PROFITABLE PRODUCTION STRATEGIES ONE GROWER PUBLISHING, LLC Processing Program Develops On-Farm Drying Guidelines APRIL 2024 www.ricefarming.com A California Legacy and Collaboration SPECIALISTS SPEAKING Water and Insect Management

It’s not just what we do, it’s who we are.

With our team’s collective 200+ years tied to agricultural production, we believe in what we do.

We make it our mission to provide profitable production strategies to our farmers with information to improve their bottom lines.

Our seasoned editors cover every stage of production — from land preparation, to seed selection, to crop protection through harvest.

www.ricefarming.com RiceFarming1 @RiceFarming @RiceFarming Contact Associate Publisher/Sales Scott Emerson at 386-462-1532 or semerson@onegrower.com to advertise

INSTAGRAM: @RICEFARMING APRIL 2024 | RICE FARMING 3 Look for the Soybean South supplement following page 12 in the the Arkansas, Louisiana, Mississippi, Missouri and Texas versions of Rice Farming 7 Global Trade Weather, War Pinch Panama, Suez Canal 8 Rice Processing Program Development of New On-Farm Drying Guidelines 10 Final Rule Department of Labor Defines Independent Contractor 14 White Water Fire A New Weed in California Rice 19 Rice Marketing A Quick Look at the 2024 Rice Market Cover Story www.ricefarming.com Vol. 58, No. 5 GET CONNECTED Stay up to date with the latest from Rice Farming www.facebook.com/ RiceFarming1 @RiceFarming @RiceFarming Columns 4 From the Editor Room for Uncertainty 6 USA Rice Update Seizing the Climate-Smart Opportunity Departments 12 Industry News Rice business scene 20 Specialists Speaking Water and Insect Management ON THE COVER: When Brian McKenzie began growing rice, they had around 1,500 acres. That has expanded considerably over four counties near Sacramento, California.

Features A California Legacy and Collaboration

Photo by Drew Mullaney

16 7 10 19 April 2024 Rice Awards: Since 1992, the Rice Farmer of the Year, Rice Industry Award and Rice Lifetime Achievement Award recognize deserving leaders within the rice industry. Nomination form on page 5. Rice Consultant of the Year: Acknowledge an outstanding consultant for dedication, leadership and innovation of this crucial segment of the U.S. rice industry. Nomination form on page 15. nominations byJuly15,2024. members encouraged. Name: the person Consultant Sponsored annual innovation agronomic Corteva consultants their 2025 special Receive recipient and NOMINATION FORM Nominate an consultant for the Rice Consultant Year Award supporting Deadline: July 15, 2024 The Rice Farmer Lifetime Achievement determination and innovation identify candidates worthy these prestigious which industry members this form and supporting nominate online. Categories: box the Year his/her leadership/development, stewardship. Industry Award government/association leadership/development. Rice provided community have nominee community succeed the please make form. Nomination 2024 Rice Awards Nomination Form Include supporting materials elaborate on your nomination: 8 14

Brian McKenzie (left) and Drew Mullaney have worked together since 2016 on McKenzie's rice operation.

Room for Uncertainty

Back in December, I mentioned how there are many aspects in the rice industry that may shift at a moment’s notice. It may be over time, or it may be almost instantaneous, but there is sure to be something that goes differently than we expected or hoped. Several articles in this month’s issue point to this truth.

Pages six and seven discuss a final rule from the Department of Labor on defining employees versus independent contractors that may be relevant to your operation: “This new rule replaces the classification framework established by the agency in 2021. Because employers do not owe the same legal obligations to independent contractors as they do their employees, employers must ensure they properly classify workers under the final rule’s new framework. If an employer misclassifies their workers, they may violate the FLSA, which could result in legal fines and penalties from the DOL.”

Dr. Whitney Brim-Deforest discusses a new rice weed discovered in California on page 16. “White water fire (Bergia capensis) was found in September of 2023, by the Butte County Agricultural Commissioner’s office in a rice field in Butte County. The weed was identified by the California Department of Food and Agriculture. It is the first find of this weed in California, and possibly in the United States.”

Trade on a global scale has been and is still a huge issue at play. On page 10, you’ll find an article where Ryan Loy, Extension economist with the University of Arkansas Division of Agriculture, discusses the 2024 rice market and India’s impact on it. “It’s worth noting that India is currently in an election year and it’s doubtful the ban would be lifted before a general election in April or May. If the ban is lifted post-election, watch for Indian rice to flood the market, and put further downward pressure on global rice prices.”

In the end, leaving some flexibility where possible in your operation for these changes — sometimes surprises — can be beneficial. Remember, too, that you can only control so much. That should give some peace of mind.

On another note, Rice Farming magazine, in conjunction with Horizon Ag and USA Rice, is opening our nomination period for our 2024 Rice Awards — Rice Farmer of the Year, Rice Industry Award, and Rice Lifetime Achievement Award. Being held later this year in Little Rock, Arkansas, these are presented at the annual Rice Outlook Conference. If you know someone deserving of any of these prestigious awards, visit www.ricefarming.com/ra.

In addition to the 2024 Rice Awards, we are opening the nomination period for the 2024 Rice Consultant of the Year. This individual serves the rice industry with dedication, leadership, and innovation. If you know a rice consultant who models these characteristics, absolutely go nominate them today. Visit www.ricefarming.com/rcoy for more information.

I hope everyone’s season is going well!

4 RICE FARMING | APRIL 2024 RICEFARMING.COM

One Grower Publishing, LLC 875 W. Poplar Ave., Suite 23, Box 305 Collierville, TN 38017 ASSOCIATED PUBLICATIONS — One Grower Publishing LLC also publishes COTTON FARMING, THE PEANUT GROWER, SOYBEAN SOUTH and CORN SOUTH magazines. RICE FARMING (ISSN 0194-0929) is published monthly January through May, and December, by One Grower Publishing LLC, 875 W. Poplar Ave., Suite 23, Box 305, Collierville, TN 38017. POSTMASTER: Send address changes to OMEDA COMMUNICATIONS, CUSTOMER SERVICE DEPARTMENT, P.O. BOX 1388, NORTHBROOK, IL 60065-1388. Annual subscriptions are $25.00. International rates are $55.00 Canada/Mexico, $90.00 all other countries for Air-Speeded Delivery. (Surface delivery not available due to problems in reliability.) $5.00 single copy. All statements, including product claims, are those of the person or organization making the statement or claim. The publisher does not adopt any such statement or claims as its own and any such statement or claim does not necessarily reflect the opinion of the publisher. RICE FARMING is a registered trademark of One Grower Publishing LLC, which reserves all rights granted by the U.S. Patent and Trademark Office in association with its registration. © Copyright 2024 Mike Lamensdorf President/Treasurer Lia Guthrie Publisher/Vice President ONE GROWER PUBLISHING, LLC EDITORIAL/PRODUCTION Editor Cassidy Nemec cnemec@onegrower.com Copy Editor Carroll Smith csmith@onegrower.com Digital Content Editor Katie Guthrie kguthrie@onegrower.com Art Director Ashley Kumpe akumpe@onegrower.com ADMINISTRATION Publisher/Vice President Lia Guthrie 901-497-3689 lguthrie@onegrower.com Associate Publisher/Editor-In-Chief Carroll Smith 901-326-4443 csmith@onegrower.com Associate Publisher/Sales Manager Scott Emerson 386-462-1532 semerson@onegrower.com Production Manager David Boyd dboyd@onegrower.com Audience Services Kate Thomas 847-559-7514 For subscription changes or change of address, call 847-559-7578 or email ricefarming@omeda.com. Cassidy Nemec Editor

The Editor Send comments to: Editor, Rice Farming Magazine, 875 W. Poplar Ave., Suite 23, Box 305, Collierville, TN 38017 or email cnemec@onegrower.com. Cassidy

From

2024 Rice Awards Nomination Form

The Rice Farmer of the Year, Rice Industry Award and Rice Lifetime Achievement Award recognize those rice leaders who have demonstrated dedication, determination and innovation to the industry. We need your help to identify candidates who are worthy of these prestigious awards. Please take time to consider which industry members in your area should be recipients of these honors and mail or scan/email this form and supporting materials or go to ricefarming.com/ra to nominate online.

Categories:

Please check the box of the appropriate award category:

� Rice Farmer of the Year Award

■ Must farm at least 200 acres.

■ A farmer who has successfully achieved goals in his/her farming operation, rice industry association, community leadership/development, innovative production practices and/or environmental stewardship.

� Rice Industry Award

■ Has been in the rice industry for more than five years.

■ A researcher, Extension person, government/association leader, etc... who has demonstrated commitment to the rice industry through innovative practices, industry association, community leadership/development.

� Rice Lifetime Achievement Award

■ Has been in the rice industry for more than 10 years.

