AN EXTENSIVE PRESENCE IN CHILEAN MINING

Collahuasi’s executive team comes together to discuss the company’s extensive contribution to Chilean mining and mineral production –particularly as resources such as copper become increasingly critical within the global energy transition – while emphasizing its role in supporting local communities and economies

Writer: Lily Sawyer | Project Manager: Lauren Robinson

Chile, the distinctive ribbon of land that runs along the west coast of South America, is a curiously shaped country abundant with vast natural landscapes – from the rolling sands of the Atacama Desert, the driest non-polar desert in the world, to the peaks of the Torres del Paine National Park.

The vibrant capital of Santiago, meanwhile, is a bustling urban metropolis that perfectly juxtaposes against this tranquility.

Among its beautiful landscapes,

Chile is also the world’s largest producer of copper, responsible for around a quarter of global production.

Bordering Peru and Bolivia, the Tarapacá region in the north of the country demonstrates Chile’s longstanding tradition as an epicenter for mining and mineral production.

In fact, many abandoned mining towns can still be found in the area, offering an insight into the region’s historical economic significance and the ways in which vital mineral resources were fought over in the War of the Pacific.

Today, Tarapacá remains home to numerous significant mining operations and some of the world’s most desired resources, including copper and naturally occurring sources of sodium and potassium nitrate.

Chilean mining company, Collahuasi, meaning ‘the house of the miner’ in the local Aymara language, boasts an extensive operation located in Tarapacá.

As one of the world’s primary copper producers and the second largest in Chile, Collahuasi is renowned for the extraction and production of copper and molybdenum concentrate.

Diligently mining its two major deposits, Rosario and Ujina, the company contributes significantly to the country’s gross domestic product (GDP) each year.

Collahuasi’s origins date back to the second half of the 19th century, when commercial exploitation of highgrade copper-silver veins began in Tarapacá.

However, mining activities in the area were interrupted in 1930 with the arrival of the Great Depression, only recommencing in Collahuasi’s current area of operation in 1978 after key features of the Rosario deposit’s exceptional copper grades were identified.

13 years later, the adjacent Ujina deposit was discovered, with the feasibility and environmental impact studies for its exploitation approved in 1995 and commercial operation commencing in 1999.

“In 2003, we more than doubled our sulfide ore treatment capacity, increasing our output from the initial project’s 60 thousand tons per day (ktpd) to around 130ktpd,” introduces Jorge Gómez, CEO.

Since then, various process optimizations have delivered an

increase in capacity, equating to around 155ktpd in 2023.

Two years prior, the company also obtained the environmental permits required to extend the operation for 20 years and increase its ore treatment capacity up to 210ktpd.

Today, Collahuasi has an installed capacity of 170ktpd, with other debottlenecking projects in the process of implementation or under review to increase this capacity further in the coming years.

In terms of production and distribution, a 203-kilometer (km)long system of slurry pipelines transports copper concentrate from the company’s concentration plant in Ujina to the Collahuasi Maritime Terminal in Punta Patache, 65km south of the city of Iquique.

From this facility, where the

company’s molybdenum and concentrate filtering plants are also located, products are shipped to international markets – primarily China and other parts of Asia.

2023 saw Collahuasi record C1 costs of $1.27 per pound of copper, positioning the company in the first

“COLLAHUASI’S FOUNDING PRINCIPLES ARE FOCUSED ON THE RESPONSIBLE AND EFFICIENT DEVELOPMENT OF RESOURCES –FIRST AND FOREMOST, THE SAFETY OF OUR WORKERS, RESPECT FOR THE ENVIRONMENT, AND THE SUPPORT OF OUR LOCAL COMMUNITIES”

–

JORGE GÓMEZ, CEO, COLLAHUASI

quartile of the industry.

Its direct and indirect economic contribution to the Chilean economy during the same year was equivalent to 1.34 percent of national GDP and 56.31 percent of GDP in the Tarapacá region.

In addition, Collahuasi generated a significant contribution to the country

through tax payments of $809 million.

“Collahuasi’s founding principles are focused on the responsible and efficient development of resources – first and foremost, the safety of our workers, respect for the environment, and the support of our local communities,” Gómez prides.

