Scan the QR code with your phone to renew today for FREE!

We know you’re busy with more important things, so we’ll get to the point. The U.S. Postal Service requires that we receive a written request from you to continue sending Cotton Farming for FREE.

Please take a few moments to renew online by scanning the QR code. We don’t want to lose you as a reader.

Although cotton is an arid crop, farmers often turn to irrigation to provide adequate water, especially during the critical growth stages. However, across the Cotton Belt, irrigation is not a one-size-fits-all practice. Experts from the different cotton-growing regions of the country share tips to consider while making decisions about watering your cotton.

Mississippi State University Extension hosted a eld day in Brooksville that featured high-speed planting and advanced planting technologies.

California’s cotton acreage is expected to make a huge rebound this season, spurred by lower prices for competing crops and receding Tulare Lake levels.

e Mississippi State University Extension Service is o ering Master Irrigator status to those who complete a course of training.

the official publication of the ginning industry

It’s time to review your overhead seed house safety and maintenance. Also, you will be surprised about the “silver lining” in cotton gin waste.

To nominate a deserving candidate for the 2024 Cotton Consultant of the Year Award, co-sponsored by Cotton Farming and Syngenta, fill out the form on page 15 or online at cottonfarming.com/ccoy

Deadline for nominations is Aug. 15.

Alabama Extension experts are the driving force behind Alabama cotton production. Cotton is an Alabama row crop staple, so much so that the Alabama Cooperative Extension System and Auburn University have dedicated resources to cotton entomological research for an entire century, and agronomic research at the university level has been ongoing longer than that. Go to www.cottonfarming.com for this Web Exclusive report.

Cassidy Nemec Associate Editor

Ihad the blessing to grow up as both the daughter and granddaughter of Texas cotton consultants. I learned early in life what hard, grueling work looked like. I learned that summer vacations were non-existent, but riding around in the truck with my dad and learning to scout the long rows of cotton every summer was so much better for building my work ethic. I learned there were a lot of early mornings and late nights, but I got to see the beauty of the sunrises and sunsets in the fields as the season progressed. Most of all, I learned it takes a special person to be a cotton consultant.

It’s one of those jobs where you don’t have the predictability of a steady work-life balance or even a steady paycheck, but you get the privilege of helping steward the land we’ve been given and see a crop through from planting to harvest — with every single decision and recommendation in between. These consultants know the value of it all and choose every day to treat the crop like their own and make the best recommendations possible for their growers’ bottom lines.

The Cotton Consultant of the Year Award, co-sponsored by Syngenta and Cotton Farming, has been around since 1981 and is celebrating its 44th anniversary this year. My grandfather was selected as the 1987 CCOY, with my dad following in his larger-than-life footsteps and being honored in 2010. I could say so much more about the meaning of this award and how special it is to my family, but I would like to go ahead and encourage you to think of someone you may know worthy of this award that honors a cotton consultant who exemplifies outstanding grower relations, leadership and innovation.

I’ve been able to meet so many other giants — now friends — in the consulting industry that I may never have known had it not been for this award, and I am beyond thankful for each and every one of them. In a career that may at times not receive a lot of thanks, this award steps in to show just how much of a role they play in this industry.

“Not all heroes wear capes,” some say. One of my main heroes sure doesn’t, but he does wear a lot of hats… and the jacket he received as a CCOY winner certainly meant more to him and us than any cape ever could.

Had it not been for someone having the thought and taking the initiative to nominate my dad, we never would have been introduced to this award program with a truly inspired legacy.

Fill out the form on page 15 or online at cottonfarming.com/ccoy to take that initiative today.

If you have comments, please send them to: Cotton Farming Magazine, 7201 Eastern Ave., Germantown, TN 38138.

EDITORIAL/PRODUCTION

Editor Carroll Smith csmith@onegrower.com

Southeast Editor Amanda Huber ahuber@onegrower.com

Associate Editor Cassidy Nemec cnemec@onegrower.com

Digital Content Editor Katie Guthrie

Art Director

Ashley Kumpe

ADMINISTRATION

Publisher/Vice President Lia Guthrie (901) 497-3689 lguthrie@onegrower.com

Associate Publisher/Editor-In-Chief Carroll Smith (901) 326-4443

Associate Publisher/Sales Scott Emerson (386) 462-1532 semerson@onegrower.com

Production Manager David Boyd dboyd@onegrower.com

Audience Services

Kate Thomas (847) 559-7514

For subscription changes or change of address, call (847) 559-7578 or email cottonfarming@omeda.com

EDITORIAL ADVISORY BOARD

David Burns – North Carolina

David Lynch – South Carolina

Bob McLendon – Georgia

Larkin Martin – Alabama

Mike Sturdivant Jr. – Mississippi

Charles Parker – Missouri

Jimmy Hargett – Tennessee

Allen Helms – Arkansas

Jay Hardwick – Louisiana

Ronnie Hopper – Texas

Ron Rayner – Arizona

John Pucheu – California

Mike Lamensdorf President/treasurer Lia Guthrie Publisher/Vice President

ACKNOWLEDGEMENT OF COOPERATION: Cooperating with COTTON FARMING are various cotton producer organizations across the Cotton Belt. Many representatives of producer organizations serve on COTTON FARMING’s editorial advisory board. Opinions expressed and conclusions reached by contributors are not necessarily those of the cooperating organizations or the editors. All statements, including product claims, are those of the person or organization making the statement or claim. The publisher does not adopt any such statement or claims as its own and any such statement or claim does not necessarily reflect the opinion of the publisher.

Copyright 2024 ©

ASSOCIATED PUBLICATIONS – One Grower Publishing, LLC also publishes RICE FARMING, THE PEANUT GROWER, SOYBEAN SOUTH and CORN SOUTH.

One Grower Publishing, LLC

875 W. Poplar Ave., Suite 23, Box 305 Collierville, TN 38017

Gary

Adams

The National Cotton Council has actively conveyed to Congress the U.S. cotton industry’s policy priorities for the next farm legislation.

What is the NCC’s stance on the House Agriculture Committee farm bill markup?

■ The National Cotton Council has expressed its strong support for the House Agriculture Committee markup of the farm bill. Despite reports in the national media highlighting divisions during the markup, I was impressed by the bipartisan desire to take action that benefits all parties involved — farmers and families alike.

The NCC emphasizes the importance of bipartisan cooperation to ensure the Farm Bill’s final passage in 2024.

Prior to the markup, the NCC sent a letter applauding House Agriculture Committee Chairman Glenn Thompson for crafting a farm bill that addresses the pressing needs of cotton producers across the United States. Considering the escalating on-farm production costs, this legislative effort is recognized as a substantial step towards alleviating the financial pressures faced by cotton growers and ensuring the sustainability of cotton production in the country.

The NCC appreciates the bill’s enhancements to risk management options available to growers, which are expected to provide more affordable avenues for protecting their crops and livelihoods. The improvements made in the marketing loan program are also acknowledged as they promise to offer much-needed relief and support to the industry.

In addition to these measures, the NCC is particularly pleased with the additional support for domestic textile manufacturers. This aspect of the bill is seen as a positive move to bolster the entire cotton supply chain, from field to fabric, ensuring the health and competitiveness of the U.S. cotton industry on a global scale.

■ The farm bill that advanced out of the House Agriculture Committee addresses many of the NCC’s key priorities. Importantly, the legislation raises the seed cotton reference price to 42 cents per pound and increases premium support for the Supplemental Coverage Option to 80% while raising the top coverage level to 90%. The bill also: 1) raises the upland cotton Marketing Assistance Loan rate to 55 cents per pound and makes numerous improvements to the loan program provisions to improve cotton flow; 2) increases the Pima cotton loan rate to $1.00 per pound and adds marketing loan repayment provisions; 3) increases the Economic Adjustment Assistance for Textile Mills rate to five cents per pound; and 4) doubles funding for U.S. Department of Agriculture’s commodity trade promotion initiatives.

