SDC Trailers is Europe’s leading manufacturer of bespoke semi-trailers. We learn more about the company’s seamless journey from humble beginnings to an industry-leading player with President, Paul Bratton

Writer: Ed Budds | Project Manager: Nicholas Kernan

The opening chapter in the incredible story of SDC Trailers (SDC) was kickstarted by its Founder, Seamus McCloy, a welder and fabricator.

Established in 1978, SDC began its initial operations from a tiny shed in Bellaghy, a small village in County Londonderry, Northern Ireland. From there, the business

blossomed rapidly, culminating in 1982 with the opening of SDC’s first factory in Toomebridge.

A historical site for the company, the facility is now known as Plant 1 and remains the group’s main headquarters to this day.

Over the past four decades, SDC has grown impressively from a oneman operation to proudly becoming the UK and Ireland’s largest semitrailer manufacturer.

In this time, the company has pioneered a number of industryfirst semi-trailer solutions for the modern-day transport operator and understands the importance of maximising trailer performance in order to support its customers’ business operations.

Appointed President of SDC in 2020, after former CEO, Enda Cushnahan, decided to move on following 23 years with the company, Paul Bratton’s introduction to the industry came in the shape of a welding apprenticeship at college, which was considered a sought-after and burgeoning trade at the time.

After transitioning to working on trailers and oil pipelines, he joined SDC almost 30 years ago, gradually climbing the ranks of the company to his current position.

“I’ve always enjoyed the discipline required to work in this industry, partly due to the amount of legislation we contend with, but also because of the kind of people you encounter who share a similar background to me in terms of approaching things from an engineering perspective and practical standpoint,” Bratton introduces.

The European trailer industry currently finds itself facing a significant downturn.

“During the COVID-19 pandemic, the pricing of trailers spiralled out of control because of the lack of access to raw materials,” Bratton recalls.

Therefore, the sector still finds itself recovering, as companies such as SDC look to rebuild their sales output to pre-COVID-19 figures. This is achieved by manufacturing a wide range of trailers for the transport and logistics industries, including curtainsiders, box vans, skeletals, and platforms.

Across the continent, the transport landscape has also become more volatile and less predictable, requiring higher flexibility from industry players.

“However, despite this broad downturn, the Irish trailer market has remained relatively steady in terms of our business, and we own a large percentage of that sector, as our

company originally started out there back in the late 1970s,” he confirms.

SDC’s main production site still remains the original facility in Toomebridge, Country Antrim, although now much expanded. With this continued investment, SDC remains focused on the local community in Northern Ireland.

In addition, SDC was acquired in 2016 by the largest trailer manufacturer in the world, China International Marine Containers (CIMC), who has continued to invest heavily in the company and significantly increased its overall market share.

SDC now boasts four modern and efficient manufacturing facilities based in Toomebridge, Antrim, Mansfield, and Southampton, which are amongst the most highly developed in Europe and home to the entire trailer manufacturing process.

EME OUTLOOK: HOW DO YOU EMPOWER YOUR STAFF AND RECOGNISE THEIR VALUABLE CONTRIBUTIONS?

Paul Bratton, President: “As an extremely hands-on sector, we are incredibly reliant on people.

“In the last few years since the COVID-19 pandemic, there has been a global shift towards working from home and remote work, but in our industry, we still need people to show up and shine in their roles. This is why we promote from within wherever possible, as so many of our team members began their careers on the shop floor or are from an engineering background like myself.

“We employ people to do a job but then provide them with the freedom and autonomy to think independently and thrive in a healthy work environment. We don’t want to employ robots; we want people to grow and develop alongside the company because we see them as the future of the business and entire industry.”

Could you briefly introduce us to the company?

Continental develops pioneering technologies and services for the sustainable and connected mobility of people and their goods. Founded in 1871, the technology company offers safe, efficient, intelligent, and affordable solutions for vehicles, machines, traffic, and transportation. In 2023, Continental generated sales of €41.4 billion and currently employs around 200,000 people in 56 countries and markets.

