PROVIDING

SUSTAINABLE

WATER INFRASTRUCTURE FOR THE OIL AND GAS INDUSTRY

SUSTAINABLE

Scott Mitchell, CEO of Texan water management company, Deep Blue, discusses the company’s key role in the provision of sustainable water infrastructure for North America’s oil and gas industry and its deep commitment to customers

Writer: Lily Sawyer | Project Manager: Lauren Robinson

One of the biggest challenges facing the oil and gas industry in North America today is fighting the misperception that these resources cannot be produced or used in a sustainable or environmentally responsible way – they can.”

The opening words of Scott Mitchell, CEO of sustainable water management company, Deep Blue, convey his passion for sustainable oil and gas exploration and production. Due to this common misperception, as outlined by Mitchell, it has become increasingly difficult for the industry as a whole to attract capital, whilst necessary and reasonable regulatory changes have added costs and

created considerable complications.

At the same time, the constant evolution of various obstacles means companies must also find ways to tap into previously inaccessible or costly natural resources, whilst solving both logistical and supply chain issues to be able to make advances in the field.

“That being said, these challenges are also part of the excitement and fuel a ‘can-do’ spirit across the industry,” Mitchell continues.

Thus, as energy demands continue to rapidly increase across the country, companies such as Deep Blue are well-placed to adapt and progress just as quickly, sustaining oil and gas as the dominant force in today’s energy mix despite potential challenges.

Furthermore, Mitchell attributes Deep Blue’s ability to keep pace with industry as a major contributor to it being able to usher in many technological advancements over the years – with more on the horizon.

“We’re seeing rapid improvements in making oil and gas production more sustainable and environmentally responsible, especially through innovative water management solutions,” he excites.

“WE’RE PROUD AND EXCITED ABOUT OUR SUSTAINABLE INITIATIVES AND ARE CONFIDENT THEY’LL PLAY A KEY ROLE IN THE FUTURE OF WATER MANAGEMENT –NOT JUST FOR US, BUT FOR THE ENTIRE INDUSTRY”

– SCOTT MITCHELL, CEO, DEEP BLUE

As a company that specializes in providing comprehensive water management solutions for exploration and production (E&P) companies, Deep Blue has witnessed the demand for oil and gas skyrocket over the past few decades.

“The industry needs a reliable, large-scale, integrated water infrastructure network to keep pace

with demand, which is where we come in,” Mitchell affirms.

Although water may not be the first thing one pictures when thinking of oil and gas production, naturally occurring, highly saline water – known as produced water – is, in fact, of the utmost importance.

Unlike water from an aquifer, produced water must be processed before being reused. As such, Deep Blue handles the entirety of the water

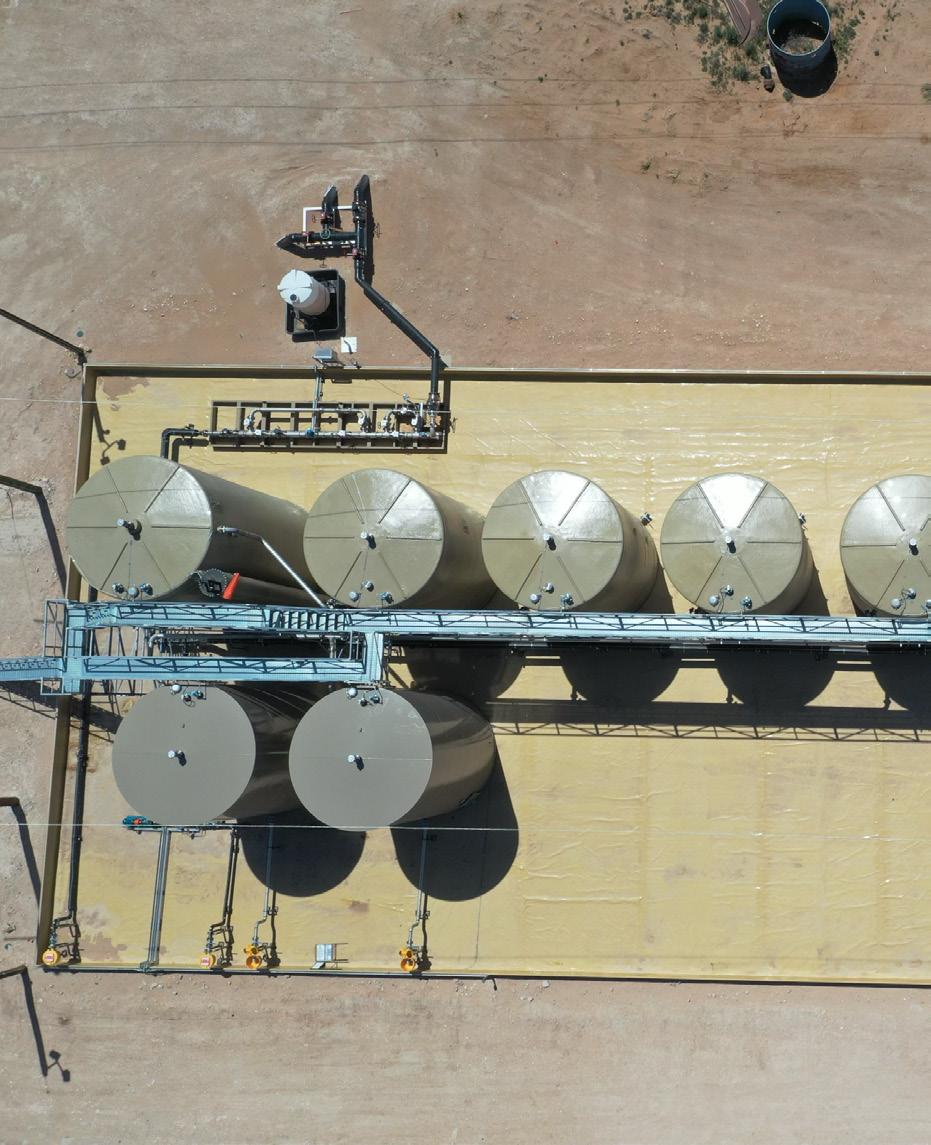

Due to the rapid growth of oil and gas production in North America, which can be largely attributed to the recent widespread adoption of horizontal drilling, Deep Blue believes large-scale, permanent water infrastructure networks are necessary to maintain current levels of production across the Permian Basin.

