EXHIBITION CENTRE: WILLESDEN JUNCTION STATION EXTENSION

• SCALING UP IN MIDDLE PART: to create a tunnel for railway

STAGE 1

STAGE 2

• SCALING DOW AT TALE PART: to create ramps

STAGE

STAGE 4

• Adding gabion walls protects project from railway and providing it the desired privacy

• Adding green areas and water features to project

• Skylight facing south to take advantage to sunlight

2

FORM

SCALE CIRCLE Willesden Junction station CUT OUT RED PART HORSE-SHOE SHAPE

HORSE-SHOE SHAPE

in

GENERATION

MIRROR

used Indesign

the process

RAILWAY

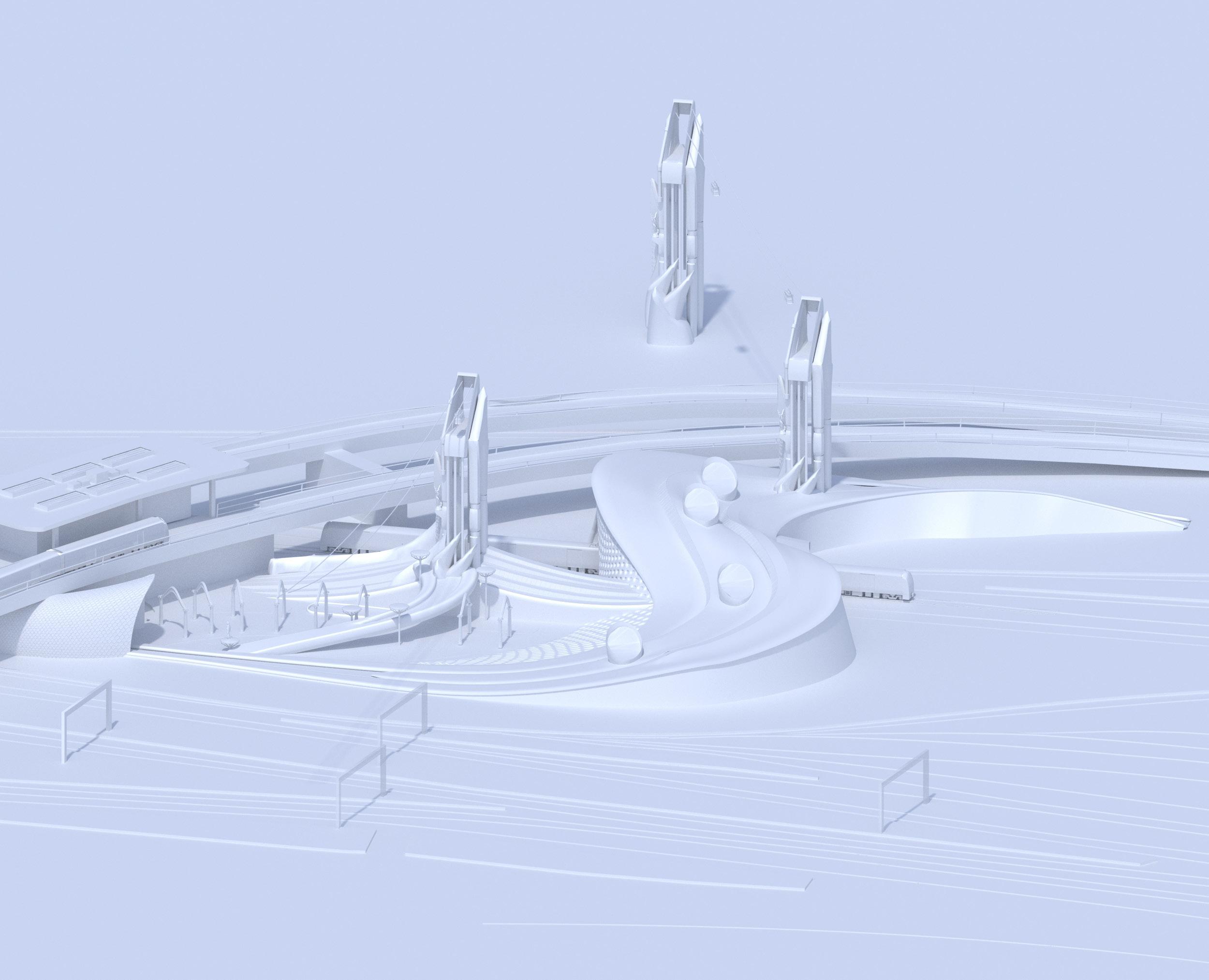

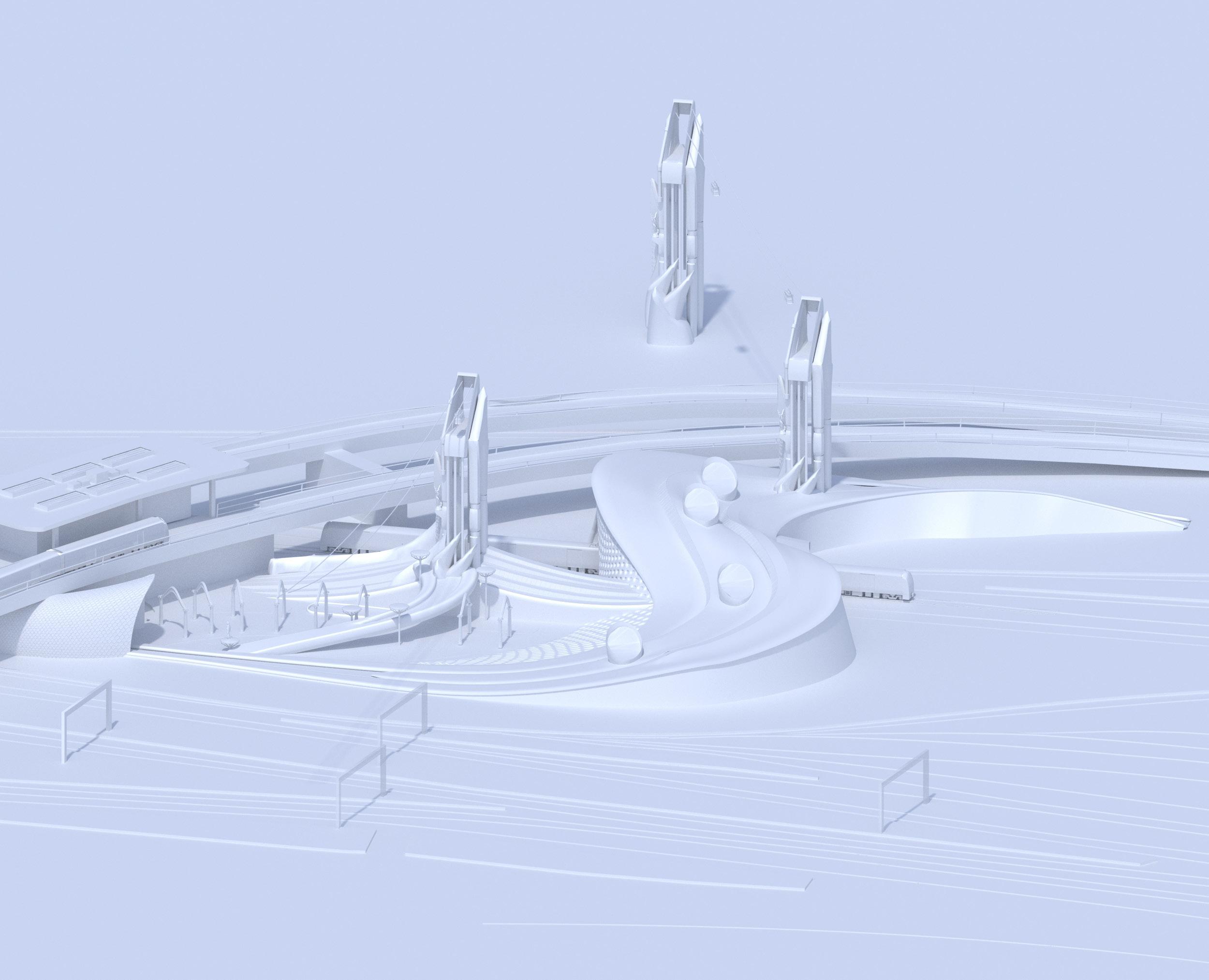

CABLE CAR TOWER 2 CABLE CAR TOWER 2 CABLE CAR TOWER 1 TOWARDS HS2 ENTRANCE Art Centre area Tubbs High St. (Neighbourhood) Exhibition RAILWAY RAILWAY

