POWERING

ENERGY SECURITY IN BOTSWANA

DEVELOPING STABILITY

Bolstering Botswana’s economy while powering the future of energy security, Maatla Resources is changing the narrative around mining with high-quality coal and sustainable operations. CEO, Jacques Badenhorst, discusses the Mmamabula coal mine site’s activities and challenges

Writer: Rachel Carr | Project Manager: Thomas Arnold

Numerous dominant physical features adorn the African continent, and buried beneath them is a wealth of critical mineral commodities.

The rich reserves are scattered across the land, encompassing precious metals such as gold, copper, and iron ore, intermingled with diamonds, cobalt, bauxite, and one of its most significant and controversial exports — coal.

Therefore, the mission of Maatla Resources (Maatla) is to develop the coalfields of Mmamabula in Botswana as a mid-tier mining company, providing a stable energy source while simultaneously fuelling the economy. Indeed, Maatla is dedicated to providing sedimentary rock to enhance the country’s finances.

The company’s coal mining activities are aligned with responsible and ethical practices, whilst its

principles strictly adhere to in its approved environmental impact assessment (EIA).

Furthermore, it is not just interested in profit but will go the extra mile to collaborate and actively participate in using innovative coal technologies.

“Coal forms an integral part of Africa’s future energy security as it is an abundant, affordable source that needs to be utilised responsibly with existing clean power generation

technologies,” opens Jacques Badenhorst, CEO of Maatla.

“We want to distinguish ourselves from the traditional perception of coal miners as ‘dirty’, which will be evident in our downstream projects,” he adds.

Badenhorst is optimistic about Africa’s future in responsible mining, as he believes the continent’s primary focus on developing its economies is improving the lives of its citizens by lifting them out of poverty and ensuring a robust energy source.

“The industry thrives in its care for employment, infrastructure development, communication, and knowledge. It has become too easy to label coal and fossil fuels as ‘dirty’; organisations such as Future Coal advocate this principle, and Maatla fully supports any effort to change the narrative,” he posits.

A CHALLENGING PROCESS

Maatla was founded in 2016 after acquiring 85 percent of a prospecting

“COAL FORMS AN INTEGRAL PART OF AFRICA’S FUTURE ENERGY SECURITY AS IT IS AN ABUNDANT, AFFORDABLE SOURCE THAT NEEDS TO BE UTILISED RESPONSIBLY WITH EXISTING CLEAN POWER GENERATION TECHNOLOGIES”

– JACQUES BADENHORST, CEO, MAATLA RESOURCES

license in the final part of a second renewal that was about to expire.

The original licence owners will remain 15 percent shareholders on a free-carry principle within the company until the Mmamabula coal mine is established and production commences.

The majority shareholders and development team have extensive experience in the mining industry, having developed numerous projects.

Thus, they have systematically used their knowledge and funds to progress the site to its current state.

Until 2018, the completed processes included a Competent Persons Report (CPR), EIA approval, surface rights acquisition, feasibility study, and mining license application.

“While developing the coal project, we encountered several challenges, such as securing financing and dealing with the prevailing negative

sentiment towards fossil fuels.

“We explored different funding options, including original equipment manufacturers (OEMs), mining contractors, and pre-offtake funding from commodity traders. However, we were unable to find anyone willing to take on the equity at the time,” Badenhorst reveals.

The delay in approving and issuing the mining license under Section 39 of Botswana’s Mines and Minerals Act was due to the requirement of a 1:3 equity-to-debt ratio on the project implementation capital expenditure (CapEx).

This, combined with the challenges posed by the COVID-19 pandemic, made the process difficult. However, despite these obstacles, the team remained committed to the project and its principles.

“In the pursuit of fairness, a South African Mineral Asset Valuation (SAMVAL) was conducted, leading Maatla to secure its current majority shareholder, HMS Bergbau AG. As a result, in 2021, an appropriate equity partner and commodity trader with a global presence formed part of the team and our mining license approval,” reports Badenhorst.

THE MAATLA MINING MAP

Maatla’s mining license encompasses three areas - A, B, and C - with the first

area being the initial development site. With construction activities underway, the company is on track to begin its initial production in Q2 2025.

“Area A is conveniently situated near the village of Mookane and 20 kilometres (km) from the A1 main road corridor between Gaborone and Francis Town. Area B is near the village of Mpashalala, and Area C is close to Dovedale village and 30km from the Stockport border post,” Badenhorst outlines.