As such, its infrastructure and systems ensure it can sustain a consistent output, with the capacity to expand production where necessary:

• 2 million+ bpd of permitted produced water capacity

• 1,000+ miles of gathering and redelivery pipelines

• 66 million+ barrels of water storage capacity

• 600,000+ bpd of water delivery

Furthermore, the company is underpinned by an innate mission to create value for its customers, striving to provide E&P companies with safe, reliable, and efficient gathering, storage, and reuse facilities through its water pipelines and related infrastructure.

In these ways, Deep Blue provides unparalleled water management solutions for North America’s oil and gas industry.

cycle, starting with the collection of produced water through its extensive network of pipelines, which span over 1,000 miles.

“On a typical day, we gather around one million barrels of water,” Mitchell tells us.

Water is also imperative for new well completion processes, allowing oil to flow. Only after Deep Blue treats and recycles the produced water is it suitable for reuse in such completion operations. With facilities able to treat and recycle roughly 600,000 barrels per day (bpd), the company recycles enough water to fill the equivalent of 38 Olympic-sized swimming pools.

“We also offer disposal services through our network of over 100 saltwater disposal wells for any water that can’t be reused.”

In addition, the company is at the forefront of developing new technologies such as desalination and enhanced evaporation to promote sustainable water reuse and disposal.

EnviroKlean’s full suite of innovative water treatment solutions protect infrastructure, improve productivity, and increase sustainability. Powered by our EK One™ chemistry platform and delivered through the EK FlowPro™ chemical delivery management system, EnviroKlean is revolutionizing the management of scale, corrosion, bacteria, and oil-water separation.

The Advantages are Clear

• Lower operating expenses

• Lower capital expenditures

• Improved system capacity

• Improved environmental sustainability

The disruptive EK One chemistry platform harnesses the power of the carbon atom in groundbreaking ways:

• Prevents solids and harmful gases by returning the elements responsible for their creation back into solution, where they remain permanently bound within the source water.

• Eliminates iron sulfides and other toxic waste by-products by chemically transforming Iron (Fe) and other elements to prevent formation of the chemical reactions that produce the toxic waste.

Join the revolution in advanced water treatment with our comprehensive suite of solutions which each include diagnostic and consulting services, EK One chemistry formulation, chemical delivery management, ongoing performance testing, and web-based reporting. Call today to learn more about the clear advantages of working with EnviroKlean.

APPLICATIONS

Produced

Pond

Field-scale

Treatability

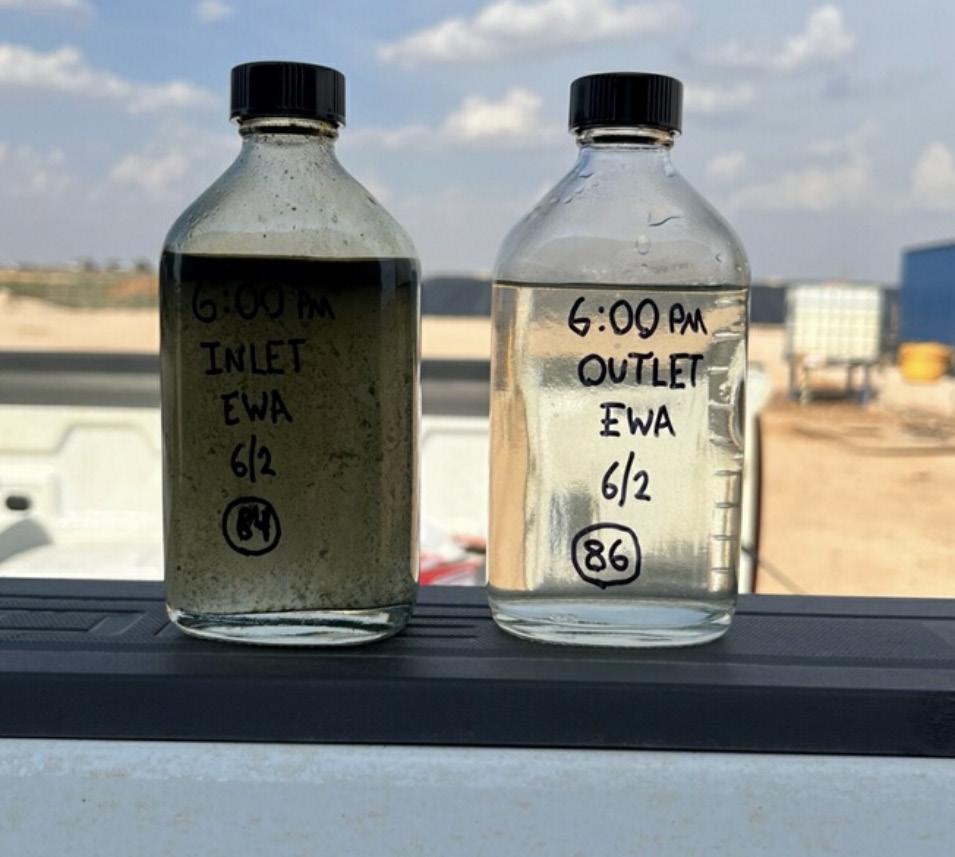

AAgroundbreaking innovation is revolutionizing produced water management in the Midland Basin. Deep Blue, a leader in sustainable water management, recognizes the power of this innovation and is collaborating with EnviroKlean and WaterTectonics on a new category in water recycling: Solids Free Discharge. This technological breakthrough promises to eliminate the need for solid waste creation and disposal when recycling produced water, enhancing operational e ciency and sustainability at an industrial scale.

groundbreaking innovation is revolutionizing produced water management in the Midland Basin. Deep Blue, a leader in sustainable water management, recognizes the power of this innovation and is collaborating with EnviroKlean and WaterTectonics on a new category in water recycling: Solids Free Discharge. This technological breakthrough promises to eliminate the need for solid waste creation and disposal when recycling produced water, enhancing operational e ciency and sustainability at an industrial scale.