United Pipeline Systems is a global specialty contractor, providing solutions to pipeline integrity challenges through high-performance thermoplastic internal pipeline lining systems for the oil and gas, industrial, mining, and municipal industries.

United works worldwide to safeguard mining companies’ pipelines by extending their life and helping to meet regulatory requirements. Our Tite Liner® solution prevents internal corrosion and erosion to help ensure the integrity of these critical pipelines.

Our long-standing partnerships with leading mining companies, along with thousands of miles of Tite Liner being in service for over two decades, attest to the effectiveness and durability of our Tite Liner solution.

Providing tangible evidence of its ability to extend pipeline durability and meet stringent regulatory requirements across all aspects of mining pipeline infrastructure, including: • Tailings • Concentrate • Acid lines • PLS • Water lines

The Tite Liner® system can often rehabilitate pipelines at half the cost and time of dig-and-replace solutions. The transportation of corrosive or abrasive materials in the oil & gas, mining, industrial and municipal markets can wreak havoc on your pipelines. Internal corrosion and abrasion can lead to leaks, pipeline failure, environmental damage and lost production.

Complete replacement of these pipelines is costly and time-consuming. Internal abrasion and corrosion can be avoided by utilizing the pipeline construction capabilities of United Pipeline Systems.

The Tite Liner® System United developed the Tite Liner® system, a technology that enables a thermoplastic liner to fit tightly inside a host pipe.

The Tite Liner® system is manufactured with a larger outside diameter (OD) than inside diameter (ID) of the host pipe.

The Tite Liner® system temporarily reduces the thermoplastic liner’s diameter for insertion. The liner then expands tight following installation. The tight-fitting liner acts as a continuous barrier between the host pipe and the corrosive or abrasive material.

The corrosion and abrasion resistance properties of thermoplastic allow the Tite Liner® system to protect pipelines from a variety of chemicals

and abrasives through a broad range of temperatures and pressures. It is an efficient and cost-effective way to protect new or existing pipelines and its use can often extend the life of a pipeline far beyond the expected life of an asset. The Tite Liner® system comes in sizes from 50 mm to 1,300 mm (2 inches to 52 inches) in diameter, with larger diameters possible in certain situations.

The Tite Liner® system offers many benefits:

• Long pull lengths: Average pull lengths are approximately 600 meters to 800 meters (1,900 feet to 2,600 feet) and longer. Pull lengths of 2.5 km (8,000 feet) have been achieved (individual section length depends on the diameter, bends, terrain and condition of the host pipe).

• Low cost and time: The Tite Liner® system can often rehabilitate your pipelines for less than one half the cost and time of dig-and-replace solutions.

• No maintenance: The Tite Liner® system is a “fit and forget” solution, unlike chemical injection alternatives that require ongoing maintenance and operating costs.

• Temperature limitation: The polyethylene pipe utilized in the Tite Liner® system exhibits superior mechanical properties

in temperatures up to 90ºC (194º) for water and oil emulsion service. For higher temperatures or more aggressive fluids, United can recommend alternative lining materials.

• Chemical resistance: Thermoplastic is very resistant to chemicals and other media such as acids, alkalis and salts, which makes it suitable in almost every process application.

• Field bends: The lining system can easily negotiate field bends of 50D or greater. Bends as low as 20D have been achieved and tighter bends may be possible.

• No pressure limitation: The Tite Liner® system has no pressure limitation since the pressure is contained by the host pipe.

• Leak-free connections: Tite Liner® system flange fittings have been successfully used in projects with pressures up to 340 bar (5,000 psi). The connection has been tested and independently verified up to 500 bar (7,500 psi).

• Increased operating efficiencies: A Tite Liner®- protected pipeline often experiences increased operating efficiencies because the smooth thermoplastic liner improves hydraulic properties over and above a slight reduction of the inside diameter.

An industry stalwart, Collahuasi has noted major transformation in South America’s copper mining industry since its inception.

“Not only has the scale of the industry grown in line with global demand, but we have also seen dramatic changes in the landscape in terms of innovation and automation, while the sector has embraced and

“WE HAVE A SUSTAINABILITY POLICY APPLICABLE TO ALL OUR ACTIVITIES, WHICH SEEKS TO HARMONIZE FOUR KEY DIMENSIONS – BUSINESS, ENVIRONMENT, COMMUNITIES, AND PEOPLE”

– MARIO QUIÑONES, VICE PRESIDENT OF DEVELOPMENT AND SUSTAINABILITY, COLLAHUASI

made significant progress toward sustainability alongside inclusion and diversity goals,” Gómez surmises.

