INNOVATIVE AND SUSTAINABLE SOLUTIONS ACROSS EUROPE, THE MIDDLE EAST, AND AFRICA

Across Europe, the Middle East, and Africa (EMEA), Orica is at the forefront of innovation, technology, and sustainability in the mining and infrastructure sectors. Victor Morales, Vice President of EMEA Mining, digs deep into developments across the region

Writer: Jack Salter | Project Manager: Eddie Clinton

The story of one of the world’s leading mining and infrastructure solutions providers began more than 150 years ago.

Founded in June 1874 as a supplier of explosives to the Victorian goldfields in Australia, Orica proudly

celebrated its sesquicentenary last year, an exciting milestone for the company.

This extensive heritage is a testament to Orica’s resilience, adaptability, and ability to thrive in a constantly evolving business landscape.

Its 150-year journey has also been one of transformation, as the company originally started out as Jones, Scott and Co. before it was bought by Nobel.

The organisation then went on to merge with Brunner Mond and Co., the United Alkali Company, and the British

Dyestuffs Corporation to form Imperial Chemical Industries Plc (ICI Plc).

In 1928, Imperial Chemical Industries of Australia and New Zealand (ICI ANZ) was incorporated to acquire and coordinate the Australasian interests of ICI Plc, later becoming ICI Australia in 1971.

When ICI Plc divested its major shareholding in ICI Australia in 1997, a new independent Australasian company was formed, known since February 1998 as Orica.

The acquisition of ICI Plc’s global explosives interests began Orica’s transformation into a global business,

one that has maintained its proud traditions of leadership, innovation, quality, and safety.

Orica has also grown to become one of the leading publicly-owned companies listed on the Australian Stock Exchange (ASX) over the course of 150 years.

Throughout 2024, the business recognised its landmark anniversary together with its people, partners, customers, and communities globally whilst taking the opportunity to reflect on its proud history and look towards the bright future of this iconic organisation.

Today, Orica employs a community of more than 12,500 engineers, scientists, technologists, operators, business specialists, and on-site crew around the world, supporting customers in surface and underground mines, quarries, construction, and oil and gas operations.

The business operates in over 100 countries worldwide, including numerous sites across the EMEA region, an extensive area that is incredibly dynamic and diverse with

unique cultures and a wide range of mining commodities and segments.

The company’s commitment to excellence in the EMEA mining sector is unwavering as it is a key region within Orica’s global operations, with a diverse talent pool of approximately 2,000 staff members dedicated to delivering value and the best customer experience.

“We serve around 1,500 customers, ranging from large mining corporations to small and mediumsized enterprises (SMEs) in quarrying, construction, and infrastructure,” outlines Victor Morales, Vice President of EMEA Mining at Orica.

“What makes EMEA particularly inspiring is the opportunity to collaborate with talented individuals from across this vast and multicultural region, combining diversity, innovation, and meaningful contributions to the mining industry’s future.”

Orica’s solutions extend beyond

blasting and integrate seamlessly into the entire value chain, from geological exploration and blast design to ore processing and addressing geotechnical challenges.

This comprehensive approach enables the company to support mining and infrastructure projects with innovative technologies and tailored services that drive efficiency and sustainability.

“Our talented teams thrive in challenging environments, developing and implementing unique solutions that address the entire value chain,” Morales acclaims.

Equally important is Orica’s dedication to creating value not only for customers, but also for the communities where it operates.

This holistic approach, powered by local expertise and cuttingedge technologies, reinforces the company’s position in EMEA as a global leader in mining and infrastructure solutions.

Sustainability continues to be a core focus of the industry as organisations work to decarbonise their operations and supply chains.

Areas such as Africa, Central Asia, the Middle East, and Southern and Eastern Europe are growing fast and rapidly evolving to play a pivotal role in supporting the global energy transition.

Demand for copper, nickel, and other future-facing commodities remains strong as the energy transition gains momentum. However, with the push towards a lower-carbon economy, there is expected to be a decline in thermal coal, which is crucial for meeting the energy needs of developing countries.

Sustainability is a key strategic component and integral to operations in EMEA and globally at Orica, whose purpose is to sustainably mobilise the earth’s resources and ambition is to achieve net zero emissions by 2050.

“My interest in mining grew as I recognised its critical role in supporting global sustainability, providing essential raw materials for the energy transition and critical minerals that are vital for modern society,” reflects Morales.

The company delivers smart, safe, and sustainable solutions for customers working in complex operating environments, playing its part in addressing climate challenges and supporting local communities.

Championing a more environmentally-friendly industry, responsibly managing its impact on society, and supporting the fair transition to a net zero economy is fundamental to Orica’s decisionmaking and the way it runs the business.

Indeed, sustainability is embedded in the company’s policies, business strategy, and practices as it pursues new opportunities, delivers on its commitments, and improves its performance.

Victor Morales, Vice President of EMEA Mining:

“In response to recent global geopolitical challenges, Orica has focused on building robust and resilient supply chains to remain a reliable partner for our customers.

“We have successfully navigated disruptions in the supply of critical raw materials, ensuring our operations continue seamlessly across EMEA and globally. Our strong relationships with key suppliers, freight forwarders, and logistics partners play a crucial role in maintaining the reliability of our services.

“This resilience, combined with our strategic partnerships, is a key differentiator that allows us to deliver consistent value to our customers, even in challenging environments.”