The synergy between EnviroKlean and WaterTectonics, two industry leaders introduced by Deep Blue, is at the heart of this revolution. EnviroKlean’s Zero Solids™ technology and WaterTectonics’ industrial scale water treatment solutions have been seamlessly integrated to create a comprehensive, turnkey Solids Free Discharge solution capable of meeting the highest volume, 24x7 recycling needs of the premier water management platform in the Midland Basin. Ben Smiley, COO of Deep Blue, shares, “We saw a unique opportunity to introduce two of our suppliers, EnviroKlean and WaterTectonics. Their partnership leverages their combined strengths in innovation

The synergy between EnviroKlean and WaterTectonics, two industry leaders introduced by Deep Blue, is at the heart of this revolution. EnviroKlean’s Zero Solids™ technology and WaterTectonics’ industrial scale water treatment solutions have been seamlessly integrated to create a comprehensive, turnkey Solids Free Discharge solution capable of meeting the highest volume, 24x7 recycling needs of the premier water management platform in the Midland Basin. Ben Smiley, COO of Deep Blue, shares, “We saw a unique opportunity to introduce two of our suppliers, EnviroKlean and WaterTectonics. Their partnership leverages their combined strengths in innovation

and operational expertise to provide us with an advanced and sustainable water recycling solution.”

and operational expertise to provide us with an advanced and sustainable water recycling solution.”

Traditional water recycling methods, such as dissolved air flotation (DAF) or “flock and float”, rely on chemical reactions that create waste solids which must then be physically removed and disposed of, creating significant environmental and operational challenges. EnviroKlean’s Zero Solids™ technology transforms this process by using proprietary

Traditional water recycling methods, such as dissolved air flotation (DAF) or “flock and float”, rely on chemical reactions that create waste solids which must then be physically removed and disposed of, creating significant environmental and operational challenges. EnviroKlean’s Zero Solids™ technology transforms this process by using proprietary

carbon-based chemistry and processing technology to produce frac-ready fluid streams available for immediate reuse without forming solids requiring removal by a DAF process.

carbon-based chemistry and processing technology to produce frac-ready fluid streams available for immediate reuse without forming solids requiring removal by a DAF process.

The industry’s first Solids Free Discharge solution, EK Zero Solids Recycle™ (ZSR), is a fully automated, modular system capable of recycling volumes of up to 25,000 barrels per day. However, Deep Blue’s requirements for significantly higher daily volumes required a larger scale solution. EnviroKlean and WaterTectonics responded

The industry’s first Solids Free Discharge solution, EK Zero Solids Recycle™ (ZSR), is a fully automated, modular system capable of recycling volumes of up to 25,000 barrels per day. However, Deep Blue’s requirements for significantly higher daily volumes required a larger scale solution. EnviroKlean and WaterTectonics responded

The adoption of Solids Free Discharge o ers numerous benefits:

The adoption of Solids Free Discharge o ers numerous benefits:

• Elimination of Solids: No more handling of oil-wet solids, reducing costs and environmental impact.

• Elimination of Solids: No more handling of oil-wet solids, reducing costs and environmental impact.

• Better Water Quality: Produces clear, solids-free recycled water ready for immediate reuse.

• Better Water Quality: Produces clear, solids-free recycled water ready for immediate reuse.

• Longer Shelf Life: Recycled water that remains stable for up to 120 days.

• Longer Shelf Life: Recycled water that remains stable for up to 120 days.

• Smaller Footprint: Dramatically reduces footprint by eliminating the need for DAFs, weir tanks and supporting infrastructure.

• Smaller Footprint: Dramatically reduces footprint by eliminating the need for DAFs, weir tanks and supporting infrastructure.

• Improved Oil Recovery: Enhances oil recovery by reducing BS&W that forms oil-wet solids.

• Improved Oil Recovery: Enhances oil recovery by reducing BS&W that forms oil-wet solids.

• Improved Sustainability: Eliminates the creation of solid waste, positively impacting the environment.

• Improved Sustainability: Eliminates the creation of solid waste, positively impacting the environment.

• Lower Total Costs: Reduces costs by eliminating the need for creation, separation, removal and disposal of solid waste.

• Lower Total Costs: Reduces costs by eliminating the need for creation, separation, removal and disposal of solid waste.

• Enhanced Profitability: Operational e iciency and cost savings translate into better financial performance.

• Enhanced Profitability: Operational e iciency and cost savings translate into better financial performance.

Compact Footprint, Powerful Performance: WaterTectonics’ state-of-the-art water treatment infrastructure, powered by EnviroKlean’s Zero SolidsTM technology, demonstrates that size isn’t everything, e ectively delivering superior recycling results from a modern space-saving design.

safer and more sustainable water treatment.

together, co-developing a turnkey solution capable of recycling continuous volumes of up to 90,000 barrels per day through a more robust system with a service delivery model that can be either fully sta ed or managed remotely.

WaterTectonics advanced water treatment expertise, filtering technology and ability to develop turnkey integrated solutions was critical to the development of this larger scale solution, ensuring that the recycled water produced for Deep Blue meets their high volume demands and their customers’ stringent water quality standards.

This collaboration signifies a disruptive shift in the water recycling landscape. With the integration of EnviroKlean’s Zero Solids™ technology and WaterTectonics’ industrial scale water treatment equipment and service platform, Deep Blue can deliver a new standard for solids free water management via this comprehensive, turnkey solution that redefines recycling and reuse, promoting both sustainability and operational e ciency.

Deep Blue’s decision to introduce EnviroKlean and WaterTectonics was motivated by their deep commitment to promote innovation and sustainability. They wanted to help create an integrated solids free water treatment solution that exceeds industry standards for e ciency and environmental responsibility. And thanks to their introduction, the result of the EnviroKlean and WaterTectonics partnership is a revolutionary system that addresses the most pressing challenges in produced water recycling.

Deep Blue is dedicated to leading the way in sustainable water management in the Midland Basin. Through strategic partnerships and innovative thinking, Deep Blue provides advanced, integrated water management solutions that improve productivity, sustainability, and profitability. deepbluewater.com

EnviroKlean o ers innovative water treatment solutions designed to protect infrastructure, improve productivity, and enhance sustainability. Their Zero Solids™ technology and carbon-based chemistry platform, EK One™, represent significant advancements in the science of water treatment, providing enhanced sustainability for water recycling and management. enviroklean.co

WaterTectonics specializes in delivering integrated water treatment solutions through turnkey design, equipment, and service solutions for the water and waste water industries. Their turnkey solutions address a wide range of water quality issues impacting midstream water and energy producers, including TSS/ turbidity, pH, metals, oils, bacteria, PFAS, and more. Their expertise ensures the highest quality recycled water, supporting environmental and operational goals. watertectonics.com

“AS INDUSTRIES EVOLVE AND WATER BECOMES EVEN MORE CRITICAL, WE’RE HERE TO ENSURE OUR CUSTOMERS ARE ALIGNED WITH THE RIGHT PARTNER FOR THE FUTURE AND THAT THEY THRIVE”

– SCOTT MITCHELL, CEO, DEEP BLUE

Deep Blue’s customers are primarily E&P companies in the resource-rich Midland Basin – one of the most prolific oil-producing regions in the world.

