PROFITABLE PRODUCTION STRATEGIES www.cottonfarming.com ONE GROWER PUBLISHING, LLC OCTOBER 2022 Enterprising West Texan Builds Career On Cotton And Peanuts

Vol. 66 No. 10

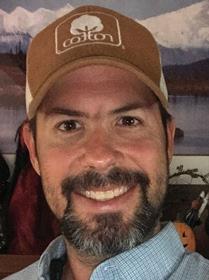

West Texas farmer Jake Teichroeb runs a 12,000-acre operation — some irrigated, some dryland. His primary crop is cotton, and he also has peanuts and cattle. Teichroeb raises winter wheat for the cows and collects some of the seed to grow a cover crop to protect his cotton. He is an owner in Trico Peanut — a buying point and a sheller — and he and his partners recently started a new business called Texas Roasting Co.

ON THE COVER: West Texan Jake Teichroeb rotates cotton and peanuts in Dawson and Gaines counties. Cover photo by Carroll Smith.

COTTON

OCTOBER 2022

www.cottonfarming.com

FEATURES

6 FIELD WATCH

In remembrance of the Cotton Consultants of the Year whose careers were marked by early mornings, busy days, but above all, a commitment to farmers.

17 THE P.I.E. TOUR

Cotton farmers who participated in the Producer Information Exchange program this year visited regions di erent from their own.

19 GINNERS MARKETPLACE

the official publication of the ginning industry J. Kelley Green, TCGA executive vice president, discusses likely increases in electricity rates and why this issue may have an impact across the Cotton Belt.

WEB EXCLUSIVE

Texas A&M AgriLife Research is anticipating the largest competitive grant in the organization’s history, up to $65 million, to execute a five-year multi-commodity project to work with Texas’ large agricultural sector on expanding climate-smart agriculture and forestry practices. The grants are part of a federal investment in 70 partnerships recently announced by the U.S. Department of Agriculture. Go to www.cottonfarming.com for this Web Exclusive report.

DIGITAL OFFERINGS

Keep up with the latest from Cotton Farming by signing up for the monthly E-News at www.cottonfarming.com. Look for the Cotton Farming E-News sign-up box in the upper right corner of the home page.

Facebook: https://www.facebook.com/cottonfarming

Twitter: @CottonFarming

Instagram: @CottonFarmingMagazine

ices.

Send address changes

Northbrook, IL 60065-1388 (Phone: 847-559-7578) (Fax: 847-564-9453). Annual subscriptions are $40. International rates are $55 in Canada/Mexico, $90 in all other countries for air-speeded delivery. Surface delivery not available due to problems in reliability.

TWITTER: @COTTONFARMING OCTOBER 2022 COTTON FARMING 3

FARMING (ISSN 0746-8385) is published monthly January through December by One Grower Publishing LLC, 875 W. Poplar Ave., Suite 23, Box 305, Collierville, TN 38017. Periodicals postage paid at Memphis, Tennessee, and at additional mailing o

POSTMASTER:

to Omeda Communications, Customer Service Department, P.O. Box 1388,

8 Cotton And Peanuts 4 Editor’s Note 5 Cotton’s Agenda 11 Industry News 12 Specialists Speaking 16 Research & Promotion 22 My Turn

PROFITABLE PRODUCTION STRATEGIES

DEPARTMENTS & COLUMNS

Editor’s Note

Cotton Pickin’ Excerpts

Fall has arrived, and it’s cotton pickin’ time. In the My Turn column that appears each month on the back page of Cotton Farming, the authors — our readers — often wax nostalgic as they recall personal cotton pickin’ experiences. To get everyone in the mood for harvest, I am sharing some My Turn excerpts that exemplify these musings from the past.

“Peanut — A Cotton Pickin’ Cat,” Cindy Faulkner, January 2022. In 2007, I wondered if Peanut would ride the picker again or freak out from the noise and movement. She was 100% house cat, not a barn cat. I took her up the steps on my shoulder. … She has picked cotton with me for 16 consecutive years even though she is only 15 years old.

“A New Cotton Sack,” Neil Joiner, October 2021. I’m not sure why I thought a new cotton sack would improve my picking skills, but it was like the call of the sirens that sailors hear on the ocean. I asked Uncle Emmett if I could charge it and pay him back when I picked some cotton. He didn’t try to talk me out of it or tell me I’d have to ask Daddy. He sent me on my way with that new cotton sack and my own charge account.

“California Cotton Picking Contest Of 1935,” Stan Wilson, September 2020. The Bakersfield Californian, which was an afternoon paper at the time, reported that just before noon, Luis Castenada had picked 368 pounds with a bag waiting to be weighed. His brother, Trinadad, was second with 352 pounds. Bets were being taken as to which brother would win.

“A Cotton Pickin’ Exciting Time,” Francis & Sally Hulshof, April 2018. So, she lifted her cotton sack onto the horse’s back. She was going to get on too, but the horse took off, and the cotton flew everywhere! Boy, was she in trouble.

“Not A Cotton Picker,” Patrick Shepard , June 2016. Hal said he was watching his brother pick, and their father remarked, “He’s a cotton-pickin’ dude.” Hal nodded. “That he is.” Then the father regarded Hal, smiled, and said, “And you’re a dude pickin’ cotton.”

“Cotton Harvest and ‘Winner’ Suckers,” Marcia Kiser, April 2016. And at six years old, I didn’t have the weight, or the strength, to tromp any cotton down. All I did was sink. As soon as I could, I cried “uncle” and asked to get out and return to the safety and security of the pickup.

“Riding To The Gin,” Robert Royal, September 2014. When the truck started the steep climb up the elevated highway bank, my face got plastered against the back glass. From there, I could see the trailer buck and kick behind us. Truck tires growled viciously in the grass. When the old Chevy jerked the trailer across the ditch, it seemed to explode as if Zeus had energized the lightning bolt logo with 10 million volts.

To read these essays in their entirety, go to cottonfarming.com, click on Departments and then click on My Turn. Here’s to a bountiful harvest!

Cotton Farming

EDITORIAL/PRODUCTION

Editor-In-Chief Carroll Smith csmith@onegrower.com

Southeast Editor Amanda Huber ahuber@onegrower.com

Associate Editor Cassidy Nemec cnemec@onegrower.com

Digital Content Editor Katie Guthrie

Art Director Ashley Kumpe

ADMINISTRATION

Publisher/Vice President

LiaGuthrie (901) 497-3689 lguthrie@onegrower.com

Associate Publisher/Editor-In-Chief CarrollSmith (901) 326-4443

Associate Publisher/Sales Scott Emerson (386) 462-1532 semerson@onegrower.com

Production Manager David Boyd dboyd@onegrower.com

Audience Services Kate Thomas (847) 559-7514

For subscription changes or change of address, call (847) 559-7578 or email cottonfarming@omeda.com

EDITORIAL ADVISORY BOARD

David Burns – North Carolina

David Lynch – South Carolina

Bob McLendon – Georgia

Larkin Martin – Alabama

Mike Sturdivant Jr. – Mississippi Charles Parker – Missouri

Jimmy Hargett – Tennessee

Allen Helms – Arkansas

Jay Hardwick – Louisiana Ronnie Hopper – Texas Ron Rayner – Arizona John Pucheu – California

Mike Lamensdorf PRESIDENT/TREASURER Lia Guthrie PUBLISHER/VICE PRESIDENT

ACKNOWLEDGEMENT OF COOPERATION: Cooperating with COTTON FARMING are various cotton producer organizations across the Cotton Belt. Many representatives of producer organizations serve on COTTON FARMING’s editorial advisory board. Opinions expressed and conclusions reached by contributors are not necessarily those of the cooperating organizations or the editors. All statements, including product claims, are those of the person or organization making the statement or claim. The publisher does not adopt any such statement or claims as its own and any such statement or claim does not necessarily reflect the opinion of the publisher.

Copyright 2022 ©

CarrollASSOCIATED PUBLICATIONS – One Grower Publishing, LLC also publishes RICE FARMING, THE PEANUT GROWER, SOYBEAN SOUTH and CORN SOUTH

If you have comments, please send them to: Cotton Farming Magazine, 7201 Eastern Ave., Germantown, TN 38138.

Carroll Smith

Carroll Smith

4 COTTON FARMING OCTOBER 2022 COTTONFARMING.COM

One Grower Publishing, LLC 875 W. Poplar Ave., Suite 23, Box 305 Collierville, TN 38017 ONE GROWER PUBLISHING, LLC

Cotton’s Agenda

A Solution For Success

The National Cotton Council’s export promotions arm, Cotton Council International (CCI), is finding its new global textile manufacturing advisory initiative very popular — and resulting in significant purchases of U.S. raw cotton.