■ While this is just a starting point, fortunately, a well-debated bill has provided clarity on where many Representatives stand. This insight will be beneficial for future negotiations as the farm bill progresses toward a potential floor vote or as discussions begin with the Senate.

In the Senate, we have separate framework proposals from Chairwoman Stabenow and Ranking Member Boozman. We are encouraged to see that Senator Boozman’s framework will significantly boost the safety net for production agriculture. The NCC urges all parties to work together to ensure a final Farm Bill is enacted in the coming months. An extension of current law is not acceptable.

Gary Adams is president/CEO of the National Cotton Council of America and Trust Protocol president.

BY CARROLL SMITH EDITOR

The MAFES Black Belt Branch Experiment Station in Brooksville, Mississippi, was the site of an inaugural field day hosted by Mississippi State University Extension featuring high-speed planting and advanced planting technologies.

Strip plots for high-speed-planted cotton, soybeans and corn were shown to attendees while MSU Extension personnel explained the significance of what they were viewing. Following are some highlights from the event that was held June 5.

The tour began in a high-speed-planted cotton field. Mike Mulvaney, Ph.D., Hartwig Endowed Chair for Soybean Agronomy, kicked off the discussion by acknowledging that although some cotton farmers are already planting fast on cotton — 6 ½ to 7 mph — the researchers decided to amp it up to 11 mph to see what would happen.

He pointed out that the stand looked fairly poor, which probably was due to missing a rain.

“We tried to dust it in at ½-inch going 11 mph, which is really hard to do,” Mulvaney said. “I should not have done that, but I was counting on getting a rain. Instead, we missed two rains right after planting, which resulted in a spotty stand. Now that it has rained on us, I can see more cotton coming up, so the stand will be alright.”

Wes Lowe, le , and Mike Mulvaney discuss planting technology in this eld of high-speed-planted cotton at the MAFES Black Belt Branch Experiment Station in Brooksville, Mississippi.

He noted that when he is using speed planting in what he called “plastic” crops — like cotton, soybeans and canola — he is not really in it for the accuracy. The reason is these crops can take some variability within the stand. They are still able to produce a good yield because the plants can branch out and fill the gaps. Corn is considered to be a non-plastic crop because it is not going to branch out to fill a skip.

Mulvaney said he is interested in increasing planting speed to allow the farmer to plant more acres within the optimum planting window.

In his presentation, Wes Lowe, Ph.D., assistant professorDepartment of Agricultural and Biological Engineering, said they are carrying out this research to try to determine just how far you can push the planting technology and what that does to your bottom line.

“The true value for this technology can be a little tricky to define, and it’s not just captured in the dollars and cents of inputs, yield and commodity prices. It’s also found in increased productivity and efficiency,” Lowe said. “We want to determine how many more acres we can plant in the optimum planting window to increase the crop’s yield potential and improve the bottom line and also evaluate how much time we can save.

During the high-speed planting field day, Wes Lowe talks about what the industry calls a “speed tube” — an automated seed delivery mechanism. He said this component is used to provide seed control from the seed meter until placement in the seed trench. Also pictured with Lowe on the right is Jacob Meadows, research technician.

These time savings ultimately free up labor to perform additional tasks on the farm and loosens the bonds of being ‘married’ to the crop. Hopefully, this reduces some farming stress and allows our producers time to do things outside the farm.”

The next stop on the tour featured speed-planted soybeans. However, this particular field was no ordinary soybean field.

The researchers had put out 1 bushel of rye per acre and then flew on 50 units of nitrogen because it was too wet to come in with a tractor. The final result was 7,000 pounds of rye biomass, which was not rolled.

“We wanted to make this experiment as hard as we could,” Mulvaney said. “I am really happy with the stand we got. We tried 16 different row cleaner configurations at 5 mph and 10 mph. All the treatments had interlocked row cleaners.”

Mississippi’s optimal planting window is between April 10 and May 1. In looking at the typical planting progress for Mississippi soybeans, the researcher said that 40% to 45% of the state’s total acreage had been planted.

“That means 60% of our total soybean acreage is planted late — outside our optimum window,” Mulvaney said. “So, in a perfect world, if we go from planting 5 mph to 10 mph, we could plant twice as fast and have 80% of our total soybean acres planted within the optimum window. I feel like this is very low-hanging fruit to increase yields.

“If we reduce the number of acres planted after the optimum window, economics show a 2,300-bushel increase on a 2,000acre soybean patch. Then, you could be looking at a net return for a single year on 2,000 acres of nearly $35,000. That is my take-home message.”

Mike Mulvaney said soybeans were speed planted into this field that contained 7,000 pounds of rye biomass, which was not rolled.

Mulvaney said the researchers’ job is to show what works and what doesn’t. “I’m trying to make this planting technology feasible for farmers who plant cover crops and those who plant double crops,” he said. “I want them to be able to speed plant.”

Lowe points out another advantage of advanced planting technology is by getting the crop planted faster, farmers can get the crop out a little quicker, allowing them to perform fall tillage, preparing fields for earlier spring planting.

For more information about automated seed delivery, visit https://cottoncultivated.cottoninc.com/precision-planter. This is the second part of a two-part series on advanced planting technologies from Cotton Cultivated written by Lowe and some of his colleagues.

Although cotton is an arid crop, farmers often turn to irrigation to provide adequate water, especially during the critical growth stages. However, across the Cotton Belt, irrigation is not a one-size-fits-all practice.

For example, all the cotton acres in Arizona are irrigated because of the arid climate and the low annual precipitation.

In describing the water availability for cotton in Arizona, Diaa Elshikha, Ph.D., assistant professor and irrigation specialist at the University of Arizona Maricopa Agriculture Center, said, “Water availability for cotton in Arizona varies by county due to differences in water allocations. Some counties may have sufficient water for irrigation, ensuring good cotton growth, while others might face restrictions, leading to challenges for cotton farmers. However, farmers can optimize water usage by fully irrigating their cotton crops if not all their land is planted.

“Arizona cotton growers must take a proactive approach to water management for their Upland and Pima cotton crops during the critical period of July to August. Monitoring soil moisture levels is essential to ensure optimal plant growth and prevent water stress.”

The UA specialist adds that employing advanced tools like soil sensors enables real-time monitoring, facilitating informed decision-making regarding irrigation timing and amount. The implementation of drip irrigation systems enhances water efficiency by delivering precise amounts directly to the plants, minimizing waste. For those utilizing flood irrigation, automatic gated systems offer improved efficiency.

“Additionally, utilizing irrigation scheduling software provides valuable insights into optimal watering schedules based on weather forecasts and crop requirements,” Elshikha said. “While deficit irrigation may be necessary, caution must be taken to avoid compromising crop growth and yield. Drip irrigation, with its uniform water distribution, simplifies this process, ensuring consistent growth across the entire field.”

In the Southwest, based on long-term Mesonet data from Altus, Oklahoma, seasonal water use for adequately watered and otherwise healthy cotton is about 30 inches in southwestern Oklahoma.

When addressing stress-sensitive periods for cotton, irrigation system type and water quality, Oklahoma State University Extension personnel noted the following:

Fruit production, retention and shedding are closely related to the availability of soil moisture. Production is optimized with

As the cotton moves through squaring and into bloom stage, over-irrigating can result in yield penalties and profit loss.

an available moisture status that allows uninterrupted development of fruiting positions while avoiding excessive vegetative development on the one hand or fruit shedding on the other.

Many producers believe it is appropriate to allow cotton plants to stress before applying the first irrigation to slow vegetative growth, force root system expansion and enhance early fruit development. While it is true excessive soil moisture during this time can cause excess vegetative growth and limit root expansion, it is important not to limit water to a point of excessive stress.

It is best to challenge cotton to expand its root system, while providing adequate water under drought conditions to allow for adequate rates of growth and maturity development. According to Cotton Physiology Today, research has shown that excessive stress prior to the first irrigation may reduce main-stem node development and result in fewer nodes above white flower at first bloom, which can ultimately reduce yield potential.