Furthermore, Mookane Coal, a company registered in Botswana, oversees construction and mine development activities and is a shareholder in Maatla.

“Mookane Coal uses Botswana citizen-owned companies as subcontractors to perform a significant portion of the engineering, procurement, and construction management (EPCM) work.

“We have appointed Trollope Mining as the contractor, and the company has a site established with a small interim team to commence with the box-cut and supply suitable material for backfilling into the processing plant area as well as the run-of-mine (ROM) ramp and wing wall.”

Throughout the construction phase, the number of individuals on-site will fluctuate between 50 and 150.

EPS-Environmental & Process Solutions

Engineering solutions for Minerals, Gas Cleaning, Energy, and Power Generation

Briefly introduce us to EPS.

EPS-Environmental & Process Solutions (EPS): The company was first registered as EPS cc in August 2005 before converting in 2008 to a company (Pty) Ltd.

The company’s each have more than 30 years of experience in the pyrometallurgical, environmental, petrochemical, and energy industries with a similar combined experience of 30 years for our senior engineers.

EPS consists of a team of chemical and mechanical engineers alongside draughtsmen and support staff based in Pretoria, South Africa. We have longstanding associations with electrical, instrumentation, civil and structural, engineers for complete design solutions.

Having an agile professional engineering team allows us to provide personalised services that cater to each client’s unique needs and preferences. Unlike larger organisations, where processes might be standardised and more

complex, we can adapt swiftly and customise our offerings. Our close-knit team fosters direct communication, ensuring we truly understand our clients’ requirements. We pride ourselves on building strong relationships and delivering quality tailored solutions.

EPS brings value to our customers in a wide range of business sectors, including minerals and metals, environmental, power generation, waste-toenergy, and gas treatment. Our engineering solutions encompass

a comprehensive range of services fitted to meet our clients’ specific needs.

EPS’ core competencies include:

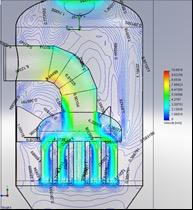

• Specialist consultancy, e.g., CFD modelling, gas flow modelling, root cause analysis, and fault finding.

• Compliance assessments, e.g., hazardous area classification, HAZOP studies, major hazardous installation assessments (MHI) coordination, and pressure equipment regulations.

• Due diligence review.

• Desktop, concept, and bankable feasibility studies.

• Project development support to financial close.

• Project financing.

Some of EPS’ previous projects that

ACP heat-to-power project, which has received numerous awards for its innovative heat-to-power approach, is still in operation today producing up to five megawatts (MW) of electricity from thermal heat. The project has generated approximately 50,000 MWh since its inception. The project was a Hall of Fame Winner at the SA Innovation Awards 2015, African Energy Innovation Winner at the African Energy Awards 2016 and SANEDI RECORD/ RERE COMMERCIAL APPLICATION AWARD 2016.

• Project execution as owner’s project manager and owner’s engineer.

• EPCM and lump sum turnkey projects.

Here’s how we add value:

• Unique solutions: Every project is unique, and we thrive on innovation. Whether it’s solving complex challenges or designing custom solutions, we pride ourselves on creativity and practicality.

• Feasibility studies: We conduct feasibility studies from conceptual up to bankable studies, considering technical, economic, and environmental aspects. Our goal is to determine project viability, identify risks, and propose optimal solutions with bankable signoff.

• Detail engineering designs: Our team can provide basic engineering designs up to complete detailed engineering packages in line with industry standards. Our engineering deliverables include process flow diagrams, piping and instrumentation diagrams, specifications, and detailed engineering drawings up to a complete issue-for-construction (IFC) package.

EPS’s expertise includes but are not limited to:

• Pyrometallurgical industries: EPS’ roots started in the pyrometallurgy industry and include ferrochrome, ferromanganese, steel, and platinum. Our experience ranges from materials handling, sinter

that we take immense pride in include:

SA Calcium Carbide power project, where EPS completed the process and detailed engineering for the 6 MW off-gas handling system and cogeneration plant for SACC. EPS further provided procurement and installation support alongside commissioning services. The SACC project was awarded the Most Innovative African Co-Generation Project (Africa Energy Awards).

Flashback arrestor CFD simulation and 3D model

The IFM Gas to Power Project was designed and constructed to produce up to 17 MW of electricity.

plants, and smelters to gas cleaning.

