Scan the QR code with your phone to renew today for FREE!

We know you’re busy with more important things, so we’ll get to the point. The U.S. Postal Service requires that we receive a written request from you to continue sending Cotton Farming for FREE.

Please take a few moments to renew online by scanning the QR code. We don’t want to lose you as a reader.

Agvocates In Their Fields: Jack Gjesvold has drawn quite the following through his photography and social media platforms. “I’ve traveled to Arkansas, Mississippi, Tennessee, Alabama and all of these cool places that remind me it all just started back home taking pictures for fun,” he said. “It’s so cool because it’s all different. The way they farm in Alabama is very different compared to the way they farm in the Delta.”

U.S. Department of Agriculture National Agricultural Statistics Service has announced the suspension of the annual U.S. objective yield sampling effort.

To give farmers an opportunity to boost income, Corteva Agriscience, Bunge and Chevron U.S.A. initiated a unique Winter Canola Program.

the official publication of the ginning industry

TCGA hosted visitors from several cotton-growing areas during its annual meeting and cotton trade show in Lubbock. Check out this year’s highlights.

To nominate a deserving candidate for the 2024 Cotton Consultant of the Year Award, co-sponsored by Cotton Farming and Syngenta, fill out the form on page 7 or online at cottonfarming.com/ccoy Deadline for nominations is Aug. 15.

Arkansas is known as the “natural state” for a reason. Lions and tigers, not so much. Bears — sure, here and there. But for residents across the state’s southern tier of counties, alligators make more than the occasional appearance. Go to www.cottonfarming.com for this Web Exclusive report.

When I was a little girl, my dad picked up an extra piece of ground in East-Central Louisiana. It was good land and well suited for cotton. But what suited me most about it were the three big pecan trees sitting in what had once been the yard of a small farmhouse. The dwelling had long since been torn down, but the trees still stood tall and were prolific pecan producers.

My mom loved to crack and eat raw pecans and also make pies with them. For some reason, I never developed a taste for pecans and was the recipient of many pitying looks when I told people this. Despite my distaste for consuming pecans, I was old enough to recognize their potential to increase my stash of Christmas money. “Picking pecans” was the perfect opportunity to add to my meager allowance savings and little bit of money I made for doing extra chores.

After school and on Saturdays in the fall, my mom loaded several buckets into the station wagon, rounded up my next younger sister and me and announced we were all going to pick up pecans. The weather was usually beautiful, and it was fun to get down on the ground and establish a system for collecting as many pecans as we could to fill up bucket after bucket. Like death and taxes, the one given that could never be disputed was that our mom was the fastest pecan picker we had ever seen.

As the afternoon drew to a close, we crawled back in the car loaded down with our pecans and made a beeline to the elevator in Ferriday, Louisiana, where they were weighed and purchased by Mr. Howard “Dado” Russell. My sister and I were thrilled with the loot in our pockets while Mom anticipated sitting at the kitchen table shelling the pecans she had held back for herself and others who actually enjoyed eating them.

I was reminded of this experience while writing “Collaboration Embraces Winter Canola” on page 8. Corteva Agriscience, Bunge and Chevron U.S.A. have created an opportunity for Mid-South farmers to boost their income and reduce fossil fuels and carbon emissions.

And like my pecan-picking endeavor supplemented my allowance savings and extra chore income, the financial aspect of the Winter Canola Program potentially brings in “new money” for farmers to complement their current cropping systems.

Never underestimate the pleasure and reward of “picking pecans.”

If you have comments, please send them to: Cotton Farming Magazine, 7201 Eastern Ave., Germantown, TN 38138.

EDITORIAL/PRODUCTION

Editor Carroll Smith csmith@onegrower.com

Southeast Editor Amanda Huber ahuber@onegrower.com

Associate Editor Cassidy Nemec cnemec@onegrower.com

Digital Content Editor Katie Guthrie

Art Director Ashley Kumpe

Publisher/Vice President Lia Guthrie (901) 497-3689 lguthrie@onegrower.com

Associate Publisher/Editor-In-Chief Carroll Smith (901) 326-4443

Associate Publisher/Sales Scott Emerson (386) 462-1532 semerson@onegrower.com

Production Manager David Boyd dboyd@onegrower.com

Audience Services

Kate Thomas (847) 559-7514

For subscription changes or change of address, call (847) 559-7578 or email cottonfarming@omeda.com

EDITORIAL ADVISORY BOARD

David Burns – North Carolina

David Lynch – South Carolina

Bob McLendon – Georgia

Larkin Martin – Alabama

Mike Sturdivant Jr. – Mississippi

Charles Parker – Missouri

Jimmy Hargett – Tennessee Allen Helms – Arkansas

Jay Hardwick – Louisiana

Ronnie Hopper – Texas

Ron Rayner – Arizona

John Pucheu – California

LLC

Mike Lamensdorf President/treasurer Lia Guthrie Publisher/Vice President

ACKNOWLEDGEMENT OF COOPERATION: Cooperating with COTTON FARMING are various cotton producer organizations across the Cotton Belt. Many representatives of producer organizations serve on COTTON FARMING’s editorial advisory board. Opinions expressed and conclusions reached by contributors are not necessarily those of the cooperating organizations or the editors. All statements, including product claims, are those of the person or organization making the statement or claim. The publisher does not adopt any such statement or claims as its own and any such statement or claim does not necessarily reflect the opinion of the publisher.

Copyright 2024 ©

ASSOCIATED PUBLICATIONS – One Grower Publishing, LLC also publishes RICE FARMING, THE PEANUT GROWER, SOYBEAN SOUTH and CORN SOUTH.

One Grower Publishing, LLC

875 W. Poplar Ave., Suite 23, Box 305 Collierville, TN 38017

Adams

The National Cotton Council is actively encouraging its members to adopt industry-approved module wrap products to reduce contamination of both seed cotton and lint.

■ In early 2022, the approval and publication of the American Society of Agricultural and Biological Engineers (ASABE) cotton module cover material performance standard, which includes specifications for round module wrap, was finalized. While the standard is voluntary, the National Cotton Council and National Cotton Ginners Association have policies that support and promote the ASABE standard.

Proper use of approved round module wrap can significantly reduce seed cotton/ lint contamination.

The U.S. cotton industry is taking all necessary measures to eliminate plastic contamination in baled cotton. The specifications serve as a minimum performance standard and were developed from existing wrap physical properties that have been proven to perform at an acceptable level. The effort and investment that go into cotton production deserve reliable outcomes. Using wrap material that meets the minimum standard provides the assurance that seed cotton will arrive at the gin in optimal condition, and the likelihood of plastic contamination entering the gin, and ultimately the ginned bale, is greatly reduced.

One of the foremost priorities of the U.S. cotton industry is the continued delivery of quality, con-

tamination-free cotton in the global marketplace, a priority that is more critical than ever due to fierce competition from other growths and man-made fibers. The U.S. cotton industry must work to eliminate plastic contamination that can be caused by round module wrap material.

■ Moving into the 2024 ginning season, there are 28 companies identified that are marketing round module wrap in the United States. The NCC has diligently worked to catalog as many of these wraps and manufacturers as possible and inform them that if they are marketing in the U.S., there is an ASABE standard for the wrap. The NCC also has received performance reports for some of these wrap materials, highlighting issues related to tail slippage, adhesives, and missing RFID tags. This has been particularly challenging for ginners who are utilizing RFID to track modules. To address these concerns, ongoing discussions are taking place within the industry. NCC’s focus is on promoting the use of round module wraps that meet the ASABE standard, ensuring better performance and reliability for ginners and cotton producers. In addition to the Tama premium wrap and S and K Premium Blue Wrap that meets the standard (as of May 8, 2024), there is one additional company that is working toward approval, and two more manufacturers that anticipate beginning testing this year.