Severe moisture stress during the peak flowering period can have a pronounced negative effect on yield and fiber quality. However, stress either early or late in the blooming period results in significant yield reductions. Ideally, moisture stress should be avoided throughout the crop development period.

Early irrigations may be justified to maintain adequate, but not excessive, vegetative growth. Matching the lower water demand late in the season is key to achieve timely cutout and

Application efficiency for furrow irrigation typically ranges from 40% to 80%, and center pivot sprinkler/spray ranges from 65% to 90%. Center pivot low energy precision application (LEPA) ranges from 85% to 95%, and sub-surface drip ranges from 85% to 99%. The theoretical goal is to be 100% efficient.

If using a spray system, make sure to use nozzle applicators that generate large droplet sizes. This should help reduce evaporation issues during application. Apply at least 1 inch per application, if it can be done without causing runoff.

Larger applications will increase the depth water infiltrates into the soil, which will decrease evaporation from the soil surface. Be thoughtful not to over-apply and cause drainage. The likelihood of drainage can be better estimated if an irrigation planner or soil moisture probes are used to estimate soil moisture status.

Irrigation water quality should not be overlooked. High salinity water and/or saline soils can adversely affect crop performance. If high-salinity water is the only source of water input for the crop, there is a high risk the crop will ultimately suffer. These effects can vary with seasonal rainfall, soil type and soil salinity.

OSU Extension Fact Sheet PSS-2401 Classification of Irrigation Water Quality provides classification of irrigation water quality, describes how irrigation water quality is determined and the conditional use of low-quality water for various crops, including cotton. If water quality is a concern, contact your local county Extension office. Educators can send a water sample in for analysis at the OSU Soil, Water and Forage Analytical Laboratory.

According to Mississippi State University Extension, the Mississippi Irrigation Scheduling Tool (MIST) relies on the

most current scientific knowledge of crop water use to assist producers in making irrigation decisions. Here is how MSU says it works.

Rather than requiring the user to take readings in the field and input data, MIST automatically collects information from

Crop evapotranspiration represents the amount of water lost through the process of evaporation (from soil surface) and transpiration (from plant tissues) from a crop, grown in a large eld, under a given climatic condition.

crop water use.

Automatically downloading information from these databases allows growers to use MIST without requiring extensive data collection or input to the model. With MIST, there are no programs to install or maintain. The program is accessed through the internet and is available on several platforms, including smartphones, tablet computers, laptops and desktop computers. This allows the user to determine future crop water needs from any location and instantly tell when a crop needs water.

Most water-balance, irrigation scheduling programs function in a similar manner, but the means of data input and the representation of the output can be very different, according to Brian Lieb with the University of Tennessee Extension. UT’s program called Management of Irrigation Systems in Tennessee (MOIST) requires weekly input of rainfall and irrigation instead of daily data. This is easier for producers to maintain and thus keep track of the needed rainfall and irrigation amounts.

The approach works fine for the more drought-tolerant row crops that are grown in the good water-holding soils of West Tennessee. However, weekly input may not be adequate for water-sensitive crops grown in low water-holding soils like sands. For center-pivot irrigation in good water-holding soils, 1.5 inches of soil water depletion is a good target because center pivots are designed to keep up with crop water use and not to catch up or replenish the soil profile.

“MOIST provides a graphical output in addition to a table format,” Lieb says. “The program also provides a forecast type of output so that center-pivot irrigators can have a plan of action once they update data into the program.

The forecast type of output allows a producer to schedule irrigation without having to go back to the MOIST program

The University of Georgia Cooperative Extension Service has numerous experts who work in all aspects of cotton production, including irrigation. In a recent UGA Cotton Team newsletter, Extension personnel provided a June cotton irrigation update along with irrigation tips going forward:

While we do not want to keep an overabundance of moisture (keeping the moisture level at capacity or “full”), we do want to keep adequate moisture to maintain the crop. Once we fall behind on moisture, it’s hard to catch up on irrigation alone, unless an adequate amount of rainfall is received. When crops are utilizing moisture as fast as we apply it, it’s hard, if not impossible, to bring soil moisture back to an adequate level.

Young cotton plants do not require a lot of moisture for the first few weeks, but it is important not to stress the crop. Earlier planted cotton will be moving into first flower by the end of June. Thus, staying on top of water requirements will become critical throughout the month of June and into July for the entirety of the crop regardless of planting date.

Additionally, even later planted cotton may need some irrigation to ensure there is enough soil moisture available for the crop. Remember, if there is no rainfall, the water requirements need to come from somewhere — in this case irrigation.

In the Irrigation Reference Guide for Corn, Cotton, Peanuts and Soybeans, UGA Cooperative Extension shows estimated water requirements in days after planting (DAP) and estimated growth stage. Based on the physiological progression of the crop, it may be better to look at the growth stage and not the DAP.

For more information about irrigating cotton in your area of the Cotton Belt, contact your local Extension agent.

BY STACEY GORMAN THE COTTON BOARD

Late last year, Daniel Radford began his role as The Cotton Board’s new Southeast Regional Communications Manager. Radford’s territory includes Alabama, Florida, Georgia, North Carolina, South Carolina and Virginia.

The Cotton Board’s RCMs work to ensure that stakeholders of the Cotton Research and Promotion Program (the Program) in their respective territories are informed of the activities stemming from the Program as conducted by Cotton Incorporated and administered by The Cotton Board. The RCMs visit producers in the field, speak at industry meetings, participate in trade shows and coordinate producer tours of Cotton Incorporated.

To help Southeast growers get to know their new RCM, I’ve asked Daniel to answer the questions below:

QTell us about yourself and your work in the cotton industry.

AI am a native of North Carolina and grew up in the Nahunta community. I have been involved in agriculture from an early age. My extended family operates a feed mill and farming operation as well as the local pork processing facility, known as Nahunta Pork Center. I attended Wayne Community College and North Carolina State University where I received my bachelor’s in agricultural science and returned to pursue my master’s in agricultural and Extension education.

Throughout my time at NC State, I was able to intern with the North Carolina Farm Bureau Federation’s agricultural and public policy team as well as work with the North Carolina Tobacco Trust Fund Commission Agricultural Leadership Development Program. These opportunities allowed me to utilize my experience in production agriculture while learning the importance of agricultural policy and how that impacts our industry daily.

Following graduation, I spent some time working closely with the North Carolina Cotton Producers Association

(NCCPA) on several projects and events. Working with NCCPA was beneficial for me to continue learning more about the cotton industry but also allowed me to develop a strong foundation for relationships within the industry. When I am not busy with my role with The Cotton Board, you can find me on the farm or assisting in the day-to-day operations of the feed mill.

QWhat are you most looking forward to in your new role?

AI am looking forward to traveling across my territory and meeting as many cotton producers and ginners as possible. I have enjoyed the past several months visiting growers, gins and industry leaders. I hope these connections will provide opportunities for me to collaborate with organizations across my territory to continue to improve the Cotton Research and Promotion Program by focusing on issues and priorities that are important for the industry.

QWhat is the most surprising thing you’ve learned about The Cotton Research and Promotion Program in your time with The Cotton Board?

APrior to joining The Cotton Board, I was familiar with The Cotton Research and Promotion Program, but I had no clue about all the research, marketing and sustainability work being done by Cotton Incorporated. Since I have joined The Cotton Board, I’ve been able to learn more about the research and experimentation that the Cotton Incorporated team performs in the field, the lab and with textile and clothing companies. From testing the strength of cotton fiber and matching trends by using lasers to distress denim, to their collaborations with washing machine and detergent companies that research best practices to maintain the quality and durability of cotton for consumers.

It is truly eye opening to see Cotton Incorporated’s work with clothing and apparel companies. I’d say the most surprising thing for me was realizing that

The Cotton Research and Promotion program was not just focused on how to assist producers and market to consumers, but all the “behind-the-scenes” work they are doing with brands and retail companies to educate them about cotton’s quality, durability and functionality.