“ORICA IS SET APART BY ITS PEOPLE, COMMITMENT TO INNOVATION, AND ADVANCED TECHNOLOGIES, ALL FOCUSED ON DELIVERING EXCEPTIONAL VALUE TO CUSTOMERS AND STAKEHOLDERS”

– VICTOR MORALES, VICE PRESIDENT OF EMEA MINING, ORICA

Guided by its sustainability strategy, which is informed by the UN’s Sustainable Development Goals (SDGs), Orica collaborates with customers and other stakeholders to find solutions to the industry’s biggest challenges and move together towards a lower-carbon future.

Along with proactively engaging with a diverse range of stakeholders in EMEA and around the world, Orica undertakes periodic materiality assessments to understand the topics that matter most to them and inform its strategy, public sustainability targets, and external reporting.

The company is focused on mobilising the materials, metals, and minerals required to help the global economy grow and transition to net zero emissions, advancing technology and innovation across the value chain and accelerating its decarbonisation commitments.

Orica is committed to securing the supply of critical raw materials for the mining industry, with the safe and reliable supply of ammonium nitrate (AN) another key component of its offering.

“As one of the world’s leading producers of AN for technical use, we operate five production facilities worldwide,” confirms Morales.

“We are also one of the main buyers of AN for technical use, especially for our operations in EMEA and Latin America, where we have long-term agreements to secure steady supply to our operations.”

In EMEA, Orica recently partnered with Fertiberia to execute the first blast using low-carbon technical ammonium nitrate (TAN) in June 2024 at the Canteras de Santullán quarry in Spain.

This innovative product, made with renewable hydrogen, marks a milestone in reducing the carbon footprint of blasting and mining operations, providing a more sustainable solution compared to conventional TAN.

The blast signifies a further step

towards the decarbonisation of mining, a crucial sector for the energy transition due to its role in extracting copper and other essential industrial minerals, as it marked the first industrial-scale use of a sustainable, low-carbon explosive product.

Alongside AN, Orica also invests in the production of various essential materials such as sodium cyanide and other critical resources.

“This ongoing investment strategy ensures we can meet the growing demands of our customers whilst supporting the industry’s long-term sustainability,” Morales emphasises.

The new mining and infrastructure projects driving the EMEA region evidently have a great focus on sustainability and efficiency, supported by the introduction of forward-thinking technologies.

“We continue to innovate with groundbreaking solutions designed to enhance efficiency, safety, and sustainability in mining operations,” Morales states.

Orica has long been at the forefront of innovation in mining and infrastructure, helping to shape the industry through leading digital and automated technologies to create safer and more productive outcomes for customers.

Continuous innovation led by talented people and fuelled by collaboration with customers and industry and research partners to solve shared challenges has been at the heart of the company’s success over the past 150 years.

Innovation at Orica is defined by its pioneering spirit and key to addressing the significant

“WHAT MAKES EMEA PARTICULARLY INSPIRING IS THE OPPORTUNITY TO COLLABORATE WITH TALENTED INDIVIDUALS FROM ACROSS THIS VAST AND MULTICULTURAL REGION, COMBINING DIVERSITY, INNOVATION, AND MEANINGFUL CONTRIBUTIONS TO THE MINING INDUSTRY’S FUTURE”

– VICTOR MORALES, VICE PRESIDENT OF EMEA MINING, ORICA

global challenges faced by the mining industry, including sustainability, safety, efficiency, resource depletion, and social responsibility.

Finding ways to address these is therefore essential for the sustainable growth and development of the industry.

Committed to continuous

technological investment, the company’s vision is to transform how drilling and blasting are used to unlock mining value.

“Our innovations reflect Orica’s dedication to providing cutting-edge, value-driven solutions for the evolving needs of the mining industry,” prides Morales.

Founded in 2006, SAS Logistics has become one of Tanzania’s leading logistics and transport companies, o ering innovative and reliable solutions. Initially, the company started with only 9 trucks, branching out from parent company, S.A. Said & Co. Ltd, which was established in the 1970s by the late Seif Abdallah Said. The company’s name, SAS Logistics, honours his legacy in the transport industry.

SAS Logistics’ success story is rooted in the vision of its CEO, Mr. Salim Seif Elbusaidy, the eldest son of Seif Abdallah Said. With wisdom and a brilliant strategy, Mr. Elbusaidy saw the opportunity to build a sustainable company that would o er top-tier logistics and transport services. Under his leadership, SAS Logistics has grown from a small operation to one of the most respected logistics providers in the country, now owning a eet of 250 trucks with capacities ranging from 3 to 30 tonnes.

At the core of SAS Logistics is its guiding principle, ‘Serving Through Safety ’ The company prioritises safety in all aspects of its operations, from the transportation of goods to the maintenance of its eet. Whether transporting dangerous goods such as ammonium nitrate or providing general cargo transport, SAS Logistics ensures that all operations are executed with the highest safety standards. This commitment is also re ected in the continuous training of its drivers and technicians to adhere to safety protocols.

To meet the country’s growing

demand for logistics services, SAS Logistics has strategically positioned its warehouse facilities in key locations across Tanzania. In Kahama, located near some of the country’s richest mining areas, the warehouse serves as a critical hub for materials and equipment used in the mining sector. This location allows the company to efficiently support the mining industry by providing timely and secure storage and transportation solutions.

