DELIVERING SUSTAINABLE SOLUTIONS FOR FISH FARMING

Bjarne Hald Olsen, Chief Sales Officer at Billund Aquaculture, speaks to us about the company’s extensive history and how it has proven to be a solid, committed partner who provides innovative solutions for the development of aquaculture

Writer: Lauren Kania | Project Manager: Poppi Burke

Fishing is one of the oldest forms of human interaction with the natural world, with fish themselves having served as a primary source of protein since the beginning of mankind.

Evidence of this crucial relationship dates back over 40,000 years, with groups of Neanderthals traversing the rivers of modern-day

Germany with stomachs full of freshwater fish.

The aquaculture industry has evolved significantly as society has progressed, however, the reliance on fish is now more fundamental than ever. As the population steadily increases, the need for more sustainable, reliable, and efficient food is pertinent, and fish are the solution.

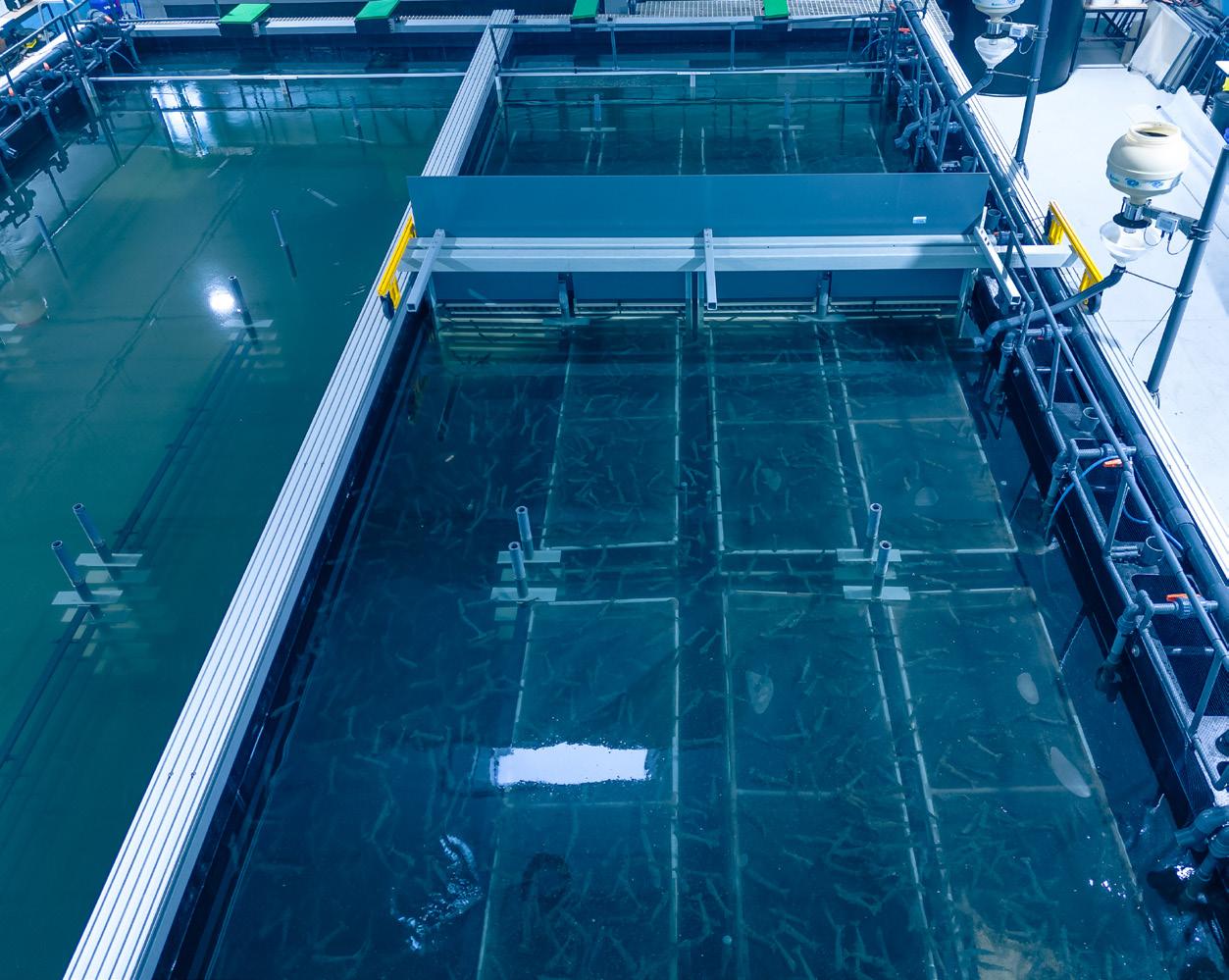

No one is better suited to answer this call than those within the aquaculture industry, specifically Billund Aquaculture (Billund), a company with more than 38 years of experience in the dimensioning, design, assembly, installation, servicing, and operation of landbased aquaculture systems based on intensive recirculation technology.

