Leading the way in the ever-important transport industry and driving South Africa’s economic future

Paul Coe, CEO, talks about ongoing operations, employee training, local procurement, and more at leading surface mining and civil earthworks contractor, BCM Group

Africa Outlook, APAC Outlook, EME Outlook, North America Outlook, Mining Outlook, Healthcare Outlook, Manufacturing Outlook, Supply Chain Outlook, and Food & Beverage Outlook are digital publications aimed at boardroom and hands-on decision-makers, reaching an audience of more than 800,000 people around the world.

With original and exclusive content compiled by our experienced editorial team, we look to promote the latest in engaging news, industry trends and success stories from across the globe.

Your company can join the leading industry heavyweights enjoying the free exposure we provide across our platforms with a free marketing brochure, extensive social media saturation, enhanced B2B networking opportunities, and a readymade forum to attract new investment and to help you grow your business.

Visit www.outpb.com/work-with-us for details on how your company can feature for free in one of our upcoming editions.

EDITORIAL

Head of Editorial: Jack Salter jack.salter@outpb.com

Deputy Head of Editorial: Lucy Pilgrim lucy.pilgrim@outpb.com

Senior Editor: Lily Sawyer lily.sawyer@outpb.com

Editor: Ed Budds ed.budds@outpb.com

Editor: Rachel Carr rachel.carr@outpb.com

Editor: Lauren Kania lauren.kania@outpb.com

PRODUCTION

Art Director: Stephen Giles steve.giles@outpb.com

Senior Designer: Devon Collins devon.collins@outpb.com

Designer: Louisa Martin louisa.martin@outpb.com

Production Manager: Alex James alex.james@outpb.com

Digital Marketing Director: Fox Tucker fox.tucker@outpb.com

Web Content Manager: Oliver Shrouder oliver.shrouder@outpb.com

Social Media Executive: Jake Crickmore jake.crickmore@outpb.com

BUSINESS

CEO: Ben Weaver ben.weaver@outpb.com

Managing Director: James Mitchell james.mitchell@outpb.com

Chief Commercial Officer: Nick Norris nick.norris@outpb.com

TRAINING & DEVELOPMENT DIRECTOR

Joshua Mann joshua.mann@outpb.com

BUSINESS DEVELOPMENT DIRECTOR

Thomas Arnold thomas.arnold@outpb.com

DIVISIONAL DIRECTOR

Deane Anderton deane.anderton@outpb.com

HEADS OF PROJECTS

Eddie Clinton eddie.clinton@outpb.com

Josh Rayfield josh.rayfield@outpb.com

Ryan Gray ryan.gray@outpb.com

SALES MANAGERS

Donovan Smith donovan.smith@outpb.com

PROJECT MANAGERS

Cameron Lawrence cameron.lawrence@outpb.com

Poppi Burke poppi.burke@outpb.com

Taylor Green taylor.green@outpb.com

ADMINISTRATION

Finance Director: Suzanne Welsh suzanne.welsh@outpb.com

Finance Assistant: Suzie Kittle suzie.kittle@outpb.com

Finance Assistant: Victoria McAllister victoria.mcallister@outpb.com

CONTACT

Africa Outlook

Norvic House, 29-33 Chapelfield Road Norwich, NR2 1RP, United Kingdom

Sales: +44 (0) 1603 804 445

Editorial: +44 (0) 1603 804 431

SUBSCRIPTIONS

Tel: +44 (0) 1603 804 431

jack.salter@outpb.com www.africaoutlookmag.com

Like us on Facebook: facebook.com/africaoutlook

Follow us on X: @africa_outlook

Welcome to our 110th edition of Africa Outlook magazine.

Transport is the beating heart of socioeconomic growth in South Africa, with a variety of modes available across the nation.

Many South African cities have therefore prioritised the transportation sector in an effort to further progress and achieve long-term development goals.

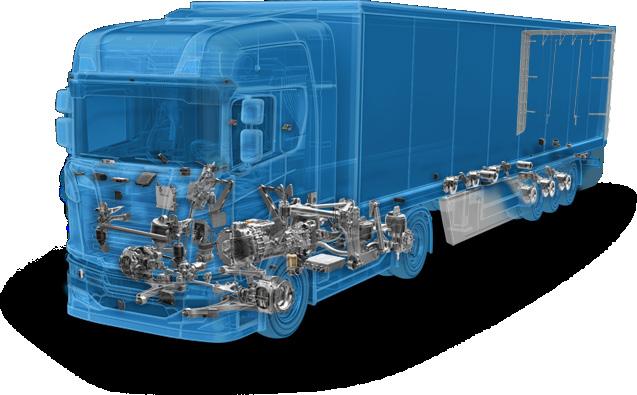

In the driver’s seat of this issue is MAN Automotive South Africa, a leading manufacturer of medium, heavy, and extra-heavy trucks as well as commuter buses and luxury coaches.

Our comprehensive coverage considers how MAN Automotive South Africa has asserted itself over the past five decades as a leader in the country’s everimportant transportation industry.

“We are dominant in this market purely because we are the only company able to produce an entire product in one go and provide customers with a single point of contact for any further assistance, whereas others combine and sell chassis and bodybuilders from different manufacturers,” expands Managing Director, Jan Aichinger.

Wheels are one of the most critical components of any road vehicle, efficiently converting engine power into movement.

Tyre manufacturing accounts for the vast majority of global natural rubber production, supporting mobility around the world.

Beyond merely producing high-quality natural rubber, SIPH proactively promotes the sustainable production of this crucial commodity across West Africa.

“We participate in various capacity-building programmes using our knowledge of rubber tree cultivation on our plantations to improve our smallholders’ agricultural and sustainability practices,” outlines General Director, Marc Genot.

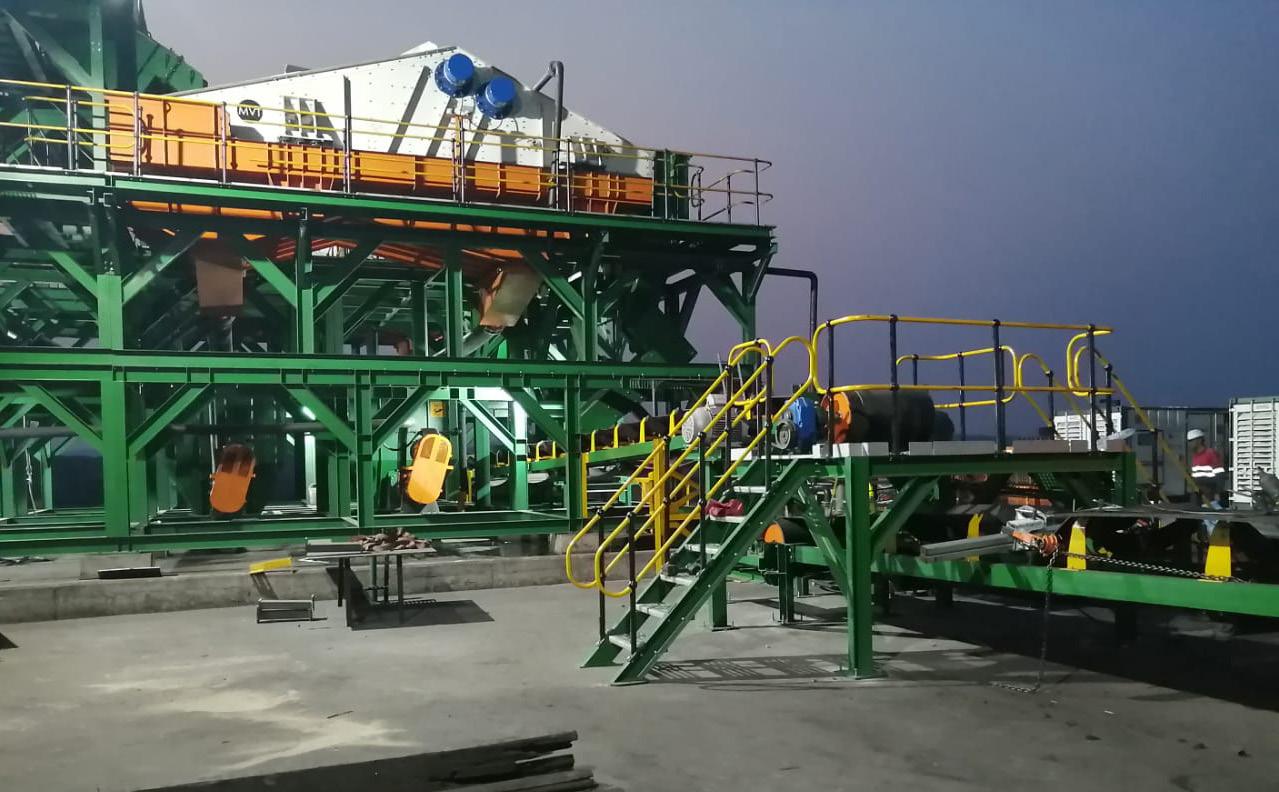

To deliver production on target and within required timelines, meanwhile, BCM Group has a deep understanding of African mining dynamics.

Indeed, the experienced surface mining and civil earthworks contractor has operated for almost a century and been firmly established in Africa since 1990.

“We have expanded our presence by serving a diverse client base throughout West Africa, Central Asia, and the Middle East,” Paul Coe, CEO, tells us.

This edition also brings you up to speed with the latest developments from The Capital Hotels, Apartments & Resorts, Ruvuma Coal, Sasini PLC, the Ugandan Chamber of Mines & Petroleum, and more.

We hope that you enjoy your read.