Tanga, another key port city, is home to a second SAS Logistics warehouse. Situated close to important trade routes, the Tanga warehouse supports both import and export activities, further enhancing the company’s ability to

o er exible logistics solutions for various industries, including mining and manufacturing.

These strategically located warehouses allow SAS Logistics to o er comprehensive logistics solutions tailored to the needs of its clients. Whether it’s transporting goods to and from the mining regions or facilitating the smooth ow of trade through the ports, the company’s logistics network plays a crucial role in supporting Tanzania’s economy. Over the years, SAS Logistics has expanded its operations beyond transport to o er a range of services, including customs clearance, freight forwarding, and the specialised handling of dangerous goods. The company’s growth has been driven by its

customer satisfaction and its ability to adapt to the changing needs of the logistics industry. SAS Logistics continues to invest in modern technology and eet management systems to enhance e ciency and maintain the highest safety standards.

SAS Logistics is also committed to sustainability. The company imple ments green logistics practices to reduce its environmental impact, such as optimising routes to reduce fuel consumption and adopting eco-friendly packaging materials. These e orts align with global sustainability goals whilst maintaining operational e ciency.

In addition to its environmental initiatives, SAS Logistics embraces innovation by integrating advanced eet management technologies and real-time tracking systems. This enables the company to provide clients with up-to-date information about their shipments, ensuring transparency and improving the overall customer experience.

The company’s dedication to safety extends to its handling of hazardous materials, such as ammonium nitrate, where stringent safety protocols and industry regulations are strictly followed. SAS Logistics’ fleet is equipped with the latest safety features, and its drivers are welltrained to manage hazardous goods safely.

From industry, a veteranled specialize transport,

its roots in 2006, SAS Logistics has become a leader in Tanzania’s logistics industry, setting the standard for safe, efficient, and customer-centric services. With veteranled team boasting over 65 years of combined experience, we specialize in handling complex logistics needs, including dangerous goods transport, freight forwarding, and customized warehousing solutions. Why Partner SAS Logistics?

Industry Expertise: Decades of experience across diverse industries, including mining and energy, to meet unique logistical needs with precision. End-to-End Services: Comprehensive solutions from road, air, and sea freight to specialized warehousing and customs clearance, o ering seamless support every step of the way.

Safety Commitment: Certi ed to handle hazardous materials with rigorous safety protocols, ensuring secure and compliant transportation.

Strategic Locations: Facilities in Dar es Salaam, Kahama, and Tanga for optimal regional market access, streamlining logistics throughout East Africa.

Competitive Pricing: Delivering high-quality service at competitive rates to maximize value for your logistics investment.

Timely Delivery: Committed to on-time delivery, keeping your supply chain moving e ciently and reliably.

heart of everything we do. The company has built a strong reputation for reliability and exibility, o ering customised logistics solutions for businesses of all sizes. Whether working with multinational corporations or smaller local enterprises, SAS Logistics takes the time to understand the unique needs of each client and tailors its services to exceed their expectations. With a strong presence at key border points in Tanzania and neighbouring countries like Zambia, SAS Logistics facilitates smooth cross-border transportation and ensures compliance with international shipping regulations. This expertise in customs procedures and regulations helps eliminate delays and ensures e cient delivery across borders. SAS Logistics’ commitment to safety, sustainability, and customer service has earned it a reputation as a reliable partner for businesses across Tanzania. As the company continues to grow, it remains focused on providing innovative, cost-e ective logistics solutions that meet the evolving needs of the industry. Guided by the legacy of Seif Abdallah Said and the leadership of Mr. Salim Seif Elbusaidy, SAS Logistics is wellpositioned for a future of continued success. With a eet of modern vehicles, cutting-edge technology, and strategically located facilities, SAS Logistics is ready to tackle the logistics challenges of tomorrow whilst staying true to its commitment to serving through safety.

Join the many satisfied clients who rely on us for secure and timely delivery. Discover the SAS Logistics advantage—where your business goals drive our commitment to excellence.

Contact Us: +255 767 841 840 Email: info@sas-logistics.co.tz Visit Our Website: sas-logistics.co.tz

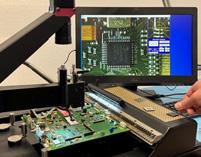

In EMEA, the company has technology centres located in Gyttorp, Sweden and Troisdorf, Germany that specialise in nonelectric (NE) initiation and electronic blasting systems (EBS), respectively.

These two regional sites complement Orica’s global technology centres in Australia, the US, Canada, and Singapore, as well as its Centre for Innovation and Collaboration in Chile.

Orica is in a unique position to leverage its expertise in technology to create solutions that deliver positive socioeconomic and environmental contributions to customers and

EUROPE – Belgium, Bulgaria, Estonia, Finland, Germany, Norway, Portugal, Spain, Sweden, UK

MIDDLE EAST – United Arab Emirates (UAE)

AFRICA – Democratic Republic of the Congo (DRC), Ghana, Mozambique, Namibia, Senegal, South Africa, Tanzania, Zambia

communities around the world through its business activities.

For example, the company is reducing environmental footprints by offering more sustainable solutions such as Exel™ Neo, which was launched in September 2023 and represents another step towards the company’s purpose.

The world’s first series of leadfree NE detonators, Exel™ Neo uses unique, proven non-primary explosives detonator (NPED) technology for the safe and reliable initiation of explosives.

“Exel™ Neo offers reliable and robust lead-free detonators for operations in challenging conditions,” Morales tells us.

