20 Peanut Pointers

is not a good indicator of leaf spot

BASF’s Abraham Fulmer talks about the years of research it takes to determine how a fungicide will fit in growers’ programs.

e UGA entomology team adds to the knowledge base of this pest while looking for risk factors and control options.

Using modern techniques, NCSU peanut breeder Jeff Dunne works to bring cultivars with improved genetics to the market more quickly and efficiently.

EDITORIAL/PRODUCTION

Editor Amanda Huber ahuber@onegrower.com

Copy Editor Cassidy Nemec cnemec@onegrower.com

Art Director Ashley Kumpe

Digital Content Manager Katie Guthrie

ADMINISTRATION

Publisher/Vice President

Lia Guthrie (901) 497-3689 lguthrie@onegrower.com

Associate Publisher/Editor-In-Chief

Carroll Smith (901) 326-4443

Associate Publisher/Sales Scott Emerson (386) 462-1532 semerson@onegrower.com

Audience Services

Kate Thomas (847) 559-7514

Production Manager David Boyd dboyd@onegrower.com

For subscription changes or change of address, call (847) 559-7578 or email peanutgrower@omeda.com

EDITORIAL ADVISORY BOARD

Scott Monfort

Extension Agronomist

University of Georgia

Dell Cotton

Peanut Growers Cooperative

Marketing Assn., Franklin, VA

Kris Balkcom

Agri-Program Associate

Auburn University

Dan Anco

Extension Peanut Specialist

Clemson University

Indeterminate. As an adjective, it means uncertain in extent, amount or nature; not definite; inconclusive; unable to be predicted, calculated or deduced. Peanuts are an indeterminate plant, and all those adjectives pretty much describe trying to nail down crop maturity and when to harvest.

Emi Kimura

Extension Agronomist

Texas A&M University

David Jordan

Extension Agronomist

North Carolina State University

Glen Harris

Extension Agronomist

University of Georgia

Jason Ferrell

Extension Weed Specialist University of Florida

ONE GROWER PUBLISHING, LLC

Mike Lamensdorf PRESIDENT/TREASURER Lia Guthrie PUBLISHER/VICE PRESIDENT

The Peanut Grower (ISSN 1042-9379) is an agribusiness magazine for U.S. peanut producers. Published in eight monthly issues, January through July and November. Annual subscriptions are $40.00. Single Copy price is $5.00. Annual overseas subscriptions are $70.00, including Canada/Mexico. Periodicals postage paid at at Memphis, Tennessee, and at additional mailing o ices. Copyright © 2023 One Grower Publishing, LLC, all rights reserved except where otherwise noted. The Peanut Grower ® is a registered trademark, which reserves all rights granted by the U.S. Patent and Trademark O ice in association with the registration.

POSTMASTER: SEND ADDRESS CHANGES TO OMEDA COMMUNICATIONS, CUSTOMER SERVICE DEPARTMENT, P.O. BOX 1388, NORTHBROOK, IL 60065-1388. All statements, including product claims, are those of the person or organization making the statement or claim. The publisher does not adopt any such statement or claim as its own, and any such statement or claim does not necessarily reflect the opinion of the publisher. Printed in the USA.

One Grower Publishing, LLC, also publishes Cotton Farming, Rice Farming, Soybean South and Corn South

One Grower Publishing, LLC 875 W. Poplar Ave., Suite 23, Box 305 Collierville, TN 38017

In February, Auburn University and the Alabama Cooperative Extension System offered a precision ag workshop. One presentation was entitled “Prediction of Peanut Maturity and Yield using Satellite and Drone Images and Artificial Intelligence.” The research was conducted and presented by AU’s Mailson Freire de Oliveira. What unfolded in those 20 minutes was an interesting discussion about how variable peanut maturity can be in one field and how much researchers are working on trying to find a more modern method than the Peanut Maturity Profile Board.

Amanda Huber Editor, e Peanut Grower

Although many factors go into the decision to dig, including weather and amount of acreage, maturity of the crop is also important. Harvest too early or too late reduces yield potential. Determining maturity by pulling samples, blasting off the hull and matching colors on a board is labor intensive and subjective to the person doing the profile board.

Wouldn’t it be great if a drone could take special imagery that correlated with maturity? What about an artificial intelligence model for predicting maturity and yield? These are some of the ways being studied in an attempt to determine maturity with newer technology.

In the discussion period, Alabama Cooperative Extension precision ag specialist Brenda Ortiz asked, “If you had an image that shows the variability in the field, would it be helpful? Would you make decisions using it?”

Several growers said they would take anything that would offer another way to look at maturity. With a picture or “map,” that shows the areas of greatest maturity and also the least, they would know better where to pull samples to get a more representative profile board.

According to Ortiz, soil texture and soil temperature in the pegging zone are important factors in peanut maturity. “I know that one day we will find a way to take the variability out of determining maturity.”

They may not be there yet, but researchers won’t give up on the search for a better way to make peanut harvest decisions a little more predictable and less “indeterminate.”

U.S. Department of Agriculture’s Commodity Credit Corporation recently announced 2023-crop loan rates for four types of peanuts. The rates take effect Aug. 1, 2023, the beginning of the peanut crop year.

Eligible producers can obtain peanut loans through their local Farm Service Agency county offices or alternative delivery partners, such as Designated Marketing Associations and Cooperative Marketing Associations. These loans provide producers with interim financing on their production and facilitate the orderly distribution of loan-eligible peanuts throughout the year.

The 2018 Farm Bill established the national loan rate for peanuts at $355 per ton. CCC calculated the price support levels for each peanut type using the same method as last year. The 2023 Crop Peanut Loan Rate was calculated using the national loan rate and fiveyear average quality factors, along with a three-year simple average weighted production. For an average-grade ton of 2023-crop peanuts, loan levels by type are:

■ Runner - $354.41 per ton

■ Spanish - $344.27 per ton

■ Valencia - 359.76 per ton

■ Virginia - $359.76 per ton

CCC applies premiums and discounts for quality factors to compute the loan value for an individual ton of peanuts. The actual loan level depends on the percentage of various sizes of kernels in each ton. CCC uses the percentage of sound mature kernels (SMK) and sound splits to compute the basic loan value of the load. SMKs are whole kernels that pass over the testing screen officially designated for each type of peanut. Sound splits are whole kernels split into two pieces. Excess sound splits receive discounts. There are discounts for other kernels, damaged kernels and foreign materials.

An additional discount occurs for loose shell kernels. Other quality discounts also may apply.

A recent study by the Peterson Institute for International Economics concludes that while the United States is growing more dependent on China as an agricultural export market, China is becoming less dependent on the United States for its agricultural goods. China is currently the United States’ third largest export market for peanuts, although the market is primarily for crushing.