What is this cotton consultancy?

■ CCI created the COTTON USA SOLUTIONS™ program to help textile manufacturing firms achieve greater profitability through improved productivity, including use of the latest technology/ techniques. The SOLUTIONS™ team of experts created five business-building programs and is working with more than 1,500 mills in 50 countries. The programs are complimentary for U.S. Cotton Trust Protocol® members or COTTON USA™ licensees, and are available in person or virtually.

How do the five SOLUTIONS™ programs help?

■ The 1:1 Mill Consults program can help manufacturers reduce operational costs by 10% to 25% as it brings to the mill a world class mill expert for a one-day, in-depth mill examination followed by a consult that can last one or two weeks and then a follow-up six months later to determine if the adopted measures have generated the desired results.

Through Technical Seminars, the SOLUTIONS™ technical consulting team advises the mill executives/staff on how to buy and optimize the use of U.S. cotton. Topics include best practices in spinning, handling, managing consistent quality and purchase strategy.

The third program, the Mill Mastery® Course, helps SOLUTIONS™ clients gain a new level of expertise with this informative course of study led by experts who have a combined 200 years plus experience. Next, the mill studies program provides a unique

collection of research that offers hard data to boost mill efficiencies. Research topics range from the technical and financial advantages of different cotton types in various stages of the process, to dye uptake, the impact of fiber quality and more.

The Mill Exchange Program enables mill executives to tour COTTON USA™ licensee “Signature Mills” and learn more about U.S. cotton’s advantages. They exchange ideas with textile mill leaders from around the world and discuss best practices in yarn manufacturing, procurement, production and more — all with the aim of becoming more competitive.

Expected future sales of 1.7 million U.S. cotton bales resulted from the 10 technical seminars/webinars conducted in seven countries. Estimated future sales of 257,000 U.S. cotton bales stemmed from 87 mill visits in nine countries. The 23 mill executives representing 23 mills from three countries who participated in the Mill Mastery® course indicated they expect to purchase an additional 531,000 U.S. cotton bales.

Have CCI’s other programs had an impact this year?

■ Participants in CCI-coordinated webinars to raise awareness of the U.S. Cotton Trust Protocol® sustainability initiative expect to purchase 452,000 additional U.S. cotton bales. The 19 Pakistani textile executives who participated in CCI’s Special Trade Mission here expect to purchase an additional 575,000 U.S. cotton bales.

CCI’s Western Hemisphere Sourcing Fair attracted 112 executives representing eight U.S. yarn and textile companies, 35 Latin American textile/garment manufacturing companies, and 20 U.S. and Latin American brand, retailer and corporate image wear firms. Some $18 million of U.S. cotton-rich product purchases are expected from the Latin American firms. CCI’s Cotton Days Northeast Asia attracted 665 brand/retailer and mill attendees — and 80% of the mills are expected to purchase an additional 630,000 U.S. cotton bales.

Gary Adams is president/CEO of the National Cotton Council of America.

Cotton Council International created the COTTON USA SOLUTIONS™ program to help global textile manufacturing firms achieve greater profitability.

Gary Adams

TWITTER: @COTTONFARMING OCTOBER 2022 COTTON FARMING 5

Bayer is a member of Excellence ThroughStewardship® (ETS). Bayer products are commercialized in accordance with ETS Product Launch Stewardship Guidance, and in compliance with Bayer’s Policy for Commercialization of BiotechnologyDerived Plant Products in Commodity Crops. Commercialized products have been approved for import into key export markets with functioning regulatory systems. Any crop or material produced from this product can only be exported to, or used, processed or sold in countries where all necessary regulatory approvals have been granted. It is a violation of national and international law to move material containing biotech traits across boundaries into nations where import is not permitted. Growers should talk to their grain handler or product purchaser to confirm their buying position forthis product. Excellence Through Stewardship® is a registered trademark of Excellence Through Stewardship.

ALWAYS READ AND FOLLOW PESTICIDE LABEL DIRECTIONS. It is a violation of federal and state law to use any pesticide product other than in accordance with its labeling. NOT ALL formulations of dicamba, glyphosate or glufosinate are approved for in-crop use withproducts with XtendFlex® Technology. ONLY USE FORMULATIONS THAT ARE SPECIFICALLY LABELED FOR SUCH USES AND APPROVED FOR SUCH USE IN THE STATE OF APPLICATION. Contact the U.S. EPA and your state pesticide regulatory agency with any questions about the approval status of dicamba herbicide products for in-crop use with products with XtendFlex® Technology.

B.t. products may not yet be registered in all states. Check with your seed brand representative for the registration status in your state.

Performance may vary, from location to location and from year to year, as local growing, soil and weather conditions may vary. Growers should evaluate data from multiple locations and years whenever possible and should consider the impacts of these conditions on the grower’s fields.

Products with XtendFlex® Technology contains genes that confer tolerance to glyphosate, glufosinate and dicamba. Glyphosate will kill crops that are not tolerant to glyphosate. Dicamba will kill crops that are not tolerant to dicamba. Glufosinate will kill crops that are not tolerant to glufosinate.

Contact your seed brand dealer or refer to the Bayer Technology Use Guide for recommended weed control programs.

Insect control technology provided by Vip3A is utilized under license from Syngenta CropProtection AG. Bayer, Bayer Cross, Bollgard®, Respect the Refuge and Cotton Design®, Roundup Ready 2 Xtend® and XtendFlex® are registered trademarks of Bayer Group.LibertyLink® and the Water Droplet Design® is a trademark of BASF Corporation. All other trademarks are the property of their respective owners. ©2022 Bayer Group. All rights reserved.

Field Watch

To Those Who Served Farmers

BY CARROLL SMITH EDITOR

Their day typically begins before sunrise as they roll out of bed, pull on their boots and head to the fields. Their trucks are full of tools of the trade — cell phones, laptops, notebooks, sweep nets, drop cloths and maybe a pack of Nabs or a protein bar to sustain them on the turnrows while they check your crops throughout the long, hot days. These are cotton consultants — most of whom will say their profession is more than a job. It’s personal.

Since 1981, the Cotton Consultant of the Year peer recognition award, sponsored by Syngenta and Cotton Farming magazine, has paid tribute to this critical segment of the cotton industry. Through the years, we have been saddened to hear of the passing of some of these individuals whose careers were marked by commitment to farmers, early mornings and busy days.

This summer, Mills Rogers Jr., who was selected as the Cotton Consultant of the Year in 1990, passed away July 12. He started Rogers Entomological Services in Cleveland, Mississippi, in 1954 for 75 cents an acre and ran it until he retired in the late 1990s. His son, Lee Rogers, took over the family business at that time.

According to a 1991 tribute written by Cotton Farming Editor Patrick Shepard, “Rogers normally services from 35 to 40 cotton producers. About 60 percent of the cotton that he handles is farmed in the Missouri Bootheel. … Five years ago, Rogers began using motorcycles to get around his cotton acreage. ‘At first, I laughed when other consultants began using

motorcycles. But I saw they were checking a little more acreage than I was and they weren’t worn out at the end of the day. So we added Honda 200 Fat Cats to our business.’”

In another tribute published that year, Rogers was asked, “You are a pioneer of the modern cotton consultant. Would you recommend consulting as a livelihood to a younger person?”

He answered, “Yes, if he or she doesn’t mind hard work in addition to being trustworthy. When the grower asks him if he walked the back of that field next to the trees, the consultant will have to be ready to tell the truth. The grower usually knows where you’ve been on his farm.

“I think we have both professional entomologists and scouts in the consulting business. Those of us who make a living out of consulting and depend on six to seven months of the year have to always assume a professional manner.”

The working relationship between a consultant and his farmers is based, in large part, on mutual respect and trust. Thanks go out to those we have lost and those who are still watching the cotton fields and making recommendations to keep their producers profitable.

In Remembrance

• Bob Stanford: 1981 CCOY – Flagstaff, Arizona

• Jep Gates: 1982 CCOY – Memphis, Tennessee

• Dennis Bouchard: 1983 CCOY – Minter City, Mississippi

•

John Nickelsen: 1984 CCOY – Shafter, California

Stanley Nemec: 1987 CCOY – Snook, Texas

Robert Moore: 1988 CCOY – Hartsville, South Carolina

Curtis Wilhelm: 1989 CCOY – Harlingen, Texas

Mills Rogers: 1990 CCOY – Cleveland, Mississippi

John Christian: 1992 CCOY – Raymondville, Texas

Lonnie Bull: 1997 CCOY – Cameron, South Carolina

John Hunter: 2005 CCOY – Lubbock, Texas

•

Mills Rogers, 1990 Cotton Consultant of the Year

6 COTTON FARMING OCTOBER 2022 COTTONFARMING.COM

PROTECTION THAT WILL PUT YOU A STEP AHEAD UNPROTECTED PROTECTED RESULTS THAT STAND OUT GET PROTECTION THAT WILL PUT YOU A STEP AHEAD WITH THE INDUSTRY’S FIRST COTTON BIOTECH TRAIT TO PROTECT AGAINST FEEDING DAMAGE FROM KEY TARNISHED PLANT BUGS AND THRIPS SPECIES* See what proven protection looks like at THRYVON.COM.