Jack Salter Head of Editorial,

Outlook Publishing

42 MAN Automotive

South Africa

Discover the Future of Transport

Driving forward the future of South African transportation

MANUFACTURING

72 SIPH

MINING

82 Ruvuma Coal

Excavating the Spirit of Exploration

Illuminating the Ruvuma region of Tanzania

92 BCM Group

Specialist Contractor

Surface mining and civil earthmoving expertise

RETAIL

106 The Capital Hotels, Apartments & Resorts

The Height of Hybrid Hospitality

Breaking boundaries in high-tech hotel services

FINANCE

112 I&M Bank

Driving Financial Inclusion

Forging a rich heritage

106 FEATURES

Rooted in People and Planet

Promoting the sustainable production of natural rubber

72

92

98 Kansanshi Mining Plc

Cornerstone Copper Operation

An update on the Kansanshi mine’s S3 Expansion Project

FOOD & BEVERAGE

122 Sasini PLC

A Sustainable Operation

Ongoing support for local communities and the environment

128 AAA Growers

The Art of Growing

The freshest produce from soil to store

JPMORGANCHASE, THE LARGEST bank in the US, plans to expand to Kenya and Ivory Coast this year, increasing its African presence.

The Central Bank of Kenya has already authorised the finance company to establish a representative office in the country.

Presently operating in over 100 countries, the bank has more than

USD$4.2 trillion in assets. JPMorgan Chase will focus its expansion on commercial and investment banking, treasury services, and potentially lending.

However, it has no immediate plans to offer asset and wealth management services that are already available in South Africa and Nigeria.

THE WORLD BANK has reduced its economic growth forecast for sub-Saharan Africa, primarily because of the damage to Sudan’s economy caused by the civil war between two rival factions of the military government as well as the impacts of climate change, including floods, droughts, and cyclones. Despite reducing the region’s

2024 growth forecast from 3.4 to three percent, this remains above the 2.4 percent growth experienced in 2023.

Meanwhile, growth in South Africa, the region’s most advanced economy, is expected to increase to 1.1 percent this year, whilst Kenya, the wealthiest economy in East Africa, is expected to expand by five percent.

AEROSPACE

AFTER RECENTLY LAUNCHING its first satellite, Senegal has joined other African nations in the space race.

Gaindesat-1A, which was effectively deployed aboard SpaceX’s Falcon 9-Transporter 11 rideshare mission, will collect data and play a crucial role in monitoring conditions nationwide, enhancing weather forecasting.

The West African country has made significant advancements in technology and science, achieving a major milestone after five years of dedicated work by STEM professionals.

A total of 17 African countries have launched over 60 satellites into orbit to date largely due to a reduction in the associated costs, which has opened up the market.

EGYPT’S NEW ADMINISTRATIVE Capital (NAC), located on the outskirts of Cairo, will soon be home to a hydrogenpowered skyscraper complete with solar panels.

The developer of the Forbes International Tower, Magnom, aims to ensure that the building removes more carbon than it emits.

The ambitious project will comprise 75 percent hydrogen and 25 percent photovoltaics. Magnom hopes this skyscraper will be the first in the world to register for a Zero Carbon Certificate from the International Living Future Institute.

The 43-floor office building will be constructed using materials

that reduce associated emissions throughout their life cycle, consequently cutting its carbon footprint by 58 percent.

TRAVELLERS FROM RWANDA

to the US will now undergo screening for the Marburg virus after the US Embassy advised its employees in the East African country to work remotely for the time being.

The Rwandan capital, Kigali, has reported a total of 58 cases,

including 13 deaths, with most of the victims being healthcare workers. Marburg belongs to the same family of viruses as Ebola and has an 88 percent fatality rate.

Last year, neighbouring Tanzania experienced an outbreak, but this is the first time the Marburg virus has been confirmed in Rwanda.

CHINA’S LARGEST PUBLICLY listed metal producer, Zijin Mining Group (Zijin), has signed an agreement to acquire 100 percent ownership of the Akyem gold mine in Ghana from US-based Newmont Corp – the world’s leading copper, silver, zinc, and lead producer.

Akyem, one of Ghana’s most significant gold mines, is expected to be sold for USD$1 billion by the end of 2024.

Ghanian entities have shown interest in acquiring a minority stake in the mine, and Zijin has expressed its openness to exploring potential transactions.

AFRICA IS BECOMING A key market for social media companies amid an uptick in engagement from young, tech-savvy users, prompting increased investments from tech titans Meta, the parent company of Facebook and Instagram, and ByteDance, the owner of TikTok.

Both companies have significantly expanded their presence in Africa in recent years, with TikTok emerging as one of the leading sources of news and entertainment.

Additionally, social media provides a platform for African creatives to monetise their work and extend their reach beyond the continent, enabling them to connect with collaborators and investors.

Christopher Meredith, Senior Vice President of Business DevelopmentEMEA at market-leading global video game commerce organisation, Xsolla, reflects on how a seamless payment ecosystem could unlock Africa’s gaming economy

Writer: Christopher Meredith, Senior Vice President of Business Development - EMEA, Xsolla

n a continent rich with potential but often overlooked by global tech giants, Africa’s gaming industry is quietly transforming into one of the world’s fastest-growing sectors.

there’s a hurdle preventing Africa’s gaming ecosystem from reaching its full potential: an outdated and fragmented payments infrastructure.

The continent boasts a young, techsavvy population and an insatiable appetite for digital entertainment. Yet,

For game developers and publishers in the continent, the question isn’t whether Africa will be a major player in the global gaming economy but

rather how the payments landscape can be restructured to unlock the vast opportunities that lie ahead.

For most, gaming payments often mean a credit card or bank transfer -

seamless, swift, and taken for granted.

However, in Africa, where financial inclusion remains a major challenge, these options must be within reach for some of the population. This is where mobile money comes into play.

Africa has leapfrogged traditional banking models, embracing mobile wallets at an unprecedented scale. Adopting mobile-first payment solutions can be a game-changer in the gaming world. For millions of Africans, a mobile wallet is their primary financial tool, and its integration within gaming platforms offers a seamless way to pay for games, make in-game purchases, and even receive rewards.

Game developers who tap into this can reach a far larger audience, including those traditionally excluded from digital economies. This shift could unlock billions for the gaming industry.

Africa is a continent of contrasts, home to more than 50 countries, each with their own currency, financial regulations, and consumer habits. This complexity makes payments challenging for global gaming platforms. So, what’s the solution? It’s simple: localisation.

Localised payment systems integrating with popular mobile services are essential for game developers to tap into this market. For many users, these platforms offer a sense of familiarity and security.

By focusing on local payment systems, developers can streamline the user experience and, more importantly, build trust - an elusive but critical factor for consumers in markets where concerns over security are rife.

In short, localisation isn’t just a technical necessity - it’s a vital way to win the hearts and minds of African gamers.

The most exciting prospect of

revolutionising gaming payments in Africa is its potential to drive financial inclusion.

While the continent’s unbanked population remains high, the rise of mobile money presents an extraordinary opportunity to bring more people into the digital financial ecosystem through gaming.

Integrating services into platforms like Xsolla can help gamers manage their funds via mobile devices without the need for traditional bank accounts. This is transformative in a region where banking infrastructure is often inaccessible.

By embracing these mobile-first solutions, the financial gap can be bridged. This will enable previously excluded populations to engage in the digital economy through buying games or participating in microtransactions.

As more people access these platforms, they aren’t just participating in entertainment - they’re gaining a foothold in the financial systems they were once excluded from.

By reshaping the payment landscape, gaming is poised to become more than a pastime in Africa but an engine for inclusion and financial growth.

Revolutionising Africa’s payments isn’t just about making buying games or paying for in-app purchases easier. It’s about tapping into the continent’s unique strengths – its mobilefirst economy, appetite for digital innovation, and youth.

With mobile-first solutions and the rise of mobile money services, gaming is no longer limited by traditional banking infrastructure. This allows even those in remote or underserved regions to participate in the digital economy.

Africa’s unique mobile ecosystem, already familiar to millions, bridges the gap between gaming and financial

access, making entertainment more inclusive.

As these localised payment systems become more widespread, they have the potential to drive economic growth by expanding across digital platforms and fostering financial literacy. Gaming, once seen solely as a form of entertainment, is now emerging as a powerful tool for economic empowerment.

The growing gaming community is poised to lead Africa into a new digital era. As such, by creating a seamless payment ecosystem, the continent’s gaming industry can become a global leader, offering lessons for other emerging markets.

More than that, it can provide millions of Africans with a new avenue for inclusion, creativity, and economic opportunity. It’s a bold vision - but one that is entirely within reach.

Christopher Meredith is the Senior Vice President of Business Development - EMEA at Xsolla, a seasoned executive with over 25 years of experience in the interactive entertainment industry.

Known for his visionary strategies and expertise in brand revitalisation, Meredith has consistently driven growth and profitability across global markets, from start-ups to corporate giants.

Dirk S. van Doorn, Managing Director of DHL Namibia, discusses the company’s wellestablished presence in Namibia as a firstchoice logistics partner, its ongoing support for the mining and oil and gas industries, and aspirations for sustainable expansion

Writer: Lily Sawyer

Established as a key player in Namibia’s logistics and courier industry over 35 years ago, DHL Namibia boasts a proud history.

Initially expanding into the Namibian market as part of DHL’s global strategy to provide efficient and reliable express delivery services around the world, the move aimed to meet growing logistical needs across Africa’s various sectors, ranging from mining, fishing, and agriculture to government services.

More recently, DHL Namibia has expanded into oil and gas logistics services, as well as green hydrogen, which have the potential to become significant contributors to the country’s economy.

“DHL Namibia’s journey over the past 35 years reflects its commitment to serving the nation’s logistical needs while continually evolving to meet new market demands, making it a cornerstone of Namibia’s logistics infrastructure,” opens Dirk S. van Doorn, Managing Director.

Headquartered in Windhoek with a key port city location in Walvis Bay, two agents in Lüderitz and Swakopmund, and 16 retail partners across the country, the company offers a wide range of express logistics solutions supported by a robust network of 110 direct and indirect staff members.

As such, DHL Namibia plays a pivotal role in connecting the nation’s business individuals to global markets whilst ensuring reliable and fast delivery services across Namibia.