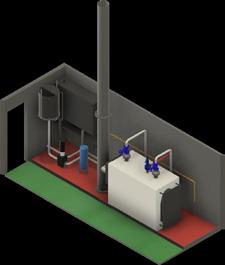

For over a decade, Combustion Technology has been the trusted supplier for Orica Africa, delivering cutting-edge mobile Steam and Water Heating Systems designed specifically for the manufacturing of explosives and blasting systems. This long-standing partnership highlights Combustion Technology’s expertise in providing reliable, energy-efficient, and innovative solutions tailored to meet the unique demands of Africa’s dynamic mining sector.

With offices in Cape Town and Johannesburg, as well as an extensive dealer network, Combustion Technology services clients across Africa and the Indian Ocean islands. With over 38 years of experience, the company’s world-class products and technical expertise have driven its consistent growth and leadership in the mining sector.

The partnership with Orica Africa exemplifies Combustion Technology’s commitment to sustainability and innovation. By providing state-of-theart systems that enable efficient on-site manufacturing of explosives, the company helps mining clients mobilise the earth’s resources responsibly.

• Proven Expertise: Decades of experience in the heating and combustion industry.

• Custom Solutions: Tailored systems designed for rugged mining environments.

• Comprehensive Support: A dedicated team offering 24/7 service.

• Global Brands: Exclusive partnerships with world-class manufacturers.

Combustion Technology takes pride in producing containerised hot water boiler systems that are not only reliable but also optimised for quick and seamless on-site deployment. Every system is designed to be “plug and play” and pre-tested for hassle-free commissioning. These features are critical for mining operations, where efficiency and uptime are paramount.

The ability to overcome harsh environmental conditions and operate in abrasive site settings has been central to Combustion Technology’s success. Through continuous innovation and customization, the company ensures its systems meet the highest standards of performance, durability, and sustainability.

Each containerised unit includes:

• A boiler and burner

• Fuel and water tanks

• Electrical panel

• Pump and pipework

This user-friendly Water Treatment System design takes approximately one month to complete and is fully transportable for easy shipment to site locations.

A critical factor in Combustion Technology’s success is its dedicated team of engineers and project experts who provide 24/7 support to mining sites across Africa. This hands-on approach guarantees smooth operations and builds long-term client trust.

Combustion Technology proudly represents leading global brands, including:

• Autoflame Combustion Management Systems

• Limpsfield Burners

• Riello Burners

• Unical Boilers

• I.VAR Industry Boilers

• Cannon Bono Energia Industrial Boilers

These premium products form the foundation of Combustion Technology’s solutions, enabling the company to deliver professional service. From pre-sales energy analysis and installations to after-sales service and spare parts support, the company ensures clients receive a professional and seamless experience.

• Geographical Reach: Operations spanning Africa and beyond.

• Effortless Setup: Plug-and-play systems for minimal disruption.

Combustion Technology remains committed to its partnership with Orica Africa, supporting the mining sector with innovative and sustainable solutions. With its proven track record and dedication to client satisfaction, Combustion Technology continues to set the standard for containerised hot water boiler systems across Africa.

Orica does not use lead or lead components in the manufacturing or production of Exel™ Neo detonators, but rather a safer and more sustainable lead-free formulation in Gyttorp, creating more eco-friendly products whilst maintaining the performance of its premium Exel™ range.

Exel™ Neo detonators are designed for use in civil infrastructure, as well as surface and underground mining operations.

The technology is manufactured close to Orica’s customer base in Europe and is currently available in the EMEA region.

The first Exel™ Neo detonators were shipped from its state-of-theart Swedish production facility in November 2023 to address the need for more sustainable initiation systems in the market.

Orica’s NE manufacturing and

supply network is expanding, with capability and capacity uplifts at a number of sites.

New equipment and processes have solidified multiple export hubs, improving the safety, efficiency, reliability, and security of shipping components to the company’s assembly plants.

Along with Exel™ Neo, Orica is also lowering environmental footprints through solutions such as Cyclo™, an automated processing system that enables used oil from heavy machinery to be recycled directly on-site and transformed into raw materials.

At Malabar Business Travel, we specialise in crafting exceptional travel experiences across the Democratic Republic of the Congo (DRC).

Our commitment to customising seamless international and domestic journeys reflects our unwavering dedication to quality and professionalism.

Since our establishment in 2003, we have offered comprehensive travel solutions that prioritise high-quality customer care and meticulous attention to detail. As a leading travel management company, we guarantee a top-notch journey filled with unparalleled services.

Begin your adventure in our VIP lounge at Luano International Airport, where our friendly professionals handle all your administrative tasks, allowing you to relax and enjoy the journey ahead.

We believe in the power of personalised travel. No matter your preferences, we strive to make each moment unforgettable. As your trusted travel partner, we prioritise environmental sustainability and provide guidance throughout your journey. Join us at Malabar Business Travel as we redefine travel experiences that leave a lasting impression. We aim to unlock possibilities and create remarkable memories whilst ensuring your travel plans align perfectly with your desires. Our commitment goes beyond traditional travel services; we focus on building strong relationships with our clients and partners.

Traveling with Malabar Business Travel means exploring the extraordinary while embracing our mission of ethical practices. Guided by transparency and sustainability, we are dedicated to responsible travel that benefits both communities and ecosystems.

Let’s explore the wonders of the world together while leaving a positive impact on the destinations we visit. We believe sustainable travel enriches our experiences and fosters a deeper connection with the places we discover.