Continental has delivered top performance for more than 150 years, is one of the world’s largest tyre manufacturers, employs more than 56,000 people worldwide, and has 20 production and 16 development sites.

Continental is undoubtedly one of the world leaders in tyre production and offers a broad product range for passenger cars, commercial and specialty vehicles, as well as two-wheelers. Through continuous investment in research and development, Continental’s pioneering technology makes a major contribution to safe, cost-effective and sustainable mobility.

Continental is contributing to society and towards shaping the future through its commitments to sustainability which is at the heart of everything it does. The company has an ambitious goal to increase the use of sustainable materials in its tyre products to 100 percent by 2050 at the latest.

What are some of the ongoing or recent projects that you are most interested in showcasing?

Continental is increasing the proportion of recycled materials in its tyres. Continental is now using polyester yarn from recycled PET bottles in series production tyres, known as ContiRe.Tex.

Continental’s ContiRe.Tex technology uses recycled PET bottles to replace conventional polyester in a tyre's carcass. The PET bottles are turned into a new sustainable polyester yarn, with a set of standard tyres using material from around 40 recycled PET bottles.

More plants have recently been converted to use polyester fabric made from recycled polyethylene terephthalate (PET) bottles. This increases the recycled content of many tyre lines by an average of three percent. The innovative ContiRe.Tex technology has been used on a small scale since 2022 at the tyre plants in Lousado, Portugal, and Otrokovice, Czech Republic. The plants in Korbach, Germany, and Sarreguemines, France, have also recently started using recycled PET bottles in series production.

The Conti EcoPlus HT3+ is specifically designed for trailers with electrified drive axles. This tyre offers exceptionally balanced performance in terms of traction and rolling resistance and an especially high load capacity. The tyre’s features are specifically geared to new-generation trailers featuring fully electric drive axles.

In 2023, Continental proudly launched the UltraContact NXT: one of the most sustainable tyres on the market and the most sustainable in Continental’s portfolio. The UltraContact NXT has a share of up to 65 percent renewable, recycled, and ISCC PLUS mass balance certified materials.

Continental has officially opened a fully automated high-bay warehouse at its tyre production plant in Otrokovice, Czech Republic. It has a storage capacity of more than 930,000 tyres. With the facility, the premium tyre manufacturer is centralising its warehouses in the area of Otrokovice. As a result, Continental’s logistics processes can be further optimised and CO2 emissions of its operations can also be lowered.

Continental has developed its fifth-generation Conti Eco tyre line for freight transportation. The new product is geared squarely to the needs of customers in the transport sector and a dynamic regulatory environment, which means it also meets all the requirements of the EU Taxonomy for fleets. It allows haulage companies to cut costs whilst significantly reducing their fuel consumption and CO2 emissions in both regional and longdistance operations.

What, for you, differentiates your business from the competition?

Continental’s Lowest Overall Driving Costs (LODC) advisory approach helps provide the transport industry with an effective lever to withstand increasing cost pressures and at the same time make its fleets more sustainable. Tyrerelated costs generally account

for around two percent of a fleet’s budget. However, tyres have a considerable impact on fuel, maintenance, and repair costs, which together can account for up to 50 percent of total fleet operating expenses. Premium tyres, data-based service management, and on-schedule tyre checks can significantly reduce the costs of running a fleet.

Continental will soon be offering automated tyre tread depth measurements for the first time thanks to its new ContiConnect sensor generation. Fleet operators will be able to obtain precise and daily updated data on the rate of wear of their commercial vehicle tyres. In conjunction with AI-based algorithms, upcoming tyre services for individual commercial vehicles as well as entire fleets can be planned with precision. This will increase the safety and efficiency of the fleet, saves costs and helps to reduce its CO2 emissions. The new tread depth measurement and the tyre service planning will complement Continental’s existing ContiConnect solutions portfolio, which already includes data on tyre pressure, temperature, and mileage. The market launch of the new ContiConnect solutions is planned for summer 2025.