Its largest customer is leading independent oil and natural gas company, Diamondback Energy (Diamondback), thanks to a recent joint venture (JV) through which the business acquired its water assets.

“Since forming this partnership in September 2023, we’ve experienced rapid growth, adding more than a dozen new clients and increasing our commercial volumes by over 200,000 bpd,” Mitchell informs.

For the most part, when adding a new customer or an existing client commits to a new area for produced water takeaway, they become part of a long-term service contract typically

lasting more than a decade. As such, Deep Blue is poised for continued growth as more companies seek to join its system.

By focusing solely on operations in the Midland Basin, the company delivers the most reliable and comprehensive service tailored specifically to this highly productive area, supplemented by its deep local expertise and extensive infrastructure to ensure it continues to meet the unique needs of its customers in this critical region.

Data lies at the heart of Deep Blue’s operations, with huge amounts of information managed every day to ensure its activities run as efficiently as possible.

“Thousands of measurement meters continuously monitor water volumes and flow rates through the

inlets and outlets of our pipelines, ponds, treatment facilities, and disposal sites,” Mitchell outlines.

In addition, hundreds of meters keep a close eye on Deep Blue’s water quality specifications, whilst it gathers subsurface geologic and pressure data from its disposal wells.

On top of this, the company integrates its customers’ volume forecasts to meet the takeaway needs of both completion and produced water.

“Operating our business efficiently means flawlessly aligning our systems, operations, and water volumes with customer requirements,” he elaborates.

As such, on the supply side, the company needs to deliver the right water to the right customer at the right time and place.

In terms of takeaway, it must also be

ready with new pipelines and enough capacity to take on customers’ water as soon as their wells begin production.

Therefore, Deep Blue is currently building out a real-time optimization program that will integrate its field measurements and customer forecasts.

The system will allow the company to forecast operations where necessary to pair its water supply or capacity with customers’ needs, whether this be treatment, transportation, or disposal. The program will also suggest optimal supply routes through the lowest cost segments of its system.

“We are excited about the system’s cutting-edge control center, where we’ll manage and crunch all the data in real time. We’ll also be able to run some operations remotely through

the center,” Mitchell reveals.

As it continues to refine this data-driven approach, Deep Blue’s customers will see significant benefits, including lower costs and exceptional reliability and readiness.

With multiple exciting and innovative projects underway, Deep Blue continues to provide the industry with advancements.

For example, one ongoing project demonstrates the company’s ability to provide recycled water for simultaneous well completion.

Historically, most water systems only provide enough recycled water for a single well completion. However, a rise in recent technological advances means completion operations must now be able to complete two wells at the same

time – also known as simultaneous fracking (simulfrac).

A considerable sustainable advancement for the industry, simulfracs are highly efficient for E&P companies but demand greatervolumes of water over shorter periods of time, which requires a massive orchestration of treatment, storage, transportation, and labor.

“In fact, thanks to the growth of simulfracs, water requirements have gone from 130,000 bpd to over 200,000 bpd per well completion crew,” Mitchell explains.

This is where Deep Blue comes in to help companies meet their development targets, having recently successfully provided recycled water for not just two, but six simultaneous well completions in the same area.

There is a new landmark visible when landing at the Midland International Airport signalling an innovative new step toward the oil and gas industry’s efforts to reduce operational costs and meet environmental goals. Depending on location, every barrel of oil comes with two to 10 barrels of “produced” wastewater that ultimately needs to be disposed of. EcoVAP’s latest Evaporative Matrix, built in partnership with the forward-thinking management team at Deep Blue is a biomimicry-based passive means of evaporation that allows for a 59 times increase in the “pan” evaporation rate without the use of energy, heat or chemicals. The technology allows the company to diversify its water disposal approach to avoid the main drawback of injection disposal (i.e., via salt water disposal wells (SWDs) that have come under scrutiny because of seismicity risk).

At the same time, the technology was developed to reduce energy, labor, and maintenance costs.

The Deep Blue EcoVAP deployment is the first in the Permian Basin, following EcoVAP’s prior 12 deployments in Utah, Wyoming, Nevada, Arizona, California, New Mexico, Florida, Canada, and Texas’ Eagle Ford. These deployments range in size (from 10 BBLS/day to 4,000 BBLS/day), water chemistry (in multiple industries including oil and gas, mining, power and industrial), and geography (including some cold and humid climates that would otherwise be unsuitable for conventional pond evaporation).

The near-airport location of Matrix can be considered an appropriate metaphor for the genesis of EcoVAP and founder Mike Patey, an aviation hall-of-famer, who has won multiple races in planes that he has designed, built, and flown. It is Patey’s aerospace, fluid dynamics, and mechanical engineering expertise that allowed him to invent the EcoVAP Evaporative Matrix technology. Some years ago, Patey’s stopover at an airport near a conventional evaporation pond led him to see the need for more efficient evaporation.

In 2017, EcoVAP launched its first full-scale Evaporative Matrix and recorded a 59 times evaporation rate versus the equivalent local pan rate for the area – and continues to exceed expectations in multiple climates. The Matrices are comprised of up to hundreds of thousands of identical, interlocking High Density Polyethylene (HDPE) panels that can be configured to any size versus the disposal need. A low-pressure pump periodically (10-15 minutes every two hours) saturates the wastewater over the Matrix, exponentially expanding the surface space of water-to-air. For Patey, using the HDPE media was the main goal and challenge. HDPE is the same basic media used for

“Daily water meter data indicate that the Evaporation Tower is 59 times more efficient in evaporating water than the approach relying on the surface water evaporation only.”