According to the 2009 Peterson report, 27% of China’s agricultural imports came from the United States. In 2022, that number was only 18%. In 2009, 13% of U.S. agricultural exports went to China; but in 2022, 19% of total U.S. agricultural exports went to China. Almost 50% of U.S. agricultural exports to China are soybeans, and those exports are increasing in terms of dollars and tonnage. However, a range of other U.S. agricultural products are seeing a decline in shipments, including for the first three months of 2023.

The American Peanut Council recently organized an educational seminar and networking event for Chinese delegates and U.S. exporters prior to the International Peanut Forum in Portugal.

This represented the first in-person meeting between the U.S. industry and the Chinese trade since 2019.

In total, more than 30 people joined the event, with 14 representatives from China. During the seminar, the National Peanut Board’s Bob Parker provided an overview of the U.S. peanut industry and Nan Xu from Qingdao Foodlink Co. gave an update on Chinese production and market conditions.

China was the U.S. peanut industry’s third-largest export market in 2022, with shipments totaling 81,921 MT valued at $78 million.

• USDA announces 2023 peanut loan rates e ective Aug. 1.

• China less dependent on U.S. ag exports, while U.S. is more dependent on China.

• Growers conference: “Building On Our Strengths.

• International forum: Peanuts are essential global food.

• Alabama ranks No. 2 in peanut production.

• Unified export strategy identifies target markets, sets goals.

• In Memoriam: Walt Mozingo

The 24th Annual Southern Peanut Growers Conference is July 27-29, 2023, at Sandestin Golf and Beach Resort in Miramar Beach, Florida. Hosted by Georgia Peanut Commission and Grower Associations in Florida, Alabama and Mississippi, the threeday event covers legislation, production marketing and promotion plus a ladies program and golf tournament. The theme this year is “Building on our Strengths.” Room reservations at Sandestin Golf and Beach Resort can be made on line at www.Sandestin.com or by calling 1-800-320-8115.

During Saturday’s general session, the keynote speaker is U.S. Rep. Austin Scott, (R-GA), vice chairman of the House Committee on Agriculture, Nutrition and Forestry.

Friday’s opening session will feature U.S. Department of Agriculture’s National Peanut Research Lab director Marshall Lamb and University of Georgia peanut breeder Nino Brown talking about the future of non-food uses of peanuts. The mid-morning ses-

sion on Friday will feature “Strengths in Precision Agriculture” with Auburn University’s Steve Li, the University of Florida’s Ian Small and the University of Georgia’s Simer Virk as speakers in this session.

Highlighting the prayer breakfast will be Kermit George, who lost his arm but survived an alligator attack. Social media influencer and ag advocate Michelle Miller, known as Farm Babe, will be the featured speaker at Friday’s luncheon.

Registration is $195 for growers. For more information and a complete schedule of events, go to www.southernpeanutfarmers.org.

For fiscal year 2023, the National Peanut Board will spend an estimated $12 million for promotions and research. Including savings, interest and late revenue from the prior year, the total available is more than $13 million.

In a breakdown of the budget, domestic promotions and market development account for $8.4 million, with export promotions and market development receiving $460,000. Production research is allotted $2.5 million, with grower and intra-industry communications set at $654,000.

The global peanut industry has experienced significant changes in recent years with social, environmental and health policies all playing a key role and being drivers of growth in the sector. This and more were discussed during the International Peanut Forum in Lisbon, Portugal, in April.

The overall sentiment is that peanuts are essential in the global food supply chain for key markets such as China, India and the United States, where the legume is used as a snack, an oil source or an affordable plant-based protein. In addition, they are an exchange currency source for many suppliers such as Argentina, Brazil, India, Nigeria and

The USDA National Agricultural Statistic Service has published the 2022 estimated peanut production for Alabama. NASS has estimated that Alabama peanut growers produced 559 million pounds of peanuts in 2022. That makes Alabama second in the nation in peanut production, with Georgia ranking first. The U.S. produced 5.57 billion pounds of peanuts in 2022. Houston County is estimated as the top peanut-producing county with 106,960,000 pounds of peanuts produced, and Geneva County comes in next at 71,680,000 pounds of peanuts produced. The top five is rounded out by Baldwin County, Henry County and Escambia County, respectively.

Senegal. Additionally, peanuts are often part of a growing cycle to enrich soils with lower production costs than other nuts in countries such as Brazil, where farmers alternate peanuts with sugar cane.

The American Peanut Council Export Committee has prepared the 2024 Unified Export Strategy, which serves as the peanut industry’s application for funding under USDA’s Market Access and Foreign Market Development programs.

The export funding programs are part of the Farm Bill and available to U.S. ag commodity groups, including

the APC. The UES identifies target markets with opportunities for export growth and lays out a plan for how to accomplish goals in each of the identified countries or regions.

The overall goal of the export program is to increase exports of U.S. peanuts, with specific goals set for each of the target markets. The export committee identified Canada, Mexico, the European Union, Japan, China, the United Kingdom and an area for projects that impact all markets described as “Global Issues.”

The 2024 UES will expand current activities and build knowledge on potential new markets. The 2024 application was completed in May.

The peanut industry lost a tremendous friend and researcher with the passing of Roy Walton Mozingo, 82, of Kenly, Virginia, in April.

Mozingo made many contributions to the peanut industry. He served as president of the American Peanut Research and Education Society in 1992-93 and is credited with establishing the Peanut Variety and Quality Evaluation program, an important peanut breeding testing program for the Virginia-Carolina region.

“Walt was one of the first people in the peanut industry that I met when I began my career at NC State in 1996,” says David Jordan, North Carolina Extension state peanut specialist. “Within the first few weeks in my role as peanut specialist, I traveled to research stations and on-farm sites associated with PVQE. Walt was always a joy to be around and

APC values its strong partnership with USDA and looks forward to furthering work to increase peanut exports.

The American Peanut Council was approved for $2,498,000 for MAP funding projects and $470,000 for FMD programs to promote peanuts and peanut products in selected markets in 2023. A group of Congressional leaders have introduced a bill to double the export promotion programs next year.

Libbie Johnson joined the Alabama Peanut Producers Association as executive director in June.

“I’m excited to get to know Alabama’s peanut producers and understand more about agriculture in Alabama,” Johnson says. “I’m thankful to represent such a unique commodity and the hard-working farmers of this state.”

As executive director, Johnson will oversee peanut checkoff projects related

freely passed along his knowledge of peanuts and the peanut industry.”

Mozingo was raised on a tobacco farm, and with the encouragement of the high school agriculture teacher, pursued higher education at NCSU after graduating from Princeton High School. He earned both a bachelor’s and master’s degree.