Malabar Business Travel: +243 815 995 588 info@malabar-group.com www.malabar-group.com

Our dedication to excellence is reflected in the seamless services we offer, designed to ease your travel experience:

• Car Rentals: Enjoy the freedom of exploring your destination comfortably and conveniently.

• Airport Protocol Service: Experience hassle-free travel with fast-track immigration and customs clearance.

• Flight Bookings: Access seamless connections, competitive fares, and personalised itineraries.

• Hotel Reservations: Secure faultless accommodation, both nationally and internationally.

• Administration Handling Benefit: Seamless operations, from logistics coordination to administrative support.

• Visa Assistance: Receive expert guidance for all your visa needs.

• 24/7 Customer Support: Our team is committed to exceptional service, providing round-the-clock assistance for your convenience.

The company works as one team and is always guided by its values. As a purpose-led, responsible business, how value is delivered for customers, communities, and other stakeholders is as important as what is delivered.

SAFETY – The most important thing is that everyone at Orica returns home safely every day.

RESPECT – Care for each other, customers, communities, and the environment builds trusted relationships.

TOGETHER – Collaboration makes Orica better, individually and collectively.

INTEGRITY – The company is open, honest, and does what is right.

EXCELLENCE – Orica takes accountability for its business and delivers outstanding results.

“TOGETHER, ORICA’S INNOVATIONS IMPROVE SAFETY, EFFICIENCY, SUSTAINABILITY, AND OPERATIONAL FLEXIBILITY IN MINING ENVIRONMENTS”

– VICTOR MORALES, VICE PRESIDENT OF EMEA MINING, ORICA

The proven technology offers efficient processing and quality output that matches the standard required for the manufacturing of emulsion explosives.

Designed to support remote operations where Orica’s site-based emulsion plants are available, Cyclo™ delivers several environmental and commercial benefits for surface metal and coal mining.

For example, up to 1,000 litres (L) of used oil can be processed per hour by the fully containerised and automated system, associated used oil disposal costs and risks can be lowered, whilst annual diesel consumption in the production of bulk explosives can be reduced by up to an estimated 800,000L per site.

Cyclo™ additionally reduces logistical risks as it removes the need for off-site disposal and

truck movements through local communities and ensures finished product quality is maintained to the standard required for bulk emulsion explosives manufacturing.

Other environmental benefits are delivered by reducing heavy vehicle movements through local communities and thereby minimising the carbon emissions they cause.

In the EMEA region, Cyclo™ units are currently installed across several customer sites in Africa. Elsewhere, there are installations in Asia, Oceania, and Latin America, with a version to suit arctic conditions also being developed for Canada, China, and Mongolia.

Thus, Cyclo™ is an example of how the company is constantly looking for ways to reduce the carbon footprint of its customers whilst creating value for stakeholders.

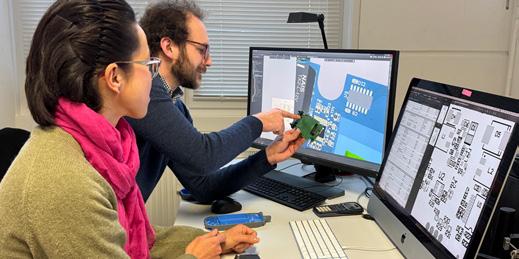

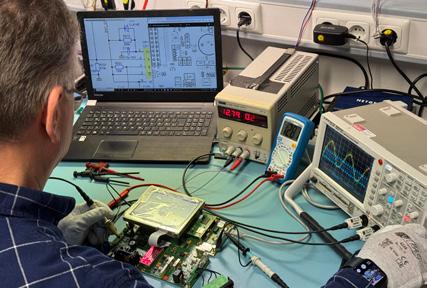

For over three decades, we have been designing and manufacturing custom electronic systems for industrial clients worldwide, thriving in the Ruhr region’s industrial hub. Our team focuses on developing solutions precisely tailored to our customers’ requirements.

As a service-driven organisation, our sole focus is on delivering quality and reliability. From concept creation to production, we cover the entire electronics life cycle, integrating external specialists for advanced mechanical components, certifications, and high-volume manufacturing.

Whether prototyping or crafting small-series systems, our expertise ensures solutions that withstand demanding conditions such as high temperatures, vibrations, and electromagnetic interference, whilst meeting thermal management, high precision, and performance requirements.

From initial design to ongoing product support, we remain a steadfast partner, delivering comprehensive development and manufacturing services with cost optimisation at every stage.

Let’s shape the future together - delivering complete electronics solutions, from design to product life cycle support, tailored to meet tomorrow’s challenges.

“Orica’s premium emulsifier technology enhances the quality and stability of bulk explosives whilst significantly reducing the carbon footprint of production processes, showcasing our commitment to sustainability,” Morales affirms.

Rapid technological advancements that are reshaping the mining and infrastructure landscape are also propelling the industry towards safer practices.

New technologies are transforming safety in the mining industry by reducing human exposure to hazardous conditions, monitoring geotechnical challenges, and enhancing precision in operations.

Orica, whose approach begins with ensuring it conducts business responsibly and prioritising the safety of people, customers, and communities, helps to improve safety and productivity with smart technologies such as WebGen™ and Avatel™.

The world’s first truly wireless initiating system, WebGen™ was launched by Orica in early 2017 and

completely eliminates the need for downlines and connecting wires in surface mining.

