We delve into the cultivating expertise of AAA Growers, whose in-house capabilities provide leading global food and beverage retailers with the freshest produce from soil to store

Writer: Lucy Pilgrim | Project Manager: Josh Rayfield

After graduating from Boston University in the US in 1995, Ariff Shamji returned to his home in Kenya and began working for his family’s small business.

However, Shamji soon realised that he wanted more from his career and moved to the capital city of Nairobi in pursuit of something bigger.

After departing the family business in search of a more sustainable income, Shamji entered the Kenyan agricultural landscape and, as a result, established AAA Growers in 2000.

Shamji knew, almost immediately, that if his farming venture was going to succeed in an ever-changing market, it would have to be a largescale operation. In order for this to materialise, he received a loan from the International Finance Corporation (IFC) of USD$500,000, which set the company’s wheels in motion.

AAA Growers’ initial site was Hippo Farm, situated in Thika, which was chosen for its water-saturated soil. Even with limited farming experience, this critical characteristic meant

that Shamji and the company could successfully grow sufficient crops to take to market.

However, AAA Growers soon faced challenges in its rate of growth, which was majorly affected by external factors such as weather patterns, periods of drought, and soil conditions, to name a few.

Internally, the company realised that, despite the number of resources it had, there was no way to speed up the growing process, which proved to be the most difficult aspect of the whole operation.

Over the first six months of the business, these challenges compounded to cause nearbankruptcy, as AAA Growers was cultivating and handling very temperature-sensitive products. Additionally, in the company’s early stages, it only had the budget for a single cold storage space, which, combined with other difficulties, nearly resulted in its closure.

However, undeterred by these obstacles, AAA Growers went back to basics. Although its owners had limited farming experience, they

decided to apply simple logic to rise above the challenging period and gain a greater understanding of the fundamentals of growing produce. Consequently, it came to light that the company required more land and space for effective crop rotation, which is key for maintaining healthy soil and optimising growth. Given that the company grows more than 20 crop varieties, a comprehensive crop rotation system allows existing soil to regenerate before the same crop is replanted and ploughed.

Therefore, by expanding its variety of produce across multiple farms, the company became more sustainable in the long run.

AAA Growers further differentiated itself in its early stages by instilling the belief of adding value at the source, an approach implemented across every facet of the business, and which was already emerging across the Kenyan horticulture sector at the time.

From here, the company developed a business model centred around in-house production, opening packaging facilities on its numerous farms, which allowed it to develop exporting capabilities.

As such, AAA Growers has evolved to become a leading grower, packager, value-adder, and exporter of crops, which has maintained the company’s success over the last 20 years.

Today, AAA Growers oversees four farms: Hippo, Turi, Chestnut, and Simba, each between 100 and 400 hectares (ha), producing top-of-therange vegetables.

The company’s vast presence means that it harvests a total of 30 megatonnes (MT) of crops a day, whilst exporting 400,000MT of the freshest vegetables worldwide with its own network of trucks that are

routinely monitored on their journeys to leading retailers, particularly in South Africa and the UK.

Having evolved from a single farm, AAA Growers now cultivates over 650ha of arable land, alongside managing a large collection of greenhouses that ensure the continued production of herbs, chillis, mangetout, and more yearround. Moreover, each farm has its own cutting-edge processing and packaging plants to maximise efficiency.

Specifically, Simba Farm, located in Nyahururu, is the company’s most recent site and is an amalgamation of everything AAA Growers has learnt in its time as a successful agricultural business.

The farm area was converted from a forest, the remainder of which surrounds the site. Creating the required environment for sufficient crop growth meant that the company

The company cares deeply about the nutrients of its soil and therefore carefully monitors its use of growth stimulators to ensure the least amount of harm possible.

Across its four farm sites, AAA Growers has implemented an integrated pest management (IPM) system and carefully composed its biochemicals in a way that abides by its zero maximum residue level (MRL) policy.

The company has thus put numerous sustainability measures in place to nurture its crops and the planet:

MULTIPLE SITES – AAA Growers spreads crops across numerous farms to ensure a stable supply of produce grown in optimum climate conditions.

DIVERSIFIED GROWING – Crops are grown using drip irrigation, pivots, and greenhouses to mitigate negative weather patterns.

INTERNAL FARM PRODUCTION – The company farms around 400ha of cultivated land, from which it produces 90 percent of its exports with in-house production facilities.

