TECHNOLOGICAL DEFENCE MANUFACTURING CAPABILITY PRODUCTS AND TAILORED SOLUTIONS

TECHNOLOGICAL DEFENCE MANUFACTURING CAPABILITY PRODUCTS AND TAILORED SOLUTIONS

Delving into the unmatched capabilities of the two divisions that comprise HighCom Group, we speak to Todd Ashurst, Group COO and General Manager of HighCom Technology, and Sally Nordeen, CEO of HighCom Armor Solutions, about how the company provides state-of-theart technological manufacturing capabilities and tailored capability solutions for both the military and industry

Writer: Lucy Pilgrim | Project Manager: Thomas Arnold

The international defence industry becomes more prevalent every day as specialist products are critically required across the world in both domestic and foreign affairs.

HighCom Group, listed on the Australian Securities Exchange (ASX), has grown over the last 40 years to become a global leader in the defence manufacturing sector, operating two distinct divisions – HighCom Armor Solutions (HighCom Armor) and HighCom Technology.

The group provides high-quality, specialist products and tailored solutions for military and law enforcement agencies whilst also expanding its global sales and distribution networks across new

markets of high-performance ballistic products and technology solutions.

Understanding a range of technologies and their integration is imperative to HighCom Group’s work, as it ensures the cohesion of its two entities.

“At the group level, the company gains process efficiencies through knowledge and technology sharing between the two divisions,” opens Todd Ashurst, Group COO and General Manager of HighCom Technology.

“Whether it’s the manufacturing process, an engineering management framework, or a technology or machine that can be utilised by both divisions, HighCom Group always aims to align the two sides of the business where practical.”

With a current focus on representing uncrewed systems and sensor payloads, HighCom Technology serves global defence and security agencies with world-leading solutions from its Canberra – the Australian Capital Territory – facilities.

This includes cutting-edge products from top-of-the-range original equipment manufacturer (OEM) AeroVironment Inc. (AeroVironment) – a US global defence supplier. HighCom Technology is the exclusive Australian representative for small uncrewed aerial systems (SUAS), including the Tomahawk Kinesis Common Control System, and non-exclusive Special Export Sales Representative for loitering munitions, alongside other ancillaries.

As such, the division’s focus on supplying global defence and security agencies highly relies on providing a complete range of services from sales to local programme, project, and engineering management, as well as systems integration, training, maintenance, composite repair and manufacture, and logistics support services.

A key HighCom Technology strength is the ability to integrate cutting-edge payload technology from Australia and overseas for the

Sally Nordeen, CEO: “Composites

One has been a long-term partner of HighCom Armor, supplying ballistic materials and composite consumables crucial to our operations.

“Over the years, the company has developed an in-depth understanding of HighCom Armor’s specific needs, maintaining a well-stocked inventory to support just-in-time (JIT) production and large-volume projects. Its commitment to weekly deliveries ensures a seamless workflow, allowing us to meet our production deadlines consistently. Additionally, Composites One’s assistance with forecasting helps us to anticipate material needs and plan accordingly.

“The partnership with Composites One goes beyond just supply; they provide experts in various areas to deliver tailored solutions for our challenges. This support includes a dedicated team for sourcing new materials and a technical sales team that excels in meeting our requirements. The company’s expertise and proactive approach make them an exceptional material source, consistently contributing to our operational efficiency and innovation.

“Composites One’s reliability and dedication have been instrumental in our ability to maintain high standards and meet production goals.”

local environment while examining opportunities to increase Australian Industry Content (AIC) through options such as local manufacture.

Heralding a 32-year stint as an Australian Army Officer, the diverse roles of Ashurst’s career have equipped him with the best skills to sharpen his strategic acumen and operational expertise.

“My background has shaped my approach to decision-making based on a structured analysis of intelligence, resource availability, risk factors, and objectives.

“The clarity of goals and execution planning is critical to success, especially in high-stake environments such as operations in conflict zones. I have found this mindset translates well to corporate strategy, particularly when making decisions about adopting or expanding technology,” he shares.

