As Petromar celebrates its 40th anniversary this year, Frederic Heintz, General Manager, tells us more about the company’s pioneering fabrication and maintenance activities that ensure its continued success

Writer: Lucy Pilgrim | Project Manager: Ryan Gray

Angola is internationally renowned for its plentiful natural resources, including specialist metals, minerals, and oil reserves found both underground and on the seafloor.

Looking at the nation’s oil and gas activities in particular, Angola has advanced to become the secondlargest oil producer in sub-Saharan Africa and a key member of the Organisation of the Petroleum Exporting Countries (OPEC).

Angola’s oil and gas industry represents tenacity and versatility in the face of historical challenges, namely the impacts of a civil war that took place between 1975 and 2002 that it is still navigating.

As such, Angola’s oil and gas developments over the last 20 years

represent a positive evolution, as the sector has enabled measurable socioeconomic impacts across the country.

For example, the 17.9 million cubic feet of natural gas production nationwide makes the industry the largest contributor to Angola’s GDP and has solidified the country’s economic growth.

As part of its progression, the oil and gas industry is pivoting more towards environmental considerations in an increasingly sustainable world.

Consequently, companies operating in the sector are adopting strategies to reduce their greenhouse gas (GHG) contributions, including using less polluting technologies and prioritising the protection of local wildlife.

Angola’s subsea sector, in particular, is a key pillar of the West African oil and gas industry, with an abundance of deep sea resources that are extracted by both global and domestic businesses.

Standing at the head of the Angolan subsea sector and floating, production, storage, and offloading (FPSO) activities is Petromar, who has pioneered forward-thinking solutions across the industry since 1984.

Petromar was established in Ambriz, a village and municipality in the Bengo

“OUR VAST EXPERIENCE IN SUBSEA STRUCTURES AND PLATFORMS

DEMONSTRATES OUR CAPACITY TO EMBRACE NEW CHALLENGES AND ENGAGE IN BIGGER PROJECTS THAT ARE MORE DEMANDING AND COMPLEX”

– FREDERIC HEINTZ, GENERAL MANAGER, PETROMAR

Province, as a joint venture between Sonangol, the state-owned Angolan operator, and originally Bouygues Offshore, later acquired by Saipem, an Italian engineering and construction services organisation.

The company was notably the first fabrication yard of its kind in Angola to partner with Sonangol and ELF, a TotalEnergies brand, making it a pioneer in its field.

Additionally, despite the rudimentary use of technology at the time, Petromar reached new heights in fabrication activities, cementing its place as an industry leader at an early stage in its journey.

The company initially focused on the fabrication of platforms for the shallow waters in Blocks 0 and 3 of Sonangol’s oil development. However, in 1997, due to the Angolan Civil War, Petromar could no longer conduct its operations in Ambriz, forcing it to transfer its assets to Soyo, where the business could continue to attend to oil and gas market demands.

During this time, Petromar gained considerable competence in subsea development projects, including the Rosa oil field project for TotalEnergies and the Kizomba Satellites project for ExxonMobil, amongst more.

In a major turning point, the

company returned to its original yard in Ambriz in 2010 and, as a result, was able to operate the two yards simultaneously for the next five years. This dual activity also meant Petromar could effectively navigate the oil and gas market, which was experiencing a major resurgence at the time.

Following these high demands and the crisis in the sector, Petromar rethought its strategy and subsequently decided to concentrate its efforts on fabrication activities in Ambriz, closing its yard in Soyo.

An additional milestone was achieved when Cabinda Gulf Oil Company (CABGOC) moved all its contractors out from its Malongo terminal in Cabinda, enabling Petromar to establish a second sixhectare (ha) yard in Malembo, thus helping to support the company’s fabrication maintenance activities with CABGOC.

Evidently, Petromar’s journey for the past four decades has been one of innovation and determination.

“We have been resilient in overcoming industry crises,

including market booms, crashes, and reductions,” introduces General Manager, Frederic Heintz.

This has been achieved by the strategic investment in its assets over the last four decades, demonstrating an outstanding flexibility in adapting to sector evolution and past crises.

Such perseverance, durability, and adaptability in an ever-changing industry has enabled Petromar to become the second-largest active fabrication yard in Angola.