PACKHOUSES – Each farm has its own packhouse, reducing the emissions typically generated when transporting raw materials and enabling greater cold chain management.

had to ensure that there was optimum access to water, which is a continuous challenge faced by farmers across Africa.

To tackle this industry-wide challenge, the company built speciality reservoirs and other cutting-edge equipment, including polytunnels and ample cold storage space.

Furthermore, AAA Growers developed highly advanced digital and scientific systems that have helped it become a highly successful commercial entity.

As a result, Simba Farm generates viable business returns and bestin-class vegetables for its overseas customers. In addition, the company ensures its staff have a clear understanding of how to operate complex systems and work efficiently within the required quality parameters.

For example, when AAA Growers implemented an average weight system across its packaging plants, operating staff were trained on how to maintain a consistent weight in every package. This precaution reduced the amount of excess produce packaged by approximately five tonnes (t) over the course of a year, equating to four percent of its total produce output.

Moreover, the company also ensures that once packaged items reach the end of the line, they hit the supermarket shelves within 48 hours, whether that be for domestic or international retail purposes.

Thus, the company guarantees that its products are shelf-ready once they leave the plant, resulting in only the freshest produce for its millions of consumers.

AAA Growers has also evolved to become a key player in the international floriculture industry, growing and exporting roses across the world for over a decade through a specialist business subsidiary.

AAA Roses was established in 2011 before beginning to export products primarily to Europe and the Middle East a year later. Thus, within 12

months, the company built a strong reputation in the Kenyan flower sector due to its unmatched rose quality, cutting-edge facilities, and passionate team.

Akin to AAA Growers’ horticulture operations, AAA Roses’ growing, packaging, and exporting processes are completely in-house, with its flowers exported across the world to Africa, the Middle East, Asia, and Europe.

Due to the continued success of the subsidiary, AAA Growers enjoys a diversified income stream and is subsequently expanding its rose

Comprising over 3,500 staff members, AAA Growers has a strong focus on employee well-being and creating sustainable jobs for the local community. Unlike other Kenyan agricultural players, the company employs staff throughout the year rather than exclusively at the height of the harvest season.

As a result, AAA Growers’ staff have access to a stable income, which ultimately leads to a better quality of life and a willingness to come to work and enjoy their jobs.

Additionally, the company’s management is not hierarchical but rather vertical, encouraging a familial atmosphere where there is a simple line of communication and staff feel they can easily talk to senior leaders.

Ultimately, AAA Growers strongly believes that important decisions should be made in the field rather than the boardroom.

operation to facilitate greater export abilities and bolster AAA Growers’ trusted in-house capabilities.

Elsewhere, the company’s horticultural expertise extends to the production of tomato seeds and a plethora of herbs across its four farming sites.

AAA Growers’ tomato seed production involves the manufacturing of hybrid seeds, coupled with its extensive agronomical knowledge and in-depth understanding of highly detailed growth and harvesting processes.

Key to this business subsector is ensuring that staff feel integrated within the company’s success. As a result, the team feels more passionate about its work, which subsequently leads to greater efficiency.

Going forwards, AAA Growers wishes to pursue cultivating a family ethos across the business as a key success factor.

Moreover, it strives to continue establishing and expanding its existing operations, whilst also branching into other areas, such as the implementation of an avocado production line in the near future.

Through the execution of these projected plans, AAA Growers will inevitably achieve the status of a global horticulture corporation.

Xpro Packaging Limited, Nairobi’s premier destination for top-tier food and beverage packaging solutions with a green edge. With over two decades of industry expertise, we craft innovative, eco-friendly products that meet the highest quality and hygiene standards. Our state-of-the-art facility, powered by skilled professionals and cutting-edge automation, ensures impeccable safety and precision while minimising our environmental impact. Fully compliant with BRCGS standards, Xpro Packaging Limited is your trusted partner for sustainable packaging excellence.

Below are the following products manufactured at Xpro Packaging Limited:

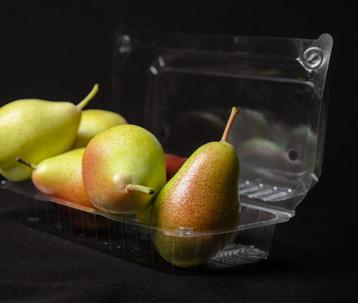

• Paper and plastic punnets for the horticulture industry

• Paper and plastic cups

• Paper and plastic plates and bowls

• Takeaway containers

• Cutleries

xpro@xpropackaging.com