■ An industry leader who has provided great contributions to the rice industry through industry associations, community leadership/development, innovative practices/projects that have advanced the industry.

Deadline:

July 15, 2024

If you are submitting more than one nomination form, please make a copy before you fill out the form. Nomination forms can be downloaded or submitted online at ricefarming.com/ra

Nominee’s name

Nominee’s address

Nominee’s phone number/email address

Nominee’s rice acreage (if applicable)

Number of years involved in the rice industry (if applicable)

Your name

Your profession

Your address

Your phone number/email address

Your signature Date

Please send completed form & supporting materials to: Carroll Smith 7201 Eastern Ave., Germantown, TN 38138

Scan/Email: csmith@onegrower.com Online: ricefarming.com/ra

Include supporting materials to elaborate on your nomination:

In addition to completing this form, on a separate piece of paper, please describe the nominee in terms of the following guidelines:

Dedication to farming and/or agriculture and the rice industry, local community and education.

Determination to succeed and overcome hurdles that have emerged while trying to reach goals.

Innovation to identify new and better ways for the industry to become more profitable, manage risk, achieve a higher level of efficiency.

It also is helpful to send letters of recommendation for the nominee from other individuals in the rice industry who are familiar with his/her accomplishments. A panel of judges from across the Rice Belt will select the recipients of the 2024 Rice Awards.

The award recipients will be honored at the USA Rice Outlook Conference, Dec. 8-10 in Little Rock, Arkansas, where an official presentation will be made at the awards luncheon. They also will be featured in a special salute sponsored by Horizon Ag, USA Rice and Rice Farming magazine in the December 2024 issue.

SPONSORS

By Josh Hankins Rice Stewardship USA Rice

By Josh Hankins Rice Stewardship USA Rice

Seizing the Climate-Smart Opportunity

Nobody can deny that the Biden Administration has put their money where their mouth is when it comes to climate change. Most prominent among their initiatives is the U.S. Department of Agriculture’s (USDA) Partnerships for Climate-Smart Commodities program. Part of our mission at USA Rice is to ensure the rice industry seizes every opportunity based on the sustainable practices you can implement — or likely already have implemented — on your farm.

Secretary of Agriculture Tom Vilsack announced the Partnerships for Climate-Smart Commodities initiative in 2022, which aimed to expand world markets for American commodities and provide tangible benefits and assistance to U.S. agriculture.

We saw this as a vital opportunity for our rice farmers, and our staff wasted no time mobilizing the sustainability troops. Our Rice Stewardship Partnership Program with Ducks Unlimited was well positioned to apply for these Climate-Smart funds, considering our historic success in delivering 13 separate Regional Conservation Partnership Program (RCPP) projects through the USDA Natural

“Our hard work paid off. USA Rice’s proposal was the highest scoring application of over 300 submissions and will be bringing in $80 million in Climate-Smart funding to support U.S. rice farmers.”

Resources Conservation Service (NRCS). So, as we have done for the past 10 years, USA Rice and Ducks Unlimited worked hand in hand to achieve this goal, also building on our relationship with the National Black Growers Council in the process.

Our hard work paid off. USA Rice’s proposal was the highest scoring application of over 300 submissions and will be bringing in $80 million in Climate-Smart funding to support U.S. rice farmers. The funds will pass through USA Rice to rice producers in Arkansas, California, Louisiana, Illinois, Mississippi, Missouri, and Texas, with funds split between states based on historical harvested acres.

Our rice producer leaders in each of the six states have been instrumental in the design and implementation of this initiative every step of the way, which gives us confidence that the Climate-Smart program will truly work for rice growers — voluntary, practical, self-led, and tailored to the unique needs and challenges of our industry.

Many states have already had their first sign-up opportunity, which was open to all rice producers; a second signup period, open to all rice producers that qualify as historically underserved under NRCS definitions, will be announced in the coming months.

Climate-friendly practices aren’t stepping out of the spotlight anytime soon, but fortunately, U.S. rice is way ahead of the game. The strength of our sustainability story will continue to reap benefits for the industry as long as our rice growers prioritize stewardship of the land—as they always have, and always will.

6 RICE FARMING | APRIL 2024 RICEFARMING.COM

USA Rice Update

Global Trade Disrupted as Weather, War Pinch Panama, Suez Canals

The Panama and Suez canals typically bear the weight of global commerce but now carry the additional, heavier burdens of weather and war.

“There are two maritime disasters going on simultaneously. One of them is political and the other one is environmental,” said Ryan Loy, Extension economist for the University of Arkansas System Division of Agriculture. “They both have a large impact on the global supply chain.”

According to the United Nations Conference on Trade and Development, monthly transits through the Panama Canal dropped 49% since October 2021, while Suez transits were down 42% across the same period.

The Panama Canal, connecting the Atlantic and Pacific oceans, is critical to trade. In 2023, the canal saw more than 14,000 transits of commercial vessels carrying more than 285 million tons of cargo. The canal relies on fresh water from the Gatun Lake to move ships through its locks. Last year, drought halved the amount of water flowing into the reservoir.

Last October, canal authorities began reducing traffic from 32 transits a day to 24 in November. Transits were then cut to 22 in December. In January, the Panama Canal Authority raised the number of transits to 24, a level it planned to keep through April.

“Panama is basically dealing with the same thing we were seeing with the Mississippi River last fall,” said Loy. Drought along a large part of the Mississippi River saw the waterway drop to a record low in September 2023.

Rising Costs

The reduction in transits has traffic backing up on both sides of the isthmus, which means shippers can either wait or choose to take the longer, more dangerous route around South America. It also means some commodities will be loaded onto trains or trucks instead.

“The long layovers affect the quality of the commodities, especially if you have something like live beef cattle or live pigs,” Loy said. There are also the additional costs of the energy required to keep a ship’s crew and systems operating while standing still.

Suez Woes

The Suez Canal is a key trade route connecting the Mediterranean and Red seas. Its construction in the 1800s meant shipping between Europe and East Asia no longer had to go all the way around Africa.

Houthi missile and drone attacks along the Suez have prompted many shipping companies to avoid the route, with container shipping dropping 67% year-over-year in late January, according to the trade journal gCaptain. In 2019, the most recent figures available from the Suez Canal Authority, the canal saw 18,880 ships bearing 1.03 billion tons of cargo.

“According to the United Nations Conference and Trade and Development, more than a fifth of the world’s container trade went through the Suez,” Loy said. “That included natural gas, oil, and materials needed for manufacturing.”

In a recent statement, global shipping and logistics company Maersk said “in the interest of safety for our vessels, crew, and customers’ cargo, all vessels previously due to transit the area have been diverted south around the Cape of Good Hope for the foreseeable future.

“While we hope for a sustainable resolution in the near future and do all we can to contribute toward it, we encourage customers to prepare for disruptions to persist in the global network,” the company said. “Transit times between the U.S. East Coast and India and the Middle East, and vice versa, will be extended by one or two weeks by this change.”

With the issues at the two canals, plus Black Sea disruptions due to the Ukraine-Russia conflict, costs are rising.

The United Nations said container freight rates on Asia–Pacific to Europe routes have risen sharply since November. Average container shipping spot rates from Shanghai in early February 2024 more than doubled — up by 122% compared to early December 2023, the UN said. The rates from Shanghai to Europe more than tripled, jumping by 256%.

“While we have not seen much price impact yet, eventually the high cost of transportation will work their way back to farmers and consumers,” Loy said.

In 2021 when the Ever Given cargo ship ran aground and blocked all traffic in the Suez Canal for six days, Lloyd’s List Intelligence said that “rough calculations suggest westbound traffic is worth around $5.1 billion daily while eastbound traffic is worth $4.5 billion.”

This article is provided by the University of Arkansas System Division of Agriculture.

INSTAGRAM: @RICEFARMING APRIL 2024 | RICE FARMING 7

Image from NASA’s Earth Observatory from August 2023 shows the backlog of ships waiting to enter the drought-afflicted Panama Canal.

