Season four of The Cotton Board’s Cotton & Coffee Zoom series is underway. This series asks the cotton-growing community to wake up with The Cotton Board, and in the time it takes to drink a morning cup of coffee, get an update from the Cotton Research and Promotion Program. This is a great way to see how the assessment dollars collected by The Cotton Board are being spent to increase the demand for and profitability of cotton. Each virtual Zoom session includes a 30-minute presentation and concludes with time for discussion and questions. Cotton & Coffee is held on the third Tuesday of each month at 7:30 am Central. Pre-registration is required, so please visit cottonboard.org/cotton-coffee if you'd like to register and participate.

COTTONBOARD.ORG/COTTON-COFFEE

COTTONBOARD.ORG/COTTON-COFFEE

Mark Yeager and his two sons, Mark Jr. and Joe, grow cotton and corn and raise cattle at the foot of the Bankhead National Forest in North Alabama. In 1994, Mark built his own gin, which gave him more control over the quality of their cotton. He also collaborated with his daughter, Anna, as well as the rest of the family, to create heirloom-inspired cotton linens sold under the brand Red Land Cotton.

ON THE COVER: Father-daughter duo — Mark and Anna Yeager — established Red Land Cotton in Moulton, Alabama. Cover photo by Cassidy Nemec.

As harvest season approaches, Camp Hand, University of Georgia Extension cotton specialist, o ers tips for successful cotton defoliation.

Randy Norton, Arizona cotton specialist, describes the e ects of heat stress on cotton during Arizona’s low desert monsoon season.

Texas A&M AgriLife sits down with Ben McKnight to discuss what the path from Texas A&M student to AgriLife Extension specialist looks like.

the official publication of the ginning industry TCGA summer interns share their mid-term reports. West Texas September safety seminars announced and CCGGA o ers Heat Illness Tool Kit.

Mississippi State University entomologists Whitney Crow, Tyler Towles and Don Cook discuss terminating insecticide applications. The suggestions are in terms of NAWF5 plus x heat units. Cutout is the point in the growing season when terminal growth slows, and the majority of plants have a first position white flower five nodes down from the unfurled terminal leaf. Go to www.cottonfarming.com for this Web Exclusive report.

Keep

Facebook: https://www.facebook.com/cottonfarming

Twitter: @CottonFarming

Instagram: @CottonFarmingMagazine

Anyone who works in agriculture knows weather is an uncontrollable factor farmers face while trying to produce their crop. A weather pattern described as a “perfect storm” is defined by the Collins Dictionary as a combination of events or things that produce an unusually bad or powerful result.

Top-of-the-news items in the last half of August were the Maui wildfires and what has been described as the “incredibly rare” Hurricane Hilary in California. Both events can be dubbed perfect storms escalated by drought and strong winds in Hawaii and high winds and excess water vapor in the sky in California. At the time of this writing, catastrophic destruction was reported across the island, along with a forecast of extensive flooding from a year’s worth of rain potentially being dropped in the southern part of the Golden State.

Unlike California, Southern farmers and those in the eastern region of Texas are more than familiar with the threat posed by hurricanes. The official season runs from June 1 through Nov. 30, although the occasional storm can form on either side of these dates. To aid producers in hurricane preparation and recovery, the U.S. Department of Agriculture Southeast Climate Hub published a Cotton Producers Guide focusing on 1) site establishments and operations and 2) considerations for defoliation and harvest before and after a hurricane.

The guide’s introduction states, “While hurricanes have always been a threat to the Southeast, with an average of over two strikes per year since 1900, the threat posed by hurricanes is growing. Recent studies suggest that as ocean temperatures continue to rise, hurricane intensity is increasing. Hurricanes of the future will likely be slower moving, higher category hurricanes that produce destructive winds and flooding.”

As harvest draws near, defoliation considerations are important. According to the guide, farmers should “avoid defoliating cotton when a hurricane is approaching unless you think you can harvest it before the hurricane arrives, as the leaves will help protect open cotton from the winds and rain.” If defoliation has begun prior to the hurricane’s arrival, be sure to “resume defoliation as soon as possible after a hurricane to help the cotton ‘straighten’ back up and reduce boll rot….The self-defoliation caused by wind damage is usually not adequate, and defoliants will still need to be applied.”

Although no one would wish for a hurricane to test their level of preparedness, it’s always a good idea to get a head start on Mother Nature.

EDITORIAL/PRODUCTION

Editor Carroll Smith csmith@onegrower.com

Southeast Editor Amanda Huber ahuber@onegrower.com

Associate Editor Cassidy Nemec cnemec@onegrower.com

Digital Content Editor Katie Guthrie

Art Director Ashley Kumpe

ADMINISTRATION

Publisher/Vice President

Lia Guthrie (901) 497-3689 lguthrie@onegrower.com

Associate Publisher/Editor-In-Chief

Carroll Smith (901) 326-4443

Associate Publisher/Sales

Scott Emerson (386) 462-1532 semerson@onegrower.com

Production Manager David Boyd dboyd@onegrower.com

Audience Services

Kate Thomas (847) 559-7514

For subscription changes or change of address, call (847) 559-7578 or email cottonfarming@omeda.com

EDITORIAL ADVISORY BOARD

David Burns – North Carolina

David Lynch – South Carolina

Bob McLendon – Georgia

Larkin Martin – Alabama

Mike Sturdivant Jr. – Mississippi

Charles Parker – Missouri

Jimmy Hargett – Tennessee

Allen Helms – Arkansas

Jay Hardwick – Louisiana

Ronnie Hopper – Texas

Ron Rayner – Arizona

John Pucheu – California

PUBLISHING, LLC

Mike Lamensdorf President/treasurer

Lia Guthrie Publisher/Vice President

ACKNOWLEDGEMENT OF COOPERATION: Cooperating with COTTON FARMING are various cotton producer organizations across the Cotton Belt. Many representatives of producer organizations serve on COTTON FARMING’s editorial advisory board. Opinions expressed and conclusions reached by contributors are not necessarily those of the cooperating organizations or the editors. All statements, including product claims, are those of the person or organization making the statement or claim. The publisher does not adopt any such statement or claims as its own and any such statement or claim does not necessarily reflect the opinion of the publisher.

Copyright 2023 ©

ASSOCIATED PUBLICATIONS – One Grower Publishing, LLC also publishes RICE FARMING, THE PEANUT GROWER, SOYBEAN SOUTH and CORN SOUTH

If you have comments, please send them to: Cotton Farming Magazine, 7201 Eastern Ave., Germantown, TN 38138.

One Grower Publishing, LLC 875 W. Poplar Ave., Suite 23, Box 305 Collierville, TN 38017

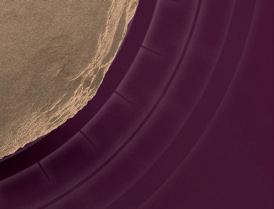

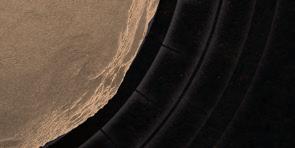

The National Cotton Council is urging its members to use industry approved module wrap products to help achieve zero contamination of seed cotton and lint.