Globally, demand for copper has grown due to the emergence of the resource as a critical mineral within the green energy transition – a trend that will continue to have a great impact on the future of the planet.

South America, and Chile in particular, therefore remain key for the

global supply of copper.

However, the sector also faces challenges such as access to water and increasing regulatory pressures, while fluctuating commodity prices are expected to remain a feature of a rapidly changing world.

“While accessing and developing the human capital needed for the future is a challenge, it is also an opportunity to accelerate the

transformation of our workforce to be more inclusive and diverse,” he notes.

Mining, particularly copper mining, is a key pillar of development for Chile and plays a key role in attracting investment, driving economic growth, and contributing significant fiscal resources to the nation.

Chile and Peru dominate copper production in South America, accounting for more than 35 percent of global production combined, while other countries in the region such as Argentina, Brazil, and Ecuador play a smaller but steadily increasing role.

South America as a whole, meanwhile, has a significant 40 to 45 percent share of world copper production as it is home to some of the world’s largest and highestyielding copper mines.

In 2023, Chile’s mining sector accounted for 11.9 percent of the

country’s GDP, while its exports accounted for 56 percent, with a total value of $53 billion.

In the same year, Collahuasi was the third-largest copper producer in the world, responsible for the direct employment of around 2,000 workers and 3,000 contractors, with a strong focus on the development of local suppliers.

“We are committed to regional growth and being a positive contributor to neighboring local communities,” informs Trevor Dyer, CFO.

“Our focus is on generating shared value, ensuring that Collahuasi’s economic progress also translates into tangible benefits for our local communities.”

Indeed, Collahuasi has implemented various initiatives through the Collahuasi Foundation which is focused on entrepreneurship, socioeconomic development, capacity building, and education.

ANGLO AMERICAN (44 PERCENT) – The largest producer of platinum on the planet, Anglo American’s portfolio also comprises copper, diamonds, iron ore, and steelmaking coal. Based primarily in the UK, the organization also has operations in North America, Africa, Asia, and Australia.

GLENCORE (44 PERCENT) –

A world leader in diversified natural resources, Glencore produces and markets more than 60 assets internationally across 35 countries.

JAPAN COLLAHUASI RESOURCES (12 PERCENT) –

A subsidiary of Mitsui & Co., the consortium of companies is involved in a variety of mining operations across Chile and is one of the largest trading and investment companies in Japan.

and Collahuasi:

In the ever-changing landscape of the mining industry, the enduring partnership between Innomotics and Minera Collahuasi stands as a prime example of how technological innovation can drive operational excellence. By working together, the two companies have implemented cutting-edge technologies that not only optimize efficiency and productivity at the giant Collahuasi copper mine but have also improved safety conditions for personnel and contractors and increased the sustainability of the business.

“Innomotics is proud to be at the forefront of mining innovation with Collahuasi. We are not just solving today’s problems; we are laying the groundwork for tomorrow’s opportunities,” said Hector Andrade, Country Business Unit Manager for Innomotics Solutions.

Central to the collaboration is the integration of advanced drive systems tailored to meet the unique needs of Minera Collahuasi’s operations.

The mining industry demands robust, reliable, and efficient equipment, and Innomotics’ drive technology is designed to handle these challenges seamlessly. These drives are crucial in enhancing the efficiency of

Collahuasi’s operations, especially in critical areas like the grinding process.

In 2016, Innomotics carried out the modernization of the Dual Pinion drive systems for four mills in Collahuasi’s Ujina concentrator plant.

This involved the installation of four 4.85MW motors for the two ball mills and four 4MW for the two SAG mils, plus four E-houses equipped with SL150 converters and auxiliary systems, and an automation system based on cutting edge technologies.

As well as providing the equipment, the company was also responsible for transporting the hardware to the plant site, located at more than 4,400 meters above sea level, as well as installation supervision, commissioning, start-up services and training.

The modernization process also complied with the customer’s requirement of just 10 days of downtime for the SAG and then the Ball mills.