IMAGE COURTESY OF NASA

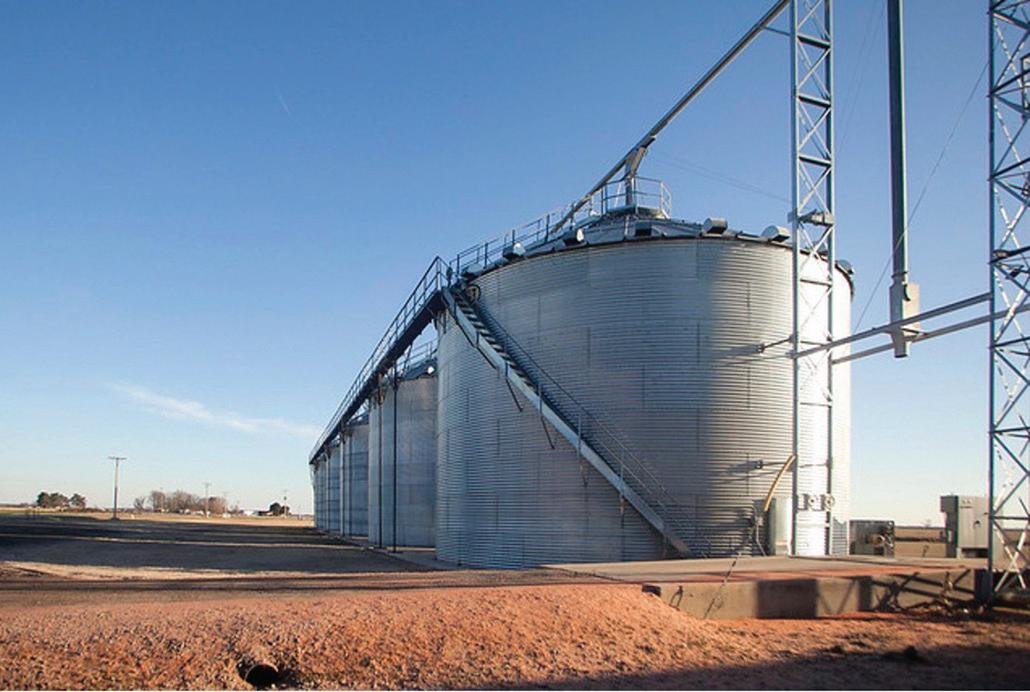

On-Farm Drying

Rice Processing Program Develops Guidelines to Maximize Quality, Reduce Energy

By John Lovett U of A System Division of Agriculture

The Arkansas Agricultural Experiment Station’s Rice Processing Program has released new recommendations to guide on-farm, in-bin rice drying in Arkansas to maximize quality and energy savings.

Griffiths Atungulu, interim director of the Rice Processing Program and associate professor of grain processing and post-harvest system engineering for the Experiment Station, the research arm of the University of Arkansas System Division of Agriculture, said the new guidelines are intended to balance rice quality, energy use, and weather considerations.

“The real problem is that the weather may not allow complete drying of the rice, particularly the upper layers, in a timely manner,” said Atungulu. “When this happens, there is a great possibility for mold growth in the grain mass, with potential mycotoxin development and quality deterioration including staining, milling yield reduction, and sensory and functional problems.”

Using data compiled over nearly a decade, Atungulu’s team created an easy-to-read chart that offers guidelines for “suitable” and “unsuitable” drying operation ranges for Arkansas rice farmers during the harvesting months of August to October. Armed with this decision tool, producers will be in a better position to evaluate their rice drying needs, Atungulu said.

Rice growers commonly harvest rice once it reaches 20% moisture content. Rice producers store the rice in bins and begin the drying process to further reduce moisture content, Atungulu said. The optimum storage level of 12.5% moisture content wards off mold growth and helps maintain the rice’s structural quality for improved head yield.

Storing grain with too much moisture can lead to the formation of mycotoxins, especially aflatoxin. These are known carcinogens that pose a severe health hazard to humans and animals, Atungulu said. Conversely, overdrying the grain can make it brittle and lead to decreased head yield from broken kernels.

Most on-farm systems in Arkansas use fans to blow either natural or slightly heated air to dry freshly harvested rice, Atungulu said. However, weather conditions come into play when determining the duration required to achieve that 12.5% optimum moisture content.

Based on this research, Atungulu said a moisture content of 18% to 19% at harvest is now recommended for on-farm, in-bin drying systems. Harvesting at a lower moisture content can save energy to dry the grain to that optimum storage level.

Adopting Technology

Arkansas rice farmers are steadily adopting moisture content monitoring technology, Atungulu said. The system is comprised of moisture content sensors buried vertically in the grain on ca-

NICE

bles, an on-site weather station and a controller that turns the drying fan on and off.

Algorithms based on the Equilibrium Moisture Content (EMC) principle, which determines the moisture content that a single grain will attain if exposed to air with a given relative humidity and temperature for a specific duration, determine if the external air is too humid to dry the rice, Atungulu said. Alternatively, if the system has a heater, it can control the humidity of the pushed air.

Atungulu said the cost to set up a new on-farm, in-bin drying system with moisture-sensing technology, a weather station, and a fan controller is about $14,000 for the first 48,000-bushel bin.

It becomes more cost-effective as more bins get linked to the system because only one weather station is needed. The cost reduces to about $10,000 for each subsequent bin. Atungulu said most Arkansas rice farmers do not opt for the air heaters, but they are not a significant expense to add to a system.

Since remote control of the drying operation is possible through the internet, some businesses have sprung up that provide remote moisture control of on-farm, in-bin systems, Atungulu said.

The Moisture Content Guideline Chart

In 2013, the Rice Processing Program began working with manufacturing companies to collect data for properly calibrating ricebin moisture control sensors. Atungulu said his team has been able to get the margin of error down to less than 1% for computer simulations using data collected in the field. Atungulu noted that the program cannot account for some variables like the amount of dust and chaff in the bin.

Atungulu used this data to develop a suitability chart, which

8 RICE FARMING | APRIL 2024 RICEFARMING.COM

UA SYSTEM DIVISION OF AGRICULTURE

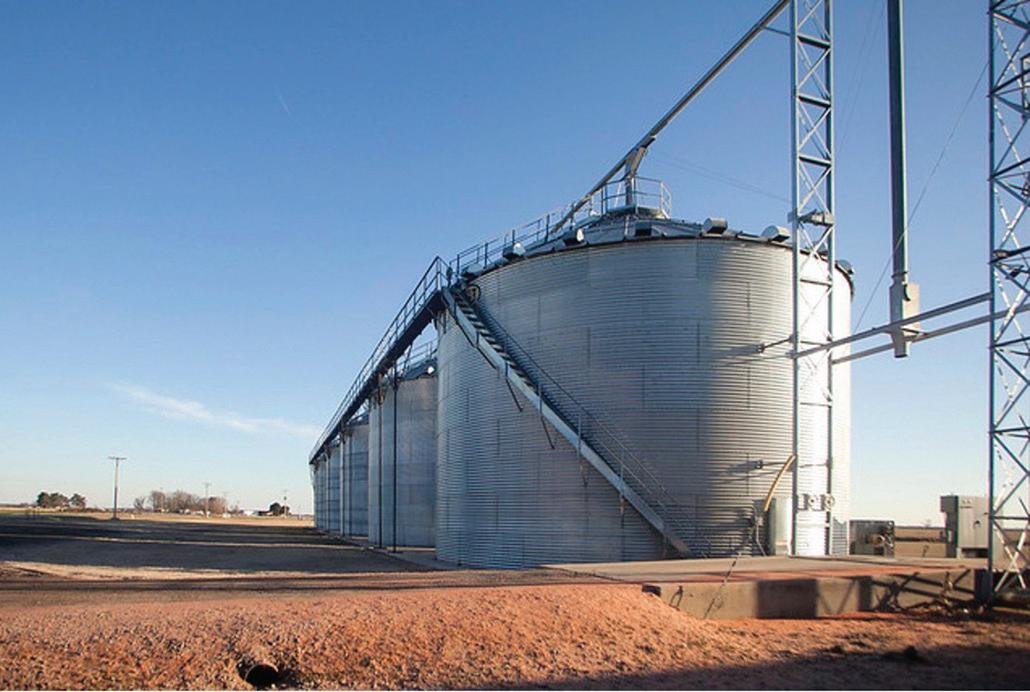

RICE — Arkansas rice farmers are adopting technologies that allow more efficient drying of rice on the farm.

addresses traditional systems that use continuous natural air without moisture monitors and the computer-assisted systems based on moisture content sensors.

The chart accounts for rice initial moisture content, typical airflow rates of 0.5, 1, 1.5, and 2 cubic feet of air per minute per bushel (cfm/ bu), fan control strategy, and drying start date. Fan control strategies include the traditional continuous natural air system (CNA) along with computer-assisted Equilibrium Moisture Content systems with both natural air (EMC-NA) and heated air (EMC-H).

The chart states that “suitability” does not factor in “quality” issues but rather focuses on “attaining safe storage,” which is 12.5% moisture content, drying duration of fewer than 30 days, maximum dry matter loss (DML) of less than 0.5%, and an over-drying rate of less than 10%.

The chart shows sensory technology systems with heated air capabilities offer the broadest range of optimum drying periods. A low-energy fan can also do the job when used with a heater. However, farmers do not like to introduce heat into the rough rice because the heat uses more energy and can compromise quality, Atungulu said. Optimum drying periods can be achieved without heated air if a more robust fan is used.