Founded in 1986, Billund is headquartered in Denmark with more than 250 employees worldwide and subsidiaries in both Chile and Australia, having prominently stationed itself as the global frontrunner in leading recirculation aquaculture system (RAS) suppliers.

“RAS uses the least resources per produced unit in all phases of the operational process. As such, there is a strong focus on the systems using minimal electricity and water, causing

negligible pollution,” opens Bjarne Hald Olsen, Chief Sales Officer at Billund.

Olsen is an environmental engineer with nearly four decades of experience in aquaculture, having worked for Billund since 2007. Passionate about the long-term benefits of RAS in the global economy, he has helped lead the company to become a fundamental pillar in the construction of sustainable and efficient aquaculture.

“With RAS, water is purified and

reused, meaning that the water consumption per kilogramme of fish produced may, in some cases, be reduced to less than one percent of the amount used in conventional aquaculture systems,” he continues. Not only is fish farming a lucrative sector that caters to individuals and large companies across the globe, but it also possesses vast opportunities for sustainability practices that promise a brighter, greener, and more healthy future.

“TODAY, MORE THAN HALF OF THE WORLD’S FISH CONSUMPTION IS BASED ON FARMED FISH, AND A LARGE PROPORTION IS PRODUCED WITH THE AID OF DANISH KNOWLEDGE AND TECHNOLOGY”

– BJARNE HALD OLSEN, CHIEF SALES OFFICER, BILLUND AQUACULTURE

Founded on the basis of respecting the environment, Denmark’s modern aquaculture sector has been a world leader in sustainable and efficient fish farming since the 1970s.

“Over 50 years ago, the Danish authorities kickstarted a major transformation by imposing the first anti-pollution regulations. Recognising that the legislation posed a massive challenge, they simultaneously introduced collaborative programmes to facilitate the development of new methodologies for farming fish without harmful emissions,” expands Olsen.

This has resulted in the likes of Billund coming to fruition and making waves with new technologies and innovations in a long-established industry.

The company distinguishes itself from the rest of the competition in a variety of ways. First and foremost, it offers design, production, installation, service and maintenance, biological

and technical support, and training and education.

“We never leave the facility until absolutely everything is working optimally!” enthuses Olsen.

Additionally, Billund has designed and implemented more than 150 projects and over 500 separate RAS modules in 30 different countries for more than 30 different freshwater and marine species, with the annual turnover of the company being 80 percent related to the salmon industry.

“We have supplied RAS facilities to almost all the big salmon producers worldwide,” explains Olsen.

Currently, Billund is working towards more traditional RAS for smolt and post-smolt with larger and more advanced systems.

This results in fish staying longer in land-based systems where they grow bigger in a controlled environment, ultimately reducing their remaining growth period in the ocean and contributing to reduced

• Project development from ideation to turnkey realisation

• Feasibility study

• Project proposal and preparation

• Biological design

• Engineering design

• Drawings

• Construction and implementation of the fish farm

• Start-up procedures and supply of customised operational and management manuals

• Training, education, and management support for staff at all levels

• 24-hour hotline and ongoing know-how availability

exposure to biological hazards in marine environments and increased productivity.

“The benefits of this are, among other things, enhanced fish welfare, increased sustainability due to lower impact on surrounding environments, and greater traceability. Placement of these systems focuses on reduced transport, lower carbon dioxide emissions, and closeness to consumers,” clarifies Olsen.

Thanks to the vast advancements, Billund has learned how to successfully combine improvements on existing technologies with remarkable engineering achievements, turning the company into a globally recognised brand.

Billund is experiencing a massive demand for its solutions, which can be directly observed within its partnership with Aquapurna, a German technology firm focusing on cost-effective shrimp RAS.

• Minimum water requirement

• Full control of production parameters

• Stable and predictable production

• Optimal sanitary conditions

• Isolation from environmental and climate-related factors

• Enables production at optimal locations

• Captures 90 percent of the solids produced in the system

• 100 percent fish escape control

• Reduced environmental impact

Although it is the secondmost popular seafood product worldwide, shrimp is one of the most environmentally damaging to produce.

“The environmental consequences of shrimp farming range from the deforestation of mangrove forests to human trafficking and slavery,” insights Olsen.

With their proven expertise and experience, Billund and Aquapurna

are working together to make up for the global gap in shrimp supply through reliable, cost-efficient, and large-scale shrimp RAS technology that is both sustainable and replicable worldwide.