“Our goal is to ensure that Collahuasi’s machinery not only meets but exceeds performance expectations. By implementing state-of-the-art drive systems, we are contributing to a more sustainable and productive mining process,” said Andrade.

Innomotics’ partnership with Minera Collahuasi has continued through

the provision of Integral Plant Maintenance service to its plants for the last ten years. One of the largest maintenance contracts in the global mining industry, the contract today covers the crushing operations at the mine, the Ujina concentrator and the port facility at Puerto Patache.

Through its IPM service, Innomotics aims to provide optimal maintenance of the equipment, minimizing costs and downtime while achieving the highest levels of safety for its personnel. Sensors embedded in drive systems, conveyors, and crushers continuously collect data on equipment performance. Innomotics is developing methodologies to analyze this data to identify early warning signs of wear and tear, enabling timely interventions and reducing unplanned shutdowns

The emphasis on integral maintenance not only extends the lifespan of critical equipment but also improves overall safety and reliability. Furthermore, it aligns with Collahuasi’s commitment to operational excellence and sustainability by reducing resource waste and enhancing equipment utilization.

“Integral Plant Maintenance is about moving from a reactive to a proactive mindset. By using data to forecast potential failures, we are moving forward together with Collahuasi reshaping how we face the mining of the future,” says Andrade.

One of the most transformative elements of the InnomoticsCollahuasi partnership is the focus on digitalization. In line with Collahuasi’s

strategy to achieve the algorithmization of its business, Innomotics has worked with its team to implement a Digital Twin, that is a virtual replica of its physical assets and operation which operators can use to test out new operating criteria without affecting the productivity of the operation.

At Collahuasi, the Digital Twin simulates the crushing process at the Rosario sector of the mine. By analyzing information such as hopper levels, ore reduction, and conveyor belt speed, the team has been able to optimize a traffic-light system based on Artificial Intelligence that indicates to operators exactly when they should unload to keep the volume of ore in the crusher chamber at optimal levels avoiding bottlenecks.

“We are excited about the promising results of the digital twin in optimizing the crushing process. The data-driven insights have shown us how much more value we can extract from our current systems helping us to define future expansions more precisely,” explains Andrade.

The collaboration between Innomotics and Minera Collahuasi is a testament to the transformative power of technology in mining. By focusing on advanced drive systems, digitalization, and innovative forms of maintenance, the partnership is setting new standards for efficiency, sustainability, and operational excellence.

“This is more than a technological upgrade; it’s a shift in how we approach mining. Together with Collahuasi, we are proving that the future of mining is intelligent, sustainable, and resilient,” comments Andrade.

Through the Collahuasi Foundation, high-quality educational establishments are co-managed and teach technical careers related to mining.

The foundation is critical in this regard, as the company actively invests in the education and co-management of two municipal technical high schools, raising the overall quality of education in the Tarapacá region.

Currently, more than 300 graduates from these schools work at Collahuasi or its contractor companies.

The contribution of mining in terms of direct employment in Chile last year reached 278,000 workers, a figure that rises to 986,000 if indirect employment is included –equivalent to 10.9 percent of national employment.

Collahuasi’s sustainability policy drives productivity, permeates every area of the company, and is based on a number of international sustainability standards, including:

UNITED NATIONS (UN) GLOBAL

COMPACT – Revolves around a set of 10 principles, including human rights, labor, environment, and anti-corruption.

UNIVERSAL DECLARATION OF HUMAN RIGHTS (UDHR) –

Developed by the UN Human Rights Commission in 1948, the UDHR seeks to ensure global freedom, equality, and dignity.

TRANSPARENCY

INTERNATIONAL – The Chilean chapter of the association promotes accountability, integrity, and transparency.

Policies implemented in Chile also ensure that mining royalties paid by companies in the sector are distributed to regional governments and municipalities throughout the country to fund community-centered initiatives.

“For example, some of these resources are allocated to national funds. These include the Territorial Equity Fund, which seeks to reduce the gaps that exist between

municipalities’ incomes, the Mining Communities Fund, which focuses on the impacts of mining activity, and a fund for citizen security,” Dyer explains.

Differentiated by its management model, Collahuasi applies a risk management cycle framework throughout the entire value chain.

