Contactors Index

Co

nt

ac

to

rs 1

1 - Contactors

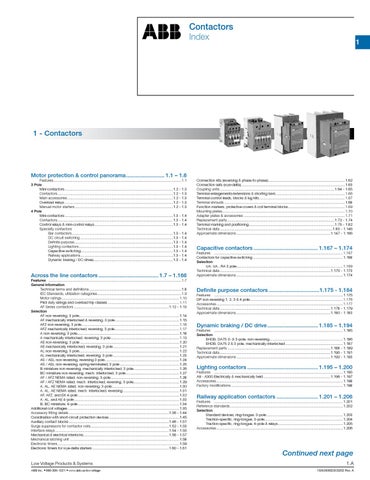

Motor protection & control panorama.......................... 1.1 – 1.6

Features..............................................................................................................................1.1 3 Pole Mini-contactors...........................................................................................................1.2 - 1.3 Contactors..................................................................................................................1.2 - 1.3 Main accessories........................................................................................................1.2 - 1.3 Overload relays...........................................................................................................1.2 - 1.3 Manual motor starters.................................................................................................1.2 - 1.3 4 Pole Mini-contactors...........................................................................................................1.3 - 1.4 Contactors................................................................................................................. 1.3 - 1.4 Control relays & mini-control relays..............................................................................1.3 - 1.4 Specialty contactors Bar contactors....................................................................................................1.3 - 1.4 DC circuit switching............................................................................................1.3 - 1.4 Definite purpose.................................................................................................1.3 - 1.4 Lighting contactors.............................................................................................1.3 - 1.4 Capacitive switching...........................................................................................1.3 - 1.4 Railway applications...........................................................................................1.3 - 1.4 Dynamic braking / DC drives..............................................................................1.3 - 1.4

Across the line contactors........................................ 1.7 – 1.166

Features ...................................................................................................................................1.7 General information Technical terms and definitions...........................................................................................1.8 IEC Standards, utilization categories...................................................................................1.9 Motor ratings....................................................................................................................1.10 Pilot duty ratings and overload trip classes.......................................................................1.11 AF Series contactors..............................................................................................1.12 - 1.13 Selection AF non-reversing, 3 pole...................................................................................................1.14 AF mechanically interlocked & reversing, 3 pole................................................................1.15 AFZ non-reversing, 3 pole.................................................................................................1.16 AFZ mechanically interlocked, reversing, 3 pole................................................................1.17 A non-reversing, 3 pole.....................................................................................................1.18 A mechanically interlocked, reversing, 3 pole....................................................................1.19 AE non-reversing, 3 pole..................................................................................................1.20 AE mechanically interlocked, reversing, 3 pole..................................................................1.21 AL non-reversing, 3 pole...................................................................................................1.22 AL mechanically interlocked, reversing, 3 pole..................................................................1.23 AS / ASL non-reversing, reversing 3 pole..........................................................................1.24 AS / ASL non-reversing, spring-terminated, 3 pole...........................................................1.25 B miniature non-reversing, mechanically interlocked, 3 pole..............................................1.26 BC miniature non-reversing, mech. interlocked, 3 pole.....................................................1.27 AF / AFZ NEMA rated, non-reversing, 3-pole....................................................................1.28 AF / AFZ NEMA rated, mech. interlocked, reversing, 3-pole.............................................1.29 A, AL, AE NEMA rated, non-reversing, 3-pole...................................................................1.30 A, AL, AE NEMA rated, mech. interlocked, reversing........................................................1.31 AF, AFZ, and EK 4-pole....................................................................................................1.32 A, AL, and AE 4-pole........................................................................................................1.33 B, BC miniature, 4-pole....................................................................................................1.34 Additional coil voltages..............................................................................................................1.35 Accessory fitting details...................................................................................................1.36 - 1.44 Coordination with short-circuit protection devices......................................................................1.45 Auxiliary contact blocks...................................................................................................1.46 - 1.51 Surge suppressors for contactor coils.............................................................................1.52 - 1.53 Interface relays................................................................................................................1.54 - 1.55 Mechanical & electrical interlocks.....................................................................................1.56 - 1.57 Mechanical latching unit............................................................................................................1.58 Electronic timers........................................................................................................................1.59 Electronic timers for wye-delta starters............................................................................1.60 - 1.61

Low Voltage Products & Systems ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Connection kits (reversing & phase-to-phase)............................................................................1.62 Connection sets (wye-delta).......................................................................................................1.63 Coupling units.................................................................................................................1.64 - 1.65 Terminal enlargements/extensions & shorting bars.....................................................................1.66 Terminal control leads, blocks & lug kits.....................................................................................1.67 Terminal shrouds.......................................................................................................................1.68 Function markers, protective covers & coil terminal blocks........................................................1.69 Mounting plates.........................................................................................................................1.70 Adapter plates & accessories....................................................................................................1.71 Replacement parts..........................................................................................................1.72 - 1.74 Terminal marking and positioning.....................................................................................1.75 - 1.82 Technical data...............................................................................................................1.83 - 1.146 Approximate dimensions.............................................................................................1.147 - 1.166

Capacitive contactors........................................... 1.167 – 1.174

Features ...............................................................................................................................1.167 Contactors for capacitive switching.........................................................................................1.168 Selection UA, UA...RA 3 pole.........................................................................................................1.169 Technical data.............................................................................................................1.170 - 1.173 Approximate dimensions.........................................................................................................1.174

Definite purpose contactors..................................1.175 - 1.184

Features ...............................................................................................................................1.175 DP non-reversing 1, 2, 3 & 4 pole............................................................................................1.176 Accessories.............................................................................................................................1.177 Technical data.............................................................................................................1.178 - 1.179 Approximate dimensions.............................................................................................1.180 - 1.183

Dynamic braking / DC drive.................................. 1.185 – 1.194

Features ...............................................................................................................................1.185 Selection EHDB, DA75 2- & 3-pole, non-reversing.........................................................................1.186 EHDB, DA75 2 & 3 pole, mechanically-interlocked.........................................................1.187 Replacement parts......................................................................................................1.188 - 1.189 Technical data.............................................................................................................1.190 - 1.191 Approximate dimensions.............................................................................................1.192 - 1.193

Lighting contactors............................................... 1.195 – 1.200

Features ...............................................................................................................................1.195 A9 - A300 Electrically & mechanically held...................................................................1.196 - 1.197 Accessories.............................................................................................................................1.198 Factory modifications...............................................................................................................1.198

Railway application contactors............................ 1.201 – 1.206

Features ...............................................................................................................................1.201 Reference standards...............................................................................................................1.202 Selection Standard devices, ring-tongue, 3-pole............................................................................1.203 Traction-specific, ring-tongue, 3-pole..............................................................................1.204 Traction-specific, ring-tongue, 4-pole & relays................................................................1.205 Accessories.............................................................................................................................1.206

Continued next page 1.A 1SXU000023C0202 Rev. A