Cotton Farming

We know you’re busy with more important things, so we’ll get to the point. The U.S. Postal Service requires that we receive a written request from you to continue sending Cotton Farming for FREE.

Please take a few moments to renew online by scanning the QR code. We don’t want to lose you as a reader.

Are cover crops right for you and your operation? Hunter Frame, Virginia cotton specialist and Tidewater Agricultural Research and Extension Center field crop agronomist, recently sat down with Cotton Farming associate editor Cassidy Nemec to discuss the benefits, challenges and basic components of cover crops. Read this Q&A article to find out whether cover cropping might be worth exploring for your farm.

Lower RGV farmers are close to running out of irrigation water, a situation that studies show could impact agricultural production and jobs in the area.

Auburn University celebrates 100 years of Extension cotton entomologists keeping harmful insects in line.

What’s next for users and makers of crop protection products in a post-dicamba, pro-Endangered Species Act environment?

the official publication of the ginning industry

NCGA names the 2023 Horace Hayden National Cotton Ginner of the Year and the 2023-24 Charles C. Owen Distinguished Service Award recipient.

4

Natural tech for “dimming” genes brings transformative potential to agriculture. Texas A&M AgriLife researcher helps outline RNAi alternative to “knock out” technology. Go to www.cottonfarming.com for this Web Exclusive report.

Carroll Smith

We spend our entire lives moving from Point A to Point B as we navigate our way through life’s journey. Along the way, we follow the progress of other journeys specific to our livelihood or interests.

For example, I’ve noticed the evolution of social media in agriculture. Years ago, Louisiana crop consultant Roger Carter sent out a newsletter he wrote under the heading of his consulting company Agricultural Management Services, Inc. He talked about what was going on in the field during the cotton-growing season as the crop moved through its journey from planting to harvest. He was a good writer who knew how to keep your attention.

At the end of the newsletter, Roger shared interesting, informative tidbits about the local people he knew. Since we are from the same area, I knew most of them, too. He might mention who was sick, who was getting married, a family who was welcoming a new baby or who had passed away. It was an excellent way for me to keep up with what was going on back home. I always looked forward to Roger’s newsletters.

Also, when AgFax was produced by Owen Taylor and his wife, Debra Ferguson, Owen literally spent hours on the phone calling ag folks to find out what was going on with agriculture in their area so he could share the information with their subscribers. As many people will attest to, it was also a social call since he spent time “visiting” and catching up on a personal level with everyone. His calls were always enthusiastically accepted. Unfortunately, we lost Owen and Debra way too soon a few years ago, but they will be fondly remembered as icons in the agricultural world.

Today, like many other aspects of agriculture, social media has evolved into the digital arena via Facebook, Instagram and X (formerly known as Twitter) to name a few.

In this issue of Cotton Farming on pages 14-15, Dr. Ron Smith, professor emeritus at Auburn University, takes us on a journey in which he chronicles 100 years of Extension cotton entomologists, beginning with Mr. Jerry Ruffin who was hired by the Alabama Polytechnic Institute, now Auburn University, Sept. 1, 1924, as the first full time Extension cotton entomologist.

Smith said Ruffin traveled the state — wherever cotton was grown — and conducted educational programs with cotton farmers on how to manage and control the boll weevil. When he returned to campus, he wrote a newsletter about his insect observations and experiences, which he titled “Tales of Insects.”

At the end of the article, Smith assures us that “the Alabama Extension Cotton IPM educational program is positioned to continue to be on top of the cotton insect situation for the foreseeable future.”

Let the journey continue...

If you have comments, please send them to: Cotton Farming Magazine, 7201 Eastern Ave., Germantown, TN 38138.

Southeast

Associate Editor

Digital Content Editor

Art Director

ADMINISTRATION

Publisher/Vice President

Lia Guthrie (901) 497-3689 lguthrie@onegrower.com

Associate Publisher/Editor-In-Chief

Carroll Smith (901) 326-4443

Associate Publisher/Sales

Scott Emerson (386) 462-1532 semerson@onegrower.com

Production Manager David Boyd dboyd@onegrower.com

Audience Services

Kate Thomas (847) 559-7514

For subscription changes or change of address, call (847) 559-7578 or email cottonfarming@omeda.com

EDITORIAL ADVISORY BOARD

David Burns – North Carolina

David Lynch – South Carolina

Bob McLendon – Georgia

Larkin Martin – Alabama

Mike Sturdivant Jr. – Mississippi

Charles Parker – Missouri

Jimmy Hargett – Tennessee

Allen Helms – Arkansas

Jay Hardwick – Louisiana

Ronnie Hopper – Texas

Ron Rayner – Arizona

John Pucheu – California

Mike Lamensdorf President/treasurer

Lia Guthrie Publisher/Vice President

ACKNOWLEDGEMENT OF COOPERATION: Cooperating with COTTON FARMING are various cotton producer organizations across the Cotton Belt. Many representatives of producer organizations serve on COTTON FARMING’s editorial advisory board. Opinions expressed and conclusions reached by contributors are not necessarily those of the cooperating organizations or the editors. All statements, including product claims, are those of the person or organization making the statement or claim. The publisher does not adopt any such statement or claims as its own and any such statement or claim does not necessarily reflect the opinion of the publisher.

Copyright 2024 ©

ASSOCIATED PUBLICATIONS – One Grower Publishing, LLC also publishes RICE FARMING, THE PEANUT GROWER, SOYBEAN SOUTH and CORN SOUTH.

One

875

The 2023 U.S. Cotton Trust Protocol Annual Report reveals that 23% of all planted U.S. Cotton acres are now enrolled in the program.

■ The U.S. Cotton Trust Protocol was launched in 2020 and is the voluntary sustainability program for U.S. cotton growers, and traceability platform for all U.S. cotton. It is the only system that provides quantifiable/verifiable goals and measurement to sustainable U.S. cotton production while driving continuous improvement in six key sustainability metrics: land use, soil carbon, water management, soil loss, greenhouse gas emissions and energy efficiency.

■ The U.S. Cotton Trust Protocol has tripled its grower membership in just three years. The third Trust Protocol Annual Report at https://report. trustuscotton.org/ revealed these specifics:

1) 1.7m acres, representing almost a quarter (23%) of the entire cotton harvested area of the United States, were enrolled in the Trust Protocol;

2) 975 growers enrolled with all 17 cotton-growing states represented;

3) Of the 975 growers, 48% chose to apply for

the Climate Smart Cotton Program, reflecting a commitment to sustainable practices.

The Trust Protocol has welcomed more than 40 companies and their brands, including some of the largest names in fashion, such as Ralph Lauren and Gap Inc., as well as new members, such as Macy’s and Kiabi. Additionally, the program has successfully enrolled more than 2,000 mills and manufacturers from 40 different global regions and countries. In 2022-23, the Trust Protocol increased mill and manufacturer membership by over 144% from the year prior and expanded to 12 new countries.

■ A significant milestone came in September 2022 when the Trust Protocol was named the lead recipient of the U.S. Climate Smart Cotton Program, receiving funding and recognition as part of the USDA’s Partnership for Climate Smart Commodities pilot projects.

The Climate Smart Cotton Program is a five-year collaborative initiative that brings together partners from across the supply chain and provides additional benefits for growers, including technical and financial support. Among the goals of the program is to produce 4.2m bales of Climate Smart Cotton™, an ambition we expect will boost the growth of the Trust Protocol. I look forward to giving an update on progress next year following the first year of enrollment.

The Trust Protocol has achieved continued progress across all six key sustainability metrics. It is important to note the increase in the enrollment of growers who actively participate in the program, even amidst a challenging growing environment. This achievement can be attributed to our strategic approach of recruiting new members from across the full cotton supply chain — from growers to mills and manufacturers to brands and retailers. Gary

The global population and its need for food, clothing and other essential goods is constantly growing. Many of our most precious resources are finite, and the need to do more with our land and resources is a top priority for many industries beyond cotton. However, as a natural fiber, cotton directly depends on the health and vitality of the environment. For more than 40 years, the cotton industry has developed new and better ways to grow, process and manufacture cotton to protect and improve the soil, air and climates in which it grows.

BY STACEY GORMAN WARREN, ARKANSAS

BY STACEY GORMAN WARREN, ARKANSAS

We all have our roles to play when it comes to cotton sustainability. The U.S. cotton farmer strives for continuous improvement by producing more cotton using fewer inputs. Cotton mills and manufacturers work toward improved efficiencies with less waste. Brands and retailers have sustainability goals built into their brand values.