Is there a module wrap standard?

■ The American Society of Agricultural and Biological Engineers (ASABE) developed a rectangular wrap standard about the time the round module wrap was gaining fast acceptance. In 2019, led by Dr. John Wanjura with USDA’s Agricultural Research Service, a subcommittee was formed to begin the round module wrap standard development. It was agreed that the standard in place for rectangular modules would be amended to include round module wrap.

importance of using approved module wrap material that meets the ASABE standard and 2) agreed to maintain the listing of wrap manufacturers who meet the minimum standard.

What progress has been made?

■ NCC staff recently updated its Quality Task Force and noted the voluntary ASABE standard had gained industrywide support. Although Tama’s pink and yellow wrap has been found to perform at an acceptable level by the U.S. cotton industry, there have been contamination issues that the NCC and National Cotton Ginners Association (NCGA) are diligently working to address. For example, there is concern due to Tama’s patents expiring, wrap materials coming into the marketplace would not perform to the level of the standard. Within the last year, there have been many wrap manufacturers introducing alternatives to Tama’s premium wrap.

The NCC supported this evaluation and wrap standard development while continuing its zero-contamination campaign. That campaign emphasizes the importance of proper round module wrap handling, transport, and removal at the gin to eliminate plastic contamination. Round modules arriving at the gin in good condition (no tears, punctures, loose material or adhesive failures) are far less likely to cause contamination. See www.cotton.org/tech/ quality/contamfree.cfm.

ASABE approved its standard, “Cotton Module Cover Material Performance,” in 2022. The NCC then 1) adopted a policy to educate industry on the

That’s why some in the industry, including the NCGA, believe the standard should include a requirement that wrap used on U.S. modules meet the minimum performance standard. The recommendation to explore the inclusion of the ASABE Standard as a loan eligibility requirement was approved by NCGA’s Board and submitted to the NCC for consideration. At its 2023 Annual Meeting, the NCC approved the recommendation, and staff are currently conducting an examination of potential loan eligibility requirements. Once staff analysis is complete, the issue will be brought back to the NCC Board for a final determination.

There are multiple companies going through the testing procedures to get their product approved. In the meantime, the NCC urges the use of compliant wrap. A listing of approved wrap manufacturers is at www.cotton.org/tech/quality/approved-rmwproducts.cfm. Doing so will greatly reduce plastic contamination and ensure the U.S. cotton industry’s reputation of providing the best quality and contamination free cotton to our textile customers.

After being behind much of the season in growing degree days, conditions in late July and August allowed the cotton crop to catch up in many areas of Georgia.

“Between severe weather, plant bug problems galore and deer damage, it has been a tough go,” said Camp Hand, University of Georgia Extension cotton specialist. “In mid- to late-July, the crop turned a corner and looks really good. We have great yield potential out there, and my hope is that we can get it in the basket and to the gin.”

As the crop approaches defoliation, Hand offers these points to keep in mind.

Pull the defoliation “trigger” at the right time. “There are many ways to determine the appropriate time to defoliate your cotton crop – 60% to 75% open boll, four nodes above cracked boll and the ‘sharp knife’ method,” said Hand, who recommends using at least two methods to determine the correct timing.

To determine percent open boll, count the number of open bolls and the number of unopened, harvestable bolls. Divide the number of open bolls by the total bolls and multiply by 100. For NACB, count the number of nodes from the uppermost first position cracked boll to the uppermost first position harvestable boll. When that number is four, on average, it is time to defoliate.

“For the ‘sharp knife’ method, cut into the uppermost boll you intend to harvest and look for a black seed coat with developed cotyledons inside. Also, you want the lint to string out,” Hand said. “Keep in mind that deer damage and severe plant bug infestations that were not controlled will likely delay maturity, thus checking your fields is of paramount importance!”

Use the correct products and rates to accomplish your intended goals. Hand said, there are three main goals in defoliation – removal of juvenile and mature leaves, regrowth prevention and boll opening. “Determining your goals, as well as the environmental conditions surrounding defoliation, will assist in the decision on products and rates.”

Products and rate recommendations can be found beginning on page 143 of the 2023 UGA Cotton Production Guide, which can be found at www.ugacotton.com/production-guide/.

Control regrowth. One of the best things you could do to manage whiteflies in the coming year is to defoliate your cotton crop in a timely manner, Hand said.

If the bottom crop is ready to defoliate, but conditions have caused it to start regrowing and blooming, is it worth waiting on this top crop? Hand said it is probably best to defoliate it.

“Investing more money to try to make a top crop doesn’t seem worth it for a couple of reasons. One, you probably have enough money tied up in the crop already, and waiting on that top to finish will cause the bottom crop to deteriorate.

“Secondly, if regrowth is allowed to keep going, that young growth is like cotton candy to whiteflies. They will keep feeding and reproducing and will contribute to a greater population

Defoliation of cotton has three main goals: leaf removal, regrowth prevention and boll opening.

JEREMY KICHLER COLQUITT COUNTY EXTENSIONgoing into the winter time and next year,” Hand said.

One shot versus two? “In Georgia, we primarily use one shot for defoliation, and it works very well,” Hand said. “Rarely will I recommend a second shot unless something went wrong on the first.”

Use more water. Hand said, “A higher sprayer output in gallons per acre works better than a lower sprayer output with respect to defoliation, even if you decide to use dicamba nozzles. Shoot for 15 GPA if you’re defoliating with a ground rig to get defoliant down in the canopy.”

Keep defoliants on target. “It is imperative to apply all pesticides, including defoliants, responsibly,” Hand said. “Keep the lessons from ‘Using Pesticides Wisely’ trainings at the forefront of your mind.”

Producers should keep in mind what is around fields, the wind speed and direction at the time of and after application and keep the spray booms 24 inches above the crop canopy. Use nozzles that produce larger droplets with a higher spray output.

“It is important to reduce pesticide drift in general, but also from the standpoint of protecting the chemistries we use,” he said.

If defoliation is still a few weeks away, the question then becomes whether fungicides may be needed to protect yields. UGA Extension plant pathologist Bob Kemerait says areolate mildew is one disease that can affect cotton later in the season.

“Growers within four weeks of defoliating their cotton need not worry about managing areolate mildew,” he said. “Where it occurs in a crop with defoliation a month or more away, and weather is favorable for continued development and spread of the disease, a fungicide may be beneficial to protect yield.”

Just as timely use of a fungicide protects hundreds of pounds of lint, timely defoliation and harvest are key to producing a high-quality crop.

In a final tip, Hand said, only defoliate what you can come back and harvest in about 10 to 14 days to help preserve crop yield and quality.

From the Coolidge, Casa Grande area west is considered the low desert production region of Arizona. It typically is characterized as having an elevation lower than 2,000 feet. The National Weather Service says monsoon season — a weather pattern that occurs in the state — officially runs from June 15 to Sept. 30. However, the presence of certain factors can influence the exact dates from year to year.

