Amongst a major revival in the global platinum group metals industry, JJ Joubert, Senior General Manager of Bokoni Platinum Mines, delves deeper into the company’s proud heritage, innovative mining technology, and commitments to community development

Writer: Lucy Pilgrim | Project Manager: Thomas Arnold

As the northernmost province of South Africa (SA), the never-ending horizon of Limpopo holds a microcosmic collection of Earth’s most outstanding views, histories, creatures, and natural resources.

Indeed, jutting out into the vast, iridescent skies of the province is an eclectic topography of mountain ranges and passes, building a unique landscape that acts as the stepping stones of giants.

Surrounded by these sky-splitting wonders, humans and animals alike gaze upon the rudimentary drawings of those who walked the land thousands of years ago, stamped across many of the mountains’ caves.

A particularly exquisite example is the Makgabeng Plateau which has been pulled and pushed into a convoluted shape, creating iconic rock formations. This site acts as a natural canvas for primitive paintings of hunter-gatherers with bows and arrows as well as large, elementary animals, providing an insight into the stories of ancient Limpopo.

These magnificent but looming mountains gently transform into the rolling hills of the province’s many rural areas and world-renowned nature reserves.

In fact, Limpopo is home to Kruger National Park, the largest wildlife sanctuary in SA. This two million hectare (ha) nature reserve is a particularly special patch of land as it is home to some of the world’s most majestic creatures, including the ‘Big Five’.

The province has for centuries been the stomping ground of African lions,

• The large igneous complex was formed in the Paleoproterozoic era over two billion years ago.

• The complex is so abundant with PGM resources that even after a century of mining, 192,000 tonnes of platinum remain.

• At the current rate of mining, the BIC will not be depleted of resources for another 700 years.

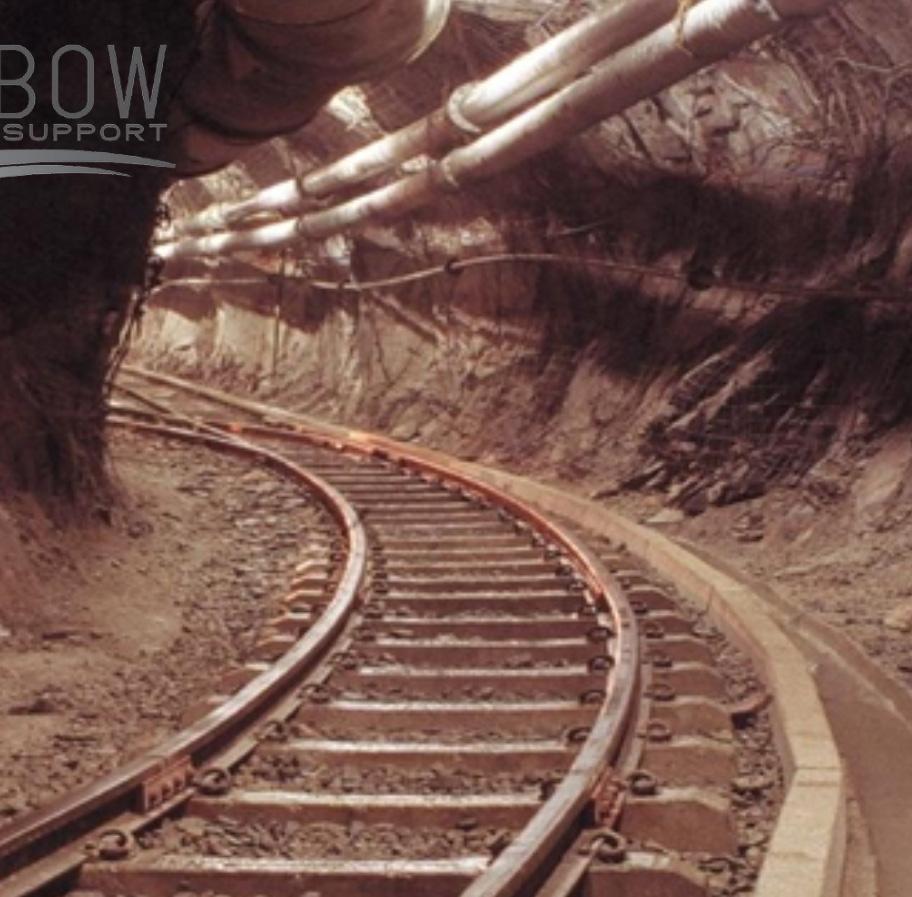

• The BIC consists of underground and open pit mining.

• There are currently 30 active organisations in the complex.

leopards, rhinoceroses, elephants, and cape buffaloes who serenely graze upon the emerald pastures of the area’s undisturbed bushvelds.

Yet, unbeknown to Limpopo’s range of magisterial beasts and roaming creatures, a complex flurry of activity occurs beneath the Earth’s crust. Indeed, nestled under the surface are some of Africa’s most bountiful natural resources and globally desired minerals.

Specifically, the Bokoni mine, one

of the continent’s largest open pit mines, heralds some of Africa’s most expansive mining discoveries and is headed by world-renowned Bokoni Platinum Mines (BPM).

Located on the eastern limb of the Bushveld Igneous Complex (BIC), BPM’s platinum mine sprawls across an impressive 15,000ha. The pear-shaped complex covers

an astonishing 66,000 square kilometres, reaching across several South African provinces including Mpumalanga, North West, and Gauteng, as well as Limpopo. Contributing 75 percent of the world’s platinum and around 50 percent of total palladium, the BIC possesses an enviable collection of platinum group metals (PGMs), including platinum, palladium, osmium, iridium, rhodium, ruthenium, and much more. The abundance of PGM resources

across the complex has a long and storied history spanning over a century. Specifically, the BIC contains the largest ultramafic igneous rock formation on the planet, holding over one million cubic metres of igneous rocks formed over two million years ago.

Initial discoveries of the metal group occurred in 1924 when a collection of platinum nuggets was uncovered in a riverbed north of Pretoria. A further two platinum deposits were brought

to light soon after, each at 100 metres in length. Due to the abundance of resources found, the area was named and crowned as one of Africa’s greatest PGM sites.

However, the South African PGM sector has faced substantial challenges in recent years, experiencing pressures caused by rising operating costs and falling market prices, making some of the country’s largest platinum mines increasingly difficult to operate.

Build your next project with professionals

Anthonia’s Construction is a 100% black female-owned and controlled organisation that is registered with the NHBRC. The company was established in 2018 and consists of a consortium of experienced businesses that specialise in the construction and manufacturing industries. We have the commitment, skills and resources to meet the requirements of our customers. We are a hands-on, start-to-finish group of experts taking on the challenge of rebuilding South Africa and beyond.

Core Values

• Honesty

• Integrity

• Reliability

• Professionalism and Quality

• Confidentiality and Integrity

We follow stringent guidelines and methodologies to deliver the finest graded structures and products which are friendly to our environment.