He was hired by Virginia Tech University to start a research program from the ground up that evaluated peanut varieties supplied by Virginia Tech and NCSU. That program, which became known as the PVQE, resulted in him winning numerous awards for his research and contributions to the peanut industry. It also earned him a promotion to a professorship at Virginia Tech.

Mozingo was active in Holland Baptist Church where he served as a deacon and was Sunday school direc-

to research, promotion and education. She’ll also work with land-grant universities and farmers on research trials, advocate for the protein-packed legume with decision-makers in Washington, D.C., and expand the peanut industry’s footprint in Alabama along with other staff in the APPA’s Dothan office.

“Libbie is energetic, knowledgeable and talented, and we are excited to see the direction she takes our organization,” says APPA President Carl Sanders, who farms in Coffee County. “The board is confident in Libbie’s ability to advocate for Alabama peanut farmers and make an impact on our industry.”

APPA is an affiliate of the Alabama Farmers Federation, the state’s largest farm organization serving 355,000

tor. In later years, he helped with the construction of home accessibility ramps for those in need, and enjoyed traveling with his wife, Judy, who preceded him in death and watching his grandchildren and great grandchildren grow.

Sincere condolences to the family and friends of peanut pioneer, Walt Mozingo.

member families. Johnson will work closely with the Federation’s Governmental & Agricultural Programs staff.

Since 2003, Johnson has served farmers in the Florida Panhandle’s Milton and Escambia counties. Areas of expertise include row crops, fruits and vegetables, livestock and natural resources.

Johnson is a past president of the Florida Association of County Agricultural Agents; and served on the University of Florida peanut team and the Sunbelt Ag Expo team. Florida Farm Bureau named her the Extension Professional of the Year in 2018, and she has earned multiple service awards from the National Association of County Agricultural Agents.

Johnson, a Louisiana native, holds bachelor’s degrees in political science and plant science from the University of Louisiana at Lafayette and a master’s degree in agroecology from UF.

Peanut producers experienced an unusually rough start in getting the crop in the ground. In the Southeast, dry and relatively cool temperatures caused peanuts to emerge slowly. One Extension specialist says that the lack of heat units in the early season has the 2023 crop seven to 10 days behind. In Georgia, wet soils caused the seed to rot and not germinate properly. One farmer replanted more than 1,000 acres. Seed vigor was cited as a major culprit.

The peanut market has been trending higher as farm leaders try to convince policy makers that inflation and increased costs of production strongly encourage producers to consider other crops. In isolated cases, some farms are not planting any crop at all because of costs. There is definitely a disconnect between what is being offered for farmer stock and what a grower is willing to sign a contract for at this time. Some producers are even waiting until harvest, or at least during the growing season, to do their contracting. Corn and cotton prices have offered no excitement, either.

Producers figure that the 2.7 million-ton crop this past year and the 18% plus increased costs of production merited a higher offer for 2023 contracts. In Washington D.C., an ag economist testified that the cost of production in 2022 was approximately $668 per ton. With acreage estimates up 7% or more, shellers started offering $500 to $525 per ton for runner-type peanuts, $525 per ton on high-oleic crop and $550 to $575 per ton on Virginia type. Some shellers offered a sheller pool with a $500 perton floor hoping for prices to increase later this season. Prices were higher for

Southwest varieties because of the cost of production on irrigated peanuts.

The market reports that there was a lot of new crop business done in late April/early May, and shellers are comfortable. Officials believe that what has been contracted has been sold, and farmers, shellers and buyers seem content to watch and wait until planting is finished and the crop gets up.

Markets are a tad firmer with good demand having been booked into new crop. The thinking is that shellers are comfortable with a bigger crop as an increase in demand from Europe will continue due to an Argentine crop shortfall. Buyers’ ideas remain in the low to mid 50 cents per pound, making it difficult for shellers to want to sell much. Shelled prices for runners for 2022 crop are 61 to 64 cents per pound.

Buyers seem content that there is a big quality crop on the way and are willing to wait at this point. European Union activity for current crop continues to come in as the Argentine crop issues have created a need for U.S. peanuts.

J. Tyron Spearman Contributing Editor,

There are inquiries for the U.S. new crop from EU buyers, but shellers are reluctant to offer until acres are better understood, and of course the quality of the crop won’t be known until harvest.

Raw peanuts in primary products are down 2.5%. Peanut butter is also down 3.6% for the nine months. In-shells are on a roll, up 9.3%, with peanut usage in snacks down 12.5%.

For the past three months, U.S. peanut exports are down 6.14%. Mexico is still the top buyer, up 9%, as Canada drops only 1% compared to the same period last year. China is the third-largest buyer, down 7.73%. Japan jumped up to the number four spot, and the Netherlands is now the fifth-largest export market.

If 96% of sown acreage is harvested and yields improve by 5% to 4,230 pounds per acre, U.S. peanut production is forecast to increase to 6.3 billion pounds or 3,150,000 tons from 5.6 billion in 2022.

accounting for lower beginning stocks, supply is forecast to reach 8.6 bil-

lion pounds, 557 million pounds higher than 2022.

The average price received by farmers is projected slightly down from its expected 2022/23 value of 27 cents per pound, or $540 per ton, to 26.5 cents per pound, or $530 per ton. Moreover, the export program is expected to benefit. The 2023/24 peanut export forecast is 200 million pounds more at 1.3 billion pounds (650,000 tons).

Markets will likely firm up even more after the estimated planted acreage report is released from USDA June 30. Farmers are concerned about the lack of rain early and worry more about the Farm Bill. Peanut leaders have presented new proposals, which all cost money; however, the response is that there is no new money. Some think that peanut producers will be lucky to keep what they have. PG

Last month, representatives of the U.S. Peanut Federation testified at both the U.S. House Agriculture Subcommittee on General Farm Commodities, Risk Management and Credit and the U.S. Senate Agriculture Subcommittee on Commodities, Risk Management and Trade hearings. The purpose of these hearings was to gain producer perspectives on the 2023 Farm Bill and the viability of the farm safety net.

The USPF testimony highlighted peanut priorities for the 2023 Farm Bill, namely an increase in the reference price for the Price Loss Coverage program. Over the past few years, peanut growers have seen a significant increase in the cost of production. According to Stanley Fletcher of Abraham Baldwin Agricultural College and Professor Emeritus at the University of Georgia, the 2021 cost of production was $545.97 per ton, and the 2022 cost of production is approximately $668 per ton.

USPF also testified in support of a voluntary base update that includes growers with and without peanut base acres. While the 2014 Farm Bill allowed for a base update for peanut growers that already had base on their farms, it excluded many young farmers and new production areas.

As we head into the summer, legislators continue their work crafting the 2023 Farm Bill.

