On a mission to be the leading supply and services group for Australia’s hydraulic, lubrication, fluid dispensing, and refuelling markets, Cooper Fluid Systems sets itself apart through its innovative solutions and people-centric approach. Brody Sewell, General Manager, and Robert Bulluss, CEO of Coventry Group Ltd, parent company since 1997, come together to tell us more

Writer: Lily Sawyer | Project Manager: Eddie Clinton

As a primary contributor to the global supply of coal, gold, copper, nickel, lithium, and iron and aluminium ore, today’s Australian mining industry thrives.

Continuing to attract major global investment due to its stability, highgrade resources, and continuous refinement of technologies, Cooper Fluid Systems (Coopers) emerges as a trusted partner to companies within this burgeoning sector.

Working with major Australian

mining firms and assisting them with reducing costs by increasing efficiencies, improving reliability, and minimising environmental impacts, the company supports its clients’ efforts to remain competitive whilst enhancing productivity on a global scale.

“Following a recent uptick in Australian mining organisations’ interest in adopting new technologies, especially those which foster a safe and efficient work culture, Coopers

has continued to prioritise these same initiatives,” introduces Brody Sewell, General Manager.

Providing a ‘cradle to grave’ approach for its clients, Coopers’ historical focus has been on hydraulics, lubrication, refuelling, fluid dispensing, pneumatics, and fire suppression systems.

More recently, technological advancement has led to the company expanding its offerings to include automation, electrification, and

Industry 4.0 products, which integrate well with the company’s legacy offerings.

Dealing with clients that value premium products and solutions and have a long-term focus on total cost of ownership, safety, and reliability is a core component of Coopers’ offerings.

“We understand that safety and reliability for our clients is paramount, and this remains our unwavering priority,” he confirms.

With 15 branches located close to its core customer bases across the country, each complete with fully equipped workshops and warehouse operations, Coopers offers comprehensive support to customers across Australia.

These branches are backed up by strong nationwide capabilities within engineering, technical sales, and procurement, providing access to best-in-class products and cuttingedge solutions.

“Our tagline – ‘Local Solutions, National Strength’ – really distils the power of our value proposition,” Sewell shares.

Alongside its national presence, Coopers seeks to guarantee consistently prompt and accurate delivery alongside quality customer service and technical assistance.

“Our success in this area is a result of an internal focus on our customer promise, which is to deliver highquality products, services, and solutions,” he adds.

As such, the company recently upgraded to Microsoft Dynamics 365 Finance and Operations, a modern enterprise resource planning (ERP) system that has helped to streamline its services and allowed the company to focus on exceeding customer expectations.

Coopers also maintains industryleading inventory levels, ensuring that it has adequate supply coverage across all its locations.

Meanwhile, each of the company’s branches boasts highly skilled employees, further complemented by a national support network of specialists.

In addition, Coopers’ team of almost 20 hydraulic mechanical and automation engineers are on hand to ensure it is always ready and able to tackle any customer problems, no matter the size or complexity.

“WE UNDERSTAND THAT SAFETY AND RELIABILITY FOR OUR CLIENTS IS PARAMOUNT, AND THIS REMAINS OUR UNWAVERING PRIORITY”

–BRODY SEWELL, GENERAL MANAGER, COOPER FLUID SYSTEMS

Amongst Coopers’ ongoing activities is an exciting plethora of projects that demonstrate the company’s continuous commitment to innovation.

For example, in Mackay, Queensland, it recently devised an automated hydraulic solutions project for eliminating live works (ELW).

Coopers was approached by a major mining company who sought to fulfil a safety initiative to drive ELW and required a solution to perform maintenance works on a major piece of equipment during a shutdown.

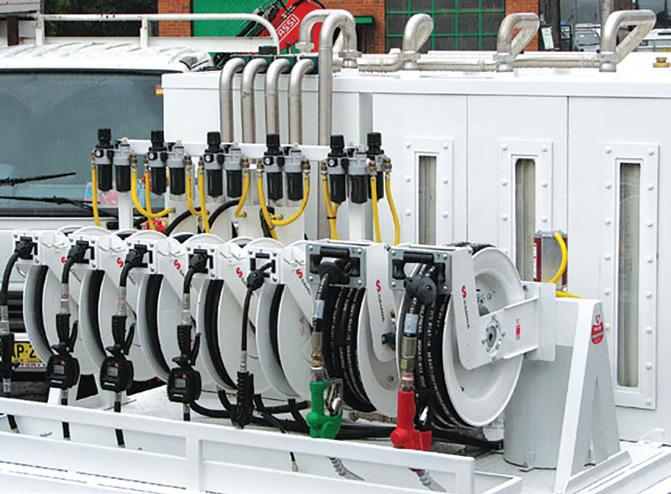

As a result, the team designed and manufactured a trailer mounted hydraulic power unit (HPU) with full automation and remote control capabilities, which allowed for the safe operation of specific components such as hydraulic cylinders, pumps, lubrication circuits, and air conditioning.