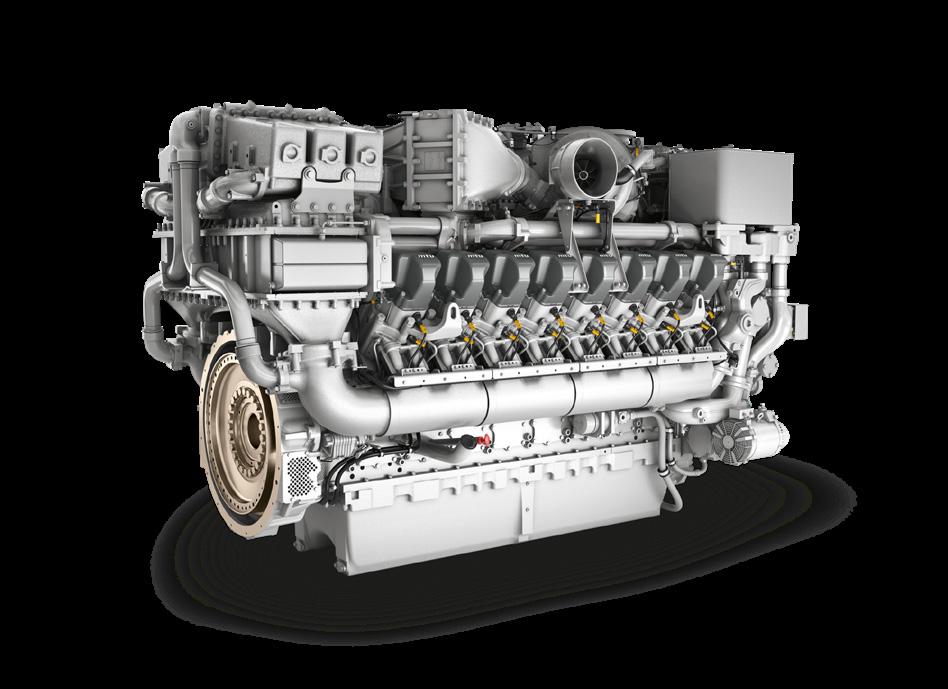

A Rolls-Royce solution

It fills us with pride and happiness to be able to accompany Collahuasi for more than 30 years of uninterrupted cooperation in its operations, reiterating our commitment to continue developing and implementing technologies that enhance mineral transportation aligned with shared values, visions and objectives of safety, energy efficiency, productivity and respect for the environment.

This has been the foundation for the company’s ongoing history of operational excellence, ensuring that learnings and opportunities are captured in a way that generate value for the business and the environment.

“Today, we stand out as one of the safest, most efficient, productive, and sustainable mining operations worldwide,” Gómez shares.

This is despite the fact Collahuasi’s main mine is located in the highlands of the Atacama Desert at an altitude of over 4,400 meters above sea level, close to the border between Chile and Bolivia, which has historically presented unique challenges in terms of operations and logistics.

As a result, the mine faces climatic conditions that vary widely from other mining operations in the country.

“For this reason, we have implemented advanced technologies to both protect the health and safety of our employees while ensuring operational continuity and productivity,” he outlines.

Collahuasi is one of the world’s true

Tier 1 copper resources, both in terms of its absolute size but also because of its exceptional quality.

The asset’s copper reserves alone stand at over four billion tons with an average grade of 0.8 percent – a key factor that will help to maintain the exceptionally strong competitive

• Environmental management and compliance through the company’s sustainability policy.

• Efficiently using water resources through the C20+ project.

• Adhering to the principles of a circular economy.

• Exclusively using renewable energy since 2020 in order to achieve its net zero goal by 2040.

• Enacting measures to reduce Scope 1, 2, and 3 emissions.

• Adhering to UN Sustainable Development Goal (SDG) 15 by protecting nearby ecosystems.

• Implementing a forest management plan for 20+ years.

• Introducing a program in 2019 to restore and revitalize 15.4 hectares (ha) of the bofedales in the local area.

• Reforestation of native queñoa trees over a 22-year period, covering a total of 102ha.

position of Collahuasi in the long term.

“To realize the full potential of our asset, there are a number of projects that are either in the execution or development stages,” Gómez asserts.

One key focus is the growth project at the Ujina plant, which incorporates a number of initiatives required to increase the treatment capacity of the concentrator to the environmentally approved maximum capacity of 210ktpd.