Rice producers can use the chart by finding the intersection of their system’s airflow rate, fan control strategy, harvest date, and initial moisture content. Suitable drying operation ranges in the chart are represented by boxes with diagonal lines in green and should provide enough time to safely reduce moisture content to 12.5%.

This University of Arkansas Rice Processing Program research expands the knowledge of a burgeoning practice of on-farm, inbin rice drying for the nation’s No. 1 rice-producing state, Atungulu said. Information gathered by the program with industry part-

ners can lower energy usage in drying the rice by knowing when to shut fans down when the air is too humid and maintain the rough rice’s structural integrity for maximum head yield after milling.

Support for this research was provided by rice check-off funding administered by the Arkansas Rice Research and Promotion Board and through contributions from the Rice Processing Program’s corporate sponsors.

INSTAGRAM: @RICEFARMING APRIL 2024 | RICE FARMING 9

UA SYSTEM DIVISION OF AGRICULTURE SPRAY TECHNOLOGY AND PRECISION FARMING SOLUTIONS NO BETTER WAY TO SPRAY Visit www.teejet.com/spray to learn more or visit your local TeeJet dealer Precision Spray Tips System Control Valves Field Computers and GPS Guidance Spray Boom Components

The On-Farm In-Bin Drying Suitability Chart was created by the Arkansas Agricultural Experiment Station’s Rice Processing Program using field data and computer modeling simulations for Arkansas rice growers.

U.S. Department of Labor Finalizes Independent Contractor Rule

Classifying workers as “employees” or “independent contractors” is an important task for agricultural employers because of the legal obligations and protections they owe to their employees. Some agricultural employers hire workers to complete various tasks or provide certain services for their operation, so there are instances where it may be difficult to determine whether a worker is an employee or independent contractor.

Recently, the U.S. Department of Labor (“DOL”) published a new final rule outlining the factors employers must consider when determining whether a worker is an “employee” or an “independent contractor” under the Fair Labor Standards Act (“FLSA”). This new rule replaces the classification framework established by the agency in 2021. Because employers do not owe the same legal obligations to independent contractors as they do their employees, employers must ensure they properly classify workers under the final rule’s new framework. If an employer misclassifies their workers, they may violate the FLSA, which could result in legal fines and penalties from the DOL.

Background

In 2021, the DOL published a rule (the “2021 rule”) establishing the factors employers must consider when designating a worker as an employee or independent contractor under the FLSA. The FLSA is a key federal statute providing labor protections to employees such as minimum wage, overtime pay, and the prohibition of retaliatory practices. While most employees are covered by the FLSA, these protections do not extend to workers classified as independent contractors. A prior NALC article provides a more in-depth overview of employees v. independent contractors.

The 2021 rule, which was expected to go into effect on March 8, 2021, established a five-factor framework employers would weigh to determine whether a worker was an employee or independent contractor.

However, the DOL delayed the effective date of this rule, and on May 5, 2021, the DOL withdrew the rule claiming that “the Rule was inconsistent with the FLSA’s text and purpose and would have had a confusing and disruptive effect on workers and businesses alike due to its departure from longstanding judicial precedent.” On Jan. 10, 2024, the DOL published a final rule, which establishes new worker classification guidelines under the FLSA. This rule went into effect on March 11, 2024.

2024 Rule

The DOL’s 2024 rule establishes a six-factor test that employers must use to determine if a worker is an employee or an independent contractor under the FLSA. According to the DOL, the purpose of the 2024 rule is to “provide guidance on proper classification and seeks to combat employee misclassification, a serious problem that impacts workers’ rights to minimum wage and overtime pay, facilitates wage theft, allows some employers to undercut their law-abiding competition, and hurts the economy at-large.” In other words,

employers must follow the DOL’s final rule framework when determining worker classifications so that employers provide, and workers receive, the legal obligations owed to them.

The final rule also permits employers to consider additional factors that relate to the dependence and independence when determining the proper classification of a worker. Under the final rule’s framework, a single factor does not determine the classification, and employers must consider each factor and all information when determining the classification of a worker.

The first factor employers must consider is the “opportunity for profit or loss depending on managerial skill” of the worker. There are several facts that can be relevant to determine if this factor weighs in favor of employee or independent contractor classification, such as whether the worker:

1. Can determine or negotiate pay.

2. Chooses to accept or decline tasks or chooses the order or time the job is performed.

3. Attempts to expand their business or secure more work.

10 RICE FARMING | APRIL 2024 RICEFARMING.COM

AG LAW & POLICY UPDATE

4. Makes hiring decisions.

5. Makes decisions on purchasing materials and equipment, and/or rent spaces.

e second factor is “investments by the worker and the potential employer.” If the investment supports a business-like function, this factor will weigh in favor of classifying the worker as an independent contractor. Examples of investments include “increasing the worker’s ability to do di erent types of or more work, reducing costs, or extending market research.” Additionally, if the worker makes investments similar to the potential employer, even if the scale is smaller, this factor likely points to the worker being an independent contractor.

e third factor is the “degree of permanence of the work relationship.” If the work is inde nite, continuous, or exclusive in nature, this factor will weigh in favor of the worker being classi ed as an employee.

e DOL clari es in the rule that seasonal or temporary work, which is a portion of the jobs in the agricultural workforce, does not by itself indicate that a worker should be classi ed as an independent contractor.

e fourth factor is the “nature and degree of control” the employer exercises over the worker. ere are several facts that can be relevant to determine if this factor weighs in favor of employee or independent contractor classi cation, such as whether the employer sets the worker’s schedule, supervises or disciplines the worker, controls the prices or rates for the worker’s services or products the worker provides, and limits the worker’s ability to work for others.

e h factor is the “extent to which the work performed is an integral part of the potential employer’s business.” If the function the worker performs is an integral part of the business, this factor weighs in favor of classifying the worker as an employee. e DOL provided an example of how this factor applies: “A large farm grows tomatoes that it sells to distributors. e farm pays workers to pick the tomatoes during the harvest season. Because a necessary part of the tomato farm is picking the tomatoes, the tomato pickers are integral to the company’s business. ese facts indicate employee status under the integral factor.”

e last factor is “skill and initiative.” If the worker depends on the potential employer to provide training and/or does not use a specialized skill, this factor points to the worker being classi ed as an employ-

ee. Although employees and independent contractors can use a specialized skill, if the specialized skill is used in a business-like manner, the worker is likely an independent contractor.

e nal rule went into e ect March 11, 2024.

Looking Forward

Overall, the DOL’s 2024 nal rule requires employers to use the six-factor framework to properly classify workers as employees or independent contractors. Currently, there is at least one legal chal-

lenge to DOL’s 2024 rule (Warren v. U.S. Dep’t of Labor, 2:24-cv-00007, N.D. Ga.).

Nevertheless, the worker classi cation test established under the nal rule was set to take e ect March 11, 2024, where employers will be expected to classify workers under these new guidelines. Employers that misclassify workers may be required to pay unpaid wages owed to the employee, civil money penalties, and/or attorneys’ fees associated with litigation.

INSTAGRAM: @RICEFARMING APRIL 2024 | RICE FARMING 11

Always read and follow label directions. TENCHU is a registered trademark of Mitsui Chemicals Crop & Life Solutions, Inc. ©2024 Belchim Crop Protection USA, LLC. EPA Reg. No. 86203-25 Contact your local retailer or email:info.usa@belchim.com TENCHU® 20SG is Available and Ready to SHIP! Kill Pyrethroid Resistant Rice Stink Bugs. Prevent Peck Damage. Greater ROI, With JUSTONEAPPLICATION Of TENCHU® 20SG!

is article is provided by the National Agricultural Law Center.

MSU Extension Names New Delta Region Coordinator

The Mississippi State University Extension Service’s Delta region will soon have new leadership.

Alex Deason, who has been an MSU Extension agent based in Sunflower County since 2013, began his new role as regional coordinator March 16.

Regional Extension coordinators provide leadership for MSU’s outreach efforts in its four regions and provide administrative direction to Extension agents in the development, implementation, and evaluation of Extension’s educational programs. The primary objective of each program is to improve economic and social conditions in the county, region, and state.

As an MSU Extension agent, Deason delivered educational programming in agriculture and natural resources as well as 4-H youth development. He holds a master’s degree in agriculture and Extension education and a bachelor’s degree in agricultural sciences, both from MSU.

“Alex is committed to helping Mississippians better themselves. As an Extension agent for over a decade, that’s exactly what he’s done,” said Steve Martin, associate director of county operations for MSU Extension. “His demonstrated ability to lead and help others make positive changes will be a great benefit to our Delta clients.”

Deason replaces Lance Newman, who had served in an interim role since 2022 while retaining his duties as coordinator of MSU Extension’s Lafayette County office. Newman was named regional coordinator for MSU Extension’s northeast region late last year.