3 Cable cars added for transportation.

EXTERIOR WORKSHOP GABION WALLS GABION WALLS ENTRANCE

3 MAPS & SITE ANALYSIS used Indesign in the process

4

GROUND FLOOR FIRST FLOOR ENTRANCE ENTRANCE GABION WALL EXTERIOR WORKSHOP WORKSHOP ART GALLERY RECEPTION AREA TOWER DESIGN EXPERIENCE ROOM 1 DOUBLE HEIGHT REST AREA REST AREA WORKSHOP 1 2 3 4 STORAGE STORAGE MEETING SCULPTURE ROOM 1 STORAGE WORKSHOP 5 WORKSHOP STORAGE MEETING ROOM 2 ROOM 3 EXHIBITION SPACE COURTYARD AREA DIGITAL ART FASHION AREA EXPERIENCE ROOM 2 STORAGE CABLE CAR TOWER A A used Revit & Photoshop in the process

PROJECT PLANS

CONSTRUCTION APPLICATIONS

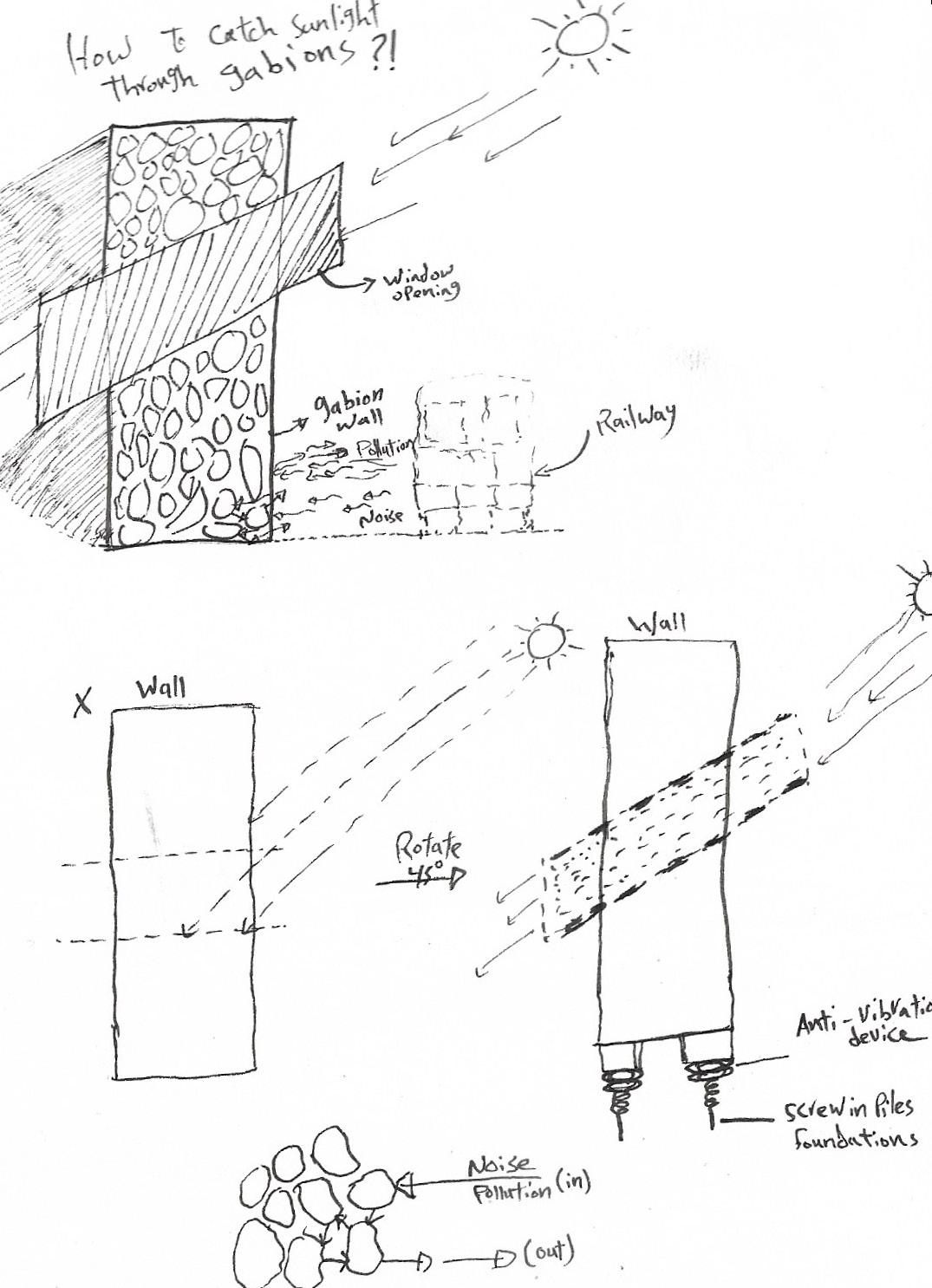

Gabion Walls

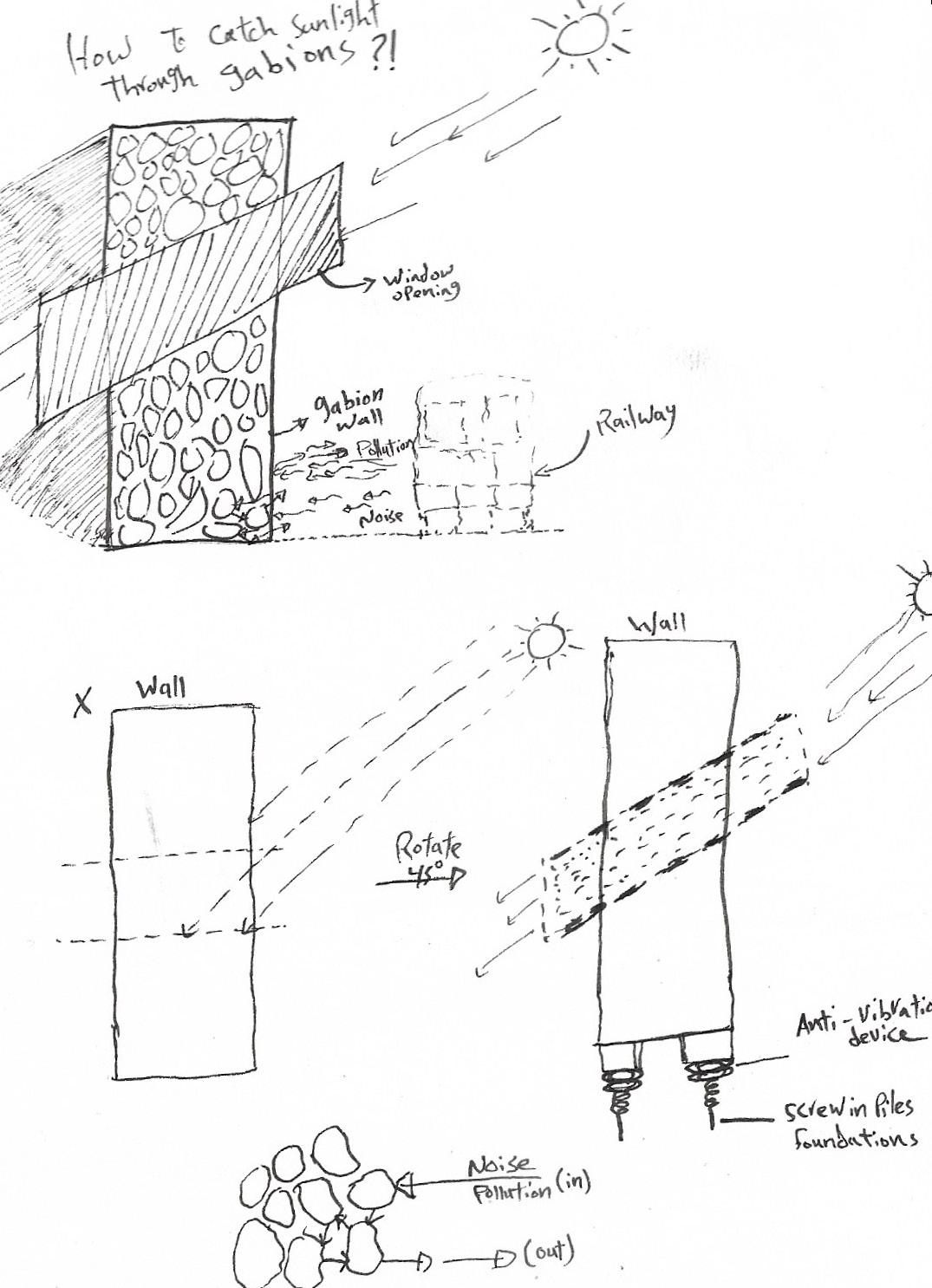

• Its purpose is to surround the site from the borders to act as a sustainable shield that will protect the building from surrounding railway harm.