According to the Chandler, Arizona, website, “Simply put, the monsoon is the time of year, or the season, when winds shift, bringing an increase in moisture to the Southwest. The resulting storms can range from minor blowing dust to severe thunderstorms.”

High nighttime temperatures tend to be prevalent during the monsoon season when high humidity prevents them from cooling off during the evening.

“We have two different types of heat stress — Level 1 and Level 2 — based not on air temperature but on the temperature of the crop canopy,” said Randy Norton, Arizona cotton specialist. “Level 1 heat stress occurs when the crop canopy temperature gets to about 82.4 degrees Fahrenheit.

“Level 2 heat stress is when the crop canopy temperature measures above 86 degrees, which is highly correlated to nighttime temperatures. That’s when we begin to see a lot of effects from Level 2 heat stress. We can still get to Level 2 heat stress in the absence of monsoon, which we did this year, but for the most part, monsoonal activity correlates with our Level 2 heat stress.”

Norton said the primary impact of heat stress on cotton is with flower formation expressed in lack of pollen. Malformation of the floral parts has also been observed. The stigma, which is the female portion of the plant, becomes elongated.

“With the lack of pollen or reduced pollen, three- to five-dayold bolls will abort off the plant because they haven’t pollinated properly,” he said. “This small boll abortion negatively impacts the yield. But the heat stress effects can vary by variety. Some varieties can handle heat stress better than others and will pollinate some compartments of the boll. This results in misshapen, ‘hooked beaked’ bolls that may not abort but will not open symmetrically, which reduces yield.”

When it comes to anticipating potential heat stress, cotton farmers can utilize mepiquat chloride as an effective growth management tool to maintain the balance between reproductive growth and vegetative growth. A cotton plant that has been allowed to get out of control complicates terminating the crop and getting it defoliated and prepped for harvest.

In choosing a cotton variety for next season, farmers should look at variety performance in local variety tests to see which

ones appear to have more tolerance to heat stress.

“Growers also need to look at a variety’s response to heat stress as a yield-determining factor,” Norton said. “A variety may be able to handle heat stress pretty well, but if it is not managed correctly, it will not yield. In addition to looking at local variety trials, farmers also should keep track of which varieties perform well on their farm.”

In some parts of the state, planting date management can be a technique to help avoid heat stress, Norton said.

“Because of the Yuma Valley’s crop rotation cycle in far western Arizona along the Colorado River, cotton is planted very early,” he said. “This means the crop is going through its fruiting cycle well before the heat stress begins to develop in Arizona. The bulk of the heat stress is coming after the crop has already gone through peak bloom. It’s on the back side of peak bloom when heat stress starts to develop.

“Not all parts of the state, even the central part, can do this because they don’t have the same type of early heat that Yuma does. The central area typically plants cotton in mid-April, which puts the crop right in the middle of potential heat stress when it is going into peak bloom.”

Some of Arizona’s cotton is double cropped with wheat that is planted in the fall. Then cotton is planted behind the wheat in late May. This means the later-planted cotton is just entering bloom during the hottest part of the summer, so the bulk of the heat stress doesn’t coincide with the bulk of the cotton’s flowering period. The late-planted cotton is avoiding heat stress on the back end of the heat stress curve.”

But because there are other risks — such as an early frost — that can affect the crop other than heat stress, Norton said Arizona cotton farmers have to carefully maintain a proper balance in all of their production practices.

Apassion for science and a drive to educate on the value of agriculture to Texas took Ben McKnight, Ph.D., from a student to a faculty member of the Texas A&M College of Agriculture and Life Sciences Department of Soil and Crop Sciences.

McKnight, originally from Leverett’s Chapel in Rusk County, earned two degrees from Texas A&M University before leaving for his doctorate and eventually returning for his career.

As the Texas A&M AgriLife Extension Service state cotton specialist for the past three years, McKnight’s job has been to conduct and translate cotton research results and provide resources specific to each region and producer’s needs. He serves in an advisory capacity at state-level commodity organizations, provides information and state updates to national-level producer organizations, conducts applied field research trials and provides results to the public. Additionally, he mentors and trains undergraduate and graduate students.

McKnight sat down with us to discuss what the path from Texas A&M student to AgriLife Extension specialist looks like.

As a youngster, I had a tremendous passion for science and learning about plants and animals. I attended Leverett’s Chapel Independent School District from kindergarten until I graduated high school. Even though it was a very small school, I had some incredible teachers.

To put small into perspective, my graduating class size was

10, including myself. I feel that because we had the enrollment numbers we did at the time, my primary and secondary school teachers were able to develop a unique teacher-student relationship with my classmates and I. They were able to spend more time getting to know each individual student.

During my time in high school, some of the faculty noticed my passion for science and that I also was very active in the agriculture program. It was only natural they encouraged me to consider Texas A&M following graduation, so I scheduled a visit and immediately knew this was where I needed to be.

Once I got here, I had some amazing experiences as an undergraduate and graduate student, working with and learning from some of the brightest minds in the agricultural sciences. Those experiences, along with Aggieland always feeling like home to me, put a career with The Texas A&M University System at the top of my list after I finished school.

I have been with AgriLife Extension for a little over three years, starting my current position in April 2020. During that time, perhaps the most enjoyable aspect of my job is the people I get to meet and work with. This includes producers, colleagues, students and folks who have no ties at all to the agricultural industry. Regardless of the role, any AgriLife Extension position is

going to be one where there is considerable interaction with colleagues and the public. I thoroughly enjoy meeting people, developing professional relationships and being a resource for our stakeholders to get the information they need to be successful.

■ Are you actively involved in conducting research?

Yes, the AgriLife Extension cotton program annually conducts several cotton variety trials in different parts of the state, along with many other research trials evaluating new and emerging products, technologies and practices. The average commercial lifespan of a new cotton variety is only three to five years before it is phased out with newer varieties. Constantly evaluating these varieties across multiple geographies is imperative to determining which varieties are going to provide the yield and fiber quality characteristics needed to keep Texas cotton producers productive and profitable.

■ What is a change you would like to see in the cotton industry?

A change I would like to see isn’t necessarily from within the cotton and agricultural industries, but rather from the outside looking in. The general public’s perception of agriculture is often fueled by news and information that doesn’t always provide the clearest picture or capture the entirety of modern-day agriculture and the practices that growers utilize to remain productive and profitable while providing food and fiber for a growing global population.

I can tell you firsthand that agricultural producers are the ultimate stewards of the land and the resources they use to provide the world with food and fiber. Growers understand responsible use of the land and resources is imperative to keep their operations profitable and sustainable. In my capacity as state cotton specialist, I am often interviewed by state and national media on different topics related to Texas cotton production. During these interviews I try to highlight how our Texas crop and livestock producers are leaders in employing innovative, sustainable and responsible production practices. This is a story that is not shared nearly enough with the public, and our producers deserve credit where much credit is due.

■ What does the path from an agronomy undergraduate student to state cotton specialist look like?

I imagine there are several different paths one could take that lead to a career as the AgriLife Extension state cotton specialist. For me, the path started by getting involved with the Department of Soil and Crop Sciences inside and outside the classroom.