• Speciality gas: With our gas cleaning background, we have completed a diverse range of gas studies and projects, from gas cleaning applications for environmental regulatory requirements to applications

Zamanco Expansion Project

EPS completed a bankable feasibility study for a Mn smelter in Zambia.

for combustible gases such as carbon monoxide and hydrogen.

• Power generation: We have a strong focus on power generation and have completed various studies and projects relating to Thermal HarvestingTM heat-to-power, gas-to-power,

Our clients include junior companies up to large companies such as Maatla Resources, Anglo Platinum, SamancorCr, and BHP Billiton (South32).

What, for you, differentiates EPS from the competition?

EPS: We have a track record for creating innovative solutions for the unique challenges that clients face, as demonstrated through our award-winning engineering and projects. We have existing relationships with most stakeholders and extensive knowledge of the core processing operations alongside gas handling circuits.

EPS is technology agnostic and selects the technologies and equipment packages that best fit the application and our clients’ requirements. This unique perspective and experience ensures our clients receive value for money on difficult solutions. Our commitment to direct interaction and personalised service creates a unique experience for our clients, fostering trust and long-lasting relationships.

Can you tell us about EPS’ mission and vision?

2 MVA DC Arc Furnace –Brazil

EPS designed, supplied, and commissioned a 2 MVA DC Arc Furnace (FeTi, FeMo, FeCr), including electrode arm and mast, copper anode, power supply and rectifier, bag filter, and related services equipment.

BHP Billiton (South32) Metalloys

EPS completed various concept studies related to Thermal HarvestingTM at the Meyerton West and South Plants, as well as the reduction of emissions and greenhouse gasses for the whole complex.

EPS: We strive to provide an optimum process solution to our clients through innovative engineering and technology applications. The EPS team are pioneers in establishing solutions to reduce carbon footprint, add value to waste streams, and power and energy consumption.

Could you elaborate on your partnership with Maatla Resources? How do the two companies mutually benefit each other, and what complementary strengths do you bring?

EPS: We have maintained a longstanding partnership with Maatla Resources, offering engineering studies and continuous support. Our collaborative efforts aim to contribute to Maatla’s success in various endeavours.

EPS and Maatla Resources are collaborating on an exciting upcoming project: a heat-to-power initiative. This innovative project aims to utilise the heat generated from Maatla’s charring plant for power generation. By harnessing this thermal energy, it can contribute to sustainable, efficient, and cost-effective electricity production.

Khumani Expansion Project

EPS completed a conceptual study and EPCM costing for a 20 million tpa iron ore crushing and screening plant.

Thermal Beneficiation Plant

precious metals refinery

EPS assisted a precious metals refinery (PMR) in implementing a thermal beneficiation plant thermally treat organic byproducts and recycle PGMs back into the process, complementing a previous project that eliminated soot emissions and reduced dioxin furan formation.

What projects or projects in the pipeline that you would like to highlight?

EPS: We are actively engaged in diverse projects, spanning power generation – waste to energy, gas cleaning, hydrogen production, and iron ore processing. However, our anticipation is highest for the upcoming collaboration with Maatla, where we will harness waste energy to generate electricity.

Ferrochrome Smelter Cogeneration Plant

Looking ahead, what are EPS’ key priorities?

EPS: Stay with our core

EPS plans to stay committed to its core, which includes flexibility, specialised engineering, and ethical and technical competence.

Life cycle optimisation

Improving life cycle and environmental footprints for our clients on their carbon emissions, legacy wastes, and energy areas of their business. This will happen through waste minimisation and dump and airspace impact reduction for mining and industrial waste, domestic waste, or coal fines by converting these to high-value commodities with economical, power generation, activated carbon, or high energy fuel value.

Focus

on waste-to-energy

With EPS’ references in this sector, it would be difficult not to focus on this for the next five to 10 years, including thermal waste heat, waste gas, MSW, biomass to landfill and liquid wastes to electrical power, liquid fuels, hydrogen, and carbon sequestration in the future.

Specialised energy sources

Within this market, EPS has

EPS completed the EPCM for the demonstration plant gas conditioning unit as input to a cogeneration plant.

Specialty gas conditioning and cleaning

EPS successfully completed the design, installation, and commissioning of a wet scrubber at Lanxess capable of removing Cr6 and recovering the chrome as a saleable byproduct.

done design engineering and construction of plant processing and producing, syngas, carbon monoxide, hydrogen, and electrical power in the mining and minerals space. This includes energyintensive commodities, with our next goal consisting of ammonia, LNG/CNG, and green fuels.