QWhat makes you passionate about the cotton industry?

AThe people are what makes me passionate about the cotton industry. The agriculture industry, specifically the cotton industry, is complex but I have found that each person I’ve met has been willing to take time out of their schedule to meet with me or answer my questions. I’m blessed to be able to wake up every day and be surrounded by a group of agriculturalists that are hardworking and dedicated to producing natural fiber. It doesn’t get any better than being able to work with such a dedicated group of individuals who strive to leave their land and the environment in the best condition possible for future generations, all while providing food and clothing to the entire population.

For more information on Daniel and the work of The Cotton Board’s Regional Communication Managers, please visit cottonboard.org/producers.

Five Bollgard 3 ThryvOn cotton with XtendFlex Technology (B3TXF) and four Bollgard 3 XtendFlex (B3XF) cotton variety candidates will be evaluated by New Product Evaluators growers this seasonfor the Class of ’25.

The lineup includes candidates with a range of maturities and native trait tolerances to reniform nematode, root-knot nematode and bacterial blight.

“There are a lot of things we are excited about in this Class of ’25 variety candidate lineup across all growing regions that includes genetics with strong yield potential and a range of native traits that our NPE growers have asked for,” said Eric Best, Deltapine cotton product manager.

Deltapine continues to work on bringing high-performing genetics and more ranges of maturities in the B3TXF trait platform to build on the success of recent variety releases, including DP 2414 B3TXF and DP 2328 B3TXF.

This year’s B3TXF variety candidates include products in more maturities and nematode resistance. The B3XF variety candidates being evaluated offer strong-yielding genetics in line with recent Deltapine releases, including DP 2127 B3XF and DP 2333 B3XF.

NPE growers located across the Cotton Belt will plant and manage variety candidates in their own growing systems and conditions.

Their feedback throughout the season and final yield and quality results will help determine which of the nine candidates have the proven performance worthy enough to make it into the Deltapine Class of ’25 for planting next season.

“The NPE Program began in 2008 as a way of identifying the best genetics to bring to market in a Deltapine bag, and now each new class of Deltapine varieties brings to the market improved yield potential and improved agronomics based on feedback from NPE growers,” Best said.

“The program has become an industry-trusted cotton variety commercial-

The program for the 33rd Milan No-Till Field Day has been announced, with topics such as pesticide restrictions, herbicide-resistant weeds and climate-smart agriculture headlining this year’s event.

Hosted on Thursday, July 25, from 8 a.m. to 1 p.m. at the AgResearch and Education Center at Milan, participants will be able to attend 15 different tours discussing no-till farming.

Each tour will be led by up to seven speakers from the University of Tennessee Institute of Agriculture and other organizations across the Mid-South. Topics will include:

■ No-Till Corn Production.

■ No-Till Cotton Production.

■ No-Till Soybean Production.

■ Update on Pesticide Labels and History of the Endangered Species Act (ESA); Georgia’s Work on Pesticide Use Limitation Areas for Endangered Species.

■ Herbicide-Resistant Weed Management.

■ Impacts of ThryvOn Technology on Economically Important Insects in Cotton.

■ Crop Water Management.

■ Cover Crops: Current and Future Trends.

■ Climate-Smart Agriculture and Soil Health.

■ Hemp Production.

■ Ag Water Treatment: Navigating the Produce Safety Rule.

■ The Ongoing Transformation of UT AgResearch Centers Through American Rescue Plan Funding.

■ Soil Fertility Management.

■ Soil-Borne Soybean Diseases.

ization program, and we look to continue raising the performance bar in cotton with our NPE growers and the Class of ’25,” Best said.

Nutrien Ag Solutions announces the acquisition of Suncor Energy’s AgroScience assets, which consists of several patented and patent-pending technologies in the area of biocontrol. This new biocontrol technology is expected to introduce chlorin-based photosensitizer to the global market as a biocontrol solution for integrated pest management (IPM).

The acquisition is aligned with Nutrien Ag Solutions’ strategy to invest in novel, patented and effective biocontrol technologies through its Loveland Products business. The proprietary technology for use in the global agriculture industry aims to offer a new mode of action, plus advantages in resistance management. Categorized as a biocon-

UT System President Randy Boyd (left) was one of many speakers at the 2022 Milan No-Till Field Day, in addition to Blake Brown (center), director of the AgResearch and Education Center at Milan, and Hongwei Xin (right), dean of UT AgResearch. The 2024 Milan No-Till Field Day will feature dozens of presenters from across the region.

“While the fundamental components of no-till have remained the same, new challenges arise,” said Blake Brown, director of the AgResearch and Education Center at Milan. “Our highly anticipated field day provides research-based information to help farmers succeed in this ever-changing industry.”

Certified Crop Adviser and pesticide recertification points will be offered.

The AgResearch and Education Center at Milan is located at 3A Ledbetter Gate Road in Milan, Tennessee. Sponsorships and exhibitor spots are currently being offered. Contact LesLee Smelser at 731-686-7362 for more information.

trol tool, research and field-trial data show the technology as having market-competing potential in delivering efficacy, stability and economic value comparable to traditional synthetic crop protection inputs.

“As the biocontrol market grows, we believe farmers will increasingly demand bio-based solutions that work within existing management practices to achieve bottom-line benefits in yield and efficiency and support efforts to improve sustainability,” said Casey McDaniel, vice president of Loveland Products.

“We believe that biologicals are important next-step tools for elevating the potential in every field. In the coming months and years, we aim to bring more of these types of offerings to market under the Loveland brand or partner brands for farmers of all scales and in all geographies.”

The new chlorin-based photosensitizer formulations are expected to launch in certain global markets by 2025.

Product submissions to the EPA in the United States are anticipated by 2026. Nutrien Ag Solutions plans to market these products as part of the Loveland Products portfolio.

According to the Californa Farm Bureau, over the past two decades, heat illness awareness and prevention has become a major focus for California farms that rely on workers to harvest crops and perform other essential work during the hottest months of the year.

Farmers and farm labor safety experts in California said heat-illness awareness and preparedness have evolved since the state established the nation’s first heat-safety law for outdoor workers in 2005.

Outdoor workers must have access to water, shade and rest when the temperature rises above 80 degrees Fahrenheit. When it hits 95 degrees, more frequent breaks are required.

Spray drones, officially known as Remotely Piloted Aerial Application Systems (RPAAS) are here and increas-

ingly a common sight in our production fields. These aircraft can treat areas that are otherwise difficult to access by traditional manned equipment and do it semi-AI person flying a drone beside a corn field autonomously.

While this technology represents a significant step forward in on-farm automation, currently, there is always a pilot/ applicator nearby, supervising operations. Safe, responsible and effective applications of pesticides and fertilizers still fall on the shoulders of these applicators.

Drones, including RPAAS, are considered aircraft by the FAA and the Arkansas Department of Agriculture. RPAAS applications are aerial applications and must follow the aerial application section of Federal label as well as comply with any applicable state laws and rules.

Anyone operating RPAAS systems is required to hold the following applicable certifications. RPAAS applications made for hire (commercial operations) require the following:

■ Commercial Firm License with aerial category, including insurance.

■ Individual Commercial License with aerial category and other applicable categories needed (i.e., agriculture plants).

Private applicators using RPAAS to make applications on their own land must comply with licensing requirements and must hold:

■ Private Applicator with pilot.

Authorization FAA requirements for private and commercial operations:

■ Pilot license under FAA Part 107 (drone).

■ Part 137 Dispensing Chemicals and Agricultural Products via UAS.

■ Section 44807 waiver: Special Authority for Certain Unmanned Aircraft Systems (over 55 lbs.).

The LSU AgCenter Agricultural Leadership Development Program is now accepting applications for Class XIX, scheduled to begin January 2025 and completed February 2027.

The deadline for leadership class applications is Aug. 23.