In 2005, I started working for the Texas A&M Soil, Water and Forage Testing Laboratory as an undergraduate student worker. It was through this experience that I began to understand the tremendous positive impact AgriLife Extension can provide to our clientele. I had quite a bit of exposure and participation in Extension programming and activities during my time as a master’s student at Texas A&M and as a doctoral student at Louisiana State University. Those experiences only strengthened my passion for taking information and innovation developed within a university system to the public.

■ Why did you choose to study agronomy as a student?

Something is always changing in crop production, and every year brings a new set of challenges to address to be successful. I enjoy solving problems, and there’s plenty of problem-solving opportunities in crop production. That aspect really appealed to me when deciding to pursue an education and career in agron-

omy. Additionally, agricultural producers and those involved in the ag industries are some of the most intelligent, resilient and innovative individuals you will ever meet.

I tell growers and AgriLife Extension agents all the time that I probably learn more from them than they learn from me. A career in agronomy has certainly afforded me the opportunity to always continue learning new things, and coupled with the professional relationships and friendships that I’ve developed along the way, it has been an extremely rewarding experience.

■ Did the way you grew up have any influence on your decision to pursue an education and career in the agronomy field?

Absolutely it did. My grandfather was an agriculture producer, and I have aunts and uncles who still produce hay and livestock, so agriculture is in my blood. The exposure I had to agriculture from an early age, my enjoyment of being and working outdoors, along with my passion for science and interest in solving problems played a major part in steering me towards a career in agronomy.

■ How have the activities you were involved in as a student benefited you?

As an undergraduate student I was a member of the Texas A&M soil judging team, and as a doctoral student I was a member of the Louisiana State University weed team, later serving as assistant coach. Both experiences benefited me academically, professionally and personally. Participating in activities like these provided me with an opportunity to further sharpen my skillset relevant to each team activity and take the things I had learned in the classroom and apply them in real-world situations. Plus, both activities involve competitions with other university teams, which can be a great way to meet your colleagues from other institutions and establish professional relationships. Being active with these two teams led to me meeting some lifelong friends who I keep in touch with frequently.

■ Do you have any key mentors?

My parents and family are the best, and they’ve played the biggest role in shaping who I am personally. Professionally, there are just too many mentors to list. Two key mentors who have probably influenced me the most are Drs. Scott Senseman and Eric Webster.

Dr. Senseman served as chair of my master’s graduate committee at Texas A&M. He currently serves as the associate vice president for the Division of Agricultural Sciences and Natural Resources at Oklahoma State University. Dr. Webster served as chair of my doctoral committee at Louisiana State and now serves as an associate dean and director for the Wyoming Agricultural Experiment Station. I can’t begin to quantify how much I learned from them, and how their mentorship has shaped my professional development and career path.

■ What advice would you give to students interested in a similar career path?

I would encourage students to get involved with their college and department outside of the classroom. That includes getting involved with student organizations and activities, getting a student worker position with a faculty member’s program, and taking advantage of any opportunities that are an avenue for networking and additional professional development. Undergraduate students would be surprised how many opportunities may arise from being active outside of the classroom.

Mark and Anna Yeager have long made their mark on their neck of the woods in Moulton, Alabama. When Anna graduated with her degree in graphic design from Auburn University, she went to work in advertising up north in New York City. After a move and a few years in Nashville, Tennessee, with her husband, she was approached with an idea from her dad in 2016 that would change the direction of her career forever. Mark’s idea? Red Land Cotton.

“I felt like I could really be an asset to make it happen. I’m nothing if not an executioner,” Anna said.

She said she then used her senior thesis as a template for their Red Land Cotton business plan. From there, the rest was history.

Mark Yeager is first-generation as far as large-scale farming goes. His father had a small farm and was a business owner as well. That combination of the agriculture and business mindset passed down to Mark as he began growing cotton and corn and raising cattle at the foot of the Bankhead National Forest in North Alabama in 1983.

Mark built his very own cotton gin in 1994, which gave him more control over the quality of their cotton. They originally ran it as a custom gin where they would gin customer cotton. He said after six or seven years, they turned it into strictly their own.

“I’m lucky I’ve got an employee who’s multi-talented,” Mark said. “He runs the gin in the fall while the rest of us pick cotton. That makes it very doable.”

His two sons, Mark Jr. and Joe, farm alongside him, and they have seven other full-time employees at the farm and gin. They planted all Deltapine cotton varieties this year including the DP 2141NR, DP 1646, DP 2239, and DP 2038. Typically, they will rotate cotton two-to-one with corn.

Mark said he sees them continuing to try and grow a better cotton crop down the road. “Cotton is my favorite crop. It is something that I truly do like.”

“I think something that sets Red Land apart is that they have their own cotton gin and are able to gin cotton the way that they want to and have the control over picking the bales that are best,” Anna said.

From Yeager Gin to Red Land Cotton, the Yeagers have 100% say in how their cotton is managed and where it goes. “We’re totally vertical,” Mark said.

All Red Land cotton products are 100% made in America.

In 2017, the Yeagers bought a place on the downtown square in Moulton and hired their first Red Land Cotton employee. That space was used as their home base until they built the warehouse in 2020 in which they occupy now.

Anna said one of the first things they did when they started Red Land Cotton was hire a retired textile consultant by the name of Jack Miller out of Greenville, South Carolina.

“As far as someone who assists pretty heavily in supply chain management and things of that nature, he would be up there.”

Anna and her dad handle most of the business aspects. She said they have quality control, customer service and order fulfillment employees at the warehouse who make everything they do possible. The front of the warehouse includes a retail space where people are able to come see, touch and feel the product offerings.

“I enjoy what I always enjoyed, which is creating stuff…telling stories, crafting narratives and creating the assets and products around those narratives,” she said.

In addition to their Alabama farm, gin and warehouse, Red Land Cotton has a cutand-sew facility in Tylertown, Mississippi.

Anna noted the massive e-commerce and retail boom that took place in 2020. “Nobody was able to keep up with it,” she said. “Supply chain was just a cluster.”

She said they seem to be able to better iterate and grow by offering apparel options in addition to their classic bedding offerings. “There seems to be more opportunity in narrow goods than in wide goods domestically, but sheeting is our No. 1 best-seller,” she

said, noting that is what gets people hooked on their brand.

She said Red Land Cotton has been fortunate to grow 20% to 30% each year they have been in business. “I feel like we have a lot of reason to be optimistic.”

So what makes Red Land Cotton different?

“I think what Red Land Cotton has been able to do very well is tell a truly transparent story from start to finish but also have a pulse on our customer.” She said they have been able to iterate on their products and expand their offerings because of their customer base and listening to what they would like.

“There’s definitely a balancing act here with inventory and new product and meeting customer needs, but what I feel is the success of that are companies like Room & Board and our recent collaborator Banana Republic. These larger companies are seeing us as a resource for a domestic product.”

“To me, that is proof we are putting ourselves out there as a reputable supplier to not only a direct-to-consumer relationship but also to brands that are looking to have a domestic supply chain to tell this story along with us.”

Anna said this is all not without risk and personal capital being poured into their vision, but the growth they have witnessed over the years has been all the proof they need to keep going.