“Our vast experience in subsea structures and platforms demonstrates our capacity to embrace new challenges and engage in bigger projects that are more demanding and complex,” he adds.

The Angolan oil and gas industry is reputed for its stringent safety, quality, and engineering standards.

Petromar endeavours to meet these standards across its two main business activities – the fabrication of subsea structures

VISION – The company strives to remain an industry leader. As an innovative provider of solutions, Petromar’s project execution and value-added operational activities offer superior value to customers and partners, as the company is continually recognised for its exceptional service standards.

MISSION – Petromar seeks to satisfy customers across the oil and gas industry, taking on all challenges with great safety and innovative solutions.

VALUES – The company possesses strong values including its dedication to customer satisfaction, openness, innovation, and competitiveness, which it upholds across all its operations.

and the maintenance of oil and gas infrastructure.

Throughout its extensive history in the sector, the company has grown to become a leader in the former thanks to its outstanding assets and angolan resources.

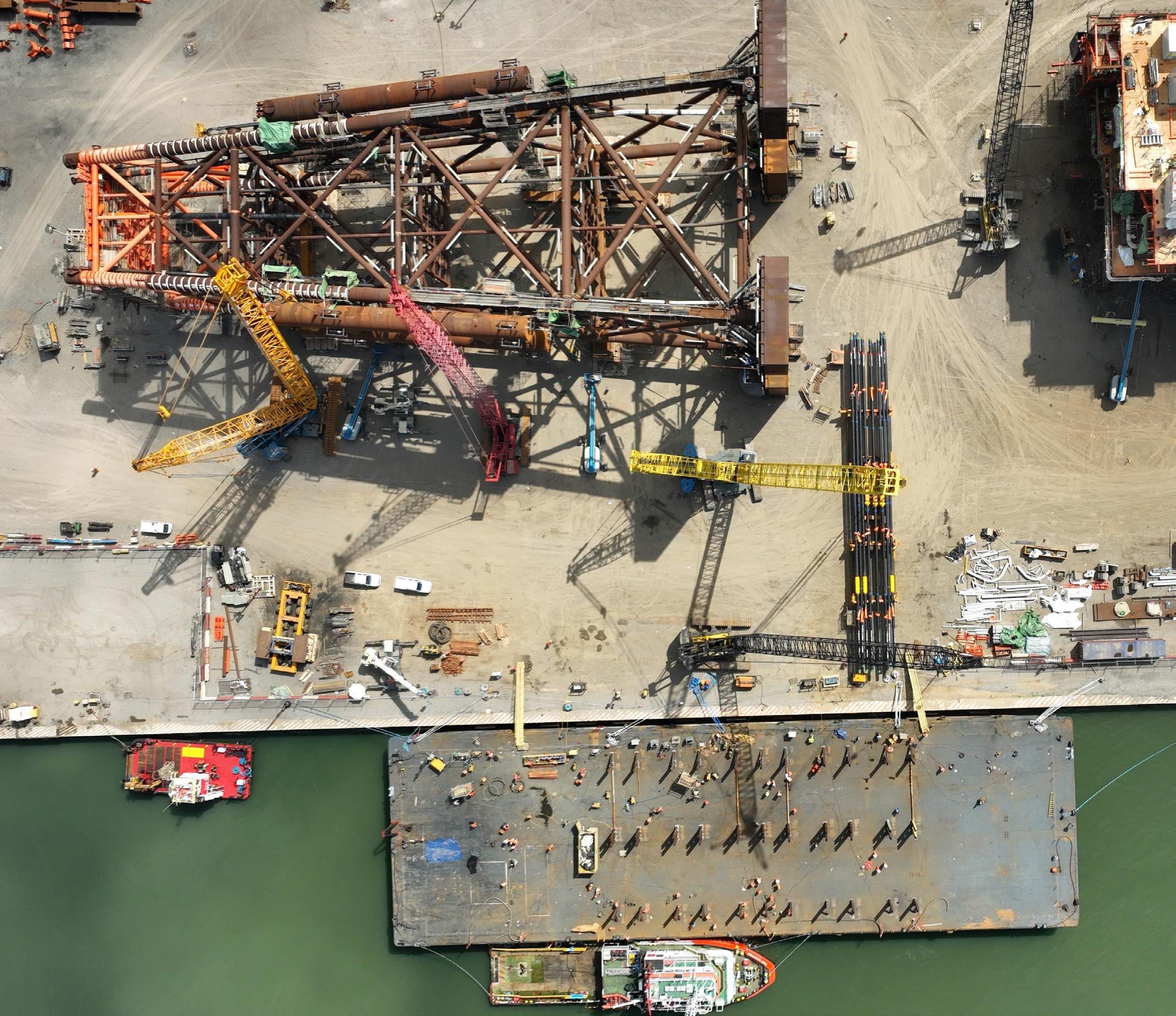

Indeed, Petromar fabricates subsea structures including pipeline end terminals (PLETs), jumpers, manifolds, mudmats, and more. Additionally, the company produces topside, module, and jacket platforms.

“Usually, those projects are developed together with our main shareholder, Saipem, who performs the engineering, procurement, and installation offshore, whilst Petromar concentrates on the fabrication of structures, currently performed in our Ambriz yard,” informs Heintz.

Meanwhile, Petromar’s maintenance of offshore and onshore oil and gas infrastructures include the Block 3 platform for Sonangol, in the

last 35 years.

Elsewhere, the company maintains Blocks 18 and 31 with two FPSOs for Azule Energy, whilst also working with CABGOC to execute fabrication maintenance activities for Blocks 0 and 14, maintaining their structure and piping.

Those operations are also supported by a logistics and industrial base in the Angolan capital of Luanda, next to the company’s headquarters, where it performs smaller fabrication jobs and preparations for offshore activities.

Across four decades of operation, Petromar has strived to gain the competence and trust of its clients.

“With the support of shareholders, there is no doubt that the execution of our projects will maximise local content and fabrication services in Angola,” explains Heintz.

As such, the company’s long-term success is aided by the support