Gabion wall is designed from recycled stone cages and rocks that can prevent pollution, noise coming from nearby railway to enter the site.

• In foundation (rubber bands)installed to prevent vibrations in gabion wall.

Construction considerations

Gabion wall is designed to be placed surrounding the site to protect the building from the nearby railway, which can cause pollution, noise and vibration.

Windows placed between gabions to allow daylight and sun to enter the site.

Steel frames and concrete columns to be placed behind gabion wall to support structure.

Pollution

Gabion rocks will prevent noise from passing through, plants on facade to filter the air pollution coming from railway.

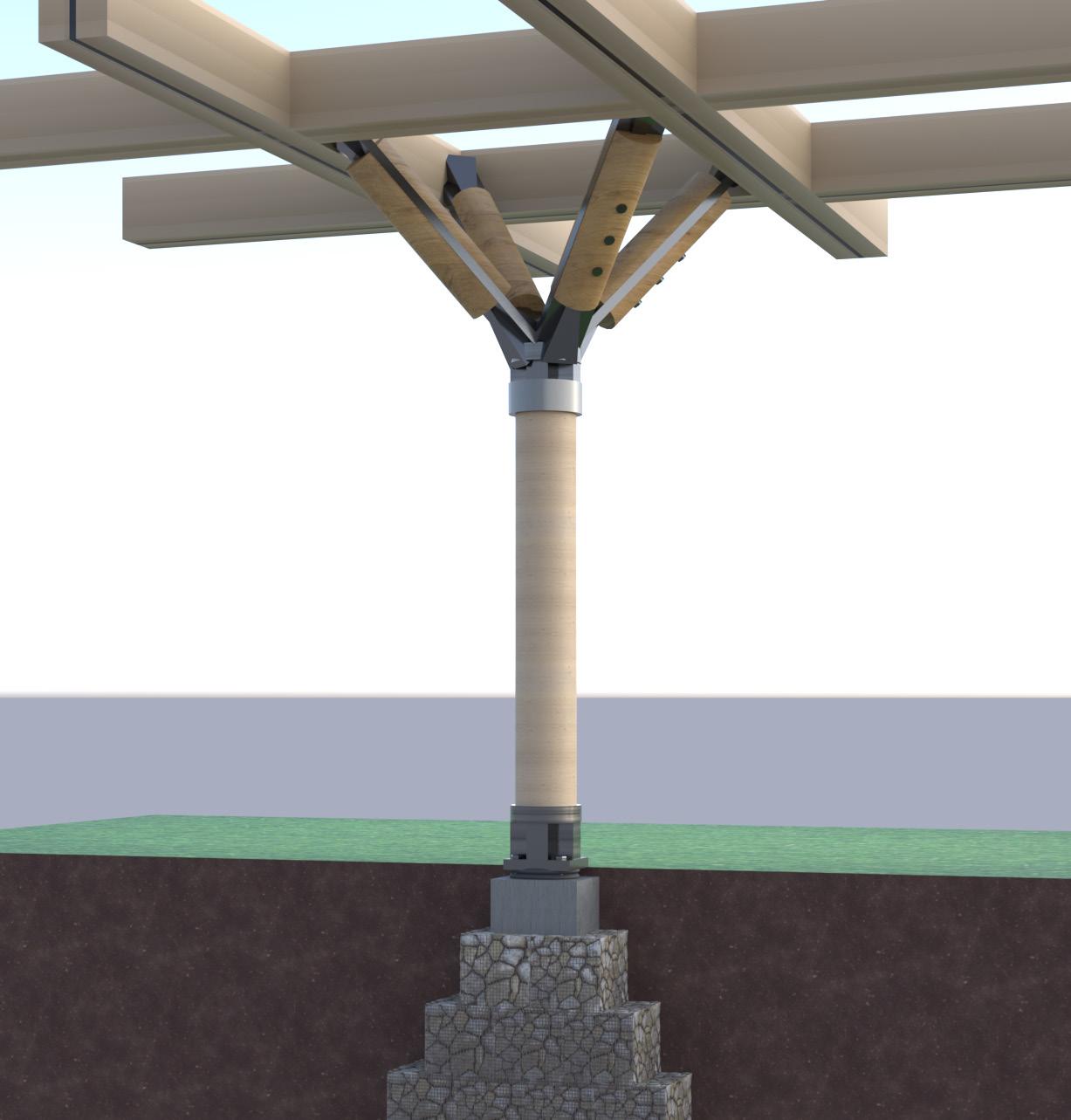

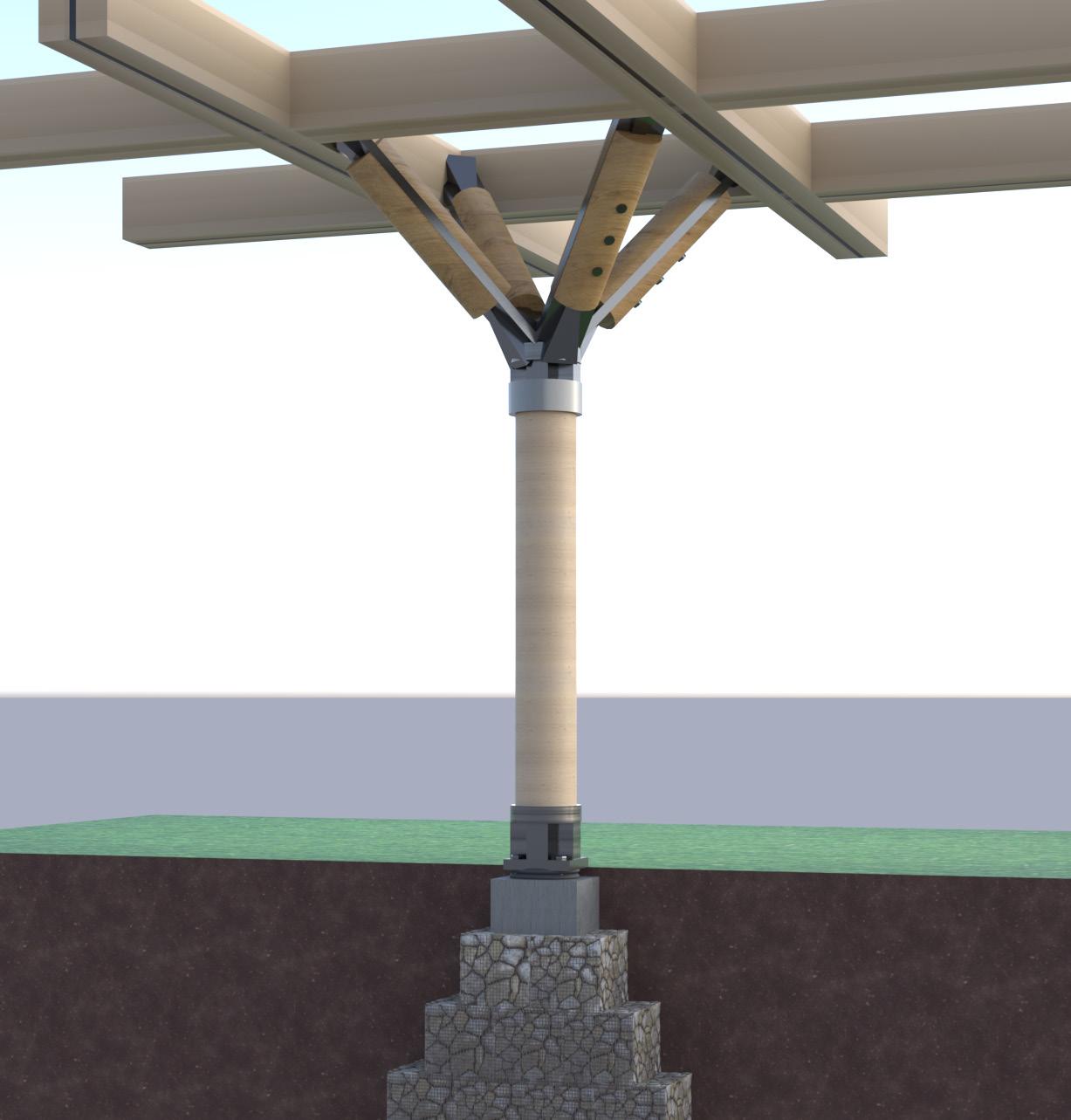

5 Earth Gabion foundation Anchor bolts Holding down bolt Concrete beam Steel connection Glulam column Rubber anti-vibration strips Steel strap Glulam column Steel sheet Galvanised steel column head Countersunk fixing Timber frame branch tapered 200x300x200mm diameter

1. Steel frame structure to support gabion back.

2. Straw insulator covered with 2 layers CLT.

3.Gabion walls (recycled steel cages and rocks).