One of the country’s leading logistics providers, DHL Namibia has been instrumental in providing businessto-business (B2B) transport services between key sectors, including

• EFFICIENCY AND SPEED: A core principle for DHL, both globally and in Namibia, has been ensuring fast and reliable delivery services. This aligns with the entire company’s global reputation for express service. DHL Namibia was also the first delivery organisation in the country to introduce its own dedicated airfreight service, operating five days a week with two rotations from Windhoek to Johannesburg, connecting Namibia to the rest of DHL’s global network.

• GLOBAL CONNECTIVITY: From the outset, DHL Namibia’s services sought to connect the country to the rest of the world. As a developing nation with a growing economy, Namibia required access to international markets. This is where DHL Namibia came in, providing the infrastructure to connect local industries, such as mining, with international partners.

• CUSTOMER-CENTRIC APPROACH: DHL Namibia has always emphasised delivering a first-class service to its customers by understanding their unique needs, from individuals to large corporations. Its operations are built around customer convenience and accessibility, allowing businesses to focus on their core activities without worrying about logistics.

• INNOVATION IN LOGISTICS: DHL Namibia’s operational model is built on adopting forward-thinking practices to meet evolving market demands. Over the decades, the company has incorporated technology-driven solutions within its operations to enhance product tracking, shipment management, and overall transparency.

• SUSTAINABILITY AND CORPORATE RESPONSIBILITY: As part of its global mission, DHL Namibia has increased its focus on reducing its environmental footprint by improving operational efficiencies and utilising cleaner technologies that form part of a strategy to achieve net zero emissions by 2050.

mining, agriculture, manufacturing, retail, oil and gas, and green hydrogen.

Offering everything from customised express freight services to supply chain optimisation, the company not only handles the movement of large equipment and regular supply shipments but manages warehousing, inventory, distribution, and last-mile delivery as part of its B2B offering.

For businesses involved in overseas trade or international partnerships, DHL Namibia also provides crossborder and international end-to-end logistics solutions, including guidance

on customs clearance and regulatory compliance.

To substantiate its reliability and provide B2B customers with full transparency, the company offers various monitoring and supply chain management solutions.

“Our integrated, advanced tracking and shipment management systems allow our clients to monitor their goods in real-time,” van Doorn details.

To complement this, a My DHL+ solution enables customers to manage several aspects of their supply chain themselves through the use of DHL proprietary software.

Responsible for a substantial 14 percent of Namibia’s GDP, the country’s mining sector is a key driver of the economy – and one in which DHL Namibia plays a crucial role.

For instance, when it comes to the transportation of large, heavy, and sensitive mining machinery or the supply of essential materials, DHL Namibia offers extensive road and air freight services alongside end-to-end logistics solutions.

“Supplemented by the company’s worldwide connectivity, we often

partner with international mining suppliers and contractors who are able to import specialised equipment from global markets efficiently,” van Doorn elaborates.

Furthermore, DHL Namibia assists mining companies in navigating the often complex regulatory and customs requirements for importing and exporting goods. Such requirements are especially important in the mining industry, which often deals with shipments that must meet stringent regulations.

“DHL Namibia’s close relationship with the mining industry showcases

How important are accolades and awards to DHL Namibia in recognising its corporate social responsibility practices?

DIRK S. VAN DOORN, MANAGING DIRECTOR: “DHL Namibia’s certified recognition as a ‘Great Place to Work in 2024’, along with being named as a ‘Top Employer in Namibia, 2024’, underscores the company’s commitment to creating a positive workplace culture and highlights its corporate social responsibility (CSR) efforts.

“Being the only business in Namibia to achieve both accolades is a significant milestone, reflecting the impact of DHL Namibia’s employee-centred initiatives and its broader commitment to social and environmental responsibility.

“Last month, this recognition was amplified when the Employment Equity Commission of Namibia awarded DHL Namibia with an A-grade certification. It’s a rare feat to be awarded all these recognitions simultaneously, acclaims van Doorn.”

He goes on to point out the importance of the awards in terms of recognising employee well-being and validating the company’s CSR practices.

“These awards are a testament to DHL Namibia’s commitment to not only driving business success but also creating a positive societal impact through ethical, responsible, and people-centric practices,” he adds.

its ability to support the country’s critical sectors with tailored, reliable, and high-capacity logistics solutions,” he affirms.

Over the last 18 months, DHL has played a key role in supporting oil exploration projects off the coast of Namibia, transporting specialised exploration equipment to the necessary sites.

“These oil discovery projects, particularly those in offshore regions such as the Orange Basin, have been a major focus for us due to the nation’s increasing prominence as a potential oil and gas producer,” van Doorn outlines.

Key aspects of DHL Namibia’s involvement include the transportation of heavy exploration equipment, such as seismic survey tools, drilling machinery, and underwater inspection devices, alongside coordination with DHL’s international network, which spans 220 countries and territories, to secure supplies and equipment.

“This includes managing customs clearance and regulatory requirements to ensure the smooth importation of the necessary equipment,” he points out.

Not only is DHL Namibia involved in the initial transportation stages of these projects, but it also provides day-to-day support for oil exploration operations, including transporting spare parts and geological samples to offshore rigs, always ensuring operations run seamlessly.

Meanwhile, given the environmental sensitivities surrounding offshore oil exploration, the company complies with local environmental regulations so that its transportation processes fall in line with international environmental health and safety standards.

“We support exploration efforts

while adhering to strict sustainability protocols to minimise environmental impact,” van Doorn explains.

Through its involvement in oil discovery projects, DHL Namibia has demonstrated its ability to handle complex logistics operations in highstakes industries, moving critical equipment efficiently and reliably to advance the country’s burgeoning oil and gas exploration efforts.

Driven by a growing demand for cross-border trade and the transportation of goods between South Africa (SA) and Namibia, DHL Namibia has noted a significant increase in road haulage between the two nations.

Given that SA is Namibia’s largest trading partner, the upsurge in road freight reflects broader economic activity in sectors such as manufacturing, retail, mining, and agriculture.

“Another factor contributing to increased road freight has been as a result of the Johannesburg OR Tambo Airport acting as a key aviation gateway for Southern Africa,” van Doorn highlights.

This increase has led to the

“DHL NAMIBIA’S JOURNEY OVER THE PAST 35 YEARS REFLECTS ITS COMMITMENT TO SERVING THE NATION’S LOGISTICAL NEEDS WHILE CONTINUALLY EVOLVING TO MEET NEW MARKET DEMANDS, MAKING IT A CORNERSTONE

OF NAMIBIA’S LOGISTICS INFRASTRUCTURE”

– DIRK S. VAN DOORN, MANAGING DIRECTOR, DHL NAMIBIA

company transporting larger volumes of goods between the two nations, including finished goods and critical supplies, bolstering Namibia’s key industries, which rely heavily on imports from SA.

On top of this, more frequent road transport services, additional direct routes, and optimised scheduling have allowed DHL Namibia to reduce delivery times for its clients in both nations.

However, the surge in road haulage has also increased the company’s workload in terms of volume, operational demands, and customs management. To account for this, DHL Namibia has contracted a larger fleet of trucks through its accredited provider and enhanced its logistics infrastructure to handle more shipments daily.

Overall, increased trade between Namibia and SA, supplemented by the company’s expert logistics solutions, has positively impacted both countries’ economies, facilitating smoother trade and helping local businesses to expand their market reach.

“DHL Namibia’s role in this process has reinforced its position as a critical logistics partner for many Namibian

businesses,” van Doorn prides.

Strengthening cross-border relations and enabling the company to better serve key industries, this expansion positions DHL Namibia as a crucial integrator in the region.

Committed to the growth of the nation’s economy, DHL Namibia continues to invest in resources to ensure it is ready and able to serve key industries such as mining, agriculture, retail, and oil and gas.

For example, with plans in place to open additional branches and logistics hubs in underserved areas of Namibia, the company hopes to establish a stronger national presence, especially in remote locations where industries like mining and agriculture are expanding.

“By establishing a stronger presence in regions across the northern and southern parts of Namibia, we aim to improve access to our logistics services for both businesses and individuals with a focus on small to medium-sized enterprises (SMEs),” van Doorn confirms.

Meanwhile, DHL Namibia also seeks

“DHL

NAMIBIA’S CLOSE RELATIONSHIP WITH THE MINING INDUSTRY SHOWCASES ITS ABILITY TO SUPPORT THE COUNTRY’S CRITICAL SECTORS WITH TAILORED, RELIABLE, AND HIGH-CAPACITY LOGISTICS SOLUTIONS”

– DIRK S.

VAN DOORN, MANAGING DIRECTOR, DHL NAMIBIA

DHL Namibia continues to strive for perfection across every facet of the company to be a responsible, community-oriented, and accountable employer. This includes:

• Implementing employee-centric programmes

o Training and development, including opportunities for skills growth, leadership training, professional courses, and mentorship programmes

o Diversity and inclusion programmes that seek to provide equal opportunities for women in a historically male-dominated sector.

o Work-life balance and employee wellness, including flexible working arrangements and welfare programmes

• Improving environmental sustainability

o GoGreen programme

o Recycling and waste management

• Community engagement and support

o Education and skills development

o Charitable contributions and volunteering

• Robust health and safety initiatives

o Regular safety training and audits

o Compliance with international health and safety standards

“By prioritising its employees, community, and the environment, DHL Namibia continues to set an example of how businesses can balance profitability with corporate responsibility,” van Doorn prides.

to enhance its rural connectivity to ensure faster and more reliable delivery services across its South African trade routes, expanding its presence along key trade corridors and connecting Namibia to SA, Botswana, Angola, and Zambia.

With intentions to further develop operations along its Walvis Bay corridor, a major trade route connecting Namibia to the rest of Southern Africa, the company leverages the strategic location as a potential hub for oil and gas support.

Elsewhere, DHL Namibia’s ongoing investment in digital infrastructure and e-commerce logistics services, such as warehousing, fulfilment, and last-mile delivery, will support the booming online retail sector alongside improving service delivery, customer experience, and operational efficiency.