Underground, the system communicates through rocks, air, and water to initiate blasts safely and reliably, removing people from harm’s way, and enables new mining methods and blasting techniques to increase productivity and reduce blasting costs.

“WebGen™ allows for remote blasting, eliminating the need for workers to enter dangerous zones,” notes Morales.

Avatel™, meanwhile, is a semiautomated charging solution that eliminates the need to handle initiating systems or manually load blast holes.

The first-of-its-kind innovation enables a single operator to prepare the development face and complete the entire charging cycle from within the safety of an enclosed roll-over protective structure (ROPS) and falling object protective structure (FOPS) cabin.

Thus, Avatel™ represents a step change in safe and productive development charging through

advanced mechanisation, automation, and digitalisation.

As well as improving accuracy in blast execution, the technology reduces the exposure of workers to hazardous environments.

“Avatel™ enhances underground mining safety by combining precision with automation, minimising human involvement in high-risk areas,” Morales elaborates.

Other Orica technologies improving safety and productivity include 4D™, a revolutionary bulk explosives system that supports surface and underground blasting operations and can be tailored instantaneously to suit varying geologies and hole conditions for the desired blast outcomes.

Enabled by Orica’s proprietary emulsion chemistry and smart technologies, operations using 4D™ can achieve accurate, automated, and efficient energy control.

On the surface, one of the key benefits of 4D™ is the technology’s augered and pumped loading methods for improved efficiency in explosives delivery.

Infinity Interglobal Company Limited, is the Company Incorporated in Tanzania on 25th October 2011 and issued certificate of incorparation number 86739. It has been registered with the Tanzania Revenue Authority and assigned Taxpayer Identification Number 117-077-543, Also it has been registered for Value Added Tax (VAT) and assigned VAT registrartion number 40-017177-B.

The company is dealing with general supplies of mining equipment, hardware stores, recruitment agency, stationeries, alluminium glass, timber and its products and other agricultural products.

Surface operations also enjoy reduced drill and blast costs through the application of greater energy, optimised fragmentation, improved productivity and wall control, lowered fume risks, and much more.

Underground, 4D™ enables instantaneous energy control, automation and repeatability, maximised orebody recovery, and sustainable blasting practices.

“4D™ is a revolutionary bulk explosives technology that allows the real-time customisation of blast energy, optimising safety, productivity, and resource efficiency whilst minimising environmental impact,” Morales details.

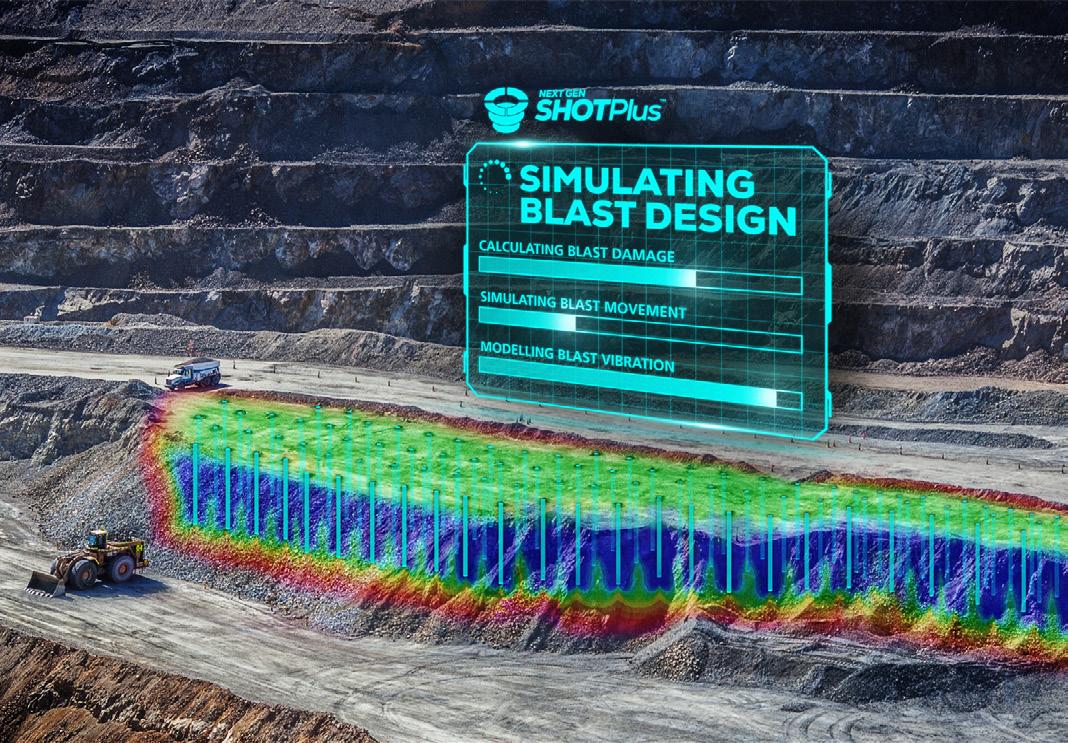

Next Gen ShotPlus™, meanwhile, is shaping the future of drill and blast by enabling users to assess the impact of engineering decisions and design the highest-value blast for any situation.

This groundbreaking innovation combines high-performance visualisation, best-in-class design tools, and modelling capabilities to

predict blast movement, damage, and vibration, leading drill and blast into a new era.

