Scan the QR code with your phone to renew today for FREE!

Scan the QR code with your phone to renew today for FREE!

We know you’re busy with more important things, so we’ll get to the point. The U.S. Postal Service requires that we receive a written request from you to continue sending The Peanut Grower for FREE.

Please take a few moments to renew online by scanning the QR code. We don’t want to lose you as a reader.

Clemson University’s precision ag team searches for an objective way to determine when to change digger blades.

UGA’s Scott Monfort says producers may be leaving yield behind.

Auburn researchers look for ways to increase average yields and manage input costs.

A Weed Science Society of America survey identifies robotics and precision weed management as needed skills.

Doing things ‘the old way’ is this Southampton, Virginia, peanut producer’s passion.

EDITORIAL/PRODUCTION

Editor Amanda Huber ahuber@onegrower.com

Copy Editor Cassidy Nemec cnemec@onegrower.com

Art Director Ashley Kumpe

Digital Content Manager Katie Guthrie

ADMINISTRATION

Publisher/Vice President Lia Guthrie (901) 497-3689 lguthrie@onegrower.com

Associate Publisher/Editor-In-Chief Carroll Smith (901) 326-4443

Associate Publisher/Sales Scott Emerson (386) 462-1532 semerson@onegrower.com

Audience Services Kate Thomas (847) 559-7514

Production Manager David Boyd dboyd@onegrower.com

For subscription changes or change of address, call (847) 559-7578 or email peanutgrower@omeda.com

EDITORIAL ADVISORY BOARD

Scott Monfort

Extension Agronomist University of Georgia

Dell Cotton

Peanut Growers Cooperative Marketing Assn., Franklin, VA

Kris Balkcom

Agri-Program Associate

Auburn University

Dan Anco

Extension Peanut Specialist

Clemson University

Emi Kimura

Extension Agronomist Texas A&M University

David Jordan

Extension Agronomist North Carolina State University

Glen Harris

Extension Agronomist University of Georgia

Jason Ferrell

Extension Weed Specialist University of Florida

ONE GROWER PUBLISHING, LLC

Mike Lamensdorf PRESIDENT/TREASURER

Lia Guthrie PUBLISHER/VICE PRESIDENT

The Peanut Grower (ISSN 1042-9379) is an agribusiness magazine for U.S. peanut producers. Published in eight monthly issues, January through July and November. Annual subscriptions are $40.00. Single Copy price is $5.00. Annual overseas subscriptions are $70.00, including Canada/Mexico. Periodicals postage paid at at Memphis, Tennessee, and at additional mailing o ices. Copyright © 2024 One Grower Publishing, LLC, all rights reserved except where otherwise noted. The Peanut Grower ® is a registered trademark, which reserves all rights granted by the U.S. Patent and Trademark O ice in association with the registration. POSTMASTER: SEND ADDRESS CHANGES TO OMEDA COMMUNICATIONS, CUSTOMER SERVICE DEPARTMENT, P.O. BOX 1388, NORTHBROOK, IL 60065-1388. All statements, including product claims, are those of the person or organization making the statement or claim. The publisher does not adopt any such statement or claim as its own, and any such statement or claim does not necessarily reflect the opinion of the publisher. Printed in the USA.

One Grower Publishing, LLC, also publishes Cotton Farming, Rice Farming, Soybean South and Corn South

One Grower Publishing, LLC

875 W. Poplar Ave., Suite 23, Box 305 Collierville, TN 38017

The Weed Science Society of America routinely surveys leaders in weed science to identify important weed research topics for the next five to 10 years. You can read the article on page 16, but what the survey found is that different skills will be needed to combat weeds in the future.

Then I came across an interesting article that proves this point. The article was about research on a sterilization technique commonly used to control insect pests that was modified to control weeds that require pollination to reproduce. More specifically, the researchers determined that employing a sterile pollen technique could effectively disrupt Palmer amaranth reproduction.

This certainly got my attention since Palmer amaranth, which is resistant now to several herbicide groups, is a serious challenge to control. Researchers in this study were able to find a promising new control method for Palmer amaranth and possibly for many other difficult-to-control weeds.

According to Mohsen B. Mesgaran, plant sciences assistant professor at the University of California Davis and researcher on the project, using irradiated pollen can be a valuable approach for reducing weed-seed production, and the sterile pollen technique holds potential for broad-spectrum weed control by mixing sterile pollen from multiple weed species in a single application. They also found this technique shows promise for managing troublesome herbicide-resistant weeds that have survived in-season control efforts.

Research into this method is ongoing, but it could be that this novel approach may be the answer into management of herbicide-resistant weeds in the future.