Finally, the company’s continued expansion will see it invest in sustainable infrastructure such as eco-friendly, energy-efficient warehouses, whilst its global GoGreen programme seeks to increase the use of Sustainable Aviation Fuel (SAF) and become the market leader.

Meanwhile, DHL Namibia continues to use electric and fuel-efficient vehicles, invest in renewable energy, and implement carbon-neutral shipping options.

“We seek to widely integrate sustainability into our supply chain operations, promoting greener logistics practices across the board,” van Doorn concludes.

DHL NAMIBIA

Tel: +264 61 204 0800

www.dhl.com/na-en/

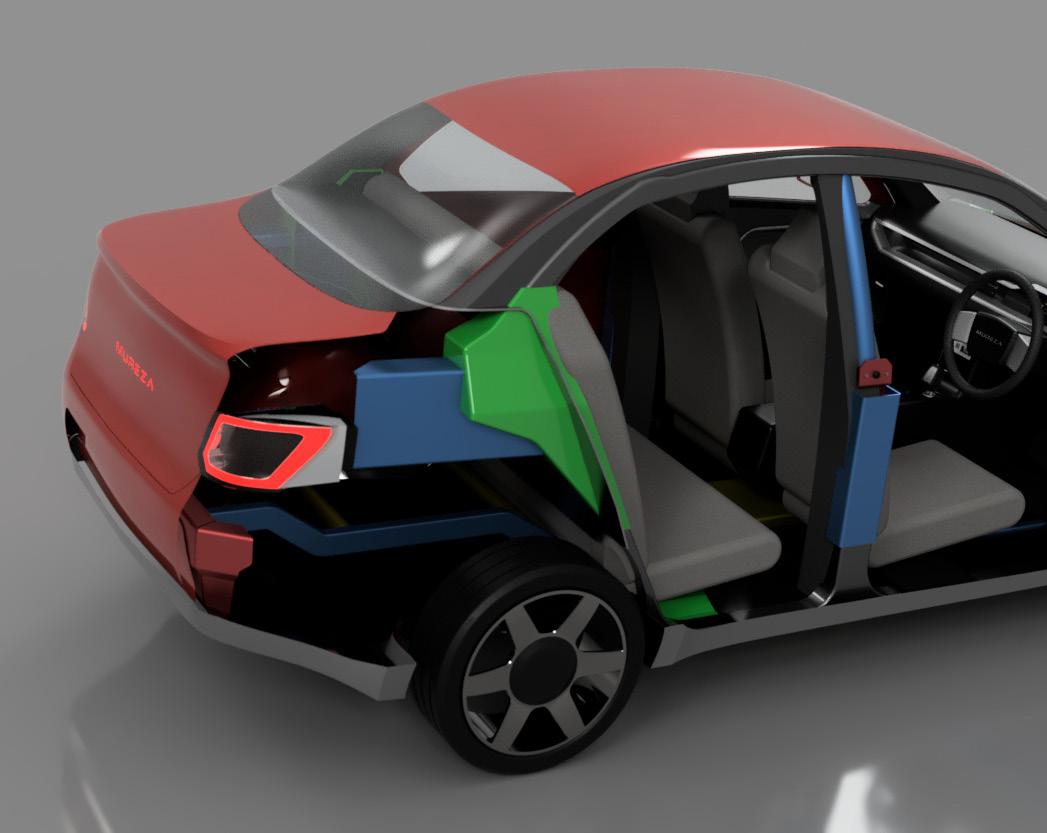

South African-based car manufacturer, Mureza Auto Co Pty Ltd, is deeply committed to serving the African market.

Tatenda Mungofa, Founder, outlines the company’s vision to become the country’s leading automotive brand

Writer: Lily Sawyer

Initially founded to address the unique transportation challenges of the African continent, Mureza Auto Co Pty Ltd (Mureza) offers affordable, high-quality vehicles designed specifically for local conditions.

Providing economically viable, sustainable transport solutions is a major part of the company’s strategy, which has led to many customers requesting unique and original vehicle solutions.

“We have fast become the go-to company for bespoke, affordable automotive solutions for the African market,” introduces Founder, Tatenda Mungofa.

As a business-to-business (B2B) company, Mureza’s customer base comprises both new and established automotive dealerships across the country.

“Our main production facility in Pilanesberg, South Africa (SA) is in its early stages of development. This is where the majority of our production will take place,” he sets out.

The company also has plans to set up assembly plants in Zimbabwe and Namibia alongside a West African manufacturing facility in Senegal.

“All our production sites are strategically located, supported by a growing distribution network,” Mungofa adds.

As an exciting and rapidly transforming space, the African automotive industry strives to support local value chains and brands.

“For us, however, the major hurdle is sourcing enough funding to build out capacity,” Mungofa discloses.

in the evolution of the continent’s automotive industry.

Lithium, cobalt, and other raw materials are key to unlocking value for the African industry, and governments across the continent are becoming increasingly aware of the advantages of local beneficiation.

Mureza works hard to promote African industrialisation and the national value chain. As such, its activities are largely focused on telling a story from grassroots to full-scale production.

Nevertheless, he notes how encouraging it is to see local investors support automotive companies like Mureza and anticipates a boom in investments over the next three years.

Meanwhile, electric vehicles (EVs) have become increasingly popular, accompanied by a shift in brand loyalty with many customers opting for newer Chinese brands over those from Europe, Japan, or the US.

Despite the attractive prospects that international competitors present, the recent widespread adoption of the African Continental Free Trade Area (AfCFTA), which seeks to unite the 55 countries of the African Union to create a single trade market for the continent, presents huge opportunities for the local economy.

“This is going to be the biggest market yet for African vehicles. I encourage major international brands to reposition their current investments into upcoming African car manufacturing companies to curb the decline most of them will experience as a result of the AfCFTA,” he advises.

As critical components in car manufacturing, Africa’s mineral resources also play an important role

“Africa needs industrial leadership. What we provide is inspiration to all Africans who dream of building largescale companies within the industrial sector,” Mungofa states boldly.

By establishing a refined and detailed development programme for every supplier in its value chain, Mureza is able to substantiate this claim.

In addition, the company’s database of over 150 suppliers ranges from small to medium-sized enterprises (SMEs) all the way to major Tier 1 contractors. This promotes crosspollination across the supply chain and an environment that supports the growth of smaller companies alongside experienced players with global exposure.

“Our microfactory strategy is a catalyst for rapid industrialisation across Africa and we plan on developing at least four main factories over the next 10 years,” he reveals.

Each of Mureza’s factories will be supported by 15 smaller assembly plants, each complete with a supplier park to support its operations.

Mureza believes that this unique growth strategy will promote local supply chains whilst benefitting surrounding communities with employment and development opportunities.

AFRICA OUTLOOK: AS MUREZA CONTINUES TO GROW

Tatenda Mungofa, Founder: “As a business, we are focusing on vehicle design and production. This has opened up many opportunities for us within the turnkey consulting space in the automotive sector.

“Therefore, we are willing to onboard clients who are looking for insight on how to set up operations similar to ours or that feed into our workflow. There is a lot of value in what we have built so far, and many investors can benefit from the research we have accumulated.

“Elsewhere, our archive of digital assets is set to be launched as a gaming platform, and we are currently looking for suitable partners to roll this out.

“Another interesting space we are venturing into is property development. This comes on the back of Mureza acquiring a lot of strategic real estate for our manufacturing facilities in SA, Zimbabwe, Namibia, and Senegal.

“We have realised the potential of these assets based on their strategic locations and alignment with the growth plans of these respective countries.”

This will naturally be accompanied by upskilling staff and training suppliers to meet international quality standards for vehicle components.

“The more we achieve our target to set up local factories, the more we are able to help Africa industrialise,” Mungofa asserts.

By creating an internal quality management system (QMS) to ensure vehicle components are compliant with stringent regulatory standards, Mureza guarantees the quality of its vehicles.

“It takes time to develop and produce each of our vehicles because we invest a lot of R&D into each of our models,” Mungofa prides.

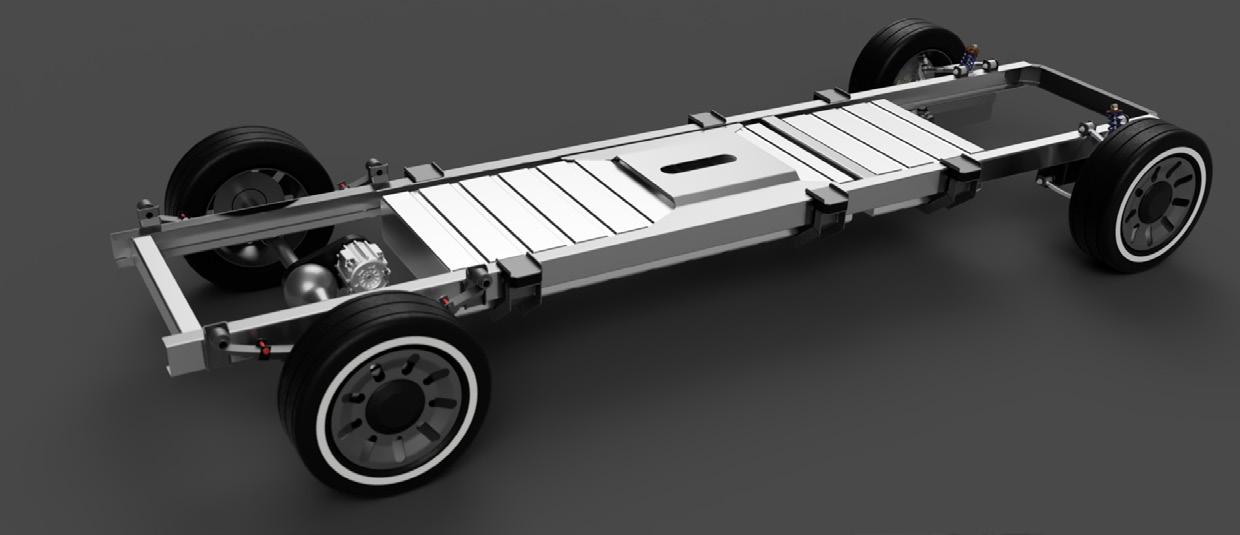

Currently, the company is working on rolling out its first EV through its microfactory process. This has so far provided a good benchmark on how Mureza’s strategy effectively reduces production times and costs to ensure affordability.