Using industry management tools and techniques, we are able to guarantee our customers exceptional products and services.

We invest in expertise to reaffirm our customers’ peace of mind. It is our utmost responsibility to ensure satisfactory results in everything we touch.

From site preparation, excavation, and blasting to mineral testing, tailings management, and environmental compliance, the company provides extensive support for mining operations, including the delivery of mine mechanical equipment, geotechnical services, and safety inspections.

We specialise in delivering high-quality results, timely project completions, and exceptional customer satisfaction. Let us bring your projects to life with our expertise and dedication.

We manage infrastructure, treating it as a developmental production.

We offer professional home renovation, home remodeling, office renovation and office remodeling services.

We manufacture bulk hand sanitisers, locally produced in South Africa.

Our reach extends beyond the borders of South Africa.

We are a company that prides itself on 'family' culture. We seek high calibre people and set even higher standards. We are a company that has, at its core, a team philosophy that is tightly integrated in our day-to-day operation – there is a real sense of responsibility among our staff. We believe in nurturing the skills of our team members and providing growing levels of responsibility and opportunity. CONTACT

44 Dorp Street, Polokwane (LP), South Africa (+27)61 586 1506 (+27)68 069 6491 admin@anthoniasconstruction.co.za anthoniasconstruction.co.za

However, the industry is currently experiencing a major turning point, leading to a resurgence in PGM demand. After decades of growth in the international electric vehicles (EVs) market, manufacturers are looking at other, more reliable options.

As a result, hybrid electric vehicles (HEVs) are an increasingly popular alternative as they provide greater range and power and are becoming a more cost-effective option, whilst still allowing motorists to reduce their environmental impact. As a result, the amount of HEVs sold in 2023 increased by 18 percent compared to the corresponding quarter the year before.

Likewise dissimilar to EVs, the catalytic converter technology used in HEVs requires a substantial level of PGMs – an even greater amount than is typically used in conventional internal combustion engines (ICEs) found in motor vehicles, once again contributing to the uptick in demand. Consequently, with reports indicating that the rise in the use of HEVs could last until 2030 or even longer, the recent resurgence in the global PGM market could be set

• Aim for operational excellence.

• Provide a safe and healthy work environment.

• Maintain a non-discriminatory workplace.

• Improve the lives of those living in communities neighbouring its operations.

• Work responsibly to achieve a balance between the economic, societal, and environmental aspects of the business.

• Maintain the highest standard of corporate governance.

to last, which bodes well for many mining entities that are currently witnessing a major revival in prices and mine site longevity.

Even though BPM has been no stranger to the industry’s previous stagnation, the company has planned accordingly to ensure that it sustains its ongoing success and capitalises on growing hybrid technology, maintaining its position as SA’s second-largest PGM resource and firmly establishing its presence in the diverse sector.

“Although we believe it will recover, the PGM market is under extreme pressure. Therefore, we have slowed down our ramp-up and expansion but have also positioned ourselves well on the cost curve to exploit improvement in the prices,” introduces JJ Joubert, Senior General Manager.

As such, BPM is well-positioned to capitalise on the market’s recovery in the face of changing global demands and contribute to the long-term sustainability of the industry in SA.

BPM’s journey to its present enviable success and reputation is marked by transformation and innovation.

Despite previously facing financial challenges that resulted in a six-year period of care and maintenance, the company’s future took a positive turn in September 2022 when Africa Rainbow Minerals (ARM) acquired the mines from Anglo American Platinum and Atlatsa Resources, marking a new chapter for BPM.

Today, ARM is the sole owner of the company, granting it a vast network of resources and market opportunities, particularly given the fact ARM stands as the leading South African mining and minerals business with operations across the country as well as in Malaysia.

Established 30 years ago, ARM has experienced a unique journey, leveraging both joint ventures and stakeholders to facilitate enhanced mining projects. Through four divisions, the organisation

“THE SUCCESSFUL IMPLEMENTATION OF NRE ACROSS OUR MINES WILL SEE HUGE BENEFITS IN THE SAFETY IN PRODUCTION FACILITIES FOR THE MINING INDUSTRY AT LARGE”

– JJ JOUBERT, SENIOR GENERAL MANAGER, BOKONI PLATINUM MINES

extracts and beneficiates iron ore, manganese ore, nickel, coal, and PGMs in SA, making it a major player in the country’s mining landscape.

Despite a significant decrease in PGM prices over the past five to 10 years – causing many other platinum organisations to suffer unprofitable production – ARM strongly believes in the prosperity of BPM and its investment attractiveness in an industry that is experiencing an upward trajectory.

Since becoming a part of ARM’s extensive and diversified portfolio over two years ago, BPM has, in turn, become a valuable asset for the organisation and its platinum

discovery and mining activities.

“BPM enhances ARM’s position in the global mining sector, particularly in the platinum market,” Joubert insights.

“It strengthens the organisation’s competitive edge and market presence, attracting potential investors and partners.”

The PGM orebodies mined by BPM complement ARM’s platinum division in particular by reducing reliance on a single commodity and balancing the company’s exposure to any market fluctuations, which is particularly critical given the historical turbulence of the African PGM sector.

Dennis Andrew Roberts (Pty) Ltd is a leading African construction company with a proven track record of success. Offering a wide range of construction and add-on services that ensure the highest possible quality, the company promises client satisfaction in every project

Presenting a comprehensive range of civil construction, water sanitation, and reticulation services, alongside fibre projects and add-on services, Dennis Andrew Roberts (Pty) Ltd (DAR) is a visionary construction partner for the industry.

Driven by a mission to provide world-class services to its clients, the company enables organisations to achieve their goals and objectives through its effective and efficient use of resources.

Under the expert guidance of Managing Director, Thulani Mashele, principles of safety, health, environment, risk, and quality (SHERQ) are closely followed, resulting in excellence across every aspect of DAR’s operations.

A strong advocate of a hands-on management approach, Mashele ensures the highest standards of quality and safety are met through his active on-site engagement with projects, underscoring the entire company’s commitment to delivering top-notch services.

DAR’s adherence to SHERQ principles highlights its dedication to maintaining a safe and healthy work environment, minimising environmental impact, and effectively managing risk.

As such, the company’s core values are centred around professionalism, high-quality products and services, and empowering the communities in which it operates.

DAR’s implementation of a robust quality management system (QMS) helps it to consistently deliver high-quality outcomes, comply with regulatory requirements, and enhance client satisfaction.

Why choose DAR As a leading construction company with a well-established history, DAR ensures the highest quality, safety, and client satisfaction in each and every one of its projects.

The company understands how a QMS is important in enhancing project quality, operational efficiency, and risk management. By consistently delivering exceptional projects, the company has built and maintains a strong market reputation.