As part of its Vision 2030 strategy programme, Continental has committed to an ambitious goal of becoming the most progressive tyre company regarding ecological and social responsibility by 2030. At the end of the decade, Continental aims to have more than 40 percent renewable and recycled materials in its tyres, whilst it seeks to increase the use of sustainable materials in its tyres to 100 percent over the next 25 years. The ContiLifeCycle programme is an important step on the road to fulfilling these core sustainability goals.

Retreaded tyres are not only a business investment but also an investment in our future. The ContiLifeCycle concept is based on cyclical thinking. It’s a smart way to save emissions for our environment. Retreaded tyres replace new ones by reusing valuable components and materials.

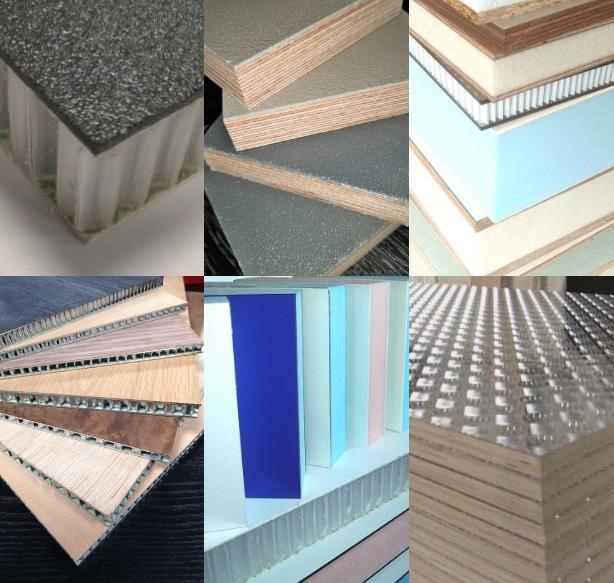

This allows the company to maintain direct control over every element of the production process and create trailer solutions based on its customers’ specific transport requirements.

“At SDC, the core of our operations is driven by our philosophy to understand our customers’ businesses and their logistic requirements, tailoring a solution to meet their needs.

“Each trailer we produce is designed and manufactured to benefit our customers’ operations,” Bratton sets out.

Working closely with its myriad clients, the company remains committed to continuously providing innovative solutions for a vast variety of transport requirements.

In this way, SDC supplies trailers to a wide range of companies and has built relationships with the industry’s leading logistics operators, supermarket chains, and hire companies, including TIP Trailer Services, Hireco, Ryder, and Trailer Resources Ltd.

“Our dedicated business areas offer the complete package from bespoke manufacturing to finance, spare parts,

and servicing,” he continues.

“When you invest in an SDC trailer, you are not only investing in the best technology, quality, and flexibility; you’re also investing in the knowledge, expertise, and understanding that comes from years of experience in the haulage industry.”

SDC’s impressive semi-trailer portfolio is backed by a comprehensive aftermarket service and a network of 18 trailer parts branches across the UK and Ireland, offering same-day and next-day delivery on over 16,000 truck and trailer parts and consumables.

Four new parts branches were opened in 2024, spanning Telford, Durham, Birmingham, and Southampton.

Initially established 23 years earlier as a new, game-changing subsidiary of the company, SDC Truck and Trailer Parts initially specialised purely in trailer spares.

However, recognising the market’s urgent need for competitively priced truck parts, the company expanded its focus, leveraging its existing connections with leading

manufacturers.

This seismic shift prompted the establishment of regional depots across Ireland, strategically positioned to minimise vehicle downtime for customers.

“Our philosophy is to understand your business and logistics requirements and then tailor a solution to meet those needs,” Bratton states.

“Looking ahead, SDC Truck and Trailer Parts is set to strengthen its position as a leader in the commercial vehicle aftermarket and a one-stop shop for our clients.”