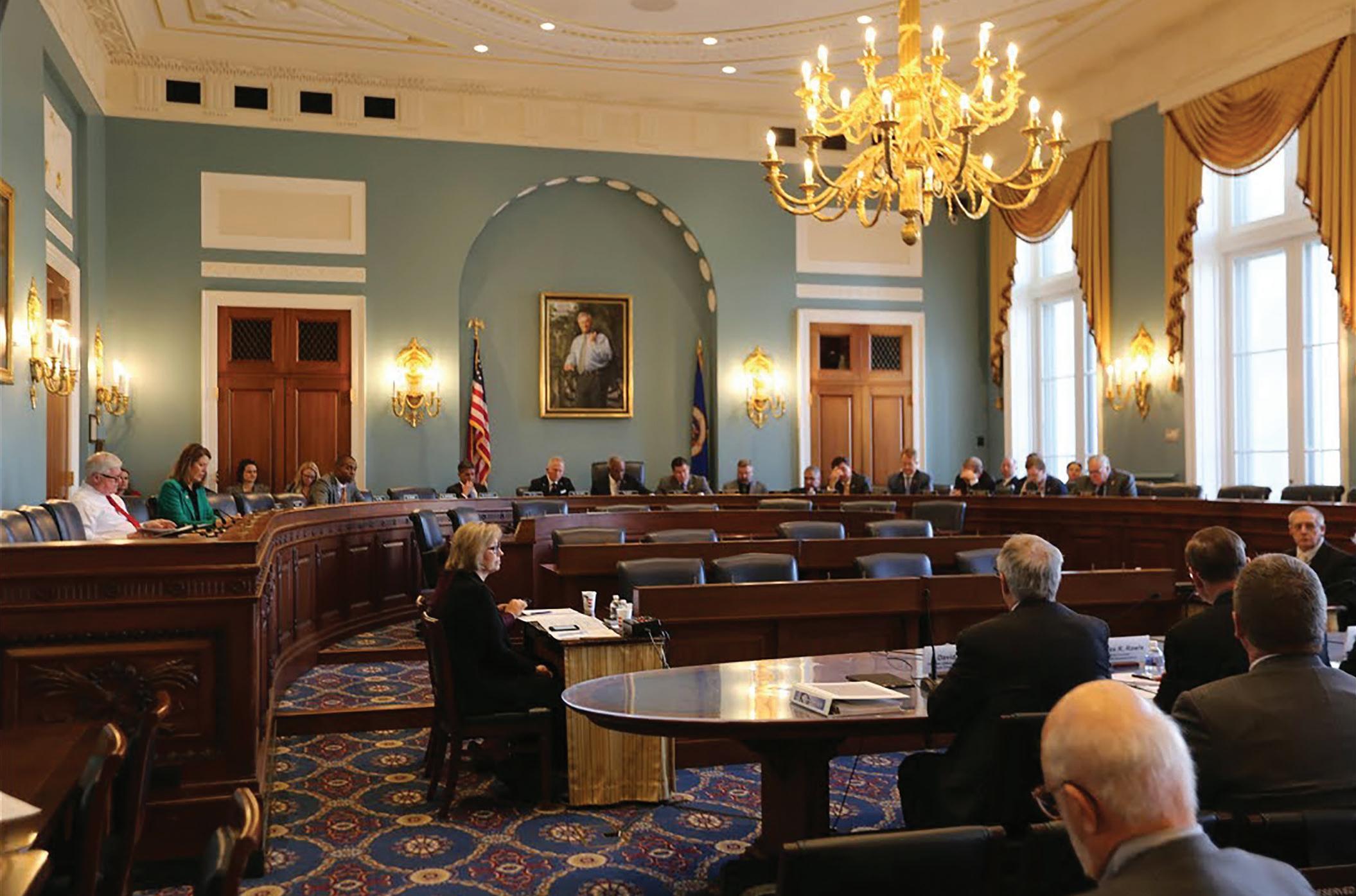

The U.S. House Committee on Agriculture voted to pass the Farm Bill, titled “The Farm, Food, and National Security Act of 2024” in a 33-21 vote. Four democrats – Reps. Sanford Bishop (GA-02), Yadira Caraveo (CO-08), Don Davis (NC-01) and Eric Sorenson (IL17) – joined with republican committee members in voting yes on this legislation.

The legislation includes a 17.8% increase in reference price for peanuts in the Price Loss Coverage program, bringing the reference price from $535 per ton to $630 per ton. It also includes other peanut priorities, including a provision for a one-time voluntary base update for young farmers and new production areas to be able to utilize the programs.

Congressman Austin Scott (GA08) says, “As vice chair of the House Agriculture Committee, I am pleased that several of my priorities to ensure a strong farm safety net were included in this legislation, and I appreciate the bipartisan support for final passage through committee.”

Following the markup, U.S. House Agriculture Committee chairman G.T. Thompson said that he does not expect the legislation to be considered on the House Floor before September due to the busy appropriations schedule for the upcoming months.

Prior to passage, the U.S. Peanut Federation sent a letter to chairman G.T. Thompson in support of the legislation, stating: “The United States Peanut Federation sincerely appreciates the hard work that went into producing the 2024 Farm Bill. This legislation will support peanut producers who have been struggling in recent years due to increases in farm inputs, labor shortages, trade barriers and supply chain disruptions.”

Throughout the Farm Bill process, the peanut industry has been united in its priorities, namely a meaningful increase

in the reference price for the Price Loss Coverage program. The historic rise in input costs and cost of production make a reference price increase a necessity to keep the farm safety net intact.

“The U.S. Peanut Federation appreciates the hard work of the U.S. House Agriculture Committee in drafting this Farm Bill and passing it out of committee,” says USPF chairman Jamie Brown. “The peanut industry has struggled in recent years due to increases in farm inputs, labor shortages, trade barriers and supply chain disruptions. This markup was an important first step in getting producers the assistance they need to continue to produce our nation’s food, fuel and fiber. USPF applauds the Members of Congress who supported farm communities by voting to advance this important legislation.”

Peanut producers voted overwhelmingly to continue the Peanut Promotion, Research and Information Program, administered by the National Peanut Board, in a referendum conducted by the U.S. Department of Agriculture April 8-19, 2024. Results show that 93.23% of voting farmers said “yes” to continuing NPB’s research, marketing and promotion program.

“We accomplished almost every goal in our strategic plan, including reaching record-high per capita consumption of 7.8 pounds in 2022, growing peanut love among millennial and Gen Z consumers and making peanut production more sustainable,” says NPB President and CEO Ryan Lepicier. “This resounding approval encourages us to continue working as hard as we can to drive impact for America’s peanut farmers and their families.”

For the continuances, a simple majority of eligible producers needed to vote in favor of continuing the order. Growers who paid assessments on peanuts pro-

• House Ag Committee Farm Bill includes increase in reference price, voluntary base update for new growers, areas.

• National Peanut Board, Georgia Peanut Commission rea irmed by growers.

• New funding supports export market.

• MANA ready-to-use therapeutic food factory opens, receives news of USAID purchase.

• Alliance formed to help families with estate-planning decisions on heirs’ property in Alabama.

duced during the representative period from Jan. 1, 2022, through Dec. 31, 2022, were eligible to vote.

“I am extremely proud of the work NPB does as a whole but especially proud of our work in the areas of production research and peanut allergy prevention,” says Greg Baltz, 2024 NPB chairman and a peanut farmer from Arkansas. “It’s great to see that USA peanut farmers see the exceptional work that the Board does promoting our sustainable, nutritious peanuts.”

The last referendum for peanuts was conducted by USDA in 2019.

USDA launched the $1.2 billion Regional Agricultural Promotion Program in 2023 in response to a bipartisan request from the U.S. Senate Committee on Agriculture, Nutrition and Forestry. RAPP aims to diversify and expand market opportunities for U.S. food and agricultural products beyond the traditional top customers – Canada, Mexico, the European Union and China (including Hong Kong and Macau) –

which collectively comprise nearly 60% of U.S. agricultural export sales.

Instead, RAPP will focus on enhancing U.S. exports to new markets in parts of the world, including South and Southeast Asia, Latin America, the Middle East and Africa, where the middle class is growing and the desire for high-quality food and farm products is increasing. Gaining market share in these diverse and dynamic markets will help U.S. exporters to better weather global shocks and to compete in an increasingly volatile global marketplace.

Total awarded funds for 2024 RAPP were $300 million. The American Peanut Council will receive $2.97 million over five years.

The board of directors of Georgia Federal State Inspection Service is pleased to announce that Clay Pirkle of Turner County has been hired as director of operations. This job is a training position leading to president. T.E. Moye will remain as president during the training period. The board chose this approach in order to have a smooth transition.

The U.S. Department of Agriculture sets the guidelines and parameters for the inspection process, and it can be a lengthy learning period to completely understand the working relationship the Georgia inspection service has with farmers, buying points shellers and USDA.

The 25th Annual Southern Peanut Growers Conference will be held July 17-19, 2024, at the Westin Savannah Harbor Golf Resort & Spa, Savannah, Georgia. The three-day event provides farmers with information about peanut production, legislative issues, marketing and promotions.