- Golder Associates; Water Balance and Validation Test Results, December 11, 2017

evaporation pond linings and is impermeable and resistant to just about any chemical and has a life expectancy of at least 50 years. Compared to the best-galvanized steel and specialty metals, it is a fraction of the cost and will never rust or corrode. However, the challenge of HDPE is that it is hydrophobic, meaning that water will bead and not adhere to the plastic, otherwise greatly reducing the water-to-air surface space. This is where Patey’s fluid dynamics and aerospace expertise comes into play, having designed each panel with a series of airfoils and diagonals to spread the water evenly over the entirety of the vertical and horizontal

surface space. With maximum coverage and minimum water thickness over the HDPE, the water-to-air surface space increases exponentially compared to a conventional evaporation pond.

To a lesser extent, the Matrices are configured to create self-generated wind, utilizing the differential of the colder water and the latent heat generated from evaporation, moving through a series of tunnels designed into each system. Finally, any sunlight will heat the black surfaces of the HDPE.

The EcoVAP Matrices can be constructed quickly and modularly deployed. To date, none of EcoVAP’s deployments have required additional regulatory approvals as there is no thermal heating or gas flaring that would result in CO2 emissions (and qualifying for CO2 credits) and no seismicity risk. Moreover, the land footprint is usually 40-60 times less than that of a conventional evaporation pond; thus, the catchment pond can be easily covered with a double lined bed with leak detection sensors and small fences and nets to prevent wildlife intrusion.

“EcoVAP’s Evaporative Matrix technology was unique in meeting Deep Blue’s goals of reducing costs and being environmentally sound. It has proven successful in our pilot area, and we are excited about its potential to add value across our system.”

- Scott Mitchell, CEO; Deep Blue

“In

addition to using practically no energy, EcoVAP Matrices have practically no additional labor or maintenance capex. Generally, we recommend a simple drive-by inspection every few days, which can also be done remotely.”

- Jason Mendenhall, CEO, ECOVAP

EcoVAP’s maintenance cost is negligible as the system is naturally self-cleaning. Every time the tower is wetted, the solid build-up is washed away, irrespective of the wastewater chemistry, thus preventing scaling. When the wastewater is reduced to a thick slurry of about two to five percent of its original volume, it can be easily removed from a catchment with a vacuum truck or other disposal methods. Only the low-pressure pumps will need to be replaced once every two to four years.

While EcoVAP Matrix’s direct operating costs compare favorably to other disposal methods, it is the ability to locate right alongside the well-head that often saves the most money. The company’s first deployment in Texas was at a remote location that required over 50 miles of RT trucking. EcoVAP was able to deploy a smaller unit alongside the well, thus allowing the client to reduce its trucking volume by over 97 percent.

EcoVAP expects that its deployment and collaboration with Deep Blue is the first of many in the Permian basin. Given Patey’s love of flying, he expects many fly-by’s over the Midland Airport as a reminder of how it all started.

“This particular project required a significant amount of water across multiple facilities and crews – five million barrels of in-ground storage, 20 people across five treatment facilities, and 12 people across six water transportation crews,” he details.

As a result, Deep Blue was able to deliver nearly 600,000 bpd for this assignment – the equivalent of 25 million gallons per day (gpd) 24/7 for 20 days.

“These numbers help illustrate the scale of what we are accomplishing in every single project.”

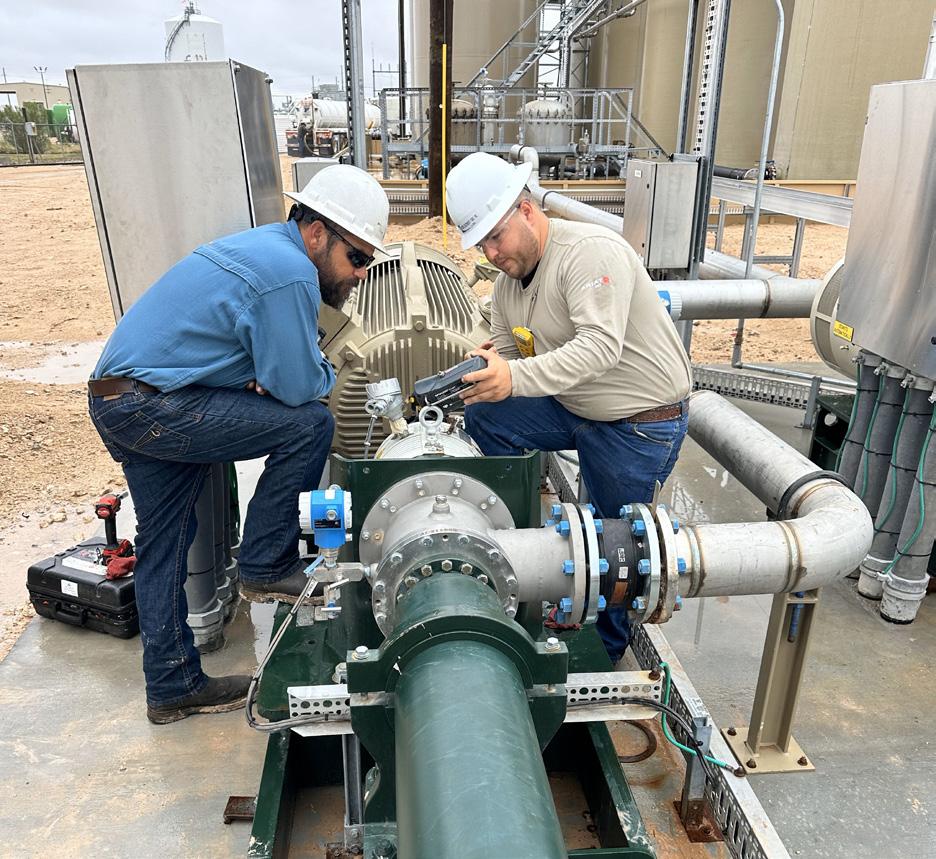

In addition, Deep Blue has been working on another exciting recycling endeavor over the last year, in which it has collaborated with Premier Equipment to design and deploy new flotation cell technology.

Traditionally, generic equipment for recycled water is only capable of treating around 20,000 bpd per facility, despite the majority of

“WE’RE NOT JUST ANOTHER WATER MANAGEMENT COMPANY – WE DEVELOP, OWN, AND OPERATE INTEGRATED MIDSTREAM WATER INFRASTRUCTURE NETWORKS SPECIFICALLY DESIGNED TO MEET OUR CUSTOMERS’ EVOLVING NEEDS”

– SCOTT MITCHELL, CEO, DEEP BLUE

completions today often requiring hundreds of thousands of bpd.