Closely following the key components of a construction QMS such as quality planning, assurance, and control, as well as continuous improvement, DAR seeks to implement corrective and pre-emptive actions to improve processes and prevent issues recurring.

Furthermore, a QMS is promoted deeply within the company through comprehensive training, which includes outlining key principles and procedures. DAR also cultivates comprehensive documentation and record-keeping, maintaining stakeholder engagement through transparent quality expectations.

By following international QMS standards, such as ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018, the company has a robust framework for quality assurance and continuous improvement.

Alongside its high QMS standards, DAR recognises the importance of occupational health and safety (OHS) management, and its integral role in minimising risk, preventing workplace incidents, and promoting a culture of safety.

The company’s own OHS system ensures the safety and well-being of employees, legal compliance, risk management, and operational efficiency, all of which contribute to its strong reputation. This is due to the effectiveness of OHS management that helps improve client trust, employee morale, and the ability to attract new business opportunities.

Key components of OHS management include policy and objectives, hazard identification and risk management, training, incident reporting, and emergency preparedness and response.

Alongside its other certifications and standards, DAR also holds ISO 45001:2018 and occupational health and safety assessment series (OHSAS) 18001, which combine to provide a framework to improve employee safety and reduce workplace risks for an optimal working environment.

By implementing a wellthought-out approach to OHS management, the

company has seen a significant reduction in workplace accidents, enhanced compliance with regulatory requirements and industry standards, and increased operational excellence.

Placing strong emphasis on skills transfer to the communities in which it operates, DAR seeks to empower society through sustainable business practices.

For example, it creates value for its labourers and subcontractors by prioritising upskilling and training, ensuring they gain tangible skills to enhance their capabilities when working on company projects. Its training programme goes beyond technical skills transfer by recognising the importance of a wellrounded skillset in its workforce.

DAR’s ongoing collaboration with Nkuhlwana Trainers & Projects demonstrates its strategic approach to skills development and its dedication to providing accredited programmes and competency certificates to its staffbase, adding depth to its commitment to comprehensive skills transfer.

Project Management

A dedicated project management team oversees all aspects of construction projects, from planning and design to construction and completion. Working closely with clients to understand their needs and goals, whilst developing a project plan that meets these requirements, the team ensures that projects stay on track and within budget.

Civil construction works

• Road

• Bridge

• Storm drainage

• Water and sewer line

• Earthworks

• Site preparation

Building construction works

• Residential

• Commercial

• Industrial

• Institutional

Water sanitation and reticulation works

• Water treatment

• Wastewater treatment

• Water distribution

• Wastewater collection and disposal

Fibre projects

• Installation

• Repair and maintenance

• Network design and engineering

Add-on services

• Fibre installation, repairs, and maintenance

• OHS

• Environmental management

This makes ARM’s position even more lucrative, as BPM’s operations will contribute a significant revenue stream through the production and sale of other PGMs, thus helping to support the financial health of ARM and allowing it to invest in other projects and strategic initiatives.

On top of the projected market prosperity, the successful management of BPM positively impacts ARM’s reputation and relationships with local communities, regulatory bodies, and other stakeholders.

“ARM is fully dedicated to BPM’s revival in a way that collaborates with local communities,” expands Joubert.

Given ARM’s extensive presence across SA, permeating into many provinces alongside Limpopo including Northern Cape, North West, Mpumalanga, KwaZulu-Natal, as well

as Sarawak in Malaysia, successful community engagement and environmentally conscious operations are increasingly important to the organisation.

So much so, ARM’s economic, social, and governance (ESG) practices infiltrate every aspect of the company’s operations as it is guided by ethical leadership that paves the way for integrity and respect across all mining activities.

Indeed, as an industry-leading business, ARM has a deep understanding of the impacts it has on the world around it and therefore strives to embrace opportunities to make a positive contribution to the growth and development surrounding societies.

“Positive community engagement and responsible mining practices bolster ARM’s social license to operate and contribute to its overall sustainability,” enlightens Joubert.

As a continuation of this, the

The company deploys a procure-to-pay strategy at the beginning of each mine site’s production, which includes a number of purposeful and engaging steps:

1) Identifying a resource or material need: The mine site team identifies that a specific product needs to be supplied or a service delivered.

2) Appointing a supplier: The procurement team goes through the process of searching for a supplier that will meet their particular business needs. Significantly, BPM follows a competitive process in which all submissions must follow market-related pricing.

3) Contracting the successful bidder: The company negotiates and signs a contract with the successful bidder. BPM then dictates the terms and conditions of the contract to make sure that all the necessary requirements are met, including pricing, delivery, and warranties.

4) Verifying that the work is completed to the required standard: The company ensures that goods or services have been provided to a high standard as set in the contract whilst also checking for any defects or issues.

5) Payment: Once the work is completed to an adequate standard and appropriately verified, BPM ensures that it pays suppliers on time and according to agreed terms and conditions.

company invested ZAR124 million in corporate social responsibility (CSR) in the 2022 financial year, and a further ZAR371 million in skills development and training.

This financial input is a testament to ARM’s dedication to fostering positive relationships across its local communities and amongst staff.

Meanwhile, through a highly comprehensive sustainable development model, the company explicitly acknowledges that good corporate governance and ample environmental stewardship are also conducive to creating strong relationships with shareholders and in turn generating greater socioeconomic value for the community.

ARM’s commitment to transformation and recognition of the role it plays in socioeconomic and people development is demonstrated by the company’s dedication to facilitating equal access to business opportunities.

Accordingly, ARM and the many organisations under its ownership, such as BPM, are acting in accordance with the Mineral and Petroleum Resources Development Act 28 of 2002, which guarantees equitable access to and the sustainable development of SA’s mineral and petroleum resources.

The organisation’s primary activities – which include mining, crushing, milling, processing, and beneficiating metals and minerals – present highly adverse working conditions.

Therefore, in recognition of industry legislation, ARM implements stringent hazard identification and risk assessment criteria. As a result, the company and its various acquisitions can ensure that its operations do not harm the planet or its people.

By adopting a more holistic view of success, ARM, and BPM by extension, are ensuring a long road ahead for corporate sustainability in South African PGM mining.

BPM’s success and long-lasting perseverance in the South African mining industry are marked by a willingness to adapt and become a catalyst for progression.

Since its change of ownership over two years ago, the company has revitalised its operations. This has proven to be an immense challenge, requiring highly specialised work and significant levels of investment.

Yet, instead of diminishing its activities, such upheaval has made

BPM more determined to succeed and pioneer innovative strategies.

For instance, the company’s recently appointed management team is currently in the process of implementing a new design layout for its mine sites. This will eventually enable the efficient underground extraction of platinum orebodies in a way that aligns with the ore’s unique characteristics and ARM’s forwardthinking mining strategy.