SDC’s ongoing development of its Toomebridge manufacturing hub has been a crucial recent investment for the company.

A further point of pride, the facility reached the impressive production milestone of its 20,000th trailer in 2024 on the site’s semi-automated production line.

“The Toomebridge production facility has been pivotal in boosting SDC’s manufacturing capacity since its upgrade six years ago,” Bratton affirms.

“Recent developments in 2024 have further enhanced the site’s capabilities, including the integration of cutting-edge technologies such as state-of-the-art spray booths and a new shot blaster system,” he adds.

These impressive upgrades were part of a crucial £8.6 million investment and have helped reinforce SDC’s commitment to environmental sustainability, safety, and elite-level operational efficiency.

“We are incredibly proud to have built our 20,000th trailer on the new semi-automated line in Toomebridge. This milestone is a testament not only to our ongoing investment in advanced manufacturing technologies but also

“AT SDC, THE CORE OF OUR OPERATIONS IS DRIVEN BY OUR PHILOSOPHY TO UNDERSTAND OUR CUSTOMERS’ BUSINESSES AND THEIR LOGISTIC REQUIREMENTS, TAILORING A SOLUTION TO MEET THEIR NEEDS”

– PAUL BRATTON, PRESIDENT, SDC TRAILERS

to the hard work and dedication of our team.”

In this way, the company has continuously pushed the boundaries of what can be achieved, and reaching this monumental milestone reflects SDC’s commitment to delivering high-quality

products to its customers.

“Utilising the latest high-tech equipment will allow us to further improve our customer service levels from the initial trailer order right through to completion and delivery,” Bratton prides.

Can you introduce us to Truck-Lite?

Truck-Lite has been a pioneer in the commercial vehicle lighting industry for over a century. Our journey began with the invention of the rubber lamp housing in 1924, and we’ve been at the forefront of commercial vehicle lighting innovation ever since.

Our European headquarters is in Harlow, Essex, UK, where we design, manufacture, and test our comprehensive range of advanced LED lighting systems for trucks, trailers, and heavy-duty vehicles. We are proud to continue designing and manufacturing in the UK. Our experienced team of 100+ operators and engineers, with their unrivalled industry knowledge, ensures that our products meet the highest standards expected by our customers.

Our in-house testing laboratory is integral to our operations, allowing us to rigorously test product reliability under harsh real-world conditions. We conduct full illuminance performance testing to ensure compliance with ECE regulations. Our ISO 9001 and IATF 16949 certifications further demonstrate our commitment to producing quality and durable cutting-edge lighting technologies.

What are your innovative market solutions?

With over 250 patents and ISO 14001 certification, we continually demonstrate technological advancement and commitment to sustainable manufacturing.

Now we’ve developed a total lighting solution built around our TruckLite harness system. This plug-and-play system features Superseal connectors and macromelt overmould technology, providing complete protection against water ingress and ensuring total system integrity. Our harness kits are available in pre-configured standard configurations or can be custom-designed to fit specific vehicles and projects, working closely with our customers. Not only that the kits simplify installation, but also reduce downtime for vehicle builders by up to 50%.

. What differentiates Truck-Lite from competitors?

Our long history has provided us with a deep understanding of the UK and European trucking industry, allowing us to identify and focus on the needs of our customers. While we are proud of our roots, we are always

moving forward. Our approach focuses on developing solutions that anticipate industry needs, ensuring manufacturers stay ahead of evolving safety and performance requirements.

We are pleased to announce the strategic integration of Labcraft LED Lighting that will help us to beat traditional industry standards. Labcraft is renowned for the design and manufacture of best-in-class interior lighting, scene lamps, and banksman systems. By offering Labcraft products into our Truck-Lite harness kits, we are able to create a comprehensive lighting solution that includes both mandatory and auxiliary lighting systems.