Deep Blue’s new flotation cell can pre-treat up to 100,000 bpd with no increase in the amount of land required – five times the number of typical methods.

“Our initial unit has now been running for six months, and based on its success, we anticipate adding another unit this year,” Mitchell discloses.

Should this technology be

deployed across the entire Deep Blue system, it has the potential to drastically increase recycling volumes by reducing the time and space required for recycled water and eliminating the need for highcost facilities such as above-ground storage tanks.

“Projects like these are why we got involved in the industry; we want to enhance sustainability while improving efficiency and introducing cost savings,” he enthuses.

As a company deeply committed to maintaining ongoing, reliable water management in the Midland Basin, sustainability is deeply embedded in Deep Blue’s ethos.

Given the oil and gas industry’s historical reliance on fresh and brackish aquifers and subsurface water injections, the company recognizes a growing need for more sustainable methods to ease pressures on the region’s water resources.

“Right now, we run the largest commercial recycling system in the Midland Basin, processing up to 25 million gpd of water, which reduces our dependence on aquifers and eliminates the need for water disposal, positioning us as a leader in sustainable practices.”

Moreover, Deep Blue has plans to expand its sustainable capabilities in the coming months.

“We’re currently exploring

innovative techniques, such as enhanced evaporation, to further minimize our environmental impact,” he states.

As such, the company recently began field testing EcoVAP Evaporative Matrix technology, which can evaporate up to 60 times more water when compared to traditional methods used on ponds of the same size.

As this technology returns water to the hydrologic cycle in the form of water vapor, it significantly reduces the amount of water requiring disposal, which is especially useful in areas where injection-based disposal proves more challenging.

Deep Blue is also pushing the boundaries of recycling with desalination, which involves treating water so it can be reused beyond the

oil and gas industry.

Trusted engineering, construction, and project management company, Bechtel Energy, recently launched a Low Energy Ejector Desalination System (LEEDS) to assist customers in advancing their environmental goals whilst preserving precious water resources.

Its recent partnership with Deep Blue, which saw it pilot LEEDS in the Midland Basin, promises a feasible, accessible, and sustainable desalination solution.

Results from Deep Blue’s initial field tests of LEEDS are promising, with the thermal desalination technology capable of turning highly saline, produced water – three to four times as salty as the ocean – into reusable, clean water.

“Simply put, we are taking a waste product from miles below the surface and turning it into fresh water,” Mitchell observes.

Could you introduce us to Premier Equipment Corp and provide an overview of its products and services, facilities, and where it is based?

Premier Equipment Corp (PEC) is a locally owned rotating equipment distributor and custom fabrication shop firmly rooted in Baton Rouge, LA. PEC offers dedicated sales, engineering, and service teams in Louisiana and Texas with our Baton Rouge, Houston, and Odessa locations. Our dedicated field service divisions perform preventative maintenance repairs and downtime failure analysis and repairs. Premier represents industry-leading brands in pumps, air compressors, blowers, cooling towers, and epoxy grout. In conjunction with our sister company, Premier Control Systems,

PEC offers customers turnkey designbuild services on facilities in the oil and gas industry. Premier Control Systems offers full-service instrumentation and electrical (I&E) services with a custom panel shop, programming, and field service capabilities.

Following that, please tell us a bit about the company’s history.

In 1965, the Young family incorporated the business as J.A. Young and Associates. PEC was established in August 1992 in response to the growing need for rotating equipment reliability in the industrial sector. Since then, PEC has expanded its reach as a distributor and design-build firm serving the Gulf Coast region’s petrochemical and oil and gas industries.

Additional businesses founded by the Young family through the years:

In 1980, Filtration Services was established, providing the first filtration units (patented technology) consisting of filter presses for treating completion fluids. Filtration Services was sold to Baker Hughes Sand Control in 1983.

In 1992, SAFE Inc. was incepted. SAFE Inc. was an oilfield waste disposal company in Mobile, Alabama, which handled drilling waste from ExxonMobile, Chevron, and Texaco for the Mobile Bay Gas field.

In 1995, Unicel Inc. was founded. The company provided an oil water separator system, producing worldwide water clarification. It is a vertical singleinduced gas floatation system (patented

technology). Unicel Inc. was sold to Cooper–Cameron in 2005.

In 2005, Premier Control Systems began as a full-service instrument and electrical company. With Premier Equipment and Premier Controls, custom-engineered packages are provided with mechanical and electrical work completed in-house.

What industries does Premier Equipment Corp operate in, and how important are client relationships to the company?

PEC has a diversified business selling equipment and services to plants along the Gulf Coast and fields in West Texas. The different requirements and deliverables of the varying industries make for a challenging project management process, as each industry has unique standards, regulations, and expectations that must be met. This complexity requires a tailored approach to address all specific needs while maintaining efficiency and quality across all deliverables. PEC handles this with regular and transparent communication. Transparency allows us to develop strong long-term relationships like the one with the principles of Deep Blue Midstream, which has lasted over the years with multiple companies.

PEC realizes that customer relationships are the backbone of our business. Loyal customers are not only repeat customers; they bring tremendous value in recommendations, referrals, and overall brand awareness. PEC has been fortunate to work with many great customers over the years, which has been a key factor in our growth and success. Each partnership has provided unique insights and challenges, allowing us to refine our processes, innovate our solutions, and better understand the diverse needs of different industries. These collaborations have helped us expand our capabilities and fostered lasting relationships built on trust, mutual respect, and shared goals. We are deeply grateful for our customers’ trust and remain committed to delivering exceptional value in every project we undertake.

What are Premier Equipment Corp’s innovative approach and state-of-theart solutions?

PEC’s primary business is built on sales and packaging of well-known rotating equipment and electrical brands. Over the years, we have introduced multiple innovative ways to treat water and

solids in various industries. This year, PEC completed a pilot project with Deep Blue Midstream on a water-treating unit. The unit was tested to remove oil, grease, and other suspended solids from produced water in one of Deep Blue’s recycling facilities. The test results from the pilot were successful, and PEC is installing another unit for Deep Blue for long-term operations. We feel this unit can change the way produced water is treated in a smaller footprint, increasing efficiency, tank storage requirements, and less day-to-day manpower.