Recently, after weeks of negotiations, the U.S. House of Representatives and the U.S. Congress passed H.R. 3746, the bipartisan debt limit deal to avoid a historic default. The deal suspends the nation’s $31.4 trillion borrowing limit until January 2025.

The legislation includes spending caps and limits non-defense discretionary spending to 1% growth in Fiscal Year 2025. This could mean cuts for the agricultural appropriations legislation, which is one of 12 appropriations bills passed yearly. The U.S. House Appropriations Subcommittee on Agriculture,

Rural Development, Food and Drug Administration and Related Agencies held a markup of the FY2024 legislation in early May. The markup by the full committee is expected later this summer.

One of the main tenets of the debt limit negotiation was changes to the work requirements for government assistance programs, namely the Supplemental Nutrition Assistance Program and the Temporary Assistance for Needy Families Program. The bill imposes new work requirements on adults ages 50-54 who don’t have children living in their home. The current law only has work requirements on adults 18-49.

When asked about how the debt ceiling deal will impact funding for the Farm Bill, Congressman G.T. Thompson (R-PA), who serves as the chair of the House Agriculture Committee, says the deal will have “no significant impact… The monies overall are capped, but how we invest those and divide those up, Congress has flexibility for that.” However, lawmakers have voiced concerns that lengthy negotiations over the debt limit may cause delays for the 2023 Farm Bill. PG

‘‘ If 96% of sown acreage is harvested and yields improve by 5% to 4,230 pounds per acre, U.S. peanut production is forecast to increase to 6.3 billion pounds or 3,150,000 tons from 5.6 billion in 2022.

Abraham Fulmer, who spent seven years as a graduate student at the University of Georgia under Bob Kemerait, Extension plant pathologist, and is now BASF technical marketing manager, has been around peanuts long enough to see how changes in weather patterns, production practices and prices can affect disease problems and fungicide selections. That experience has also underscored that it can take several years of research and collaboration to know where a product has the best fit, which is critical in his current role. Then again, the way Fulmer looks at it, the goal is to help producers, no matter whether the solution is from BASF or another company.

“The best conversations with growers are when you get down to their unique situation and then help them figure out a solu-

tion,” he says. “That’s where I think boots on the ground are so important, along with our relationships with universities, cooperative Extension, specialists, crop advisors and consultants.”

It takes everyone working together to keep up with the changing landscape that is peanut production. One example is the change in the type of leaf spot found in peanuts.

“Early leaf spot was predominant through Georgia Green until 2008-2010,” Fulmer says, although prior to the Georgia Green variety, it was late leaf spot that growers encountered more. Now, it’s back to late leaf spot found often, which is likely a combination of factors, such as later planting dates, introduction of new varieties, extended spray intervals and frequent

rainfall, plus a lot of higher-risk fields.

Another possible reason for the increasing late leaf spot pressure is shorter rotations.

“Crop rotation is the best and most critical factor in crop pest management,” Fulmer says. “That’s why it’s weighted heavily on the Peanut Rx. Crop prices have forced growers to go to peanuts more often because they don’t have many options to rotate to. There’s a lot of cotton-peanut-cotton-peanut rotations and significantly fewer that can put three, or even better four, years between peanut crops.

Not only has the type of leaf spot changed over time, but it has also become a more significant problem, especially in the past few years. Besides shorter rotations, more rainfall during the season led to trouble getting into the field in a timely manner to apply fungicides.

“In 2021, there was a complete leaf spot blowout because of all the rain,” Fulmer says. “The past couple years, there were 10 to 12 rain events, which is typically defined to be greater than 1/10 inch, during June and July. Plus, you’ve got dew. That leads to a long leaf wetness period and will definitely have an impact on disease. We’ve had several years back-to-back that were very conducive to leaf spot.

“When conditions are wet, growers are not able to get into the field at the appropriate timing. It is naturally stretching spray intervals,” he says.

Starting out already behind is also not a good place to be.

“If you’re in a situation where your planting date has gotten pushed back and now it’s mid-May to the first of June, your leaf spot risk has been raised to a whole other level,” Fulmer says.

“The planting date effect is real for leaf spot and white mold.”

Most times, it is too wet to plant, or you are waiting on rain to plant, but if it’s neither of these, then it is a tradeoff of risks.

“Is it worth avoiding Tomato Spotted Wilt Virus and accepting the higher risk for leaf spot and white mold? Most growers know, if they get delayed on planting date, they’ll have to really stay on top of disease control,” he says.

Fulmer spent most of his time in graduate school working on Peanut Rx, which he says growers can use to help plan what type of disease program they are going to apply.

“Even if you don’t use it to make a field prescription, Peanut Rx is an important tool to help you understand the factors that impact disease potential in a field. It can be more of an internal check to say, ‘Where am I at in my risk?’ and to get a holistic view of the tradeoffs of focusing on TSWV versus leaf spot.

“Every fungicide company has a Peanut Rx program that can be utilized in low,

moderate and high-risk situations. BASF has one as well that we’ve developed with our university cooperators.”

But Fulmer says very few growers can calculate a low-risk field.

“If you go back to my doctorate work, it was shocking to me how few fields that I evaluated out of the hundreds in those years were actually low risk. It is difficult to achieve a low-risk field. Most fields are moderate or high risk, and I would say most are in the high-risk area.”

“There are occasional growers who have a four- to five-year rotation and plant at the right time.

However, most varieties are at least somewhat susceptible to spotted wilt, leaf spot or white mold. Georgia-06G is moderately susceptible. That’s why low risk is hard to achieve.”

Another benefit of Peanut Rx is that it is an added resource to help farmers choose potential varieties to plant.

“It helps you decide, ‘Am I looking to expand my footprint in varieties this year?’ I know growers are looking beyond Georgia-06G wondering what will be next,” Fulmer says. “Some are going to Georgia-12Y. They like the disease resistance from a white mold standpoint, although you need to keep the growth regulator handy.”

Seed treatments, too, are an important step in starting the crop off with good protection from seedling and other diseases.

“Seed treatments are doing a great job protecting seedlings from Aspergillus sp., and keeping Rhizoctonia and white mold at bay, but it’s very important to follow that up with something strong out of the gate,” he says.

“I always go into the season thinking white mold will strike early, and from the time you close the furrow to the time you begin making applications, that is the time to lay the groundwork for a strong white mold program.”

Fulmer says a lot of research goes into finding the right fit for fungicide products.

“Based on work we’ve done the past few years, I think we know better how to position some of our products. Priaxor is a key foundational fungicide option at the 45-day spray,” he says. “It is good on white mold and Rhizoctonia and is from the Fungicide Resistance Action Committee Group 7 and Group 11.

“Based on Dr. Tim Brenneman’s studies, it’s hard to beat Priaxor on Rhizoctonia. It’s also a great white mold product when you get it down to the soil.”