Tell us about Clarience Technologies

Clarience Technologies was established to lead innovation in the rapidly changing transportation industry. With over 4,000 employees across 50 global locations, the company brings together innovative technologies and trusted brands under one roof, including renowned European brands such as Truck-Lite, Labcraft, ECCO, Durite, LED Autolamps and Code 3.

The organisation is committed to driving innovation and safety across the industry, providing comprehensive solutions that protect lives, secure assets, and enhance productivity. By operating at the speed of technology, Clarience Technologies supports a growing number of customers worldwide.

What’s next for Truck-Lite?

Our engineering team is constantly developing new products to meet evolving customer needs. We’re excited to introduce a new range of interior strip lighting, developed in collaboration with trailer-builder customers specifically for the heavy-duty box trailer sector.

We’re also developing new rear lamps, auxiliary lighting products, and vehicle safety solutions. Our goal remains to offer manufacturers a reliable partnership that transforms vehicle safety and operational efficiency, providing intelligent systems that anticipate and solve complex transportation challenges.

“OUR DEDICATED BUSINESS AREAS OFFER THE COMPLETE PACKAGE FROM BESPOKE MANUFACTURING TO FINANCE, SPARE PARTS, AND SERVICING”

– PAUL BRATTON, PRESIDENT, SDC TRAILERS

SDC is resolutely committed to developing its business in a sustainable way and has made a number of significant investments in renewable technologies to minimise its overall operational carbon footprint.

As part of this transition, the company has installed biomass boilers as a direct fuel replacement for oil or electricity at its office buildings in Toomebridge and Antrim.

These sustainable boilers are capable of burning both wood pellets and wood chips offering a significant reduction in carbon dioxide emissions.

In addition, SDC has invested in the introduction of electric vehicle charging points across all sites. Both employees and visitors can now take advantage of this technology, encouraging its people to continue reducing their annual fuel consumption and associated carbon emissions.

CURTAINSIDER RANGE – Designed to maximise operator flexibility and reliability in a wide range of road haulage and logistics applications.

BOX VAN RANGE – Specifically envisaged to provide optimum security and durability across a plethora of road haulage and logistics applications.