Are there any advantages and values associated with being a family-owned and operated company?

We are all in business to make money, but our family-owned business’s atmosphere and decision-making process are very different from those of a large corporation. The work environment is more familial, with many employees working for our company for 20+ years. The decision-making process with our small management group allows us to be nimble in the fast-moving project environment of the petrochemical and oil and gas industries. Our flexibility and willingness to think outside the box can help optimize and reduce lead times for customers. Coming from Corporate America, the ability to make decisions quicker gives us a huge advantage over

larger companies. As a diverse mediumsized company, PEC also has the unique ability to complete most of the proposed work in-house, thus significantly reducing the cost while managing the entire scope of the project to give you a single point of contact.

What, would you say, differentiates Premier Equipment Corp from the competition?

No company is perfect, and challenges are inevitable in any business. What sets us apart is how we handle those issues when they arise. We believe in addressing problems head-on with honesty, transparency, and a commitment to finding solutions that align with our customers’ goals. Our approach is to listen carefully, assess the situation thoroughly, and work collaboratively to resolve any concerns promptly. By maintaining open communication and focusing on continuous improvement, we learn, adapt, and emerge stronger together, even when things do not go as planned.

Contact Name: Miles Torregano Office Number: 225-755-2240

Email: mtorregano@premierequiptx.com

Websites: www.premierequipla.com www.premiercontrolsystems.com/

Social Media: www.linkedin.com/company/ premier-equipment-corp-inc-/

Once fresh water has been successfully generated, it can be used to supplement or displace fresh water used in many industrial, municipal, or agricultural processes.

This is an exciting, longer-term solution, but one that will take years to

build and integrate at full scale across Deep Blue’s existing system.

“We’re proud and excited about our sustainable initiatives and are confident they’ll play a key role in the future of water management – not just for us, but for the entire industry,” he prides.

Deep Blue’s strategic location in the Midland Basin is part of the larger Permian Basin – the US’ most abundant oil-producing region.

Processing hydrocarbons for around 100 years, the Permian Basin is formed of a complex sedimentary system primarily located in the resource-rich MarathonOuachita fold belt in Texas.

Over the past decade, it has seen the implementation of advancements such as hydraulic fracturing, horizontal drilling, and completion technologies, which have contributed to the basin supplying more than 35.6 billion barrels of oil and 125 trillion cubic feet (cbft) of natural gas as of January 2020

Covering approximately 86,000 square miles (sqmi) and encompassing 52 counties across New Mexico and Texas, the Permian Basin is divided into three main sub-regions:

• Midland Basin

• Central Basin Platform

• Delaware Basin

As a result of Diamondback and Five Point Energy’s recent JV, Deep Blue is now the largest independent water infrastructure platform in the Midland Basin, with substantial excess capacity in place to secure continued growth.

Both owning and operating its integrated midstream water infrastructure provides Deep Blue with a distinct advantage in today’s rapidly evolving energy landscape.

As the industry has grown, scale and flexibility have become more important than ever.

“We’ve seen a major increase in demand from E&P companies for water supply and takeaway services. Meeting this demand requires infrastructure that’s both robust and adaptable – something smaller systems often struggle to deliver,” Mitchell reports.

As such, smaller E&P-owned commercial systems are beginning to struggle to keep pace, often lacking the capacity and integration needed to handle today’s development practices, leading to constraints on water management.

What sets Deep Blue apart in this sense is its scale. By consolidating smaller systems into its large, integrated network, the company is able to offer more reliable and flexible services at a lower cost.

“Our extensive network allows us to quickly adjust to changing demands, ensuring water services are delivered exactly when and where they’re needed,” Mitchell confirms.

This not only gives Deep Blue’s customers confidence that their needs will be met but also frees them up to focus on their core business.

“Our integrated approach positions us to meet the industry’s increasingly complex needs more effectively. We’re committed to providing a topnotch service while keeping costs down – a clear advantage that helps our customers succeed and remain competitive in the market.”

In addition to the independent operation of its Midland Basin infrastructure, Deep Blue is also supported and driven by strong

Over the last half-decade, Milford Companies has undergone a significant and purposeful transformation. Following the divestiture of its pipeline construction division in 2021, Milford redefined its business model to become a leading force in the PVF (Pipe, Valve, and Fitting) supply industry, with a specialized focus on polyethylene pipe, fusion equipment, and related technologies.

Chase Brown, President of Milford, often encapsulates his guiding philosophy with the quote, “Success is never owned; it’s rented, and the rent is due daily.” This philosophy drives Milford’s customer-focused approach, which is central to the company's continued success.

Milford’s role as a key supplier for Deep Blue, a leader in sustainable water management, highlights its commitment to providing top-tier polyethylene pipe solutions. This collaboration supports Deep Blue’s mission to create environmentally responsible water infrastructure, particularly in the Midland Basin, a critical area for U.S. energy production.

In recent years, Milford has significantly broadened its supplier network and strengthened existing partnerships. The company’s strategic buyout in 2023 further positioned them for growth by integrating with Winsupply, a family of companies that includes more than 650 Win-branded and regional wholesalers across the United States; service companies for business support and sourcing; and Winsupply Inc., enabling Milford to capture a larger share of the U.S. market and further advocate for fusible plastics over legacy piping materials.

Milford’s industry achievements have been widely recognized. In 2023, the company received the President’s Award from McElroy Manufacturing, an honor given to only a

few companies worldwide. Additionally, Milford earned a Leadership Award from the Alliance for PE Pipe for innovative trenchless HDPE pipe installation, in partnership with San Antonio Water System (SAWS).

“Success is never owned; it’s rented, and the rent is due daily.”

Milford has also become a significant player in the municipal sector. It secured the annual contract as the primary HDPE pipe supplier for SAWS and won multi-million-dollar material bids across Oklahoma, Texas, and New Mexico, demonstrating its strong reputation and proven track record.

Backed by Winsupply, Milford Companies continues to reach new milestones and set increasingly ambitious goals. It expects to achieve them through its experienced, knowledgeable, and dedicated team members, who are focused on strategic growth through customer-focused excellence.

partnerships, which are ultimately considered to be the backbone of the company’s success.