The NCC serves as the depository for the names and manufacturers who meet the minimum standard. A copy of the standard, along with other relevant information, including the names of companies and the specific module wraps that meet the performance standard, can be found on the NCC website at https://www.cotton.org/tech/quality/contamfree.cfm.

I encourage our members to prioritize contamination prevention by utilizing these resources and working as a team from the field to the gin. With vigilance and strong communication, we can successfully eliminate contamination.

Gary Adams is president/CEO of the National Cotton Council of America.

During April, the U.S. Department of Agriculture National Agricultural Statistics Service announced the suspension of selected statistical reports and processes, including the annual objective yield sampling effort for U.S. cotton. The latter was a process of field sampling of squares and bolls in major cotton-producing states, from which an objective estimate of yield was calculated. This estimate presumably informed the monthly U.S. cotton production forecasts, beginning with the August forecast, with potential to confirm or contradict the earlier (May, June, July) forecasts that are traditionally based on historical average yield and abandonment, along with subjective opinion. It should be noted that in 2019, the start date for objective yield sampling for most of the United States was moved from August to September.

The delaying of the objective yield survey process, followed by its announced elimination, has potential for increasing the forecasting error of U.S. cotton production, which has implications for market planning and even price volatility.

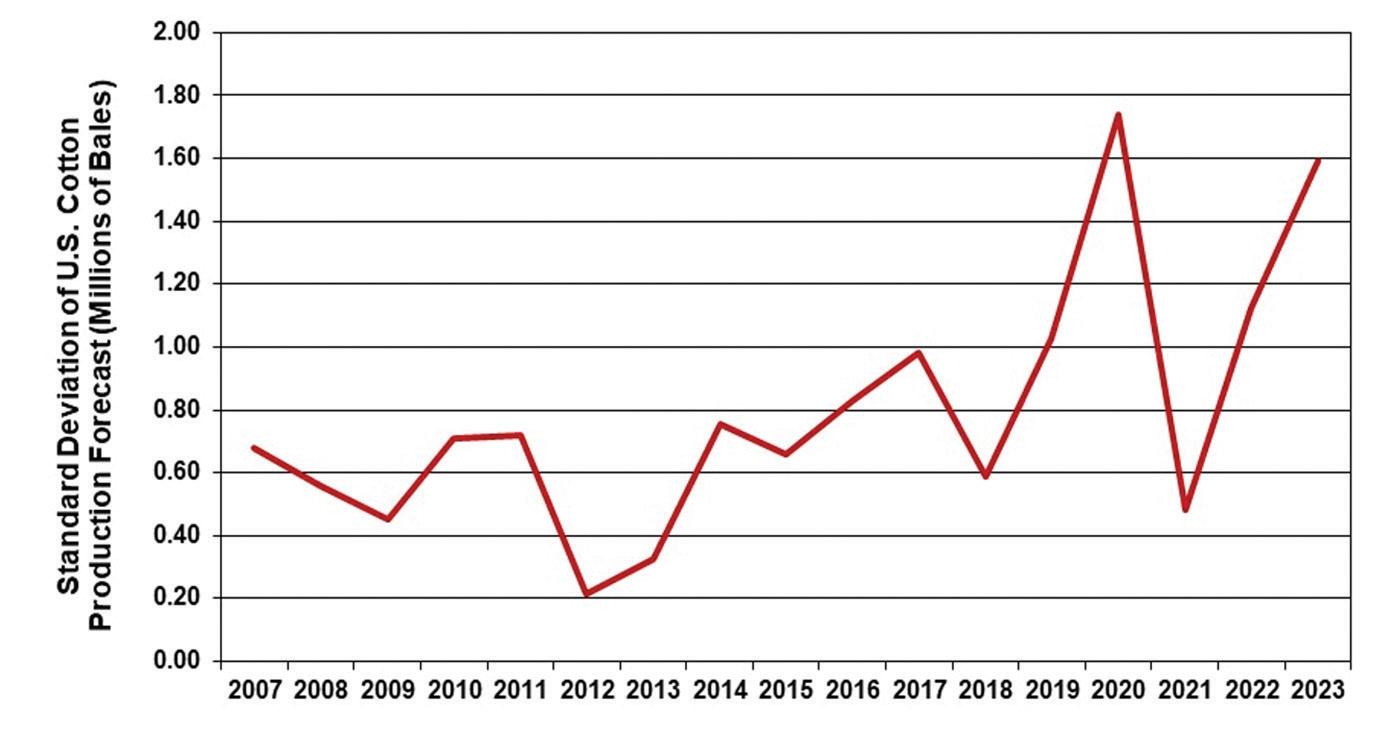

Figure 1 provides a description of the variability of USDA NASS monthly forecasts of U.S. cotton by crop year. For example, the year 2012 in Figure 1 graphs the standard deviation (roughly 200,000 bales) around the average of forecasted cotton production from the May 2012 initial monthly forecast through the following April (2013) forecast of 2012 cotton production.

The graphed points in Figure 1 represent the variation associated with revised production estimates. Through 2018, the public data collection and publication of information to inform the production estimates was the same. Over this period, the variability of those monthly

estimates within a given crop year fluctuated between 200,000 and one million bales around the average production for that year. This appears as a fairly narrow, sideways pattern.

Since 2019, there has been a marked increase in variability of the monthly production forecasts around average crop year production for the past five years. This variability reached 1.7 million bales in 2020 and 1.6 million in 2023. The increase in production forecast variability since 2019 is visually correlated with the delay of objective field sampling for most of the U.S. Cotton Belt until September. It is unknown whether there is any causal influence.

However, the complete elimination of cotton objective yield sampling represents an even larger disruption of previously available information. Our hypothesis is that confirming information on the size of the U.S. crop will have to wait until data from NASS surveys of ginning, as well as bale counts from USDA classing offices, are finalized in the winter. The absence of in-season, objective yield information adds to market uncertainty with likely price implications.

John Robinson, Ph.D., is a professor and Extension economist with Texas A&M AgriLife Extension.

The Cotton Consultant of the Year (CCOY) Award marks more than four decades. The award recognizes a consultant who has made great contributions to the cotton industry through outstanding customer relations, leadership and innovation. It honors a consultant who not only meets these requirements but also exceeds them.

Syngenta and Cotton Farming magazine — CCOY sponsors — are soliciting your help in selecting the 2024 recipient, who will be named at a special celebration Friday, Feb. 28, 2025, at the Peabody Hotel in Memphis, Tennessee.

The winning consultant and the person who nominates the winner receive a two-night hotel stay and airfare to Memphis. The 2024 CCOY recipient also will be featured in a four-page salute in the February 2025 issue of Cotton Farming.

Submit nominations by Aug. 15, 2024.

Mail: Carroll Smith

7201 Eastern Ave. Germantown, TN 38138

Scan/Email: csmith@onegrower.com

You can print an electronic version of the form located on the Cotton Farming website at www.cottonfarming.com.

Nominate online: cottonfarming.com/ccoy

If you would like to nominate a consultant deserving of this outstanding recognition, please take a moment to fill out the following form.

Please use a separate page for biographical/professional information. Additional recommendations via letters or emails from other farmers, consultants and industry members are also encouraged to provide support for the nominee.