BPM’s platinum orebody is one of the largest and richest in SA and grades between six grams per tonne

(g/t) and 9 g/t which, according to the World Gold Council, makes it an incredibly high-quality resource.

The company’s orebody is further characterised by its complex geology, narrow and dipping at an average of 14 and 23 degrees. Due to this diverse formation, the required concentrations of platinum orebody to make it economically viable are harder to obtain. Therefore, BPM must employ specialised technology to ensure its PGM products are sufficient for the market.

Established in 1991, DOK-ING is an engineering powerhouse of heavy-duty robotics & autonomous systems, serving high-risk industries worldwide. With a presence in over 40+ countries, the company has earned a reputation for delivering safety, efficiency, and reliability in some of the world’s most hazardous environments.

DOK-ING’s innovative robotic solutions are designed to address a range of critical operations, including Underground Mining, Military and Humanitarian Demining, Military Engineering, CBRNe, Emergency Response and Counter-terrorism.

The company’s commitment to innovation is embodied in their motto, “Don’t send a man to do a machine’s job,” reflecting the company’s dedication to developing cutting-edge technologies that protect lives, the environment, and critical assets in dangerous conditions.

With over 30 years of experience, DOK-ING has garnered international recognition for its industry-leading advancements, earning more than 100 awards for revolutionising standards across multiple sectors. From safe exploitation of narrow reef layers and clearing minefields to responding to natural disasters and industrial hazards, DOK-ING’s mission remains focused on safeguarding people and improving operational safety with groundbreaking technologies.

The headquarter is in the Croatian capital, Zagreb, and, besides the European office, DOK-ING is incorporated on the following continents: North America, Africa and Asia.

Contact DOK-ING Mining:

Mr. Luka Petro, Managing Director

Mobile: +385 (95) 903 06 14 | Email: luka.petro@dok-ing.hr

Address: Slavonska avenija 22 G, 10000 Zagreb, Croatia

The DOK-ING portfolio of cutting-edge robotic systems for Underground Mining includes: NRE Fleet and XLPD Groundhog dozer to enhance safety and efficiency. The NRE fleet consists of three robotic systems: NRE dozer, NRE Support Rig and NRE Drill Rig that seamlessly complete the drilling, cleaning, and supporting processes. These groundbreaking innovations were specially designed for platinum, chrome and gold extraction. DOK-ING’s innovative product is a VR training simulator designed to train operators on the NRE Dozer for underground mines, allowing them to train control of these systems effectively before entering the mines.

Contact DOK-ING Africa:

Mr. Tom Sertić, Managing Director, DOK-ING Africa

Phone: +27 82 5530 674 I E-mail: tom@doking.co.za

Address: DOK-ING House & Workshop, 237 Joseph Street, CNR Nyewerheid, Gemiston 1401, Johannesburg, SA

DOK-ING underground mining equipment and remote-controlled systems are built to tackle the challenges of deep excavation and hazardous materials, revolutionising how mining operations are conducted. The NRE technology enables mechanised exploitation in ultra-low profiles (0.9 m to 1.7 m), increasing safety, productivity, and ore concentration, leading to less waste and more selective extraction whilst reducing capital investment, less rock is excavated, which can reduce costs. With the development and production of NRE, DOK-ING is expanding its product range, bringing innovation to the mining industry and pushing the boundaries of the efficiency of mining methods.

DOK-ING’s NRE fleet can handle slopes of up to 22°, surpassing the 10° limit of wheeled machines and providing the underground mining industry with new opportunities.

The ability to operate on higher slopes opens up access to deposits that conventional machines can’t reach or would make unprofitable. This flexibility not only enhances mine design but also leads to significant cost savings.

The NRE fleet is remote ly controlled, eliminating the need for personnel in unsecured areas. The fully automated roof drill ing and supporting oper ations further enhance operator safety, ensuring a safer and more efficient mining process.

DOK-ING’s unique innovative NRE, measuring just 65 cm tall, is designed to navigate the world’s most challenging mines. The electric drive eliminates the noise and impact of exhaust gases in confined spaces and reduces the carbon footprint of the overall exploitation process. Mechanisation of the production process increases production efficiency, improves occupational conditions, and drastically reduces risks for workers.

This technology comes in the form of narrow reef equipment (NRE), which vastly improves mining efficiencies beyond conventional recovery methods.

Although NRE has been utilised across many South African mining operations, it is best deployed across a homogenous orebody, making it ideally suited for BPM’s platinum operations. This also means the technology can be used across the company’s many mining areas.

“By purchasing the equipment, BPM has made a generous capital commitment. The successful implementation of NRE across our mines will see huge benefits in the safety of production facilities for the mining industry at large,” Joubert informs.

Set to be commissioned and handed over by December 2024, the company must strategically deploy the equipment in order to

make the most of the PGMs forming underground.

Firstly, BPM will carry out trackless development methods, using mobile equipment to establish the footprint of the mine reef. This will advance the initial evolutions of the mine by contributing to the early extraction of resources, thus reducing capital pressure at the first stages of the mine.

Once the initial footprint has been established, the NRE suite will be used to establish a stope that will maximise the ore grade output.

The stoping methods will provide direct access to the orebody, reducing the creation of waste in the underground mine and ensuring the careful management of tunnels, equipment, and infrastructure.

Such efficiencies are vital for ensuring improved worker safety, and NRE will facilitate optimum environments for recovering

As part of its vast range of corporate commitments, the company strongly advocates for and supports local women in becoming business owners and prosperous entrepreneurs.

In May 2024, Kenneth Mbewe, Head of Social Performance at the time, held a communal meeting in the village of Sefateng to allow the community’s voice to be heard regarding women’s skills training and empowerment.

Many of those at the meeting shared their concerns about the lack of female empowerment as well as their dreams to own a business. The gathering also facilitated the opportunity to learn more about the important skills needed to run a company and significant supply chain procedures.

The key goals of the meeting included:

- Empowering women through entrepreneurship opportunities.

- Sharing potential business ideas.

- Assisting aspiring female company owners.

- Motivating and educating attendees on prosperous business sectors.

- Identifying potential business ideas that fit with BPM’s objectives.

The meeting allowed attendees to voice their opinions and take control of their futures.

orebodies in a way that maximises safety and minimises potential hazards.

Moreover, using NRE means that even the most inclined reefs and narrow tubular orebodies can be effectively extracted, enhancing the overall productivity of the mine.

As such, by utilising this exceptional infrastructure, the company can remain up-to-date with the latest industry evolutions and ensure burgeoning success under the ARM umbrella.

“The NRE stoping method will revolutionise the mining techniques employed in narrow reef mining across SA,” Joubert affirms.

As the critical next step to the strategic extraction of required resources, BPM is currently working

on a further open pit mine to help increase the amount of ore processed in its plants.

As a result, the company is hoping to enhance early ounce production across the Bokoni area.