Engineers can also share the outcomes of these predictive models with multiple stakeholders, allowing for collaborative assessment of the

PURPOSE – To sustainably mobilise the earth’s resources.

VISION – To be the world’s leading mining and infrastructure solutions company.

STRATEGY – To deliver solutions and technologies that drive productivity for customers across the globe. Orica’s strategy is centred on three key pillars – optimising its operations, delivering smarter solutions, and partnering for progress.

highest-value blast designs in the context of the entire mining value chain.

Launched in September 2024, Next Gen ShotPlus™ therefore empowers drill and blast engineers to move beyond descriptive designs.

“NextGen ShotPlus™ redefines blast design and visualisation, offering advanced 3D modelling and simulation capabilities,” highlights Morales.

“It allows customers to optimise blast outcomes, streamline planning, and enhance operational efficiency.”

Then there’s Orica’s market-leading GroundProbe radars, which support the control of wall movements across mining operations worldwide, and i-kon™ III, the most sophisticated EBS on the market.

Reliable even in harsh conditions, i-kon™ III helps customers to achieve their blasting goals and enhances productivity through faster

Our integrated teams deliver creative solutions and tailored support for customers around the world, placing Efficient Sea at the forefront of the shipbroking industry. We operate in Mauritania, Senegal, and Spain.

Freightworx: Excellence in Logistics Since 1999 Since 1999, Freightworx has been at the forefront of logistics in Africa as a proud family-owned enterprise. With a century of combined experience, we provide exceptional service and peace of mind through state-of-the-art warehousing, expert crating, and seamless air, road, and sea transportation, all backed by comprehensive insurance. As an IATA-affiliated company, we maintain international standards and competitive rates for all imports and exports. Being 100% female-owned, we champion diversity and inclusivity. Choose Freightworx for a reliable and innovative logistics experience tailored to your needs.

deployment and setup for both small and large-scale blasting.

“Our i-kon™ III EBS provides unparalleled accuracy and control, reducing the risks associated with misfires,” adds Morales.

Orica’s EBS manufacturing and supply network has been actively expanding worldwide, with new plants and equipment strategically deployed in all major regions, including EMEA, to enhance the company’s proximity to customers.

As a result, Orica has grown from two EBS manufacturing sites globally to six, significantly bolstering its EBS capacity and subsequently enhancing the company’s responsiveness to customer demands, ensuring a more robust supply chain.

Following the successful introduction of the Exel™ Neo range, with early adopters reaping the benefits, Orica is expanding its leadfree NPED technology to manufacture EBS Neo, its first lead-free EBS at its Gyttorp plant.

This is the first time Orica’s EBS are being manufactured at its state-ofthe-art facility in Sweden, bolstering supply security and optimisation.

The Gyttorp plant will initially be used to assemble Orica’s standard EBS detonators and will subsequently be used to assemble the lead-free EBS range based on NPED technology.

Like the Exel™ Neo range, EBS Neo is free of any Substances of Very High Concern (SVHCs) according to the EU’s regulation on the registration, evaluation, authorisation, and restriction of chemicals (REACH).

Both product lines also comply with the EU’s Restriction of Hazardous Substances (RoHS) Directive beyond the current deadline of April 2025 and will help customers meet their own environmental, social, and governance (ESG) compliance targets.

Customer trials of EBS Neo got underway in 2024 ahead of market launch, as the company continues to explore how it can use innovative

www.satellitetransghana.com

With more than 30 years of experience, TEUP provides tailored solutions to optimise and automate production processes.

technologies to help achieve their ESG goals.

Alongside ESG, Orica is deeply committed to corporate social responsibility (CSR) with a strong focus on community engagement.

Indeed, in 2024, the company invested USD$4 million into communities globally, which puts Orica on track to exceed its corporate community investment goal of USD$15 million by the end of FY25. CSR projects across EMEA include promoting diversity and providing local talent opportunities, such as supporting women in technical roles in Africa and aiding social equality efforts.

Vulnerable African communities are also assisted by Orica through efforts such as combatting human trafficking in Tanzania, developing schools for

children in Zambia, providing medical support in Ghana, and ensuring access to clean water in remote areas of the continent.

“These efforts reflect our ongoing dedication to creating meaningful social impact,” Morales informs us.

As well as investing in communities, Orica’s success is equally built on continuous investment in developing its people.

“We are an innovative, technologydriven company, so having the best talent is crucial – not only for driving innovation, but also fostering resilience, commitment, and a focus on generating value for all stakeholders,” he enthuses.

This dedication to continuous improvement and ability to adapt in challenging environments are key attributes of Orica’s team, which ultimately enables it to deliver exceptional and lasting value to

customers and communities.

Likewise, the company continues to invest in strategic acquisitions to enhance its offerings and expand its global footprint.

These acquisitions also further broaden Orica’s business and create global opportunities amongst new customers and industries in diverse locations.

For example, in February 2024, the company acquired Cyanco, a US-based leader in manufacturing and distributing sodium cyanide, primarily serving the gold mining industries in the US, Canada, Mexico, Latin America, and Africa.

The acquisition has enhanced the safety and reliability of Orica’s systems and processes, improved security of supply through global supply optimisation, and

expanded the company’s portfolio of technologies and services to differentiate its speciality mining chemicals offering.

It has also more than doubled Orica’s existing sodium cyanide production capacity to approximately 240 kilotonnes per annum (ktpa) courtesy of Cyanco’s two manufacturing plants in Nevada and Texas.