Consultant’s Name:

Company Name:

Mailing Address:

City:

Phone:

State: ZIP:

Email:

In your own words, please tell us why you are nominating the consultant above for the Cotton Consultant of the Year Award. Additional pages may be attached, emailed or attached to the online nomination form.

Background:

Biographical/Industry Involvement Background. This information as well as support letters may be attached to this form, emailed or attached to the online nomination form.

Your Name:

Mailing Address:

City:

Phone:

State: ZIP:

Email:

Alex Hibler, le , grain marketing commercial manager with Bunge, and Kyle Holmberg, Pioneer field agronomist, observe a eld of winter canola.

To give farmers an opportunity to boost their income and reduce fossil fuels and carbon emissions, Corteva Agriscience, Bunge and Chevron U.S.A. initiated a unique Winter Canola Program in 2023. Corteva is supplying the Pioneer hybrid seed, while Bunge and Chevron are working together through their joint venture Bunge Chevron Ag Renewables to help develop the infrastructure of the program. Bunge is contracting the acres and handling the grain and crushing plant. Chevron is committed to producing and marketing the renewable, sustainable biofuel.

The collaborators note that the Winter Canola Program is designed “to create a new revenue opportunity for farmers with a sustainable rotational cash crop. … Due to unique genetics and recommended agronomic practices, this crop can achieve lower carbon intensity levels while bringing opportunities to adopt sustainable practices.”

Chad Berghoefer, global product director of biofuels for Corteva Agriscience, said, “It’s very rare to have a situation where you can bring a new cropping system to the grower, new opportunity that includes the research side, the seed production side and the boots on the ground along with the crusher part of it, which is Bunge, and then the actual end user to make it into a viable product.

“In this case, the products would be things like renewable diesel or sustainable aviation fuel from Chevron. To bring all those components together has been key.”

After several years of testing and small-scale pilots, the fall 23/ spring 24 crop was the Winter Canola Program’s first large-scale commercial planting. This fall (fall 24/spring 25) will be the second large-scale commercial planting. Corteva Agriscience has announced that “Pioneer brand winter canola is available from authorized sales locations in Kentucky, Tennessee and surrounding states that sell and service the Pioneer brand.”

Luis Copeland, senior director low carbon intensity seeds for Bunge, said, “We are looking at this crop to fit the winter fallow period and have the functional benefits of a cover crop,” he said. “But it also brings an additional opportunity for income for the grower, and it provides an additional oil supply for the market.”

Steve Klein, senior analyst for business development for Chevron Renewable Energy Group, said, “In regard to market stability, I noticed something interesting when I was with Kyle and Chad talking with growers who planted winter canola this year. While we were in their office or equipment shed, it seemed to make an impact on them to see Corteva, Bunge and Chevron as part of this winter canola effort and launching it in the MidSouth. I think this added a lot of credibility to the market and is something I am excited to be a part of.”

According to Pioneer, “With elite genetics, our canola hybrids deliver industry-leading yield potential and consistent oil content.”

Jonathan Siebert, area agronomy lead, Corteva, said winter canola also uses the same equipment — with minor adjustments — as crops like winter wheat and soybeans.

“Canola is a good rotational crop for cotton and soybeans, but it may not fit some soil types,” he said. “To get good advice about the agronomics of growing winter canola, contact your local Pioneer field representative.”

Winter Canola FAQs

Here are several frequently asked questions about winter canola answered by Corteva Agriscience and BCAR.

Q: How would winter canola fit into a farmer’s system?

A: Winter canola can be planted in September on what could have been fallow acres. It can be used in rotation with wheat or other double cropping systems every two to three years. Canola generally matures earlier than wheat, which can allow earlier planting of the spring crop. Canola also leaves less residue in the field than wheat, which makes no-till planting of the summer crop easier.

Q: Would winter canola replace winter wheat in the rotation?

A: No. Winter canola would be used in rotation with winter wheat since it needs two to three years before planting in the same field for disease prevention.

Q: What kind of yields can farmers expect from Pioneer brand winter canola in the southern United States?

A: Anticipated yields of 45-55 bu/acre is a common target based off of university trial results, with potential to be higher based on individual operations.

Q: If farmers contracted with Bunge, where do they need to take the grain?

A: In 2024, farmers can deliver winter canola grain to multiple

• Contact Alex Hibler, Bunge commercial manager, at alex.hibler@ bunge.com or 270-214-1667; or contact your local Bunge rep to sign up a specific number of acres. Pioneer provides agronomic guidance and stewardship support through local area experts. For agronomic support and advice, contact Kyle Holmberg, Pioneer field agronomist, at kyle.holmberg@corteva.com or 317-671-1719.

• Contract acres of production at a fixed price based on the July 2025 Canola Futures, +/- local area basis. “Act of God” clause is included and additional pricing alternatives are available.

• Deliver any and all crop production to a nearby river loading facility and get paid by Bunge Chevron Ag Renewables — a joint venture between Bunge and Chevron. Grain delivered is subject to quality grading standards.

Bunge enabled elevators in Northwest Tennessee and Southwest Kentucky along the Mississippi and Ohio rivers. Delivery locations continue to be expanded. Refer to your grain contract for details or contact Bunge for future prospects.

Brandon Whitt, an eighth generation grower with Batey Farms near Murfreesboro, Tennessee, is participating in the 2023/24 Winter Canola Program.

“We’re always looking for ways to advance, improve and move, not only our operation, but all of agriculture to the future and be more relevant to today’s consumers,” he said. “With that mindset, my operation depends on finding value and relevance to the community.

“We are rotating winter canola with strawberries, but we also wanted to put it where the general public could see it and ask questions. Being involved with an innovative project like the Winter Canola Program is very appealing to me.”

The National Cotton Council applauds House Agriculture Committee Chairman Glenn “G.T.” Thompson for producing a Farm Bill that significantly increases the support levels for cotton producers, who have been weighed down by the recent rise in on-farm production costs.

This legislation also gives growers more affordable options for their risk management strategies, makes important improvements in the marketing loan program and restores critical support for our domestic textile manufacturers.

The NCC urges this legislation to move forward in a bi-partisan manner with our industry committed to working with the leadership of the House and Senate to ensure final passage in 2024.

The 2024 Syngenta Pest Patrol program is designed to equip growers with timely alerts so they can protect their crops against potential pest threats. The alerts come from a team of local university partners and Syngenta representatives across the Mid-South and East Coast.

By signing up for this free, SMSbased program, growers can receive news about emerging pest populations and issues specific to their area throughout the growing season.

We invite you to spread awareness about the Pest Patrol program and its benefits. Together we can help growers stay ahead of pest threats and empower them with the knowledge and tools they need to combat pests during the season.

The Pest Patrol program will run from March 31 – October 31, 2024. To sign up, visit https://www.syngenta-us.com/ pest-patrol.Pest Patrol experts and entomologists will be posting timely alerts for growers throughout the growing season, these experts include:

■ Nick Bateman, Ph.D., assistant professor/crop entomologist, University of

Arkansas.

■ Ben Thrash, Ph.D., assistant professor/entomologist, University of Arkansas.

■ Whitney Crow, Ph.D., entomologist, Mississippi State University.

■ Chase Floyd, Ph.D., Extension entomologist, University of Missouri.

■ Sebe Brown, Ph.D., entomologist, University of Tennessee.

For any questions, please contact Luke Matson at 919-460-9020 or lmatson@ gscommunications.com.

The Environmental Protection Agency is soliciting public comment on a registration review decision where the EPA proposes to cancel all uses of acephate, except for injections to non-food bearing trees.