Enterprising West Texan

Builds Career On Cotton And Peanuts

BY CARROLL SMITH EDITOR

Jake Teichroeb’s father, John, was part of a Mennonite community in Mexico that moved to west Gaines County, Texas, to pursue various agricultural occupations. The elder Teichroeb began as a custom harvester of wheat and cotton and eventually got into farming.

“As a little kid following Dad around, I grew up in farming,” Jake said. “That’s all I knew. In my early 20s, I worked for a short time for one of my brothers who was established in the irrigation business building circle pivots. But I soon realized I missed farming.”

While working in construction, the young Texan was always out in other people’s fields from the Rio Grande Valley to Kentucky and everywhere in between. As he learned about dif-

ferent crops and production techniques, he knew farming was in his blood, and he needed to go back.

“When Dad got a little older, he offered to lease the farm to some of my brothers and me,” Jake said. “There wasn’t enough land for all of us, so my brother, Poncho, and I split the farm in half in 2005, and the other brothers found land to rent somewhere else. Prices were fair, and it was a rainier time, so we were making good crops and doing well.”

The two brothers began looking for more land, but the competition was heavy in Gaines County. When 640 acres became available in Dawson County, Jake and Poncho worked out a deal that resulted in Jake farming the Dawson County property and Poncho taking over Jake’s half of the family land in Gaines

Cotton and peanut farmer Jake Teichroeb is pictured with his family in Dawson County, Texas. From left are: Kooper, Maelie, Diamond, wife Chloe, Jake, Clay, Lane and Malachi.

PHOTO COURTESY OF JAKE TEICHROEB

Cotton and peanut farmer Jake Teichroeb is pictured with his family in Dawson County, Texas. From left are: Kooper, Maelie, Diamond, wife Chloe, Jake, Clay, Lane and Malachi.

PHOTO COURTESY OF JAKE TEICHROEB

8 COTTON FARMING OCTOBER 2022 COTTONFARMING.COM COVER STORY

County.

“I was lucky enough to be surrounded by some older farmers in Dawson County who were getting ready to retire and didn’t have kids standing in line to take over,” Jake said. “This allowed me to pick up land, mostly in Dawson County, pretty much every year since I started farming. Although I let the family land go in Gaines County, I did end up picking up some more land in that area.

“Today, we run a 12,000-acre operation — some irrigated, some dryland. Our primary crop is cotton, and we also have peanuts and cattle. We raise winter wheat for the cows and collect some of the seed to grow a cover crop to protect our cotton the next year.

“My oldest son, Clay, who is 20, is working for me on the farm now. I will eventually move Lane, 18, and Malachi, 16, out here as well. Right now, Lane is working at the peanut plant, and Malachi is still in school.”

Cotton And Peanut Rotation

As his father had always done, Jake rotates cotton and peanuts. He said the system most farmers use around there is to plant peanuts where water is available and put cotton on the dryland. The exception is where the dirt is not that good for peanuts, they will plant cotton and irrigate it.

Gaines County is often called peanut country, and Dawson County is known as cotton country.

“The reason for this is that cotton tolerates salinity in the water pretty well, but peanuts do not,” Jake said. “The quantity of water on my Gaines County farm is no

better than it is here in Dawson County, but the water quality is better so the peanut crop in Gaines County is beautiful compared to the one in Dawson County.

“At times, I’ve been laughed at for farming peanuts in Dawson County. A man once told me, ‘You’re trying to grow peanuts in cotton country,’ and he has a good point. That’s why I typically have about a third more peanut production per acre in Gaines County.”

In 2021, Jake planted almost 100% to PHY 480 W3FE on his cotton acres.

“Unlike this year, in wetter years when there is underground moisture, and you know you stand a chance of making a dryland crop, 480 is a good one to plant,” he said. “It does well on my farm. Last year, my average yield for 480 was 1,300

pounds per acre. We also had a PhytoGen test plot with an experimental variety (now available as PHY 411 W3FE), and it did really well. It may be one we switch to on our better, irrigated land.

“One of the reasons I grow PhytoGen cottonseed is that it is the best I’ve ever seen when it comes to vigor. When I plant my cotton, I chase moisture. If I have some underground moisture, I put the cotton in a little deeper to make sure I am in a good moisture bed.

“But if I get a rain on it and the sun comes out the next day and it is hot, it’s like pouring a layer of concrete over your cotton. That happened to me last year, but I didn’t have to replant all of those fields. That’s when I became a big believer in PhytoGen’s vigor.”

The West Texas farmer said choosing the right variety for your farm is critical. He considers numerous factors when making his variety choices and relies heavily on the research done by Scott Fuchs, his PhytoGen cotton development specialist.

“If Scott tells me a certain PhytoGen variety is good for my area, I am going to plant some of it,” he said. “I also make sure the varieties I plant are nematode resistant.”

Herbicide Resolves Challenges

The primary nuisance weeds Jake has to contend with in his cotton crop are pigweed and tumbleweed. When pigweed developed resistance to glyphosate, and the population exploded, he couldn’t find enough people to chop them out of his fields.

West Texan Jake Teichroeb rotates cotton and peanuts in Dawson and Gaines counties.

TWITTER: @COTTONFARMING OCTOBER 2022 COTTON FARMING 9

DVEST/DREAMSTIME

“The weeds were growing faster than we could contain them,” Jake said. “I had to walk away from some fields because we lost control. I was discouraged and wondered if it was time to quit farming. Then the Enlist weed control system was launched, and I started using it. Enlist herbicides killed the grass and tumbleweeds, as well as pigweeds. This gave me a whole new outlook on the farming business.”

Another challenge Jake faced in his cotton and peanut rotation was having one half of a circle in cotton and the other half in peanuts, so the rows touched each other. Over the years, he knew he would burn and kill some cotton rows and some peanut rows because of the different herbicides used on each crop. 2,4-Db was used to kill weeds in peanuts but would damage any cotton it drifted onto. On the other hand, herbicides used to kill weeds in cotton damaged the peanuts.

“One of the main reasons I switched to PhytoGen varieties is the Enlist herbicide technology,” Jake said. “When the Enlist weed control system was launched, it made my life a lot easier because I am

essentially using a form of 2,4-D on both crops. If Enlist drifts on peanuts or 2,4Db drifts on cotton, there is no damage. That herbicide system saved my career.”

Peanut Facilities

To make his peanut operation more sustainable, Jake and two other farmers established Trico Peanut — a peanut buying point and a sheller — in 2015 in Seminole, Texas.

“The way it works is the farmer sells the peanuts to a buying point, and then we shell them, clean them up, put them in 2,000-pound bulk bags and sell them to consumers,” he said. “We are mostly Virginias, which are not grown for peanut butter. We found a market for them, and it works for us.”

In a move to become vertically integrated, the partners recently started a new business called Texas Roasting Co. next door to Trico.

“Now we are the farmer, the sheller and the roaster,” Jake said. “We have a manager who runs the business. Right now, we grow a lot more peanuts than the roasting company can handle, but we hope one day to get to the point that the

company can consume all our peanuts.

“This past year when we were preparing to launch the company, I spent a lot of time over there building the business and marketing our product. Once we are consistently roasting and turning out packaged, branded product, I can step back some. But while the company is in development, I need to be hands on.”

A Five-Year Plan

Jake said this year was a tough one because of the drought — the worst he has seen during his farming career, including 2011. Following a season of challenging environmental conditions can make it difficult to mentally prepare yourself to move forward and plan for the upcoming season.

“It worries you,” he said. “This was a rough year, but last year was very good to us. I’ve always said, ‘Never farm one year at a time. Farm five years at a time.’ I’ve seen years where I couldn’t pay the bank back and had to finance something to finish up.

“Because we had a good year last year, I paid off as much as I could to build some equity and looked for ways to minimize my expenses. Then when another rough year comes around, we can survive it.”

Texas Roasting Co. offers salted, in-shell peanuts. Flavors for the kernels include salted, lemon salted, hot and spicy, habanero, jalapeño and chili and lime.