In terms of product reliability, Mureza carries out careful individual component testing to ensure each element is fully functional before being widely utilised in the production line.

It also homologates its vehicles to ensure they comply with local regulations.

“Before launching a vehicle, extensive tests are done in-house at our testing facility to assess the impacts of real-life conditions,” he explains.

Mureza’s newest vehicle was inspired by an initial internal combustion engine (ICE) model, originally intended for launch in 2019, which became severely disrupted by the onset of the COVID-19 pandemic.

“Having previously shelved the model, we’ve now redesigned it for a new platform that will be

manufactured in Africa from the ground up,” Mungofa informs.

The new sedan vehicle, SHONA, takes its name from native Zimbabwean and has significant alliance with Mureza’s own brand name.

Inspiration was also drawn from one of SA’s great actors and film producers, the late Shona Ferguson.

“Our target retail price for SHONA is ZAR225,000, available in both an EV and ICE model,” he sets out.

The EV model will have a range of 300 kilometres (km), fully charge in just two hours, and reach speeds of up to 180km per hour.

The architecture of the car is inspired by Formula 1 technology, whilst a simplified manufacturing process has been made possible by its innovative design.

“Most of the technology and features of SHONA are new and forward-thinking, providing a memorable driving experience to

each customer,” Mungofa points out.

The petrol ICE version of SHONA will be powered by a choice of three engine sizes – 1.3 litre (L), 1.6L, or 1.8L, some of which will be turbopowered to provide both enhanced performance and fuel economy.

“More details on these engines and power ratings will be shared at our upcoming launch event,” he promises.

Design is at the heart of Mureza, exemplified by the dedicated design studio and R&D centre at its manufacturing site.

“Although still relatively small, supported by a team of just 12, the design studio is the heart of our operation,” Mungofa impassions.

He goes on to explain how multiple hours are dedicated to concept creation for each of the company’s vehicles.

In addition, having recently incorporated artificial intelligence

(AI) into its design process, Mureza makes significant cost and time savings by utilising new technologies as it is able to carefully evaluate each design before proceeding to the development stage.

The company’s design engineers work collaboratively with its fabrication team, specifying colours and materials before the first mock-up.

“A lot of 3D printing is used in this process to make prototype parts. We have eliminated clay modelling at this stage as it adds significant time and cost and is an outdated craft that no longer serves our purpose,” he divulges.

Once a 1:4 scale model has been 3D printed, Mureza can rapidly re-work surfaces using computer-aided design (CAD), building a scale model with a complete interior.

At this stage, the company also simultaneously engages with suppliers to begin work on the

“WE HAVE FAST BECOME THE GO-TO COMPANY FOR BESPOKE, AFFORDABLE AUTOMOTIVE SOLUTIONS FOR THE AFRICAN MARKET”

– TATENDA MUNGOFA, FOUNDER, MUREZA AUTO CO PTY LTD

components required.

“We entrust the drive train to our suppliers and utilise an interactive project development process as a model. From idea to complete

conception, a car takes us around 90 days to finalise, costing at least 60 percent less than that of traditional automotive design studio,” Mungofa highlights.

Aiming to set a new benchmark for the African car design and production process, Mureza seeks to establish a new generation of African vehicles through innovation.

Going forwards, Mureza’s main objective is to commence the delivery of its SHONA sedan to expectant customers.

Despite an influx of demand for SHONA, the company’s current capacity only allowed it to offer 1,000 pre-orders. In order to fulfil this, it aims

to complete production and start rolling off units in Q4 2024.

In addition, Mureza hopes to grow its human resources department from 65 employees to 150, supported by its suppliers’ anticipated workforce increase.

Meanwhile, showrooms and dealerships will be commissioned for 2025, whilst a continental expansion plan will be rolled out to manage the wider distribution of vehicles.

“We also look forward to getting long-term test reviews returned from different stakeholders,” Mungofa

outlines.

Further to this, Mureza hopes to be listed on the Johannesburg Stock Exchange (JSE), which is dependent on it delivering its 1,000 SHONA models within the proposed timeframe.

“We also want to give Africans an opportunity to be part owners of Africa’s flagship automotive brand, and we believe our growth will be faster if we work together,” he reveals.

Overall, the company aims to continue having fun growing the business and bringing its vision to life.

“If we manage to break into international markets beyond Africa, we look forward to collaborating with new prospective partners who share our vision of making the world a better place,” he concludes.

The latest evolution in healthcare logistics, drone delivery is helping those most in need across Africa. We look at how the state-ofthe-art technology dispenses vital medical supplies urgently and efficiently

Writer: Lucy Pilgrim

Unmanned aerial vehicles (UAVs), commonly referred to as drones, are becoming an increasingly significant aid to public sectors, primarily utilised by some of the world’s strongest militaries as a cutting-edge advantage in conflict and national security.

On the flip side, the use of nonmilitary drones is also growing, as the technology is leveraged worldwide to transform the logistics of medical supplies across a range of challenging environments and populations in need.

In Africa, the use of drones extends to hospitals and medical outreach clinics that are battling insurmountable pressures from growing levels of disease, rural areas in sub-Saharan Africa with limited transport networks, and other regions that have been affected by conflict or natural disasters in desperate need of humanitarian aid.

Regarding the latter, the benefits of this advanced technology are farreaching and felt deeply across the continent.

Indeed, a drone’s ability to provide last-mile delivery of vital equipment and medication to hardto-reach areas is an integral part of humanitarian aid.

Drones are increasingly being deployed by government bodies and humanitarian networks, such as UNICEF and the International

Committee of the Red Cross (ICRC), for medical air operations due to their improved technological characteristics that enable them to deliver medical supplies in accessconstrained environments.

Namely, drones can travel and transport medical supplies in minimal time, making the technology a vital link in the medical supply chain.

Their airborne function also means that they are not deterred by the inadequate infrastructure often seen across Africa’s most rural areas. This may include limited road or rail networks, which can result in excess time and effort when transporting critical medication and equipment.

As such, drone technology is advantageous in areas such as remote islands, unreachable mountain paths, or regions affected by natural disaster and conflict.

Additionally, drones are more cost-effective in comparison to other forms of airborne transport, such as helicopters. Although the delivery capacity of drones is only a few kilogrammes, their adaptability to different environments and high speeds make them a viable alternative.

On top of this, the GPS and mapping technology fitted to drones can be used to map the spread of infectious disease across a vast area and therefore have a more targeted understanding of where deliveries must be dropped.

Moreover, the complex environments where drones are typically required necessitate highly specialised parts and purpose-built elements that are often unavailable across Africa and must be exported from abroad.

Therefore, healthcare and humanitarian aid organisations must ensure that the required technology and spare parts are readily available before a drone takes flight.

To this end, companies need

to also have a robust training and education programme in place to ensure maintenance and repairs are conducted quickly and efficiently by skilled individuals.

On top of this, a drone’s ability to be remote-controlled means that medical supplies can be safely delivered without having to involve any direct human contact, thus keeping people out of harm’s way in potentially dangerous situations.

Drone technology can likewise provide additional efficiencies to

existing medical logistics services by quickly and efficiently responding to supply chain restrictions and any delivery challenges faced when providing aid.

Currently, government and humanitarian agencies across Africa provide logistics and supply chain support via two modes of drone delivery: reverse logistics and forward logistics.