The conference schedule includes the following:

■ General Session I: Piloting Peanuts through the Course with speakers Bob Parker, Peanut Solutions, and former U.S. Secretary of Agriculture and current chancellor of the University System of

Georgia, Sonny Perdue;

■ General Session II: Setting a New Course for Peanuts with Drs. Michael Deliberto, Louisiana State University, and Ondulla Toomer, Food Science and Market Quality and Handling Research Unit, USDA-ARS;

■ General Session III: Navigating Difficult Waters: Peanut Policy and Economics with U.S. Rep. Frank Lucas, former chairman of the U.S. House Committee on Agriculture, and a report from Bob Redding, The Redding Firm.

For more information on SPGC, go to southernpeanutfarmers.org.

The Georgia Peanut Commission received reaffirmation with a vote of 91.99% during the recent referendum, held March 8 through April 8, 2024.

“I appreciate the farmers’ confidence in the commission, and we are committed to continue earning that confidence,” says Joe Boddiford, farmer from Sylvania, Georgia, and GPC chairman.

“The commission continues to work together as a partnership between Georgia’s peanut farmers and the commission board and staff, in funding research projects, promoting peanuts and working on the farmers’ behalf in Washington, D.C. All of these combined efforts allow us to provide a healthy, nutritious product for consumers and help keep farmers profitable for the future,” he says.

“Our staff is humbled by the support of peanut farmers in Georgia,” says Don Koehler, GPC’s executive director. “We will continue to seek opportunities through programs in research, education and promotion to enhance profit opportunities on the farm.”

Georgia peanut farmers invest $2 per ton annually to the commission to be used in the program areas of research, promotion and education. As required by Georgia state law, the state’s peanut farmers vote on the commission every three years.

For additional information on the Georgia Peanut Commission and its activities, visit their website at www. gapeanuts.com.

More than 200 friends, supporters, employees and neighbors joined the celebration at MANA factory in Fitzgerald, Georgia.

CEO Mark Moore says, “Today marks a milestone for MANA. It has been a 14-year journey, starting with a dream, little expertise, even less money and lots of grit and optimism. Today, we are launching the biggest plant in the world for making Ready-to-Use Therapeutic Food. RUTF is the key intervention for feeding and saving severely malnourished children. Along the way we have fed more than eight million children with over one billion little packets.

Moore thanked the many donors, investors and collaborators who have helped them reach this milestone, most notably Sir Chris Holm as their capital investment partner and USAID as the purchasing partner.

Samantha Power, Administrator of the U.S. Agency for International Development, says 164 million kids are at risk of food insecurity and 8,000 die every day. Globally, 29% of children under five suffer from malnutrition, and under-nutrition is an underlying cause of 45% of deaths among children under five, mainly in low and middle-income countries.

Power says in 2022, USAID invested $200 million with private matching donors raising $330 million. “Today, we are announcing that USAID will provide another $200 million to make resourc-

Heirs’ property, or family land, is common in Alabama. Whether families are attempting to develop or sell the land left by previous generations, the lack of a clear title makes it difficult for families to move forward.

Adam Rabinowitz, Alabama Cooperative Extension agricultural economist, says heirs’ property is an issue that is created when someone dies without having a will or without the will being properly probated in the courts. “As a result, all of the heirs of the deceased become shared owners of the land. This can lead to a large number of family members having a fractional interest in the land.”

The Alabama Heirs Property Alliance is a partnership between Auburn University, Alabama A&M University and Tuskegee University with the purpose of providing guidance to landowners in need of direction about heirs’ property.

Rabinowitz says the level of need in Alabama is one of the reasons that he and colleagues partnered together. A training program for Extension agents and specialists, as well as legal professionals, was created and helps enable these professionals to be more effective in their conversations and assistance with stakeholders.

“The team that we have been building in Alabama is going to help address landowner challenges that can create tension in families, limit income and wealth opportunities and potentially lead to land loss,” says Rabinowitz. “By training and further supporting Extension professionals, the alliance will have a much wider impact in minimizing the negative effects of heirs’ property.”

Portia Johnson, Auburn College of Human Science’s department of Consumer and Design Sciences assistant professor, says a common misconception is that when leaving property to others, the easiest and most fair thing to do is to

es that will purchase many more RUTF packages and get them around the world. Global Hunger is a solvable problem as we make investments in this life saving system by turning peanuts into medicine.”

One of the American Peanut Council’s core responsibilities is to administer an export promotion program for U.S. peanuts with the objective of increasing the consumption of U.S.-grown peanuts and peanut products internationally. The APC does not process or sell peanuts; instead, its resources are devoted to market development and dissemination of trade information on behalf of the U.S. industry.

Funding for APC export promotion

pass land down to all heirs jointly.

“Leaving physical property, whether that be land or a home, to all your children equally and collectively can cause a lot of unintended consequences,” Johnson says. “Leaving joint ownership creates rifts and disagreements within the family about how to manage or divide use of the property. It can also leave the property vulnerable and legally unprotected.”

One of the best things families can do as they are making estate planning decisions is to leave ancestral land with clear titles and an understanding of their wishes.

“Sometimes the decisions made in a will with the intention of keeping the family land together could be the very things that end up tearing the family and the land apart in the end,” she says.

Learn more about heirs’ property and how you can prevent it by visiting the Alabama Heirs Property Alliance web page at www.aces.edu/blog/topics/farm-management/ alabama-heirs-property-alliance. You can also search the Extension website calendar or call your county Extension office to see if there is an heirs’ property event scheduled in your area.

activities is shared between the U.S. peanut industry and U.S. Department of Agriculture’s Foreign Agricultural Service. The efforts are funded through the Market Access Program, Foreign Market Development and other related programs administered by USDA.

On average, the U.S. peanut industry exports 20%-30% of the crop. Maintaining strong export markets is an important strategic priority.

APC members can find export data “one pagers” for the top six 2023 peanut export markets on their website at peanutsusa.com . Each one contains 2023 peanut export statistics, as well as insights into consumption habits and snacking trends.

The peanut industry continues in a wait-and-see mode as the startup of 2024 adds more unknowns to the market mix. Peanut producers and industry leaders agree that since cotton and corn prices were not as profitable, peanuts would likely save this season with favorable contracts.

As April rolled around, producers made their final decisions on how many acres to plant. Early on, soils were still cool and damp at the start of the planting window. In the Southeast and Virginia-Carolina area, an estimated 30% of acreage was planted by this time.

In early May, more rain came, sometimes four to six inches, and farmers had to put further planting on hold until the soil dried out. By May 15, another 30% of the acreage was planted. Then, another round of rains covered the heart of the Southeast peanut belt, bringing with it flooded fields, stuck equipment, water-logged seedlings and general poor conditions. Waiting is often an agonizing thing for a farmer when conditions are completely out of their control.

By June 1, the remaining 20% to 30% of acreage was yet to be planted. Unfortunately, the Southwest remains under drought conditions.

Have we missed the window for optimum yields in 2024, especially in Georgia? That remains to be seen. Current crop buyers can come in and buy from the 2023 crop if needed. Their hope is that the market will weaken toward the new crop. Both buyers and shellers that wanted to do some business for 2025 coverage have done so, and now we wait and watch the weather. Current crop shelled peanuts are in the high $.60s to low $.70s, and new crop peanuts are in the high $.50s.