PHOTO COURTESY OF JAKE TEICHROEB

West Texas farmer Jake Teichroeb runs a 12,000-acre operation and is a partner in Trico Peanut and the newly launched Texas Roasting Co.

CARROLL SMITH

10 COTTON FARMING | OCTOBER 2022 COTTONFARMING.COM

Industry News

U.S. Cotton Trust Protocol Launches 3-Year Enrollment

Trust Protocol participating producers will find the new streamlined enrollment for the 2022-2024 crops easy and quick. Production data, which remains confidential, now can be more efficiently uploaded into the Protocol platform, thus paving the way for a potential redistribution of program revenue.

As before, crop consultants can be authorized to enter information and the John Deere Operations Center can pre-populate up to 40% of the data needed to complete the Fieldprint analysis for those utilizing the Protocol platform.

Conservation Districts trap loan program or receive direct control through APHIS.

The Texas Feral Swine Eradication and Control Pilot Program activities are funded through a U.S. Department of Agriculture-Natural Resources Conservation Services grant and administered by the Texas State Soil and Water Conservation Board.

TFB Distributes Nearly $178,000 To Wildfire Victims

established 1981

Footprints In The Field

To learn more or begin enrollment, visit www.TrustUSCotton.org or reach out to the Grower Helpdesk at growers@ trustuscotton.org.

Thanks to nearly 150 generous contributions, Texas Farm Bureau (TFB) and its West Texas Wildfire Relief Fund recently distributed $177,930 to farmers and ranchers impacted by spring wildfires in the state.

Feral Hog Control Workshop: Nueces County, Texas, Oct. 13

A group of Texas agencies is working together to help landowners address the issues that feral swine pose to agriculture, ecosystems and the health of humans and animals.

Several workshops were held in September, and one will be offered in Nueces County Oct. 13 from 10:30 a.m. to 1:30 p.m. at the Johnny Caledron Building, 710 E. Main St. Suite 1, Robstown. Contact Jaime Lopez, AgriLife Extension agent for Nueces County at jaime.lopez@ag.tamu.edu.

Feral swine are a threat to waterways and ecosystems as their numbers rapidly increase daily across the state. Texas is a private-land state, with 83% of its land mass in family owned farms, ranches and forests, making education and awareness of wild pig damage a priority for maintaining healthy ecosystems.

Providing learning opportunities to landowners about effective management strategies remains crucial to the success of abating damages associated with these feral swine.

The Feral Swine Control Pilot Program consists of a “smart trap” loan program, educational and outreach activities, and direct-control activities by Animal and Plant Health Inspection Service. Landowners in participating counties may be eligible to use a feral swine smart trap on their property through the Soil and Water

“While the wildfires were still burning, Farm Bureau members, organizations and others from across the state called in asking how they could help,” TFB President Russell Boening said. “While this aid cannot replace everything that was lost, we hope it truly helps those still recovering from the disaster.”

Wildfires burned more than 150,000 acres across the state in March, causing millions of dollars in damage. Fires devoured pastureland and farmland, livestock, homes, barns and equipment.

Farmers and ranchers with unreimbursed agricultural losses were encouraged to apply for assistance. The TFB West Texas Wildfire Relief Fund was established through the organization’s nonprofit Agriculture Research and Education Foundation.

“We cannot say thank you enough for the generous contributions sent in to help our fellow Texans,” Boening said. “Farm Bureau members have always stepped up to help their neighbors in need, and this wildfire relief fund collected tax-deductible donations to meet the needs in affected areas.”

A group of volunteer leaders selected by the TFB board of directors determined the allotment of aid. TFB and non-TFB members received funding for unreimbursed expenses related to the wildfires.

“Farming and ranching is an expensive business,” Boening said. “We hope with this support, those impacted can continue to rebuild and recover from the wildfires that devastated areas of our state.”

CCO

The Cotton Consultant of the Year award, sponsored by Syngenta and Cotton Farming magazine, has honored the “boots on the ground” segment of the industry for more than four decades. The prestigious award recognizes a cotton consultant who demonstrates outstanding customer relations, leadership and innovation.

Each year, the nominees are voted on by the past CCOY recipients. This award is even more special as the winner is chosen by his or her peers.

Syngenta and Cotton Farming are pleased to sponsor an award that recognizes the vital role cotton consultants play in production agriculture.

The services consultants provide their farmer clients are invaluable for achieving e iciency and profitability.

Cotton Consultant of the Year sponsored by

Cotton Farming

YOne sionate farmers Trust Gary president ment Protocol retailers in sustainable also tainability over-year data anonymously producers.” White Protocol “We retailers are growing right says. increase ter price, Cotton nies Everyone vide “There and Go to and you mon You a few

TWITTER: @COTTONFARMING OCTOBER 2022 | COTTON FARMING 11 “We safe, a chance U.S.

Cotton Consultant of the Year

10 COTTON FARMING | OCTOBER 2021

CCOY

2022 Harvest Update

NORTH CAROLINA Keith Edmisten

Growers should be checking fields for boll maturity to get an idea of which fields can be defoliated first. The easiest way to get a good start scheduling fields for defoliation is to check for nodes above cracked boll (NACB). Just like scouting for insects, you should get a random sample of the field as some areas may be more or less mature than others. Generally, it is safe to defoliate when NACB is four or less.

To measure NACB, you find plants with a boll cracked open enough to see some lint and count the nodes from there to the highest harvestable boll. It is a good idea to check further by cutting some of the youngest harvestable bolls to make sure that the seed is developed and that the seed coat is turning brown.

On skippy stands, you need to consider not only the top portion of the crop, but also look at younger bolls down in the canopy on outer positions and vegetative branches. Starting defoliation on time can get the pickers in the field to take advantage of longer days to shorten the harvest period and minimize losses. keith_edmisten@ncsu.edu

TENNESSEE Tyson Raper

As I write this Sept. 10, only a handful of acres have received a harvest aid application. Our earliest planted acres will likely see applications next week as the forecast moves into what appears to be a warm, dry window. Temperatures in September have been milder than average, but we all hope the warming trend holds through October.

August made clear that the yield potential of our later planted dryland acres far exceeds that of our earliest planted dryland acres, but just how good those late-planted acres will be hinges upon our length of season. Most canopies are full of juvenile growth, and some already have basal regrowth. Thidiazuron will be our product of choice until nighttime temperatures slip out of the 60s due to its effectiveness on this type of growth.

Because of our season, I don’t expect much control of regrowth — even at high rates. Timing the picker behind the sprayer is going to be very important this year until temperatures fall into the 50s. I’ll be updating recommendations as we move through September and into October, so check news.utcrops.com periodically for that information. traper@utk.edu

GEORGIA Camp Hand

As I write this Sept. 9, we are currently in a weather pattern in Georgia no one wants to be in if you are in agriculture. Overcast, extremely humid and rainy almost every day. We have even had some flooding in the past week in the northern part of the state. My hope is that we exit this weather pattern sooner rather than later so we can really get going on some of this cotton.

Historically, by the first week of October, Georgia growers have harvested approximately 13% of their crop according to the USDA Crop Progress Report. As I’ve mentioned in my previous Specialists Speaking comments, our 2022 crop is ahead of schedule in my opinion, so I hope we are at or above that number by the time you are reading this. I know of a few fields in South Georgia that have been defoliated in the first week of September, so it is only a matter of time before we get started.

As we approach defoliation and harvest, one thing I have been mentioning is that we have too much money tied up in this crop. Many growers tell me it is the most money they have ever spent growing a cotton crop. Let’s be timely with defoliation and harvest, get the crop out of the field and on the gin yard and get our growers paid.

As always, your local UGA county Extension agent and specialists are here to help! Reach out if you have any questions. camphand@uga.edu

FLORIDA David Wright

Timely harvest keeps quality and yield of cotton. October is generally the driest month of the year, and the number of daylight hours are limited as growers try to finish harvest. Tropical storms and hurricanes can ruin the crop if you are harvesting other crops while cotton should be harvesting.

Cotton, peanut and soybean will generally finish up in October aside from late-planted crops harvested in November. It is very critical to take advantage of good harvest days since November is cooler and takes longer for the dew to dry off. Harvest capacity for all crops should be sufficient for maximum quality and yield.

Defoliating cotton under cool conditions later in the fall is different than defoliating in September and early October. Rates of harvest aids should increase to expect the same kind of results as you received earlier in the season. Most cotton should be picked by late October. The number of harvestable acres decreases rapidly due to short days and cooler temperatures, which also results in a longer time to dry out after rains.