“Alex has all the qualities you want to see in an Extension agent, and this role gives him an opportunity to pass his positive attributes on to other agents in the Mississippi Delta,” said Angus Catchot, director of MSU Extension. “He will be a tremendous asset to our leadership team.”

The counties in the Delta Region of MSU Extension include DeSoto, Tate, Tunica, Panola, Quitman, Coahoma, Tallahatchie, Bolivar, Sunflower, Leflore, Grenada, Montgomery, Carroll, Holmes,

Humphreys, Washington, Sharkey, Issaquena, and Yazoo.

MU Pesticide Safety Program Vital to State’s Ag Economy

Sam Polly, coordinator of University of Missouri Extension’s Pesticide Safety Education Program, wants to make Missouri a safer place that allows Missouri’s agricultural economy to continue to grow.

Polly says the program is the backbone of agricultural and commercial pest management in Missouri. Agriculture, forestry, and fisheries contribute $369 million annually to the state’s economy.

MU Extension and the U.S. Environmental Protection Agency observed National Pesticide Safety Education Month in February to raise awareness for pesticide safety education and shared best practices for using pesticides in and around the farm and home.

In 2023, Polly and his team taught more than 3,300 people at 130 private applicator training programs and 1,600 people at 35 commercial applicator trainings statewide.

Licensed commercial applicators must pass an exam and participate in continuing education courses on environmentally sound uses of pesticides. The Missouri Department of Agriculture’s Bureau of Pesticide Control mandates commercial applicator training.

Polly’s MU Extension team includes agronomists, agricultural engineers, horticulturists, and specialists in natural re-

sources. Daniel Sjarpe serves as assistant coordinator.

In 2023, the team developed, updated, or supplemented 18 of the 21 pesticide training manuals needed for Missouri applicators to comply with new federal regulations. The team also created an online private applicator certification/recertification portal for on-demand training.

In addition to teaching pesticide safety to adults, Polly and his team also taught younger groups through 4-H and FFA.

Polly suggests reviewing these tips during National Pesticide Safety Education Month:

■ Always read and follow the labels on pesticides.

■ Store pesticides in their original containers with proper labels.

■ Store pesticides out of the reach of children and pets.

■ Use the amount specified on the label. Using more will not be more effective and may harm you, your loved ones and the environment.

■ Wash hands with soap and water after using pesticides. Wash clothes that have been in contact with pesticides immediately and separately from other items.

■ Don’t let children and pets enter sprayed areas while they are still wet.

■ Keep pesticides away from food and dishes.

To learn more, search for “pesticide safety” at https://extension.missouri.edu or visit https://www.epa.gov/pesticides.

12 RICE FARMING | APRIL 2024 RICEFARMING.COM

Industry News

Alex Deason

Agronomist Nick Wesslak is part of a team of MU Extension specialists that presents pesticide safety training to adults and youths in Missouri. In 2023, the team, headed by Sam Polly, taught more than 3,300 people at 130 private applicator training programs and 1,600 people at 35 commercial applicator trainings statewide.

PHOTO COURTESY OF SAM POLLY

Experimenting with CO2 Sensors for Grain Bin Quality Control

Sinking Mississippi River levels in recent years have caused grain shipping disruptions, prompting farmers to pursue on-farm grain bins to preserve quality and market potential.

“Storage is becoming a critical thing,” said Griffiths Atungulu, director of the Rice Processing Program for the University of Arkansas System Division of Agriculture. “Even in just the Delta, the farmers I visit every year have added one bin, and some of them have doubled their number of bins. That tells me how critical it is becoming for them to have their own storage.”

The Rice Processing Program aims to help farmers maximize the value of their stored rice by developing recommendations for reducing moisture and monitoring quality. To that end, Atungulu has recently begun experimenting with carbon dioxide sensors to improve on-farm grain bin quality control.

Atungulu is an associate professor of food science for the Arkansas Agricultural Experiment Station, the research arm of the Division of Agriculture. As an agricultural engineer, he specializes in grain processing and post-harvest system engineering.

Temperature and moisture sensors attached to thin cables hanging from a grain bin’s roof are currently the most advanced monitoring system for on-farm grain bins. Carbon dioxide sensors have the potential to serve as a relatively inexpensive upgrade to go with the cables, Atungulu says.

He hypothesizes that carbon dioxide sensors can detect the presence of mold and insect pests in rice before they become a significant problem. However, the temperature sensors on the cables help determine the area in the grain bin where the abnormality is located. A farmer could decide whether to move out all the grain or just a portion.

Upgrading Technology

The cable systems that now serve as the bin’s moisture and temperature sensors aren’t perfect. The force that grain places on them creates the potential to collapse a grain bin’s roof. The temperature and moisture sensors on cables are also prone to being clogged by dust and can malfunction over time.

In the future, Atungulu envisions adapting high-frequency wavelength technologies to detect temperature and moisture.

“Our research is focused on what we can do to make sure that rice, when it comes in at a higher moisture content, is dried effectively, the best way possible, and then after drying it, the quality of that rice can still be maintained,” Atungulu said.

Atungulu has previously conducted extensive research on calibrating temperature probes on cables, predicting temperature changes in grain bins, and guidelines for drying rice in on-farm bins for storage.

Mini Grain Bin from Brazil

A miniature grain bin, about the size of a residential water heater tank, is currently housed at the experiment station’s food science pilot plant in Fayetteville. Built by Garten Automation in Brazil, the little grain bin has a carbon dioxide sensor at the top, temperature sensors on simulated steel cables, and a control panel that allows for remote computer monitoring. A false bottom and air inlet also allow for a fan for drying.

Atungulu toured rice processing facilities in Brazil’s Rio Grande do Sul area last year. He also presented on American rice processing research as the international guest speaker at the Conecta Grano Safe 2023 conference.

University of Arkansas Ph.D. student

Samuel Olaoni is conducting experiments on the mini grain bin to test for correlations between temperature and carbon dioxide increases and relationships between insect growth and carbon dioxide dynamics.

“The carbon dioxide sensors look promising, but they can’t stand alone because they can’t tell us exactly where the problem is,” Atungulu said. “Integrating both the cables and the carbon dioxide sensors can move the industry in a better direction than just having one system.”

Eventually, Olaoni and Atungulu can look at how the grain quality changes with those insect and carbon dioxide dynamics.

— John Lovett, University of Arkansas System Division of Agriculture

INSTAGRAM: @RICEFARMING APRIL 2024 | RICE FARMING 13

Industry News

OF A SYSTEM DIVISION OF

Griffiths Atungulu, left, director of the Rice Processing Program, works with Samuel Olaoni, Ph.D. student, on a miniature grain bin to test carbon dioxide sensors for monitoring grain quality.

U

AGRICULTURE

Submit a nomination for the 2024 Rice Consultant of the Year Award.

Recognize an outstanding consultant for his or her dedication, leadership and innovation in the U.S. rice industry.

For more information, go to ricefarming.com/rcoy or go toPage 15in this issue of Rice Farming.

Submit nominations by July15, 2024.

New Weed in California Rice: White Water Fire

By Whitney Brim-Deforest University of California Cooperative Extension

White water re (Bergia capensis) was found in September 2023, by the Butte County Agricultural Commissioner’s o ce in a Butte County rice eld. e weed was identi ed by the California Department of Food and Agriculture. It is the rst nd of this weed in California, and possibly in the United States. It is native to Africa, southern China, and tropical Asia. It is known to be in rice elds in Europe, Central and South America, as well as the Caribbean.

is weed was found in one rice eld, and the Agricultural Commissioner’s o ce surveyed surrounding elds but found no additional infestations. e introduction method in California is currently unknown.

It has a “Q” rating by CDFA: “An organism or disorder suspected to be of economic or environmental detriment, but whose status is uncertain because of incomplete identi cation or inadequate information”. At this point, it is not considered a quarantinable pest, so if it is found, there is no penalty or restriction for nding it in a eld.

Identification

White water re looks similar to another common rice eld weed, redstem (Ammania spp). However, the two species are not from the same plant family and are not closely related. Due to the similarity, white water re is di cult to identify in the eld. One key distinction is the thickness of the leaves, which are much broader in white water re than in redstem. Another key distinction is ower color. e ower color of white water re is white, whereas redstem can have either purple or red owers.

Possible control

UCCE will be scouting and collecting seeds in the previously infested eld again in 2024. In other countries, pretilachlor has been used, as has metsulfuron. However, neither of these products are registered in California rice, although some herbicides in the same mode of action are registered and may be e ective. Extensive testing with

registered herbicides and herbicides in the registration pipeline will need to occur before recommendations are made.

Currently, the best recommendation for control is to hand-rogue (pull) out the plants. Other recommendations are to thoroughly clean equipment between elds when moving from an infested eld to a non-infested eld.