The market will likely remain firm with mediums at $.57 or so for the new crop.

The edible market may be less than the U.S. Department of Agriculture estimate. A new peanut warehouse lost its licensing from USDA, and what will happen to that tonnage is unknown. Will they reach the edible market?

Contract offers in the Southeast were above $500 to $525 per ton for runner-type peanuts and higher for Virginia varieties in the V-C region. Buying points reported heavy action, especially if a sheller/buying point pool was an option since there is the hope of a price increase later in the year.

As a first estimate for the 2024 crop, USDA expects a 1% increase in harvested acres; however, the trade believes acreage will be higher. USDA estimates production at 6.34 million pounds or 3.17 million tons. The estimate on average yields is 4,000 pounds per acre, up from 3,742 pounds per acre on 1.58 million harvested acres.

Disappearance is estimated for domestic food, crush, exports and seed/residual

J. Tyron Spearman Contributing Editor, e Peanut Grower

at 3,080,500 tons. Surprisingly, this estimate calls for domestic food use to be up 1.2%. The USDA Farm Service Agency reports that peanut exports are up 33% for August through March. Ending stocks are now estimated at 1,136,000 tons. That is a good cushion to keep the market supplied with a constant supply of good quality U.S. peanuts.

The U.S. market for peanuts is showing a 3% decrease in usage. All categories are showing a decline, including peanut butter down .5% in the past nine months. Manufacturers experience the same economic conditions faced by peanut farmers, higher costs of production and inflation.

The Farm Bill is taking shape. The House Ag Committee’s Farm Bill makes targeted improvements for each commodity through increases to the statutory reference price and improving agriculture risk coverage for all commodities. The reference price for peanuts would be $630 per ton, up from $535 per ton.

Other changes are that producers would have an opportunity to add base

acres to their farm, and farmers without access to Title I programs would be able to sign up. Marketing assistance loans are strengthened through increases in the loan rate for all commodities. The loan rate for peanuts would increase from $355 per ton to $390 per ton. Crop insurance coverage for producers would be expanded though the enhancement of area-wide coverage options, making insurance more affordable. Payment limits would also be increased to keep pace with inflation.

Chairman G.T. Thompson says that he does not expect the legislation to be considered on the House floor before September because of the busy appropriations schedule for the upcoming months.

On the Senate side, a general statement has been issued by Chairperson Stabenow. Senator Rev. Raphael Warnock (D-GA) proposed a Farm Bill framework that includes provisions from every piece of agriculture legislation introduced by the Senator since being sworn into office in 2021. The frame-

‘‘ For producers who have not contracted, there is no rush. You have time, and, hopefully, the market will come to you at a profitable level. Shellers and manufacturers want your peanuts and want you back next year.

work includes reference price increases of 5%, market assistance loan increases and additional base allocation.

Democrats and Republicans sparred over the main issue of funding for the total Farm Bill. The proposed legislation would draw on the Supplemental Nutrition Assistance Program, or SNAP, as a source of funds to cover commodity programs. Overall, 87% of the Farm Bill is the cost of SNAP. With a vote of 33-21, the House ag committee advanced its reauthorization of the Farm Bill. However, you would have thought that cold water was thrown into the faces

of some legislators when the cutting of funding to SNAP, the old “food stamps,” was mentioned. Expect a fight on this topic in the future.

Overall, the Farm Bill is a long way from the finish line, and don’t be surprised if they move the goal posts again, such as into next year.

Meanwhile, peanut producers have enough to worry about production-wise, including weather, costs and the normal weeds, insects and diseases. For producers who have not contracted, there is no rush. You have time, and, hopefully, the market will come to you at a profitable level. Shellers and manufacturers want your peanuts and want you back next year.

University’s precision ag team searches for an objective way to determine when to change digger blades.

By Amanda Huber

Scooping up and slicing the taproot is the start of peanut harvest, and blades are a primary part of this.

“Blades should be sharp so they can slice through the soil and roots cleanly and smoothly,” says North Carolina State University Extension peanut specialist David Jordan in the 2024 NCSU Peanut Information. “The blade should be nearly flat with a slight lift in the rear, typically ½ inch.

“Most peanut blades have a smooth side and a beveled side. The beveled side offers more aggressive digging action for harder soils,” he says. “The smooth side works best in softer soils. Blades with hardened steel edges are also available. These blades promise extended life and the ability to maintain a sharper edge. Check blade condition frequently, and replace as soon as they become worn.”

Jordan says both blades and the nearby rods that help guide vines onto the shaker belt will wear differently. “They will need to be monitored to ensure that they are working properly.”

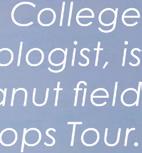

Although this may sound fairly straightforward, Kendall Kirk, a Clemson University agricultural engineer says a good, objective way to know when to change out blades doesn’t exist, and the decision comes with costs either way.

“If you change your blades out too early or too soon, then your blade costs on a per-acre basis is going to be higher than it should be. But, if you are getting additional losses because you wait too long or too late to change them out, then your yield losses become higher,” he says. “Is there an opportunity to optimize this?

“That’s what we are working on. Can we objectively figure out when to change blades?” Kirk says of Clemson University’s precision ag team.

Whether it’s a general suggestion, an app or other method, he says the economics of blade replacement make the decision a complex one.

Although this study found that the blade costs and yield loss intersected at 40 acres for the optimal time to change blades, Kirk says not all wear is the same. It is a much more complicated decision that depends greatly on soil type.

In one study, Kirk says they took 16 sets of blades that had varying levels of wear.

“Some of these were blades from local farmers’ machines that we knew had a good many acres on them from familiar soil types,” he says. Knowing the conditions under which they were used, Kirk says they considered these to be controlled wear in a controlled environment, but there was no relationship between wear and yield loss on the light-textured soils.

“Early data in a light-textured soil showed no real relationship, but heavier-textured soil did show much more of a correlation,” he says.

“On heavier-textured soils, there is a definite reduction in yield for every additional acre you run your digger through beyond optimal blade change. By our calculations, you will have an additional 1.7 pounds per acre of losses. While that’s not that much, it will add up.”

However, Kirk says this was a heavier soil type for peanuts to be grown in anyway.

“If you flip that data around for peanuts, we looked at what the yield loss would be as a function of acres that are on those blades. If you factor in the price of $400 per ton on your peanuts, then you can calculate that loss in dollars per acre,” he says.

University of Georgia Extension precision ag specialist Simer Virk o ers a few considerations for growers to keep in mind for proper digger setup and operation.

“Along with proper timing of digging peanuts, proper setup and operation of peanut harvest equipment is also an important factor to minimize harvest losses and to ensure peak equipment performance and e iciency during harvest,” Virk says. “Here are a few considerations for growers to keep in mind when digging peanuts to prevent any mechanically induced yield losses due to improper digger setup and/or operation.”