Cotton Incorporated, a not-for-profit research organization funded by U.S. cotton growers and importers, provides resources and research to help develop superior, innovative and profitable cotton products. Over the past 40 years, Cotton Incorporated has been a guiding leader for all segments of the U.S. cotton industry in the sustainability space and continues to do so today. Dr. Jesse Daystar, Cotton Incorporated’s chief sustainability officer, said, “Our sustainability efforts are spread across every facet of the cotton life cycle from fiber through finished product.”

Cotton Incorporated has stepped into the industry leadership role, giving us a “seat at the table” in many important sustainability circles. A recent example of this leadership is Cotton Incorporated’s membership in Europe’s Product Environmental Footprint (PEF) Technical Secretariat (TS). PEF is a European Commission initiative to measure and label the environmental impacts of individual products.

PEF aims to give individual products a score for how sustainable they are. One category specifically included in the PEF discussion is the apparel and footwear sector, which includes products like t-shirts, pants and socks. The PEF TS is responsible for developing robust, science-based calculation rules that detail the PEF methodology for apparel and footwear product subcategories.

Cotton Incorporated’s Michele Wallace, director of sustainability standards, is a technical expert and an active voting member of the PEF TS. Other members of the group include brands, NGOs and government agencies. The PEF TS does not create or influence policy for the European Union.

Cotton Incorporated provides technical guidance through the PEF TS to help establish sound methodology standards. “By having a seat at the table for U.S. cotton, we can work to safeguard the playing field for cotton and help ensure the methodology PEF uses is appropriate and accurate,” Daystar said.

He wants the methodology recommended by the PEF TS to account for all the impacts of fiber choice, including synthetic microfiber shedding and microplastic pollution, which provides an opportunity for cotton to come out ahead of its synthetic competitors. Trends like the PEF issue that occur in Europe often make their way to the United States and could have implications for U.S. cotton production and textiles.

As sustainability becomes an increasingly important topic in the textile industry, so does the research and data that helps Cotton Incorporated make claims and tell the sustainability story of U.S. cotton. The Sustainability Division at Cotton Incorporated is leading two life cycle assessment (LCA) projects to create better cotton data on U.S. cotton production and U.S. cottonseed utilization for cattle feed.

“Brands and retailers are demanding credible environmental assessment data to make claims and decisions surrounding their fiber choices,” Daystar said.

The current LCA projects will provide a robust dataset to use when telling the story of U.S. cotton production.

For more information on Cotton Incorporated’s myriad sustainability initiatives, visit cottontoday.cottoninc.com. The Cotton Today website brings to life the facts and the latest scientific discoveries in the world of cotton and sustainability.

Stacey Gorman is The Cotton Board’s director of communications. Contact her at sgorman@cottonboard.org.

New Madrid, Missouri

During college, I started scouting cotton as an intern for a local retailer who had hired a consultant. After I graduated, they hired me to consult on their cotton acres for about four years until I moved into sales. What piqued my interest in cotton and kept me scouting on the weekends was knowing I was helping farmers control insects, manage their crop and maximize yields. In 2012, I started my own consulting business — M&M Crop Specialties — in New Madrid, Missouri.

Last year was extremely dry, but a lot of the cotton acres in this area are irrigated. Because it was so dry throughout the growing season, we had tremendous mite pressure all year long. A huge rain came through the second week of August and threw a lot of fruit, but our crop was still a little bit above average.

I don’t mind a cover crop, but I advise growers to plant into a clean environment because weeds are a host for insects. The more weeds you have, the more insect pressure you have because there are two hosts in the field — weeds and cotton plants. Farmers need to layer residual herbicides to start off clean and try to prevent Palmer pigweed from emerging.

When we treated for thrips last year, we noticed the effectiveness of the thrips control products we used in the past had diminished. Some provided zero control. At that point, we applied Intrepid Edge® insecticide, which provided very good thrips control. This year, when we reach economic threshold for thrips, we will apply Intrepid Edge insecticide the first time. We are going to use the product that works.

Another target pest is tarnished plant bug. Early in the season, we scout for them with sweep nets. As the cotton gets bigger, we use black drop cloths to get our counts. We typically apply Transform® WG insecticide with Isoclast active around first bloom to control plant bugs in this area. It gives us a higher percentage of adult plant bug control than the products we used in the past and provides longer residual, too. About 80% of the time, one application of Transform WG insecticide has done a good job. If we have extremely high plant bug pressure, we make two applications of Transform WG insecticide back to back.

We got a great deal of fieldwork done this past fall and have the potential for an early cotton crop and a strong cotton crop, which is what we need to be successful in our area.

• Bachelor of Science degree in agronomy, Southeast Missouri State University.

• Started M&M Crop Specialties in 2012.

• Consults on cotton, soybeans and corn.

• Covers counties in Missouri, including New Madrid, Scott, Stoddard and Mississippi.

• Wife Kathy. Daughter Makenzie and her husband, Gage. Son Mason. Three grandchildren: Elle, Chandler and Forrest.

• Member of Church of Christ in New Madrid, Missouri.

• Enjoys golf and duck and deer hunting.

1. When we treated for thrips last year, we noticed the effectiveness of the thrips control products we used in the past had diminished. Some provided zero control.

2. At that point, we applied Intrepid Edge® insecticide, which provided very good thrips control.

3. This year, when we reach economic threshold for thrips, we will apply Intrepid Edge insecticide the first time.

4. We typically apply Transform® WG insecticide around first bloom to control tarnished plant bug. It gives us a higher percentage of adult plant bug control than the products we used in the past and provides longer residual.

Editor’s Note — Hunter Frame, Virginia cotton specialist and Tidewater Agricultural Research and Extension Center field crop agronomist, recently sat down with associate editor Cassidy Nemec to discuss the benefits, challenges and basic components of cover crops. Read the following Q&A to find out whether cover cropping might be worth exploring for your operation.

Q. How do I know if the ground in my area is suitable for cover crops?

A. All soil/ground is suitable for cover crops. The ground that is historically more weathered, eroded and/or tilled may often have the greatest returns in the short term from cover crops. Ground that has lower productivity (yields) is going to produce lower biomass levels than more productive ground, which also means less nutrient cycling. An important point to remember is that if you are looking to improve less-productive ground with cover crops, it will be a long-term commitment. Current results from a long-term experiment in Virginia shows that cover crops coupled with conservation

tillage systems increased soil carbon 50% over the conventional control in just six years.

Q. What are some initial considerations I should have when just starting to think about implementing cover crops into my operation?

A. The primary consideration is “what are your operation’s goals?” Do you want to improve soil chemical and physical properties? Nutrient cycling? Weed control? Take advantage of cover crop cost share programs? Each objective will result in different species selection, biomass goals and management of cover crops.

Q. Based on research up to this point, what type(s) of cover crops have shown the most benefit? For yield? For weed control? For plant health?

A. So overall, if you want to manage cover crops for the short-term, you are looking at nutrient cycling from

“Studies have shown that nitrogen application following legume cover crops can be reduced 50% to 100% while maintaining cotton lint yields of two to three and a half bales per acre.”

green manure crops. To achieve this, managing legumes for high biomass will give you the most bang for your buck. Species such as hairy vetch, crimson clover and Austrian winter peas are the safest options for winter annual covers throughout the cotton belt. These have shown to have high nitrogen and potassium cycling (>200 pounds of N or K2O per acre), which are the most advantageous to cotton production. We have shown in Virginia that we can grow cotton without additional fertilizers following a crimson clover/hairy vetch cover and maintain lint yields 1,100 pounds to 1,500 pounds per acre.

If weed control or building soils is your primary goal, having a small grain (cereal rye, triticale, oats, wheat or barley) in the mix is a necessity. These high carbon-to-nitrogen (C:N) ratio covers with small grains provide a great mulch to limit weed emergence. However, to increase the benefit, you will need to maximize biomass for greater effect.

These covers all provide carbon to the soil and have the potential to increase soil carbon and organic matter, which will aid in improving soil structure, water holding capacity and nutrient-holding capacity.

Q. How do I go about getting started with cover crops? NRCS? Extension office?

A. The first thing to do is define your goals and be realistic in what you want to achieve. Then plan out what species you may want to plant to achieve these goals. Then you can research and look into programs through NRCS and state agencies that have cost share programs. There are good resources across the cotton belt on characteristics of different cover crops and what their greatest benefits might be.

Q. What if I tried cover crops last year, but they didn’t really add any benefit? How long might it typically take to see an added benefit?