Deep Blue stands on three pillars: strong management, the right strategy, and key partners – such as its ongoing relationships with Five Point Energy and Diamondback.

A leading private equity firm focused on building businesses within the environmental water management and sustainable infrastructure sectors, Five Point Energy brings deep knowledge of energy, midstream, and water management to the table, as well as a proven track record of success and commitment within the Permian Basin.

“Five Point Energy’s reputation for reliability speaks volumes,” Mitchell reflects.

As for Diamondback, a proven dynamic leader amongst large E&P companies, it has supported Deep Blue by providing water assets as part of the 2023 JV, whilst it continues to contribute water volume to the company’s system in the long term.

“This contribution allowed us to start on a significant scale and continues to confirm our efficiency and reliability to others,” Mitchell divulges.

Further to Deep Blue’s historical

“WE’RE NOT JUST ANOTHER WATER MANAGEMENT COMPANY – WE DEVELOP, OWN, AND OPERATE INTEGRATED MIDSTREAM WATER INFRASTRUCTURE NETWORKS SPECIFICALLY DESIGNED TO MEET OUR CUSTOMERS’ EVOLVING NEEDS”

– SCOTT MITCHELL, CEO, DEEP BLUE

and ongoing partnerships, the company continues to make new acquisitions, such as that of Lagoon Water Management’s system.

Having been built recently, the system sits beside Deep Blue’s in one of the busiest parts of the Midland Basin. When Deep Blue acquired the lagoon at the end of May 2024, it was able to expand its network by over 100 miles as a result, including water gathering and delivery pipelines alongside other valuable assets.

“This move didn’t just broaden our reach – it brought in new customers and deepened our relationships with current ones,” Mitchell recalls.

By boosting capacity, reliability, and flexibility as it has done with the Lagoon acquisition in this critical area, Deep Blue has been able to elevate and expand its service offerings.

Looking to the future, Deep Blue regards its continued growth through a specific lens – to inform its priorities, goals, and targets, the company contemplates how best to serve customers and move forward sustainably, thus allowing it to serve more people.

“We always want to improve our services, add more customers, and expand our relationship with them,” Mitchell imparts.

Deep Blue sets out to achieve this by increasing its recycling capacity, saving costs through improved efficiency, and deploying new, proven technologies, all of which simultaneously enhance sustainability.

As such, the company carefully selects priorities that work together in a cycle of continuous improvement.

In September 2023, Diamondback and Five Point Energy entered a strategic JV, which has since positioned Deep Blue as a prolific oil and gas player in the Midland Basin and wider Permian Basin, with each company individually contributing important attributes:

• FIVE POINT ENERGY – Founded by industry members with an interest in investing, building, and running midstream infrastructure companies, Five Point Energy’s overall strategy involves buying and building assets, creating companies, and growing them into sustainable enterprises. Backed by firstclass management teams and leading E&P partners who have contributed valuable industry expertise to Deep Blue’s burgeoning activities, Five Point Energy’s historical oil and gas acquisitions have proven highly successful.

For instance, growing the business adds water and capacity to the system which, in turn, makes the company more reliable, flexible, and cost-effective for customers.

“Our results attract more customers, and the cycle continues to build upon itself,” he claims.

• DIAMONDBACK – Texas-based Diamondback is involved in the exploration and development of unconventional oil and gas reserves, primarily in the Permian Basin. The company’s operations are anchored around the five core values of integrity, leadership, excellence, people, and teamwork, setting a high bar for its industry interactions with the likes of Deep Blue.

In addition, as part of the JV, Diamondback is set to dedicate 15 years of its produced and supplied water to Deep Blue, whilst both Five Point Energy and Diamondback will collectively contribute $500 million to fund future projects.

In terms of overall goals, Deep Blue’s is simple: to create long-term value by addressing the growing demand for efficient and reliable water management.

As water continues to be a critical resource for every industry across the US and beyond, Deep Blue leads the charge in delivering innovative, sustainable solutions.

“We’re not just another water management company – we develop, own, and operate integrated midstream water infrastructure networks specifically designed to meet our customers’ evolving needs.”

At Deep Blue, water management is about more than just infrastructure –it’s about innovation.

The company is continually developing advanced technologies, from desalination to enhanced evaporation, to promote sustainable water reuse and disposal,

technologies designed with unique features to ensure their effectiveness and sustainability.

In this way, Deep Blue’s customers gain access to unparalleled expertise, cutting-edge infrastructure, and a relentless commitment to sustainability and efficiency.

“As industries evolve and water becomes even more critical, we’re here to ensure our customers are aligned with the right partner for the future and that they thrive,” Mitchell concludes.

E: toni@lythix.com

P: (432-664-9343)

E: kkalt@lythix.com W: www.lythix.com

LinkedIn: Lythix LLC Facebook: Lythix LLC

Lythix Engineering’s mission is to partner with our customers to educate and help them succeed with all their power needs. We offer turnkey solutions for UAV inspections and complete design and engineering solutions for powerline and transmission. With a combined 300+ years in the oil and gas industry, our team brings expert knowledge to the projects and companies we serve.

As a small, focused firm, we remain grounded in integrity and honesty in all business relationships. We understand that no customers’ needs are identical, so we work hard to provide customized products for the industry to meet our clients’ diverse growth plans.

To know us is to know where we come from, starting with our name! Dark Horse – a candidate or competitor about whom little is known but who unexpectedly wins or succeeds. We understand you have a choice. However, taking a risk on the underdog can reap great rewards. During our time in business, we have had the opportunity to focus on developing efficiencies that are unexpected and unmatched in this industry to help get our customers to be the exacta across the leader board. We are here too double-down on business in an unconventional way.

Dark Horse Safety Inc, 801 N Main, Ste M, Andrews, Texas 79714 T+432-223-3161 | www.darkhorsesafety.com

Shields Pipe Corporation (SPC) is the leading oil country tubular goods supplier, based in Edmond, Oklahoma. We have been serving the oil and gas exploration industry since 1987. Service, quality and price - some say you can’t have all three. Our customers will beg to differ. Whether you’re a large oil and gas exploration company or just starting out, you need a supplier you can count on. One that will get you the right oilfield tubulars, threading, pipe, steel and more, when and where you need them, and at the most competitive price. That’s SPC, and that’s why customers have relied on us for over 35 years. Contact us: (405) 818-0909 www.shieldspipe.com