Reporting

If you suspect you have this plant in your eld, please give your nearest Rice Farm Advisor a call. ey can assist with identication, as well as control strategies.

14 RICE FARMING | APRIL 2024 RICEFARMING.COM

™ Trademark of Corteva Agriscience and its respective owners. ©2024 Corteva. SPONSORED BY

Abbreviated Rules. No Purchase Necessary. Contest ends on 7/31/24 at 11:59:59 PM (CT). To enter, go to http://www.ricefarming.com/rcoy. Nominators must be legal residents of the fifty (50) United States and District of Columbia who are 18 years of age or older at the time of entry and possess knowledge and/or experience in the rice farming industry. Entrants must be legal residents of the fifty (50) United States and District of Columbia who are 18 years of age or older at the time of entry and serve as a rice consultant in the rice farming industry.Void where prohibited. Sponsor: Corteva Agriscience, 9330 Zionsville Road, Indianapolis,IN 46268. Scan here to see previous RCOY Award winners. Or visit Corteva. us/2024RCOY

Redstem (Ammania coccinea)

White water fire (Bergia capensis) TROOS VAN DER MERWE JENNIFER MO

Nominate

NOMINATION FORM

an outstanding consultant for the Rice Consultant of the Year Award

Sponsored by Corteva Agriscience and Rice Farming magazine, the annual award recognizes the dedication, leadership and innovation of this crucial segment of the U.S. rice industry.

“Corteva Agriscience™ is committed to rice consultants and the key role they play in agronomic guidance and support,” said Drew Clark, Corteva Agriscience product manager, rice and cereals.

“As the sponsor of the Rice Consultant of the Year program, Corteva is honored to recognize consultants who continuously strive to impact the rice industry and their local communities,” he said.

The RCOY Award recipient will:

Be featured in a four-page salute in the February 2025 Rice Farming magazine and honored at a special recognition event Feb. 27, 2025.

Receive a personalized Rice Consultant of the Year jacket.

The award recipient and nominator each will receive two night’s hotel stay and round-trip travel to the event.

SUBMIT SUPPORTING DOCUMENTATION

Please use a separate page for biographical/professional information.

Additional recommendation letters from rice farmers, consultants and industry members in support of the nominee are encouraged.

Submit all materials via:

Email: csmith@onegrower.com

Mail: Carroll Smith 7201 Eastern Ave. Germantown, TN 38138

Online: ricefarming.com/rcoy

Submit nominations by July 15, 2024.

Consultant’s Name:

Company Name:

Please describe the dedication, leadership and innovation that makes this person a good candidate for the 2024 Rice Consultant of the Year Award. (Be as specific as possible, and use a separate sheet, if needed.)

Your Name: Address:

Mailing Address: City: State: ZIP: Phone: Email:

City: State: ZIP: Phone: Email: SPONSORED BY ™ Trademark of Corteva Agriscience and its affiliated companies. ©2024 Corteva. Abbreviated Rules. No Purchase Necessary. Contest ends on 7/31/24 at 11:59:59 PM (CT). To enter, go to http://www.ricefarming.com/rcoy. Nominators must be legal residents of the fifty (50) United States and District of Columbia who are 18 years of age or older at the time of entry and possess knowledge and/or experience in the rice farming industry. Entrants must be legal residents of the fifty (50) United States and District of Columbia who are 18 years of age or older at the time of entry and serve as a rice consultant in the rice farming industry. Void where prohibited. Sponsor: Corteva Agriscience, 9330 Zionsville Road, Indianapolis, IN 46268.

Or

Scan here to see previous RCOYAward winners.

visit Corteva. us/2024RCOY

A California Legacy and Collaboration

Working as a Team to Find Ways to Improve

By Cassidy Nemec Editor

Brian McKenzie is a fourth-generation rice grower and California native. While he at first had his sights set on a corporate occupation, he is now sitting around the 20year mark for growing rice and has not regretted that choice.

“I had some really good people I worked for out of college who were not in agriculture, and I learned a lot from them, but the farm life — where you’re more in control of your own successes and failures — seemed like a no brainer. At 18, I didn’t want to do it; at 22, there was no place I’d rather be.”

Some History and the Operation

McKenzie said his great grandfather began growing rice in the 1950s, and his grandfather and father followed suit before he continued the tradition. Kent McKenzie, McKenzie’s uncle, served at the California Rice Experiment Station for 32 years before his retirement.

When McKenzie began growing rice, they had around 1,500 acres. That has expanded considerably into four counties — Sutter, Sacramento, Placer, and Yolo — with the support of great landowners all near Sacramento, California.

“The whole rice market has been fairly strong throughout that time,” McKenzie said.

His dad Chris is still involved as well as his partner Brian Barrett, a 2012 Rice Leadership Development Program graduate. They have 10 employees to help across those four counties.

“Sutter County is where we will start,” McKenzie said. “If you try to start at one place and march through your fields, you could potentially need to keep restarting. When you're working everything at the same time regionally, you have a better chance of not needing to rework those fields or having a higher number of acres being planted than having to be reworked.”

McKenzie noted that rice, while not as labor-intensive as some other crops, can be a complex crop. “There’s a lot of moving parts on a rice operation. You need a lot of employees — there’s a lot of equipment, a lot of upkeep, a lot of maintenance — and it can be difficult to find those employees. You want to keep good people around as long as you can.”

Calrose varieties M-105, M-206, and M-211, as well as Calaroma 201, are all grown as paddy rice for consumption and as seed production.

“Our soils are all different, but what makes them all suitable

for rice production is the fact that they have a lot of clay and hold water really well.," he said.

As far as technology goes, McKenzie said they run auto-steer on all their tractors. “This lessens our time in the fields as it’s more precise in your spacing and passes.”

In addition, they run yield monitors in all of their harvesters, use GPS for leveling, and make use of variable rate on spraying and fertilizer applications.

He said challenges fluctuate from year to year, but supply and demand impacting prices always seems to take the biggest precedence. “It starts at the beginning of the year with anhydrous prices and natural gas prices. Everything was obviously really high in 2022, so it was nice that it came down a bit in 2023.”

Urban sprawl is an another area of concern for their operation.

16 RICE FARMING | APRIL 2024 RICEFARMING.COM

Brian McKenzie (left) and Drew Mullaney have worked together since 2016 on McKenzie’s rice operation. Together, they find what works best management-wise year-to-year based on the challenges and opportunities at hand.

CASSIDY NEMEC

“We have a lot of urban pressure around here,” McKenzie said. “We’ve lost a lot of farm ground. There’s just pressure from West Roseville and Sacramento coming this way.”

In addition to these challenges, McKenzie said they also face water rights being challenged, off-and-on drought issues, and the continued disconnect people have from their food.

Despite all the difficult demands of the job, McKenzie sees the bright side.

“Someone once told me, ‘Good price — grow a good crop. Bad price — grow a good crop.’ Because that’s all you can do,” he said. “To me, the most rewarding thing is when you’re harvesting and you see all the work you’ve done hopefully equate to a good yield because I can’t control the price.”

The Grow West Connection

Drew Mullaney, a pest control advisor at Grow West, has worked with the company for a total of 10 years now, five years with them as a retail PCA. Before he was a licensed PCA, he worked on the service side of the Grow West operation that included supplying customers with equipment for fertilizer and chemical applications, coordinating with growers to assist in the delivery of products, and maintaining a wide range of equipment the company has available to its customers.

Grow West, formerly a large group of individual and integrated companies, is an independently owned and operated agribusiness organization composed of agronomic, financial, and retail services along with a variety of other offerings.

Mullaney's grower territory expands from Marysville, California, to south Davis, California. He said what he sees on McKenzie’s ranch can vary from year to year.

"Early in the growing season, the almost-inevitable North

winds during planting make establishing a stand in a water-seeded environment very challenging. From the day the water meets the seed bed, the biggest hurdle we face is the wide range of evolving weed species. Both grasses and broadleaf infestations pose a threat to the yields and quality of our product. Not only are the pre and postemergent herbicides expensive, but we have a limited amount of chemistries avaliable to the California rice market."

Mullaney said they do not have many new chemistries on the horizon.

"The most effective tool we have is precise water management," he said. "Irrigation is often overlooked, but it is everything in my opinion. Alongside of the weather conditions God hands us early on, we are keeping a close watch on damage caused by rice water weevil, tadpole shrimp, and rice seed midge. If we see an issue, we will treat for these pests."

“Everybody farms different types of soils," McKenzie said. "Here we have very light to very heavy soils. The weeds that come with those are different and their timings are different, so that can create a problem for Drew looking at everything out here.”