Fulmer says white mold is one of those diseases you need to always assume is going to be present, and if it doesn’t show up, then take it as a win. At the 45-to-50-day timing, he says it is still fairly easy to penetrate the canopy and get Priaxor down to the soil line where it matters.

“On top of that, you also get leaf spot control that provides a foundation for a solid program, as well as additional plant health benefits. We have seen in peanut, cotton and other crops, that when you make an application of Priaxor, you tend to get a greening effect. What that tells me is there is just a little bit extra insurance toward a healthy plant,” Fulmer says.

After providing a foundational spray for white mold, Rhizoctonia and leaf spot, the 60- and 90-day sprays are looking to continue white mold coverage, Fulmer explains.

“We’re blessed to have a lot of good products for this. From Convoy – a longtime product – to a new product like Excalia, to a tried-and-true product like Elatus – all of these are excellent white mold products that can stand on their own.

“However, I like mixing Bravo with a lot of these, simply because we need to keep chlorothalonil in the system. The more tankmixes we can make, the more pressure we’ll keep on any building resistant populations.”

Fulmer says there are a lot of possible products for this spray timing, but most white mold products are Group 7s or Group 7s + Group 11s, and rotating product modes of action needs to be kept in mind.

Because most white mold products are FRAC Group 7s and 11s, a change in the mode of action is a good idea at the 75-day spray.

“What I think we as an industry are starting to realize is we need to work together to position all of our products in such a way that makes sense from a resistance management strategy,” Fulmer says. “We want to incorporate as many different products in a program as possible.

“That’s what I like about Provysol, it’s kind of a new and improved Group 3. It’s a different MOA that has excellent leaf spot control but also white mold suppression and that’s key,” he says.

“In some of our studies, we mixed 3 ounces of Provysol and 7.2 ounces of tebuconazole together and found that when these are put together, it kind of revives the tebuconazole, plus provides a quick uptake, long residual control with the Provysol and enhanced leaf spot control. It also breaks up the Group 7 and 11 combo and provides a solid bridge of leaf spot control and a dose of white mold suppression.

“We looked at Provysol a lot of ways before determining that was the best fit,” Fulmer says. “That’s what’s good about working with the universities like UGA, Auburn and others. We can work collaboratively to bring a product to the market, and by then, everybody is comfortable with where it fits.

“That process took three to four years, but now we feel that Provysol at the 75- and 105-day sprays are our two primary pillars for good disease management. It is also a flexible product, and you can safely mix it with a lot of products. You can mix it with fungicides, herbicides, nutritionals and adjuvants. It doesn’t cause any burn and is incredibly rainfast. As soon as it dries on the leaf, it’s in the leaf. So having a tool like that in your arsenal, it can be used in any program, anywhere.”

The typical spray program doesn’t exist because there are a million iterations of it, Fulmer says. “What we try to do with our research is figure out all the ‘if, then’ scenarios, and that’s why it’s great that we have so many people in the field. If we haven’t answered your exact question, give us a call. We can talk through your situation, whether it is on the farm or the retail store or the county Extension office, we’d be glad to help

• Crop rotation is the best and most critical factor in crop pest management.

• Planting from mid-May to early June increases leaf spot risk.

• Peanut Rx can help you understand the factors that impact disease potential.

• Most varieties are somewhat susceptible to TSWV, leaf spot or white mold.

• Years of research go into finding the right fit for fungicide products.

• Rotating modes of action and tankmixes keep pressure on any resistant populations.

• The last spray is an opportunity to use a product that hasn’t been used all season.

you think through your situation with a product like Provysol or any others.

“It’s a product that can be used in a lot of different situations, which can lead to confusion. But what I like about it, I feel like it is providing a very important tool for controlling late leaf spot and early leaf spot and contributing to the suppression of white mold in a playing field that is reliant on Group 7s and Group 11s. Being able to bring a Group 3 to the market is exciting,” he says.

Another quandary for growers is knowing when to pull the trigger on that last spray of the season.

“It depends on your scenario and what your conditions are,” Fulmer says. “With varieties going longer and taking more days to reach maturity, I can see another spray at 130 days.”

At this point, the goal is to keep the vines in good enough shape for the kernels to reach maturity and to keep the pegs strong to hold on to the pod for digging. As for fungicides, it is also an opportunity to practice resistant management and/or use products that have not been used during the season.

“Bravo could be used at 120 days for resistance management. If you haven’t used Provysol, you can use it here. A lot of growers still like Bravo and Topsin as a last spray, and some people think it helps with peg strength.

“In many scenarios and if the field is in good shape, a tebuconazole+Bravo tankmix has looked really solid in this timing to finish out the season.”

Fulmer says some growers in that southwest Georgia hot spot have done well with Provost Silver as the last spray.

“At 120 to 130 days, if you are in a situation where you have already used Priaxor and Provysol and other products, but haven’t used Provost Silver, I would be in favor of using a product like that.”

If all has gone relatively well with the fungicide program: applications were timely at 14-day intervals, different modes of action were used and rain nourished the crop more than it kept farmers out of the field, then vines should be in good enough shape for the crop to reach maturity and digging to take place.

Fulmer says, “My hat is off to growers who juggle all the scenarios and figure out what’s best for their situation.” PG

The peanut burrower bug is a tricky pest. Not only is an infestation invisible in a field from above the ground, damage done by the bugs’ piercing mouthparts can only be detected after peanuts are harvested and sent for processing, resulting in revenue loss.

University of Georgia entomologists, along with Extension agents, continue to monitor peanut producers’ fields for the subterranean bug while looking for methods of control. The only pesticide effective against the peanut burrower bug, chlorpyrifos, was banned in 2021.

Mark Abney, UGA researcher and Extension peanut entomologist, recounts that peanut burrower bug is native to the United States but had not been specifically recognized as a pest in Georgia until 2010. “It was first reported as a pest in Texas in the 1970s, but we didn’t hear a lot about it in Georgia.” It was in 2010 that burrower bug showed up in a big way in producers’ fields.

Related to stink bugs, peanut burrower bugs are “smaller than a pinky fingernail. In the family Cydnidae, they are true bugs, a specific type of insect with piercing-sucking mouth parts. Their mouths are like a hypodermic needle that pierces

through the hull of the peanut to the seed — they suck the juice out of the seed,” Abney says. This results in sunken, yellowish, brown or black lesions on the peanut seed, often multiplied due to repeated feedings.

The UGA entomology team adds to the knowledge base of this subterranean pest while looking for risk factors and control options.

While peanut burrower bug has not caused as much widespread damage in Georgia since 2010, the potential for damage from the bugs is always present and is difficult to predict and control.