Partnerships

As a small company, EPS understands the value of partnerships. Examples include Maatla as a power plant development partner, Vuselela Energy as an operational partner, and Environmental and Carbon Trading Solutions (ECTS) as a gas partner. These partnerships provide EPS with the ability to develop, design, execute, and operate small facilities in the industrial, mining, and minerals space.

Specialised

equipment design and heavy-duty table feeder

Specialist in-house design for unique equipment pieces such as table feeder for wet chromite suitable for heavy fines up to 90tph. Various units are supplied to ferrochrome producers.

DC Smelter Cogeneration Plant

EPS completed the process and detailed engineering for the pilot plant gas conditioning as input to a cogeneration plant. EPS further provided procurement and installation support as well as commissioning services.

COMPLETED CONSTRUCTION ACTIVITIES

• The new installation of a 22km, 33 kilovolt ampere (kVA) powerline from the Sererome sub-station to the mining site

• A temporary accommodation camp

• Processing plant civil work

• 90 percent completion of the processing plant fabrication

• Motor Control Centre (MCC) fabrication

• A 4.5km access road from the new Dibete – Martins Drift tarred road

• Bush clearing of all infrastructure areas

• Water supply boreholes

• Mining area fencing

• Wing wall and ROM ramp

During the first six months of planned ramp-up activities, the workforce will exceed 270; in a steady-state operational phase, this number will rise to over 420.

“As part of the preparations for construction, Maatla completed in-fill drilling activities in Area A. This resulted in the discovery of additional measured coal resources and confirmed specific qualities of the coal, such as low ash and phosphorus, which will yield a premium in certain markets. Additionally, the D1 and M2 seams planned to be mined also exhibit charring characteristics,” enlightens Badenhorst.

QUALITY AND PEOPLE FIRST

The company used data from its exploration activities to ensure that specific markets are targeted, and reliable and consistent-quality coal will be supplied as a ‘Maatla-branded product’.

“Our commitment to providing a first-rate product is evident in

“OUR COMMITMENT TO PROVIDING A FIRST-RATE PRODUCT IS EVIDENT IN OUR APPROACH TO THE DESIGN OF OUR PROCESSING PLANT AND OUR VERSATILITY IN DELIVERING DIFFERENT SPECIFICATIONS AND SIZING FOR VARIOUS CLIENTS”

– JACQUES BADENHORST, CEO, MAATLA RESOURCES

our approach to the design of our processing plant and our versatility in delivering different specifications and sizing for various clients.

“This impacted planning which areas within the opencast mines and coal seams should be targeted first to ensure quality is achieved at the highest possible yield and lowest mining cost,” Badenhorst explains.

The development strategy is focused on distinguishing ‘Maatlabranded’ coal by concentrating on

quality advantages such as low ash and low phosphorus products.

“The charring characteristics of our coal will allow us to collaborate with a local company for upwards of 20 to 25 percent of Maatla’s washed sized coal products destined for the charring facility, partaking in a symbiotic relationship where we enjoy a sustainable local market for some of its sized coal production.

“In addition, the company will benefit from secure green power that

sethren@outlook.com

mthebe@sethren.co.bw admin@sethren.co.bw

will be generated from the excess heat from the charring process in an Organic Rankine Cycle (ORC) plant,” he details.

Not only is Maatla dedicated to producing quality coal, but the company will also create more than 420 permanent job opportunities for people in the local communities of Mookane, Mpashalala, Dibete, and Dovedale in the future.

This will lead to the development of primary and secondary industries in the area, resulting in significant employment prospects.

“This is complemented by our neighbour, Jindal Botswana, who is developing a 300 megawatt (MW) coal-based power station that will also create more than 1,000 permanent jobs,” Badenhorst divulges.

The impact of coal mining on Botswana’s communities will be significant, and Maatla is looking forward to witnessing the positive effects.

“Unfortunately, the Western world controls the narrative through banking and financing systems, making securing funding for new coal projects difficult.

Unlike traditional bankers and financiers, Maatla considers environmental, social, and governance (ESG) aspects.

“We strongly believe that coal will continue to play a vital role in the energy and industrial sectors. Developing a project in this area will benefit the communities around Maatla and contribute to Botswana’s Vision 2036. This will help alleviate poverty, transform the country into a knowledge-based economy, and support its growth targets as a developing nation,” he prides.