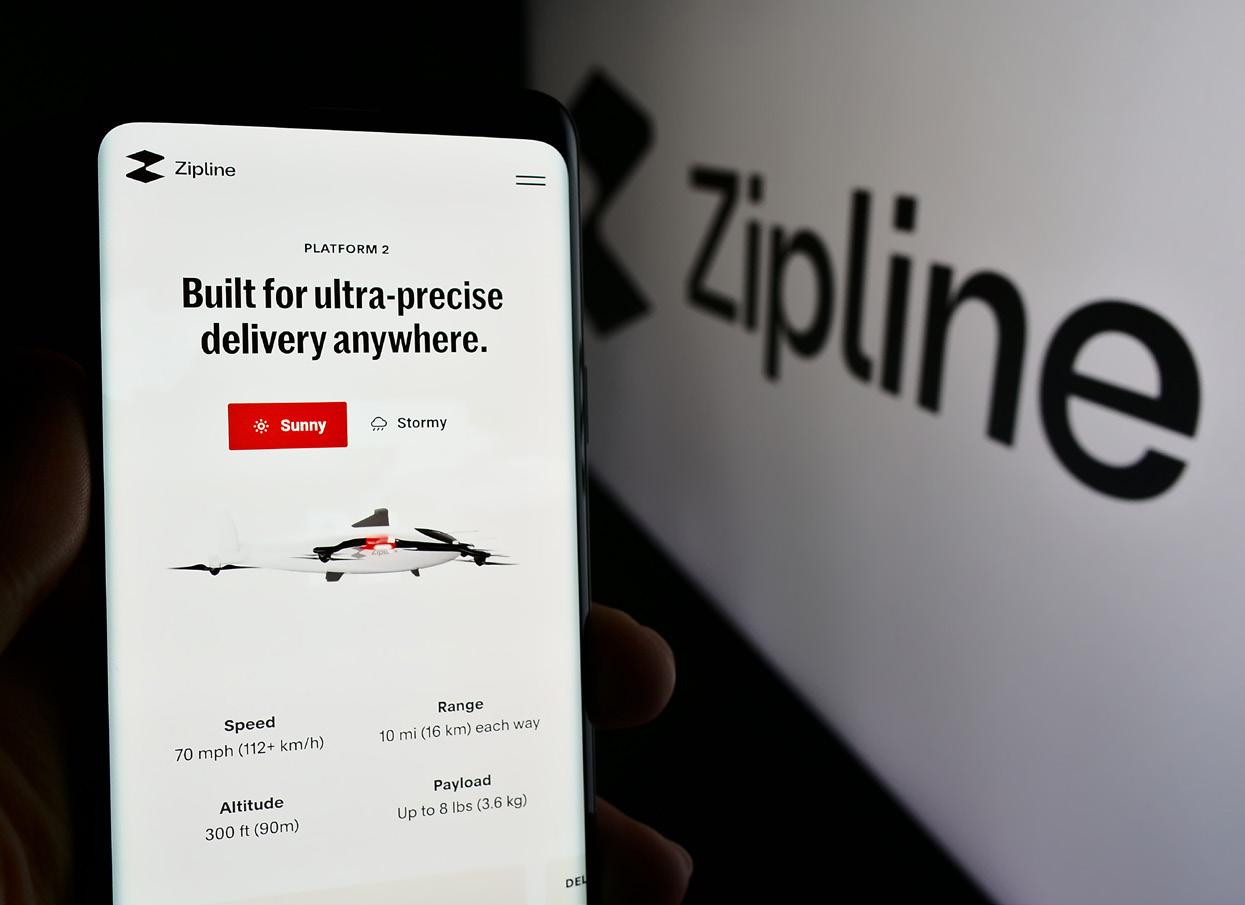

Launched in 2019, the Ghana Drone Delivery Service has become one of the world’s largest drone logistics providers. The initiative was created through the collaborative work of the Ghana Health Service and Zipline, a US-based organisation that manufactures and distributes drones.

Zipline has established numerous distribution centres across the country and played a critical role in the delivery of medical supplies using 3PL drone technology. The service delivers urgent medicines, vaccines, equipment, and more from distribution sites in Omenako, Mpanya, Vobsi, Sefwi Wiawso, Kete Krachi, and Anum, making it one of the largest distribution networks in the world.

Ultimately, the Ghana Drone Delivery Service ensures that medical supplies reach rural areas of the country with limited transport infrastructure, making the initiative critically important.

The latter uses fixed-wing drones to drop deliveries to the required recipient rather than landing on-site at a health facility, for instance.

This form of delivery means that materials are typically delivered from a central distribution facility to the required area using a hub-and-spoke transport network model. As such, forward logistics requires specialist infrastructure such as warehousing, fulfilment centres, and launch and retrieval systems for successful delivery.

Reverse logistics, meanwhile, utilises vertical take-off and landing (VTOL) aircraft that deliver goods in both hub-and-spoke and point-topoint transport network models.

Unlike forward logistics, this mode of delivery provides organisations with more logistical flexibility as the drone is able to land and take off at each location.

Thus, reverse logistics is less dependent on existing on-site infrastructure and therefore offers more advanced services.

Moving on to the logistical delivery

of goods, there are two primary forms of drone-as-a-service (DaaS) used in medical logistics.

On one hand, the third-party logistics (3PL) model offers endto-end logistics services across the entire supply chain. Indeed, 3PL service providers oversee procurement, warehousing, central order management, inventory

storage, contract management, and IT solutions, alongside its main purpose of transportation.

This centralised approach means that healthcare and humanitarian organisations can outsource equipment where needed.

Currently, healthcare entities across Ghana and Rwanda are making the most of the comprehensive 3PL model.

On the other hand, carrier logistics models, currently used in Malawi and the Democratic Republic of the Congo (DRC), involve the point-topoint delivery of goods.

This model offers more flexibility when incorporated into existing supply chains as it is not dependent on specialised infrastructure, requires less corporate investment, and has minimal set-up costs.

As such, the delivery of medical services via drone is growing in prevalence across Africa’s medical supply chain, offering critical last-mile delivery and supporting underserved, remote, and access-constrained areas across the continent.

Uganda’s abundance of natural mineral deposits, coupled with its lucrative ongoing oil and gas exploration, present a burgeoning extractive sector with the potential to enable continued socioeconomic development

Writer: Lily Sawyer | Project Manager: Josh Edwards

With notable deposits including gold, copper, highgrade tin, tungsten, salt, beryllium, cobalt, kaolin, iron ore, glass sand, vermiculite, phosphates (for fertilisers), uranium, and rare earth elements, Uganda’s mineral resources are rich and diverse.

However, despite this breadth, the country’s mineral potential has not been extensively leveraged, leaving the sector behind its counterparts in Botswana, Tanzania, South Africa, and Zimbabwe.

Furthermore, challenges such as inadequate infrastructure in remote areas, limited geological data, and the need for improved regulatory enforcement must be addressed.

As such, Uganda’s National Development Plan number four (NDPIV) emphasises the implementation of the Mining and Minerals Act, 2022 to address difficulties in the sector by promoting local growth and creating a conducive environment for mining operations.

The government has also introduced incentives including tax holidays to lessen costs and attract investors to the largely unexplored sector, whilst it further seeks to establish its first Uganda National Mining Company to manage commercial and participating interests in mineral agreements.

Moreover, the industry anticipates the additional formalisation of operations through new laws, including licensing artisanal and small-scale mining (ASM), scaling up the biometric registration system, and fast-tracking the construction of water facilities for industrial use.

As global demand for minerals gradually rises, it is hoped such initiatives will help lower production costs, increase returns on investment (ROI), and expand the availability of locally manufactured mineral products such as cement, iron, and steel in the country.

On the other hand, the Ugandan government continues to make new discoveries in the oil and gas sector with

significant recent investments for new projects and supportive infrastructure.

These projects include the Tilenga and Kingfisher projects, the East African Crude Oil Pipeline (EACOP), and the Uganda Refinery project, all of which represent the nation’s renewed focus on oil and gas exploration.

At the same time, to ensure the sustainable development of petroleum resources is in tandem with the current dynamic global environment, The Ministry of Energy and Mineral Development (MEMD) is currently finalising its review of the National Oil and Gas Policy, which seeks to contribute to the early achievement of poverty eradication and create a lasting value for society.

In this way, balancing economic growth, social development, and environmental conservation remains a priority as Uganda navigates its path to prosperity in the oil and gas sector.

Gold – One of Uganda’s most valuable resources, with significant deposits in Busia, Mubende, Karamoja, and Buhweju. While ASM is common, developments are underway to develop largescale commercial mining operations.

Cobalt and copper – Historically important sources of cobalt and copper are experiencing renewed interest, such as the Kilembe Mines in Western Uganda. This resurgence aims to meet the growing global demand for cobalt, especially for use in batteries.

Iron ore – Uganda has substantial iron ore deposits, particularly in the Muko area in the southwest and the Sukulu region in the east. These resources are critical for developing a domestic iron and steel industry, which could further industrialise the country.

Tin, tungsten, and tantalum (3Ts) – Significant deposits of 3Ts can be found in Uganda’s southwestern region. These minerals are essential for the electronics industry and highly sought after on the global market.

Phosphates – Large phosphate deposits in the Sukulu region of the Tororo District are crucial for fertiliser production, supporting Uganda’s agricultural sector and contributing to regional food security and economic transformation.

Limestone and marble – Abundant deposits of limestone and marble are found in the Karamoja region and around Lake Victoria. These materials are vital for the construction industry, particularly cement production.

Gemstones – A rich variety of gemstones, including rubies, sapphires, and tourmaline, can be found in Uganda’s Eastern and Western regions, contributing to the country’s growing reputation as a source of valuable mineral resources.

Salt – Lake Katwe has long been a source of salt in Uganda, with ongoing efforts to modernise and expand this industry to better serve domestic and regional markets.

Chamber of

unpacks the opportunities and challenges facing Uganda’s extractive sector and its role as a key driver of the country’s socioeconomic development

Africa Outlook (AO): Firstly, could you talk us through the beginnings of the Uganda Chamber of Mines & Petroleum and its original vision and mission?

Humphrey Asiimwe, CEO (HA): The Uganda Chamber of Mines & Petroleum (UCMP) is a not-for-profit, memberbased, voluntary organisation representing private players’ interests in Uganda’s extractive sector, specifically petroleum and mining, whilst working closely with the state to develop the sector.

Launched in 2010, UCMP coordinates and facilitates information sharing, advisory, and administrative support to prospective and current investors in Uganda’s mining and petroleum sectors.

It also promotes, encourages, protects, and fosters responsible mining, beneficiation, and service delivery.

UCMP’s activities are linked to five main goals – lobbying and advocacy, R&D, business support services, stakeholder engagement, and efficient internal organisation.

AO: What is your current take on the extractive sector in Uganda? Is it a particularly exciting or challenging environment to work in?

HA: The extractive sector in Uganda is exciting. First, the government banned the export of unrefined minerals to promote value addition, earn the country significant export revenues as well as create jobs and other opportunities.

Uganda’s National Development Plan number three (NDPIII), running from 2020/21-2024/25, prioritised the development of five categories of minerals, namely iron ore, gold, copper, phosphates, and development minerals (marble, silica sand, aggregate, and limestone). This was largely carried out to ascertain their commercial viability and to devise relevant data.

The government is clear in NDPIII and the new NDPIV, where it set specific fundamentals such as infrastructure and human capital development and good governance, amongst others, that will foster possibilities for full value chain development across the sector.

In recent years, the country has also reported tremendous progress in attracting investments into the exploration of green energy minerals that include rare earth elements, graphite, copper, cobalt, manganese, lithium, and nickel.

The Mining and Minerals Act, 2022 is expected to further boost the sector’s growth from primary production and throughout the entire value chain.

Meanwhile, for the oil and gas industry, a lot has already been achieved since the signing of the final investment decision that kickstarted the sector’s development stage.

The latest numbers indicate that a total of USD$7.5 billion had been invested in the sector by the end of 2023, with USD$1.09 billion and USD$1.93 billion invested in 2022 and 2023, respectively.