“The various elements of this project will allow us to reach a production of over 600kt of copper per year, positioning Collahuasi as one of the leading copper producers in the world,” he adds.

At the same time, the company is also executing the construction of the C20+ project, which will provide the operation with a desalinated water supply.

The project, which will have an initial capacity of 1,050 liters per second, includes the construction of the desalination plant and water impulsion system, which will see water transported 194km from sea to mine.

The world needs more metals to thrive. At Collahuasi, the integration of ShovelSense® and BeltSense® delivers complete ore stream coverage, enabling actionable decisions that drive downstream optimization and maximize recovery. Across the globe, millions of tons of valuable ore are lost each year due to material misclassification as a result of limited orebody knowledge, blast movement and mixing, and allocation errors – factors that lead to dilution entering the ore stream and loss of potentially valuable resources.

MineSense’s mine-to-mill digital solutions deliver real-time data to optimize mining operations, starting at the beginning of the mining process – extraction. At the mine face, ShovelSense uniquely delivers real-time ore characterization by the bucket, using innovative X-Ray Fluorescence (XRF) sensors custom installed in the shovel of existing excavators, creating powerful datasets that drive more informed operational decisions. By integrating with a mine’s Fleet Management System (FMS), ShovelSense also enables automated truck routing, ensuring that assessed payloads are routed to the mill, stockpiles,

or waste dumps based on their economic viability. This stepchange in efficiency, driven by advanced material classification and ore sorting, improves the mill head grade and reduces grade variability, resulting in a more efficient mill process.

BeltSense is equipped with the same XRF technology as ShovelSense and installed on top of conveyor belts at key control points along the grinding circuit to complement ShovelSense’s at-face readings, resulting in continuous, end-to-end material tracking. The combined measurements of both technologies deliver actionable data that reduce grade variability, refine process control, and optimize the entire mining operation.

MineSense’s mine-to-mill optimization begins at the mine face and continues seamlessly across the entire production process. By leveraging high-resolution datasets and real-time actionable insights, the company helps mines improve efficiency, boost productivity, and enhance sustainability. Trusted by the world’s largest mining operations, MineSense’s proven digital solutions increase the recovery of payable metals, delivering significant data-driven gains in profitability and sustainability.

This will ensure the supply of desalinated water for current operations and future growth projects, reducing pressure on local water resources, thus achieving a very significant milestone in line with enhancing the sustainability of Collahuasi’s processes.

“This is a crucial step to ensure operational continuity in an environment where water is a limited resource,” Gómez outlines.

While the project is still in its construction phase, it is expected to

“WE SEEK TO BE MUCH MORE THAN JUST A COPPER MINING COMPANY –OUR PURPOSE IS TO CONTRIBUTE TO A BETTER SOCIETY”

– TREVOR DYER, CFO, COLLAHUASI

lower emissions.

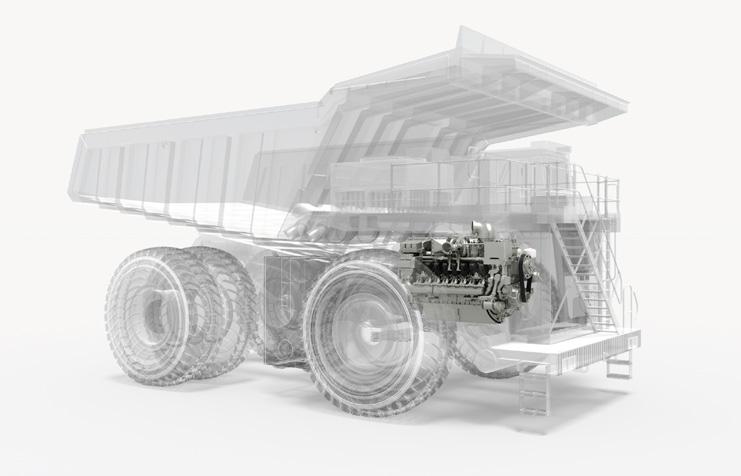

These include the operation of autonomous trucks, the use of a trolley system for its trucks in dumps, and the robotization of maintenance activities at the Ujina plant.