Thus, his experience and knowledge provide Ashurst with a greater understanding of the steps that need to be taken in complex defence projects.

For instance, HighCom Technology recently successfully finalised the

delivery of an acquisition contract for a mixed fleet of AeroVironment SUAS for the Australian Defence Force (ADF). This will see the division continue to deliver support services including engineering, maintenance, logistics, flying, and training for approximately four to 10 years.

This long-term contract commitment allows HighCom Technology to directly support the ADF’s mission and purpose: to defend Australia and its national interests to advance the country’s security and prosperity.

The division continues its unwavering commitment to demonstrate how AeroVironment capability product lines, including SUAS, the Tomahawk Kinesis Common Control System and loitering munitions, integrate to form a cohesive and winning capability solution.

“HighCom Technology’s goal is clear: deliver to the ADF common control across all UAS to combine with loitering munitions, thereby expanding the operational response scenarios and range, while reducing the cognitive workload of operators,” affirms Ashurst.

At the same time, the contract reinforces HighCom Group’s long-standing partnership with AeroVironment, of which it has been an exclusive SUAS partner across Australia and New Zealand for a number of years and continues to expand this relationship across a broader range of battle-proven capabilities.

Alongside supporting the ADF, HighCom Technology also supplies and supports defence, security, and law enforcement agencies across the world with leading uncrewed and control systems, as well as sensor technology.

The division continues to provide a range of services, including directly supporting the acquisition process, integrating solutions, project management, engineering, repair and maintenance services, product support, and training.

“HighCom Technology’s goal is to be the trusted partner of choice in supplying, supporting, and integrating capabilities for use by defence, security, and law enforcement agencies,” Ashurst highlights.

For example, the company continues to work closely with the Australian Department of Defence (DoD) in order to meet its current and future requirements in a rapidly changing strategic environment.

This is achieved by the introduction of a new suite of small and medium UAS products, as well as the Tomahawk Robotics’ (Tomahawk) Kinesis controller. This system is part of the Tomahawk ecosystem, an artificial intelligence (AI)-enhanced, open architecture, common control system primarily designed for warfighter aircraft.

“Built for ease of use, the ecosystem seamlessly connects the humanmachine team across the tactical network to enable the execution of

“WHETHER IT’S THE MANUFACTURING PROCESS, AN ENGINEERING MANAGEMENT FRAMEWORK, OR A TECHNOLOGY OR MACHINE THAT CAN BE UTILISED BY BOTH DIVISIONS, HIGHCOM GROUP ALWAYS AIMS TO ALIGN THE TWO SIDES OF THE BUSINESS WHERE PRACTICAL”

– TODD ASHURST, GROUP COO AND GENERAL MANAGER, HIGHCOM TECHNOLOGY

critical missions spanning intelligence, surveillance, and reconnaissance (ISR) to lethal effects,” explains Ashurst.

On top of this, HighCom Technology is excited about representing the Switchblade® 300 and 600 loitering munition systems on behalf of AeroVironment.

Both are man-portable systems that are combat-proven to enhance soldiers’ capabilities in precision flight control, provide greater lethality against fortified targets such as armoured vehicles and tanks, and improve the ability to track and engage moving non-line-of-sight targets.

Given that the Australian government recently publicly announced the acquisition of the Switchblade® 300 precision loitering munition system, which will be delivered in late 2024,

HighCom Technology looks forward to continuing to represent and demonstrate AeroVironment’s capabilities to the DoD.

The same commitment to the advancement of international defence capabilities is reflected by HighCom Armor, the group’s twin division, that designs, develops, tests, manufactures, and distributes state-of-the-art armour and personal protective equipment (PPE) worldwide.

With a 63,500 square foot (sqft) manufacturing and distribution facility in Columbus, Ohio, the division is wellpositioned to meet large-scale and time-sensitive global supply needs. HighCom Armor products include

Ohio’s military defence industrial complex is exceptionally well-positioned due to several key factors that make it a hub for manufacturing and distribution:

STRATEGIC LOCATION: Ohio’s central location in the US makes it a prime hub for distribution and allows military contractors to efficiently deliver products across the country, particularly given the state’s robust infrastructure network.