• Using an RTK Guidance system/auto-steer on the tractor while digging peanut helps in maintaining the digger path directly over the row center or over the planting path and results in approximately 10% reduction in yield losses compared to digging peanuts with a tractor without an auto-steer system.

• Before beginning harvest and making any adjustments specific to the harvest conditions, inspect the digger carefully for any broken, bent or missing parts as well as the sharpness of the blades. Dull blades that fail to cut the tap root will result in dragging roots or dislodging pods from the plant.

• Adjust the digging angle (and therefore depth) by adjusting the length of the top link on the digger. Digger blades should be set at a slight forward pitch and at the depth where they cut the tap root just below the pod zone. Both an excessively shallower and deeper depth of the digger blade can result in significant digging losses.

• Blade angle/depth is also dependent on soil type and texture. Any considerable change in soil type within or among the fields will also require a change in blade angle/depth adjustments as clay soils usually need a more aggressive angle whereas sandy soils require a less aggressive blade angle.

• Digging speed should be optimized based on the prevalent in-field conditions at harvest. Generally, the optimal ground speed for digging peanuts is between 2 and 3 miles per hour. Speeds above 3 mph can result in an increase in digging losses and should be avoided.

• Set the conveyor speed to match the forward travel speed of the tractor while digging peanuts. Conveyor speeds slower or faster than the tractor speed can both result in increased pod losses.

• The conveyor depth should also be adjusted where it picks up vines with its teeth just clearing the soil. Additionally, if needed, adjust the knocker wheels up or down to regulate the amount of shaking where it is just enough to remove the soil from the vines.

Remember, properly dug and inverted peanut plants will form a uniform, flu y, well-aerated windrow with very few pods touching the soil. Make sure to keep a close eye on the digger operation in the field and adjust settings accordingly as and when needed. PG

Clemson University engineer Kendall Kirk and his precision ag team are looking for an objective method of determining when to change digger blades.

“That’s one piece of the puzzle. But there’s also the cost of

Kirk says for now, growers can look back at the windrow for

Currently, watching the window for proper inversion is the best way to tell when blades need changing. Dull blades will tend to drag plants forward, causing them to ride the inbound on the conveyor, not engage properly with the star wheels and rods and invert improperly.

By Amanda Huber

Most everyone would agree that determining when to dig peanuts was a challenge this past year, and many farmers did not get the grades and yields they wanted, especially on the earliest harvested portion of the crop. Hopefully, the 2024 crop will not be as difficult.

University of Georgia Extension peanut specialist says if anything was to be learned from the 2023 harvest it is that folks need to be flexible with the maturity profile board and patient for the crop to reach maturity.

“The board is a guide,” Monfort says. “It is not an absolute. “We need to be flexible, but it is still the best tool we have for determining when to dig based on maturity.

Weaknesses of the maturity profile board are that it’s time-consuming and requires several sample collections to accurately predict maturity before the crop is ready for harvest. “Separating pods by color is highly subjective because it relies on visual color differentiation that can vary dramatically among individuals,” Monfort says.

On the other hand, he says when peanuts are dug early, producers are cutting themselves short on yield.

“If you don’t take samples and have a maturity profile board run, you could lose as much as 500 pounds per acre if you don’t gauge maturity right,” he says. “I think when peanuts are dug early at 130 to 135 days and they could have gone to 145 to 150 days, if you look at the crop coming along on the profile board, I think we are leaving some weight behind.

“A lot of people do a good job with running the profile boards,” Monfort says. “These maturity clinics are one of the biggest things we do that pays dividends.”

A less subjective method for gauging

maturity by tracking growing degree days. The value for adjusted growing degree days is calculated by taking into account the maximum and minimum temperatures as well as rainfall and irrigation received.

“Peanuts reach physiological maturity after the accumulation of approximately 2,500 growing degree days,” says Mark Mauldin, agriculture and natural resources Extension agent in Washington County, Florida.

The adjusted growing degree day, (aGDD) tracker can be used to approximate how your fields are progressing. For more precise tracking of your fields, go to PeanutFARM.org and set up your fields in the system. You will be able to enter field-specific rainfall/irrigation data and soil type. Temperature data will come from the closest weather station system.

Even with the use of the aGDD tracker, Mauldin says it is still important to have a good, resprentative sample pod-blased so that the maturity board can help optimize harvest timing.

“There are many factors that determine how rapidly peanuts mature with the two most important factors being heat and available moisture,” he says.

One thing both Extension agents agree on is that days after planting should not be used to determine harvest.

“I know you have to start somewhere,” Monfort says. “Is the board 100% right, no because it is a subset of the whole crop, but it is definitely the best tool we’ve got to judge maturity. You shouldn’t use days after planting at all.”

Mauldin says, “In Extension, we say every year, ‘don’t dig based solely on the calendar.’ While this adage is always true, it is especially applicable in years when the crop faced challenging conditions.”

He adds that disease management is crucial to holding fields together long enough to reach optimum maturity.

Wes Porter, UGA Extension precision ag specialist, says irrigation remains important until all peanuts are dug.

“If a maturity check says the crop is a couple weeks away, and it’s supposed to be dry, you should not terminate irrigation. The crop will need water to reach maturity,” he says. “Keep the soil profile at least somewhat moist.”

However, Porter says what can happen, especially in a hot, dry year, is that harvesting starts, but there are still acres of peanuts in the ground that you may not get to for a few weeks. “Keep monitoring those peanuts and irrigating as needed,” he says.

Mark Abney, UGA Extension entomologist, says the same can be said for insect management.

“When you put the digger in the field the first day, 90% of your peanuts are still growing, and it will be a while before you get them. Velvetbean caterpillar can defoliate your peanuts in a matter of days.

“On the remaining crop, you can’t stop paying attention to insects, disease, irrigation or whatever it is that you’ve done for the first 120 days and lose the crop in the last 25-35 days.” PG

Peaks and valleys is one way to describe yields U.S. peanut producers have had over the years. These inconsistencies are prompting Auburn University researchers to search for ways to boost and maintain profitable crops.

An analysis of yields since 1970 made by a College of Agriculture economist shows that yields have been flat for the past 12 years. This came after reaching a record-high of more than 4,000 pounds per acre in 2012.

“Putting into context where this year’s U.S. average yield of 3,740 pounds per acre falls historically, we need to look at peanut yield trends since 1970,” says Wendiam Sawadgo, assistant professor in the Department of Agricultural Economics and Rural Sociology and a researcher with the Alabama Agricultural Experiment Station.

The 2023 average yield was down 7% from 2022 and was the lowest yield since 2016.

“The majority of states’ peanut yields declined in 2023, relative to the previous year, largely due to drought in the South,” Sawadgo says. “The major peanut-producing states of Alabama and Florida both saw 17% decreases in yields. Georgia, the leading state, had a 3% decline to 4,070 pounds per acre.

Over the entire 1970-2023 period, peanut yields increased by 36 pounds per acre annually, on average, but with considerable variations, he says.