“All our projects are key to achieving Collahuasi’s objective to realize the full potential of our asset in the context of a growing global demand for copper.

be fully operational during the first half of 2026.

Collahuasi is also moving forward at pace with studies to prepare for the future growth of the company, with the intention of significantly increasing its ore processing capacity.

Finally, the company is investing in the modernization of its mining facilities and processes by incorporating automation technology in mineral transport and processing, which will allow it to operate more efficiently and with

“Further, these projects will enable the delivery of a more resilient, competitive, and sustainable operation, which will benefit all our stakeholders,” he asserts.

The Chilean mining industry has adopted more sustainable practices, such as the use of renewable energy sources and desalinated water and the optimization of processes through digitalization and automation, promoting the longevity of the country’s copper mining industry and long-term employment.

Find a better way.

Safeguarding assets and operations for one of the largest copper mines in the world.

Together with Collahuasi, a global leader in mining operational efficiency, Ausenco delivered an Integrity Management System for their mine’s concentrate pipelines, tailings management facilities, and water management system. We provided an overarching framework to guide the management of critical non-processing infrastructure that resulted in increased productivity, reduced downtime and minimised environmental and safety risks.

Collahuasi is a pioneer of sustainability in the country due to its use of renewable energy, with 100 percent of the company’s energy coming from clean sources such as solar and wind power.

Sustainability is therefore a core guiding framework for Collahuasi and applies to all levels of the organization, spanning people, projects, operations, facilities, and products.

“For this reason, we have a sustainability policy applicable to all our activities, which seeks to harmonize four key dimensions –business, environment, communities, and people,” clarifies Mario Quiñones, Vice President of Development and Sustainability.

Since 2021, the company has been implementing an environmental, social, and governance (ESG) management strategy, which includes specific medium and long-term commitments.

Another example of Collahuasi’s support for local communities, Cuidemos Tarapacá – which translates as ‘let’s take care of Tarapacá’ – directly benefits residents in the region.

In the spirit of collaboration and through alliances with public and private partners, the program seeks to deepen Collahuasi’s contribution to the socioeconomic development of Tarapacá and respond to the needs of its inhabitants.

ITS ACTION LINES INCLUDE: TARAPACÁ SONRÍE – Improving the dental health of more than 300 women in the area.

IQUIQUE SE CUIDA – Related to the care and recovery of the historic center of Iquique so that the city remains a safe and attractive meeting place for residents and visitors.

MUJER AVANZA – Supports the work of 300 female entrepreneurs from the Tarapacá region through financing, training, and the formalization of their ventures.

IQUIQUE CIRCULAR – Strengthening Collahuasi’s commitment to caring for the environment by promoting circular economy initiatives to reduce waste generated in the city, making the current refuse problem an opportunity for local development.

A Worldwide Company with Strong Expertise in the Energy & Resources Segment.

At Sodexo, we understand that the well-being and motivation of your workers are crucial to your success. That’s why we work to ensure operational continuity, predictable cost management, and adherence to environmental and social standards.

We Are Remote Living. To achieve this, Sodexo incorporates top-level innovations, such as our Culinary Base Plant and a Command Center that standardizes processes, increases e ciency, and tracks everything, analyzing information in real-time.

Together, let's create a thriving community where remote living is not just a necessity, but a choice.

At Copec, official distributor of MobilTM in Chile, we highlight the successful tests carried out in collaboration with the mining company Doña Ines de Collahuasi, who committed to their sustainability vision, relied on Mobil Delvac Modern™ 15W-40 Advanced Protection Mine for their haul truck fleet.

This test, conducted in collaboration with ExxonMobil and equipment manufacturers, reduced the environmental impact by doubling oil change intervals resulting in less waste generation and reducing the carbon footprint, while simultaneously increasing productivity.

We would like to thank the Mining Vice Presidency and its entire team for their trust and leadership in pioneering this initiative, which promotes a more efficient, safer, and environmentally respectful mining industry.

Scan the QR code and discover more about the complete line of Mobil™ lubricants for the mining industry

This entire policy is framed within the ambition to deliver sustainable development – harmonizing the company’s economic growth with the construction of a transparent and ethical relationship with stakeholders, alongside the consideration of the ESG needs and expectations of communities.

“Sustainability considerations are an integral part of our business planning and decision-making processes.