“As this technology can be implemented anywhere, similar projects can be developed to help decrease food transportation distances and reduce the reliance on food imports,” Olsen continues.

The founder of Aquateknikk has an abundance of experience with feeding systems in agriculture and fish farming. Much of the equipment used at Aquateknikk comes from an agricultural background, which happens to show a strong advancement from previously used equipment.

For Aquateknikk, quality is one of its main focal points. It chooses products and suppliers with the highest quality in mind, and most of the goods are produced locally in Norway.

Aquateknikk has developed feeding technology that gives full control over feed consumption, by weighing all the feed as it leaves the silos. It knows that no two farms are the same, which is why it tailors the solutions to each individual client. It focuses on utilising every space available, ensuring efficient, gentle, and accurate feeding. Aquateknikk’s feeding systems are very accurate, reliable, and user-friendly.

The company’s control system was developed in Norway together with its clients. The software has a number of functions such as feeding times, silo measurement, feeding tables, and easy control of the daily hours of feeding etc. Controlling the system can be done remotely via VPN, and all data can be exported from the system, or imported via external data.

It is important for Aquateknikk to deliver the best end-user experience, based on its client’s needs. Delivering excellence from the smallest to the largest facilities, no challenge is too big for them.

This next generation of landbased shrimp farms has surpassed all objectives in lab-scale trials and commercial prototypes, and is now preparing for large-scale production to initiate at the beginning of 2026.

This construction, which will take place at the Sigmundshall industrial site west of Wunstorf, Germany, is anticipated to become the world’s largest high-intensity RAS shrimp system. This choice of location not only transforms a former mining area into an innovation hub but is also closely located to one of Europe’s major seafood consumption markets.

“The facility will serve as a largescale proof of concept, showcasing the expertise developed by both companies over the past few years,” enthuses Olsen.

“THE OVERALL GOAL IS THAT RAS PRODUCED BY BILLUND WILL BECOME SYNONYMOUS WITH SUSTAINABLE FISH FARMING”

– BJARNE HALD OLSEN, CHIEF SALES OFFICER,

With around eight million tonnes of shrimp consumed worldwide each year, the mission of the two companies is to provide shrimp lovers with a sustainable, clean, healthy, and delicious product at a wholesale price so shrimp will no longer be a guilty pleasure.

With nearly four decades worth of experience in leading a diverse range

of international initiatives, Billund leaves its unique stamp on each project, characterised by its pursuit of perfection and determination to be the best.

“Our strength is largely built around substantial goodwill in the industry. We have a large and well-documented reference list that highlights decades of experience in the planning, installation, operation, and service of intensive RAS,” confides Olsen.

The injection moulded biofilter media, RK BioElements, from Dania Plast A/S is a unique designed biomedia which can be used for both nitrification and denitrification in fixed-bed filters and moving-bed filters.

Dania Plast A/S Fabriksvej 10, DK-7800 Skive

Plast-Line A/S was founded in 1993. We have more than 30 years of experience selling plastic piping systems, valves and fittings for the aquaculture industry. We stock a wide range of quality products from some of the leading European manufacturers. Our office, production and warehouse is located in Middelfart, central Denmark. We are a serious and reliable partner, where the customer’s wishes and needs are our first priority.

Our newly established department continuously develops new products and production methods. In Middelfart we have 3000m² modern production facilities. We have invested in larger machinery and are continuously developing our production facilities with new technologies. This helps ensure high quality and flexibility so that the customer has security for fast delivery of quality products.

In our 300m² large test area we carry out pressure and vacuum tests to guarantee the operational reliability of the valve. All valves are tested in specially designed machines, with individual test procedures. Valves which are designed for pressurised piping systems will all be operationally tested before dispatch.

This is demonstrated through the myriad projects that Billund has embarked upon over recent years, including Whale Point, SalMar Senja 1 and 2, and Los Arrayanes.

Whale Point, a smolt nursery located in Tasmania, was constructed in 2019 and combines different cutting-edge technologies and innovations to create the largest tanks and longest pipeline the company has ever designed for a smolt system.

The design, construction, and implementation of this state-of-theart RAS facility allowed Billund to push the limits of modern aquaculture technology, ultimately resulting in larger, healthier fish.