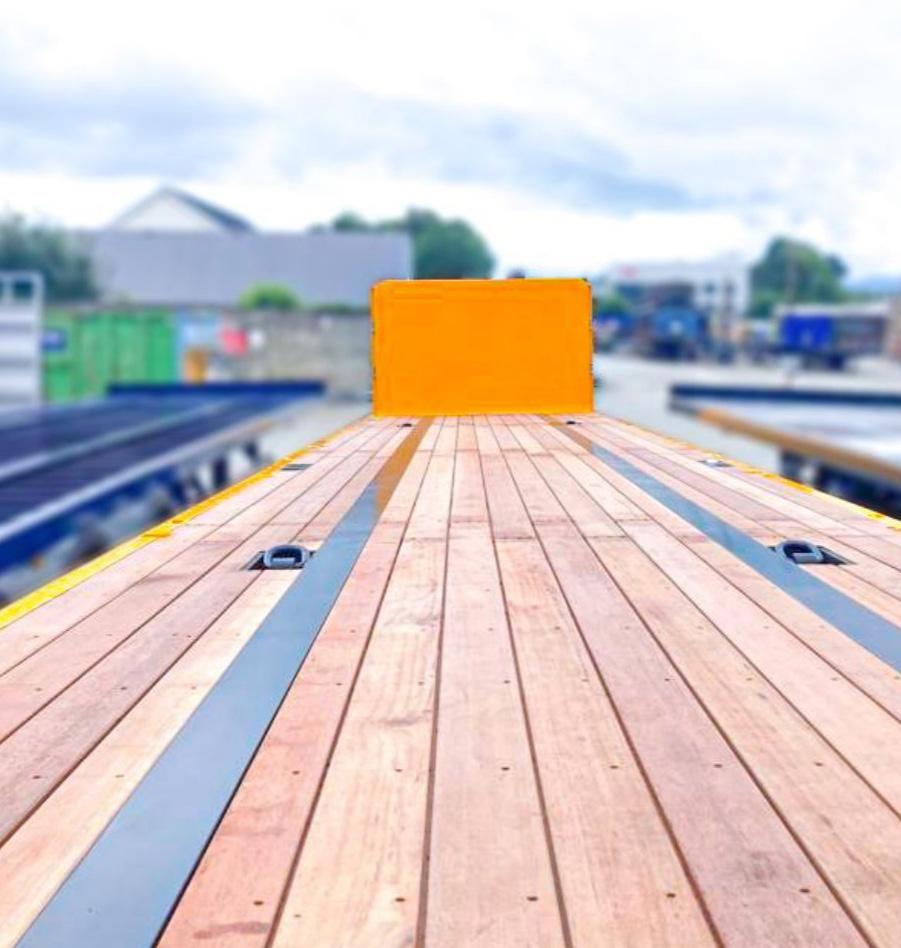

PLATFORM RANGE – Designed to deliver maximum strength for heavy duty applications, specifically made for use within the construction industry.

SKELETAL RANGE – Offers a mixture of both fixed and sliding designs, ensuring that any container can be transported.

MACHINE CARRIER RANGE – Created according to specific customer specifications, ensuring optimum operational flexibility.

DRAWBAR RANGE – Designed with a large array of models to choose from, making it extremely versatile.

A network of over 50 industrial coatings production facilities and 40 laboratories worldwide.

We develop breakthrough coating solutions by investing nearly 3% of annual revenue in R&D.

We shape the color direction of more products than any other paint manufacturer.

We offer the industry’s best on-demand, laboratory and technical support. Testing service and on-site problem solving.

Our robust global supply chain quickly adapts to changing customer needs.

We promote product quality, durability and performance with coatings in all major technologies.

Bespoke coating systems tailored to the trailer and transportation industry providing high corrosion protection and robustness to aid the finished products longevity. For more info, visit us at ppg.com/industrialcoatings.

“WHEN YOU INVEST IN AN SDC TRAILER, YOU ARE NOT ONLY INVESTING IN THE BEST TECHNOLOGY, QUALITY, AND FLEXIBILITY; YOU’RE ALSO INVESTING IN THE KNOWLEDGE, EXPERTISE, AND UNDERSTANDING THAT COMES FROM YEARS OF EXPERIENCE IN THE HAULAGE INDUSTRY”

– PAUL BRATTON, PRESIDENT, SDC TRAILERS

Elsewhere, the company has installed an electric system of photovoltaic (PV) solar panels in two locations as a more environmentally-friendly direct electricity replacement, demonstrating its ongoing commitment to sustainability.

The outlook remains exceedingly bright for SDC as the company continues its upward trajectory following the turbulent years of the COVID-19 pandemic and chaotic effects that this difficult period had on the entire industry.

Manufacturing close to 5,000 trailers in 2024, SDC’s intentions are to improve on this in the years coming despite local and global challenges.

Bratton acknowledges that the key factor in reacting to any potential future challenges is speed of response.

“We must endeavour to adapt quickly to any adversity faced, which is where the strength of our supplier partnerships becomes crucial for reacting to hurdles encountered within the industry,” he states.

“Through our investment in innovation and upgrading our manufacturing facilities for the future, SDC is well positioned to meet the evolving needs of our customers and challenges of the modern manufacturing landscape.”

Whilst it remains hard to envisage what the sector may look like in the next few years, SDC is set to adapt and overcome any fresh challenges of a fluctuating transport landscape with its solid set of operational foundations.

Quality is undoubtedly at the centre of the company’s operations with an overarching mission to provide products and services that meet and exceed customer expectations, no matter what.

“Our long-standing commitment to quality has led to the success of the SDC brand, both in domestic and international markets, and we are confident that we will continue to go from strength to strength,” Bratton concludes proudly.

Tel: +44 (0) 28 7965 0765 info@sdctrailers.com www.sdctrailers.com