“They contribute to responsible resource management and allow us to better manage risks while achieving improved outcomes for all,” Quiñones explains.

Alongside the environment, Collahuasi recognizes the importance of sustaining people as its most valuable asset. Therefore, it promotes a company-wide culture of safety, inclusion, and personal development.

“Our continuous training programs ensure that employees and contractor partners can improve their skills and grow within the organization,” Gómez tells us.

The company also fosters an inclusive environment where diversity is seen as a strength and recognizes talent through incentive and recognition programs that value both individual and team contributions.

“The goal is not only to offer employment but create opportunities for professional growth,” he adds.

In line with the aforementioned,

Collahuasi’s partnership with MineSense is transforming mining operations, leveraging the power of data through technologies such as ShovelSense® and BeltSense® to revolutionize ore stream management. Through MineSense’s solutions, companies can achieve complete ore stream coverage, enabling real-time, actionable insights that drive downstream optimization, maximize metal recovery, and improve sustainability.

MineSense’s revolutionary ShovelSense technology powers mine-to-mill optimization, beginning at the point of extraction. ShovelSense delivers several advantages at the mine face, beginning with accurate ore characterizations and grading with each bucket. Equally, ShovelSense seamlessly integrates with Fleet Management Systems to enable automated truck routing to the mill, stockpiles, or waste dump based on the payload grade to greatly increase recovery and reduce dilution.

Deployed in strategic areas along the grinding circuit, BeltSense provides continuous material tracking to further optimize and improve ore control and enhance downstream performance at the mill.

Collahuasi exemplifies the success of MineSense’s innovative technologies, achieving significant improvements in efficiency, productivity, and profitability while setting new benchmarks for operational excellence. www.minesense.com

Collahuasi has developed a range of employee development programs.

Among them, the Professionals in Training initiative seeks to strengthen and diversify its portfolio of emerging professionals, encouraging their participation in and contribution to various strategic and functional areas of the company.

Alongside its employee

development programs, Collahuasi’s local supplier development programs encourage the hiring of regional companies, generating employment and economic growth in the Tarapacá region.

During 2023, 47 percent of supplier spending was made with local or mixed companies, reaching $1.398 million across 853 companies.

Founded and led by engineers with over 25 years of experience,

Management: maedo@eltoqui.cl | jhernandez@eltoqui.cl | chernandez@eltoqui.cl Compliance Director: vsandoval@eltoqui.cl | +56979690098

“We seek to be much more than just a copper mining company – our purpose is to contribute to a better society,” asserts Dyer.

Collahuasi’s local supplier development programs are part a series of initiatives and measures that go beyond the business.

“We also maintain commitments with different indigenous and local organizations which, among other things, consist of carrying out participatory environmental monitoring that considers flora, fauna, and water resources,” adds Quiñones. By joining community organizations in this work, the company ensures complete traceability regarding its work methodologies, measurements, and reporting.

“In this way, we have made progress in achieving greater transparency and strengthening trust in our management,” he points out.

Going forward, in the short term, Collahuasi’s priorities include expanding production capacity in a sustainable manner, implementing new technologies to optimize operations, and completing the construction of the C20+ project.

“We are also advancing our strategy of reducing carbon emissions and the digitalization of our processes,” Quiñones divulges.

In addition, the company is deepening its commitment to local communities by expanding regional development programs.

Collahuasi is also working to deliver its medium and long-term growth agenda through the implementation of various ongoing projects.

“Given the aforementioned potential of Collahuasi´s resources, this includes the advancement of studies, which will allow us to continue on the pathway of growth for our

Focused on exceeding client expectations, El Toqui stands out for its adaptability to industry challenges. Through an innovative vision and personalized service, it strives not only to meet standards but also to create a positive and responsible impact on the environment. Its leadership team is firmly committed to excellence, ensuring that every project meets the highest standards of quality and sustainability.

company,” he adds.

As Collahuasi’s purpose and values state, it seeks to challenge the present to contribute to a better society for the future.

“Through this goal, we seek to create a positive legacy for our employees and local communities, as well as for the country,” prides Gómez.

Equally, it seeks to be a facilitator of development – socially, economically, and environmentally.

“All of this aligns with our commitment to develop a more sustainable mining company,” he passionately concludes.

www.collahuasi.cl/en/