The drilling of oil wells at Kingfisher (operated by CNOOC Uganda Limited) and Tilenga (operated by TotalEnergies) is underway as the nation anticipates its first oil discovery in the financial year 2025/26.

Critical infrastructure such as roads has been developed in the Albertine oil region, with more in the pipeline.

We have seen a significant number of Ugandans securing jobs in the sector and other Ugandan companies winning contracts.

Two big projects, including the EACOP and the refinery, are being fast-tracked by the government, and we expect these to further fuel the sector’s growth at the commercial stage.

AO: How does UCMP represent the private sector and promote the interests of its members?

• Tilenga Project – A flagship upstream petroleum production project consisting of six oil fields and 426 petroleum wells across 31 locations.

• Kingfisher Development Area Project (KFDA) – A key oil and gas project located in the Southeast of Lake Albert, including a central processing facility (CPF) with a capacity of 40,000 barrels per day (bpd) and 31 wells across four well pads.

MIDSTREAM

• EACOP – A 1,443-kilometre (km) crude oil pipeline that will transport oil from the Tilenga and KFDA projects to the Port of Tanga, Tanzania, where the product can be sold and transported globally.

• Uganda Refinery Project – A 60,000 bpd oil refinery project located in Kabaale, Hoima District, which includes a 211km multi-product pipeline, a refined storage terminal, and a raw water pipeline, adding value to the country’s domestic oil resources and establishing a regional energy facility.

• Kabalega Industrial Park (KIP) – Anticipated to comprise Uganda’s second international airport, a crude oil export hub, a refinery, petrochemical, and fertiliser facility, amongst others. The park seeks to promote the rapid development of the oil and gas industry and support other economic activities in the area.

HA: Our work is aligned with different sectors including oil and gas exploration, labour, skilling and entrepreneurship, the quality health safety environment (QHSE) framework, insurance, legal and compliance, media and communications, logistics and transport, engineering and construction, manufacturing, mining and mineral development, and finance and energy.

We run targeted media campaigns, such as 90 Days of Oil and Gas, geared towards information gathering and dissemination to educate investment and related decisions.

We often hold high-profile sector conferences and meetings with industry players to achieve our mandate. Annually, we organise the Oil and Gas Convention (OGC) recently held in April this year, and the Mineral Wealth Conference, the 13th of which was held in early October.

These conferences bring together national and international participants to share industry updates, including opportunities, challenges, and business prospects.

Alongside these two significant events, we also hold sector meetings throughout the year targeting the different subsectors aligned to the extractive sector.

AO: What other specific goals does UCMP have, and what strategy have you adopted to achieve these goals?

HA: Broadly, we are the go-between for the government and the private sector when it comes to advocating for the right environment for the extractive sector.

We have set the bar high for our national annual events, which include the Mineral Wealth Conference, OGC, and media campaigns for all sector players across the globe to converge and deliberate on issues critical for defining the future of the extractive sector.

We are acutely aware of the conversation on environmental, social, and governance (ESG) issues and the global energy transition debate. We agree with the government’s ‘first in, first out’ view as outlined in the Energy Transition Plan (ETP), given its ongoing contribution to the fight against energy poverty.

We intend to rebrand UCMP to cover other areas of energy beyond petroleum. This is a work in progress across different levels of our organisation.

We look forward to forging more formal partnerships with relevant sector players including development partners and other private sector groups to push the industry’s agenda forward.

AO: How do you see the extractive sector in Uganda developing over the next five years?

HA: The mining sub-sector alone is expected to attract big investments to the country’s priority minerals industry.

The formalisation of ASM and the lack of an institutional

Opening hours:

Saturday: Sunday : Monday:

Tuesday:

Wednesday:

7:30am – 6pm

7:30am – 6pm 7:30am – 6pm

Thursday: Friday: 9am – 3pm Closed 7:30am – 6pm 7:30am – 6pm

Address: Kampala, Uganda

Phone: +256 776 024658

Website: www.cubeengineeringltd.com

framework among other issues had previously hampered the subsector’s growth, but with the new Mining and Minerals Act, 2022, the sector is heading in the right direction.

UCMP remains focused on contributing to any changes in policy and updates to the regulatory environment in the interest of its members and the sector in general. Across the oil and gas industry, we expect to see more investments of over USD$15 billion as Uganda awaits commercial production of its oil resources.

AO: Finally, what are your key priorities to continue representing Uganda’s extractive sector players?

HA: We want to continue advocating for a supportive

investment environment for our members and the private sector in general. This environment includes authorities upholding National Content provisions which broadly involve Ugandans and Ugandan companies.

We will also continue to collaborate with sector players to improve the capacity of our members in key areas of ESG, corporate governance, access to affordable credit, and pushing for workable joint ventures.

Other areas of interest include having a fair tax regime for sector players and granting our members access to information to inform their planning and investment decisions.

We are keen to expand our mandate to include other forms of energy beyond petroleum to provide our members with services aligned to emerging global issues.

Tel: +256(0) 752-527-540, +256(0) 784 228-224

ucmp.ug

Numerous and diverse metals and minerals are found in subterranean Mozambique, contributing significantly to the country’s economy and its production of critical materials. We delve deeper into the potential of the thriving mining industry

Writer: Rachel Carr | Project Manager: Alfie Wilson

Situated on the southeastern coast of Africa, Mozambique is characterised by its extensive coastline bordering the Indian Ocean. Endowed with abundant and manifold mineral deposits, the country’s landscape encompasses vast lowland plateaus and imposing mountains, while a treasure trove of natural resources lies beneath its surface.

The Mozambican economy greatly benefits from a wealth of sought-after gemstones such as rubies, garnets, and aquamarine, as well as valuable minerals such as graphite, spodumene, and heavy sands minerals. In addition, the presence of metals like gold, as well as practical compounds and elements like coal and gas, make mining a significant contributor to the country’s prosperity.

For more than 1,000 years, Mozambique has been steeped in the tradition of gold mining, as this precious metal was produced on a small scale by artisanal miners. Today, however, the country possesses high-quality commercial coking and thermal coal, iron ore, titanium, and marble. Other valuable commodities include petroleum, steel, niobium, cement, and aluminium.

Regarding the latter, aluminium plays a critical role in manufacturing aeroplanes and various transportation modes. It also surpasses copper in its ability to conduct electricity, making it a popular choice for use in transmission lines.

In Maputo, Mozambique’s capital city, you can find Mozal, S.A, an aluminium smelter located in the Beluluane Industrial Park. The joint project stands as a testament to the collaborative efforts between South32, Mitsubishi Corporation, the Industrial Development Corporation of South Africa, and the Government of Mozambique.

The journey to achieving mining success in Mozambique may be lined with valuable metals and minerals, but it is not without obstacles. The industry requires a collaborative approach to promote sustainable growth, with a particular emphasis on expanding infrastructure such as roads and railways and creating a reliable electricity supply to bolster business strategies.

Increased exploration and exploitation of Mozambique’s minerals has the potential to grow the country’s economy significantly.

As the voice of the country’s mining sector, the Chamber of Mines of Mozambique advocates for its members’ interests while promoting sustainable practices. We explore the industry’s prospects with its President, Geert Klok

Africa Outlook (AO): Firstly, please tell us about the origins of the Chamber of Mines of Mozambique, how it was incepted, and its initial vision?

Geert Klok, President (GK): The Chamber of Mines of Mozambique (CMM) was established in 2012 when the mining industry was in its early stages. The country’s formal large-scale mining industry is relatively young, less than 20 years old. The CMM functions as an industry association to advocate for mining interests. Due to the industry’s small size at the time, it did not gain much traction.

After a period of inactivity in the beginning, CMM experienced a resurgence as the mining industry

expanded. While it was established during Mozambique’s coal boom, we observed significant growth in graphite, heavy sand minerals, and the emergence of new companies engaged in ruby mining, leading to a more diverse industry.

In 2022, we secured a project supported by Germany in collaboration with the Chamber of Commerce of Chemnitz (Germany). The project’s objective was to strengthen the CMM and conduct outreach and training programmes for the nation’s artisanal mining industry, enabling us to relaunch the association. Since the relaunch, we have gained numerous members and currently stand at around 60, including most of the major mining companies. We now feel we really represent the formal part of the organised Mozambican mining industry.

AO: What is the most exciting aspect of the industry in Mozambique?

GK: Mozambique has significant potential in the mining industry. Historically, there has been limited mining and exploration in the country, despite its abundance of important minerals, including graphite, making it

the world’s third-largest natural graphite producer. Mozambique also has heavy sands, gemstones, semiprecious stones, and coal resources. Despite the dwindling role of the latter, there are still many opportunities for growth and development in the mining sector.

AO: What are the biggest challenges facing the industry at the moment?

GK: The energy transition is a big challenge and an obvious opportunity. It’s a game-changer for the African mining industry, mainly because of the huge expected increase in demand for critical raw materials, of which we have several in Mozambique, such as graphite, lithium, and rare earth minerals.

The industry has the potential for growth through the beneficiation of critical raw materials and the development of new supply chains; the challenge is to figure out how to take advantage of this potential. Making the mining industry more sustainable, or “greening” it, involves reaching net zero in energy consumption.

Fortunately, electricity from Mozambique’s national grid is primarily from hydro sources. In rural, off-the-grid areas, some mining companies that initially relied on dieselgenerated power plants are now transitioning to costcompetitive solar energy. There have also been efforts to introduce electric moving equipment. Overall, achieving carbon dioxide neutrality presents a significant challenge for the industry.

In the context of the energy transition, it is evident that there is a need for increased production and mining output to meet growing demand. Yet, there is a lack of available financing for exploration, particularly in countries like Mozambique, where the mining industry is still perceived as high-risk and geopolitical instability further hinders access to funding.

AO: Are there any key aspects of the industry you’d like to highlight?