Sebe Brown, University of Tennessee IPM Extension specialist, said, “Acephate is widely used in Tennessee row-crop agriculture and is a critical component of IPM programs. Cancelling an important crop protection product would place increased pressure on a limited number of control options available to producers.

“We are encouraging agricultural professionals to comment to the EPA on the impacts acephate has on your production systems. If you need assistance with comments, please contact your UT Extension specialist.”

To comment, go to https://www. regulations.gov/docket/EPA-HQOPP-2008-0915/document. The deadline for comments is July 1, 2024.

Following an Arizona federal court ruling that vacated the label in February, users of dicamba herbicides are waiting to see what happens now that a new registration for over-the-top use of XtendiMax during the 2025 season has been submitted to the Environmental Protection Agency.

Herbicides containing dicamba have been widely used by cotton and soybean growers to fight weeds that have developed resistance to other chemical controls. The EPA regulates herbicides and must approve the labels, which include directions for use and precautions.

Brigit Rollins, staff attorney, National

Agricultural Law Center, says the review period for the latest dicamba registration submission could be a long one.

Three dicamba brands are registered for use by the EPA: XtendiMax, Engenia and Tavium.

The proposed new label for XtendiMax includes a significant change — not allowing for over-the-top use on soybeans,” said Rollins.

The XtendiMax submission also included a new twist: an R170 registration for food use. According to the EPA, R170 would include “uses on areas where food may be grown or raised such as pasture, rangeland, home garden, beehive and uses involving livestock, such as livestock housing, livestock dips and livestock ear tags.”

Rollins noted, “The court said the manufacturer needed to pursue a new use registration. Bayer probably saw the R170 additional food use as the best fit as a new use registration, but they might have a completely different reason. However, the review timeline may be longer than the growing season.

“The public comment period that’s currently open on this label is for 30 days, but there is a good chance that it will be extended. Various environmental groups have indicated that they would like to push for at least a 60-day comment period.”

The current comment period opened May 2 and ends June 3. EPA also has a 15-month review just for the R170.

“With the extended comment period and EPA’s 15-month decision time for the R170 label, “that’s a review period of 17 months,” Rollins said. “It’s hard to see how this label would be approved before the 2025 growing season. The label could be approved as early as fall 2025, if we’re doing our math correctly.”

Rollins did say that the EPA could choose to modify and shorten the review period, but any follow-up lawsuits would again target the procedures “because that worked so well last time.”

The Arizona court order allows for existing stocks of XtendiMax, Tavium and Engenia to be used in 2024 and defines those stocks as being previously registered pesticide products that are currently in the United States and were packaged, labeled and released for shipment prior

to Feb. 6, 2024, the date of its order. The products must be used according to the label.

Dicamba has been registered for use in the United States since 1967 and controversial for its tendency to move, or drift, from its target application area. Newer formulations using dicamba were approved by the EPA in 2016.

The 2024 Arizona decision focused on procedural issues linked to how the EPA reviewed labels for registration in 2020, rather than the herbicide itself.

At the heart of the 2016 lawsuit, and subsequent lawsuits, are the Endangered Species Act and FIFRA, or the Federal Insecticide, Fungicide, and Rodenticide Act, which regulates pesticide use in the United States. The Endangered Species Act requires all federal agencies to ensure their actions will not jeopardize endangered or threatened species. Under the Endangered Species Act, the EPA must consult the U.S. Fish and Wildlife Service and the Marine Fisheries Service when approving pesticides.

However, the herbicides’ labels for use expired before the courts could take up the 2016 case. The herbicide makers filed for an expanded label, which was granted in 2018.

Plaintiffs refiled their lawsuit in 2018 and a 2020 decision by the 9th U.S. Circuit Court of Appeals stated, “that the 2018 pesticide registrations violated FIFRA because EPA had wrongly concluded that the label amendments right that this sort of registration of over-thetop use would not significantly increase the risk of unreasonable adverse effects on the environment,” Rollins said.

“Specifically, the 9th Circuit called out EPA for substantially understating three risks that EPA had identified when it analyzed the label, and also that EPA had failed to acknowledge three other risks in its analysis.”

The labels were vacated in 2020 and manufacturers sought new registrations to allow over-the-top use of the dicamba herbicides from 2021-25. This multiyear registration was the subject of the Arizona court decision this year.

In both rulings vacating the registrations, the court allowed farmers to use existing stocks. As for the future, Rollins said litigation over dicamba herbicides centered around FIFRA and the Endangered Species Act are not likely to go away anytime soon.

We know these are more than just fields is where you picked cotton with your grandad and where your daughter’s children will scout for the first time. That’s why our family of cotton products features trusted performers and elite newcomers your family

Jack Gjesvold started Timber Solutions to promote agriculture throughout the Delta. “If you use social media correctly, it can be a huge tool for your business or even just sharing what you’re doing every day,” he said.

It was not until Jack Gjesvold was a senior in high school that he stepped foot onto a farm. Today, just having wrapped up his sophomore year at Mississippi State University for forestry and habitat management, he has drawn quite the following through his photography and social media platforms.

Photographic Beginnings

A Madison, Alabama, native, Jack Gjesvold is the son of an engineer and a business analyst. His first big exposure to agriculture came through a friend.

“I was never on a farm until I was in a church small group with my now roommate in college. His family owns a farm, and he would always tell us stories about all of the stuff they were doing. It sounded cool, so I went out there one day just to take pictures. I got some good pictures, and that turned into going out almost every weekend to take pictures.”

He said the farm then started using the pictures as promotional material for some of the companies. Gjesvold then began taking more pictures in the fields — lots of them.

“I saw that these pictures could be used, which led to me

Ultimately, Gjesvold’s goal is to bring increased awareness to the agricultural industry by connecting others who are outside of it.

taking more pictures and working out there for a summer just to get experience,” Gjesvold said. “I started my social media around that time just to share those pictures.”

He said that he started Timber Solutions and realized he still did not have much ag experience so he wanted to get back out in the field.

“You can learn a lot from just being on a farm, but if you put yourself in the position where you’re out there working every day, you can learn a lot more.”

Gjesvold said he began to make connections all throughout the Delta, leading him to expand his knowledge base and social media impact. “I’ve been able to travel to Arkansas, Mississippi, Tennessee, Alabama, and all of these cool places that remind me it all just started back home taking pictures for fun.

“It’s so cool because it’s all different. The way they farm in Alabama is very different compared to the way they farm in the Delta. Growing up in one spot, you’re kind of limited to what you see.”

With all of the pros and cons that accompany social media, Gjesvold said the reasoning behind it all is key.

“You have to use it for the right intentions. It’s easy to turn social media into a negative, but if you use social media correctly, it can be a huge tool for your business or even just sharing what you’re doing every day.”

Gjesvold said he is more active on Instagram but also has Facebook and TikTok. “Starting out with all my pictures, Instagram was just the place to be. Now that I’ve been taking pictures at other farms and knowing a lot of the farmers are on Facebook, I’ve started posting some to Facebook for those farmers as well.”

Interacting with others across social media is important to

“You can learn a lot from just being on a farm, but if you put yourself in the position where you’re out there working every day, you can learn a lot more.”

Gjesvold. “I think that brings a ton to the table because you can learn from them, gain a unique perspective, and just learn a lot in general,” he said. “I’ve learned so much even about photography and videography from some of these guys. Most of them are older than me, and I’m 20 so still have a lot to learn.”

Riggs Ware is someone Gjesvold met early on who has become a friend and someone whose content he looks forward to seeing. “He does some cool stuff and promotes agriculture in the Delta. Riggs and I have started a YouTube channel called Turn Row Talk. We aren’t as active on that right now, but that’s our platform where we are trying to add a little bit more personality and force ourselves to get in front of the camera more.”