“From 1970 to 2000, peanut yields increased by an average of seven pounds per year,” Sawadgo says. “Then, in 2001, peanut yields reached 3,000 pounds per acre for the first time, and over the subsequent decade, peanut yields would increase by 57 pounds per year on average.”

The substantial yield increase from 2001-2012 likely was driven by the introduction of Georgia-06G, a high-yielding runner-type peanut cultivar that was released in 2006 and soon gained a significant market share in the Southeast, he says.

“In 2012, peanut yield surpassed 4,000 pounds per acre for the first time. However, over the past 12 years, peanut yields have been flat and averaged 3,948 pounds per acre. In fact, the 2012 mark has yet to be topped.”

Peanut yields are an even more critical aspect for profitability due to increased input prices, he says.

“Production costs are expected to remain elevated in 2024 at $598 per ton, assuming yields equal the five-year average,” Sawadgo says. “This means that even with peanut prices expected to reach a decade-high $550 per ton, producers would still likely operate at a loss. Strong yields would help lower these breakeven prices, but the recent yield volatility raises concerns that this might not occur.”

Helping Alabama peanut producers improve yields while at the same time managing input costs is a primary goal of researchers at Auburn University.

This past year was one of the most difficult for Alabama in quite some time, says Kris Balkcom, Auburn University Extension peanut agronomist, who visits hundreds of farmers’ fields each year during the growing season.

“This past year was the first time in many years that our

state average dropped below 3,000 pounds per acre,” Balkcom says. “Our estimated yield will be around 2,700 pounds per acre by the time it’s all said and done. This was mainly because of the lack of rainfall in the lower half of the state from east to west.”

But lack of rain wasn’t the only reason for disappointing yields in 2023, he says. “We had some extreme temperatures last year for a couple of weeks solid without a break. Not only were the daytime temperatures high, but the nighttime temps were higher, which didn’t allow the plants to breathe.”

Since the majority of Alabama’s crop is not irrigated, most growers are dependent on rainfall to help produce their crop, Balkcom says, and this factor is dictating current field research.

“We continue to look at and work more with cover crops

peanut disease trials at five experiment station units, including the Wiregrass Research and Extension Center, the Brewton Agricultural Research Unit, the Gulf Coast Research and Extension Center, the E.V. Smith Plant Breeding Unit and the Chilton Research and Extension Center.

“In Alabama and the Southeastern U.S., there are several foliar and soilborne diseases that can cause severe yield losses in peanuts,” says Amanda Scherer, assistant professor and Extension plant pathologist.

The most economically important diseases include Tomato Spotted Wilt Virus, early and late leaf spot, white mold and root-knot nematodes, which, if left unmanaged, can cause yield losses of 50% or more.

These diseases are managed through a combination of practices, including planting resistant peanut varieties, fungicide and insecticide applications, planting date selection, crop rotation, tillage practices, seeding rates and row patterns.

“Our research focuses primarily on evaluating the reaction of susceptible and tolerant peanut varieties and the impact of commercial and experimental fungicides to these diseases,” Scherer says. “Additional disease research is also being conducted by or in collaboration with entomologist Scott Graham, agronomist Kris Balkcom and variety trial coordinator Henry Jordan.”

Resistant varieties continue to play a major role in preventing or minimizing peanut disease damage, she says.

“Over the past few years, several new peanut varieties have been released to help reduce losses,” Scherer says. “FloRun T61, released in 2020, is a high-oleic, medium-seed size variety with high-yield potential and high grading with resistance to TSWV. TifNV-HG is another newly released high-oleic, high-yielding variety with root-knot nematode and TSWV resistance as a replacement for TifNV-HighO/L. Georgia20VHO, also released in 2020, is a high-grading, high-oleic, runner-type peanut with TSWV resistance. These varieties, among others, will be available for planting this year.”

Weather conditions in Alabama are highly conducive to disease development, and producers must use a variety of strategies to minimize yield losses, Scherer says.

and irrigation in addition to VRI, or variable rate irrigation, to best utilize the water we do have,” he says. “We are also using VRI to try and help us measure the benefits of a cover crop.”

Balkcom agrees that growers’ margins are extremely tight this year due to a lower market price and continuing high input costs. Still, he expects peanut acreage to increase in Alabama.

“Producers are really trying to watch their inputs and not overspend but at the same time not cut themselves short and reduce their yield,” he says. “We will certainly see an increase in peanut acres this year because cotton prices are too low in relation to input costs, and acres will move from cotton to peanuts and soybeans. Most producers feel comfortable growing more acres of these legumes in the years when fertilizer costs and other expenses remain high.”

Researchers also are conducting integrated pest management

“Producers are encouraged to diversify their varieties across planting dates to minimize losses. Resistant peanut varieties are going to perform best in fields with a history of disease and high risk factors, especially in south Alabama. However, growers can still utilize their favorite susceptible variety in low-risk conditions or in medium- to high-risk fields with the aid of preventive fungicides.”

The Auburn University crop physiology lab, led by Alvaro Sanz-Saez, in collaboration with the peanut breeding program, led by Charles Chen, is also working to increase peanut yields through a project that seeks to understand the different mechanisms of peanut drought tolerance. One peanut cultivar being tested is AU-NPL 17, the first runner peanut variety released by Auburn’s peanut breeding program and one that has been designated as being drought and disease tolerant. PG

Article by Auburn University College of Agriculture communication specialist Paul Hollis.

A Weed Science Society of America survey identifies robotics and precision weed management as needed skills.

Technical competencies among weed scientists will likely need to expand quickly to accomplish future research priorities, according to recent results from a Weed Science Society of America online survey. The survey asked U.S. and Canadian leaders in weed science to identify pertinent weed research topics for the next five to 10 years. The survey also asked these leaders to identify expertise and funding gaps that will be needed to address the newly identified research priorities.

Survey respondents identified one particular concern related to skillsets needed for precision weed management and robotics. Precision weed management combines artificial intelligence and machine learning with ground robotics and unmanned aerial vehicle technologies to map and identify weeds and implement management solutions for farmers.

“We see gaps in expertise in these areas,” says Vijay Singh, Virginia Tech weed science assistant professor, whose research team uses machine-learning systems to generate weed databases.

“That’s especially true with UAV-based herbicide applications, which require specific licenses and training, plus data analytics expertise. We do not find many people who possess these attributes.

“A similar challenge is finding engineering graduates — who have knowledge in areas such as AI and machine learning and are ready to work on interdisciplinary research,” he says.

Singh’s concerns reflect WSSA’s online survey findings, which garnered 475 responses in nine research areas. According to the survey results, herbicides have greatly decreased as a research priority since WSSA last surveyed weed scientists in 2007, when herbicides far surpassed any other weed management research area in priority. This time, herbicides ranked third in priority among respondents (52%) behind cultural and preventative weed management (68%) and precision weed management and robotics (53%).

In contrast, respondents to the prior survey (63%) reported expertise in herbicide discovery and development. Yet, just 8% identified technologies such as robotics and AI as an expertise area.

