THE

T HE U LTIMATE F ISHING LINE

HISTORY

Pioneering the first-ever UHMWPE (ultra-highmolecular-weight-polyethylene) braided fishing line, TUF-LINE continues to redefine perfection. Through years of experience and persistence, we continue to manufacture a variety of products that are sure to fill every need of our fellow anglers. Our manufacturing partners have grown consistently along with TUF-LINE’s reputation of unwavering quality and are known as the industry leaders in textile braiding.

TECHNOLOGY

What makes TUF-LINE The Ultimate Fishing Line? Being avid anglers ourselves, throughout the decades we have continually tested and proven the superiority of our braid. Understanding the needs and wants of our customers, quality has always been and always will be our number one priority. There is nothing worse than losing the fish of a lifetime due to a breakage in your line, which is why TUF-LINE is pound for pound 15 times stronger than steel. Our proprietary coating process has created the most “bullet-proof” line on the market. The coating process permeates into the fibers of the braid creating a stronger, more abrasion-resistant, long-lasting superline. Through years of research and development, we have perfected our unparalleled coating process.

WHAT MAKES TUF-LINE DIFFERENT?

Our manufacturing partner produces a large variety of products that are used in high-tech industries including medical, automotive, electric motor manufacturing, aerospace, and military applications. Registered and approved as an ISO 9001 and AS 9100 organization, our production partners have proven that quality is their core concern. Currently, products made on the same machines and with similar materials are on NASA’s Mars Curiosity rover, in Formula 1 race cars, on the airplanes you fly in and are utilized throughout the entire American Armed Forces. TUF-LINE is built to the same rigorous quality and durability standards demanded by top US military and commercial partners. TUF-LINE is backed by proprietary technology that is only found on our products. Paired with the most advanced materials and production, you can rest assured that you’re using the best line you could ever put on your reel.

WHY CHOOSE TUF-LINE?

COATING

Our Force Fusion™ coating process ensures a longerlasting color and coating life due to the permeation of the coating throughout the braid. Our coating provides superior abrasion resistance but also a more permanent coloration of the line resulting in zero shedding or color bleeding.

ABRASION RESISTANCE

Independent lab results against the major competitors show just how “TUF” our lines are.

Accelerated Fiber to Metal Abrasion Resistance Cycles

TIPS

CHOOSE LINE BY DIAMETER, NOT BREAKING STRENGTH

When choosing a TUF-LINE product to replace a monofilament line, it’s usually best to choose a TUF-LINE with comparative diameter to the monofilament you would use in similar conditions. The benefit of this approach is maintaining similar handling characteristics and surface area to what you are used to.

SPOOL THE LINE TIGHT

TUF-LINE does not grip a reel spool as monofilaments do. Before spooling up with TUF-LINE, put a wrap of electrical tape on the reel spool. This gives the line something to bite into. Alternatively, you can also put a few yards of monofilament and tie the line directly to the mono. Wind the line on tightly and under steady pressure. Packing the reel well will eliminate any opportunity for the line to dig into the spool.

SET DRAGS PROPERLY AND USE A CONTROLLED HOOK SET

Set your drag to no more than 30% of the line’s breaking strength. If using a monofilament or fluorocarbon leader, set the drag to protect the leader. All TUF-LINE products have considerably less stretch than monofilament lines. Therefore, a monster hook set is not necessary. Be firm and controlled.

DOUBLE KNOTS PERFORM BETTER

TUF-LINE’s fibers and coatings don’t bite into one another when knotted. For this reason, poorly tied knots can slip under a load. For general applications, the use of a Palomar knot will hold with exceptional strength. To incorporate a wide family of knots, tie them with a doubled length of TUF-LINE to add significant strength.

MAX DISTANCE | ABRASION RESISTANT | SUPREME CASTING FOR MAXIMUM PERFORMANCE IN FRESH OR SALTWATER

Our Force-Fusion™ coating process provides superior abrasion resistance and a more permanent coloration of the line resulting in zero shedding or color bleeding.

ROUND PROFILE

Fused fibers create a rounded profile that stays consistent throughout the entire spool for even casting.

SUPERIOR DISTANCE & HANDLING FOR A SMOOTH, ACCURATE CAST.

Our flagship, most premium eight-carrier superline provides performance on the water second to none. Utilizing Force-Fusion™ Technology, this superior offering is braided under extremely high tension, resulting in ultra-compact fibers and an overall more cylindrical form. This silky finish offers anglers a supreme casting experience while increasing reliability due to reduced wear. Additionally, its bonding and coating process ensures the longevity of color hook-up after hook-up. Cast it for yourself – you’ll catch the difference.

Extraordinary Diameter-to-Breaking Strength Ratio

Effortless Casting Performance

Super-Smooth Cylindrical Construction

Essentially Zero Stretch

Reduced Friction

ABRASION RESISTANCE

With TUF-LINE’s proprietary coating process, XP+ is tough enough for fishing in heavy cover or dragging baits along rough, rocky bottom.