He said that encroachment has changed the way they are able to do things. “Applying chemical and fertilizer by air has always been the most effective and preferred method to apply products into a flooded environment like a rice field. However, it seems we are continually losing air zones due to urban sprawl and increased buffer zones to sensitive crops. Aerial applications are a critical piece of the entire rice puzzle.”

Mullaney said he most enjoys seeing his customers succeed and be profitable in their operation.

Sustainability as a Two-Way Street

“In California, we hear sustainability as, ‘Oh, this isn’t good for

INSTAGRAM: @RICEFARMING APRIL 2024 | RICE FARMING 17

When McKenzie began growing rice, they had around 1,500 acres. That has expanded considerably over four counties — Sutter, Sacramento, Placer, and Yolo — all near Sacramento, California.

DREW MULLANEY

the environment,’ but sustainability has to work for the farmer, too,” McKenzie said.

He then discussed the sustainability measures they do employ on their operation.

“ e water bird program is something we participate in. A er the crop is harvested, we chop the remaining rice straw and disc the elds to incorporate the remaining organic matter. Once this is nished, we reintroduce a ood water back across the elds, which provides a desirable habitat and food source for birds migrating along the Paci c Flyway.”

On the farm, they level every acre of every eld to conserve water and precisely irrigate their elds. “It's tough to quantify, but just imagine an inch of water over 10 acres — or 4,000 acres — that’s a lot of water,” McKenzie said.

He said they can level and relevel these elds at a rate of about eight acres per hour.

“ e initial cost of GPS is a big investment, but the accuracy it provides is worth the capital.”

“ ere are so many factors that go into a bumper crop yield — from the groundwork, to the herbicide program, to the water, to the timings — so many little things that you take for granted sometimes, and the one thing the farmer can't control is the weather. is is just as crucial of a factor as any,” McKenzie said.

Mullaney said they do periodic soil sampling on the farm as well. “We do our best each year to make sure we are replacing the macro and micro nutrients the previous crop mined out of the soil.”

Industry Involvement and Hopeful Mindsets

McKenzie participated in the 2018-2020 USA Rice Leadership

McKenzie noted that rice, while not as labor-intensive as some other crops, can be a complex crop. “There’s a lot of moving parts on a rice operation. You need a lot of employees — there’s a lot of equipment, a lot of upkeep, a lot of maintenance — and it can be di icult to find those employees. You want to keep good people around as long as you can.”

“Someone once told me, ‘Good price — grow a good crop. Bad price — grow a good crop.’ Because that’s all you can do.

To me, the most rewarding thing is when you’re harvesting and you see all the work you’ve done hopefully equate to a good yield because I can’t control the price.”

Development Program Class and is on multiple USA Rice committees. He is also on the Rice Research Board and California Rice Commission. He said the leadership program gave him a better understanding of what others in di erent rice-producing states are going through and how they all t together.

“ e economics [in those other states] can look substantially di erent than ours. Practices such as maintaining water on the eld nearly all year could negatively impact others in areas like Texas where water is very expensive,” he said.

In addition to these, McKenzie also grows and sells seed rice to around 30,000 acres-worth of California rice growers.

ROXY rice is of great interest to McKenzie and Mullaney.

“Having this chemistry as a tool and something for rotation herbicide-wise, even if it’s not for the whole California crop, would be great,” McKenzie said.

He also said they tried some dry-seeded rice and are looking forward to seeing what they can improve with that in future years.

Mullaney said he appreciates the general comaraderie the agricultural industry shares and how nice it is to be able to work outdoors for a living. “Without guys like Brian, our business doesn’t exist. e farmer's success is our success.”

McKenzie said he most enjoys getting to see the di erent stages of sunrises throughout the season, especially once the water hits the eld. He said he would like to continue to be rewarded with good pricing and a good future.

“In the long run, I’d like farming to be a viable and pro table option for my son if he chose to pursue it.”

RICEFARMING.COM

DREW MULLANEY

A Quick Look at the 2024 Rice Market

By Ryan Loy University of Arkansas Division of Agriculture

Following two consecutive years of decline (see Figure 1), United States rice production increased to roughly 2.9 million acres in 2023. In 2022 and 2023, the world was consuming more rice, which showed up in the long grain rice Marketing Year Average Prices (MYAP) of $16.70/cwt and $15.7/ cwt, respectively. Production increases in 2023 (see Figure 1) followed 2022 high prices that were last seen around harvest of 2013. Fast forward to March 2024, where the then current November rough rice futures contract was trading at $14.66/cwt. The November contract price decline has been steady since late December 2023 but has recently begun to increase again ($0.44/ cwt since Feb. 27, 2024).

There was an extreme multi-year drought in California during the 2022 growing season. During this time, California rice producers could not plant nearly 300,000 acres, due to a lack of water for irrigation. Arkansas (a state that almost exclusively grows long-grain varieties) responded by increasing its acreage of medium-grain rice by 55,000 acres in 2023. However, California rebounded in 2023 and surpassed 500,000 acres of medium-grain rice. An abundance of medium-grain rice could hinder any upside price potential if the demand for medium-grain remains at normal levels.

An Eastern Pacific El Niño has also disrupted off-season rice production for Thailand, Burma, and Indonesia. These countries rely on off-season production to improve their stocks and export amounts. Now, they face extreme drought, impacting yields and production, and may not have enough carry over and ending stocks to bring rice to the global economy. The U.S. Department of Agriculture forecasts that global rice production for 2023/24 will exceed 2022/23 by only 0.1% (583,000 metric tons). Thus, the El Niño conditions are poised to further tighten global rice supplies in these major exporting countries.

Global rice supplies are also strained from India’s July 2023 export ban on non-basmati rice. The ban was implemented to help lower domestic rice prices and to

Figure 1. U.S. Rice Production, Exports, and Stocks.

Source: USDA-FAS, 2024

Figure 2. India Rice Exports.

Source: International Food Policy Research Institute, 2024.

ensure rice availability in India. On a global scale, India accounted for nearly 40% of all rice exports in 2022, further showing the global impact of India’s exports. Referring to Figure 2, the ban forced a 93% decline in non-basmati rice exports between August and November of 2023. Importing countries are now forced to turn to alternative suppliers to meet their rice demands. It’s worth noting that India is currently in an election year and it’s doubtful the ban would be lifted before a general election in April or May. If the ban is lifted post-election, watch for Indian rice to flood the market and put further downward pressure on global rice prices.

Overall, the 2024 rice market will be extremely sensitive to ongoing global conflicts, weather, government policies, and shipping issues such as low water levels in

the Panama Canal, a potential return to low water levels in the Mississippi River, and conflicts in the Red Sea. There could continue to be opportunities in the export market should Mississippi River levels stabilize during harvest and if India’s export ban continues. With it being early in the season, it’s worth highlighting that on a per-bushel basis, the recent soybean-to-rice price ratio for November 2024 delivery was 1.78 ($11.73/$6.60). This ratio has continued to decline since 2021, when the ratio was 2.41. All to say that the relative prices of other commodities, such as soybeans, are in a similar declining price environment as rice.

This article is provided by Southern Ag Today. For the full article with references, visit www.southernagtoday.org.

INSTAGRAM: @RICEFARMING APRIL 2024 | RICE FARMING 19

Seeding Rate Work in Furrow-Irrigated Rice

DR. JUSTIN CHLAPECKA MISSOURI

DR. JUSTIN CHLAPECKA MISSOURI

Assistant Research Professor/ Rice Extension Specialist University of Missouri jchlapecka@missouri.edu

We recently wrapped up the “meeting season” circuit, where it seems like we speak about every other day on various research topics that we’ve been looking at throughout the year(s). While meeting season is a great avenue to exchange ideas with other researchers, farmers, consultants, and retailers, I believe most of us are sitting around looking at the calendar and sitting on go. Recent bouts of dry weather and 75 degree+ temperatures through February and March have my internal clock thinking it’s a lot later than it actually is.

e meeting circuit this winter included various destinations in Missouri, Arkansas, and even California. e No. 1 topic coming out of the Missouri rice research program is the possibility of increasing yield potential in furrow-irrigated rice through variable rate seeding technology. Small plot research for two years in a row has consistently shown that increasing seeding rate beyond current recommendations in non- ooded portions of the eld can increase yield potential.

While signi cantly increasing the eld’s overall seeding rate is likely not economically bene cial, especially with $6.50 per bushel rice, shi ing seed to where it can have a greater positive impact on yield is something that we will continue to look at in the next few years. e same seeding rate studies that have shown a positive relationship between seeding rate and yield beyond the current seeding rate recommendations have also suggested that it is much more di cult to get the same response in ooded portions of the eld, i.e. the bottom of the eld.