The new open pit mine will bring a plethora of benefits to the fore. For example, the project will help increase the ore tonnage delivered to the plant, subsequently enabling the optimum extraction of PGMs.

Additionally, the open pit mine will have a specially designated stockpile in front of its plant to improve production efficiency and speed and prove the viability of opencast material.

Towards the end of 2025, BPM will also commission a chrome recovery plant, which will be used to remove chrome from ore to become a marketable and profitable by-product.

This process will increase the number of plant recoveries that can be sold off as chrome, which will not only fully optimise the minerals but also increase the company’s eventual profits.

The commissioning of the chrome recovery plant will arrive at a fortunate time, given that the market is comparatively robust and bullish, allowing many mining entities to find more ways to generate profit from what was once considered a waste product of PGM mining.

Moreover, the increasing prominence of the chrome market will help offset the original costs of the mine and support the growing demand for the material in China, which is showing a growing investment interest in the mineral.

Elsewhere, BPM is keenly expanding its underground operations at its Klipgat site, where the surface box cut

has now been completed.

The company is also currently in the process of developing three main site declines to intersect with its existing underground workings. This will prove highly advantageous for the productivity of the Klipgat mine as it will increase the site’s ore handling capacity and allow enough room for larger equipment to be deployed across the project’s underground operations.

In the last year, the Klipgat mine has already facilitated numerous opportunities for BPM and the local community, as the project was purposefully designed with advanced safety measures and constructed with operative staff in mind.

This has proven particularly important given the project was completed by a dedicated group of local labourers and tradespeople that comprised 60 percent of the workforce.

As such, the Klipgat project is proving advantageous for both BPM and the local community as it is contributing to SA’s growing minerals and metals industry whilst bolstering job opportunities in nearby communities.

To ensure a sustainable and successful mine site that also benefits nearby communities, BPM has a purposeful procurement strategy that entails consistency and success across every mining endeavour.

As a key part of BPM’s SLP, the company recently constructed a significant access bridge, demonstrating its commitment to improving local infrastructure and making a positive impact by increasing accessibility.

IMPROVING ACCESS: The project created greater transport routes for both vehicles and pedestrians to churches, clinics, schools, and workplaces. As such, the infrastructure benefits a vast amount of the local population.

FUNDING: In order to ensure that the project reached completion, BPM fully funded the ZAR5 million bridge in collaboration with the local municipality.

IMPROVING DAILY LIFE: By constructing the bridge, BPM addressed a critical need as it facilitates a safe mode of travel across difficult terrain, especially during the rainy season when roads become difficult to navigate. As such, the project made a huge improvement to daily life.

“Our local procurement strategy is designed to support and uplift surrounding communities by promoting entrepreneurship and fostering the development of small, medium, and micro enterprises (SMMEs),” Joubert explains.

Indeed, the dedicated process for acquiring a team of local talent and suppliers cultivates many benefits for nearby businesses and those potentially impacted by mining operations.

For example, in line with corporate SA’s commitment to broad-based Black economic empowerment (B-BBEE), the company strives to maximise purchases from Blackowned (BO), Black women-owned (BWO), and Black youth-owned (BYO) entities, known as its preferential procurement strategy.

“This approach helps promote entrepreneurship and supplier development in local communities by providing access to mainstream procurement opportunities,” elaborates Joubert.

In a similar vein, the company also supports historically disadvantaged South Africans (HDSAs), including those who were unfairly treated prior to the Constitution of the Republic of South Africa.

As such, BPM’s procurement strategy actively promotes entrepreneurship in unfairly disadvantaged communities, giving HDSA-owned enterprises in host and local communities access to conduct business in the nation’s mainstream economy.

This includes proactively supporting procurement from BO-exempt micro enterprises and qualifying small enterprises to reduce unemployment amongst these groups.

An additional component of the company’s preferential procurement process is the education of stakeholders and spreading the importance and meaningful impact of the strategy.

“Spreading awareness about preferential procurement and its potential positive impact on the community is crucial as it helps create an enabling environment for sustainable Black businesses,” impassions Joubert.

Akin to spreading awareness of Black empowerment, BPM follows through on its beliefs by strategically awarding tenders and contracts to community development projects, as well as BO, BWO, and BYO enterprises

and suppliers.

In collaboration with BPM, these businesses, as well as other local entities, have the opportunity to be part of Enterprise and Supplier Development (ESD) programmes.

The company’s procurement strategy aligns ESD with preferential procurement by actively managing the growth and development of HDSA enterprises within host communities. This involves educating end users

– including heads of departments, contract managers, engineers, and budget holders – on the importance of their participating role in the procurement process.

By creating such a comprehensive and steadfast strategy for sourcing suppliers and employment, BPM is creating long-term sustainable value by positively contributing to those who are disadvantaged in neighbouring communities.

“The local procurement strategy not only supports the national agenda for SMME development but also contributes to poverty alleviation, employment creation, and shared economic growth in local communities,” informs Joubert.

In turn, this ensures that these businesses continue to prosper beyond the life of the mine whilst also contributing to the company’s corporate citizenship.

Written by Jaco Lotheringen, Managing Director and Spencer Eckstein, Chief Operating Officer, Ukwazi

Briefly introduce us to Ukwazi, including a short overview of your main products and services, locations, client base, number of employees, etc.

Ukwazi celebrates 20 years in operation this year. We are a niched, mining advisory company that specialises in providing critical services like integrated mining studies, mine engineering and planning, engineering infrastructure design, environmental, social, and governance (ESG), project valuations, public reporting, on-site technical services, and transaction advisory services to mining clients in the sub-Saharan Africa and the Middle East regions. We have also recently concluded an exclusive distribution agreement with the Canadian yellow equipment supplier, K-Tec, for its pull scrapers. The application thereof is diverse and focuses on the mining of typical materials associated with tailings facilities and residue deposits. As part of mine rehabilitation activities, the equipment removes soft overburden material as part of the conventional mining cycle and general earthmoving as part of large civil projects.

We are based in Pretoria, South Africa (SA), and have offices in the coal fields of Mpumalanga and the iron and manganese fields of the Northern Cape. More recently, we opened an office in Dubai.

We are a mid-sized business with more than 50 fulltime employees and another 50 associates, whom we collaborate with on a project-by-project basis. We provide services to most of the major mining companies, as well as mid-sized and junior miners across Africa.

What, for you, differentiates Ukwazi from the competition?

In general, our competitive advantage comes from being based in Africa, which is home to some of the world’s most important bulk metals and minerals, precious metals, energy minerals, rare earths, and battery metal deposits. More specifically our competitive advantage comes from three main sources:

Firstly, how we are organised – our organisational DNA focuses on collaboration with our clients and our Superteams. These Superteams work together with the client to respond with agility and deliver on the demand for innovative solutions, which are provided according to

project specification, on time, and on budget. This way, clients have direct easy access to disciplined expertise for better collaboration and well-designed projects.