SKILLED WORKFORCE: Ohio’s deep-rooted manufacturing tradition offers a skilled workforce well-versed in precision manufacturing and advanced engineering – both characteristics that are essential for producing militarygrade equipment.

DIVERSE INDUSTRIAL BASE: The state’s strong presence in industries such as aerospace, automotive, and advanced materials supports the defence sector’s diverse needs, fostering innovation and collaboration.

BUSINESS-FRIENDLY ENVIRONMENT: Ohio offers a competitive tax structure, incentives for manufacturing, and a pro-business regulatory environment, making it attractive to companies looking to invest and grow.

ENERGY RESOURCES: The state’s access to affordable and reliable energy resources, including natural gas, helps maintain lower operational costs for defence manufacturers, making Ohio an economically viable location for largescale production.

GROWING ECONOMY: Ohio’s defence sector is an integral part of its overall economy, contributing significantly to both state and national security. The government’s commitment to expanding this sector ensures a steady demand for military goods and services.

armour plates, plate accessories, soft armour, helmets, shields, and carriers.

Moreover, the division’s vertically integrated approach to ballisticresistant product engineering and manufacturing enables it to maintain strict control over costs and material quality, ensuring that its products consistently exceed the missioncritical demands of end users.

Indeed, Highcom Armor delivers comprehensive capabilities for inspecting, testing, and validating every stage of the product lifecycle, from raw materials to finished goods ready for deployment.

“This rigorous process allows us to achieve a high output capacity, producing tens of thousands of pieces of protective equipment each month,” notes CEO, Sally Nordeen.

Evidently, in just 113 days, the division successfully dispatched over 120,000 pieces of body armour to the Ukrainian Ministry of Defence.

• Extensive Inventory: Gain access to an unmatched range of high-quality composite materials and processing supplies.

• Expert Support: Access to material and process technical experts to help with efficient part manufacturing.

• Reliable Service: Ensuring the right product is in the right place at the right time.

• Unique Partnerships: Experience a partnership that’s designed to achieve your desired goals.

Scan the QR code to visit our website to start your journey towards enhanced efficiency and innovation with Composites One

HighCom Technology engaged many international partners, suppliers, and freight and logistics specialists in order to deliver the substantial order in full and on time.

“Our commitment to experience, reliability, innovation, quality, and collaboration is at the core of everything we do,” she adds.

