food Manufacturing

By Workplace Safety & Prevention Services

By Workplace Safety & Prevention Services

This April, Meat & Poultry Ontario proudly introduced the Centre for Meat Innovation and Technology (CMIT), the leading hub for the meat industry in Canada. CMIT is all about collaboration and innovation, which is Ontario’s secret sauce for standing out. And guess what? It can be your secret weapon too, setting you apart from the competition.

In this edition of BlockTalk, we’re exploring how Innovation and Technology can give your business a serious boost. Innovation goes beyond your product lineup—it touches every aspect of your business, from sourcing to marketing, operations, and talent. As you read through these pages, ask yourself: How can I shake things up? What can I do differently to leave the competition behind?

Innovation is the key to growth in an ever-changing world. If you’re not growing, you’re fading away. So where do you start? It begins with a simple thought or question. What can you do tomorrow to make your business even better? Embrace change— it’s the driving force behind innovation.

Change doesn’t have to be daunting; it starts with you. Each one of us has a responsibility to make innovation happen. It’s not

Nobody wants to pay for insurance.

something that magically occurs or can be bought—it’s a process that can be learned, practiced, and improved upon.

Take the time to explore and discover what innovation can do for your business. Trust me, it’s a game-changer. Industry Leaders Identify Top Health & Safety Risks in Food Manufacturing

Ontario is home to North America’s third-largest food manufacturing sector, with meat processing and bakery production leading the way. Yearly sales total more than $34 billion, making it a critical part of Canada’s food supply chain. It recently became the latest industry to undergo an in-depth risk assessment and root cause analysis facilitated by Workplace Safety & Prevention Services (WSPS). Ontario’s Ministry of

Continued on page 40

If something were to happen, that would not be the right time to find out you bought ground beef when you were sure you purchased a rib eye. Not all things are equal and not all things cost the same.

Reasonably painless reviews of your insurance policies is always best done before a claim occurs.

We are committed to your livelihood, your association and the community we live in. Please give us a call.

www.meatpoultryon.ca 38 BlockTalk - Summer 2023 SAFETY FIRST

Business, Home and Auto Insurance | Employee Benefits We Care. (905) 319-2252 | (877) 338-2252 | peterd@donnellins.com

BlockTalk - Summer 2023 39 CANADA COMPOUND Your food industry specialists since 1927 CCC Custom Blending Solutions Looking to create a new blend, rework an existing blend or match a recipe or product? Our BRC certified blending facility provides complete solutions for flavours, functional blends and complete custom units. Our in-house services ensure that you are speaking directly with our experts and getting the value and consistency in your products that we are trusted for. Contact us today to find the perfect solution for you. www.canadacompound.com Canada Compound Corporation 391 Rowntree Dairy Rd., Woodbridge, Ontario L4L 8H1 Canada P. 905-856-5005 E. info@canadacompound.com

Labour, Immigration, Training, and Skills Development (MLITSD) established this methodology as a way to engage industry stakeholders to better understand the top risks to workers’ health and safety and solutions and controls to reduce risk to lost-time injuries. The MLITSD’s methodology focuses on leading indicators, rather than lagging indicators, and leverages the knowledge and insights of front-line workers and managers. This approach has been successfully applied in the transportation, mining, and construction sectors.

Input from Industry Experts

For food processing, WSPS facilitated the risk assessment workshop this past October. Industry experts from across the sector were invited to participate—an even split of workers and employers—representing companies of various sizes and focus, from unionized and non-unionized environments.

Industry associations attended as observers, including Food and Beverage Ontario and Meat and Poultry Ontario. “As the professional organization for food and beverage processors across Ontario, we welcome this initiative to identify hazards and their causes. It’s a valuable opportunity to play a vital role in accident prevention and the reduction of harm across our sector,” said Chris Conway, CEO of Food and Beverage Ontario. “We’ll help to reduce injury and illness any way we can.”

“Companies were enthusiastic about participating and put a lot of thought into the pre-workshop activities,” said Hamish Morgan, Manager of Consulting Services with WSPS. To prepare, each

participant identified health and safety hazards in the sector. Collectively, 60 hazardous events were identified in all.”

“We gathered feedback from a diverse group of people from food manufacturing. For example, I have a background in the commercial baking industry, as well as meat manufacturing. We had others who are also involved in meat processing but use different manufacturing methods because they work mainly with raw meat, which means they have different hazards,” said Michael Pesce, an employee of FGF Brands Inc., a commercial baker. “We were able to look at different hazards through the lens of the people who do those jobs everyday.”

The group reviewed each of the 60 hazardous events in detail together. “There was some ambiguity with some of the risks, but we were able to consolidate similar risks and narrow our list,” noted Rizwan Arshad from MARS Pet Care. “It was enlightening. I learned a little bit from everyone in that room”.

Rating by Likelihood and Severity

To determine level of risk, each hazardous event was rated in terms of likelihood and severity of harm. “Representatives of MLITSD and industry associations participated in the discussions; however, only the worker and employer representatives voted in the risk evaluation,” explained Hamish. The votes were recorded anonymously and validated on a one-on-one basis.

What emerged was a top ten list, with inadequate lockout and tag out—which occurs when energy from equipment is not effectively isolated and blocked from being released while maintenance or other work is performed—in the number one spot. Other risk events included in the top ten list are bypassing or having inadequate safeguarding on equipment; being struck by or caught in mobile equipment (e.g., lift trucks, electric rider pallet trucks); and slips, trips and falls. Loading/unloading trailers and material handling also made the list, along with issues related to temporary workers and their unfamiliarity with the workplace.

The second phase of this approach—the root cause analysis workshop—took place in February. The goal was to uncover the specific factors that contribute to inadequate lockout and tag out. Industry experts identified and recommended the types of controls needed to address the root causes. These recommendations, in part, will form the basis of resources and training developed for the industry, which will create safer working conditions for all involved. “I have four kids who are going to hit the workforce soon. I feel good that I’m helping to make improvements that may have an impact on their experience,” said Rizwan. “We’re doing this because we want to leave the industry better than it is now.”

This article was prepared by Workplace Safety and Prevention Services (WSPS). For more information visit Food Manufacturing & Root Cause