Secondly, our unique skill combination within each Superteam is based on permanent groupings of individuals with in-depth industry knowledge, creating a collective of experienced engineers and technical experts. This way, each client or project gets the A-team for their specific requirements so we can provide solutions that are sustainable and practical to implement and are safe and cost effective.

Thirdly, our service delivery methodology is based on integration within and between different disciplines, to deliver a bottom-up approach to projects that ensures seamless integration from pit to port or mine to market, delivering cohesive operations.

Could you elaborate on your partnership with Bokoni Platinum Mines? How long have you worked together and what is the nature of your interaction with the company?

Ukwazi has been involved with Bokoni Platinum Mines (BPM), owned by African Rainbow Minerals, since the inception of the project almost three years ago. Our brief was to focus on mine planning and engineering for the open pit, the related infrastructure engineering, and a review of the permitting solutions. This included elements of closure, civil engineering for storm water management and pollution control dams, haul road development, project controls and assistance with survey, mining geotechnical, and contract mining appointments.

We have over the course of the operation provided important technical insights to improve the cost profile of the project, improving its valuation despite a sustained reduction in international commodity prices of the 6E, platinum group metals (PGM) basket.

How do the two companies mutually benefit each other and what complementary strengths do you bring?

BPM has assembled a highly talented ownership team, with support from various mining advisors, including Ukwazi. Whilst other companies have worked on the underground portion of the project, we have focused on the open pit.

Our collaboration with the BPM team has been professional

and beneficial in terms of our ability to provide technical support and strategic advice in aid of the ownership team. Our strength and contributions have been particularly focused on providing scenario planning, engineering design, and ESG solutions.

Are there any recent or upcoming projects that you would like to highlight?

Given the shifts in commodity prices and geopolitical tensions globally, mining companies are looking to augment their existing operations by switching out certain commodities (e.g. coal) with other materials, most notably copper, and have focused on acquisitions rather than exploration. Certain companies with large open pit operations have looked to transition into underground and others have focused on reprocessing tailings and mine residue deposits.

Therefore, Ukwazi has focused on K-Tec scraper applications to be used in appropriate cases as a potential alternative to wet re-mining of historic deposits. We are seeing a decline in PGM projects and an increased interest in gold and uranium sites both in the southern and central Africa regions.

Please could you tell us more about how Ukwazi contributes to the economic growth of South Africa? How important is this to the company’s mission?

Ukwazi believes we have a role to play in the development of SA, particularly the mining industry, as we believe it can contribute to job creation and GDP growth in the right policy environment. We contribute by helping our clients to create a mineral exploitation strategy that is safe, cost effective, and sustainable. In particular, Ukwazi has been

involved in providing small, medium, and micro enterprise (SMME) support and has also created Tsebokgadi, which us our women in mining initiative.

Similarly, how does the business contribute to local employment?

Ukwazi has helped mining companies with their mining rights applications, which require a Mine Works Program (MWP), Social and Labour Plans (SLP), and Environmental Management Plan (EMP). Although these are statutory requirements, we are able to provide technical input to these processes, which ultimately result in job creation in some cases but also align with local economic development initiatives in communities where the mine is located.

How do you try to empower your staff and recognise the contributions that they make?

Ukwazi has a Level 2 Black economic empowerment (BEE) rating and we contribute to the empowerment of our staff via skills development, mentoring and coaching, as well as corporate social investment. We also have a programme of long service awards and performance bonuses to reward our staff.

Looking ahead, what are Ukwazi’s key priorities?

Our key priorities are to grow our Africa and Middle Eastern footprint, manage our growth, and retain our staff who are our most important asset. We want to ensure that we maintain high brand recognition for our technical competence and service excellence within the industry locally and, increasingly we hope, globally.

The South African mining and metals industry accounts for a highly substantial level of the world’s platinum supply per year and is the vital first link in the long chain of processes that eventually lead to the final product, whether in aircraft manufacturing, stateof-the-art technology, or precious jewellery.

Consequently, the PGM sector is an integral part of the international supply of metals and minerals for a vast range of industrial, medical, and electronic applications, generating considerable opportunities for suppliers.

SA’s place in the global PGM supply chain draws significant value for the country’s economic growth, especially given the fact that the sector is currently one of the highest earners in the domestic mineral

“THE GOAL IS TO ENSURE THAT THE RIGHT PRODUCTS ARE DELIVERED TO THE RIGHT PLACE AT THE RIGHT TIME WHILST MINIMISING COSTS AND MAXIMISING EFFICIENCY”

– JJ JOUBERT, SENIOR GENERAL MANAGER, BOKONI PLATINUM MINES

industry and is seeing an increase in worldwide demand.

Taking into account the critical role that BPM plays in the world’s PGM industry, the company’s supply chain operations are carefully considered and thought out to maximise overall output and productivity.

Indeed, BPM implements a comprehensive strategy to manage and optimise the flow of goods, services, and information from suppliers to customers.

“The goal is to ensure that the right products are delivered to the

right place at the right time whilst minimising costs and maximising efficiency,” Joubert states.

Unlike other mining entities in SA, BPM utilises top-of-the-range central supply chain management practices that afford the company a multitude of benefits.

For starters, centralising its supply chain management results in significantly improved efficiency as this particular method allows for better coordination and integration of activities, leading to a refined flow of goods at minimal cost.

SERVICES:

• All products are either manufactured or repaired

• Strict adherence to all OEM standards and specifications

• Consignment stock and various service exchange units

• 24/7 field service

• Civil and Building Construction

• Renovations and Maintenance

• Fencing

• Yellow Plant Hire

We are a service orientated company that specialises in construction and civil works as well as yellow plant hire, supply of hydraulic cylinders, pumps, motors, and control valves.

It is our vision to establish a sustainable, progressive, gender sensitive, proactive empowered business that will consistently provide unparalleled service with the highest possible quality at competitive rates, whilst building and maintaining long-term mutually beneficial business relationships with our customers that grow from strength to strength as well as assuring our customers of the shortest possible collection, repair and delivery turnaround times in the industry.

It is our mission to ensure that our level of quality and service will exceed all our customers’ expectations at all times.

It is our objective to contribute in alleviating poverty by creating jobs where possible to uplift and improve the economy of the local community as well as empowering women and the disabled youth.

Additionally, a centralised supply chain grants the company greater visibility and control across the entire global logistics network, which consequently enables better tracking and monitoring of inventory levels, order statuses, and delivery schedules.

The key to this advanced level of insight is the abundance of generated data and analytics, allowing BPM’s team to make informed and timely decisions that facilitate improved logistical performance.

A centralised supply chain ultimately benefits the end user; by ensuring the timely and accurate delivery of resources and products, the company’s supply chain strategy enhances customer satisfaction and loyalty.