of its stakeholders, which include the local authorities, financial and institutional partners, suppliers, and subcontractors that help Petromar achieve high standards in timely delivery, with the reactivity of mobilisation equipment and resources.

Between August 2023-24, Petromar continued to develop two ongoing manufacturing projects for Azule Energy at its Ambriz yard.

Firstly, the company manufactured 20 PLETs to accompany 10 mudmats already installed at sea in January 2024 as part of the Agogo Integrated West Hub project, which is in the final phase of loadout testing.

Petromar has also manufactured 297 pipe-in-pipe quadruple joints for the pipelines used in the flowlines at the bottom of the sea, which aim to reduce installation times offshore.

Surface preparation

• Grit blasting;

• Mechanical tools;

• High pressure Washing / Hidroblasting

Industrial Coatings

• Airless equipment’s;

• Conventional;

• Manual (brush, roller, etc.)

Metal Thermal spray linings (Zinc; Stainless steel; Aluminium; Copper; and other)

Passive Fire Protection (Bonding & Sealing; Intumescent foams and paints)

Insulation

• Thermic insulation

• Special insulation

• Canusa

• Trelleborg

• Industry Insulation

Scaffolding

• Layher type

• Multidirectional

“We are the only company in the country to realise this technology, as the entirety of the pipeline, including the outer pipe, inner pipe, and the insertion of the latter into the former pipe, is all manufactured on one production line in a specially-built workshop,” Heintz highlights.

Petromar’s second project is to manufacture the Quiluma platform for the New Gas Consortium (NGC), Angola’s first non-associated gas project operated by Azule Energy.

The structure comprises a 2,200tonne (t) jacket and 2,500-deck with four levels, containing hundreds of kilometres of cable.

“It represents a milestone for the industry, led by Azule Energy and their partners, for which Petromar is enthusiastic about participating in its achievement,” he expands.

Both structures are yet to be completed, but the company has witnessed visible progress across the two operations.

In order to face those additional challenges expected by clients, in

2022 the company expanded its surface area by 7ha, reaching a total of 33ha. Furthermore, Petromar became the largest employer in the Bengo province with approximately 1,500 direct workers.

Finally, the company has also been awarded an additional subsea development contract by Azule Energy in the Ndungu field, working on Block 15/06.

“This has granted continuity in the workload of the yard and brought a new work front for next year, with multiple structures to fabricate.”

Petromar is already enthusiastic to work again with TotalEnergies, who has confirmed its investment decision in the new Block 20 at the Kaminho project, implementing a new FPSO.