A. Again, it depends on the goals. If you are looking to reduce your fertilizer bill, then biomass is king, and you need to have a legume in that mix or just use a single legume species. You should be able to see the impact of a legume cover in the first year as that nitrogen will be released to the cotton following the cover crop. Again, if you have biomass levels of 4,000 pounds to 8,000 pounds of dry biomass per acre, there should be enough nitrogen and potassium to supply the cotton for high yields.

To improve soil quality or productivity is the long-term objective. It will take multiple years to see the benefits of cover crops when coupled with other conservation practices. You should start to see some measurable benefits in three to five years.

A. This is where growing high biomass cover crops can become difficult in a cotton production system. When

“Current results from a long-term experiment in Virginia shows that cover crops coupled with conservation tillage systems increased soil carbon 50% over the conventional control in just six years,” Frame said. Pictured here are cereal rye, crimson clover and hairy vetch cover crops in a field.

you have 5,000 to 8,000 pounds of dry biomass per acre, there is a substantial residue mat to plant through. Seeding depth is critical for cotton and ensuring that 0.5-inch to 0.75-inch planting depth is essential for having cotton emerge. This is going to take changes to planters and attention to detail when operating the planter. To maximize nitrogen cycling, legume covers need to be allowed to get to 50% bloom in order to maximize nitrogen accumulation for the legume. Doing this can sometimes delay cotton planting as the cover is easier to plant through when it is completely dead. In Virginia, we are nearly all strip tillage, so ensuring a good kill aids in preparing a seed bed for cotton planting.

For small grains, you will need to allow that plant to get to a minimum of the heading stage. This will allow for greater biomass production and a high C:N ratio to allow for the residue mat to persist throughout the growing season to control weeds. Again, these can be tricky to plant through, and some of our producers have found that rolling small grain the same direction of planting is beneficial. We have experimented with leaving non-planted strips where strip tillage will be done the following spring, and this has resulted in better stand establishment.

Another drawback to small grain cover crops is that nitrogen can be immobilized from the high C:N ratio, so cutting back a soil fertility program is not recommended, and your nitrogen fertilization rates may need to be increased slightly.

Q. When do I terminate the cover crop? How long after planting?

A. For the Southeast U.S., cover crop termination is going to take place most likely in late March through early May depending on your latitude. Again, you want to terminate at 50% flowering or heading depending on legumes and small grains. Cover crop variety selection is important to select species and/or varieties to synchronize flowering for optimum termination to achieve goals.

If chemically terminating, it will take approximately two to four weeks for a complete kill of cover so that you can plant into it successfully. A complete kill is when all of the biomass is brown and desiccated to make it easier to cut through with coulters and double disc openers on the planter. You can also plant without terminating (planting “green”), and it would be beneficial to roll the cover in the same direction as planting, especially if you have strip tilling. These decisions largely depend on equipment available and how comfortable you are that you can successfully produce cotton stands for optimum yields.

Q. What about drier areas that lack excess moisture for another crop (ex. The cover crop is taking up the moisture I need to grow my cotton, etc.)? What would you recommend?

A.In areas where moisture can be limiting, cover crops can be detrimental to cotton establishment and early season growth. I would recommend consulting your state’s Extension specialist on best management practices for cover crops. This goes along with what information may be needed to ensure cover crops can work on your farming operation. Even in Virginia, we had a situation where late-planted cover crops delayed maturity until late May. As a result, soil moisture was depleted at the site and cotton establishment was poor. Situations can arise, even in humid regions, where soil moisture depletion can come into play using cover crops.

Q. How would fertilizer recommendations change with cover crops?

A. The one area where cover crops can have an immediate impact on economic returns to producers is reducing

“The one area where cover crops can have an immediate impact on economic returns to producers is reducing fertilizer costs, especially nitrogen costs in cotton,” Frame said. Pictured here is a cotton crop planted into cereal rye, crimson clover and hairy vetch.

fertilizer costs, especially nitrogen costs in cotton. First, you have to select the appropriate legume species to maximize nitrogen uptake and potential release upon decomposition. For us in Virginia, this has been hairy vetch, crimson clover and Austrian winter peas. These species routinely can achieve biomass between 4,000 pounds to 8,000 pounds of dry biomass and can accumulate nitrogen in the aboveground biomass from 140 pounds to 210 pounds of nitrogen per acre.

Studies have shown that nitrogen application following legume cover crops can be reduced 50% to 100% while maintaining cotton lint yields of two to three and a half bales per acre. An additional benefit is the legume cover crops also uptaking 180 pounds to 250 pounds of potassium oxide per acre. This would be highly significant to cotton that suffers from potassium deficiencies. Research is ongoing to determine whether this potassium is plant available following termination.

If using small grains as cover crops, the opposite may be true regarding nitrogen fertilizer management. As the small grain cover crop elongates and approaches heading stages, a carbon penalty is incurred each day, meaning that the C:N ratio increases. As a result, upon decomposition, soil microbial communities will scavenge free nitrogen in order to metabolize the small grain biomass. Thus, they are competing with (also known as immobilization) the crop plant for applied nitrogen in the form of fertilizers. If the C:N is greater than 25, it may take more nitrogen fertilizer to produce the same lint yields due to immobilization.

There are trade offs depending on what system or objectives you may have for cover crops. Understanding these will help you plan a sound fertilizer management strategy prior to implementing cover crops on your operation.

Q.

A.How do I go about getting started with cover crops? NRCS? Extension office?

The first thing to do is define your goals and be realistic in what you want to achieve. Then plan out what species you may want to plant to achieve these goals. Then you can research and look into programs through NRCS and state agencies that have cost share programs. There are good resources across the cotton belt on characteristics of different cover crops and what their greatest benefits might be.

Lower Rio Grande Valley farmers are close to running out of irrigation water, a situation that studies show could have major impacts on agricultural production and jobs in the area.

Texas Farm Bureau state directors toured the Valley with Hidalgo County Farm Bureau leaders recently to learn more about the issue. The area is often referred to as the Land of Two Summers. It’s an ideal growing climate for fruits, vegetables and major row crops.

“But it is very hot here, and our water supply is our lifeline. It’s crucial to our crop production,” said Courtney Schuster, organic farming director at Rio Fresh.

In the Valley, temperatures rise to over 100 degrees for sometimes 100 days in a row. The intense heat, combined with crippling drought, takes a toll on the area’s agricultural production.

And just because farmers have water rights doesn’t mean they’ll have water this year. Many districts in the region have no irrigation water allocated for farmers in the area, and the situation is made worse by the ongoing drought conditions.

Reservoirs are at an all-time low. Lake Falcon’s water levels have fallen to 18.2%, and Lake Amistad has dropped to 24.8%.

“It’s very challenging to plan your year when your water availability is so uncertain,” Isaac Sulemana, Hidalgo County Farm Bureau president, said. “Unlike other parts of the state, our water is almost entirely surface water. It comes from the Rio Grande, which we share with Mexico.”

The neighboring country is significantly behind on the water it owes the United States under the 1944 Water Treaty, further exacerbating the water issue for Valley farmers.

“I’m a 100% irrigated farmer with zero water right now, so my plan is still a little bit in flux,” said Brian Jones, TFB District 13 state director from Edcouch.

He said it’s important to continue

To view the 1944 Water Treaty, go to https:// www.ibwc.gov/wp-content/uploads/2022/ 11/1944Treaty.pdf

bringing the water issue with Mexico to the forefront to help U.S. farmers who are struggling without water.

“We need to find some type of pressure point to apply to Mexico to make them comply and release the water that needs to be released,” Jones said. “We need the Biden administration to step up and enforce the treaty that’s not being enforced right now.”

Drought conditions are cyclical, but Jones noted this cycle seems to be taking longer to clear out and get back to normal.

“And once we do get water into the dams, the situation once again goes on the back burner,” he said. “We need to come to a solution where Mexico’s delivering the water that they owe us annually. Under the treaty, they’re supposed to deliver 350,000 acre-feet per year, and they’re not doing that.”

Enforcing the 1944 Water Treaty is a priority issue for Texas Farm Bureau.

“The tour gave us more insight into the issues farmers and ranchers are facing here,” TFB District 9 state director John Griffith said. “Their livelihood is so dependent upon the water release and waiting for a rainstorm, a tropical event or a hurricane to bring them water.

“This was an eye-opening tour, and the meetings we have the opportunity to conduct and be part of, not only on the state level but on the federal level, can hopefully bring more awareness to the current situation they’re facing down here,” Griffith said.