A couple of months prior, the company expanded its digital solutions portfolio by acquiring Terra Insights, a leading provider of innovative sensors and data delivery technology for geotechnical, structural, and geospatial monitoring in mining and infrastructure.

Terra Insights adds additional products and capabilities across these two value chains, allowing Orica to provide a more complete offering.

“The acquisition of Terra Insights

strengthens our capabilities in geotechnical monitoring and geological solutions, creating opportunities in the civil infrastructure environment and energy industries,” Morales acknowledges.

These acquisitions reflect Orica’s commitment to expanding beyond traditional blasting services and developing integrated, added-value technologies.

“We remain focused on identifying and investing in new technologies that drive efficiency and sustainability in mining and infrastructure operations.”

Other priorities for the year ahead include delivering greater value for customers, communities, and stakeholders.

Orica aims to support customers in achieving their sustainability goals in 2025, particularly reducing greenhouse gas (GHG) emissions, advancing the energy transition

through future-facing commodities or critical minerals, and enhancing operational reliability and productivity.

“We are excited by the growth of key markets such as the copper belts in Africa and Central Asia, gold belts across Africa, mining growth in the Middle East, and major infrastructure projects in Southern Europe and the Middle East,” shares Morales.

“Our focus remains on being the preferred partner in these regions, driving sustainable growth for our customers,” he concludes.

Tel: +351 213 571 311

Henri Cheko General ManagerMuche Graphique

With a proud history of supplying spare parts, printing services to various sectors for over a is a company driven by customer satisfaction

Headquartered in Lubumbashi, Haut-Katanga, in the Democratic Republic of Congo (DRC), Muche Graphique’s offerings are wideranging.

The company supplies spare parts to original equipment manufacturers (OEMs), alongside safety equipment, printing services, chemical products, and laboratory equipment to other clients.

Founded on innovation and an entrepreneurial spirit, Muche Graphique has recruited a dynamic and qualified team that is experienced in their respective fields and able to meet the market’s evolving needs. Underpinned by over ten years of industry experience, the company has gained the trust of several large companies in Grand Katanga, consistently meeting their supply and equipment needs. On leader intends relationships vision service fair FIRST-CLASS Muche its all services, throughout project and Offering quality way, and company satisfaction reputation

parts, safety equipment, and decade, Muche Graphique

satisfaction and service excellence

On a mission to be a progressive leader in its field, Muche Graphique intends to build strong, lasting relationships with its clients, with a vision to offer exceptional customer service and top-quality products at a fair price.

Muche Graphique prides itself on ability to provide customers with the requisite information on its services, remaining in communication throughout the execution of each project due to its diligent monitoring and communication department.

Offering each of its customers quality assurance every step of the way, deeply personalised service, and a results-oriented attitude, the company ensures total customer satisfaction – a key factor of its reputation for excellence.

Genuine lubricants spare parts for trucks and machines: Volvo, Caterpillar, Sinotruck Howo, Shacman, Foton, Auman, Isuzu, and Faw, Man. For compressors and pumps: Atlas Copco, Balma, Abca, Almig, Alup, Airman, Vaccumpump, Bosch, Bowie, Napco, Wilden, Becker, etc.

Offering long-term safety solutions, Muche Graphique’s safety equipment and engineering experts are on hand to guide customers.

To ensure consistently high health, safety, and environmental (HSE) standards, the company has established strong partnerships with some of the best manufacturers.

As always, Muche Graphique offers the best products at even better prices. This includes safety equipment supplies and signage for both residential and commercial use.

Deep-rooted trust and reliability between Muche Graphique, its customers, and its partners are also of the utmost importance. By prioritising long-term satisfaction over immediate success, the company proudly centres everything it does around customer fulfilment.

Innovating to stay ahead of the curve, Muche Graphique seeks to continuously improve its services. It encourages the creativity of its employees, utilising progressive technical innovations to think outside the box, benefitting its customers.

Proud Muche its This financial over to Seeking across ambition and success To regularly production

With over a decade of experience in printing and utilising various professional machines, Muche Graphique is an ideal partner for companies to work with.

Its clients range from small and medium enterprises (SMEs) to large groups throughout the Greater Katanga region, demonstrating its wide-reaching capabilities.

Regardless of volume, size, or quantity, the company prints on all types of media, offering a complete suite of services – from design to printing and delivery.

Muche Graphique even goes as far as to provide manuscripts of digital files provided by clients upon request.

Chemicals and laboratory equipment –

Comprising various lab materials, chemical products, and mining blasting materials such as installation of argon gas lines, acetylene, and nitrous.

Proud to be an independent supplier, Muche Graphique enjoys freedom in decision-making. This freedom is largely based on its financial independence, acquired over many years of operation thanks good management.

Seeking to obtain maximum quality across all its activities, the company’s ambition is to always keep its promises and continue to contribute to the success of its customers.

achieve this, Muche Graphique regularly invests in modernising its production tools.

DR Congo

128, Avenue Kasa”i, Quartier Makutano, Commune et ville de Lubumbashi

Information Line: +243 899 363 067

Zambia

567/3b Pelican Road makeni, Lusaka Zambia

Information Line: +260 971152 243

South Africa

129 Walton Rd, No. 2A Carlswald Estate Midrand, Johannesburg

Information Line: +27 66 314 6742

info@muchegraphique.com graphiquemuche@gmail.com www.muchegraphique.com

@muchegraphique