TotalEnergies awarded Saipem and Petromar a contract to build the required FPSO as well as the entire subsea system, including subsea umbilicals, risers, and flowlines (SURFs).

The company diligently develops for its customers:

- Prefabrication, fabrication, and testing of subsea structures

- Fabrication and construction of platforms, jackets, topsides, and modules

- Load out services and marine terminal operations

- Maintenance and asset integrity of oil and gas platforms

- Mechanical, process, electrical, instrumentation, and safety maintenance services onboard FPSOs

- Maintenance services for refineries and production plants

- Shipyard support services

- Dismantling of decommissioned structures

Hamad Energy has been a trusted partner in Angola’s Oil and Gas industry since 2010. With 100% Angolan ownership and a strong commitment to quality, we specialize in delivering a comprehensive range of goods and services designed to meet the evolving needs of this vital sector.

In September 2024, Hamad Energy and Petromar entered into a strategic Memorandum of Understanding (MoU) to drive forward the development of a cutting-edge shipyard project in Soyo, Angola. This collaboration marks a pivotal milestone in exploring and assessing key shipyard development and investment opportunities within the Republic of Angola and the broader southern African region.

While recognizing the substantial investment required, the project’s potential is undeniable. With an estimated 9 hectares dedicated to shipyard Project, the facility will create significant direct and indirect jobs and put Angola’s presence on the global shipyard map.

Currently, the project is in the early phase which is expected to be concluded in Q1-2025.

HAMAD Energy has been committed to directly and positively participate in Socio-economic development of the Country by providing services and transforming lives through job creations throughout the Country.

This project will benefit the Country on the Shipyard contributing positively of the Social-Economic impact and put Angola into the Map of Maritime Industry, Job Creation, Revenue to the Country, Upscale the labor force and Business opportunities through service subcontracting.

At Hamad Energy, we offer a comprehensive portfolio designed to support the below operations effectively:

• Supply of Chemicals and Associated Services

• Engineering, Procurement, Construction And Installation Services

• Subsea Operations (including ROVs and Diving)

• Marine fleet supply services

• Installation, Repair and Maintenance

Hamad Energy has partnerships with leading multinationals corporations, which enable us to deliver competitive and high-quality solutions. We adhere to national and international safety and quality standards, ensuring that our services are both effective and efficient.

“WE HAVE MANAGED TO ADAPT OURSELVES AND OUR ASSETS, WHILST ALSO TRAINING OUR ASSOCIATES, WHICH WILL ALLOW US TO MAINTAIN OPERATIONS FOR ANOTHER 40 YEARS”

– FREDERIC HEINTZ, GENERAL MANAGER, PETROMAR

The construction of the project’s FPSO will be conducted by Saipem and its team of contractors, whilst Petromar will fabricate the 12 anchoring piles and a riser protector that will eventually be fitted to the FPSO.

The SURF portion of the project, which will be fully fabricated at the Ambriz yard from 2026 onwards, includes creating subsea structures for the ocean floor that will link the FPSO to the ground.

The company is proud to be working with TotalEnergies again after completing its last project with the client in 2017.

“Petromar will take this new project as an opportunity to keep investing

in its assets and maintaining its competencies that it has amassed over the years,” Heintz elaborates.

The company will introduce a new workshop dedicated to rolling plates for pipes used throughout the project.

This not only demonstrates Petromar’s commitment to maintaining its footprint in Angola, and Ambriz in particular, but also emphasises its ability to adapt its infrastructure to the best construction methods.

Additionally, the company is diligently evaluating how best to support Saipem in operating and maintaining the FPSO that will be installed in Block 20.

Petromar’s FPSO expertise is most aptly demonstrated by its maintenance support services on Blocks 18 and 31 for Azule Energy.

“Whilst the client is in charge of defining and implementing the maintenance plan, we support them by providing permanent service teams and mobilising original equipment manufacturers (OEMs) or temporary crews defined by the client for specific needs,” outlines Heintz.

To ensure this is completed effectively, the company requires substantial financial strength, coordination, and a means of control.

Petromar has a dedicated procurement and supply team in Luanda that is committed to engaging reliable suppliers in difficult business environments and manages all offshore maintenance projects.