A situation, that if not addressed permanently, leaves Lower Rio Grande Valley farmers facing a tough decision — to hang on as long as they can or step away from farming.

Julie Tomascik is editor at Texas Farm Bureau.

The Cotton Consultant of the Year celebration was held March 1 at the Peabody Hotel in Memphis, Tennessee, to honor the 2023 CCOY and all past CCOY recipients. This prestigious annual award is sponsored by Syngenta and Cotton Farming magazine.

Eric Bell (left) of Huntingdon, Tennessee, was recognized as the 2023 CCOY.

Je Mink, Agronomy Services Manager at Syngenta Crop Protection, congratulated Bell and expressed his pleasure as a sponsor of the CCOY award that has been in place for more than 40 years.

Bell’s friends and family attended the reception to honor him and celebrate the e orts of all cotton consultants across the Cotton Belt.

The Arkansas Boll Weevil Eradication Foundation (ABWEF) board of directors voted Feb. 7 to authorize the distribution of a $1 per acre cash rebate to growers for reported 2023 cotton acres registered with the Arkansas Boll Weevil Eradication Program. A total payout of $485,730 will be returned to Arkansas cotton farmers.

“Production agriculture has never been more expensive and financially burdensome on the growers than it is today,” said Joe Mencer, a grower from Chicot County and ABWEF Chairman. “We’re pleased to support the grower in this way to alleviate some of those financial pressures and return their money to their pockets.”

“The board is committed to the stewardship and effective use of the dollars we’re entrusted with to reduce expenses while maintaining exceptional service,” said Arkansas Boll Weevil Eradication Foundation Executive Director Regina Coleman. “This rebate is another way we support our growers and protect their bottom lines.”

The Arkansas Boll Weevil Eradication Foundation began eradication operations in 1997, making annual expansions that ultimately grew to include all cotton-producing areas in the state. ABWEF successfully eradicated the boll weevil in Arkansas in 2008. Since then, ABWEF continues to operate under a maintenance program, monitoring the state for the presence of boll weevils, which is entirely a prevention effort.

Learn more about ABWEF and its mission to protect the Arkansas cotton industry at ABWEP.org.

Corteva continues its drive to deliver farmer-focused solutions with the launch of Enversa herbicide. The new versatile solution received U.S. Environmental Protection Agency registration in December 2023.

Pending state registrations, Enversa herbicide is expected to be available for use on cotton, soybeans, corn, sorghum, peanuts and sugar beets in the 2025

growing season.

“Enversa is a residual herbicide that will handle some of the toughest, hardto-control broadleaf and grass weeds that farmers face today,” says Shawna Hubbard, strategic marketing manager, Corteva Agriscience. “This will be the first soybean and cotton herbicide in Corteva’s portfolio to feature a proprietary encapsulated acetochlor component to help protect plants from emerging weeds.”

The encapsulated acetochlor complements tankmix partners by allowing Enversa herbicide to move from the leaf surface and drive to the soil, resulting in a residual barrier around the soybean or cotton plant.

In addition to its versatility across crops, Enversa herbicide provides farmers with a wide application window — preplant up to R2 for soybeans and preplant up to first bloom for cotton — to help navigate challenging weather conditions. Enversa herbicide offers easy handling and tankmix compatibility, particularly with Enlist One herbicide for Enlist E3 soybeans and Enlist cotton.

“Enversa is designed to serve farmers by providing high crop tolerance along with the residual weed control they’ve come to expect with Group 15 herbicides as part of their weed control program,” Hubbard says.

Enversa herbicide delivers extended weed control for up to four weeks on more than 25 of the toughest broadleaf and grass weeds, including Palmer amaranth and waterhemp. In addition to compatibility with Enlist One herbicide for Enlist E3 soybeans, Enversa herbicide will fit perfectly into a program approach along with other Corteva Agriscience soybean herbicides, such as Sonic and Trivence.

To learn more about Enversa herbicide, talk with your local Corteva representative or visit Corteva.us/Enversa.

The U.S. Cotton Trust Protocol is introducing an expanded field-level team dedicated to providing regional support for U.S. cotton growers participating in the voluntary sustainability initiative. This includes aiding producers with

finalizing Trust Protocol enrollment and data entry as well as applications for the Climate Smart Cotton Program by the April 30 midnight deadline.

Charles “Chaz” Holt is serving as Director of Field Programs and will lead the team, which also includes Tillman White serving as Program Manager. Field-level Grower Enrollment Specialists have also been added to the team, which will provide not only cotton industry resources and networks, but also the ability to tailor their services to the unique needs of the Cotton Belt region they serve. Grower Enrollment Specialists include Bailey Nesmith serving the High Plains & West Region, Willis Frazer in the Mid-South, and Maryn Findley for the Southeast.

“Each region of the Cotton Belt presents its own distinct set of opportunities and challenges, with no one-sizefits all approach to production,” said Daren Abney, executive director of the U.S. Cotton Trust Protocol. “In 2023, we experienced our largest enrollment of planted U.S. cotton acres yet, which further underscores our producers’ commitment to sustainability and progress. As we move forward, our field-level team is available to offer regionally relevant support to growers as they make continuous improvements. This momentum builds upon the growth in our global supply chain membership, which now includes 40+ companies and their brands, alongside more than 2,000 mill and manufacturer members.”

For the 2023 crop year, more than 1.7m planted cotton acres were enrolled in the Trust Protocol, representing almost a quarter (23%) of the Cotton Belt. Growers who completed their enrollment during either period in 2023 need to re-enroll for the 2024 crop year.

During enrollment, growers can apply for the Climate Smart Cotton Program, which provides producers with financial and technical support to de-risk the implementation and adoption of Climate Smart Agriculture practices while potentially reducing costs and boosting efficiencies. For brands and retailers, the program aims to help support efforts to improve their greenhouse gas emissions

reductions and reporting.

The Climate Smart Cotton program began less than one year ago and has already approved applications for 778 farming entities in Level 1 of the 1,650 available, including 330 from historically underserved communities. Growers are encouraged to get started today as applications are reviewed on a first-comefirst-serve basis.

To complete enrollment in the Trust Protocol and apply for the Climate Smart Cotton Program ahead of the April 30 midnight deadline, visit TrustUSCotton. org.

Joe Nicosia, a Cordova, Tennessee, merchant, was elected National Cotton Council chairman for 2024 during the organization’s annual meeting in Orlando, Florida.

Patrick Johnson, a producer from Tunica, Mississippi, will serve as vice chairman for 2024.

Nicosia has been a member of the board of directors of the National Cotton Council since 2011, was a segment vice president from 2014 to 2020, and currently also serves on the Executive Committee.

He has served on multiple NCC committees including current membership on the NCC Farm Policy Task Force and the Performance and Standards Task Force.

Nicosia is the Global Trading Operations Officer for Louis Dreyfus Co. as well as the Head of the Cotton Platform. He is also the Executive Vice President of Louis Dreyfus Co. LLC and Chief Executive Officer of Allenberg Cotton Co.

In 1981, Nicosia completed his Bachelor of Arts degree in economics from Dartmouth College and immediately embarked on his career as a grain trader at the Louis Dreyfus Co. in Minneapolis. The following year, he transferred to Allenberg Cotton Co. and in 1985 assumed responsibility for cotton trading worldwide.

He is active in several cotton industry associations and is a past chairman and serves on the board of directors of the American Cotton Shippers Association

(ACSA). He is also the long-time chairman of the Futures Committee of ACSA.

Elected as a NCC vice president was Mike Quinn, a manufacturer from Sanford, North Carolina.

Re-elected as NCC vice presidents were Hank N. Reichle, Jr., a Greenwood, Mississippi, cooperative official; Raymond Faus, a Richardson, Texas, merchant; Sammy Wright, a Tifton, Georgia, cottonseed processor; Kirk Gilkey, a Corcoran, California, ginner; and Jay Cowart, an Altus, Oklahoma, warehouser. Reelected as secretary-treasurer is Mark McKean, a producer from Riverdale, California.

Re-elected as NCC staff officers were Gary Adams, president and chief executive officer; Marjory Walker, vice president, Operations; Jody Campiche, vice president, Economics and Policy Analysis; John Gibson, vice president, Member Services; Tas Smith, vice president, Producer Affairs; Harrison Ashley, vice president, Ginner Services; Chad Brewer, vice president, Technical Services; and Robbie Minnich, vice president, Washington Operations.

AMVAC Chemical Corp. is pleased to announce that Zalo herbicide, enabled by ProLease technology, has received federal registration.