Many growers plant cover crops after harvest/stalk mowing. Fields can be leveled with a harrow if ruts were formed in the growing season or at harvest. If fields are to be grazed, cover crops should be planted as soon as possible following harvest to expect early grazing. If all operations are done using no-till, and cotton is to be planted again the next year, precision placement of rows can make a difference in yield the following year. By moving rows from the previous year’s row to the row middles, yields can be increased by 25% to 35%. Nematodes can also survive on cotton roots and grow until mid-December if this is not done.

Timeliness is critical for each operation to make the best quality and yield. wright@ufl.edu

ALABAMA Steve M. Brown

Early in September, it’s difficult to accurately predict what kind of crop we’ll gin. Past years have demonstrated that September and October, which rank among our driest periods according to long-term data, can steal our crop because of inclement weather. Late August was not kind to many because of extended cloudy days, frequent showers and subsequent hard lock and boll rot. In early September, we experienced a few days of sunshine and then more cloudy weather and scattered rainfall. So much for weather averages.

Harvest is often a time of RUSH. Hurry up; get ‘er done! Let’s pick this crop. I’m all for that, but it must include attention to safety, especially on the road as equipment moves from field to field.

In that regard, I climbed in a pickup with a farmer this summer to look at stand problems and quickly realized I shared the front seat with a rifle and a shotgun. I assumed the firearms were for hog control, but when asked, the farmer let me know he stuck one out the window when impatient motorists blew the horn behind his crew as they moved equipment

12 COTTON FARMING | OCTOBER 2022 COTTONFARMING.COM

Specialists Speaking

Specialists Speaking

along the back roads and highways. I assumed he was kidding.

In recent months, I’ve followed minutes behind two collisions involving 18-wheelers and farm equipment. e rst occurred in June at the end of planting. On a wide, four-lane highway with a signi cant grassy median and perfect visibility, a big tractor-trailer truck clipped a planter. e planter was damaged but nothing more, and, thankfully, no one was hurt.

A second event occurred in August on the same highway a few miles north of the earlier accident. An 18-wheeler with a atbed trailer carrying copper collided squarely with a large John Deere sprayer. e truck front hit both back tires/legs of the sprayer and totaled truck and sprayer, but the truck looked considerably worse. A er I weaved around debris on the highway, I encountered multiple law enforcement and emergency vehicles headed to the site. I heard later no one was seriously injured, which was rather remarkable given the severity of damage.

Farm equipment and vehicle collisions usually end much worse for the farmer. Be safe. cottonbrown@auburn.edu

MISSISSIPPI Brian Pieralisi

As I write this Sept. 9, we are toeing the line between defoliation and harvest. Some harvest aids were applied this week, but most growers are waiting until next week (Sept. 12). Scattered showers and thunderstorms compromised these applications in some areas, forcing most growers to wait on better conditions.

is year’s crop is earlier than the past few years, and we will have pickers in the eld by Sept. 15. Cotton harvest in Mississippi should be in full swing by the third week in September. Weather from now through October is critical to the success of the 2022 crop.

is year’s crop has experienced tough environmental conditions from the start, and it’s only gotten progressively worse since last month.

Late August rains comprised every acre of Mississippi cotton to some degree. A slow-moving weather system brought torrential rainfall and ash ooding to central and southern Mississippi, including the black prairie and the south Delta regions. e degree of damage was directly related to the level of rainfall, which resulted in back-water ooding and prolonged wet conditions. Most every eld has a level of boll rot and hard-locked bolls low in the canopy. Depending on the maturity of the crop, most of the damage is slight to moderate.

Cotton that was not opening had minimal damage, but some elds were cracking on the bottom ve to eight nodes, which is concerning. Back-water ooding from rivers and creeks, including the Pearl River, submerged eld crops in Mississippi for over a week, resulting in far greater damage to the crops. North and central Mississippi received much less rainfall, but the prolonged wet, foggy conditions contributed to boll rot; however, the level of damage was much less severe compared to areas south of Highway 82.

Despite the weather, we are moving forward with a favorable forecast aligning with the onset of cotton harvest '22. Hopefully, this forecast will remain true, and we can put this year’s crop in the record books. Good luck! bkp4@msstate.edu

ARKANSAS Bill Robertson

We are quickly approaching the nish line with this cotton crop. e hot dry summer moved cotton toward cutout faster than some wanted to see. Rainfall and a break in temperatures the end of July and into August gave our crop second wind. Moving into September, the plants were very active and will need an almost-perfect September for a good nish.

e Crop Production report for Arkansas released in September by USDA-NASS estimated cotton production at 1.6 million bales, 365,000 bales above last year. Based on conditions as of Sept. 1, yield is expected to average 1,219 lbs. per harvested acre, down 29 lbs. from 2021. Planted acreage is revised to 640,000 acres, up 140,000 acres from June 2022.

If the current yield projection stands, it will rank as our second highest yield on record. Our ve-year lint yield average is 1,184 lbs. per harvested acre. Lint yields the last three years have been our best three on record.

As mid-September rolled around, we were just getting our defoliation underway. Heat unit accumulation appears to be following a more normal trend and generally fades fast in October.

e 2022 crop is likely our most expensive we’ve ever produced. We’ve seen a great number of challenges thrown at us, and there are still challenges we must be prepared to address as the season comes to an end. Get cover crops on your radar if they are not part of your current plan. We all look forward to seeing how this season wraps up as we make plans for 2023. brobertson@uada.edu

A er a tough environmental season, cotton farmers are beginning to defoliate elds in preparation for harvest.

OCTOBER 2022

TEXAS Murilo Maeda

As discussed in past issues of Cotton Farming, we’ve seen large abandonment this year due to the lack of adequate moisture during most of the fall and winter through planting. e last o cial FSA certi ed acre numbers came out Aug. 22 and really illustrate the brutal reality in West Texas (1N and 1S regions) this year. According to that report, West Texas growers seeded 4.56 million acres of cotton in 2022, of which 60% were dryland and 40% were irrigated.

Overall, FSA noted in their report a total of 1.88 million and 628 thousand acres (dryland and irrigated, respectively) failed across the region.

is represents 55% of our total certi ed planted acres. While there is some good cotton in the region, there are also dryland acres in poor condition still standing that may (or may not) end up being harvested. However, ither way we look at it, it is safe to say production from West Texas will be severely impacted this year.

For some good news — as I write this in early September — we have recently seen widespread rains in West Texas. A bit too late to make a big di erence on overall production, yes, but this will help us nish most of the crop we have in the eld while providing a much-needed break for irrigation wells that have been running around the clock since planting. Most of the region received about as much, if not more, rain in the past 15 days or so than what we had seen from January through the end of June this year. For reference, we o cially recorded 4.9 inches of rain in Lubbock during that period. While you are very unlikely to see anyone around here complaining about rain, excessive moisture this late in the season can create issues with plant regrowth and challenging defoliation conditions. is is something we will be keeping a close eye on.

Our updated 2022 harvest aid guide is available on the Lubbock.tamu.

edu website. As we progress into the late season, we’ll be looking for some warm, open weather to help us nish this crop. Hopefully, conditions will also be favorable for an e cient harvest season. As it is customary this time of year, we start seeing an uptick in farm machinery moving around. Please remain patient, and stay safe out there. mmaeda@ag.tamu.edu

LOUISIANA Matt Foster

Cotton defoliation began in some areas of the state during the latter part of August. Only around 1% of the crop has been harvested as of Sept. 9. e Louisiana cotton crop faced hot and dry conditions for most of the growing season but was plagued with excessive rainfall during the month of August.

Preliminary seed counts per lock are averaging lower than usual, most likely due to stress from the hot and dry conditions. Wet and cloudy conditions have delayed defoliation and harvest operations in most areas of the state. Fields that had open bolls were most susceptible to damage from the rainfall. I’ve seen some elds with substantial target spot, boll rot, sprouting and hardlock. Regrowth has been a tremendous problem and is making defoliation more challenging. What was once a promising cotton crop is slowly going downhill.

About 75% of this year’s crop is in the fair-to-good range with state yields estimated to average around 800 to 875 lbs. of lint per acre. However, only time will tell. Most growers that I’ve spoken with were optimistic about their crop prior to the excessive rainfall but now have a di erent outlook. Hopefully, the weather will cooperate, and we can get this crop out of the eld. mfoster@agcenter.lsu.edu

14 COTTON FARMING | OCTOBER 2022 COTTONFARMING.COM

We go above and beyond to get you field-proven solutions for any farming challenge you face. Right when you need them. Our locally-focused ag experts help you maximize yields on every acre with personalized advice and accurate agronomic expertise. @2022 J.R. Simplot Company. All Rights Reserved. Simplot Grower Solutions is a registered trademark of the J.R. Simplot Company. BEFORE SEED BEYOND HARVEST Contact us today to learn how to maximize your field Visit SimplotGrowerSolutions.com Call (662) 873-4338 Specialists Speaking Continued on page 18

Stoneville Celebrates A Century Of Cotton

BY CARROLL SMITH EDITOR

When George B. Walker and his partners launched the Stoneville Pedigreed Seed Company in 1922, his business plan was simple: “To increase the economic value of an acre of cotton.”