“I would love to see more strategic partnerships that we can leverage the community that is the U.S.-textile supply chain to continue to lift it up and make it more successful,” Anna said. “Really, a lot of the setbacks, quality issues or limitations that we have are really because the U.S.-textile supply chain has been so decimated over the past few years.”

Mark commented on the troublesome state of the textile

industry as it stands now.

“We’re importing everything,” he said, emphasizing that an astounding amount of U.S. cotton is exported overseas where it is sewed, milled and sent back, draining profits in America. “U.S. agriculture is the biggest, most efficient machine in the world with the ability to feed and clothe, and the majority of the country thinks we’re evil.”

Anna mentioned the current state of cobalt as it relates to China’s restrictions is part of the story as well. “All of the farming equipment now relies on those chips. It impacts everything.”

She emphasized her desire to collaborate, tell more stories and bring more awareness in order to build the textile industry back up, noting it would help everyone in the long haul.

Anna and Mark have become a well-known father-daughter duo in the cotton industry, and they are enjoying their careers as they continue to take shape. “I love the challenge,” Mark said.

“I really believe in the purpose of Red Land Cotton — not only that it’s a good product and good business but that it’s also trying to lift up small towns and a textile industry that’s waning,” Anna said. “It gives us a platform to talk about agriculture — we’re a much more tangible thing for them to see and understand.

“I think agriculture can be abstract to a lot of people — even people who live locally as funny as that is — I think there’s a part of that in when the mills went away and you stopped seeing the raw product be converted into something that you use in your daily life.

“If we can educate more with this platform, I think that gives much more added value.”

All crops are susceptible to deficiencies, but even when your macronutrients are strategized to maximize yield potential, something could be missing. Set your crops up for success with a balanced nutrition plan using WOLF TRAX ® micronutrients. With closer proximity to growing roots, plants will consistently access the right rate at the right time.

Water and irrigation management are among the most essential production practices for growing cotton today. The limited amount of rainfall typical in the Southern Plains region of the United States Cotton Belt makes producers in that area especially keen to understand the complexities of water-use efficiency.

Cotton Incorporated has been involved in water research for more than 40 years. The current focus of Cotton Incorporated’s water research is a fourpronged approach and includes:

Maximizing rainfall capture.

Optimizing irrigation water use.

Increasing plant water productivity.

Evaluate data with credible metrics.

Through core funding and State Support Program funding, Cotton Incorporated is implementing research to address water management in the

BY SHELLEY HEINRICH SLATON, TEXASSouthern Plains.

Many Southern Plains producers use center-pivot irrigation systems to irrigate and supplement the rainwater for their cotton fields. One project funded through the Oklahoma State Support Program looked at the benefits of slowing down water delivery when using pivot irrigation. This field demonstration study, led by Dr. Jason Warren, associate professor at Oklahoma State University,

slowed pivot irrigation to deliver .8 to 1.2 inches of water per revolution before the cotton needed moisture uptake. In-field evaluation of the slowed-down delivery showed an immediate increase in plant physiology and health.

Oklahoma cotton producer Reid Nichols participated in the project and was excited about what he saw when they slowed the pivots down. “I noticed more uniformity across the field, and the slower pivot irrigation seemed to improve the boll load. We also noticed that the maintenance on the pivot decreased. We had to do less work on the center drives and gearboxes. We also had fewer flat tires. Once we started seeing the changes in the demonstration fields, we started slowing down all our pivots, which made a huge difference,” he said.

Another question that is always topof-mind when using pivot irrigation is when to stop the irrigation. In the project’s demonstration field, the irrigation termination decision was much easier to ascertain due to the better overall crop conditions.

Nichols highlighted the importance of this kind of research. “When you farm in Southwest Oklahoma, you know that irrigation management is going to be a key focus year in and year out,” he said. “The work that Cotton Incorporated is funding at OSU with irrigation monitoring is huge for producers in my area, especially in a summer like this one.”

Innovative new technologies and management systems can improve the ease and accuracy with which growers determine and respond to cotton’s water needs. Cotton Incorporated supports new and ongoing research each year. In 2023 alone, researchers across the U.S. worked myriad projects that advance easier and more accurate ways to determine and respond to cotton’s water needs.

“It is with great pleasure that I announce the hiring of Jim Davis of New Market, Alabama, as the next CEO of Southern Cotton Growers Inc.,” said Joe Martin, president, Southern Cotton Growers. “Raised on a fifth-generation family farm that includes cotton as their primary crop, Jim will be only the fourth CEO of the organization founded in 1964.”

Current CEO, Dave Ruppenicker, will retire Dec. 31. Davis will officially come on board Oct. 1. Southern Cotton Growers Inc. represents every cotton producer in the six states that comprise the Southeast region (Alabama, Florida, Georgia, North Carolina, South Carolina and Virginia.

“Jim comes to the organization with a wealth of knowledge and experience having been employed by National Cotton Council for more than 30 years,” Martin said.

“I feel confident that through Jim’s leadership, the organization will continue to prosper and uphold the motto of maintaining prosperity for the Southeast cotton producer. He will no doubt leave his mark in the storied legacy of this sixdecade-old organization.”

Dr. Tyler Towles has joined Delta Research and Extension Center as an entomologist focusing on bollworm control strategies in Mississippi cotton.

“New technologies for bollworm control don’t come to market very often so protecting what we currently have at hand is extremely important,” Towles said. “I think there is great value in developing a research program that conducts proactive experiments that will prolong insecticidal resistance development in bollworms.”

A Leland native, Towles’ interest in agriculture was piqued as a teen when he

began working in the summer for Dow AgroScience.

Working alongside MSU faculty Drs. Angus Catchot, Jeff Gore and Don Cook, Towles earned his Ph.D. while studying various refuging strategies and quantifying bollworm production from various Bt field corn hybrids. He then worked at the Louisiana State University AgCenter as a research entomologist.

“The major reason I felt compelled to return to Mississippi was heavily influenced by Mississippi State University and the state’s stakeholders. I was offered the opportunity to study one of my favorite subjects at a highly prestigious landgrant institution. Since this venture was largely funded by the state’s agricultural industry, I saw myself as an investment in the agricultural future of Mississippi,” Towles said.

“From an entomological standpoint, the Delta is the epicenter for many insect issues that Mississippi stakeholders are faced with in the field. Being domiciled in the Mississippi Delta will allow me to connect directly to my stakeholders on a personal level,” he continued. “Additionally, working in the Delta allows me the opportunity to experience the insect-related problems firsthand, so I can address these issues more effectively.”

BASF has received key import approvals for its newest cotton innovations, Axant Flex Herbicide Tolerance Technology and Axant Flex TwinLink Plus Insect Control Technologies. This was the final step needed to support planting of Axant Flex Cotton in the United States, both with and without TwinLink Plus.

The company said, “The Axant Flex stacked trait has been bred into the bestin-class germplasm that growers have come to trust in FiberMax and Stoneville cotton. Axant Flex technologies provide a complete solution for cotton growers who want high-yield potential, outstanding fiber quality and top-tier insect and weed control.”