Zalo is now registered for early to mid-post-emergence use in glufosinate trait-enabled soybean, cotton and canola. In addition, the label will include pome and stone fruit crops. Zalo will be available for the spring 2024 season following state registrations.

“We are very excited to be able to bring Zalo to market because of the significant advantages it provides farmers. In addition to broad spectrum broadleaf weed control, Zalo provides enhanced grass weed control with crop safety,” says AMVAC Corn, Soybean, and Sugar Beet Marketing Manager, Mark Foster. “Zalo combines multiple active ingredients and modes of action to take weed control up a level, delivering control of labeled broadleaf weeds plus control of labeled annual and perennial grass species, including non-Enlist traited volunteer corn.”

Zalo is a premix of glufosinate (the active ingredient in Liberty 280 SL her-

bicide) and quizalofop (the active ingredient in Assure II herbicide) — two proven active ingredients in one powerful formulation. Strong control of broadleaf weeds is combined with broad-spectrum control of annual grasses including non-Enlist traited volunteer corn, giant foxtail, fall panicum, and shattercane, and perennial grasses, including johnsongrass and quackgrass.

“Zalo also stands apart from other herbicides because it is enabled by ProLease technology, a unique process developed by AMVAC that protects the herbicide molecules from performance inhibitors, allowing them to reach the target weed where the molecules are released for superior activity,” says Foster. “Specifically, research shows that ProLease technology helps overcome degradation, separation and compatibility or mixing issues in the container and as a mixture in the sprayer.”

Zalo is designed for grower applicators and custom applicators with the following needs:

Glufosinate users who want a simple, more consistent performing product for grass control versus glufosinate alone.

Those who are currently tankmixing fop or dim ingredients with glufosinate and looking for convenience, better spray tank product stability and less container disposal.

Those looking for an alternating treatment with an auxin herbicide on Enlist or XtendFlex crops for resistance management.

Growers needing broad-spectrum broadleaf and grass weed control beyond mandated dicamba “cutoff” dates.

Zalo is a superior liquid technology with an easy-to-understand rate structure. The use rate of Zalo is similar to that of a 280 formulation of glufosinate, while delivering two active ingredients for enhanced weed control.

Academic and private contract research in 2023 show that Zalo provided 9 percentage points better grass and weed control than Liberty 280 SL herbicide. When compared to generic glufosinate, the Zalo control advantage was even greater, outperforming on both labeled grass and broadleaf control.

When considering price and performance, Zalo enabled by ProLease technology is an effective treatment for early to mid-post control of labeled grass and broadleaf weeds.

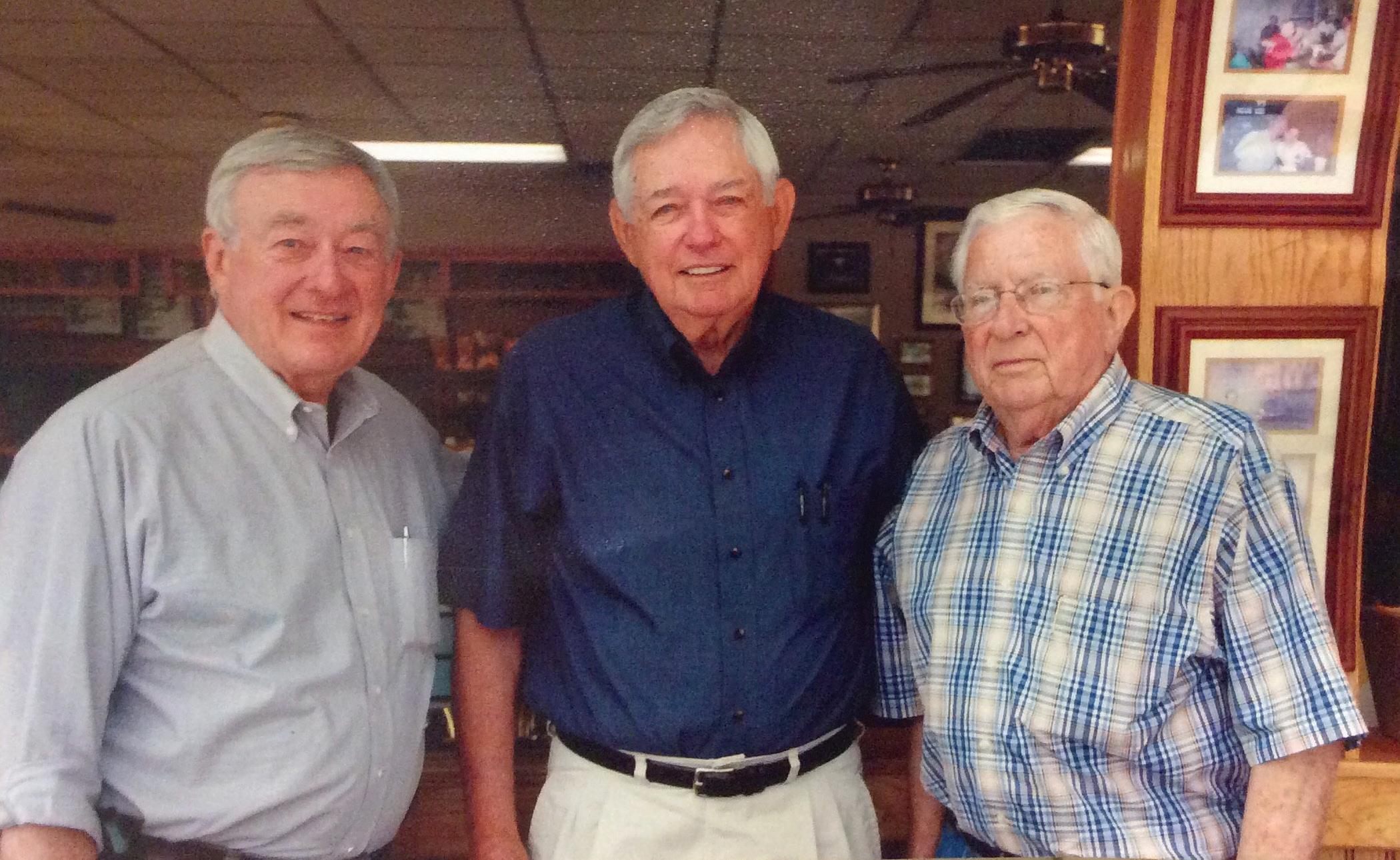

On Sept. 1, 1924, Mr. Jerry Ruffin was hired by the Alabama Polytechnic Institute, now Auburn University, as the first full time Extension cotton entomologist. Prior to that time, from 1908 to 1924, Dr. Warren E. Hines served as both researcher and Extension for cotton entomology. Ruffin served in his capacity as the Auburn Extension cotton entomologist for the next 36 years, until he retired Jan. 15, 1961. Upon his retirement, Ruffin served the Alabama Department of Agriculture and Industries as Assistant Commissioner of Agriculture into the mid 1970s.

While Ruffin was serving as Extension cotton entomologist, he traveled the state — wherever cotton was grown — and conducted educational programs with cotton farmers on how to manage and control the boll weevil. Since roads were limited in many rural areas of the state, Ruffin often traveled to many counties by train. Local county agents would meet the train and transport Ruffin out to the cotton farms. When Ruffin returned to campus, he would write a newsletter about his insect observations and experiences, which he titled “Tales of Insects.” These newsletters are currently located in the Archives of the Auburn University library.

Upon Ruffin’s retirement, Dr. Walter Grimes was employed in 1961 as his replacement. Grimes could be listed as the father and originator of the “Cotton Insect Scouting Program.” This program is still ongoing in 2024 and is the longest running continuous Extension educational program in the now Alabama Cooperative Extension System.

The program consisted of training students — primarily college age — to monitor or scout grower’s fields on a weekly basis and provide a written report to each grower on the level of damaging insects present that week. This information was used by growers to make

treatment decisions when insects were causing economic damage.

Prior to that time, many growers just applied insecticides for damaging insects (primarily boll weevils) on a four-tofive-day schedule throughout the season. After getting this scouting program established and running, Grimes went on to a distinguished career in the agrichemical industry. He concluded his career as vice president of research with the Chemagro Corp. (now known as Bayer) with headquarters in Kansas City, Missouri.