“This is a sporadic pest in that the injury is sporadic. The insect is pretty common. For several years we used light traps all over south Georgia, and everywhere we put a light trap, we would catch peanut burrower bug, no matter where we were or whether there was a history of injury or not,” Abney says. “From a research standpoint, the big, glaring question is why was this such a problem in 2010? And now, why will one grower have a problem with peanut burrower bug, but his neighbor does not? One year a farmer’s peanuts are rated segregation 2, and the next year it doesn’t happen. That has been the focus of a lot of research.”

Solutions to control peanut burrower bug are limited. Aside from the now-banned insecticide chlorpyrifos, peanut burrower bug is mainly controlled through deep tillage — a practice not used as much anymore because of the switch to conservation tillage.

“The more aggressive the tillage, the lower the risk is of having burrower bug injury. There are a lot of good environmental and economic reasons to use conservation tillage, but a lot of producers have gone back to more aggressive tillage or discing because it is the only tool our growers have since the one chemical tool we had is no longer available,” Abney says. “We’ve looked at virtually every insecticide that is approved for use in peanut — and some that were not — and even if we find that there are insecticides that have activity against the bug, there is no way to deliver it to the populations in the field as they exist.”

In the field, the bugs spend most of their time underground. Because they don’t feed above ground, it is difficult both to scout for the bugs and to target them with an insecticide. While Abney has worked steadily on the problem since joining UGA, he says it is difficult to perform research on peanut burrower bugs because both finding them in the field and keeping them in lab colonies for testing has been a challenge.

“The population is so sporadic, it is hard to get data on them,” he says.

Ben Aigner, a doctoral student on Abney’s team, is currently working to identify risk factors that may contribute to the presence of peanut burrower bugs and burrower bug injury in any given year. His research is funded through grants from the Georgia Peanut Commission, the National Peanut Board and the U.S. Department of Agriculture’s National Institute of Food and Agriculture.

“Ben has a record of nearly all burrower bug injury in the state for four years, then he spoke to growers about what they did in the affected field — crop rotations, management practices, irrigation — and what the environmental conditions were in terms of rainfall. A big part of his job is to put all of that data into a model to explain some of the variations on where burrower bugs are,” Abney says.

While he says there have been no real “Eureka” moments, the team continues to add to the knowledge base about the bugs in the continuing effort to find solutions.

“It tends to be worse in non-irrigated fields, but it can occur in irrigated fields. It can be worse in certain types of soil, but it can be in any type of soil. It would be easy to sensationalize the burrower bug, but the truth is that, more often than not, the problem is limited to a relatively small proportion of the total crop in Georgia year over year,” Abney says. “If growers could get peanut burrower bug insurance, no one would care, but that is not an option. It is truly an existential threat for growers in high-risk areas.”

Until then Abney will continue to work on this and all pest problems as the only dedicated peanut entomologist.

“We have been working to identify alternative (pesticides) for five years for burrower bugs and rootworms,” he says. “Solving entomological problems for farmers is what makes me happy. There are a lot of farmers whose livelihoods depend on what I do and that is why I do it.” PG

By Amanda Huber

By Amanda Huber

Four years ago, Jeff Dunne took over the helm of peanut breeding at North Carolina State University after the retirement of the well-known and highly respected peanut breeder Tom Isleib, who introduced a number of high-yielding, industry favorite cultivars through conventional breeding methods. While these were big shoes to fill, Dunne’s timing could not have been more perfect in that his goal was to implement the use of genetic markers in peanut breeding. After all, the first phase of the Peanut Genomic Initiative had been completed and the use of this technology was ramping up.

The goal of any peanut breeding program is to achieve high-yielding, disease-resistant, high-oleic cultivars with good flavor and other marketable characteristics. Conventional peanut breeding emphasizes cultivar pedigree, backcrossing and single-seed descent to include useful genes into elite, agronomic backgrounds to attain the breeding objectives.

Today’s more modern breeding programs include the use of marker-assisted breeding techniques with predictive genomic selection capabilities. This approach also offers the opportunity to reduce operating costs, bring cultivars to the market more quickly and improve genetic gain. Making that shift to more modern techniques, changing the way they do things is not as easy as it sounds. Like other peanut breeders, Dunne has spent considerable time simply modernizing and bringing efficiency to their program.

“Over the past four years, we have worked to make sure this breeding program is running as efficiently as possible so that if we do get some new disease or pest threat, our breeding program is ready to address it quickly and efficiently,” Dunne says.

For example, he says root-knot nematode has not been a

threat in the Virginia-Carolina production area; however, it could become a problem in the future.

“Is our breeding program ready to quickly and efficiently select for that marker or germplasm line that we know has nematode resistance to produce a cultivar, get it through testing and make it available to producers in a few years? We want our program to be prepared for future and emerging issues.

“The biggest impact we’ve made is getting our program ready to not only address what is here now, such as leaf spot and Tomato Spotted Wilt Virus and improved pod traits for Virginia-type peanuts, but also what’s coming. Can our program adapt quickly enough to respond and get our lines tested quickly enough to cover our growers? These are the questions we’ve been addressing,” Dunne says.

As for traits of interest he and others in V-C peanut breeding are evaluating for are regional in nature for the Virginia in-shell roasted market. Traits currently in NCSU phenotyping include: yield (test weight), pod and seed grading, oleic acid content and purity, leaf spot severity, tomato spotted wilt incidence, sclerotinia blight incidence and flavor quality. Dunne says these are the quintessential high-value, high-impact traits for their market and influence the breeding program on a day-to-day basis.

“Three traits we are mainly focused on is work supported by The Peanut Foundation, and the move in this direction fits in with the second phase of The Peanut Genomic Initiative, which puts into practice what was learned in phase one,” he says. “We’re looking at disease quantification methods and better mapping of traits in terms of the marker-selection program.

“In the case of leaf spot, we do both visual ratings and low throughput quantification separating out lesion counts. We also measure defoliation using a drone, and we are doing more multi-spectral analysis along with cell phone capture to better quantify or correlate the visual leaf spot ratings,” Dunne says.

“From a Virginia market standpoint, we are very interested in pod characteristics in terms of color and size. Using a QualySense Qsorter Explorer, which is cutting-edge technology for the inspection and fine sorting of seed, we’re able to make better selections in terms of pod size and other characterizations, like maturity.”

Lastly, Dunne says they are focused on the high-oleic acid trait, which is valuable in terms of Virginia-type peanuts that are mostly consumed as roasted in-shells or canned.

“We are 100% high oleic, so keeping seedstock pure is of high importance. To do that, we either screen molecularly for the correct marker early on in the generations to make sure we have that trait incorporated into all our advanced lines and/or we are screening large volumes of seed lots for the high oleic content using the QualySense Qsorter Explorer,” he says.