“Developing leaders is essential to advancing agriculture, especially in areas such as finance, policy issues and regulatory matters,” said Matt Lee, vice president for agriculture and dean of the College of Agriculture.

Bobby Soileau, program director, said class members will be exposed to critical agricultural issues and strategies that can be used to inform the public how they affect ag and the general populace.

The curriculum includes 10 seminars: seven lecture-based seminars in various locations across the state and three travel seminars. The travel seminars entail a trip to Washington, D.C. and travel to another state to learn about ag issues there. The culmination of the program and last seminar is an international study tour.

Participants are expected to commit to attending all the seminars throughout the two-year program. They will also be expected to pay a small portion of their costs for their studies and travel.

Most of the program is underwritten by endowments and annual giving through the LSU Foundation, including the Chalkley Family Endowment, the H. Rouse Caffey Endowment, the Robert R. Soileau Endowment and the Ag Leaders of Louisiana Endowment.

To apply, visit www.lsuagcenter.com/ agleadership. The interview process for being accepted into the program will begin in September.

BY VICKY BOYD

California’s cotton acreage is expected to make a huge rebound this season, spurred by lower prices for competing crops and receding Tulare Lake levels.

But Pima cotton, the premium variety predominantly grown in the state, has its own market challenges and has endured depressed prices for more than two years. With a potentially larger crop this year, the outlook for a market bump isn’t good.

“Pima has been really tough for growers,” said Merced County farmer Aaron Barcellos, who farms diversified crops near Dos Palos.

If growing conditions are ideal this summer, the Pima crop could yield roughly 550,000 to 600,000 500-pound bales, adding more supply to an already sluggish market.

From Tomatoes To Cotton

California Cotton Ginners and Growers Association President and CEO Roger Isom pointed to two main reasons for the state’s expected larger cotton acreage this year: In 2023, processing tomato canneries aggressively courted producers with recordhigh contracts of $138 per ton. This lured many away from cotton and into tomatoes, he said.

But tomato canneries contracted for fewer acres at $112.50 per ton this year, and garlic prices are lower. This made cotton more attractive, Isom said.

In addition, last year’s near-record rains and the reappearance of Tulare Lake flooded thousands of acres of historic cotton ground. Water levels have since receded, opening much of that ground to planting again.

Barcellos said he doubled his cotton acres this year, compared to 2023, because of economics and few alternative crop options. In addition, he lost a processing tomato contract.

“I had to find something to do with that ground,” he said.

Merced County farmer Cannon Michael, president of the family-owned diversified Bowles Farming Co. near Los Banos, said his conventional cotton acres are up about 9% this year, while organic acres are up about 150%. He increased organic acreage because land he was transitioning to organic became certified this season.

Michael said water supplies and commodity prices were factors in growers’ decisions to plant cotton this season.

“With tomato prices declining, there aren’t many good options, so growers are picking cheaper crops to grow,” Michael said.

Gary Martin, who farms tree and row crops near Firebaugh, said he increased his cotton acres by about 15% this year, adding he wasn’t able to plant some of his land last year due to flooding.

Much of the state’s cotton ground is served by south-of-delta water districts that are part of the federal Central Valley Project,

A tractor works a young cotton field in Merced County. Cotton is regarded as a less expensive crop to grow than processing tomatoes. Still, some cotton farmers are grappling with disappointing water deliveries, high interest rates and other market challenges.

which last month announced a 40% water allocation. This is despite full reservoirs and a slightly above-normal snowpack.

CVP exchange contractors, which have senior water rights, will receive 100% allocations. Martin is in one of those districts and will receive full deliveries.

The CVP announced an initial water allocation of 15% in mid-February as many growers were making planting plans. Without knowing whether that quantity would increase, Michael said many growers chose cotton, which is less expensive to plant and more drought tolerant than tomatoes.

Because of its quality, California ELS cotton has historically earned substantially more per pound than Upland varieties. California ELS is running about $2 per pound, which Barcellos said doesn’t even cover production costs.

“Because of the regulations we have, we have higher costs of inputs, higher labor costs. It’s just really challenging,” he said.

One of the challenges with Pima, Martin said, is growers can’t lock in a price with a futures contract on one of the commodity trading platforms. This leaves them to take whatever price the market will offer at the time they want to sell.

“As far as new crop, we’re a little concerned once all of this increase of acreage gets out there and the effect it will have on the market,” Martin said.

Although growers keep hoping sales and prices will rebound, Barcellos said they haven’t seen it yet. When interest rates were much lower, it was easier to pencil out warehousing processed cotton bales until the market picked up. But he said interest rates topping 7% “really hurt.”

The California Farm Bureau Federation granted permission to publish this article. Vicky Boyd (vlboyd@att.net) is a reporter in Modesto, California.

The Cotton Consultant of the Year (CCOY) Award marks more than four decades. The award recognizes a consultant who has made great contributions to the cotton industry through outstanding customer relations, leadership and innovation. It honors a consultant who not only meets these requirements but also exceeds them.

Syngenta and Cotton Farming magazine — CCOY sponsors — are soliciting your help in selecting the 2024 recipient, who will be named at a special celebration Friday, Feb. 28, 2025, at the Peabody Hotel in Memphis, Tennessee.

The winning consultant and the person who nominates the winner receive a two-night hotel stay and airfare to Memphis. The 2024 CCOY recipient also will be featured in a four-page salute in the February 2025 issue of Cotton Farming.

Submit nominations by Aug. 15, 2024.

Mail: Carroll Smith

7201 Eastern Ave. Germantown, TN 38138

Scan/Email: csmith@onegrower.com

You can print an electronic version of the form located on the Cotton Farming website at www.cottonfarming.com.

Nominate online: cottonfarming.com/ccoy

If you would like to nominate a consultant deserving of this outstanding recognition, please take a moment to fill out the following form.

Please use a separate page for biographical/professional information. Additional recommendations via letters or emails from other farmers, consultants and industry members are also encouraged to provide support for the nominee.

Consultant’s Name:

Company Name:

Mailing Address:

City:

Phone:

State: ZIP:

Email:

In your own words, please tell us why you are nominating the consultant above for the Cotton Consultant of the Year Award. Additional pages may be attached, emailed or attached to the online nomination form.

Background:

Biographical/Industry Involvement Background. This information as well as support letters may be attached to this form, emailed or attached to the online nomination form.

Your Name:

Mailing Address:

City:

Phone:

State: ZIP:

Email:

Perched in my office in the hanging fluorescent light fixture typical of old buildings is a crow. Yes, a crow. Actually, it is a life-size crow decoy that looks every bit the part. It has connections to past farmer meetings at Crow’s BBQ — I’m rather fond of BBQ, but their offering never was my favorite — and from the times my crop predictions made me “eat crow.” Hardly anyone ever notices the crow, but I occasionally glance up to be reminded of the fallibility of my forecasts.

Indeed, Alabama is so diverse in production environments — soils, rainfall patterns, cultural practices, pest issues and competing crops — that an accurate, current assessment of the crop is always challenging.

As of this writing, December futures are trading near 73 cents. Ugh! One prediction I can make with confidence, one that will not mean a “crow pie” in the fall, is that anything approaching a profit this year will require strong yields. There is simply no other way to cover costs.

Fertilizer folks have a ready, appropriate mini-sermon, “The 4Rs of Nutrient Stewardship.” The right fertilizer SOURCE at the right RATE at the right TIME and in the right PLACE

We might broaden that to say profitability depends on implementing the right PRACTICE or applying the right PRODUCT at the right RATE, TIME and MANNER. Easy to scratch out on paper but often challenging to implement. Nothing new in this sermon either. Still, maximizing returns for each and every input is the only path to making ends meet.

We can control — or manage — some things but not others. The difference between 1300- and 1750- pound cotton is often not determined by farmer practice but by season-end weather. Long-term averages in the Lower Southeast indicate the latter half of September and all of October are our driest periods. Great for finishing and picking cotton. We saw last year what that means, and unfortunately, we’ve seen years in which the average was overwhelmed by tropical storms and hurricanes.