4. Facade plants to collect dust.

5. Double glazed 45 degree window.

6. Louvred window to protect from rainfall.

7. Concrete column (structure engineer to determine spacing between columns).

8. Roof story supported with steel rails (900mm height), contractor to ensure safety strategy for falling from heights risk.

2 7 6 5 4 1 8 3 9 Gabion wall idea

9. Railway overground train.

sketch

2 2 1 1 45 Noise Vibration Plants on facade To collect dust Opening in concrete column for floor slab to be placed. Ground 1st floor 1st floor 2nd floor 2nd floor Roof Roof Steel frames to support gabion back.

cages place on top of each other in a way to divide the load .

1 is rotated 45degrees

maximum sun to

the site. Window 2 louvred to

rain water from entering.

Gabion

Window

to allow

enter

prevent

used AuroCAD in the process

6 Earth Gabion foundation Anchor bolts Holding down bolt Concrete beam Steel column placed vertical each 5m Steel sheet Gabion column 500mm each Rubber anti-vibration strips Timber frames Straw blocks (insulation) 450 Concrete beam Gabion wall Gabion foundation Anti-vibration rubber strips Straw (insulator) Timber frames Double glazed window Timber louvres Thermal insulation Timber frames Glulam column type 1 Glulam Beam 500mm depth CLT 8 layers 400mm Triple glazed window Timber cladding Breather membrane Exterior wall and curtain wall Gallery facade material used is timber cladding with curtain wall and window openings in the desired areas. • Window are controlled using wooden louvres in rooms with oil paintings. Breathable control, thermal insulation and vapour control layers installed to exterior wall to control environment defects. Glulam beam Cut in half Steel plate placed in between Beam bolted from sides Gabion foundation Glulam column Column steel head Flitch beams Glulam column Threaded rod diameter 16mm Floor finish Wood skirting cover Wood skirting cover Steel connection (Plug connector) Glulam Column design used AuroCAD in the process

While installing tower crane element, spider crane will left elements for installation.

Contractor and safety engineers to ensure safe installation process.

HEALTH AND SAFETY

Risk of falling from heights when building and working with crane. Contractor to ensure safety strategy.

CLADDING & INSULATION SYSTEM

Cable car

Glulam beam(primary) Glulam beam(secondary) +20m

Glulam tree column

Staircase & lift

Timber frames

CLT flooring

Glulam column sets on RC slab with gabion wall foundation

Pile cap

9m

Glulam type 1 column

Glulam beam CLT Drainage below slab

RC piles 300mm diameter Soil

Timber framed double glazed window

CLT panel

Sloped roof to fall into guttering

Insulation

RC concrete wall

Green area (up hill)

Green roof Insulation and drainage layer

CLT 6 layers

Glulam beams

Glulam beam CLT

Drainage below slab Soil

7

crane elements

crane foundation TFL construction element delivery train

Tower

RC

used 3DsMax & Indesign in the process

8 HAND SKETCHES & RENDERS used 3DsMax & Hand-sketch in the process

GENERAL HOSPITAL PROJECT

This area (Cairo, Egypt) lack health care facilities, in which the existed buildings were either too old or does not have the proper services and required departments.

Form inspired by human body, heart is the core of the building, the arteries which is connected to the heart provide body parts with blood, considered as the hospital departments and wings. (Movement of blood represents circulation inside hospital).

Concrete construction is a good way to improve the function, value and whole life performance of the facility. Using RC columns dimensions between each is 12m maximum.

Waffle slab to support column with loads, and Hospital ceiling services can be managed through waffles spaces.

9

first floor plan floor plans & form generation used Revit in the process

master plan

10 used Revit in the process

11 used 3DsMax in the process

12

13