Dunne says they have also put emphasis on flavor and are fortunate to have U.S. Department of Agriculture Agricultural Research Service food technologist Lisa Dean helping work on this trait.

“She has been helpful in utilizing her resources in the food science lab to help improve the value of the crop by enhancing flavor, as well as nutrition and post-harvest processing. We are also starting to address some non-target quality traits such as pod thickness: What impact does that have from a shelling standpoint? How does it impact the consumer?

“Quality traits are not always easily addressed. It is hard to narrow down the priority list because we often have other immediate impact-type traits like disease resistance and drought tolerance,” he says.

Leaf spot severity is one of the high-value, high-impact traits for the Virginia-Carolina market being studied on a day-to-day basis in the NCSU breeding program.

Conventional peanut breeding often took 10 years to bring a new variety to the market because a program could only have one generation per year. The number of generations could be increased to two per year if the winter nursery in Puerto Rico was used. However, space in the winter nursery has become a premium with a significant price tag to match.

More recent studies have shown that greenhouses can be used to further increase the number of generations per year by controlling and optimizing the daily light quality and intensity.

“By using a 20- to 22-hour light cycle, >600 micromole of full spectrum intensity and controlling temperatures and automated irrigation, mature peanut seed can be developed in 75 to 90 days, translating to four generations per year,” Dunne says. “Overall, the efficiency of selection and the rapid cycling in the greenhouse can move high-performing breeding materials to testing faster.

“We’re also using robots to extract DNA from our samples and basically doing everything we can to more efficiently push breeding materials through our greenhouses as quickly as possible to get it into the field and to growers as soon as we can.”

As yet another modernization into using today’s technology, nearly a decade’s worth of data from the NCSU and Peanut Variety and Quality Evaluation testing programs is now available to researchers, Extension specialists, county Extension agents and growers

through a web-based application that can be found at go.ncsu.edu/peanut-cultivars. Data such as yield, pod weight, perfect fancy pods, loose-shelled kernels, disease ratings and more are available for multiple areas and years.

Three new cultivars have been released from the NCSU breeding program since Bailey II. One is Comrade, a joint release with USDA-ARS peanut breeder Kelly Chamberlin that will provide material with Sclerotinia blight resistance and early maturity for the Oklahoma breeding program.

The other two are NC 20 and NC 21, which will not be available until 2024 or later. Both cultivars have characteristics equivalent to yield, pod and seed size, and disease resistance of Bailey II and Emery, respectively. NC 20 has slightly larger pod and seed sizes than Bailey II but provides similar leaf spot and TSWV resistance. NC 21 has a yield, pod and seed size, and disease package similar to Emery, but is later to mature and holds on to pods under heavy leaf-spot pressure. More information about these releases can be found in 2023 Peanut Information found on the NCSU peanut website at peanut.ces.ncsu.edu.

All of the changes and modernization brought about by Dunne in the NCSU peanut breeding program are being conducted with the Virginia-Carolina peanut growers in mind. No doubt, this storied and successful program is now positioned to develop and deliver cultivars for commercial production in the region well into the future. PG

Lisa Dean is a food technologist with the USDA ARS Food Science and Market Quality and Handling Research Unit in Raleigh, North Carolina. She and her team investigate nutritional content, flavor attributes and shelflife to maintain and improve the overall quality of peanuts.

In this Q & A, she talks about flavor testing in peanuts as well as work making peanut skins, normally discarded as waste or used in animal feeds, into a food ingredient.

Q:How do you and your team evaluate peanut varieties?

A: At the Food Science and Market Quality and Handling Research Unit, my group evaluates peanut flavor using Descriptive Sensory Analysis with the Spectrum® method. Each attribute is given a number score and the scores are averaged across the number of panelists, including members of the lab group, students and staff from the Department of Food, Bioprocessing and Nutrition Sciences at NCSU. Everyone on the panel is trained to score the attributes listed in the peanut lexicon, and some members have over 2,000 hours of experience.

We work with the USDA ARS National Peanut Research Laboratory in Dawson, Georgia. Peanut samples are sent there from the various breeding programs around the United States as part of the Uniform Peanut Performance Trials where they are shelled and graded.

Once the samples are sent to us in Raleigh, North Carolina, the peanuts are evaluated for “roastability,” that is, what conditions are needed for optimum roasting and how evenly does the sample roast? The composition, protein, moisture, sugar, fatty acid and vitamin E content is determined using wet chemistry and chromatography.

from other food processing waste such as coffee grounds, spent tea leaves, grape pomace, fruit peels, cocoa hulls and similar materials. It would stand to reason that peanut skins could be used in these ways as well.

What ways are you using peanut skins?

A:Our group has isolated the active compounds from the peanut skins, leaving behind a debittered fiber material that makes a better animal feed ingredient. The tannin compound extract can also be spray-dried to make a functional food ingredient to fortify milk chocolate and to make flavored coatings for peanuts.

Q:

Peanut skins are usually removed before processing and consumption, but could skins have a benefit to the consumer?

A: Peanut skins are very high in tannin compounds, which make them bitter and astringent. The compounds present are similar to those in tea, chocolate and cranberries. As a result, most people remove them when eating in-shell peanuts. When making peanut butter, the skins are removed by blanching. If left on, the peanut butter is a darker color with flecks. It is also a stiffer peanut butter that cannot be spread as easily.

The same compounds that cause the bitter flavor also have antioxidant and anti-inflammatory properties in cell culture. They may also have anti-aging and anti-cancer properties. In nature, they serve to reduce insect infestation to some degree due to the bitterness.

Research has shown that these properties can be captured

USDA ARS scientists have developed a way to use peanut skins to fortify milk chocolate to increase the antioxidant levels. Peanut skins contain phenolic compounds including procyanidins, which have been shown to reduce inflammation and act as natural antimicrobials.

A way has developed to combine soluble extracts of the phenolic compounds with maltodextrin, a starch-based polysaccharide, to make a free-flowing powder that was easier to handle and could control the bitterness. The resulting powder could then be used as a functional food ingredient, albeit, with the caution that the allergenicity of peanuts carries over to peanut skins and subsequent reporting of peanut allergy information on the label.

In taste tests, most consumers could not tell that peanut skins were added to the milk chocolate until the level was well above that where the antioxidant level was equal to dark chocolate. PG

We have received good precipitation through May, which has reduced drought intensity in the Southwest. However, the West Texas region remains under drought conditions. This region has received only an inch and a half of rain since the beginning of 2023.

While temperatures have been milder than they were in 2022, more rainfall is needed to maintain good soil moisture for the optimum development of peanuts. Depending on the amount of precipitation and humidity levels, production plans may need to be adjusted accordingly.

The higher the precipitation and humidity levels, the more pest issues are expected. Although many of our growers are using preventative fungicide programs, weekly scouting is needed to adjust these plans as necessary.