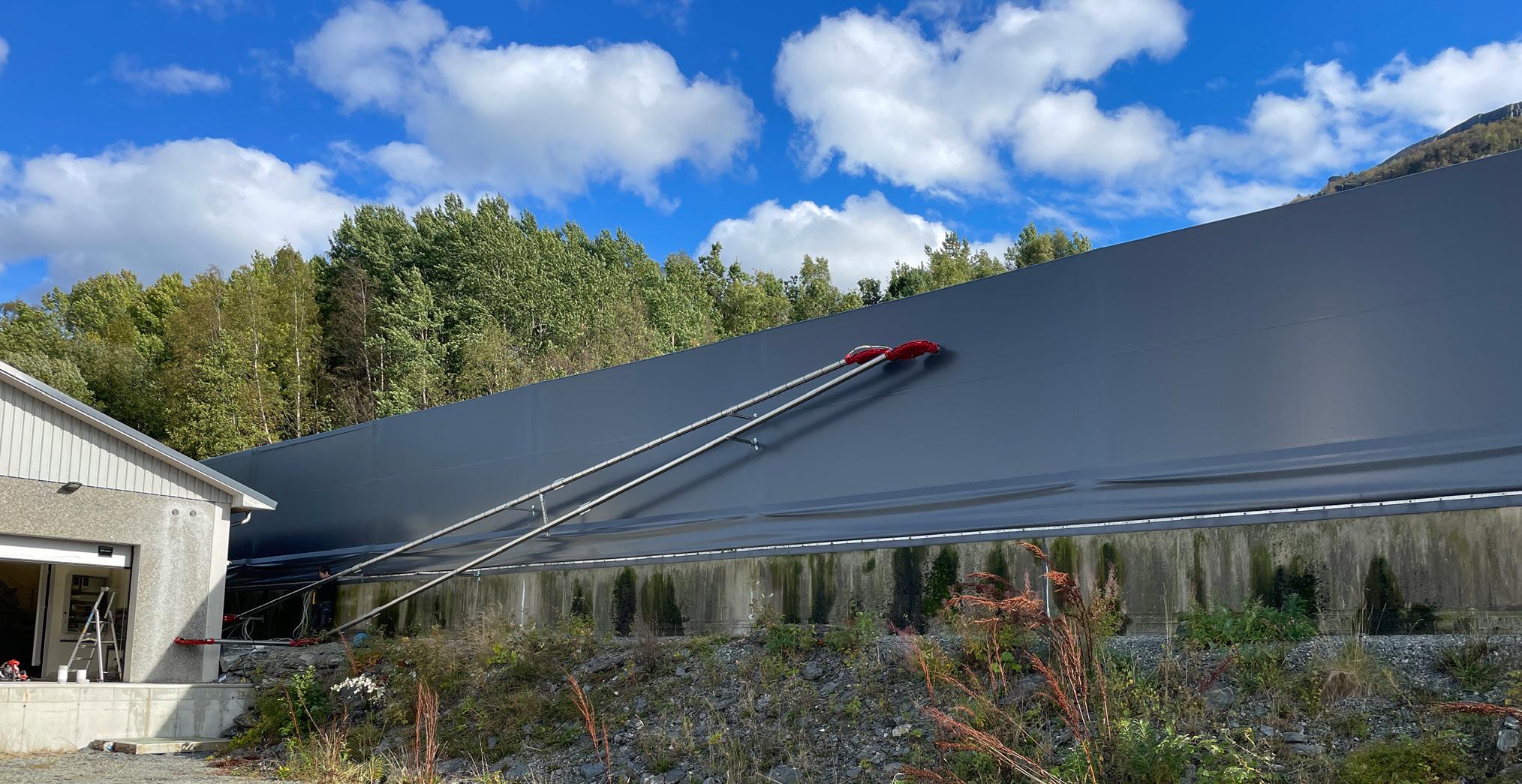

SalMar Senja 1 and 2, meanwhile, were designed to supply smolt to the company’s sea sites in northern Norway. The two projects were constructed in 2017 and 2023,

respectively, and include two RAS units with a combined capacity of approximately 29 million Atlantic salmon smolt of approximately 120 grams per year.

Los Arrayanes is particularly noteworthy, as it was the first postsmolt salmon land-based RAS project to be built in Chile. Completed in 2022, the farm is designed to rear Atlantic salmon from fingerlings to post-smolt, with three independent RAS units – winter, summer, and post-smolt – which all operate with different levels of salinity.

All of these endeavours showcase Billund’s vision to be a company that is capable of committing to large projects and supporting the development of innovative solutions that transform the future of aquaculture.

With a promise to be more than

just a supplier, Billund pledges to be a true project partner, offering advice during implementation, service, and operation, ultimately positioning itself as a pillar in the fish farming industry for decades to come.

“Our global market-leading position is retained by innovation and the newest technologies. Our established know-how, together with a local presence in significant fish-producing countries and long-lasting customer relations, provides a great foundation for long-term growth and continuous innovation,” concludes Olsen.

Tel: +45 2240 6720

bjol@billundaquaculture.com

www.billundaquaculture.com

EXPO-NET

EXPO-NET