Capturing good yields means implementing all the good Rs now and praying, hoping for a good fall. That’s how this old crow sees it. cottonbrown@auburn.edu

The summer is finally beginning to heat up. After a mild to cool and wet spring, we are beginning to turn the corner and face the furnace head-on. A few days of above 110 degrees in the low deserts have already been experienced. Most of the central and eastern Arizona crop is just heading into early squaring as of this writing. The western Arizona crop, planted much earlier, is in the early stages of flowering.

Significant heat stress at this time of the season has a less negative impact on the crop than it will as the crop begins to approach mid- to full bloom. However, it is still a good idea to monitor the crop for fruit load and vigor. Maintaining a balance between vegetative and reproductive growth is critical to optimize production and maximize crop productivity. Trends in the vegetative and reproductive balance of the crop can easily be accomplished by taking measurements of fruit retention and height-tonode ratios. Comparing measured values of these two parameters to baselines that have been developed from thousands of data points can lead to more informed management decisions with respect to various practices including fertilizer applications, irrigation frequency and the application

of plant growth regulators (PGRs). Information on how to collect the data needed for these parameters and the reference baselines can be found on the University of Arizona Extension Crops and Soils website at https:// extension.arizona.edu/cotton-resources. rnorton@cals.arizona.edu

As I sat down to write this, I began under the assigned topic of “Mid-Season Management” by talking about plant growth regulator use and how Georgia isn’t like the Mid-South, how we have a long season and all that fun stuff. Then I went and read my June article and saw I had pretty much just rewritten it! So here goes again for the second attempt.

Cotton planting was a slow go in Georgia through May and early June. With constant rain showers across the state, it’s really a miracle we have been able to plant as many acres as quickly as we did. As I am writing this June 7, I just finished planting our cotton June 5 at our last farm on the station. It is a good feeling to have that behind us, but now on to making the crop.

One question I’ve gotten is that since everyone is so behind on everything as we sit today, they are wanting to throw multiple products in the tank to spray in a single pass “so we don’t get further behind than we already are.” In many cases, causing injury to an already slow-growing and delayed crop is not a good thing, so we want to mitigate unnecessary injury from too many products in the tank as possible, while also keeping in mind the cost of diesel fuel, other inputs and your time.

Dr. Phillip Roberts, University of Georgia cotton entomologist, and I initiated a deer repellent trial today, and we are excited to be looking into potential Band-Aids for the deer issue. I actually visited with a grower about that today as well, but if anyone has questions, feel free to contact me.

As always, if you ever need anything, don’t hesitate to reach out. Your local UGA County Extension agents and specialists are here to help! camphand@uga.edu

As I write this in early June, most of Mississippi’s cotton acres are around the five-leaf stage. So, we are in between what we refer to as early season and mid-season. However, weather has played a huge role (as it always does) in variability of crop progress. During May, rain pelted south central and north Mississippi, hindering planting progress for many farmers. Repeated rain events resulted in delays and even prevented planting in some cases.

As we transition from early season management to mid-season management, there are a few considerations to keep in mind. Managing plant architecture with growth regulators is key to producing the most efficient and effective plants. Application decisions should be rooted in knowledge of varietal growth habit and vegetative potential of the crop. Field history and environmental factors influence vegetative potential, and this can vary from year to year. In many cases, an introductory application of a plant growth regulator can be effective for eight- to 10-node cotton. This helps keep a proactive versus a reactive PGR management plan. As the crop matures, managing the distance in between the fourth and fifth node down from the terminal to a 2”-3” spacing will result in a plant capable of a sturdy boll load that is efficient to harvest.

Nitrogen management through mid-season is important during June,

and there are many strategies that are effective in nitrogen management. Keeping nitrogen-use efficiency in the forefront, split applications tend to increase use efficiency by hedging against N losses due to environmental factors. Regardless of N strategy, all nitrogen should be applied prior to bloom. As cotton enters bloom, ideally all N would have been applied and a fully charged soil moisture profile present as cotton begins setting fruit. This will help reduce fruit shed and mitigate stress on the plant. bkp4@msstate.edu

The Missouri Bootheel cotton progress is widely different at the time of writing these comments. Cotton growth stages range from cotyledon to eight to nine nodes in areas of the Bootheel.

We have been stuck in a rainy pattern on the mid- to northern edge of the cotton-growing region in Southeast Missouri for most of May and even early parts of June. Several acres have been underwater due to the rainfall pattern. Late replants have been needed due to hail damage and flooded acres. Management considerations for cotton that is squaring at this time include the need for an additional nitrogen application (second shot), plant growth regulator applications to slow vegetative production and likely insecticide applications for tarnished plant bugs that will feed on small squares.

Management considerations for later-planted cotton will likely include the same management regime; however, I believe lowering the nitrogen rate will be beneficial to mature the crop in our short-season environment. Recommendations of nitrogen on late-planted cotton are at 80 pounds of total nitrogen. Also, being more aggressive with our PGR regime may benefit the crop to mature quicker as we are in an increased risk for running out of time to fully mature this crop. brwilson@missouri.edu

As I write this May 29, the last few acres of cotton are being planted or spot replanted. Overall, stands have been very good across most of the state, except in a few areas that received intense and repeated rainfall during the middle to latter half of May. Most of the intended acreage was planted in a timely fashion and is off to a decent start. There are a few intended acres planted to beans primarily in areas that were too wet before the crop insurance deadlines for cotton.

Thrips, which are one of our most consistent insect pests, were a challenge in some areas depending on planting date. Temperatures have been on our side since very late April and remained decent throughout most of the planting season, allowing for more rapid early season growth than what we saw in 2023.

A lot can happen between now and next month, but July is usually the time for plant growth regulators and the last fertilizer applications for some growers. The need for PGRs is determined by many factors, including moisture leading up to a potential application, the weather forecast following application, planting date, variety, current and past insect pressure and other factors. Field-by-field monitoring of plant growth (current height relative to target height, nodes above white bloom, week of bloom, internode distance between the fourth and fifth true leaf near the top of the plant, etc.) is necessary in order to make the best decisions. Remembering last year, many growers were concerned about late maturity during early July of 2023, simply due to the slow growth we observed in June. However, hot dry weather in late July and into August drastically sped up maturity, and too much so, in some cases. It will be important to remember that when making decisions this year.

Applications that are too aggressive, especially when made too early, can force the crop into a premature cutout if hot and dry conditions prevail following application. Additionally, research has shown that there is very little impact on plant growth, and essentially no impact on yields, when PGRs are applied at cutout. guy_collins@ncsu.edu

Large rainfall events spaced relatively evenly throughout the month of May wreaked havoc on planting intentions and challenged the health of many of our earliest planted acres. While the area noted one of the best late April planting windows we have seen in recent memory, that window quickly transitioned to the worst May most can recall.

Although the overall rainfall amount for the month is large, it was the interval between rainfall events that has been so challenging; with few exceptions, as soon as most fields dried enough to allow for the crop to be “mudded-in,” another rainfall event — often several — would occur over the course of several days. For those who were able to grit their teeth and close their eyes for long enough to get part of this crop planted, prolonged periods of saturation severely damaged seedling health and has delayed growth. In my June comments, I mentioned that many would likely have an opportunity to pick in September. The chances of that, now, look very, very slim.

As I write this on the third of June, I would encourage you to consider every option for emphasizing earliness in this crop. As you read this in the first few days of July, that would include aggressive management of plant growth, an overall reduction in the amount of nitrogen applied and very aggressive management of plant bugs in an attempt to hold first position fruit low on each plant. The 2024 crop still has potential, but in Tennessee, it will be remembered very differently than the 2023 crop. traper@utk.edu

As I write this the first week of June, it is evident that summer has arrived as daytime high temperatures are consistently in the 90s and creeping upward every week. Rainfall in the month of May across South, Central and East Texas has been a mixed bag. The Lower Rio Grande Valley and Coastal Bend are both in need of additional rainfall as moderate drought conditions begin to set in. Cotton in these regions is at cutout or is quickly approaching cutout. Scouting for plant bugs and stink bugs should begin to ramp up in these areas, especially as the harvesting of grain crops begins.