When performing procurement services for clients, Petromar aims to mobilise Angola’s specialised foreign subcontractors as well as Angolan subcontractors, which are required

to perform dedicated maintenance tasks and FPSO training, whilst also attending to its own needs in terms of reactivity, domestic stock availability, and competitiveness.

Undoubtedly, the reliability and cooperation of vendors is essential in the oil and gas sector.

“Our clients and administrative processes are demanding – Angolan

regulations are such that, for some foreign vendors, the project might appear complex or too difficult to deal with. Therefore, it is important to establish transparent and reliable relationships,” details Heintz.

Thus, the company requires reliable suppliers who can meet its requirements for materials, consumables, spare parts, workshop

infrastructure, warehousing, and items related to civil works.

During fabrication activities, for instance, the company needs to source the right welding consumables, personal protective equipment (PPE), painting and nondestructive testing (NDT) services, and rental equipment.

Therefore, Petromar contracts the appropriate service businesses with the highest standards of certification and safety.

Moreover, when working with major suppliers, Petromar has the transportation capabilities to ship directly to its quay at the Ambriz yard. However, this is dependent on the draft limitations of a vessel being respected and shipped materials being cleared with customs authorities and made available for projects.

Staff are critical to the success of Petromar, who currently has 2,300 direct and indirect employees, albeit the number of team members

Energias de Angola, Lda

Focusing on excellence and innovation, ENAGOL and Petromar collaborate to redefine standards in the Oil & Gas industry. Our journey is marked by services that ensure operational and social success, always committed to sustainability and the future of the industry.

Diversified Services with Proven Quality

• Non-Destructive Testing = QA/QC Inspection

• Welding Inspection

• Coating Inspection

• Inspection of Lifting Materials

• Vacuum Testing

• Renewable Energy Generation

www.africaoutlookmag.com/work-with-us

+244 226 430 011 geral@enagol.co.ao comercial@enagol.co.ao comercial@enagol.com enagol.co.ao

• Tubular/Piping Inspections and Services

• Advanced Eddy Current

• Ectane 2, with Iris

• Film Digitisation

• PAUT

depends on market conditions.

Nevertheless, Petromar strives to maintain a core team in Ambriz, Cabinda, and Luanda, comprising of individuals from the local area, providing greater employment and development opportunities for the surrounding community.

In order to maintain a dependable team, the company strives to continuously train, retrain, and upskill its employees.

“In our 40 years of existence, many people have joined Petromar, done a lot with their careers, and reached retirement with the company,” Heintz points out.

The long-standing retention of staff speaks volumes about Petromar’s ability to recognise the value of team members and, in turn, equip its staff with the appropriate skills for professional development, instilled through regular training programmes across Ambriz.

These particular skills include welding, technical office functions, project management, fabrication methods, and more, which result in a sustainable development path for staff, the local community, and Angola as a whole.

“Generally, the engagement of our office and field staff is

target-orientated, and any new challenge is seen as an opportunity to grow,” he adds.

Due to the increase of activity at the Ambriz yard, Petromar is drawing potential candidates from further afield.

As part of this expansion, the company is currently in the planning stages of a local housing initiative that will incentivise workers from across Angola to find residence in the area.

In support of this, the company is working with the municipality’s local developers to transform vacant buildings and unused sites into functional and comfortable accommodation for Ambriz yard employees.

As such, this is one of the many ways in which Petromar works to support the local community and improve employee well-being.

Going forward into 2025, Petromar’s target is to deliver on its current projects, including the construction of the Quiluma platform for NGC.

After the load-out of the jacket, the company anticipates completing

the load-out of the Agogo PLET before delivering the deck in Q1 2025 and progressing the fabrication of structures in the Ndungu field.

Petromar is also ready to seize any opportunities that arise from other types of business.

“In particular, some operators are currently planning abandonment and decommissioning programmes for some of their facilities. We believe that Petromar could play a key role in these, partnering with several actors in this new market,” insights Heintz.

Having remained at the forefront of the industry over the last four decades, Petromar is evidently not resting on its laurels.

“We have managed to adapt ourselves and our assets, whilst also training our associates, which will allow us to maintain operations for another 40 years,” Heintz closes.

Tel: (+244) 923 167 620 / (+244) 923 167 629

comercial@petromar.co.ao

www.petromar.co.ao