Grimes was followed in 1962 by Dr. Roy J. Ledbetter, who served as Extension cotton entomologist until 1976, at which time he moved into Extension administration as assistant director of Extension for Agriculture and Natural Resources. Ledbetter’s greatest contribution to Extension cotton entomology came from his temporary assignment in 1971 in Washington D.C. During

this time, he served as part of a small committee in an advisory capacity to the Under Secretary of Agriculture.

The role of this committee was to devise a national plan on how to use additional funding to better manage cotton insects. This funding was provided cooperatively by two entities of the U.S. Department of Agriculture, the Extension service and the Animal and Plant Health Inspection Service (APHIS). The funds were to be made available to each cottonproducing state to employ an additional cotton entomologist.

Ledbetter was the key person who developed the formula for how these funds would be divided among the different states. His formula considered the severity of boll weevil pressure (dollar losses), the historical number of insecticide applications made annually for boll weevil control and the total number of individual cotton growers within each state.

Based on Ledbetter’s formula and his close working relationship with Dr. Ned

Bailey, Under Secretary of Agriculture, and Dr. Ray Scott, Associate Secretary of Agriculture, Alabama, was able to receive approximately $150,000 additional dollars each season to support this intensified Extension program. The additional funds continued for more than 30 years and amounted to almost $5 million. Today, this still stands as one of the largest grants of additional fundings in the history of the Alabama Extension Service.

The funding also supported the hiring of Dr. Ron Smith on April 4, 1972, to provide leadership for the program. Smith’s career overlapped with Ledbetter for approximately four years. The cotton scouting programs and information on the management of cotton insects were significantly advanced during the decades that followed. Smith provided leadership for the cotton Integrated Pest Management program until his retirement Dec. 31, 2003. During the period from 1964 to 1977, a survey entomologist by the name of Frank McQueen also provided valuable educational support for Alabama Extension cotton IPM.

During Smith’s leadership, scouting schools were expanded to other cotton production regions of the state in addition to the one held annually on campus at

Auburn. Weekly insect situation newsletters went out to counties, scout supervisors were employed, two area cotton entomologists were added along with four multi-county agents solely for cotton IPM.

Weekly news articles on cotton IPM were provided to regional and national ag media (more than 500 in the Southeast Farm Press), and 800 phone lines with up-to-date weekly management advice were available during the growing season. In addition, winter educational meetings and in-season turnrow meetings were held in most every cottonproducing county on an annual basis.

Following Smith’s retirement in December 2003, he continued his service to Extension and the Alabama cotton industry on an annual contract basis. These annual contracts, which began in 2004, will be continued through the 2024 season. 2024 will be Smith’s 53rd cotton production season as an Extension entomologist.

Tim Reed also provided leadership for this program from his off-campus location in the Tennessee Valley. Two other area cotton entomologists provided major contributions to this intensified cotton IPM educational program. They were Barry Freeman in the Tennessee Valley and Glen Worley in central and south Alabama from his Selma location.

After Reed’s untimely death, Dr. Scott Graham, a native of Mississippi, came to the Alabama Cooperation Extension System with an excellent background in cotton IPM. In earning his master’s degree at Mississippi State University and Ph.D. at the University of Tennessee, Graham worked under several of the most prominent cotton entomologists of the current generation.

During the past four seasons, he has advanced the Alabama cotton insect management program to new levels of excellence. Graham has developed relationships and respect with and from growers, private consultants, agri-fieldmen, Extension agents and others in every area of the state. He has gained the respect of all and is in position to move this established and long running Extension program to new heights.

Many things have changed regarding cotton insects over the past 100 years that are too numerous to discuss in this article. But rest assured, the Alabama Extension Cotton IPM educational program is positioned to continue to be on top of the cotton insect situation for the foreseeable future.

Dr. Ron Smith is professor emeritus, Auburn University.

Establishing a cotton stand can be tricky. Given the current time of year, I will give an analogy that compares college baseball to healthy cotton stand establishment. Here it goes: in baseball, it all begins with planning and recruiting the best players, using solid equipment, lots of practice, execution and a little luck. Cotton stand establishment can be viewed the same way. Cotton producers study variety performance as it pertains to their region and agronomic practices to hedge against poor variety placement right out of the gate.

Prior to planting, planter maintenance is paramount to ensure nothing is worn out or needs replacing, and hopefully the planter got a little “practice” in planting both corn and soybean (Mississippi). It’s also about execution and getting proper seed-to-soil contact at proper depth and soil moisture. Precision planters are good about informing you of current seed-to-soil situation, but with proper diligence, the same seed placement can be achieved with most any good working condition planter.

emergence is likely to be greater when utilizing a resistant cultivar. When planting with susceptible cultivars in these conditions, it is recommended to use a seed-applied nematicide along with an in-furrow nematicide to protect young cotton seedlings. brwilson@missouri.edu

We are hearing more about growers increasing cotton acreage since earlier in the year as cotton prices have rebounded relative to corn and soybeans. With mid-80s pricing, we still have to be very careful with inputs. In January, we talked about concentrating on basic expenditures that can make us money. These are variety selection, fertility, weed and insect control and avoiding unproven inputs.

Reducing risk is also a good strategy to help when facing tight economics. There are several ways to reduce risk. Spreading out the planting season can help reduce risk so that all of your crop is not subject to the same adverse weather conditions like drought or tropical storms. Using multiple varieties can also reduce risk. Avoiding the use of disruptive insecticides where they are not needed can help reduce the risk of causing other insect problems. Additionally, plan ahead to use more stormproof varieties for fields that you will likely harvest last. keith_edmisten@ncsu.edu

bkp4@msstate.edu

And finally, a little luck goes a long way, whether it’s from Mother Nature or attributed to one of those perfect planting seasons! Perfect planting conditions and timing can help bring in the win in terms of yield about as much as anything else. From a Mississippi State perspective, it couldn’t have gone more right in 2021, and we struggled in both 2022 and 2023. Even when you do everything right, sometimes it just doesn’t all add up… so, I’m hoping for a little luck this year!

Healthy plant stands are extremely important to produce a timely cotton crop in the Missouri Bootheel. Being on the northern end of the cotton growing region, unhealthy or reduced plant stands can delay crop maturity and can cause reduced cotton yields at harvest. Furthermore, replanting due to unhealthy or reduced stands also leads to a delay in crop maturity. At planting, conditions can change rapidly in our cotton-growing region, it is not uncommon to have high amounts of rainfall and cool conditions following the planting window. The environmental conditions mentioned above at planting are known to increase seedling diseases in young cotton seedlings. When planting early or in adverse conditions, it is beneficial to utilize an in-furrow fungicide to protect seedlings from organisms that cause seedling diseases.

When making the decision to put seed in the ground, we want environmental conditions to have a favorable outlook in the first five days. When cotton DD-60s are predicted to accumulate 36 to 50 inches in the five-day outlook, we deem these as favorable conditions to place seed in the ground. Soil temperatures two inches to four inches in depth should be at 65° Fahrenheit before seed is placed into the ground for optimum germination.

It is common to observe cover crop utilization in Missouri for protection of young cotton seedlings from sandblasting. Generally, it is recommended to terminate cover two to three weeks prior to planting to reduce competition. Additionally, planting into weed-free conditions will also reduce growth competition and eliminate insect hosts from the field. Planting into living cover is generally not recommended as it can cause reduced stand establishment and result in a “green bridge” effect that increases cotton insect pests. In fields infested with nematodes, seedling

Establishing a healthy cotton stand is critical along the northern edge of the cotton belt, as unhealthy stands often result in delayed maturity and put us at risk of running out of heat units. The healthiest stands will be in fields which do not have “green” plant material present — whether that be cover crops or weeds. Properly burning down will prevent green bridge pests from bleeding over into our cash crop and will ease weed control activities in-season. Achieving adequate seed-to-soil contact without placing the seed too deep will also help each seedling get off to a great start. If not planting ThryvOn, an insecticide application targeting thrips at the emergence of the first true leaf will likely be warranted. Acephate resistance in thrips has pushed us to other chemistries for this spray. This insecticide application is very important if thrips pressure is moderate and cool, wet conditions are in the forecast. Keep in mind that pop-up fertilizers are not needed in Tennessee cotton; most of our soils are capable of meeting early season cotton nutrient demands through squaring. traper@utk.edu

April is burndown month for cotton here in Virginia and sprayers will be covering as many acres as possible. As I write this in March, it looks like cotton acres will be up in Virginia as corn and soybean prices remain lower and less competitive. However, things can change in a hurry as we all know. Proper burndown is key to achieving adequate cotton stands. Winter cover crops are becoming increasingly utilized in Virginia with research demonstrating that cotton can be produced following legume cover crops without the need for fertilizer nitrogen.