He said they have a podcast as well. “There are so many ag podcasts out there right now that you can listen to,” Gjesvold said. “Hazel Creek Farms and Clayton Lind started one, and they did a great job. It seems like more and more are popping up every day.”

In addition to Ware, Gjesvold said he enjoys following the XtremeAg group. “They’re goal is to educate farmers on different practices,” he said. “I obviously don’t educate farmers, but I’ve found that to be pretty cool over the past few months. It’s neat because I’ll learn things from the XtremeAg guys and

then be learning the basics about those same things in my classes at Mississippi State. It connects dots; you learn a lot better [in the classroom] when you’ve seen it in the field.”

He emphasized the significance of having his platform to connect with and educate others.

“You have this platform that you can reach so many people,” he said. “Whether telling a story or promoting a business, it’s basically a free advertising tool. You just have to use it correctly.”

Ultimately, Gjesvold’s goal is to bring increased awareness to the agricultural industry and do that by connecting others who are outside of it.

He spoke on how his outside perspective helps rather than hinders him in exploring the industry. “It’s all common knowledge to these kids who grew up on a farm. I feel like its great for me because I can relate to people who might not have grown up on a farm or even ever been on one.”

Gjesvold noted the many others throughout the industry doing the same thing he is doing in taking pictures and sharing what goes on around the farm. He said there were many stories before those past five years that had not yet been told. “I feel like a great way to use social media is to share those stories and explain what happens on the farm.”

“If you didn’t grow up on a farm, it’s all kind of a foreign concept that farmers are working in the field, on a forklift, in a tractor, checking pivots, and more. They might picture a farmer in a tractor, but they don’t really know what all a farmer does and what all goes into their operation.”

Solutions full time. “I don’t know if I’ll be able to do that or not, but it would be cool to see Timber Solutions become a full-time job. It’s very cool to be able to travel and see what other parts of the country have to offer with ag as well as meeting all the great people in between.”

“AGvocates In Their Fields” features those providing a voice for American agriculture through their platforms. If you know of an “agvocate” or group of agricultural advocates you would like to see featured, contact Cassidy Nemec at cnemec@onegrower.com.

In the end, Gjesvold said he would love to continue Timber

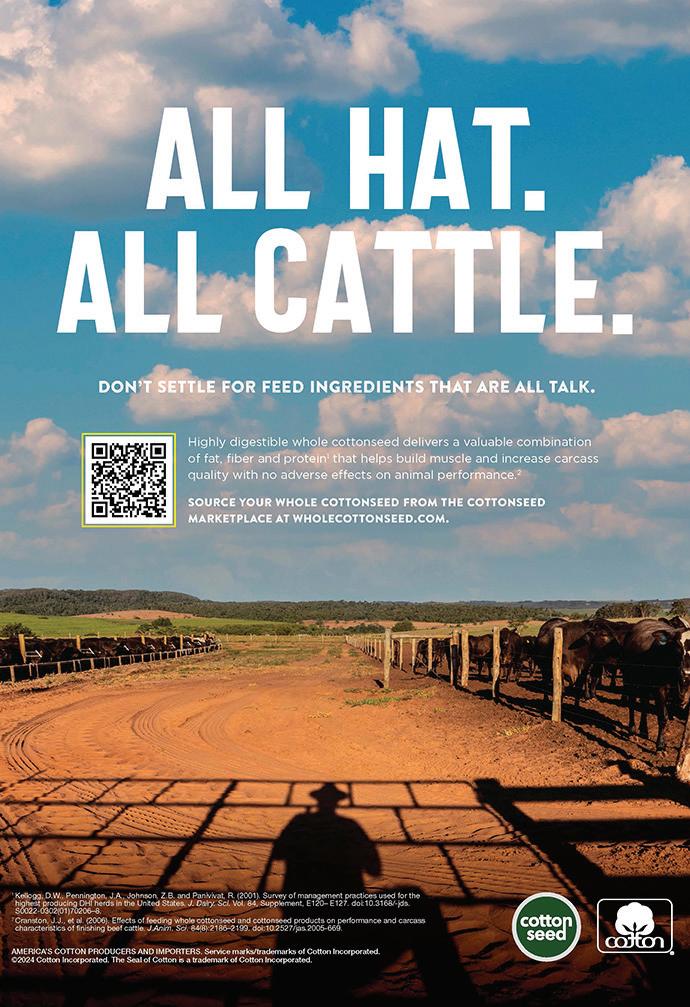

Cotton growers and dairy farmers alike know the value of cotton lies not only in its textile uses but also in its byproduct, whole cottonseed. Cotton Incorporated’s Cottonseed Research and Marketing program works to maximize cotton-grower profit from whole cottonseed through education and marketing to dairy and beef cattle farmers.

The organization’s efforts into promoting whole cottonseed in the cattle-feed market began in the 1990s but continue to grow and evolve. Today, Cotton Incorporated uses its website wholecottonseed.com and year-long advertising and marketing initiatives to keep whole cottonseed top of mind in the market.

Whole cottonseed is an excellent feed ingredient for all cattle, especially lactating cows. The high level of energy, protein and effective fiber in cottonseed has the potential to increase milk production and butterfat when added to the ration.

According to Cotton Incorporated’s wholecottonseed.com website, whole cottonseed is a triple-nutrient feed ingredient, containing protein, available fat and effective fiber. This unique composition is especially valuable in cattle diets, making it a sought-after feedstuff for dairies, ranches and feedlots across the United States.

The fat in the seed helps improve body condition, which is vital for successful breeding. The protein supports muscle growth, animal development and lactation. The seed’s kernel is the source of its energy and protein.

The fiber supports rumen function and digestive health. Its fiber is found in the short, white, hair-like strands, called linters, that remain on each seed following ginning. These tiny linters are the reason whole cottonseed is often referred to as “fuzzy.” This fuzz is not residual cotton lint, but rather cellulose, a highly

BY STACEY GORMAN WARREN, ARKANSAS

BY STACEY GORMAN WARREN, ARKANSAS

effective source of fiber.

One very important logistical advantage in using whole cottonseed is a reduced number of feed ingredients. The high nutritional quality of whole cottonseed often reduces the total number of other feedstuffs needed in the ration. Thus, less ingredient storage and less management time is required for purchasing and inventory control.

We’ve all heard the saying “all hat, no cattle” for those people who are all talk and no action. Well, Cotton Incorporated is putting a spin on that colloquialism with its “All Hat. All Cattle” advertising campaign. Launched in early 2024, the campaign urges beef cattle producers and nutritionists not to settle for ingredients that are all talk, and to instead add whole cottonseed to their cattle’s diet.

“The new creative campaign resonates and reaffirms the benefits of feeding whole cottonseed,” notes Lynn Kilroy, director of corporate communications with Cotton Incorporated. “It reinforces our message in a clever way that speaks to our key audiences.”

Wholecottonseed.com is an information-rich hub full of articles, resources and educational content explaining the benefits of whole cottonseed as a cattle feed ration. The wholecottonseed.

com website moves beyond awareness and education about whole cottonseed into action through its Cottonseed Marketplace sourcing portal, an easyto-use connection point for buyers and sellers of whole cottonseed.

Users can request a cottonseed quote directly from qualified sellers based on their own unique specifications. Additionally, Cotton Incorporated and wholecottonseed.com have compiled a state-by-state map of potential suppliers of cottonseed allowing users to reach out directly to sellers.