“As this solution was going to

be utilised in the Australian mining industry, we ensured that it was built to last with independent, off-road suspension and our own marketleading CooperBuilt hydraulic hose reels,” Sewell informs.

The unit also features a fully programmable logic controller (PLC), pre-programmed to the different circuit requirements of each piece of equipment being serviced.

Another interesting project completed by the company towards

the end of 2024 was its solar-powered degreaser dispensing system for use in remote mining applications.

“This really tied together our capabilities in fluid dispensing as well as automation and electrification engineering,” he explains.

“We designed and manufactured a complete solution which included solar panels, battery back-up, and a dispensing circuit that allowed for the connection of degreaser pods in remote locations with no access to power.”

Having worked closely with Australia’s major hay exporters and significantly improved their cycle times, Coopers has demonstrated its diversity.

“Our work with Australia’s hay industry has improved its ability to

• A safety-first culture

• 50+ years of industry experience

• A national network of 15 branches

• ISO 9001:2015 certified across all locations

• Engineering and technical support

• Qualified service staff

• Premium brands

• Specially manufactured products

• Bespoke engineered solutions

compete in the global market,” Sewell prides.

With some of the projects it has undertaken in this industry worth several million dollars and featuring incredibly complex hydraulic and automation solutions, thousands of engineering and manufacturing hours are often required.

“We’re currently working on an incredibly exciting hay plant. Whilst not specific to the mining industry, the solutions we employ can have many uses, especially in fixed-plant applications,” he outlines.

The company’s flexible, multisector approach feeds into to its vast supplier base, which ranges from local to international brands, as it must account for a wide array of needs and requirements.

“We find that local suppliers generally understand the requirements of our domestic customers and businesses, whilst we

Since its inception in 1972 as John Cooper Hydraulics and Pneumatics, the company has grown significantly.

Purchased by industrial products and services distributor, Coventry Group Ltd, in 1997, it has since acquired six additional businesses, enabling it to provide local knowledge and solutions tailored to customers’ needs.

Today, Coopers is as a national leader in Australia’s hydraulic, lubrication, fluid dispensing, and refuelling market, with over 45 years of industry experience and an extensive network of 15 branches.

also embrace premium brands from across the globe, particularly where products are highly technical in nature or we need to leverage international manufacturing networks,” Sewell reveals.

“One thing that remains consistent is our commitment to partnering with vendors who share our strong focus on quality.”

With people at the heart of the business, Coopers tries to bring in the best talent and provide them with the tools and guidance to do their job.

“It is vitally important in an organisation to make sure people know it’s okay to view mistakes as opportunities to learn and develop,” Sewell divulges.

As such, the company has numerous initiatives to help develop its people, including graduate, apprentice, trainee, and technical

Alemlube, a family-owned business with 55 years of industry leadership, continues to stand out as a proactive, dynamic force in the Australian market. Known for its commitment to quality, design, and innovation, Alemlube has set the bar high across multiple sectors, including automotive, industrial, commercial and mining.

With branches strategically located across Australia and New Zealand, Alemlube has built a solid foundation in providing tailored solutions to its customers. Its focus on mining is particularly noteworthy, where the company boasts a team of design engineers capable of creating bespoke outcomes for its diverse client base in the ANZ region. Alemlube’s expert team collaborates with its Business Development Managers (BDMs) to ensure that each customer’s needs are met with a complete, end-to-end solution.

Alemlube’s exceptional customer service is bolstered by its network of six branch locations, giving the company a genuine national platform. This strategic positioning allows for prompt order fulfillment, sales support, design assistance, and on-site after-sales service. Whether it’s providing a tailored design solutions for OEM dealership workshops or installing lube systems for stacker reclaimers in the Pilbara, Alemlube consistently goes above and beyond to exceed customer expectations.