GK: When the Ministry of Mineral Resources and Energy conducted a census of Mozambique’s artisanal mining industry for the first time a few years ago, they uncovered some major issues.

Artisanal mining, according to this study, directly and indirectly employs over 800,000 people in the country, making it a more significant source of employment than the formal industry. As such, similar to the situation in Southern Africa, artisanal mining also presents numerous challenges due to its lack of regulation. Most miners operate without a license, rendering their activities informal or illegal. As a result, there are issues related to uncollected taxes, environmental pollution, and poor working conditions.

As part of our programme with Germany, we aim to provide training in conjunction with the mining inspectors and ministry in the fields of health and safety standards, environmental practices, and best practices of the industry. In this regard, we consider the promotion of best practices to be part of CMM’s role in the mining sector.

Initially much of the equipment, spare parts, and services for the mining industry had to be sourced from overseas due to limited availability within the country. However, it is in the mining industry’s best interest to engage local suppliers who can be more efficient and faster. It is also in the country’s interest to promote local development by creating employment opportunities, particularly in rural areas.

If executed properly, it would be a win-win situation, as working with local suppliers will establish an ecosystem for the mining industry, attracting new entrants and additional mining companies, while also developing the local economy. However, it cannot simply involve importing equipment and spare parts, marking them up, and selling

them. We need to engage local manufacturers and service providers to build capacity within the country.

Lastly, there is an extensive discussion in Mozambique and the region concerning critical raw materials and their beneficiation. African countries and the world need these critical raw materials. The question is, how can countries containing them benefit beyond mining and mineral extraction? How can they participate in the value chains? This is an important discussion in Mozambique, and CMM believes it needs careful consideration.

It is essential to enact enabling policies rather than legislate in a restrictive manner. Thus, there needs to be coherent regulations that create the right conditions to be competitive, as the domestic market is too small to support specific industries.

Graphite, for instance, is used in batteries for electric vehicles (EVs), but Mozambique does not have an automotive industry. Therefore, when considering the beneficiation of graphite as an anode precursor material for EV batteries, it becomes evident that this component fits into a supply chain that does not yet exist in Mozambique. To compete internationally, therefore, the infrastructure for electricity and human resources must be developed.

We believe it is important to consider international cooperation, especially at a southern African level. Understandably, each region’s countries would like to engage in beneficiation and build batteries for EVs, but in practice, this is a large-scale industry.

South Africa already has an automotive industry, so exploring this opportunity from a regional perspective and

“THE INDUSTRY HAS THE POTENTIAL FOR GROWTH THROUGH THE BENEFICIATION OF CRITICAL RAW MATERIALS AND THE DEVELOPMENT OF NEW SUPPLY CHAINS”

– GEERT KLOK, PRESIDENT, CHAMBER OF MINES OF MOZAMBIQUE

working together to establish a supply chain between this nation and Mozambique is important. This could be done in collaboration with the end user markets in Europe and North America, which are crucial.

We are also members of the Mining Industry Association of Southern Africa (MIASA). As a chamber, we actively participate in global discussions, contribute to developing appropriate policies and strategies, and engage internationally. We aim to promote Mozambique, emphasise the opportunities available in mining, share ideas and best practices, and learn from other countries and mining chambers across the world. This extends to both industrial and artisanal mining.

We must explore how to capitalise on these opportunities to benefit our industry and country. The energy transition presents a significant opportunity, and it is crucial for us to engage in regional dialogues. CMM plays a key role as an interface and contributes to our international engagement.

• Promote and support gender equality in the mining industry, as well as in scientific and technical research and training.

• Participate in national and international meetings, lectures, and forums in the interest of the chamber and its members in order to achieve its objectives.

• Develop corporate social responsibility (CSR) and health and safety standards.

• Share the results of studies, research, and cooperative programmes related to its objectives with members and, when appropriate, with society.

• Promote and support cooperation between the chamber and other mining industry associations, ministries, relevant government bodies, research institutions, development agencies, and companies.

• Take part in projects to promote and develop infrastructure and logistical services necessary for mining activities.

• Protect the interests of its members in labour negotiations with trade union organisations and the government, and participate in developing pension plans, social security, and medical assistance funds for member workers.

• Advocate for the interests of its members in mining activities and provide input on legislation that could impact them.

• Get involved in defining and implementing policies, strategies, and plans related to infrastructure development necessary for mining activities.

AO: Are there any plans or projects in the pipeline for CMM?

GK: We’ve recently developed a strategic plan that is member-approved and aims to strengthen CMM further. The plan also enables the association to serve the industry better, create new products, participate in regulatory reforms, and attract new investments. Our goal is to maintain a strong presence in representing the sector nationally and internationally, engaging in debates and showcasing the industry and, by extension, our country.

AO: Finally, how do you see the industry developing over the next five years?

GK: The industry in Mozambique has considerable growth potential. This is due to the underdeveloped mineral resources and opportunities presented by the energy transition, particularly in critical raw materials. If we can create the right conditions and provide an enabling environment for investments in the mining sector, we can expect significant expansion in the coming years.

CHAMBER OF MINES OF MOZAMBIQUE

Tel: +258 84 531 7144 / +258 86 854 3210 info@cmm.org.mz www.cmm.org.mz

As manufacturing organisations worldwide confront unprecedented change, embracing technological innovations and incorporating critical environmental sustainability agendas, now more than ever is the time to showcase the strides being taken in this dynamic sector.

A multi-channel brand, Manufacturing Outlook brings you the positive developments driven by organisations across the global manufacturing industry through its various platforms.

Discover exclusive content distributed through its website, online magazine, social media campaigns and digital dispatches, delivered straight to your inbox with a bi-weekly newsletter.

Through these compelling media channels, Manufacturing Outlook will continue to foreground the movers and shakers of the industry.

To participate as a featured company and join us in this exciting endeavour, contact one of our Project Managers today.

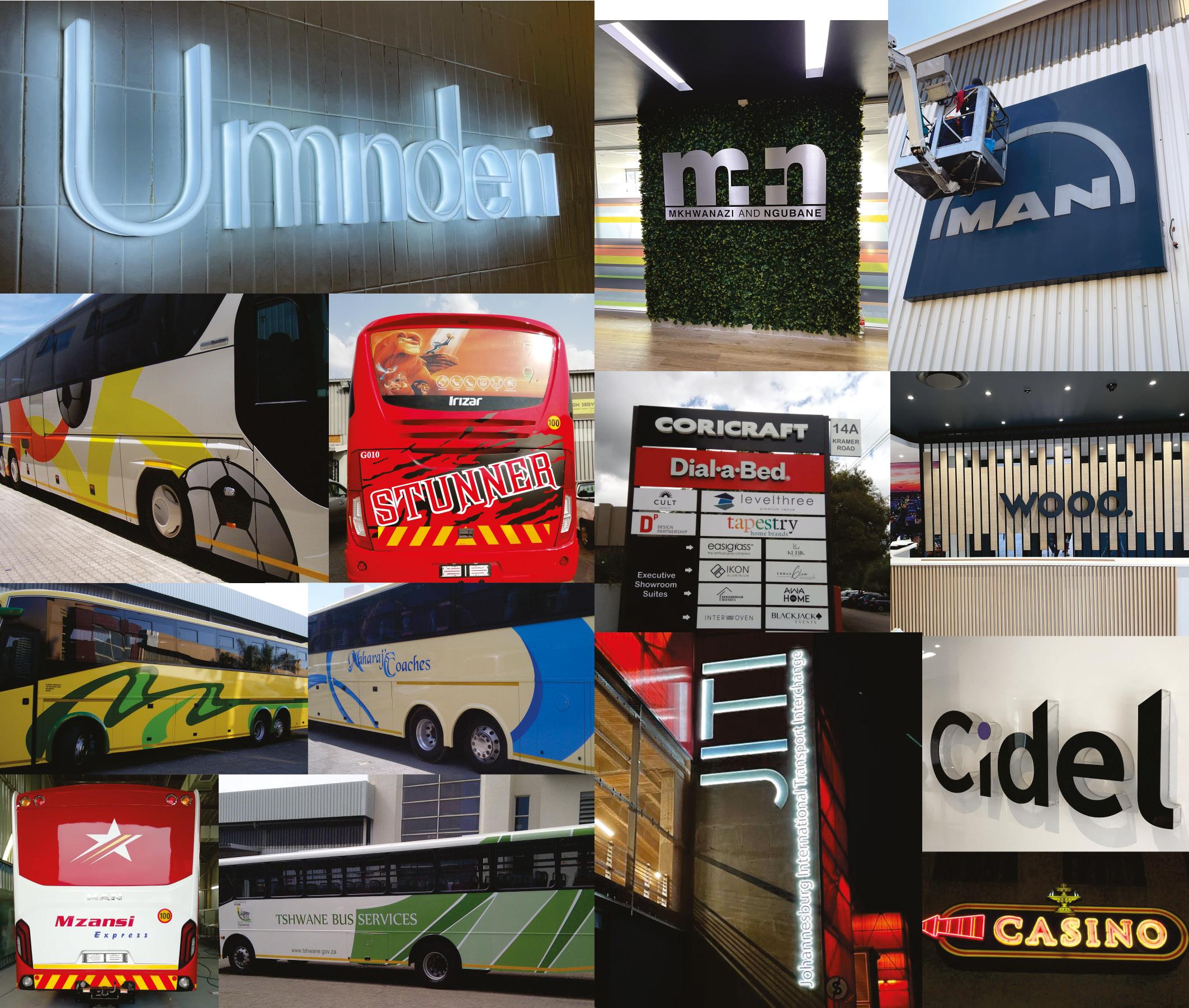

With the aim of simplifying customer business through leading sustainable solutions, MAN Automotive South Africa proudly 60 years’ worth of shaping the country’s transportation industry.

Jan Aichinger, Managing Director, tells us more about the newest innovations and plans for a long-lasting future

Writer: Lauren Kania | Project Manager: Taylor Green

leading proudly boasts industry.

the company’s