Growers in areas with high precipitation need to carefully monitor weed infestations, and treat them accordingly. It is important to scout fields, especially as the crop transitions to flowering and pegging, where yield potential can be greatly affected by the biotic and abiotic stress factors.

Our primary focus in July is establishing and maintaining an effective fungicide program for leaf spot and stem rot. In North Carolina, we recommend that the first spray be made at the R3 stage of peanut growth but no later than July 10. We typically have a five-spray program in our area when considering two-week intervals. If you have a shorter rotation that may have more disease inoculum, starting the program a week or so earlier will minimize risk.

It is recommended that you start with a chlorothalonil treatment either alone or with a tankmix partner that has some curative activity. If you are closer to mid-July with your start, then a fungicide treatment that also has stem rot activity is recommended. Sprays three, four and five (if you start in early July) will need both leaf spot and stem rot fungicides. Numerous combinations are effective on pathogens that cause these diseases.

The key is to stay on a two-week interval for many of the fungicides you might apply, and rotate chemistry for resistance management. Some fungicides will provide control

will become more prevalent. Other insecticides, although more expensive, can minimize the risk of spider mites and are more effective on pyrethroid-resistant individuals in the population.

If it turns out we have good growing conditions, Bailey II and Emery, and in some cases Sullivan, can have excessive vine growth. Apogee or Kudos can help a lot here. The first spray goes out when 50% of vines from adjacent rows are touching. A second application can be made two to three weeks later, if needed. Do not force the second spray. You will begin seeing regrowth and that is the time to make the follow-up application. We can set peanuts back if we apply these plant growth regulators under dry conditions or if we start the sprays too early. Always include nitrogen with these PGRs. There are many questions in July and August about tankmixing, but there is not nearly enough room to address those questions here.

longer than two weeks.

The final spray should include chlorothalonil. In some years, and depending on when you started your spray program, a sixth spray may be needed, especially if September is warm and peanuts are not going to be dug until sometime in October.

We have seen less and less Sclerotinia blight over the past decade, but it is still out there. Resistance in our Virginiamarket type varieties (Bailey II and Sullivan) is good for this disease. The exception is Emery, but it is much better than the older varieties like CHAMPS and Perry. Depending on the fungicides you are using for leaf spot, you may also be controlling any Sclerotinia blight you might have with those products.

If we get dry during July and August, keep in mind that rainfall is not always the best indicator of whether leaf spot will continue developing. We have observed significant leaf spot under drought — defined by no rain — if dew points are high at night. The leaf spot advisory can help you keep spraying when risk is high and stop spraying when the risk is low.

Our current thresholds for foliar-feeding insects, such as fall armyworm, corn earworm and tobacco budworm, are relatively high. However, if you need to make an application, use caution, especially if it is dry and spider mites are building. If you use a pyrethroid, it is very likely mites

The planting season has been a little crazy with the cool weather and seed quality issues, mostly seed vigor. The good news is that a majority of the crop is up and looking good so far. There are several items to note with the crop at this point.

One, several fields had a tough time reaching adequate stands because of low-seed vigor and cool, wet weather. In the first part of May, weather caused most of the issues, but as we moved into late May, poor seed quality (seed vigor) became more evident.

SCOTT MONFORT University of Georgia Extension Agronomist

Two, the cool weather also slowed growth and delayed blooming across most of Georgia.

Three, the cool wet weather also delayed planting by one to two weeks, causing a majority of field plantings to be in mid-to-late May with about 15% to 20% in June. Keep these delays in mind as we go through the season as maturity will be impacted. Also, remember that the yield potential of peanuts planted in June will be reduced 10% to 15% depending on the weather in September and October. Juneplanted peanuts will need a very warm fall to maximize yield potential.

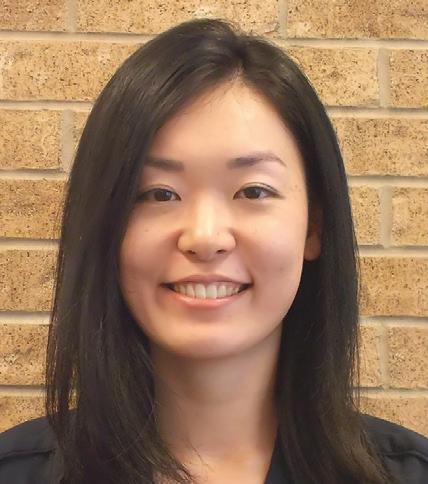

One way you can keep up with heat units is through the UGA weather network at www.weather.uga.edu. Click on “Calculator,” and then “Heating Degree Day.”

Talk at the coffee shop lately is how can we push the crop to get back on track. I wish there was a simple solution to get the crop moving to limit potential yield loss. The most important thing for the crop in July is warmer temperatures with weekly rainfall/irrigation.

Outside of having great weather, yield potential will be dependent on managing key weed, disease and insect issues by using the most effective pesticide and being timely with herbicide and fungicide applications. Growers do not need to forget boron and calcium.

To make sure plants and pods are growing in the right direction, growers need to make sure to apply calcium if soil levels are below 500 pounds per acre (gypsum 750 to 1,000 pounds per acre) prior to blooming. Apply boron at 0.25 pounds per acre twice at 30 and 45 days after planting. Applying the wrong type of product or rate will not offer productive results. Please give your county agricultural agent a call if you need more information or have an issue you need help with.

Hopefully everyone has received adequate rainfall over the past month. I know our weather has been unusual this season with May seeming like April and June more like May because of the drier weather. This has created some challenges, mainly getting the crop in on time and having a good stand due to too little moisture or too much, coupled with

a packing rain. These later peanuts that went in or that were replanted still have adequate time to reach maturity. All in all, peanuts are looking decent right now. Considering the planting season, we were not able to take advantage of early planting, which sometimes puts us in a tough spot depending on what kind of moisture we have later.

We have some weed issues to be addressed here and there but nothing too big. Hopefully you have cleaned those up and have some more residual protection down now.

Remember, even though disease pressure has been light so far, it doesn’t mean that will continue to be the case. I want to remind everyone of the importance of scouting peanuts to be aware of pests, whether it is insects or diseases. Some of us tend to relax and not scout like we should. July is when most growers start to apply their soilborne disease fungicides, which happens to be when the peanuts are typically around 60 days of age. Be mindful of the weather conditions that we have this summer and of the late crop. We very well may need to start earlier, at 35 to 40 days after planting, with the soilborne disease materials if we endure a lot of heat coupled with moisture.

I hope everyone has a great rest of the season this year, and I look forward to seeing you in the field. PG

With

powerful defense against leaf spot and suppression of white mold, your peanuts can focus on one thing—living up to their most profitable potential.