This gap in technology expertise among current weed science leaders runs counter to the promise that utilizing such advanced systems have for future weed control success, says Singh, whose team works on standardizing UAV-based herbicide applications in vegetables and row-crops. He points to a recent Virginia Tech research finding that shows UAV-based herbicide applications provide greater efficacy at postemergence stages compared with conventional application systems. This is just one example that highlights the need for greater precision weed management expertise to conduct further research on adjuvants, nozzles, drift issues and machine vision to bring automation to agriculture.

The WSSA survey also asked weed science leaders about research funding. Respondents reported that public funding has declined since the 2007 survey. Many also reported a concern that some important research areas — such as using cover crops and crop rotation that prevent weeds from emerging in the first place — might not attract private research dollars. Thus, the survey concluded weed scientists must stress the need for public money.

“We need more public funding for integrated weed management research, both fundamental and applied investigations,” says Muthu Bagavathiannan, weed ecology and management professor, Texas A&M University, who has conducted multiple pioneering research projects to foster precision integrated weed management. “More funding to accelerate the development and application of AI and machine learning technologies to improve the precision and efficacy of integrated weed management is particularly imperative.”

The Weed Science Society of America, a nonprofit scientific society, was founded in 1956 to encourage and promote the development of knowledge concerning weeds and their impact on the environment. The Society promotes research, education and Extension outreach activities related to weeds, provides science-based information to the public and policy makers, fosters awareness of weeds and their impact on managed and natural ecosystems and promotes cooperation among weed science organizations across the nation and the world. PG

Article provided by the Weed Science Society of America. For more information, visit visit www.wssa.net

Jacob Forehand was recently named Tidewater Agricultural Research and Extension Center’s new peanut Extension specialist. He will provide information to producers in the Virginia peanut-growing region, organize field day events and conduct applied research focusing on peanut variety evaluation across Virginia, North Carolina and South Carolina.

Forehand is originally from Edenton, North Carolina, and credits working as a fifth-generation family farmer for the experience that fueled his enthusiasm for agriculture. He received his bachelor’s degree in crop science from N.C. State University. During a summer internship, he discovered a passion for applied research, Extension and weed science.

He is currently completing a master’s degree in crop science at NCSU with a research focus on cotton seed quality and its implications on pre-emergent herbicide tolerance. Forehand answered some questions about why he joined Virginia Tech and the Tidewater AREC:

Q: What drew your attention to this position?

A:

The ability to have an impact on the whole Virginia-Carolinas region through the work of the Peanut Variety Quality Evaluation program is one thing that really drew me to this position. I also enjoy being able to interact directly with growers and help them solve problems. Getting back close to home was an additional bonus.

Q: Why do you enjoy working with this crop?

A: I have enjoyed working with peanuts from an early age. I like how different they are from many other row crops in their management, how they grow and the logistics surrounding harvesting.

Q: What are you most looking forward to in your new role?

A: I really look forward to being able to interact directly with farmers. Through working with NCSU Extension weed specialist Charlie Cahoon, I got a brief glimpse of how Cooperative Extension can support growers, and it showed me how valuable the unbiased information coming out of Extension programs is for growers. I also look forward to being able to provide growers with research-backed information regarding varieties, as variety selection can be one of the most important decisions growers can make.”

Article provided by the Virginia Tech College of Agriculture and Life Sciences

Doing things ‘the old way’ is this Southampton, Virginia, peanut producer’s passion.

By Amanda Huber

From articles in both Southern Living and Garden and Gun , to a feature on the U.S. Department of Agriculture’s Farmers.gov “Friday’s on the Farm” blog, to coverage in numerous news and food outlets, to people simply stopping at his farm to ask what he’s doing, Southampton County, Virginia, peanut farmer Elisha Barnes is much in demand these days. What has drawn the attention of both locals and iconic Southern lifestyle magazines? Is it a new type of equipment or innovative farming technique? Not quite. Then again, he is the only farmer in the United States doing what his father, grandfather and great-grandfather before him did at harvest –shocking peanuts.

Preserving History

“Shocking” is what the process of putting peanuts and vines stacked up on a pole in the field for drying and curing is called. The result is a taste so different it is being offered by Hubbard Peanut Co., Sedley, Virginia, as

a single-origin redskin peanut.

Barnes says, “It’s a blessing to me that Hubs has recognized what it is that I’m doing. I have a passion for the old ways.

“I want to maintain something so that generations now and ones that will come will be able to see a snippet of what used to be on a country farm,” he says.

For Barnes, pride comes from doing things the old-fashioned way.

“Tilling the soil teaches a spiritual lesson,” he says. “Do your part to invest in the land and the land will give you an increase.

“Some say, ‘He’s just a small farmer.’ But there’s a bountiful harvest of peanuts out there. We are a fourth-generation farm. My father, grandfather and great-grandfather all farmed peanuts.”

Barnes says as the only farm that shocks the peanuts like he does, people will ride by, see the peanuts and stop to ask him what he’s doing.

“In the 1930s and ‘40s, this was the landscape at this time of year,” he says of the peanut vines stacked on poles. “The reason that I do it is because it preserves where we came from and what got us here.”

Barnes says he appreciates that Hubs has recognized what he is doing to preserve history and is allowing this to be financially beneficial so that he can continue.

Even with the goal of preserving history, the peanuts Barnes collects through shocking provide a different taste for the consumer.

drying method.

“If you air dry them, the germination rate is 99.8%. With the profit margin we have in farming, you want every peanut you put in the field to produce,” he says.

Aside from peanuts, Barnes grows other crops, most of which he donates through a partnership with The Foodbank of Southeastern Virginia and the Eastern Shore. He also manages Izzie’s Field, a farm-to-foodbank project funded by Kroger and supported by New Life Chuch, Pop Son Farm and Hubbard Peanut Co., which aims to address the historical barriers faced by socially disadvantaged farmers and strengthen the food system by providing fresh produce in the area.

“We put the peanuts and vines on the poles for six weeks,” he says. “During that time, the peanut cures and allows the sweetness of the peanuts to collect.”

Barnes, who began working on his family’s peanut farm at age six, says peanuts cured this traditional way end up with a sweeter taste than those that are heat dried.

He also touts the germination rate compared to the other

In a world of rapid change, some traditions endure, thanks to the dedication of individuals like Elisha Barnes. As a fourth-generation farmer, Elisha honors the lost art of shocking peanuts, preserving a tradition that defines his heritage. Hubbard Peanut Company is proud to partner with Elisha on this highly limited “single origin” peanut crop.

As Hubbard Peanut Co., which has been in business for 65 years, says in their video introducing Barnes as the producer of their single-origin redskin peanuts, when Hubs first started, all peanuts were shocked and dried this way. Today, except for Elisha’s, none are.