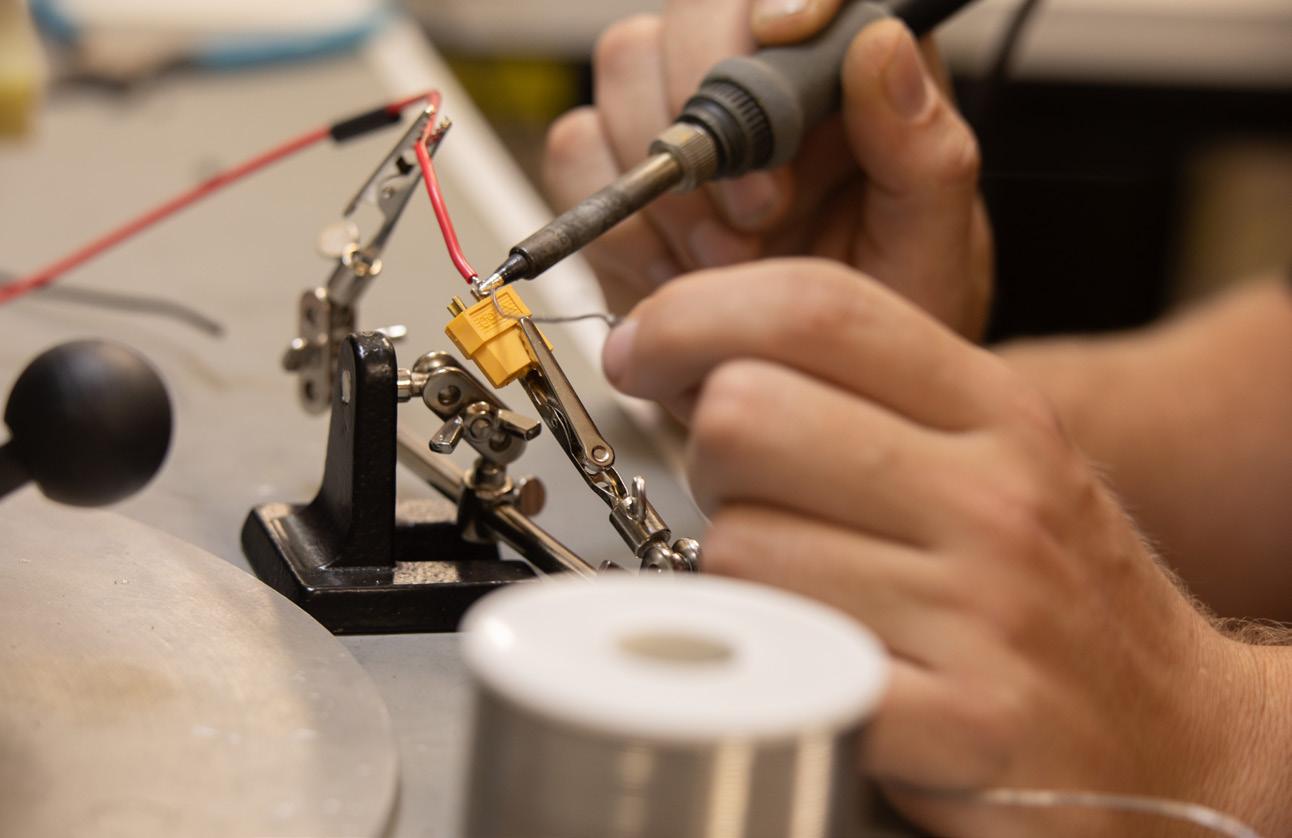

As the armour manufacturing branch of the group, the integration of technology underpins the division’s day-to-day operations.

From teams of materials scientists and engineers to product solutions produced from its XTclave™ technology, all these inputs need to be carefully managed and integrated to meet the current demand for armour products and expand the group’s market offerings.

XTclave™, in particular, is a proprietary-patented technology

Call 816-283-3330 to connect to a Composites One expert today.

“HIGHCOM TECHNOLOGY’S GOAL IS TO BE THE TRUSTED PARTNER OF CHOICE IN SUPPLYING, SUPPORTING, AND INTEGRATING CAPABILITIES FOR USE BY DEFENCE, SECURITY, AND LAW ENFORCEMENT AGENCIES”

– TODD ASHURST, GROUP COO AND GENERAL MANAGER, HIGHCOM TECHNOLOGY

that is unique in its capabilities. The system includes tooling and system processes as well as fluids and other components that have been specifically designed for the highpressure and heat application of aerospace and armour consolidation capabilities.

The hardware manufactures ultralight, thin, and strong ballistic products highly suitable for military use, government agencies, and specialised police elements.

Additionally, XTclave™ can produce

complex curves combined with ceramic and other facing materials, yielding advanced hard armour products suitable for a broader range of body types, genders, and applications, such as aviation or vehicle armour.

“XTclave™ provides an industryleading advantage in the US market due to its ability to create complex contours and improved consolidation resulting in increased strength and lighter weight products,” Nordeen emphasises.

Australia’s engineering skills and labour shortage have reached their highest level in over a decade, which makes HighCom Technology’s positive work culture even more critical for attracting and retaining highly specialised and sought-after talent.

The division’s engineering team comprises individuals with exceptional skills and capabilities in aeronautical, electrical, radio frequency, systems, and system safety engineering.