ULTRA-CASTABLE

With new coating and a premium 8-carrier braid, XP+ easily casts at incredible distances.

AVAILABILITY

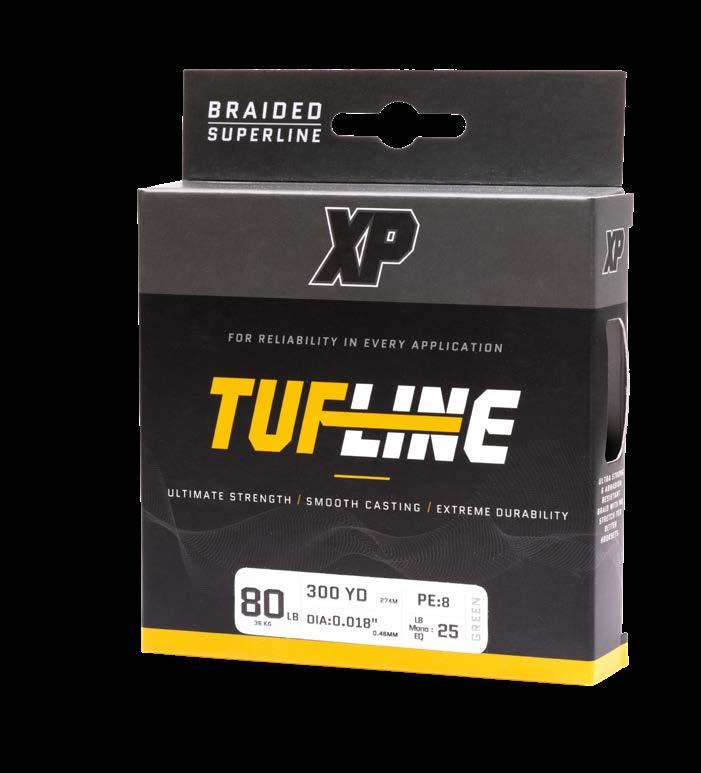

ULTIMATE STRENGTH | SMOOTH CASTING | EXTREME DURABILITY FOR RELIABILITY IN EVERY APPLICATION

ULTRA STRONG & ABRASION RESISTANT BRAID WITH NO STRETCH FOR BETTER HOOKSETS.

Aerospace advancements have been leveraged to produce TUF-LINE® XP, our best-selling braided superline. Tension Lock Technology is used in the manufacturing process to braid under extremely high tension, creating more compaction of the fibers and a rounder profile than competitive lines. As a result, XP is more compact, smaller in diameter, packs better on reels, offers better knot performance, casts longer, reduces rod tip wraps, and boasts higher abrasion resistance. Its state-of-the-art coating remains permanently bonded to the fibers, offering an incredibly long service life with zero shedding.

• Interwoven Multi-carrier Ranging from Four to Eight Carriers

• Abrasion-resistant for Maximum Durability

• Quieter, Longer Casting Ability

• Reduced Friction

ULTIMATE STRENGTH

When it’s time to break out the big guns; this extremely dependable line is sure to get you through the fight.

MAX DISTANCE

A round ultra-smooth finish gives XP superior handling and makes it virtually silent as it glides through the water.

AVAILABILITY

With less stretch and slack, XP delivers solid hooksets, even at long distances.

REDUCED DIAMETER

XP allows you to fit more line on your reel, with a small diameter that doesn’t sacrifice strength or toughness.

8 CARRIERS | TOUGH & RUGGED | ROUND PROFILE FOR EXCELLENT PERFORMANCE IN ANY FISHERY

When it’s time to break out the big guns; this extremely dependable line is sure to get you through the fight.

MAX DISTANCE

A round ultra-smooth finish gives ADX Enforcer superior handling and makes it virtually silent as it glides through the water.

WE FILLED THIS LINE WITH TECH. JUST ADD WATER.

Addicted Enforcer 8x is a favorite among the TUF-LINE® offering, catering to many applications. The Close Angle Braid Technology™ makes it one of the most compact braided lines on the market. The ultra-round profile delivers smooth handling, long casts, and almost no rod guide noise when casting. Made with micro-PE fibers, it has the highest strength-to-weight ratio in its class. Colored with a proprietary, colorfast, bi-component coating process, you’re ensured amazing abrasion-resistance and long color life.

REDUCED STRETCH

Extremely tight material tolerances significantly reduce stretch when hooked up.

REDUCED DIAMETER

Allows you to fit more line on your reel, with a small diameter that doesn’t sacrifice strength or toughness.

AVAILABILITY

REDUCED STRETCH | PURE LEAD CORE | COLOR METERING FOR ACCURATE TROLLING AT CONTROLLED DEPTHS

An absolute pure lead core offers less stretch and a denser center than the competition.

REDUCED DRAG

A smoother profile in the water column decreases drag when dropping or trolling.