Moreover, the company’s pipeline of downstream projects will undoubtedly strengthen the business case for the Mmamabula coal mine and further contribute to sustainable employment in the area.

A SUSTAINABLE SUPPLY

The Earth is currently in the Anthropocene age because humans have become the most influential species, causing significant global warming and other changes to the land.

Therefore, responsible mining practices are essential to Maatla, whilst environmental monitoring is necessary for any experienced mining company to ensure minimal impact.

However, Badenhorst thinks the narrative created by the developed world that coal and fossil fuels are ‘dirty’ and should be eradicated at all costs is extremely dangerous.

With this in mind, Maatla aims to grow into a responsible mid-tier coal and energy company that is strongly focused on not only being recognised as a coal miner but also as an innovator, utilising existing technology and participating in downstream projects that will propel sustainability, echoing Botswana’s export-driven and diversified mining

economy.

“They are playing with lives as people are less impoverished than they were a century ago, and the reason for this is due to the energy that was used to develop countries, build infrastructure, and create healthy societies. This was achieved on the back of affordable and abundant energy sources such as coal,” he voices.

Badenhorst believes that eradicating coal or fossil fuels as a reliable and cost-effective base load source of energy and replacing it with highly subsidised, expensive solar and wind power, without even considering their true environmental impact and carbon footprint, will increase poverty in developing countries.

“As the global population continues to grow and more people require electricity, there is a greater need for alternative energy sources. The idea that we should completely transition away from fossil fuels and replace

MINING OUTLOOK: WHAT SPECIALIST SKILLSET DOES

YOUR TEAM POSSESS THAT MAKES IT SO SUCCESSFUL?

Jacques Badenhorst, CEO: “Our team is exceptional. We are blessed with a strong, experienced team that has interacted, worked together, or been business partners for over 20 years. For example, three development team members have managed junior listed mining entities.

“Moreover, we have an extremely solid in-house design, engineering, fabrication, and construction team with over 30 years of project management experience, complemented by a robust financial control and entrepreneurial team.

“We lacked the logistical and marketing skillset on the team, but those particular capabilities were brought on board by HMS Bergbau AG. Although we would be marketing our initial production from Area A into the regional-sized coal market, there are plans for tap into the worldwide network and experience of our majority equity partner with future production from our Area C secondary mine.”

them with renewable power is not a practical model.

“You need a diverse energy mix in the future, incorporating new generation capacity such as nuclear, solar, wind, hydro, and clean coal technology, rather than simply replacing existing fossil fuels with renewables,” Badenhorst expresses.

PLANNING AHEAD

Maatla is currently collaborating with technology partners and strategic companies on two downstream projects.

These will enhance the company’s sustainability, carbon footprint, competitiveness, shareholder returns, and social impact in Botswana.

“One project is at the feasibility level, while the other is at the prefeasibility level. We also understand that logistics play a crucial role in getting the product to market, and we need to find innovative solutions to ensure our clients receive their branded product on time and at a competitive price,” insights Badenhorst.

Additionally, the company has been instrumental in collaborating with other stakeholders over the past few years to advocate for the Mmamabula to Lephalale rail link.

This will provide freight owners in Botswana with a logistical solution for accessing both the sea-borne export and regional markets. The proposed railway will pass through Maatla’s mining license area and cross the Limpopo River into South Africa.

“The realisation of the rail link will enable Maatla to develop our secondary mine earlier than anticipated. This will create obvious employment, export, and supply chain opportunities for local businesses.”

Moreover, construction activities are progressing well for Maatla, and the company is confident it will begin to ramp-up production in Q2 2025.

“We will have day shift operations for the first six months of production to ensure sufficient pit room in the mine and facilitate personnel training. Our focus is on hiring from local communities before transitioning to a 24/7 operation.

“We intend to produce over 50,000 tonnes per month (tpm) of saleable coal product during the initial six months of operation, before increasing to to over 100,000 tpm. The processing plant will be operated at 80 percent of its nameplate capacity within a 24/7 operational cycle, allowing for additional tonnages to be processed and minimising the impact of unplanned stoppages,” Badenhorst concludes.

As Maatla’s plans continue to unfold, driven by its unwavering dedication to producing high-grade coal and its ambitious development goals to ensure a stable energy supply for the future, it will be a rewarding story of progress for both the company and Botswana.

info@maatlaresources.com

www.maatlaresources.com