To recognize the cotton brand’s 100year legacy and service to growers, a Stoneville Celebration was held recently in the Delta Research and Extension Center in Stoneville, Mississippi.

Some notable Stoneville varieties include:

Stoneville 213 — 1961

ST 474 — 1994

BXN 47 — 1998

ST 4892BR — 2000

ST 4946GLB2 — 2008

Looking Back

“We are standing on hallowed ground,” said Don Threet, Cotton Operations Manager for BASF. “Stoneville was born here at the Delta Branch Experiment Station.”

During his 32-year career with Stoneville, Threet has witnessed six changes of ownership, held 10 key positions and participated in many memorable experiences.

“I was involved in the development of the BXN-Buctril System, which was the first genetically engineered trait in a field crop,” he said. “We worked side by side with Rhone Poulenc even though we were two completely different companies. They had the chemical (herbicide), and we had the trait and varieties. It was exciting to see a large chemical company and a small seed company work together to accomplish this task.”

Threet also recalled an opportunity that arose in the late 1990s for some of the cottonseed companies to enter Upland cottons in the San Joaquin Valley variety trials. Typically, only Acala cottons were allowed to enter.

“We sent BXN 47 out there, and if my memory serves me correctly, there were nine trials and BXN 47 won eight

Stoneville 2B, which was introduced in 1934, was a very successful variety for the company. One of the original Stoneville 2B seed bags — designed to hold 100 pounds of fuzzy seed — was on display during the celebration of the cotton seed company’s 100th anniversary.

of them and came in second on the ninth trial,” Threet said. “We licensed the BXN trait with CPCSD (California Planting Cotton Seed Distributors), they put it in Maxxa — their most popular variety — and sold it as BXN Nova. We let CPCSD distribute it for us and sold 10,000 bags of cottonseed in two weeks.”

What’s Next?

Steve Nichols, Ph.D., South Region Agronomy Lead for BASF, grew up in the Mississippi Delta and lived there until 2006. His family didn’t farm, but he recalls his first job at age 9 was working for friends of his parents chopping cotton with a hoe.

“That was my way to earn a little money, and it also set the stage for my appreciation of agriculture and the people who work in agriculture,” he said. “After I graduated from Mississippi State, I worked for a consulting company for 16 years, returned to Mississippi State to complete my Ph.D. and went to work for Bayer in 2006.”

During his tenure with Bayer, Nichols had the opportunity to work with the

Stoneville and FiberMax brands. BASF acquired the brands in 2018 and for Nichols, the rest is history. Today, he is in on the ground floor of the “next big thing” for BASF and select Stoneville and FiberMax varieties — Axant Flex herbicide trait technology, cotton’s first quadstacked herbicide trait package.

The plan, Nichols said, is to develop varieties well adapted to all growing regions and then place the trait technology in them. He said once the geographic fit is established, then the next step is to determine the best way to manage them.

“That’s how you get the best genetic potential out of these varieties when you understand where to place them and how to manage them,” Nichols said.

“I am excited about the future of Stoneville. But at the end of the day, it’s the grower, the consultant and the Extension and research folks who say, ‘This is a product we will recommend.’ Then you have a sense of pride when you see it performing well on a farm.

“I thank the growers for having confidence in the brand and wanting to plant our varieties.”

TWITTER: @COTTONFARMING OCTOBER 2022 | COTTON FARMING 15

CottonBoard.Org Website — Same Name, New Look And Feel

The Cotton Board’s public-facing website, CottonBoard.Org was recently updated and refreshed. A new look and feel, along with added features, make this website an even better resource for the cotton-growing community.

Whether a cotton producer, importer or member of the general public, the CottonBoard.Org website offers users access to resources and information related to the Cotton Research and Promotion Program.

Lexie Jones, The Cotton Board’s Director of Information Technology, and I started the redesign project in early 2022, and the updated website went live in September. “The CottonBoard.org site was last updated in 2013, so the refresh of the site was needed for both aesthetic improvements and reasons of functionality,” said Jones.

Attractive, User-Friendly Website

The new site leads with beautiful cotton imagery, in a sleek and modern design. The new design is also ADA compliant, meeting the most recent standards to accommodate visually impaired users. Improved navigation makes it easier than ever for users to find the information they need.

When viewing the site on a desktop or laptop computer, there is a scrolling head-

BY STACEY GORMAN WARREN, ARKANSAS

er that moves along with the page, making navigation seamless. The site is also mobile-responsive, which means it will adapt to the screen of whatever device it is being viewed on, be it a mobile phone or tablet.

The homepage has a resource center that directs users directly to sections of the site they may find most useful. The homepage also has a stream of The Cotton Board’s social media content and allows users to share information directly from the site — all with the click of a button.

Up-To-Date Sections

New pages and sections of the site provide portals to information and useful resources.

Cotton & Coffee: The new site has a page dedicated to The Cotton Board’s

Cotton & Coffee series. Here, users can browse upcoming Cotton & Coffee topics, register to attend a future session or view the recordings of past episodes.

Stakeholder Transparency: Information in the Stakeholder Transparency section of CottonBoard.Org includes links to The Cotton Board and Cotton Incorporated’s Annual Reports, Program governing documents, budget breakdowns, audited financial information and board rosters.

Our Leadership: Visitors who are curious about The Cotton Board’s membership can go to the “Our Leadership” page and see a current listing of all Cotton Board Members, Alternates and Advisors. Taking this a step further, the new design allows membership to be filtered by region, industry segment or membership type.

“Ultimately, we redesigned the site to ensure that people who were looking for information about The Cotton Board or the Cotton Research and Promotion Program had a positive experience and found the site useful, robust and easy to navigate,” said Jones.

To check out the new website, please visit CottonBoard.Org.

Stacey Gorman is The Cotton Board’s director of communications and may be reached at sgorman@cottonboard.org.

16 COTTON FARMING | OCTOBER 2022 COTTONFARMING.COM RESEARCH & PROMOTION

The P.I.E. Tour

A Slice Of Perspective To Be Gained

BY CASSIDY NEMEC ASSOCIATE EDITOR

Upon its inception in 1989, P.I.E. — otherwise known as the Producer Information Exchange — has been instrumental in creating avenues for producers to experience regions different from their own.

The P.I.E. tour is a special education project of the Cotton Foundation, sponsored by BASF and managed by the National Cotton Council.

In this program, a grower from Texas could be immersed in the same growing conditions as a grower from North Carolina. In the 2022 Southeast P.I.E. tour, that is exactly what happened — and vice versa with the 2022 Southwest P.I.E. tour.

Bryan Perry, US Head of Seeds & Traits at BASF, spoke on the importance of BASF’s partnership with the tours.

“I was able to share with them [producers] about the company and its direction, but then I was able to turn it back to them and get their feedback,” he said.

“BASF reinvests 11% of every dollar into research and development for ag, and I think if you’re a producer, you want to know what people are spending that money on. Being able to see firsthand what’s happening with that investment can be really beneficial.”

Southeast P.I.E. tour members from the Southwest region were made up of producers from California to Texas. They saw multiple farms throughout North Carolina, BASF’s headquarters outside of Raleigh and other research facilities along the way.

Landon Mires, a producer out of O’Donnell, Texas, originally heard about the program from his father and then suggested he would do the program again at the drop of a hat. He said it was interesting to see what other regions grow alongside their cotton, such as the vegetables and tobacco in North Carolina.

On the other side, Southwest P.I.E. tour members consisted of producers from Virginia to Mississippi. They toured BASF’s Seed Innovations Center in Lubbock, Texas, and they wrapped up

their time of learning and engaging in the Lower Rio Grande Valley with other facilities and farms.

Bo Leatherman, a Mississippi farm manager for Brad Cobb Farms in Tunica County who participated in this year’s Southeast P.I.E. tour, had one piece of advice when it came to anyone who may be interested in participating in the program: “Go.”

He said it was a unique opportunity to understand what other areas are doing as far as techniques, to see what might work on his own farm and to know how fortunate they are when it comes to resources other regions may lack — such as water.