With Axant Flex technologies, BASF continues to provide BASF customers with more weed control options including tolerance to glyphosate, glufosinate and dicamba, as well as HPPD — pend-

ing regulatory approval. The HPPD mode of action — isoxaflutole — has not yet been approved for use on Axant Flex TwinLink Plus cotton by the U.S. EPA.

XtendLink technology now enables FiberMax and Stoneville cotton farmers to spray over-the-top applications of Engenia. This dicamba-tolerant trait package provides an additional weed control option for the first time for FiberMax cotton growers.

Axant Flex varieties also are stacked with multiple native traits to protect against some of cotton’s toughest pests, including root-knot nematode, reniform nematode and bacterial leaf blight

At The Cotton Board’s 2023 Annual Meeting, board members serving the Cotton Research and Promotion Program reviewed, analyzed and voted to recommend Cotton Incorporated’s 2024 budget of $89 million to the Secretary of Agriculture.

The Cotton Board elected a new slate of officers to serve one-year terms, including Mark Nichols, a cotton producer from Altus, Oklahoma, to serve as chairman of the board. Nichols is the president of Jess Mark Nichols Farms, Inc. and president of Hess Farms, Inc., a fourth-generation farm he has managed since 1980. He farms with his brother-inlaw, son and son-in-law, growing irrigated cotton, wheat and milo.

Other Cotton Board officers include Akiko Inui, importer from New York City, New York, vice chairman; Matt Farmer, producer from Lamesa, Texas, secretary and Rusty Darby, producer from Chester, South Carolina, treasurer.

As I write this July 28, the North Carolina crop is highly variable but in a lot better shape than it was just over a month ago. July has brought timely rains to most parts of the state and quite a bit of heat that we were begging for in June. I would argue that the mid 90s are a little more than we need right now as it rapidly depletes our soil moisture, but overall, growth is good in most areas. Dry pockets are evident but tend to be in the minority of our acres at this time.

The months of August and September will be very telling. In most years we tend to believe that June and July weather sets the crop up, but our crop is made in August. That will be even more true this year due to the compressed bloom period we have this year. Most fields began blooming between July 15–30, resulting in some fields being two to four weeks behind schedule.

Recent research regarding last effective bloom dates suggests that blooms made by the end of August have a decent and reasonable chance of developing into harvestable bolls; however, in years with warmer September and October weather, blooms made as late as Sept. 13 have a decent chance of developing into harvestable bolls. So conservatively speaking, the later portion of our crop may only have a four-week bloom period. In those cases, we really need August weather to cooperate, and we need to stay on top of insects — perhaps into September this year.

This crop continues to be late at this point in time. August and September could expand or contract that. A dry August could rapidly accelerate maturity, but that would not be ideal in terms of yield. We need timely rains in August and perhaps a week or two into September, then a sunny and drier late September, preferably warm. The same for October. We’re not asking for much.

If this crop remains to be a little later than normal as we enter the Fall, it will be important to watch temperatures at or around defoliation time. If defoliation happens to fall more into cooler weather this year, we may need to select products with enhanced activity in those temperatures. Time will tell. guy_collins@ncsu.edu

As I write this in early August, our crop — overall — looks good to very good. Several area-wide rainfall events have moved through Tennessee and more are in the forecast. By the time we reach the first of September, I expect most of our acres will have bloomed out of the top; NAWF counts are often running around five with (generally) high retention rates. I doubt we will defoliate many acres in September, given our crop is just a little behind where we would normally be this time of year. For those earliest acres that will be defoliated under warm conditions, thidiazuron is my product of choice. The 3.2-ounce rate of thidiazuron plus ethephon at 16 ounces to 24 ounces is a great first shot when temperatures are warm.

Mid-September provides a great opportunity to assess your fertility practices. If you’ve properly applied N and K and retention levels are good, I would expect the lowest leaves to begin to show N deficiency symptoms with only slight K deficiency symptoms appearing in the upper canopy. If you note a deep, dark green canopy moving into the last stages of boll fill or, on the opposite end of the spectrum, strong N or K deficiencies present within the canopy, adjustments to your fertility

program are likely warranted. Note these observations and use them to adjust rates as you move into next year. traper@utk.edu

Cotton is rapidly approaching cutout in Missouri in the earlier planting dates, meaning we are approaching the finish line for the 2023 season. Conditions throughout June were dry and forced producers to begin watering earlier than usual. In July, we began to catch much-needed rainfall in certain areas across the Bootheel while some areas continued to miss these events.

As we begin to reach cutout, it is time to start evaluating insecticide termination. Tarnished plant bug pressure has been an issue over the past several weeks, and it is important to point out insecticide termination for tarnished plant bugs has been recommended when plants reach cutout (Node above white flower = 5) plus 350 heat units.

While we are approaching the finish line and much of the crop looks to be above average with a good yield potential, warm temperatures and sunny conditions will be needed to mature the crop. As I am writing this, August has not started the way we needed, with some areas in the region receiving six to 10 inches of rainfall in a short period with several days of cloudy conditions and lower-than-normal temperatures. This could reduce fruit retention and slow boll maturation if the conditions remain through the month of August. brwilson@missouri.edu

As I write this Aug. 4, cotton harvesting is in full swing in the Lower Rio Grande Valley, and by the time you are reading this in September, harvesting should be completed ahead of the Sept. 1 stalk destruction deadline. Soon to follow in the month of August will be the Coastal Bend and Upper Gulf Coast regions. Mid- to late-season drought conditions across much of the state have and will continue to push our harvesting timeframe a little earlier when compared to previous years in many locations throughout the central and southern parts of Texas.

As growers begin to formulate a plan for the upcoming harvest, one of the biggest considerations is what their harvest-aid programs will look like. This can be especially challenging in very hot and dry environmental conditions like we are experiencing the later half of 2023. A droughtstressed cotton leaf has a thicker waxy cuticle, which can reduce uptake and absorption of certain harvest-aid products, compared to a lusher, non-stressed leaf.

One of the things that applicators can do to improve the activity of harvest aids on drought-stressed cotton is to increase spray volumes and use appropriate spray nozzles to enhance coverage. A minimum spray volume of 10 gallons per acre should be the baseline spray volume from a ground rig and increasing to 12 or even 15 gallons per acre can further increase coverage, often resulting in enhanced product activity. Selecting spray nozzles that will deliver uniform coverage and penetration of spray droplets through the crop canopy to lower parts of the plant will often enhance product activity.

Additionally, including an adjuvant may increase the activity of harvest-aid products on drought-stressed cotton, especially the herbicidal products. All cotton harvest-aid products are accompanied with a product label detailing recommended application methods, product rates,

tank-mix partners, compatible adjuvants, along with other important information to consider before making an application. Similar to the chemical pest control products we use each growing season, it is essential to familiarize ourselves with the product labels in an effort to maximize each and every harvest-aid product application. bmcknight@tamu.edu

Cotton is a unique crop in that you can attempt to gauge its performance and yield potential in many ways. Ultimately, it is what makes it to the gin that counts in terms of yield. The easiest way to dissect the growing season is to segment it into three 40-day blocks. Currently, we are entering the last 40 days. I would say the first and last 40 days are the most crucial in terms of establishing and finishing out the crop, respectively.