In order to streamline and optimise its supply chain management and procurement processes, BPM has introduced Coupa, a leading digital e-procurement platform that helps connect the company to its diverse breadth of suppliers.

Coupa is capable of accommodating a vast range of systems to help identify suitable suppliers, make smarter buying decisions, and optimise any purchases.

The supplier portal is used by BPM to request specialist materials and services as well as create and communicate purchase orders and invoices.

Additionally, Coupa equips the company with a deep understanding of any supplier disruptions, which

helps to build the integrity of the entire procurement system and provides artificial intelligence (AI)driven insights to help BPM identify and unlock efficiencies that ensure supply chain continuity.

Coupa also reduces third-party risk, streamlines onboarding, and monitors the ongoing performance of products and materials, making the software a valuable asset to BPM’s procurement team.

Moreover, the company’s dedicated ESG commitments extend to its supply chain operations, as it monitors and reports on its environment, health, and safety (EHS) performance following the recent introduction of IsoMetrix EHS software.

This software digitalises BPM’s EHS processes by integrating modules such as incident and risk

Rainbow Mining Support stands as a leading authority in providing specialised, cutting-edge solutions for the mining sector, with an unwavering commitment to enhancing both safety and operational efficiency in underground environments. Recognising the complex and hazardous nature of subterranean mining, we are dedicated to delivering highquality, resilient products that not only safeguard the workforce but also uphold productivity and sustainability.

Our ethos revolves around a meticulous understanding of the mining landscape, allowing us to craft innovative support systems that respond to the evolving demands of the industry. This strategic focus has established Rainbow Mining Support as a trusted partner within South Africa’s mining community, where our bespoke solutions have consistently ensured smooth operations across a multitude of sites.

Our Core Expertise at Rainbow Mining Support, lies in the development of versatile and dependable support systems that are both simple to install and integral to enhancing operational uptime. Our products, designed with the rigours of underground mining in mind, undergo rigorous testing to ensure they meet the most stringent safety standards, setting new benchmarks for operational safety and efficiency.

Our key offerings include:

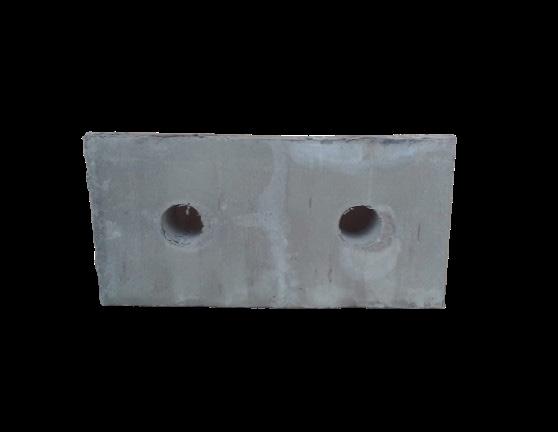

Cementitious Solutions: We manufacture high-strength cementitious products and bulk bag systems, purpose-built for enduring the extreme conditions of underground mining. With an annual production capacity of 32,000+ tonnes of cement, cementitious grouts and pumpable grouts, we serve both largescale and mining operations, offering solutions that provide lasting support in subterranean environments.

Stand-Up Support Systems:

Our pioneering product, the BossProp, exemplifies our commitment to innovation in mine safety. Renowned for its robust design, ease of installation, and exceptional durability, the BossProp significantly enhances underground support, reducing downtime and improving operational outcomes.

Complementing this, our Durapak and Grinpak systems are engineered to withstand the severe pressures of deeplevel mining, ensuring comprehensive support across various applications.

Customised Solutions:

Recognising that each mining operation presents its own distinct challenges, we offer tailored solutions that address specific project requirements. This ensures that every mine is equipped with the most effective tools, thereby optimising safety and operational efficiency.

Durapak, Grinpak, Endgrain and Timber: Comprehensive underground support systems that cater to a wide array of mining environments, ensuring robustness and adaptability across operations.

Sleepers and Flolok Solutions: Essential for reinforcing underground mine infrastructure, these products ensure that even the most challenging operational demands are met with uncompromising safety and reliability.

Website URL: www.rainbowms.co.za

Email Addresses: sales@rainbowms.co.za salesmanager@rainbowms.co.za

Contact Number: 010 448 4746

management, compliance auditing, and environmental monitoring and reporting to ensure compliance with regulations, minimised risk, and most importantly, a safe and sustainable working environment.

In line with BPM’s dedication to shaping a brighter future in mining, the company leverages a robust and impactful environmental strategy, keeping a close eye on its carbon contributions.

“We report both monthly and quarterly on sustainability data that indicates BPM’s contributions towards environmental stewardship, which is one of the key pillars of ARM’s sustainable strategy,” Joubert points out.

In line with this commitment, the business has embarked on the ambitious mission of modernising its mining activities to ensure long-term sustainability.

At the heart of this vision, BPM is upgrading several core processes, which it hopes will filter out into the

“SPREADING AWARENESS ABOUT PREFERENTIAL PROCUREMENT AND ITS POTENTIAL POSITIVE IMPACT ON THE COMMUNITY IS CRUCIAL AS IT HELPS CREATE AN ENABLING ENVIRONMENT FOR SUSTAINABLE BLACK BUSINESSES”

– JJ JOUBERT, SENIOR GENERAL MANAGER, BOKONI PLATINUM MINES

rest of the company’s operations.

At the same time, BPM also deploys innovative methods to ensure the mine’s longevity as the industry pivots more towards environmental stewardship.

The company has implemented many sustainable practices that are having a substantial and meaningful impact, minimising BPM’s ecological footprint as well as safeguarding and preserving the environment for future generations.

For instance, the company has begun tracking its water consumption across the entire business, looking at both the quantity and quality of

the water it is using, and proactively participating in a number of watersaving initiatives.

BPM also has a comprehensive water and wastewater management system that carefully oversees disposal.

On top of this, the company regularly monitors its emissions through the regulation of dust, electricity usage, as well as diesel and petrol consumption.

Moreover, BPM has installed lowenergy lights at its plant and the Middlepunt Hill UG2 shaft section. In addition, it has replaced major energy-consuming air conditioning

We are an engineering and metal fabrication organisation based in Lebowakgomo and Burgersfort. Our organisation was founded in 2011 by three entrepreneurs from engineering and academic backgrounds with a combined experience of more than 60 years. We are a Level 1 BBBEE contributor and 100% black owned.

We provide efficient and effective engineering, manufacturing, fabrication, hydraulics and welding solutions to the mining, manufacturing and automotive industries. Our people adhere to our quality management system ensuring that the work is done correctly the first time, every time.