“We try to mix it up,” said John Gibson,

Vice President of Member Services at National Cotton Council. “We want to expose them [the producers] to a variety of experiences so they can take what they learn back with them to the farm.”

More than 1,200 U.S. cotton producers have participated in the program since its 1989 launch. The program exchanges much more than just simple information — it also exchanges regions and new perspectives, making it invaluable to anyone who joins.

Producers interested in getting involved with the P.I.E. tours should contact their local National Cotton Council Member Services representative or local cotton producer association representative.

Dustin Black, a BASF research development specialist, updates Southwest and West P.I.E. producer participants on the company’s trait development trials at its research facility in Pikeville, North Carolina.

Producers from the Southeast and Mid-South saw cotton and other agricultural operations in Texas’ High Plains and Lower Rio Grande Valley regions.

TWITTER: @COTTONFARMING OCTOBER 2022 | COTTON FARMING 17

ARIZONA Randy Norton

As we enter the 2022 harvest season, I am optimistic about yield potential of this year’s crop. Far southwest Arizona has already harvested some of their crop, and early indications are for yields slightly above average. Our first UArizona cotton variety trial ranged from just under three bales per acre to right at four bales per acre. The result from this early harvested trial continues to show the importance of proper variety selection. With a difference of slightly over 500 pounds of lint per acre, proper variety selection is demonstrated again to be crucial to optimum return.

Many growers will plant several different varieties on their farm each year to spread their risk. Keeping detailed records of variety performance on your own farm will provide valuable information for the upcoming year. Harvest time is a busy time of year, but taking the time to accurately track variety performance will pay dividends in the end.

As we have surveyed farms across the state this fall, we continue to see problematic fields with populations of palmer amaranth that have escaped glyphosate applications and are likely resistant. Allowing these plants to produce seed and then running a harvester through the field will continue to spread the problem to additional areas. Now is the time to take note of problem areas and, if possible, remove existing pigweed plants from the field before going to seed and running a harvester through them. Adjusting production practices for the 2023 season is critical to prevent the further spread of these glyphosate resistant pigweed. Incorporating additional herbicide options besides glyphosate is

necessary to control these populations.

More detailed information regarding this topic and others related to late-season crop management can be found at the UArizona Extension website extension.arizona.edu/crops-soils. rnorton@cals.arizona.edu

TEXAS Ben McKnight

As I write this Sept. 8, cotton harvesting activity is winding down in the Lower Rio Grande Valley. Recent rainfall has slowed things down a bit, but more than 90% of the acreage in this region has currently been harvested. Upon completion of harvesting, growers have been diligent with stalk destruction practices to render any remaining cotton plant material non-hostable to the boll weevil. Cotton stalk destruction efforts of growers in South Texas, along with the efforts of the Texas Boll Weevil Eradication Foundation, are the Cotton Belt’s first line of defense against the proliferation of these pests.

Harvesting activity in the Coastal Bend has wrapped up for the year, and stalk destruction efforts are running smoothly ahead of the Sept. 15 stalk destruction deadline for this region. Yield reports in the Coastal Bend have been below average compared to previous years, and growers are hoping to get some much-needed rainfall heading into the 2023 growing season. The Upper Gulf Coast is also winding down the 2022 harvest and should be completed by the time you read this in October.

Recent rainfall in the Blackland Prairie has slowed progress with getting the bulk of the region’s cotton crop out of the field. Some fields that were defoliated prior to the rainfall will most likely need an additional harvest-aid application prior to harvesting as regrowth following the initial application has been problematic in some instances. bmcknight@tamu.edu

18 COTTON FARMING | OCTOBER 2022 COTTONFARMING.COM

Specialists Speaking Continued from page 14 STATEMENT OF OWNERSHIP MANAGEMENT AND CIRCULATION 1. Publication Title: Cotton Farming 2. Publication Number: 0746-8385 3. Filing Date: October 2022 4. Issue Frequency: Jan - Dec 5. Number of Issues: 12x/year 6. Annual Subscription Price: Free to qualified subscribers 7&8. Mailing Address of Known Office/Headquarters: 875 W. Poplar Ave., Ste. 23, Box 305, Collierville, TN 38017 Contact Person: David Boyd (901-626-1730) 9. Publisher: Lia Guthrie, 7100 Black Bart Trail, Redwood Valley, CA 95470 Editor: Carroll Smith, 875 W. Poplar Ave., Ste. 23, Box 305, Collierville, TN 38017 10. Owners: Cornelia Guthrie, 7100 Black Bart Trail, Redwood Valley, CA 95470; Dr. David Scott Guthrie,Sr., 7100 Black Bart Trail, Redwood Valley, CA 95470; Morris Ike Lamensdorf, 17 S. Third St., Rolling Fork, MS 39159; Mary Jane Lamensdorf, 17 S. Third St., Rolling Fork, MS 39159 11. Known Bondholders, Mortgagees and Other Security Holders Owning/Holding 1% or More of Total Amount of Bonds, Mortgages or Other Securities: None 12. Tax Status: Has Not Changed During Preceding 12 Months 14. Issue Date for Circulation Data Below: September 2022 15.a. Total Number of Copies (net press run): (Average No. Copies each Issue During Preceding 12 Months – 21,957) (No. Copies of Single Issue Published Nearest to Filing Date – 22,161) 15.b.(1) Outside County Paid/Requested Mail Subscriptions: (Average No. Copies Each Issue During Preceding 12 Months – 11,886) (No. Copies of Single Issue Nearest to Filing Date – 12,186) 15.c. Total Paid and/or Requested Circulation: (Average No. Copies Each Issue During Preceding 12 Months – 11,886) (No. Copies of Single Issue Nearest to Filing Date – 12,186) 15.d.(1) Outside County Nonrequested Copies: (Average No. Copies Each Issue During Preceding 12 Months – 9,770) (No. Copies of Single Issue Published Nearest to Filing Date – 9,461) 15.d.(4) Nonrequested Copies Distributed Outside the Mail: (Average No. Copies Each Issue During Preceding 12 Months - 29) (No. Copies of Single Issue Published Nearest to Filing Date - 0) 15.e. Total Nonrequested Distribution: (Average No. Copies Each Issue During Preceding 12 Months – 9,799) (No Copies of Single Issue Published Nearest to Filing Date – 9,461) 15.f. Total Distribution: (Average No. Copies Each Issue During Preceding 12 Months - 21,685) (No Copies of Single Issue Published Nearest to Filing Date – 21,647) 15.g. Copies Not Distributed: (Average No. Copies Each Issue During Preceding 12 Months - 272) (No. Copies of Single Issue Published Nearest to Filing Date - 514) 15.h. Total: (Average No. copies Each Issue During Preceding 12 Months –21,957) (No. Copies of Single Issue Published Nearest to Filing Date – 22,161) 15.i. Percent Paid and/or Requested Circulation: (Average No. Copies Each Issue During Preceding 12 Months – 54.81%) (No. Copies of Single Issue Published Nearest to Filing Date – 56.29%) 18. I certify that all information furnished above is true and complete. Lia Guthrie, Publisher

Ginners Marketplace

Electricity Rates Likely To Increase For 2022

Take A Hard Look At Insurance Costs And Safety Culture At The Gin

In Texas, we have spent a good bit of time and energy trying to untangle the mess that was caused by Winter Storm Uri. We have seen legislation passed, new rules written and now various actions by our Public Utility Commission. If you are reading this from outside of Texas, hang on for just a little bit, and I’ll get to why I think this issue may have an impact across the Cotton Belt.

Distractions have become “routine” in our daily lives. Our phones go o , we get text messages and we’re bombarded by the never-ending news cycle. Everything seems to be trying to get our attention, and it’s easy to lose sight of what’s important. Things can sneak up on you, and those are the ones that will jump up and bite you.

the natural gas supply system, which is one of the things that caused natural gas to jump substantially during the turbulence. As power plants were shut down by the storm, some of the motors that pressurized the natural gas lines lost power.

tions have been aware of this and have brought it to the attention of our memberships. But I think many of us got distracted by the other things going on and have now been hit with the reality that it’s not getting better.

If you followed this in the news, there was a lot of talk about ERCOT, the power grid in Texas, and the huge power outages we faced during the storm. Parts of ERCOT were out for a week or more. One common comment heard was that this wouldn’t have happened if ERCOT were part of the “National Power Grid.”

In the last year or so, we’ve seen huge increases in our costs. As I write this, we’re getting news of the highest inflation in more than a generation… maybe two.

While I’m personally seeing some of the things that increased so much ease down a bit, it’s not common for costs that have gone up this much, this fast, to come down or come down very much. We will likely have to learn to live with some of them.