A tightly-braided high-tenacity polyester multi-filament yarn encapsulates a 99.9% pure lead core offering 60% less stretch in comparison to traditional nylon-sheathed lines. This substantially reduces the chances of line lengthening when you’ve got the business end of a massive fish. A completely pure lead construction offers a smaller diameter, reducing drag in the water while trolling and fighting. Color metering in ten-yard increments with a highvisibility dye improves depth estimation at any length.

High-tenacity Multi-filament Braid Reduces Stretch by Up to 60% Color Metering Offers Easy Depth Estimation

REDUCED STRETCH

Extremely tight material tolerances significantly reduce stretch when hooked up.

PRECISE

METERING

Lead Core features precise color metering in for technical, controlled depths.

AVAILABILITY

MINIMAL STRETCH | RESPONSIVE | SPLICES EASILY FOR A SUPREME ANGLING EXPERIENCE

LOW STRETCH TOLERANCE OFFERS EXTREME SENSITIVITY.

The highest quality Dacron® fibers and most advanced braiding machines in the industry are combined to manufacture this premium line. Its low stretch gives quick response to strikes and increases sensitivity. The spliceable construction and specially formulated wax eliminate strength loss from knots which reduces your chances of losing fish.

• Increased Sensitivity

• Reduced Stretch

• Easily Spliceable Construction

• Specially Formulated Wax

REDUCED STRETCH

Extremely tight material tolerances significantly reduce stretch when hooked up.

ULTIMATE STRENGTH

When it’s time to break out the big guns; this extremely dependable line is sure to get you through the fight.

SENSITIVITY

Dacron® transmits more energy than traditional lines, meaning you feel every bit and piece of cover.

REDUCED DIAMETER

Allows you to fit more line on your reel, with a small diameter that doesn’t sacrifice strength or toughness.

AVAILABILITY

REPLACES CABLE | STRETCH-RESISTANT | ELIMINATES ELECTROLYSIS FOR THE BENEFITS OF BRAID WITHOUT THE HASSLE OF CABLE

ULTIMATE STRENGTH

When it’s time to break out the big guns; this extremely dependable line is sure to get you through the fight.

NO ELECTROLYSIS

Replacing traditional cable with high-functioning braid removes all the hassle the electrolysis brings to your gear.

RUST-PROOF. KINK-PROOF. FRAY-PROOF.

TUF-LINE® Downrigger replacement line simply changes the game. Replacing wire cable affords all the benefits of braid and eliminates the hassle of cable. This superior offering provides maximum strength and weight handling capabilities and cannot rust, kink or fray; it’s also stretchresistant. While eliminating electrolysis and significantly reducing wire hum, this premium performance braid handles whatever you hook in to.

Eliminates Electrolysis Created By Steel Cables That Interfere With On-board Electronics Will Not Rust, Kink Or Fray

REDUCED STRETCH

Extremely tight material tolerances significantly reduce stretch when hooked up.

REDUCED DRAG

A smoother profile in the water column decreases drag when dropping or trolling.

AVAILABILITY

SMALLER DIAMETER | SMOOTH RUNNING | MINIMAL STRETCH FOR PERFECT PLANING EVERY TIME

RUNS SMOOTHER, LONGER.

High-visibility, fluorescent orange braided line has the advantage of low stretch and a long service life. A smaller diameter than standard, this premium line allows the planer to run more smoothly with less drag. Available in two different pound tests and spool lengths for every application.

REDUCED DIAMETER

Allows you to fit more line on your reel, with a small diameter that doesn’t sacrifice strength or toughness.

SENSITIVITY

Planer Board transmits more energy than traditional lines, meaning you feel every bit of the action.

REDUCED STRETCH

Extremely tight material tolerances significantly reduce stretch when hooked up.

REDUCED DRAG

A smoother profile in the water column decreases drag when dropping or trolling.

AVAILABILITY

REDUCED DIAMETER | WATERPROOF & ROT-PROOF | LOW-STRETCH FOR SUPREME CONFIDENCE IN YOUR FLY SPOOL

Waterproof and rot-proof braided material drastically improves lifespan.

REDUCED DIAMETER

Allows you to fit more line on your reel, with a small diameter that doesn’t sacrifice strength or toughness.

DEPENDABLE FLY LINE FOUNDATION FOR FRESH AND SALTWATER REELS.

This small diameter, low-stretch braided backing is waterproof and will not rot or mildew. Made from the highest-quality braided Dacron® fiber, it’s lightly braided for a smaller diameter providing higher reel capacity. The colorfast cationic (head/pressure) dye process ensures a uniform colorfast construction that’s ideal for both fresh and saltwater.

Reduced Diameter for Improved Reel Capacity

Waterproof & Rot-Proof

Capable in Both Fresh and Saltwater Advanced Dye Process Ensures Uniformity and Long-Life

AVAILABILITY

20, 30 LB TEST 100 & 2,500 YARDS

SOLID FOUNDATION

Extremely tight material tolerances significantly reduce stretch when hooked up.

SUSTAINABLE COLOR

Colorfast cationic dye process ensures long life of color, even in saltwater.

CHARTREUSE