Services:

FABRICATION OF STEEL COMPONENTS

PRECISION MACHINING OF MECHANICAL COMPONENTS

REPAIR OF MECHANICAL AND HYDRAULIC COMPONENTS

SUPPLY, INSTALLATION AND MAINTENANCE OF ENGINEERING COMPONENTS

to low-consumption systems whilst also installing heat pumps at its vertical shaft at Middlepunt Hill.

Regarding the company’s trackless mobile machinery (TMM), it has refurbished the equipment to include Tier 3 engines across all its machines and introduced hydraulic-operated handheld drills, which ultimately use less power.

“We hold the highest standard of tailing storage facilities management, disturbed land rehabilitation, and biodiversity management,” Joubert surmises.

As community lies at the heart of BPM’s mining activities, robust corporate governance therefore shines as a leading light throughout the company.

Indeed, BPM believes that mining doesn’t just revolve around extracting precious metals but building sustainable partnerships and generating shared value.

In line with ARM’s CSR commitments, the company proactively embraces the needs of its surrounding areas, working with nearby tribal leaders and collaborating with government agencies to ensure that the voices of local communities are always heard.

Regarding state administration, the company works with government agencies to navigate regulatory frameworks and contribute to regional development.

For example, BPM recently facilitated state-of-the-art water purification capabilities for a local community in the form of a water treatment plant. As a continuation of the company’s recent open pit mine operations, the water treatment plant was acquired to provide potable drinking water to the entire company and its surrounding areas.

Set for completion by the end of 2024, the plant will streamline the area’s water provision by negating

“WE HOLD THE HIGHEST STANDARD OF TAILING STORAGE FACILITIES MANAGEMENT, DISTURBED LAND REHABILITATION, AND BIODIVERSITY MANAGEMENT”

– JJ JOUBERT, SENIOR GENERAL MANAGER, BOKONI PLATINUM MINES

the need for a number of smaller water plants that require substantial maintenance, whilst also enabling an influx of water for the planned growth of the open pit mine.

BPM will likewise bring the company in line with the latest Department of Mineral Resources and Energy (DMRE) requirements by going through a stringent dam realignment process in the near future.

“This will save on water and protect our underground water supply for generations to come,” Joubert points out.

The mandatory legislature dictates that all mining dams must be lined to prevent underwater contamination for future generations, increasing the company’s credible standing in the industry.

Therefore, this project will not only benefit BPM’s ability to provide potable water, but by doing so, it will have a major impact on many institutions across the surrounding area.

“For example, we received a request from two of our neighbouring schools - Potlake Secondary School and Motsepe Primary School - to assist with the provision of safe drinking water.

“This required us to assess the situation and ensure that the water was purified and made safe for consumption,” he adds.

Additionally, the company recently completed a landmark community project through the construction of Mogabane Mobile Clinic, a pillar of BPM’s social and labour plan (SLP) initiative.

What is FUTURELIFE®?

FUTURELIFE® is Smart because it is the first and only scientifically LOW GI food, to combine 25 VITAMINS and MINERALS, 19 AMINO ACIDS, OMEGA-3, SELENIUM and MODUCARE®.

It is also high in ENERGY, PROTEIN and DIETARY FIBRE and can be enjoyed as a complete meal or snack anytime of the day. It can be MIXED INSTANTLY WITH JUST WATER AND REQUIRES NO COOKING.

The TWIN POUCH concept combines an excellent FUTURELIFE® nutritional powder with purified water separated by a temporary seal in a twin pouch. Keeping the nutrtional powder and the purified water separate, with a shelf life of six months, is what makes it very practical to use in any situation.

By squeezing the water pouch, the seal is broken and the powder and water combine. The result is a delicious and nutritious meal in a pouch! 260ml (60g / 200ml) 275ml (75g / 200ml) available in For enquiries please

Correlating with the company’s overarching mission, the clinic has addressed the critical need for healthcare access across all areas of the local community.

The mobile clinic will help bring urgent patient care closer to home in underserved areas and meet the needs of those who may not be able to travel far due to limited transport infrastructure in certain areas.

The Mogabane Mobile Clinic was constructed and opened in close collaboration with the Department of Health, as the company helped fund the ZAR6 million project.

With the aim of restoring dignity by ensuring accessible and appropriate healthcare, the clinic supports caregivers from food security programmes and social development organisations, reflecting BPM’s commitment to the advancement and well-being of the community.

BPM’s commitments go beyond that of mineral extraction, as the company consistently endeavours to positively impact the lives of its team, as well as their families and local communities.

In recognition of this aim, BPM has implemented strategic measures to ensure that its workforce is effectively upskilled and reskilled to align with the future needs of the PGM sector and African mining landscape.

Firstly, the company regularly conducts a skills audit to assess the

“ARM IS FULLY DEDICATED TO BPM’S REVIVAL IN A WAY THAT COLLABORATES WITH LOCAL COMMUNITIES”

– JJ JOUBERT, SENIOR GENERAL MANAGER, BOKONI PLATINUM MINES

Value is elusive. You know it exists, but bringing it to the fore is never easy when it is shrouded by the complexities of your day-to-day.

We’re a wholly owned black management consultancy focused on unlocking value. Our expertise spans across diverse industries, allowing us to bring unique insights and methods to your supply chain challenges.

Our approach transforms challenges into clear, actionable solutions, stripping out complexity and undue pressure on people, processes and systems. Reach out to us to produce clear, practical, and repeatable results.

ability of its staff and identify gaps to improve efficiencies with various training initiatives.

For instance, BPM offers a plethora of training programmes across the organisation. These include digital literacy, training for the use of specialised equipment such as NRE, and online learning courses such as Artisan 4.0™, ultimately ensuring operator and automation excellence.

Additionally, the company actively encourages and supports the higher education of its staff, as demonstrated by its many educational partnerships in which it collaborates with regional further education and training colleges to facilitate specialist upskilling.

BPM alternatively offers an on-thejob training initiative in which team members are assigned a mentor that offers guidance and continuous feedback on learnerships, internships, and cadetships, which are also offered

to those in the local community.

Through online and flexible courses, the company has introduced simulators, virtual reality (VR) for practical learning, and gamification in order to transform learning.

“With a strong emphasis on training, we encourage continuous learning through incentives and recognition programmes, such as our General Manager’s Quarterly Update and awards sessions,” Joubert shares.

In constant pursuit of efficiency, BPM gathers employee feedback, regularly assesses its training effectiveness, and subsequently updates its programmes accordingly.

BPM’s future holds great potential as the company anticipates 2025, marked by investing in the modernisation of operations and preparing its mine for the next generation.

“We are ensuring that our

operations are globally competitive and profitable whilst maintaining a robust balance sheet. We align production capacity to logistical and infrastructure constraints while exploring value-enhancing growth opportunities,” Joubert closes.

Therefore, at the core of its mission, BPM is continuously introducing innovative methods and maintaining successful operating standards across its mine sites, whilst also fostering community development and ensuring longevity in an evolving PGM industry.