Timely burndown is critical to minimizing competition for soil moisture and prevent cover crops from becoming weeds themselves. Also,

seed preparation is complicated with the use of cover crops, so producers need to commit to a complete kill of the cover crop or planting “green” when it comes to cotton. Most are burning down to alleviate complications when utilizing strip-tillage for cotton planting. Little to no cotton is produced using conventional tillage in Virginia, and only a small acreage is grown under no-till.

The difficultly of high biomass cover crops is maintaining proper seeding depth when you have a residue layer two to five inches thick and want a cotton seed no deeper than 0.75 inches. When equipment is set properly, even in heavy cover crop biomass, cotton stands can be achieved with surprising results. An adequate stand in Virginia is final population of two plants per row foot equaling 29,000 plants per acre on 36-inch row spacing. We recommend to have a goal of 2.5 plants per row foot and a final plant population of around 36,000 plants per acre. This would mean a seeding rate of 2.75 to 3.0 seeds per row foot. Finally, check your cool and warm germination for your seed lot and plant when environmental conditions are conducive for cotton emergence. whframe@vt.edu

“Anybody can plant cotton...” There’s a lot of truth in that — anybody can put the seed in the ground, but that doesn’t guarantee a good stand. A lot goes into getting a stand of cotton and below are some of the things I’d be thinking about.

Planting seed quality — Putting good seed in the ground is extremely important. The best measures we currently have for seed quality are warm and cool germ tests, but other things in the seed contribute to seed quality as well. If you would like to get your seed tested prior to planting, please contact your local University of Georgia county Extension agent.

Seedbed preparation — Regardless of conventional or strip tillage, having a good, clean seedbed at planting is vital for seed-to-soil contact, thus resulting in a higher likelihood of a good stand. Good moisture at planting might be the most critical step to getting a gold stand in Georgia. Of course, in our dryland fields, we need to plant when we have moisture. In irrigated situations, we can help ourselves a little more, but it is vital in both situations to plant into good moisture.

Planter performance — Make sure your planter is performing properly prior to and during planting. Drs. Wes Porter and Simer Virk created a planter checklist to help with this that can be found here: https://iipa. uga.edu/docs/iipa/publications/Row-Crop-Planter-Checklist.PDF.

Anybody can plant cotton, but everybody can’t get a stand. I’m hoping for incredible conditions and wish you all a safe and productive planting season. As always, if you ever need anything, don’t hesitate to reach out. Your local UGA county Extension agents and specialists are here to help! camphand@uga.edu

Is it not amazing that we can poke a rock-like kernel in the ground and ultimately make our living from that?! Though much preparation proceeds planting, stand establishment launches the season.

According to my favorite weather expert Eric Snodgrass, who posts his thoughts weekly on Cotton Incorporated’s Cotton Cultivated webpage, April and May 2024 are expected to be slightly wetter than normal. He also admits that extended forecasts for this period — prime time for planting cotton in the Lower Southeast — are not rock-solid. Jet stream patterns, slow-moving or stationary highs and lows, etc. are somewhat unpredictable during mid-spring and make for difficult, slippery forecasts.

Remember what happened in 2023? April and the early days of May

last year were much cooler than normal. At Prattville, we counted only a 20% stand seven days after a May 2 planting. That was surprising but should have been expected — for three days after planting, the daily lows averaged 46 degrees F. We normally see strong emergence four to five days after planting. Cool weather made for a slow start last year… but we caught up in July and August with HOT temperatures.

Assuming near-normal April temperatures and a favorable forecast, many should take advantage of available soil moisture any time after April 15-20 and commence planting, especially if the time required for planting exceeds 18 days. For us, soil moisture is usually a greater limiting factor than soil temperature.

Two more suggestions. In terms of seed, know what you’ve got. Request from your dealer the warm and cool germ data as well as seed count per pound for each seed lot. Varieties with low cool germ values and small seed generally have limited pushing power. These should be planted when conditions are ideal for emergence, which means soil temps in the 70s or better with good soil moisture. Secondly, check and adjust planters to ensure accuracy of seed singulation, seeding rates and depth.

And since planting season is a time of hurry, give extra thought and vigilance to safety. cottonbrown@auburn.edu

On the day of this writing, my research team and I spent the day establishing reference and background plots for our nematode trials scheduled for 2024. Microscopic parasitic roundworms, better known as nematodes, are present in many of our cotton-producing soils across Arizona. The most prevalent and most damaging to our cotton production systems is the root-knot nematode (RKN - Meloidogyne incognita). Under heavy pressure, production can be severely limited.

Symptoms of a nematode issue are often overlooked or dismissed as some other abiotic stressor such as water or nutrient stress. The only way to determine if nematodes are an issue is to inspect the plant roots and look for the presence of swellings on the root, which is an indication of an RKN infection. Soil samples analyzed by a nematology laboratory can determine the magnitude of the population in the soil and the distribution of the species in the sample. Due to their increased mobility

in coarser-textured soils, we typically observe higher populations and more damaging conditions in sandier soils as compared to finer textured clay soils.

Characterizing the distribution of soil texture within a field can be used to spatially treat a nematode problem by applying control measures only in areas of the field where nematodes are a significant issue. Utilizing GPS and GIS systems allows for the effective and more efficient management of this soil-borne pest. The material being applied in our test plots today was the soil fumigant, Telone. Soil fumigants such as Telone are extremely effective control measures for RKN. Other effective options as evaluated in our research trials include aldicarb (AgLogic) and fluopyram (Velum).

Recently, we have seen the release of an increasing number of cotton varieties with resistance to RKN with several seed companies expanding their offerings of RKN-resistant varieties. In local nematode management trials, one of the most consistent methods for managing RKN populations has proven to be resistant varieties. The 2024 nematode management trials will continue to evaluate resistant and susceptible varieties in conjunction with other treatment options for managing this damaging cotton pest. In 2024, we will also be including the long-standing and effective treatment of Telone as a baseline for comparison. rnorton@cals.arizona.edu

With warm temperatures recently in West Texas, growers have begun thinking about variety selection and preparing for planting in a little over 60 days from now. Variety selection is an important decision, as it can be made once and establishes the genetic yield potential of a field.

Once the variety selection decision is made, growers should focus on the quality of the seed they are receiving. High quality seed is key to establishing a uniform stand of cotton — uniform in spacing and uniform in plant age is the goal, regardless of the desired plant population. Planting seed will have a tag that reads “80% germination,” which reflects the minimum standard required by state and federal seed laws; however, warm germ will most likely be higher.

Additionally, the more important seed quality information to be aware of is the cool germination percentage, which provides a better assessment of seed vigor and a better prediction of field emergence under field conditions. While not required by state or federal seed laws, the industry standard for cool germ is 60%. Combining the warm and cool germ percentages creates the Cool-Warm Vigor Index (CWVI), which is a very informative guide for the grower regarding seed quality. For example, adding 80% warm and 60% cool germ equates to a 140 CWVI, which is a very good minimum standard for planting seed and gives the growers lots of options on when and in what conditions to plant that seed. If the CWVI is less than 140, the grower should either increase seeding rate or plant under more optimal conditions to compensate for the lower quality. This may be necessary for new or limited-supply varieties that is a grower’s favorite.

Soil conditions at planting is also important for proper germination. Good contact between soil particles and seed is necessary for the imbibition to take place to initiate the germination process. Proper adjustment of planters to ensure optimum, but not excessive, pressure is important. A well-prepared seed bed, void of large clods and with good moisture, plays an important role in achieving good soil-to-seed contact as well.

Seeding depth greatly affects how quickly the seedling will emerge. Particularly in dryland scenarios, it is important to determine at what depth adequate moisture is present to support seed germination. Uniformity of seeding depth down the row is important for achieving a uniform stand of cotton; an optimum stand of cotton is one where seedlings across the field emerge within a few hours of one another. Typically, planter

speed and proper adjustment of seeding depth among row units are the factors most often affecting the uniformity of emergence across the field.

Cotton is very sensitive to cool temperatures. Since most West Texas growers have to wait on a “planting rain” to sow cottonseed, there are times they are forced to plant when moisture is available, but perhaps under suboptimal temperatures. Chilling injury can result when temperatures at seed depth are below 50 degrees F during imbibition, so always monitor soil temperature (everyone should have and use a soil thermometer!).