Soil moisture conditions in the Upper Gulf Coast have remained good with regular rounds of rainfall occurring throughout most of the region. Early season thrips and cotton fleahopper pressure was extremely high in many portions of the Upper Gulf Coast this year, and as boll development progresses, scouting efforts should include evaluating for stinkbug feeding damage.

The Blackland Prairie region has received abundant rainfall over the past few months, and many growers with intentions of planting cotton never had the opportunity to do so as the clay soils of this region never dried enough to get planting equipment in the field. Many growers that were able to get the crop planted have experienced a few rounds of hail, and damage has ranged from minimal to severe. In some cases, waterlogged soils in the Blacklands have led to poor early season cotton root development, which may result in an early onset of drought symptoms if conditions dry out rapidly as the summer months progress.

Good rainfall in the Rolling Plains has improved conditions in the region as growers finalize planting activities during the first few weeks of

June. Rainfall over the past few months has improved soil moisture conditions in the West Central region, but additional rainfall would greatly bene t the cotton crop in this region as abnormally dry conditions have again returned to begin the month of June.

bmcknight@tamu.edu

Ever since I have worked in West Texas, I have found that everyone is obsessed with having a bloom by July Fourth. Over the decades, I have found these Independence Day blooms very elusive, aside from an occasional volunteer plant. Should growers truly be concerned if they do not have blooms by July 4? e data from modern varieties indicate there is no need to panic.

Dr. Craig Bednarz and a recent West Texas A&M graduate, Emily Brorman, reported some excellent ndings on earliness from a study conducted in the Texas Panhandle at Etter. e target development curve from the old COTMAN days (developed primarily from South Texas and Mid-South data), indicated that we should have a bloom by 60 days a er planting (DAP). Dr. Bednarz’s work indicates that in the Texas Panhandle (and I would suggest, also in the southern high plains of the Lubbock area), we reach rst bloom in 70-78 DAP, which didn’t surprise any of us in West Texas who closely track such things.

Related to this, the old model suggested that each new node prior to bloom developed at one node per 2.7 days (most of us routinely round this to 3); Dr. Bednarz’s model showed that the West Texas node development is more like 3.5 days per node. is is signi cant for West Texas growers who constantly strive for early maturity to avoid harvest season losses from fall storms and battle low micronaire from cool, fall temperatures during boll ll. And this all relates to how you manage the crop mid-season.

to how much mepiquat chloride hastens maturity and when to apply it to get that desired e ect. Most of our data in West Texas indicate that, if you want to hasten maturity, applications during squaring and the rst week or so of bloom are most e ective. And even then, maturity will only be hastened a few days (not weeks!).

So now that we have realistic expectations for when to expect rst bloom, what management strategies should West Texas growers employ to achieve early maturity? Some are obvious: good weed control can avoid maturity delays due to weed competition, and good insect control (particularly thrips and eahoppers in West Texas) will help ensure high square and young boll retention and, therefore, translate to earlier maturity.

However, many growers have unrealistic expectations when it comes

Su ce it to say, under moisture-limited environments like West Texas, use caution when applying mepiquat chloride to avoid any yield reductions and extreme plant height e ects. Applying mepiquat chloride in excessive amounts during late bloom and boll ll has little to no e ect on maturity in West Texas. Growers may see color change and even height e ects, but if the purpose of these late applications is to hasten maturity, they will be disappointed. Target those applications during squaring if striving for earlier maturity. ken.lege@ag.tamu.edu

As we move into July, most of the cotton has been sidedressed with nitrogen and the later-planted cotton is le to be fertilized. Managing that added fertility will be the primary focus of your season moving forward. Some cotton has received plant growth regulator applications and most will be receiving the remaining applications. Research in Virginia has shown that applying PGRs at matchhead square is the most e ective application timing in order to manage plant height. A key consideration will be the variety that is being managed as it has been well documented that certain varieties need higher application rates of PGRs than other varieties. Knowing your variety growth habit on your farm is critical to successful PGR management. e second aspect of mid-season management is scouting for insect pests, especially tarnished plant bugs, during this time. Consult Extension recommendations for your state, but remember that rotating modes of action for insecticides will greatly reduce the risk of insecticide resistance. When scouting, it is also important to take into account the surrounding crops and landscapes as this will impact plant bug populations, and elds may be more susceptible to predation when neighboring certain other crops. Overall, management during this phase of the growing season is directing the energy of the plant towards reproductive growth and retaining the maximum number of bolls per plant as possible. whframe@vt.edu

BY BONNIE COBLENTZ MSU EXTENSION SERVICE

The Mississippi State University Extension Service is taking irrigation education a step further by offering Master Irrigator status to those who complete a course of training.

There is no cost to growers to participate in this training, which includes eight hours of online classes and 16 hours of in-person training. Drew Gholson, MSU Extension irrigation specialist and coordinator of the National Center for Alluvial Aquifer Research, said the goal is for participants to put into practice the skills acquired in the program.

“Once someone has completed this training, they will go off and implement this on their farm or on the acres they consult with,” Gholson said.

MSU is continuously involved in research projects aimed at improving irrigation efficiency. Their findings are passed on to the public through on-farm, one-on-one consultations, short courses and demonstrations. Creating a Master Irrigator designation formalizes this expertise in irrigation and water management.

“We’ve researched and learned about several tools that work to make irrigation more efficient, and as an institution, we’ve promoted the adoption of these practices,” Gholson said. “But to save money and become more efficient with water use, growers must understand and properly implement these tools on their farms.

“We’re trying to fill that gap of training,” he said.

The Master Irrigator program was launched in the fall of 2023 after being in development for several years. Mississippi joins Texas, Oklahoma and Colorado as states that have launched a formal irrigation training program. Several others are in the process of creating their own state programs.

“These states have worked together to create these programs, but it is important to keep a regional and state-specific focus that is applicable to our growers,” Gholson said.

Mississippi’s program is unlike the others as it is a hybrid that combines online classes with in-person training. Unlike the other Master programs, such as Master Gardeners offered through the MSU Extension Service, the irrigation program does not have a volunteer component.

Dillon Russell coordinates MSU Extension’s Master Irrigator program from the MSU Delta Research and Extension Center in Stoneville. He said the online portion covers fundamental irrigation principles, terminology and an introduction to soil moisture sensors and soil-water relationship.

There are also videos that introduce participants to non-Extension resources available to them, such as the Natural Resources Conservation Service and the Yazoo Mississippi Delta Joint Water Management District.

“The in-person part of the training is both in a classroom and outdoors and is meant to be more hands-on and interactive,” Russell said. “We introduce new topics and dive deeper into some of the topics we covered online.”

At the two-day session, presenters talk about the different types of soil moisture sensors, how to install them and how to interpret the data; how to set up a field in the web-based application, Pipe Planner; pump efficiency testing; soil health management; and the economics of irrigated agriculture.

The Master Irrigator class will be offered each year. It starts in October when the online modules are open, and participants have until Jan. 31 to complete them. The in-person session is held in February. This year, 38 people completed the inaugural class.

Those who finish the program receive a certificate of completion, and some companies give a discount on soil moisture sensors and other instruments to those who complete the course. Those enrolled in some Natural Resources Conservation Service programs can meet program requirements by submitting this certificate.

Work is being done to expand the financial incentives tied to the Master Irrigator program. Learn more about MSU’s research in irrigation efficiency, water conservation and the Master Irrigator program at http://ncaar.msstate.edu.

Elevated seed houses are valuable for short-term seed storage, wet seed storage and gins with limited yard space. Design improvements allow overhead seed houses to be an e icient method for loading trucks from flat-storage houses and gins. When fully loaded, a double-hopper seed house can weigh 200,000 pounds or more. Structural integrity is critical. Volatile weather can put older seed houses at risk, especially those not properly maintained.