At the same time, the remaining natural gas-fired power plants were ramped up to handle the additional load. Most had to buy more gas on the spot market to keep running. The spot price for electricity went through the roof as well, hitting $4/ kWh outside of ERCOT and $9/kWh inside ERCOT. The utilities that had to buy spot electricity during this time frame incurred substantial losses.

This is a simplified explanation, but insurance companies are going to do what they need to in order to stay in business. They must make money like we do. The companies take our premium and invest it. They pay claims with it, and they expect to have some left over. If losses are low and return on investment is good, you have happy insurance companies. We get stable premiums and competition.

What’s Happening In Texas

The Cost Of Insurance

This is a bit of a misstatement because there actually are nine grid systems in the United States. ERCOT just happens to be the only one that does not cross a state line, and so is not regulated by the Federal Energy Regulatory Commission. There are several areas of Texas that are not in ERCOT, and this is where the e ect from the storm on these areas may be of interest to folks across the Belt.

One of the costs that snuck up on many gins in the past year or so is the cost of insurance. Normally, this is a once-a-year expense we get hit with.

If they have poor investment returns and higher-than-expected cost of claims (read inflation), you have unhappy insurance companies. They may decide to pull out of the market and/or significantly increase rates. This is where we are today.

Gas And Electricity Spot Prices

The past renewal cycle or two have been more than a bit of sticker shock for many in the ginning industry. Your associa-

During Winter Storm Uri, there was a large disruption in

In Texas, we are just now seeing the results of this increase in gas and electricity prices. Electric utilities have assessed their losses and are now passing these costs on to their customers. Additional charges in the range of $0.01 - $0.03/kWh are being assessed to make up for losses during the storm. This amount is highly variable, based on what mix of generation the power company was using and whether they had adequate fuel contracted.

Your ginners associations and the National Cotton Ginners’ Association have been concerned about this for some time. We need healthy insurers and competition, but we really can only help one side of the insurance problem…losses. NCGA has put together a list of questions to ask yourself, so you can evaluate

The City of Austin Utility, for example, did not lose any money

PhysicalAddress:225BourneBoulevard•Savannah,Georgia31408-9586USA

PhysicalAddress:225BourneBoulevard•Savannah,Georgia31408-9586USA

MailingAddress:P.O.Box929•Pooler,Georgia31322-0929USA

MailingAddress:P.O.Box929•Pooler,Georgia31322-0929USA

Phone:(912)447-9000•Fax:(912)447-9250

Phone:(912)447-9000•Fax:(912)447-9250

TollFree(USAOnly): 1-800-4LUMMUS (1-800-458-6687)

TollFree(USAOnly): 1-800-4LUMMUS (1-800-458-6687)

WebSite:www.lummus.com•E-mail:lummus.sales@lummus.com

WebSite:www.lummus.com•E-mail:lummus.sales@lummus.com

COTTON FARMING IS THE OFFICIAL PUBLICATION OF THE GINNING INDUSTRY.

COTTON FARMING IS THE OFFICIAL PUBLICATION OF THE GINNING INDUSTRY.

Lummus Ag Technologywants to express its appreciation to our many loyal customers for their continued support and

With the challenges we face in our industry, we are continually workingto evolve and adapt to changing market conditions and customer needs.

to

be efficient and

to discuss

goals and needsto ensure

COTTON

TWITTER: @COTTONFARMING OTOBER 2022 | COTTON FARMING 19 Cotton Ginners Marketplace

TWITTER: @COTTONFARMING AUGUST 2022 | COTTON FARMING 19

®

© 2022 Lummus Ag Technology

business.

Lummusoffersa wide range of products and services, all geared

help your operation

profitable. Regardless of the project scope, contact Lummus

your

your success. Just a short listof items we offer: All-new complete Gin Plants Ginning Machinery (individual machines, stand-alone systems, presses, etc.) Press Consoles and Main Control Consoles Burner and Moisture Unit Gas Train/Controls upgrades Air Monitoring and Fire Detection Kits DGC 2020 Gin and Feeder Controls Gin Dor-Les® and E.E. Dor-Les® Press upgrades 16” diameter Bottom Ram Conversion Hydraulic Tramper/Pusher Conversion Premier™ III Series Hydraulic Pumping Units Press Rebuilds (strain rods, boxes, sills, etc.) Quality OEM Repair Parts UnmatchedTechnical Service The future is bright! Cotton prices have optimism at levels we haven’t seen in a while. A renewed commitment to customer service has Lummus excited for the future – join us as we move forward! © 2022Lummus Corporation

during the storm and actually made money. This was mainly because so much of the Austin system was down, and they were able to sell the additional electricity they could not get into the city to other utilities in ERCOT at a hefty profit.

On the other hand, one of our power plants outside of ERCOT went down, and the utilities that relied on this power were forced into the spot market. These companies now have a large deficit they are having to make up.

Natural Gas Plants And Electric Utilities

The costs we are seeing to make up for losses during the storm are only one side of the equation. Adding to this is the fact that gas prices are up today. Spot prices for natural gas this August averaged $8.81/MMBtu on the Henry Hub. Last August, this same average was $4.07/MMBtu.

While this di erence will only a ect natural gas power plants, our electric utilities across the country are relying more on natural gas plants, as the coal-fired plants are being phased out.

Stated in cost per kWh, we see fuel typically at about $0.02. Doubling of the natural gas price could mean an additional $0.02/kWh. Fortunately, most of the natural gas is not purchased on the spot market. But you can see the potential problem if the price of natural gas continues to stay at these levels.

Renewable Sources Of Generation

Our utilities are facing increasing pressure to use renewable sources of generation, especially wind and solar. The problem with wind and solar is they only work with the correct weather. Utilities must continually balance generation against the load on the system.

The main method most utilities use to balance the load is through natural gas-fired power plants. With the renewables on the system, the natural gas plants must balance both the changing load and the changing amount of generation provided by the renewables. If you have a major cold snap with snow and freezing rain, you will likely lose most of your renewable energy generation, forcing the natural gas plants to ramp up considerably.

Ginning Cost Survey Participation Is Critical

All these variables combine to put significant upward pressure on electricity prices. This season, it is important that you communicate with your electricity provider to be sure you know what they will be charging. If you have not participated in the past, this year would be an excellent time to begin taking part in the ginning cost survey coordinated by the National Cotton Ginners Association.

The ginners associations use these survey results to track energy prices across the United States. It is important that we have good participation across the country to have an accurate understanding of how prices are changing in di erent regions.

The more participation we get for the survey, the better the data quality will be. This data is a key part of our e orts to help the industry operate in the most e icient manner possible.

J. Kelley Green, TCGA executive vice president, contributed this article. Contact him at kelley@tcga.org.

the Air District’s Governing Board Meeting following a presentation by sta on receiving funding for heavy-duty trucks. With more than $12 million in funding, the District is encouraging interested parties to apply. Unfortunately, the funding is tied directly to e orts to electrify the goods movement industry and only allocates money towards zero and near-zero trucks.

McGlothin testified that the agricultural industry has made significant investments in compliant trucks following ARB’s Truck and Bus Regulation. Unfortunately, many subhaulers who were vital to the industry have had to cease operation due to the regulatory requirements associated with heavy-duty trucks.

Along with that point, those businesses that invested in updating fleets to Engine Model Year 2010 or newer equipment are now facing another mandate to upgrade to unproven, electric equipment in the coming years.

The association supports incentives towards updating fleets and meeting compliance, but the electrification plan has been relied upon too heavily over this past year.

Cotton’s Calendar

Oct. 19: PCCA Board, Delegate Body & Marketing Pool Committee Meetings, Lubbock, Texas

Nov. 18: Calcot Board of Directors Meeting, California

Dec. 14: PCCA Board, Delegate Body & Marketing Pool Committee Meetings, Lubbock, Texas

2023

Jan. 10-12: 2023 Beltwide Cotton Conferences, New Orleans Marriott, New Orleans, Louisiana

Jan. 11: North Carolina Cotton Producers Association 2023 Annual Meeting

Jan. 18-21: Southern Southeastern Annual Meeting, Marriott Myrtle Beach Grand Dunes, Myrtle Beach, South Carolina

Jan. 22-24: 2023 ACSA Mid-Winter Board Meeting, Fort Lauderdale, Florida

Jan. 23-27: 2023 NAICC Annual Meeting and AG PRO EXPO, Omni Nashville Hotel, Nashville, Tennessee

Jan. 25: 2023 Georgia Cotton Commission Annual Meeting, UGA Tifton Campus Conference Center, Tifton, Georgia

Feb. 8-10: Louisiana Agricultural Technology & Management Conference, Paragon Casino Resort, Marksville, Louisiana