Yield potential for Mississippi crops in 2023 is promising. Most of our acres were planted on time with timely rains through June and most of July. Despite some hail and deer damage during June, this crop has high fruit retention and is racing past cutout. Late July and early August was hot and dry, likely affecting some dryland acres, but overall, this year’s crop looks better than last year.

As I write this Aug. 4, we still have some time before we are considering defoliation. However, a couple of timely rains will really benefit this crop. Also, success of this crop will ultimately be determined by a dry or a wet harvest season. Some models predict an active Atlantic hurricane season. Hopefully, the last 40 days will be hot and dry, making for a successful defoliation and dry harvest! bkp4@msstate.edu

“Hurry up, Nell!” I heard my Daddy say that to my Momma countless times. He was a Get ‘Er Done kind of guy and often approached his “30-minute projects” with an intensity and impatience that bypassed preparation and (reading the) instructions.

I inherited at least some of that disposition. My wife thinks I frequently value completion of a task far more than the quality of my efforts. If I have a scheduled project, I usually wake up eager and raring to go. Urgency toward the finish obscures pleasure in the job; in other words, my sense of enjoyment typically comes only at the end of the work, not in the doing of it. Such an

attitude is not given to a sense of pace, especially for activities that are akin to a marathon rather than a sprint… not a good approach for the cotton farmer at harvest.

Harvest is indeed a marathon, demanding preparation, pace, perseverance and persistence. It cannot be accomplished in a day but requires hours upon hours and day after day of careful, attentive work, with a vigilance for safety, every day, every hour.

Harvest is coming. Get ready. The race is long. Enjoy the work each and every day — well, maybe except the days with extended breakdowns. Be safe. cottonbrown@auburn.edu

As we approach the finish line on this crop, I hope we are presented with warm, dry weather and all of our cotton winds up at the gin.

As I have discussed at different meetings and field days this summer, and as many have expressed to me, our crop is behind. What matters now is if we can accumulate enough heat units now through October to finish it. Our yield potential that I have seen is really good, but we really need a warm fall. Based on our degree days accumulated this summer — if cotton was planted May 1 to 15 — we are a good 10 days behind. Additionally, plant bug damage from earlier in the season and deer damage could potentially set us further behind. Likely the most critical thing you can do now is be sure you are getting out in your fields and checking prior to defoliation so we can pull the trigger at the right time.

You can learn a lot about how your season went this time of year. As mentioned in previous renditions of Specialists Speaking, the plant bugs were horrendous in Georgia this year. Although we can’t say that growers got eaten up by plant bugs “postmortem,” if there isn’t any fruit on your crop below node 12, I would be suspicious. You will be able to see what I’m talking about from the picker seat. Take note of what worked for you this year and what didn’t, and let’s start getting a game plan together for next season.

Lastly, as you are defoliating your cotton crop, let’s remember to keep ALL pesticides on target, including cotton defoliants. I am in constant contact with our UGA county agents this time of year regarding the weather and impacts on defoliation. As always, your local UGA county Extension agent and specialists are here to help! Reach out if you have any questions. camphand@uga.edu

Last month we introduced the Texas Cotton Ginners’ Association’s two interns who joined the organization this summer for an opportunity to experience the cotton ginning industry. Both have been with member gins throughout the summer.

Josiah Keck is a student at Texas A&M University majoring in agricultural systems management. He will graduate in 2025. Keck has also worked for Texas A&M AgriLife Extension as a student worker. He is interning at Petersburg Co-Op Gin and Smith Gin Co-Op in Odem, Texas.

Riley Gryder is a student at Texas Tech University majoring in mechanical engineering. His expected graduation date is May 2024. Gryder is a member of the Texas Tech Honors College and is interning at Edcot Gin in Edmonson, Texas, and Edcot Co-op Gin in Odem.

The TCGA internship program provides college students with a chance to show their value to potential employers. They gain valuable “real-world experience” to take the next step in their careers. Below are their mid-term reports.

During my last two weeks in the Panhandle under the supervision of Phillip Kidd, I visited Adobe Walls and Lonestar gins in Spearman and Pampa, Texas, where I worked alongside Aaron Moore and Dalton Skinner. During my time at these gins, I got to see what the o season was like in the ginning industry — installing upgrades, pulling new wires, servicing bearings and fixing pipe ducts — only some of the jobs I was tasked with. Overall, I learned more than expected while greatly enjoying my time there. I give my greatest thanks to the supervisors and managers who looked after me.

Moving to Edcot Coop in Odem, Texas, under the supervision of Daniel Luehrs, I have seen what startup is like in the ginning world. Making final preparations for what looks like a promising season, I have met several specialists such as Mark Gentry, Clay Whitley and Kyle Gill while carrying out final inspections of the gin. These inspections include changing spark plugs and flame rods, running and calibrating the humidaire machine and installing a new gear box for the module feeder. While being hands-on in the gin is productive, Daniel also taught me how to drive a forklift and count cotton to estimate bales per acre.

Altogether, I would like to thank Daniel Luehrs for being very welcoming and TCGA for putting me with great people who are allowing me to have these amazing experiences.

Josiah KeckI have been working for Tyler Cross at Smith Gin Co-Op, in Odem, Texas. During the first week, I worked with Mark Gentry, owner of Gentry Controls & Consulting. Mark taught me how to do maintenance work on the burner heads to the cotton

heaters and humidaire machines. During the maintenance process, Mark and I would take o the burner heads and check the flame rod and spark plug.

If there was some rust present, it would have to be hand sanded to keep a good connection with the flame rod and provide a better spark. I also hand sanded the burner head where the flame rod would sense the flame. After all these steps had been completed, Mark and I tested them to make sure everything was working correctly.

Later that same week, I worked outside marking and putting in T-posts for the modules. Depending on the price of cotton this year, insurance companies will only allow a certain number of modules together. The higher the price, the more feet apart the next module set must be.

Currently, the ginners at Odem have been working throughout the gin testing the machines to make sure everything is ready for the upcoming season. I would like to thank Tyler Cross for teaching and getting me prepared for the approaching ginning season. I would also like to thank Aaron Nelsen and the TCGA for this amazing internship opportunity.

As fall approaches, we are entering the final stretch of our safety seminars. The schedule is a little di erent than last year, so study it and pick the meeting that works best for you and your gin crew.

If you were unable to make one of the earlier seminars, you have several additional opportunities in mid-September. We will provide a seminar in Canyon this year on Sept. 19. That will be followed by a Sept. 20 meeting in Childress. We will wrap up our schedule on Sept. 21 in Lubbock.

Go to https://tinyurl.com/5fausv6a to see the complete 2023 schedule and registration information. The document includes a memorandum, flyer and registration form.