A good rule of thumb is that the soil temperature at seeding depth will normally be within 1 degree Fahrenheit at dawn (which typically is the low temperature for a 24-hour period). Tracking the forecasted heat units for the next five days following a proposed planting date provides a useful guide to planting. Ideally, at least 26 or more DD60s should accumulate in the next five days to achieve a good stand; 50 or more is even better. We are very fortunate to have the West Texas Mesonet (https://www. mesonet.ttu.edu/) that provides air temperature and soil temperatures at most locations.

Soil conditions, moisture and temperature are very important for achieving a good stand; the highest-quality seed with very large seed size and the best seed treatment cannot overcome poor planting conditions.

Optimum planting date is a question I get frequently, and it has always been difficult to answer. I think every grower has a date in his or her mind they want to start planting cotton, oftentimes because Grandpa always started planting cotton on that date. The truth is, there is likely a really good reason Grandpa started on that date, as he likely had repeated success. However, agronomically, it is always a good idea to look at the weather conditions, consider your planting capacity and make sound decisions about when to put seed in the ground for the best chance of success. Another important thing to remember is that most growers can plant a lot faster than they can harvest, so always begin with the end in mind. And listen to Grandpa and at least have the planter maintained and ready to go by his favorite date! ken.lege@ag.tamu.edu

As I write this March 5, the temperature in College Station is 85 degrees, and the planting of grain crops is nearing completion in the Upper Gulf Coast and Blackland Prairie growing regions. With the recent stretch of warm weather, cotton planting has progressed northward from the Lower Rio Grande Valley into the Coastal Bend. By the time you are reading this in early April, cotton planting will most likely be well underway or nearing completion in the Upper Gulf Coast so long as the weather forecast remains favorable for planting cotton.

Achieving a good cotton stand is often the result of deciding to plant during favorable environmental conditions. Soil temperatures at a fourinch depth in the mid- to upper-60s, along with adequate soil moisture and a good extended weather forecast are a big step in the right direction. An excellent tool growers can utilize to take some of the guesswork out of making a planting-timing decision is the Cotton Planting Conditions Calculator found at https://products.climate.ncsu.edu/ag/cotton-planting/. Aside from environmental conditions, there are some things we can do to further enhance the ability to get the 2024 growing season off to a good start.

Ensuring that our planting equipment is working properly and maximizing consistent seed placement will further assist in achieving a successful plant stand. For a cotton seed to begin the germination process, soil water must be imbibed by the seed, and achieving good soil-to-seed contact during planting can improve the initial water uptake by a cotton seed. For growers electing to reduce their seeding rates, this is especially important for obtaining the highest rate of germination and seedling emergence. bmcknight@tamu.edu

What’s next for users and makers of crop protection products in a post-dicamba, pro-Endangered Species Act environment? That’s among the questions to be answered at the 11th Annual Mid-South Agricultural & Environmental Law Conference on June 6-7, 2024, in Memphis, Tennessee.

Rod Snyder, senior advisor for agriculture to the U.S. Environmental Protection Agency administrator, and Brigit Rollins, staff attorney at the National Agricultural Law Center, will be addressing the issue as co-presenters for “Tomorrow’s Harvest: An Overview of the Regulatory and Litigation Landscape for Crop Protection Products.”

Rollins said recent litigation has spurred significant changes in pesticide regulation, including vacating the registration for widely used herbicides and shifts in EPA enforcement philosophy.

“Over the past few years, we’ve seen dicamba become unavailable for use more than once as the direct result of lawsuits and subsequent court decisions,” she said. “Going forward, we’re expecting to see additional restrictions on pesticide use as the EPA works to come into better compliance with the Endangered Species Act.”

One outcome of the EPA’s shift toward a closer alignment with ESA will likely mean increased use restrictions for applicators.

“With changes to pesticide labels coming in rapidly, and sometimes unexpectedly for producers, staying informed is critical,” Rollins said.

The 2024 Mid-South conference will be held at the University of Memphis Cecil C. Humphreys School of Law. The annual “Beer & BBQ” networking dinner will be held the evening of June 6 at The Rendezvous ahead of the main conference program on June 7.

“The Mid-South is an important event for the NALC and our stakeholders,” Harrison Pittman, director of the NALC, said. “The Mid-South region of the country is uniquely impacted by numerous agricultural issues, both long-standing and emerging. Our goal with the Mid-South is always to bring topnotch presenter talent and information, and we are again accomplishing that in our 11th year.”

The Mid-South also features an “Early Bird” online program Tuesday, May 14. Rollins will be providing an ag and food law update alongside NALC Senior Staff Attorney Elizabeth Rumley. Their session will cover topics like Prop 12, waters of the U.S. and the Farm Bill.

Conference attendees who register for the Mid-South by Monday, May 13 can view the online Early Bird.

“The Mid-South region of the country is uniquely impacted by numerous agricultural issues, both long-standing and emerging.”

HARRISON PITTMAN Director of the NALC

Full session titles and speakers for the main conference program include:

• Estate Planning and The Farm: Top Tips and Practice Pointers — Connie Haden, founder and partner at The Law Firm of Haden & Colbert.

• Fourth Amendment and Agriculture: Warrantless Access to Ag and Private Rural Lands — Robert Frommer, senior attorney, Institute for Justice and Joshua Windham, attorney and Elfie Gallun, Fellow in Freedom and the Constitution, Institute for Justice.

• Tomorrow’s Harvest: An Overview of the Regulatory and Litigation Landscape for Crop Protection Products — Rod Snyder, senior adviser for agriculture to the EPA Administrator and Brigit Rollins, staff attorney, NALC.

• U.S. Department of Agriculture National Appeals Division 101: What You and Your Farm Client Need to Know — Danielle Lake, deputy regional director, USDA National Appeals Division.

• Artificial Intelligence in Law Practice: Navigating the Ethical Landscape — Ellen Murphy, professor of practice, Wake Forest University School of Law.

• 2024 and Beyond: Ag Tax Update and the Corporate Transparency Act — Kristine Tidgren, director, Center for Agricultural Law & Taxation, Dolezal Adjunct Associate Professor, Agricultural Education, Iowa State University.

The Mid-South will be submitted for Continuing Legal Education (CLE) accreditation in Arkansas, Kansas, Mississippi, Missouri and Tennessee. Approval for Continuing Education (CE) will also be sought from the American Society of Farm Managers and Rural Appraisers.

For information about the National Agricultural Law Center, visit nationalaglawcenter.org or follow @Nataglaw on X. The NALC is also on Facebook and LinkedIn. For updates on agricultural law and policy developments, subscribe free of charge to The Feed, the NALC’s twice-monthly newsletter highlighting the recent legal developments facing agriculture.

Drew Viguet is with the National Agricultural Law Center, University of Arkansas System Division of Agriculture. The NALC is a federally funded, nonpartisan research and information center that serves as the nation’s leading source of agricultural and food law research information.

Wes Morgan, a veteran North Carolina ginner who has provided outstanding service and leadership to the U.S. cotton industry, is the 2023 Horace Hayden National Cotton Ginner of the Year. He was recognized at the recent 2024 National Cotton Ginners Association’s annual meeting in Orlando, Florida.

The annual NCGA award is presented to a ginner in recognition of: 1) able, e icient and faithful service to the ginning industry and 2) continuing those principles exemplified and practiced by Horace Hayden, a former NCGA executive secretary.

Morgan is manager of Rolling Hills Gin, LLC, in New London, North Carolina. He has provided dedicated service and leadership to the industry during his career through participation in multiple organizations. He served as NCGA’s

president in 2019 and is a past president of Southeastern Cotton Ginners Association, among others. A graduate of the National Cotton Council’s Leadership Program, Morgan has served on multiple NCC committees and as a NCC director. He also is a member of the Joint Cotton Industry Bale Packaging Committee.

The North Carolina native graduated from King’s College in Charlotte, North Carolina, in 1987 with an accounting degree. Upon recognizing the nearest cotton gin was 80 miles away, Morgan, along with his father, built a cotton gin in 1996 to serve their local farming community. Even though he initially had no experience with cotton gins, he learned to manage the gin himself and made his gin one of the most e icient in the country.

The NCGA also recognized Dr. Derek Whitelock as recipient of the NCGA’s 2023-24 Charles C. Owen Distinguished Service Award. That award honors those who have provided a career of distinguished service to the U.S. ginning industry.

Whitelock, research leader at the U.S. Department of Agriculture’s Southwestern Cotton Ginning Research Laboratory in Mesilla Park, New Mexico, received bachelor’s and master’s degrees from Texas A&M University and then his Ph.D. in agricultural engineering at Oklahoma State University.