The effort around promoting whole cottonseed is a great example of how Cotton Incorporated is dedicated to creating markets and value opportunities for cotton. For more information, and to sign up to receive updates, newsletters and stories related to whole cottonseed, visit wholecottonseed.com today.

Stacey Gorman is The Cotton Board’s director of communications. Contact her at sgorman@cottonboard.org.

Cotton Incorporated has created a new print ad for cattle magazines promoting the benefits of feeding whole cottonseed.

Dry weather — prolonged dry weather — scares me. I recall a summer that the “spigot” shut off, and I thought it would never rain again. It finally did so… when I was at a Friday night football game in mid-September; then it rained at least every third or fourth day until the following planting season.

For growers in the Lower Southeast, soil moisture typically affects stand establishment more so than temperature. Both weather factors delayed planting this year, though I still contend that if we have available soil moisture after April 15-20, we need to get into the field. The few April-planted acres — USDA reported less than 10% of our crop was seeded before April 30 — seemed to fare well despite a rainy cold front that passed through April 20-21. Predictions for May, though highly varied, generally call for below-normal rainfall. That, coupled with prevailing windy conditions, pose challenges for early cotton stands.

Crop yields in 2023 in Alabama ranged from terrible to spectacular. Some in northern areas made their “best crop ever.” Even those that harvested a bountiful crop greeted this season with muted prospects because of the squeeze of input costs and labor concerns. All entered 2024 thinking, “we need a good crop, a really good crop.” The April price drop was another blow to hopes and expectations.

As we proceed with May plantings, we are increasingly concerned about drought. By this reading in early June, we’ll have a better picture of where we stand, for the near term and the bigger picture of the 2024 crop. cottonbrown@auburn.edu

The 2024 cotton growing has seen an interesting start. Abnormal precipitation events in late March and early April and cooler-than-average temperatures resulted in a delay in much of the planting across the various cotton-growing regions of Arizona. However, mid-April experienced a turn in weather patterns to drier and much warmer trends resulting in optimum conditions for planting and crop establishment.

Beginning around April 15, the planters started moving quickly across the state with a significant amount of the crop being planted in the last two weeks of April and early May. It is projected that Arizona will grow just slightly over 100,000 acres in 2024 with approximately 80,000 being Upland cotton and the remaining 20,000 being extra-long staple (ELS) cotton.

Early season cotton development from emergence to initiation of fruiting is important in setting up the vegetative structure of the crop to sustain future development of fruiting forms. Monitoring and managing early season insect pests, maintaining adequate soil moisture to reduce potential stress on young cotton plants and ensuring availability to adequate fertility levels in the soil are among the many important management decisions that will help establish a strong and healthy vegetative structure early in the season.

Decisions related to the management of pests, moisture and fertility status in the crop become even more critical as the plant transitions from a vegetative to a reproductive state. It has been, and in some cases still is a common practice to impose early season water stress to help induce crop fruiting and flowering and to also control excessive vegetative growth. With today’s newer, more determinant varieties, with-

holding water to induce flowering and control vegetative growth has the potential to impose sufficient stress causing the plant to rapidly progress toward cut-out and induce abortion of small pinhead squares. This can result in a negative impact on yield and fiber quality. Properly managing soil-plant moisture status is critical to obtaining optimum yield and fiber quality. Information related to these and other crop management topics can be found at the University of Arizona Cooperative Extension website (extension.arizona.edu/crops-soils).

rnorton@cals.arizona.edu

As I am writing this May 3, cotton planters are rolling in Georgia. While it seems we are slightly ahead of schedule today relative to previous years, we all know things can change in a hurry. Of course, by the time you are reading this, I hope we will be almost done!!

As most folks are hopefully done or close to done planting at this point, the next thing on many growers’ minds will be managing this crop with plant growth regulators. As we start looking at this, some of the most widely publicized data and strategies for PGR use come from my colleagues in the Mid-South. When I talk about PGR use in Georgia compared to the Mid-South, I generally include a map showing that Georgia, in fact, is not in the Mid-South. Theres a couple of things we have going for us in Georgia that make PGR strategies different from other places in the Cotton Belt. The first is that in the Mid-South, tarnished plant bugs are a more consistent and intense pest than they are for us in Georgia, and in taller cotton, it is harder to gain control of these insects, thus the need to keep it short. But the other thing that benefits Georgia growers is the length of our season. I have looked at PGR trials we have conducted a number of ways — yield response to plant height in my trials is inconsistent (but I will say I’ve never seen yield increase as plant height decreases in Georgia), but in one set of trials, we took some pretty intense data and one thing was interesting to me. In this specific set of trials, yield increased as season length increased. Indicating that taking advantage of our long season was more associated with yield increases than other measures like plant heights.

PGRs are used for two reasons: reducing plant heights and hastening maturity. So, let’s use them appropriately for our production environments — maintain a plant height conducive to harvest, but let’s not shoot ourselves in the foot by unnecessarily shortening our season by being overly aggressive with PGRs.

As always, if you ever need anything, don’t hesitate to reach out. Your local University of Georgia county Extension agents and specialists are here to help! camphand@uga.edu

It is hot and dry here in Mississippi, and planting is in full swing. As April slipped away, along with turkey season, an opportunity for farmers to plant during the optimal window is upon us (May 1-10). I mentioned hot and dry, but I am referring to a window of opportunity to get seeds into the ground. Often times, we are cool and wet during the first week of May. But not this year. Our cotton growers were able to plant during the last week of April in some locations.

Our soil temperatures have been hanging around 60 degrees Fahren-

heit for more than 10 days giving our growers a chance to plant at least eight of them. Soil moisture has been extremely adequate and lingering around, which has produced emerged seedlings in as little as 3.5 to four days. I think that is a bit unusual for this time of year in Mississippi, but I’ll take it!

It’s hard to say the exact progress as I write this because things are happening fast. Currently, with the equipment that is used to plant cotton, we could easily get more than 50% of our acres planted in less than two weeks (maybe 10 days). e extended forecast is looking good for the next two weeks. e amount of rain we get over the weekend (May 4-5) will dictate how much of the state is planted. We are forecasted to seed 500,000 acres of cotton in 2024. At this point, things are looking good, and we are “sending it” hoping for some big yields this year!

Good luck! bkp4@msstate.edu

Cotton planting in Missouri started earlier in 2024 than I have seen in the recent past. May 5 through May 15 is when the majority of the cotton is usually planted. is year, producers started around April 22, with instances of minimal acres planted around April 6, which is the earliest-planted cotton that I have heard about.

At this point, planted acres seem to be approximately 60% to 65% planted. We are expecting more acres here than in past years, likely 350,000 acres to 355,000 acres. If you split the Bootheel in half from south to north, I would likely say the southern part is 70% to 80% planted. e northern end of the Bootheel has had greater rainfall, which slowed planting progress. I would say they are approximately 40% to 50% planted. ere are several producers who elected to wait until May to begin planting; therefore, some have recently just started planting.