The seminars will run from 8:30 a.m. to 4:30 p.m. with a catered lunch. Please note all seminars will begin at 8:30 a.m.

sharp. There will be two identical sessions conducted. The morning session is from 8:30 a.m. to noon and will be presented in English while the afternoon session will be the same in content but will be presented in Spanish. Those attending the afternoon session are encouraged to show up at 11:45 a.m. to eat lunch. The morning session attendees will eat once their session concludes. They will be free to go after lunch. The Texas Cotton Ginners Trust manager session will begin at 1 p.m. as well. Remember, TCGT staff conducts manager meetings following each TCGA district meeting. Texas Cotton Ginners’ Trust is the sole sponsor of the 2023 safety seminars.

The idea behind the seminars is to go through the ginning process from picking up the module to hauling the finished bale off the yard. Throughout the entire presentation, we will let you know some of the different accidents that happened during the past ginning season.

We hope you will make every effort to attend one of the remaining seminars. If you have questions about the upcoming safety seminars, please contact Aaron Nelsen 512-476-8388 at your TCGA office. Hope to see you in West Texas!

Temperatures are increasing, and heat illness prevention training remains at the forefront. To aid in helping members and clients stay in compliance, the California Cotton Ginners and Growers Association has developed a Heat Illness Program Tool Kit that can be carried in your supervisors’ pick-ups.

The updated kit consists of a rugged plastic folder with tabs and materials inside. The kit includes heat illness cards, safety

toolbox talks and places for your Heat Illness Prevention Policy, emergency numbers and field maps as required by the Heat Illness Standard. The cost is $13 each, and CCGGA recommends you purchase one kit for each vehicle used by supervisors or foremen.

Here is a link to the Heat Illness Prevention Program Tool Kit order form — t.ly/FaOEO. Just complete the form and mail back with a check or pay online via PayPal through the link provided, and your order will fulfilled immediately.

If you have any questions, please call 559-455-9272.

¢ Sept. 19: PCCA Board of Directors & Annual Meetings, Lubbock, Texas

¢ Sept. 20: Staplcotn Board Meeting, 214 W Market Street Greenwood, Mississippi

¢ Sept. 26: Calcot 96th Annual Meeting, Phoenix, Arizona

¢ Oct. 11: Plains Cotton Growers Board of Directors Meeting, Lubbock, Texas

¢ Oct. 18: PCCA Board & Delegate Body Meetings, Lubbock, Texas

¢ Dec. 5-7: Cotton Board/Cotton Inc. Joint Meeting, St. Pete Beach, Florida – Lowes Don Cesar Hotel

¢ Dec. 13: PCCA Board, Delegate Body & Marketing Pool Committee Meetings, Lubbock, Texas

¢ Jan. 3-5: 2024 Beltwide Cotton Conferences, Omni Fort Worth, Ft. Worth, Texas

¢ Jan. 22-25: 2024 Southern Southeastern Annual Meeting, The Westin, Hilton Head Island, South Carolina

¢ Jan. 31: 2024 Georgia Cotton Commission Annual Meeting, UGA Tifton Campus Conference Center, Tifton, Georgia

The stream on my grandfather’s farm is shallow and narrow where it begins, only inches deep and two feet wide. The spring, which feeds it, is small but reliable even in the dry months of summer. A hundred feet in the woods, however, is a much different look.

Two tributaries, located closely together, join the flow. They run about half the year, mostly in winter and spring, then go dry for a while. Their contribution is nominal much of the time, but substantial after hard rains.

Not much has changed on the first part of the stream since my early childhood. Intermittent flooding from the branches, however, has eroded the earthen walls farther down and deepened the stream bed. Some banks have a four-foot drop and are 10 feet apart rather than two. Erosion has taken a gradual toll as seasonal water has whittled away soil and washed it toward the Ocmulgee River. I’m trying to stop that process, or at least slow it down. That’s why I’ve been hauling rocks.

My first efforts were focused on a small peninsula. It’s only 30 feet long and 20 feet across, but clearing vines and underbrush revealed undeniable charm. It’s a minuscule replica of Florida, complemented by one main attraction, a leaning tree. Our granddaughter, Megan, once climbed it to escape an alligator. The tree and the memory are special.

Eight boulders are in a cluster near the spring, each about the size of a rocking chair. They’re artistically positioned to overlook the branch. My brother, Jimmy, wondered aloud one day how such large rocks came to rest there. I thought God arranged them, but now I’m guessing Granddaddy lent a hand.

Stones from baseball size to five-gallon buckets are scattered throughout the woods. I’ve been tossing them in piles for a couple of years, saving them for later use. And I’ve come across a dozen or so rock piles that have been there for decades. Some were only partially hidden by nature. Others had multiple layers of rocks covered in topsoil and required some persuasion to leave.

I had been pulling up old fencing for several weeks before I realized the proximity of rock collections to the wire. They were all on the interior side of the fence nearest to the water, which led to another theory about my grandfather’s fences.

Woods are on both sides of the fencing, which I thought was put there to give livestock access to the stream. The piled rocks, however, cause me to believe that part of what I’ve always known as woodlands was once in pasture. It would make sense that rocks were thrown over the fence to get them out of the way, or maybe piled there before the fence was put up. The boulders are too heavy for lifting, but a mule team could have pulled them down the slope.

Maude and Tom were a mule-horse pair that my mother remembers from early childhood. Maude, the horse, was gentle, and Mama would take slow rides as her father or older brothers held the reins and led her. Tom was a good worker but not keen on entertaining.

How the pair fell into an open well in the field, I’m not sure. Apparently, the wooden sides had collapsed or been taken down, perhaps to make it easier to fill an abandoned hole with rocks. Maude went in headfirst with Tom falling on top of her. Tom was okay but Maude had to be shot by my grandfather, a sad day on the farm.

Rocks have always intrigued me, partly because my mother has collected them over the years for her flower garden and patio. They don’t bloom but never need watering, plus have stories to share if we listen closely.

The same stones that were unwelcome in the pasture were thankfully not discarded. Now they’re quite useful for lining the banks of the stream. I trust they’ll slow the erosion, and perhaps even help regain lost ground as a respite for passing sand. During the past decades these rocks have changed very little. Yet they’ve transitioned from being unwanted to greatly valued. It was a matter of finding a purpose and being given an opportunity.

Granddaddy would be pleased those rocks are being put to use. I hope 50 years from now someone will find they were beneficial to the stream and maybe even listen to their story. That’s why I’ve been hauling rocks.

— Neil Joiner Vienna, Georgia gneiljoiner@gmail.com, joinerscorner.com

“Granddaddy would be pleased those rocks are being put to use.”

WE BELIEVE IN BETTER PLANTERS WITH BETTER ROW CLEANERS.

Have you heard of ttingretrofi or upgrading your planter but you’re just not sure it’s worth it? Join thousands of other farmers who have added Reveal and experience what it’s like to move your row cleaners off of the row unit, improve your row unit ride, and keep your row cleaners engaged without bouncing. The easiest way for you to try Precision Planting this year is by purchasing one row of Reveal.

WE CHALLENGE YOU TO PUT ONE ROW OF REVEAL® ON YOUR PLANTER THIS YEAR.

Hint: Rotate this ad to reveal one of the best places to start.