Through the years, moisture and chemicals from seed along with humidity cause the inevitable — rust and corrosion. Since the damage primarily occurs inside the seed house, it is out of sight and mind. If a structural failure occurs, personnel are at risk of injury. All cotton gin managers should review their overhead seed house safety and maintenance procedures before the start of the 2024 cotton ginning season.

■ Never go beneath a seed hopper that contains seed.

■ Provide proper fall protection for all ladders and catwalks.

■ Never enter the seed trailer or climb on the side walls of the trailer while beneath a hopper that contains seed.

■ Post decals, “DANGER – DO NOT ENTER AREA BELOW HOPPER DOORS WHEN SEED IS IN STORAGE HOUSE.” These are free from your local ginning association or from www.cli granberrycorp.com

■ Contact your ginning association or loss control representative to get a copy of the “Cottonseed System Safety Policy” for employees, visitors and outside contractors, such as seed haulers. This is also available at www.cli granberrycorp.com.

■ Be sure to use all other known gin safety procedures daily.

■ All proper safety precautions including the use of personal protective equipment (PPE) should be taken by all personnel who perform maintenance and repairs.

■ Clean out all seed.

■ Clean hopper panels to remove seed oil.

■ Smooth the inside surfaces of the hopper panels again.

■ Carefully examine the entire seed house for stress fractures and loose hardware, especially if industrial vibrators have been used.

■ Remove rust and corrosion.

Best industry practices include using a trailer-viewing catwalk mounted on the outside of the vertical columns, about 9.5 feet above the driveway. This structure provides a good vantage point to see into the tops of the trailers to determine when to open and close the hopper doors.

Jim Granberry, president of Cli Granberry Corp., contributed this article. Email jim@cli granberrycorp.com or call 972-381-8899.

Cotton gin waste, also known as cotton gin trash, is a byproduct of the cotton ginning process and occurs when the cotton fibers are separated from the seed boll. For cotton gin waste, the treasure is its hidden potential to transform silver ions into silver nanoparticles and create a new hybrid material that could be used to add antimicrobial properties to consumer products, like aerogels, packaging or composites.

Silver nanoparticles are highly sought-after products in the

industry because of their antibacterial, antifungal, antiviral, electrical and optical properties. These nanoparticles have an estimated global production of 500 tons per year and are widely applied to consumer goods such as textiles, coatings, paints, pigments, electronics, optics and packaging.

In a study published in ACS Omega, researchers from the U.S. Department of Agriculture’s Agricultural Research Service revealed the ability of cotton gin waste to synthesize and generate silver nanoparticles in the presence of silver ions.

“Our method not only lets cotton gin waste act as chemical agents for producing silver nanoparticles, which makes it cost-effective and environmentally friendly but also enables embedding the nanoparticles within the cotton gin waste matrix,” said Sunghyun Nam, research engineer at ARS’s Cotton Chemistry and Utilization Research Unit in New Orleans. “By embedding them in the cotton gin waste, these materials acquire antimicrobial properties.”

Nam said the researchers used a simple heat treatment of cotton gin waste materials in water containing silver ions that produced silver nanoparticles without the need for additional chemical agents.

This finding is significant since making silver nanoparticles usually requires chemical agents that can be costly and pose environmental concerns. Embedding nanoparticles into a material can also be challenging.

Developing nanoparticle embedding technology is not new for Nam and her team. They previously developed washable antimicrobial wipes by using raw cotton fiber that produced silver nanoparticles inside the fiber. The embedded silver nanoparticles can continue to kill harmful bacteria wash after wash.

Large quantities of cotton gin waste are generated annually,

and the cotton ginning industry is always seeking new sustainable processes that upcycle crop residue.

“Our research paves the way for new material applications of cotton gin waste that can protect against microbial contamination,” Nam said.

A provisional patent application on the self-embedding silver nanoparticle biomass waste compositions has been filed.

The Agricultural Research Service is the U.S. Department of Agriculture’s chief scientific in-house research agency. Daily, ARS focuses on solutions to agricultural problems affecting America. Each dollar invested in agricultural research results in $20 of economic impact.

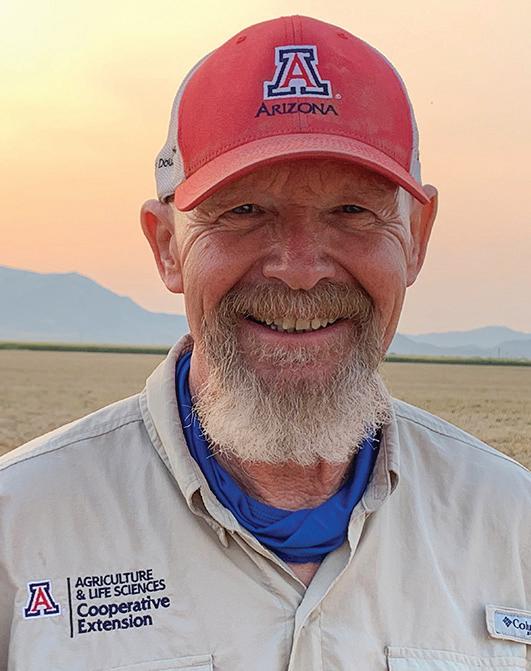

My path to the cotton world really began in the wheat and alfalfa fields of southern Kansas and northwest Oklahoma. In 1966, when I was 12 years old, I began working on local farms, starting out with hay baling operations. I continued to work on local farms, particularly the Richardson Farm near Valley Center, Kansas, until I was 22 and graduated from Kansas State University with a B.S. degree in agronomy in 1976.

After leaving K-State, I worked for five years as an agronomist — crop consultant in southwestern Kansas, based in Montezuma. Following those excellent formative experiences, I started graduate school at Oklahoma State University under the direction of Dr. Robert L. Westerman in soil fertility and plant nutrition.

I applied for the University of Arizona cotton specialist position in the fall of 1986 when I was finishing a Ph.D. program in soil science at OSU. At that time, we had a 1 ½ year old son and another child due in April 1987. Very simply, I needed a job, and I cast a rather broad net in search of one.

farm in Dodson, Texas, where they were sharecroppers. During my time at OSU, I worked directly with cotton production in southwest Oklahoma with Dr. Westerman’s program. One of my colleagues, Randy Boman, was frequently extolling the marvels of the cotton plant. I trusted Randy’s wisdom on this, but I did not fully appreciate the nature of his passion for cotton at the time. Collectively, that was the sum of my direct exposure to cotton production before I arrived in Arizona in the spring of 1987.

My immersion into the cotton industry began immediately, and it was an intense experience, like drinking from a fire hose. Farming is a generally intense operation, and growing crops in the desert is extremely intense by the very nature of working to counteract the huge environmental forces — heat, salinity and extremely dry conditions — that can destroy a crop very quickly.

My work in Arizona has provided many rewarding experiences that include numerous students who have graduated and developed successful careers. Some of them have worked internationally, and many of them have been working in the cotton industry.

“It was an intense experience, like drinking from a fire hose.”

In January 1987, I interviewed and then accepted the offer to serve as an Extension agronomist — cotton, aka the cotton specialist at the University of Arizona. This was not at all premeditated nor was it a specific goal. In truth, I was fortunate to have a good job in my area of expertise as I was leaving graduate school.

After completing the spring 1987 semester teaching a soil chemistry class for the OSU Agronomy Department, we loaded up and headed west to Arizona a little over three weeks after our second son was born. This was kind of like the Clampetts leaving Texas and heading west to California in the “Beverly Hillbilly’s,” except we were certainly not wealthy, and we had to spend about everything we had to make the move. Then, upon arriving in Arizona, my cotton journey began immediately.

One might expect someone coming in as a new cotton specialist to have a wealth of experience and knowledge in cotton production. I did not. My only exposure to cotton production had been as a child visiting my great-grandparents (my father’s maternal grandparents)