We just received rainfall across the Bootheel on May 2, and parts of the southern region were needing a rain to activate preemergent herbicides. Overall, we are a little ahead of where we have been in the past in Southeast Missouri. brwilson@missouri.edu

We have had pretty good temperatures as I write this in early May with maybe 5% to 10% of cotton acreage planted. Many growers have been concentrating their efforts on peanuts so far. As we nish up peanut planting in the next few days, our cotton planting should take o . e outlook for cotton planting looks good as far as temperatures are concerned. Unfortunately, we are getting very dry in some areas. Generally, we are better o to plant shallow and wait for a rain to bring the cotton up rather than plant too deep trying to chase moisture. We are concerned that cotton planted deep might nd enough moisture to germinate and then die due to drying conditions. Also, cotton planted deep may struggle to emerge if we get rains that cause soil crusting. Fortunately, the current outlook looks a lot better for precipitation in North Carolina. keith_edmisten@ncsu.edu

As I write this on the fourth of May, we have just had a string of storms slowly close the door on arguably the best late April/early May planting window of the past 10 years. Pockets of our production area have seen large percentages of our planned cotton acres planted, while in other areas many were focused on wrapping up full-season soybean and corn planting.

I currently believe we have more than 30% of our planned cotton acres planted, and now that most have their corn and soybean plantings completed, I believe we may be able to move through the remainder of our acres quickly should we be given another series of dry days soon. By the time you read this in early June, I hope many of you have begun to notice large squares on these earlier planted elds. While overall plant bug pressure last year was relatively light, clouded and tarnished plant bugs seemed to move into our cotton earlier than normal last year. is o en occurs during dry periods when eld edges appear less enticing

than our young cotton crop. I would encourage you to be vigilant early when scouting for these pests; if we can set low fruit on this crop, we could theoretically be looking at picking a large portion of our acres in September. traper@utk.edu

As I write this in early May, approximately 18% of the statewide cotton acres have been planted in Texas. According to the U.S. Department of Agriculture – National Agricultural Statistics Service Texas crop progress report, planting progress is about on pace with the ve-year average. Late winter and spring rainfall has greatly helped recharge soil moisture in many of the cotton-growing regions across the state, which is a welcome relief from the conditions growers have experienced the previous two years. Currently, the Upper Gulf Coast, Blackland Prairie, Rolling Plains and portions of the Southern High Plains are not in abnormally dry or drought conditions.

Many elds in the Lower Rio Grande Valley and Coastal Bend are squaring, and I’m hearing a few reports of elds just beginning to bloom in these regions. Scouting emphasis has shi ed over to cotton eahopper in these areas, and there have been reports of some elds being above economic threshold, triggering insecticide application. rips pressure has been particularly bad in areas of the Upper Gulf Coast early in the season, triggering over-the-top applications for these pests once young cotton grew beyond the two-leaf stage.

Rain has slowed planting progress in the Blackland Prairie, with some areas receiving as much as eight inches of rainfall in one event lately. Fields in this area will require an extended period of drying before growers can plant the remaining crop in the Blacklands. Growers in the Rolling Plains have received good rainfall in the past few weeks and months, and planting of irrigated cotton in this region will most likely ramp up beginning the second or third week of May and then shi over toward planting the dryland acres in late May and early June. bmcknight@tamu.edu

Warm air and soil temperatures in the Texas high plains have given growers a case of “planting fever” as we look to begin planting cotton earlier than normal. We typically anticipate a strong cool front the second week of May, but thus far have not seen that in the forecast. Frequent rainfall on the east side of the region has lled the soil pro le for most, making for a very optimistic start. However, soil moisture is still lacking on the west side of the region, especially along the Texas/New Mexico border area, where moderate drought and/or abnormally dry conditions persist.

Every season I attempt to advise growers to mitigate their risk by spreading their planting dates throughout May and early June (depending on their location), but inevitably, if growers get a window of opportunity in early May, they tend to keep planting! is is understandable, especially if planting is going well in that early time period. However, more o en than not, a cool front will move in and some portion of that early planted acreage needs replanting.

Speaking of replanting, I tend to be fairly conservative when it comes to replanting decisions because it is so costly. Although most transgenic seed companies have very good replant programs that cover as much as 75% of the seed costs, the remainder of the seed cost is still substantial, and there is the cost of diesel and opportunity costs (i.e., grower could be applying herbicides/insecticides in other elds,

etc.) to consider. Additionally, in most cases, a later-planted crop most likely will not yield as high as a more timely planted crop, so growers should also tabulate that risk. Even though there are instances where replanting makes the most sense, it should be rare and should be approached with caution.

ere is much interest in how many acres of cotton will be planted in the high plains this year. Acres have already begun to be planted in the northern plains (north of Amarillo); that area saw many prevented acres in 2023, and we expect to have the typical acreage planted in 2024. In the southern high plains, it is all about moisture, and there are few crop alternatives beyond cotton. As mentioned previously, the east side of the region has very good soil moisture conditions, and cotton acreage should be stable to up there. e west side and much of the sandier areas south of Lubbock do not have as much soil moisture; however, timely planting rains will make all the di erence. If the current weather pattern, which has chances of showers every ve to seven days, continues throughout May and early June, we could see acreage increase above that forecasted by USDA. If the pattern changes, it could be dramatically lower. Time will tell. ken.lege@ag.tamu.edu

The Texas Cotton Ginners’ Association hosted visitors from several cotton-growing areas during its annual meeting and cotton trade show in Lubbock this year. In recapping the event, the organization made the following comments:

“For our 116th gin show, we reached out across the Cotton Belt to bring ginners from across the country together under one roof in Lubbock. We rebranded our show as the ‘Cotton Belt Gin Connection’ and our theme for the year was ‘Linking Ginners Across the Cotton Belt.’

“We wanted to market this event as a ‘ginners show’ and be sure that cotton ginners across the country knew they were welcome to attend. We had several ginners from across the Cotton Belt come to Lubbock and hope to see our Beltwide attendance increase even more next year.

“Thank you to our exhibitors who invested time and resources into our show. Our exhibitors are the engine that drives the show, making it possible for ginners from across the Cotton Belt to come together and seek answers to some common problems. While in Lubbock, ginners can view the innovative technologies that are available to increase e iciency in their operations.

“The event brings excellent value just because of the group of people it brings together. The venue o ers the opportunity to see all the major suppliers in the cotton gin industry.”

The Texas Cotton Ginners’ Association also announced its slate of o icers for the new fiscal year. They include:

• Phillip Kidd (Lockney) – President

• Rex Ford (Stamford) – Vice President

• John Steelhammer (Mathis) - Secretary

• Mike Thompson (Bishop) – Immediate Past President

• Lance Bradford (Batesville) – Region 1

• John Engel (Palacios) – Region 2

• Willis Taubert (Miles) – Region 3

• Michael Yeary (Midki ) – Region 4

• Dan Jackson (Meadow) – Region 5

• Tony Newton (Slaton) – Region 6

• Curtis Stewart (Spade) – Region 7

• J. Kelley Green (Round Rock) – Executive Vice President & Treasurer

Several cotton industry leaders were honored for their significant accomplishments. In recognition of TCGA President Mike Thompson concluding his tenure, he and his wife, Letha, were presented a bourbon decanter with matching glasses and a bowl in appreciation of their leadership over the past year.

Ken Ross, manager of Needmore Gin in Meadow, was presented with TCGA’s most prestigious award – Ginner of the Year.

Ken will tell you when he first started at Needmore Gin, 90 bales in a shift was a productive day. The gin averaged around nine bales per hour. Many changes have been made at the gin over the course of Ken’s career, including splitting the overhead and moving to higher-capacity equipment.

The changes were done in small increments as Ken and his crew did much of the work on site. Ken has a small machine shop on-site and often cut and key-wayed shafts on his own. He notes this was a bit easier when the shafts were six feet long. With upgrades and higher-capacity equipment, the gin now averages around 34 bales per hour.