“I am the only one who does this now because I want to preserve history,” Barnes says. “Maybe I’ll inspire somebody to keep this old history alive.” PG

University of Georgia Extension Agronomist

I’ve been asked this question a lot over the past few weeks, “What is the condition of the peanut crop?” Overall, the crop has improved during this time, but issues this season include the separation in planting dates, the variation in physiological growth because of the weather and seed quality, among other challenges. The crop that was planted in late April to early May is off to a great start in most areas with only a few isolated issues. However, the early planted crop only accounted for about 40% of the total peanut crop. Rains in May caused many acres to be planted two to three weeks later than normal. The excessive rains also caused growers to replant several fields at least once, if not twice.

Other than weather, wildlife damage — both hog and deer — is still causing significant stand and/or growth issues in several counties. Growers are encouraged to participate in trapping programs for hogs and to try repellants for deer to get some relief so plants can lap up. It is becoming increasingly apparent that growers need better wildlife control tactics. Please call your local Department of Natural Resources office for more information.

As I mentioned before, the early planted crop is off to a good start and is now approaching 60 to 70 days old. This means growers should be transitioning from planting to protecting the crop. Growers have many tools to work with when it comes to fungicides and insecticides. A well thought out, properly timed pest management program will offer a return on your investment. Success of a pest management program does not necessarily rely on the price point of chemicals. The best way to make sure you are making the right decision is to know your pest history (disease pressure) and/or have someone scout your crop weekly to let you know what kind of pests you have. Developing an informed management strategy that can be adjusted as things change is a recipe for success. Another important resource is your county agricultural agent. Feel free to contact them if you have questions or need assistance.

As of right now, we certainly have two distinct crops of peanuts because of the two-week gap during the planting season. The rain was very much needed in Alabama, as y’all well know. I know many don’t like to have this huge gap in your crop, but you never know, it may well be the best thing for us.

The extended forecast shows favorable weather for us to make and finish out the crop, so let’s hope this holds true. We all know how bad we need to produce a good crop this year. I know money is tight on the farm, but don’t cut yourself too short trying to save money and give up too much yield from doing so.

Also, many have asked about the time left to make the crop and expressed not wanting to spend too much if not. We have adequate time, and the forecast is predicting above-average heat units. Therefore, we must remain diligent and stay focused on producing the crop as normal.

Keep in mind the higher temperatures, coupled with moisture, and be proactive with your fungicide program this season. Also, don’t forget the late peanuts as far as calcium is concerned. Check calcium levels in the soil to see if you may need gypsum. I wish everyone a great rest of the season and look forward to seeing you in the field.

Most peanut fields are up to a good stand and growing well in the Southwest. May and June moisture increased weed pressure, and growers need to clean up weeds and weed escapes. Despite the periodic rainfall, West and South Texas, and eastern New Mexico, are still under abnormally dry-to-moderate drought conditions. Although not as severe as in the past two years, the Southwest’s main concern for peanut production remains the lack of enough water.

As we move into hot and dry July and August, growers need to adjust the irrigation requirements for peanuts based on the rainfall and evapotranspiration. Peak water use of peanuts will arrive around 10 to 16 weeks after

planting during pegging and flowering to pod formation.

Peanuts require approximately 1.5 inches to 2 inches of water per week during this time. The amount of water lost through evapotranspiration was 2.6 inches to 2.9 inches in the Southwest during the first week of August in 2023. Growers are strongly encouraged to track the rainfall and evapotranspiration throughout the season and adjust the irrigation amount accordingly.

Water use of peanuts will start decreasing around 14 to 16 weeks and keep declining through the end of the season. Overwatering peanuts, although it rarely happens in the Southwest, can reduce potential yields by increasing disease incidents.

Late June and July bring a transition from controlling weeds and thrips to putting in place a solid fungicide program for leaf spot and stem rot. In the upper Virginia-Carolina region, we need to keep our eyes out for Sclerotinia blight, but virtually all farmers need to protect peanuts from leaf spot and stem rot.

It is also possible to have outbreaks of tobacco budworm, corn earworm and fall armyworm, but infestations can be erratic. Thresholds are in place for these foliar-feeding insects. It is also possible that we will have spider mite outbreaks to contend with.

In our part of the woods, we generally have a five-spray program for leaf spot. We recommend that you start and finish with the multi-site fungicide chlorothalonil (sprays 1 and 5) with combinations of fungicides for sprays 2, 3 and 4 that control leaf spot and stem rot. If you have fields with Sclerotinia blight, consider including Miravis and Elatus for sprays 3 or 4. In fields with high levels of this disease, sequential sprays

are likely warranted. Historically, this decision was much more challenging because Omega 500 (fluazinam) was expensive and did not control leaf spot. The mixture of Miravis and Elatus offers protection of all three diseases.

With respect to leaf spot, practice resistance management for sprays 2, 3 and 4 by rotating sites of action. There are numerous ways to protect peanuts from leaf spot and stem rot without selecting for resistance. We encourage farmers to use our leaf spot and Sclerotinia blight advisories. These tools can help you avoid unnecessary sprays but also take the guess work out of the decision.

Sometimes we think we don’t need to spray because it has been a while since we had rain. However, dew points may be high enough to encourage disease development even when we feel like we are close to being in a drought. Be timely with sprays when they are needed, and use the recommended rates for each fungicide.

There will be some weed escapes in many fields as we move

through July and August. Make sure you are within the preharvest interval for herbicide products. With the exception of grasses and some broadleaf weeds, mid-season and late-season herbicide applications will, in most cases, only suppress weeds. However, this can make a big difference when digging and inverting vines and can reduce contributions of weed seed to the soil seedbank.

In the V-C region, prohexadione calcium (Apogee, Kudos, and Cryova) is often sprayed beginning in the middle of July when peanuts are lapping. Apply this product when 50% of laterals from adjacent rows are touching. A second application can be made two to three weeks after, depending on regrowth. The new liquid formulation of Kudos performs well, but use caution when applying with other plant-protection products. Depending on the tank-mix partner, Kudos OD can burn peanuts.

A key for the next two months is to keep vines as healthy as possible. This will help optimize yield in general but will also give us the greatest flexibility in digging.

Gary Roberson, a native son of North Carolina and agricultural engineer at North Carolina State University, retired in early 2024 after four decades as a teacher and Extension specialist in the Department of Agricultural Engineering. He retired as the Charles W. Sugg Distinguished Professor and Extension Specialist in the College of Agriculture and Life Sciences.

Roberson received his Bachelor of Science degrees in agricultural education and agricultural engineering in 1978 along with a master’s degree and Ph.D. in 1980 and 1988, respectively, all from North Carolina State University. He was a recipient of the 2016 College of Agriculture and Life Sciences Outstanding Teaching Award because of his outstanding instructional efforts.

Roberson made many contributions and provided solutions to agriculture across numerous crops, including peanuts, and a wide range of subjects associated with agricultural engineering. One of his

most notable contributions was work on precision digging of peanuts using the RTK system. Many farmers across the Virginia-Carolina region have adopted this technology based on his findings. The result has been major increases in both

digging efficiency and peanut yield.

Thank you, Gary, for your service to peanut growers in North Carolina and surrounding states and to the larger peanut industry. We wish you well as you move into retirement.