Moreover, each member of the engineering team has a diverse background in customer engagement and management roles within the Australian DoD, which compliments their current work in the design, development, and supply of technology, thus having a greater understanding of customers’ expectations.

The team’s variety of skills and backgrounds also enable HighCom Technology to lawfully import technologies and systems into Australia in a way that is compliant with the country’s work, health, and safety legislation, particularly in cases when technologies and systems are developed by overseas partners.

“Our engineers are able to address real-world problems and improve existing systems. They drive innovation and technological advancement within the company and help solve critical problems, enhancing our customer offerings,” Ashurst prides.

In November 2023, after two years of XTclave™ operations being based in the Adelaide manufacturing centre in Australia, the HighCom Group Board of Directors made the decision to close the operation and relocate all the manufacturing processes to one HighCom Armor production facility in Ohio.

“The manufacturing of products in Australia affected our ability to penetrate the world-leading US market with our unique XTclave™made products, particularly the US DoD, which was the main, underlying reason for the facility relocation,” Nordeen explains.

The XTclave™ operation was successfully relocated from Adelaide to Ohio in early 2024, where the reassembly process commenced. This included designing a new cooling system for XTclave™ to operate outside the facility and cater to the contrasting extreme climate compared to the Australian facility.

The relocation has already generated significant interest from various areas of the US military and federal law enforcement, who are willing and eager to discover what is possible with the state-of-the-art XTclave™ technology.

For example, HighCom Armor is

maintaining a cooperative research and development agreement (CRADA) with the US Army Development Command and has also been tasked with funding a ‘special threat’ development contract with the US DoD for the R&D of selected ballistic products.

“By closely working with the US military, there is an opportunity to receive ongoing R&D income

and develop products that will go to tender during 2025, allowing HighCom Technology to compete for major contracts,” she affirms.

Going forward, HighCom Group will continue to diversify both its manufacturing and technological capabilities.

Regarding the latter, HighCom Armor will modernise its capabilities by recommissioning the XTclave™ technology while diversifying other production methods to broaden its product range across multiple markets.

“Our technology makes it possible to manufacture stronger, thinner, and lighter armour solutions. With more armour in development, HighCom Armor will focus on quality and performance as it continues to advance the market with innovative solutions,” emphasises Nordeen.

Indeed, the strengthening of the division’s armour solutions is integral to the solidification of the new US-based production facility and reinforcing the bond between the two nations.

“HighCom Group’s involvement with US-based companies and involvement in integrating their offerings into the ADF and broader security environment is certainly one of our strengths, and we continue to work towards expanding this effort because of the mutual benefits that can be realised,” Ashurst emphasises.

This mutual exchange of value is further replicated by HighCom Technology’s steadfast partnership with AeroVironment, who in turn are learning valuable lessons about employing innovative systems in the Australian context to help advance product designs.

“Knowing that through its supply activities, HighCom Technology is contributing to and supporting closer operational ties between the ADF and its key allies makes us proud and demonstrates how both countries mutually benefit each other in this regard.

“We will continue to do this by working with our commercial partners for innovative ways to explore and introduce more AIC through technology leading locally sourced consumables through to parts

manufacture or assembly,” Ashurst expands.

Additionally critical to HighCom Group’s involvement in integrating US companies into the ADF, the organisation’s activities help drive and test new initiatives such as an Australia, UK, and US (AUKUS) trilateral security partnership, facilitating an export license-free environment.

“The mutual benefits of AUKUS include stimulating innovation in our product range, accelerating advances in capability and technology, and learning from one another –particularly ways to more rapidly integrate commercial technologies to solve warfighting needs,” Ashurst concludes.

Overall, HighCom Group, together with US and Australian-based partner companies, will now be able to get capabilities and equipment into the hands of allies and partner nations’ military, police, and first responders sooner than ever before.

“We will be able to continue to spearhead similar future initiatives as a member of the defence industry for outcomes mutually beneficial to Australian and US companies, as well as allies and partner nations’ militaries, security, and law enforcement agencies,” Ashurst concludes.