Alemlube’s mission is clear: to be the most consistent, reliable, and valuable supplier of products and services in the mining sector. The company prides itself on its deep expertise, gained both from within the organisation and through overseas partnerships. Alemlube’s experienced teams understand the critical role their products and services play in maximising the efficiency and longevity of fixed plant, mobile equipment, machinery, and power generation facilities.

Specialising in the mining sector, Alemlube offers an extensive range of products from the humble grease nipple to large-capacity vehicle hoists. Each product is designed to enhance productivity and safety at mine site workshops. Alemlube has made significant contributions to Australasian industry, particularly through the design, fit out, and commissioning of workshops, as well as the design, supply, and installation of lube systems for mobile and fixed plant.

Alemlube operates across several key divisions, each focused on providing high-quality solutions to various industries:

· Refuelling Equipment: Alemlube offers a range of refuelling products designed to cater to a variety of sectors, including mining, manufacturing, food & beverage, agriculture, and transport. Their box-in-box-out options and branded products ensure that clients receive top-tier equipment and consistent after-sales service.

· Capital Workshop Equipment & Workshop Fitout Design: Alemlube specialises in the design, installation, commissioning, and after-sales service of workshops for mine sites. With advanced 3D graphics and animations, Alemlube helps customers plan and optimise their workshop operations, ensuring higher efficiency and profitability.

· Lubrication Systems and Solutions: Alemlube’s expert team offers design, installation, and maintenance services for lubrication systems across mobile and fixed plant applications. Their services include the supply of single and multi-point grease and oil lubricators, fluid flow and level management solutions, and advanced oil and fuel management systems. The company’s flexible, programmable lubricators help businesses optimie maintenance schedules and enhance equipment lifespan.

LEADING THE WAY FORWARD

Alemlube’s success over the past 55 years is a testament to its unwavering dedication to quality, service, and innovation. As the market continues to evolve, Alemlube remains at the forefront, ensuring that its products and services meet the ever-changing needs of the mining industry and beyond. With its extensive experience and commitment to excellence, Alemlube is poised to continue leading the way for years to come.

training programmes, and engages third-party organisations to provide both commercial and specialised technical training.

It also encourages willing employees to undertake university studies, with Sewell himself having earned a degree with the support of Coopers.

“My view is that there’s no point in recruiting and developing people if you can’t retain them,” he comments.

“We also ensure that our people are properly and fairly renumerated for the good work they do and have an organisation-wide incentive plan that applies to all employees.”

Therefore, whilst the company is a corporate organisation, it still maintains a personal touch and views each of its 1,000+ staff members as part of its extended family, celebrating them accordingly.

“WE PRIDE OURSELVES ON LIVING OUT OUR VALUES EVERY DAY AND USING THEM TO GUIDE OUR DECISION MAKING”

–ROBERT BULLUSS, CEO, COVENTRY GROUP LTD

To mark each employee’s birthday, for example, they receive a personalised email from Coventry Group Ltd CEO, Robert Bulluss, and a birthday card from their General Manager.

The company also has weekly staff ‘shout-outs’, monthly ‘values champions’, and quarterly CEO awards.

With people critical to the success of the company, they are viewed as more than mere assets – they are the beating heart.

“I often hear people being described as a company’s assets – I

don’t agree, as assets are things you own,” reflects Bulluss.

“People can choose to leave an organisation and only stay when they feel they resonate with its values and have opportunities to grow. Therefore, we need to work on multiple fronts to build a culture that people want to work in,” he adds.

On a continuous mission to establish innovative ways to better serve its customers, Coopers is constantly opening new avenues to market.

Meanwhile, it is staying ahead of the technological curve with advancements in electrification, battery technology, and electrohydraulic components.

“These all offer great opportunities for us to improve our customers’ operations,” Sewell shares.

The company is also investing in its expanding legacy capabilities due to its core belief in the value of continuous improvement.

“We understand that there’s always room to improve the equipment we have, further train and educate our

people, and ensure we facilitate knowledge sharing across the market,” he adds.

With people at the heart of its success, a key priority for Coopers’ leadership team going forwards remains building a culture that attracts and retains the right people to grow the business.

“We pride ourselves on living out our values every day and using them to guide our decision making,” Bulluss reflects.

In this way, the company is well placed for future success as it continues to provide full turn-key solutions for its customers.

“One thing I can guarantee is that whatever we do, it will be in line with our purpose of providing specialist solutions that our customers can trust,” Sewell confidently concludes.

Tel: 1300 026 673

cfsadmin@cfs.cgl.com.au

www.cooperfluidsystems.com.au