Pretty much every cultivar we have tested, whether it be hybrid or inbred variety, appears to have no negative response when decreasing seeding rates by 10% to 20% from recommended. I have spoken with several farmers and consultants over the past few weeks who plan to try out a eld or two with a 10% to 20% decrease at the bottom of the eld and a 10% to 20% increase at the top of the eld, leaving the middle third at the recommended or average rate. I would caution individuals to not drop the seeding rate by any more than 20% due to the potential for a weak or patchy stand in areas. Keep in mind that you know your eld better than anyone when deciding whether seeding rate could be reduced and still obtain an adequate stand.

is year should be a good indicator of what, if any, seeding rate tweaks need to be made in furrow-irrigated rice. We plan to do several larger-scale tests ourselves, in cooperation with the University of Arkansas, to see if the small plot data will translate to production-sized elds. If you’ve got any questions or would like to participate, don’t hesitate to give me a shout. As always, God bless and eat MO rice!

APRIL 2024

Specialists Speaking

JUSTIN CHLAPECKA

Water Seeding Rice

DR. RONNIE LEVY

LOUISIANA

Extension Rice Specialist

Louisiana State University

RLevy@agcenter.lsu.edu

Extreme wet conditions or red rice weed suppression are conditions that encourage water seeding. The most common water-seeding method is the pinpoint flood system. After seeding, the field is drained briefly. The initial drain period is only long enough to allow the radicle to penetrate the soil (peg down) and anchor the seedling. A threeto five-day drain period is usually sufficient under normal conditions.

The field is then permanently flooded until rice nears maturity (an exception is mid-season drainage to alleviate straighthead). In this system, rice seedlings emerge through the floodwater, and seedlings must be above the water surface by at least the fourleaf rice stage. Before this stage, seedlings normally have sufficient stored food and available oxygen to survive.

Atmospheric oxygen and other gases are necessary for the plant

Water Right, Water Light

DR.

JARROD T. HARDKE

ARKANSAS

Professor/Rice Extension Agronomist

University of Arkansas System Division of Agriculture

jhardke@uada.edu

Alternate wetting and drying (AWD) can be a useful tool to reduce water use and greenhouse gas emissions. As a result, a number of programs are incentivizing this practice. In cascade flooded systems, benefits can be realized, but it’s harder to implement effectively. Full benefits and reduced risk are most often realized in fields using multiple inlet rice irrigation (MIRI) or zero grade.

To use AWD properly, we need to avoid: 1) having to reflood too soon after establishment of initial flood and preflood nitrogen (N) application; 2) drought stress at ½” internode elongation; and 3) drought stress at flowering and grain fill.

The first big risk is N loss — it’s not the loss of the initial flood that causes N loss, but rather the reflooding event. We want to maintain the initial flood for around three weeks and avoid having to reflood until closer to four weeks; and be re-flooded prior to ½” IE. By four weeks, rice has fully taken up preflood N.

Then after ½” IE, we have a window of a few weeks for another drying event prior to flowering. Drought stress at ½” can impact grain and panicle formation. Drought stress from flow-

to grow and develop. The pinpoint flood system is an excellent means of suppressing red rice emergence from seeds in the soil because oxygen necessary for red rice germination is not available as long as the field is maintained in a flooded (or saturated) condition.

ering through grain fill can impact pollination and complete grain fill.

So ultimately, there are two reasonably safe windows to accomplish drying events for flooded fields. The first between initial flood and ½” IE and the second between ½” IE and flowering.

Note that a “drying” event isn’t really trying to get the soil dry; it can still be tacky to muddy. If you use a Pani pipe to monitor water levels, we only want to see the water depth fall about two inches below the soil surface in the upper side of the paddy (bottom still flooded). Soil type and other factors affect this recommendation, but for general management and crop insurance purposes, a two-inch depth should be used.

Some type of tool, whether Pani pipe or soil moisture sensor, should be used to monitor changes in soil moisture in the field. Flying blind for these practices can make realizing their full benefit much more difficult.

Weed control in an AWD system should not generally differ from your regular program. If following these guidelines, soil will remain flooded to mostly saturated, which will minimize the chances for additional weeds to emerge. Overdrying the soil, however, could result in additional escapes.

When used properly, AWD maintains maximum yield potential while reducing water use and pumping costs (win-win). If attempting AWD on levee fields, it is best to use MIRI rather than to cascade flood. For help with implementing these practices, contact your local county Extension agent as well as irrigation and agronomy specialists to maximize your benefit and minimize risk.

INSTAGRAM: @RICEFARMING APRIL 2024 | RICE FARMING 21

Specialists Speaking

RONNIE LEVY

Seedbed preparation is somewhat different when water seeding is used compared with dry seeding. With water seeding, the seedbed is left in a rougher condition than for dry seeding. A flood is established, and rice is seeded within three to four days. This will reduce potential weed problems and provide a more favorable oxygen situation at the soil/water interface. Low oxygen levels are often a problem where floodwater is held for a long time before seeding.

A preferable alternative to a rough seedbed is preparation of a seedbed similar to that for drill seeding. The seedbed is firmed with a grooving implement, resulting in a seedbed with grooves (one to two inches deep) on seven- to 10-inch spacings. In some situations, a field cultivator can achieve the desired grooves.

Conservation tillage has gained acceptance in many rice-growing areas. No-till and reduced-tillage systems, such as fall- and spring-stale seedbeds, have been shown to significantly improve the quality of floodwater being removed from rice fields by reducing sediment losses. Research has established the advantages and disadvantages of reduced-tillage rice production, and it has identified stand establishment and early season plant density as critical components of managing a reduced-tillage rice production system. The stale seedbed system, however, offers one important benefit; during wet springs it improves the likelihood of timely planting. Time, money, and labor are conserved by controlling preplant vegetation with a burndown herbicide rather than waiting for the seedbed to dry for planting when excessive rainfall occurs.

Inadequate stand establishment is a common problem in water-seeded and conservation tillage rice, especially in a pinpoint flood system. The seeding rate when water seeding is 80 pounds to 120 pounds compared to 50 pounds to 80 pounds when drill seeding. Where seed depredation by blackbirds is potentially high, use a higher seeding rate and consider using a bird-repellent seed treatment.

Insect Management

DR. LUIS ESPINO

DR. LUIS ESPINO

CALIFORNIA

Rice Farming Systems Advisor

University of California Cooperative Extension

laespino@ucanr.edu

Arthropods have not been very problematic in California the past few years. However, do not let your guard down and let the bugs catch you unprepared. The tadpole shrimp is our key pest. Shrimp tend to be a problem in the same fields year after year because their eggs remain in the soil from one season to the next. Make sure to scout fields soon after seeding, maybe even before seeding, especially fields that take more than a few days to flood. Tadpole shrimp eggs hatch very soon after the field is flooded, and the young shrimp grow quickly. Seeding into a field with shrimp present, even small shrimp, is asking for trouble. Small shrimp (about half an inch or less) can injure

Rice seed midge tubes in an affected field. Notice the tube attached to the damaged seed in the middle of the picture.

rice, just not as much as larger shrimp. Also, do not just rely on the muddiness of the water. When they are small, shrimp do not disturb the soil much; therefore, you might not see muddy water even though shrimp are present.

Another arthropod that can be problematic in California is the armyworm. Many fields had significant yield losses during the outbreak of 2015. We have not seen a similar outbreak since, but in some years, worm numbers have been high. I have been monitoring armyworm moth populations with pheromone traps across the rice area since 2018. Last year we had the highest moth numbers we have ever seen, but that did not translate into high worm numbers in the field. In fact, the worm pressure was very low. While the traps do not predict worm numbers, they can help us improve the timing of scouting. We know that we will see the highest worm numbers one to two weeks after the moth numbers peak. With Intrepid now fully registered for use in rice, we have a good tool that we can use to control armyworm populations if they get out of hand. You can sign up for my armyworm updates on the University of California rice website.

The last pest that can be of concern is rice seed midge. In the past three years, we have seen some fields suffer stand reduction due to midge. This is a difficult pest to manage given its sporadic nature. Ian Grettenberger, UC Davis Extension entomologist, has been doing insecticide trials for midge control. His work shows that pyrethroids are not very effective against midge, but at this point, it is the only tool we have. Like tadpole shrimp, rice seed midge can be worse in fields that take a long time to flood. Also, late-planted fields are at more at risk. Scout your field right at seeding and for the next few days, looking for the silken tubes rice seed midge form on the soil surface and inspecting seed looking for injury. If there is enough injury to reduce the stand significantly, use an insecticide. A brief drain will also work; however, take into consideration any effects the drain may have in weed control and fertility.

22 RICE FARMING | APRIL 2024 RICEFARMING.COM

Specialists Speaking

LUIS ESPINO

Scan the QR code with your phone to renew today for FREE! To advertise, contact Associate Publisher/Sales Scott Emerson, 386-462-1532 or semerson@onegrower.com ricefarming.com RiceFarming1 @RiceFarming @RiceFarming