Ken credits his sta with the success he has had with the

gin. When he and Renee leave for a few days, he knows the gin is in good hands. LeeAnn Hancock Padgett is his o ice manager. Both her mother and grandmother worked at Needmore Gin. LeeAnn’s mother retired in the late 90s. Ken has two ginners who are instrumental to the success of the gin — Rafael Contreras and “Polo” Rodriguez. Rafael has been there since he was 16 years old, actually longer than Ken has been there. Polo has been there for 20 years.

Past President Chris Berry (general manager of Southwest Cotton Growers in Wellman) was presented with a Life Membership Award. He became the manager of Southwest Cotton Growers in 2022. Prior to this, Chris worked at Long “S” Gin and was the manager of Center Point Gin.

Before 2008, Chris was not in the ginning industry but was engaged in agriculture. He served as principal investigator and project manager at South Texas Ag Research — conducting chemical research trials and GMO trials — among other things.

Chris has served on many boards and continues to serve on others. He is a past president of Texas Cotton Ginners’ Association and Texas Independent Ginners Association as well as Plains Ginners Association. Chris currently serves as Chairman of the National Cotton Council’s Joint Cotton Industry Bale Packaging Committee as well as Chairman of the Packaging and Distribution Committee.

He is currently chairman of the TCGA Nominating Committee and is on the Board of Directors at the FiberMax Center for Discovery. Chris also was the driving force in getting the Goodman gin relocated into its new home at the FiberMax Center for Discovery.

A Life Membership Award also was given to TCGA Executive Vice President J. Kelley Green.

Chris Berry, le , was presented with a Life Membership Award. Joining Chris are Brendan Jaeger and Rändi Berry.

Kelley Green, TCGA executive vice president was also presented with a Life Membership Award this year. Joining Kelley are, from le , David Perez, Gwen Green-Perez, Adam Bartek, Marguerite Bartek, Kelley, Lynn Green and Madeline Brown.

Kelley’s first job in the ginning industry was gin field engineer in Fresno, California, with Western Cotton Services. In 1989, he was o ered an engineering position with Samuel Jackson, Inc., and he and his family moved to Lubbock, Texas. In 1991, he was hired as director of technical services for the TCGA. Kelley served as liaison between the TCEQ and the Texas ginning industry, helping to develop and implement the current cotton ginning permitting system that is used today. He also monitored, intervened and testified at multiple electrical tari hearings. Kelley participated in multiple organizations a ecting the industry on a national basis. He was a member of the U.S. Department of Agriculture air quality task force on multiple occasions and a member of the EPA clean air advisory committee. He served in this role until 2022 when he

Lummus Ag support an and adapt Lummus of profitable. your succe

Just a shor

g Solutions w d business. W to changing m

wants to expre With the chal market condi

ess its apprec llenges we fa itions and cus

became the TCGA executive vice president.

Kelley is a registered professional engineer in the state of Texas and member of the American Society of Agricultural and Biological Engineering. Along with serving on multiple committees in ASABE, he earned the Industry Service Award, the Agricultural Engineer of the Year Award and the Mayfield Cotton Engineering Award. Kelley currently serves on multiple important committees with the National Cotton Ginners’ Association and received the Distinguished Service Award in 2007. If there is a problem being dealt with in this industry, this individual is working on the solution.

To view more photos and short videos from the meeting and trade show, please visit TCGA’s Facebook page (Texas Cotton Ginners’ Association) and website (tcga.org).

ciation to our ce in our indu stomer needs

r many loyal c ustry, we are s.

ffers a wide ra Regardless ss.

t list of items w complete Gin P g Machinery (in ms, presses, etc. Consoles and M

All-new Ginning system Press C Burner Air Mon DGC 20

r and Moisture U nitoring and Fire 020 Gin and Fee

ange of produ of the project s we offer: Plants ndividual machin ) ain Control Con Unit Gas Train/C e Detection Kits eder Controls

ucts and serv t scope, cont

As our nam parts, servi

me states, we ice, or techni

nes, stand-alon

nsoles

stand ready t ical expertise

Controls upgrad s to offer you S e, we will be h

vices, all gear tact Lummus e des Gin

red to help yo to discuss yo

customers for continually w our operation our goals and

r their continu working to evo

n Dor-Les® and E

• 16” diameter

• Hydraulic Tram

E.E. Dor-Les® Pr r Bottom Ram Co mper/Pusher C

• Premier™ III S

Qua Unm

SOLUTIONS fo here for you n

be efficient a d needs to ens ress upgrades onversion

Conversion

Series Hydraulic ds (strain rods, b ir Parts ical Service

• Press Rebuild ality OEM Repai matched Techn or your busine ow….and into

ess. Whether o the future. ©

c Pumping Units boxes, sills, etc

ued olve and sure s .) it is machinery,

George D. Hodge

Istarted picking cotton when I was 10, Mama made a pick sack out of a 25-pound flour sack, and I was expected to fill it up, empty it and pick another. All the kids at that time started picking cotton at an early age and were expected to pick, not play. I thought it was fun because Mama cooked dinner (lunch), brought it to the field and started picking herself. At 12 o’clock, she spread an old quilt on the ground, and we ate. By the time I was 13 or 14, I realized this was work, not fun, and no matter how good dinner was, I didn’t like it.

In 1959, Dad bought a cotton picker. A onerow John Deere mounted on a model A John Deere. No power steering, a lousy hydraulic system and no cab. Normally, 12-15 people were picking two bales a day, and now I could pick two bales a day by myself. It don’t get better than this.

and rolling out the cotton. I had a better cab, and it was more comfortable to drive. It don’t get better than this.

As I rented more land, I needed more picking capacity. Despite advice not to do it from a good friend, I spread my planter to five rows and converted the four-row pickers (I had two now) to five rows. After trying this for a couple of years, I realized it CAN get better than this. It was time to trade again, so a 12-row planter and a six-row picker was purchased. WOW! I had a cab, a heater, an air conditioner, a better seat and a radio. I purchased a second six-row picker, and we were picking 70 acres a day. It don’t get better than this.

Almost overnight, module builders replaced trailers. After getting all the necessary equipment for building modules, I thought, it don’t get better than this.

“It had a CAB! No heater or air conditioner, but it had a CAB!”

After graduating from Auburn and serving Uncle Sam, I came home and had to finish Dad’s crop due to his illness. I continued to farm after his death and eventually traded for a used two-row picker. It had a CAB! No heater or air conditioner, but it had a CAB! No more trash going down my neck, no more wind whipping me, no more getting wet when I tried to go another round with rain visible in the distance. It don’t get better than this.

Eventually, I got up to four two-row pickers, but one day when two drivers faced each other on the same rows and came within five feet of a head-on collision, I knew it was time to change, so I bought a used four-row picker. Man, now I was picking four rows at a time

Just when everything seems to be stable, IH came out with a module-building picker followed by the “roller” picker by John Deere. Even though I never owned one of these pickers, I thought, it don’t get better than this. But it probably will. After picking cotton in some form or fashion for 72 years, my time has come to let younger farmers discover the next thing ‘that don’t get better than this.’ I’m sure it will come, just as it has in chemicals, seed and all the technology associated with farming over the past several years.

In 58 years of farming mostly cotton, I have gone from chopping and picking cotton by hand to chemical weed control, the eradication of the boll weevil and equipment that can literally run itself. Watching from the sidelines, I can’t wait to see what gets better than this.

— George D. Hodge Northern Alabama gdhodge4@gmail.comCotton Farming’s back page is devoted to telling unusual “farm tales” or timely stories from across the Cotton Belt. Now it’s your turn. If you’ve got an interesting story to tell, send a short summary to csmith@onegrower.com. We look forward to hearing from you.