We return to Turner Construction, whose Vice President and General Manager, Stuart Smith Jr., tells us how the company is proactively expanding its market presence and supporting local organizations

Writer: Lucy Pilgrim | Project Manager: Michael Sommerfield

Historically experiencing a number of fluctuations, the Canadian construction industry has remained comparatively stable over the last year.

Although many market areas have experienced reduced activity, such as the commercial market across Toronto, other sectors have continued to flourish, including critical facilities and data centers, higher education and life sciences projects, as well as the nation’s healthcare industry.

Following this trend, the construction sector has also witnessed a significant push toward the creation of affordable housing to support communities across Canada, and in the Ontario area in particular.

“Our biggest focus remains on building the next generation of craft labor and trade contractors within the market, ensuring that labor is available

to keep pace with scaling housing projects and increased market demands,” introduces Stuart Smith Jr., Vice President and General Manager of Turner Construction (Turner), an industry-leading construction services company operating across Canada and worldwide.

Established in 1902, the business was founded on the core values of teamwork, integrity, and commitment, which still drive Turner today.

“As the business has grown over the past century, we have really made an effort to evolve and learn from the market and community, and evolve the company,” insights Smith.

Indeed, central to Turner’s growth is its focus on actively caring for the local areas where it works, which has guided the company philosophy over the last seven years, relating to areas of engagement, culture, and diversity,

equity, and inclusion (DEI).

More recently, Turner has also had a strong grip on its environmental, social, and governance (ESG) practices, further cementing its role as a frontrunner in the international construction industry.

“We want to transform the industry landscape to be the best possible place for people who want to be a part of it, building long-lasting careers,” he affirms.

Over the past year, Turner has increased its presence across critical facilities and advanced manufacturing markets in Europe thanks to the completion of a diverse and strategic acquisition.

Through a collaboration with parent organizations Hochtief and HCS Construction, Turner recently finished a transaction for the acquisition of Doran Consulting, an Irish civil and

structural engineering consultancy agency that operates across the European critical facilities market.

The company’s drive and growth strategy are further bolstered by the merging of Turner’s two sister companies, Flatiron Construction and Dragados.

The unity between the two organizations will be headed by Turner’s President and CEO, Peter Davoren, who will become the new entity’s Chairman for North America.

“The combined entity will be the leading civil contractor in the region, which is a huge asset for us, particularly as we look more toward larger infrastructure and advanced manufacturing initiatives holistically,” expands Smith.

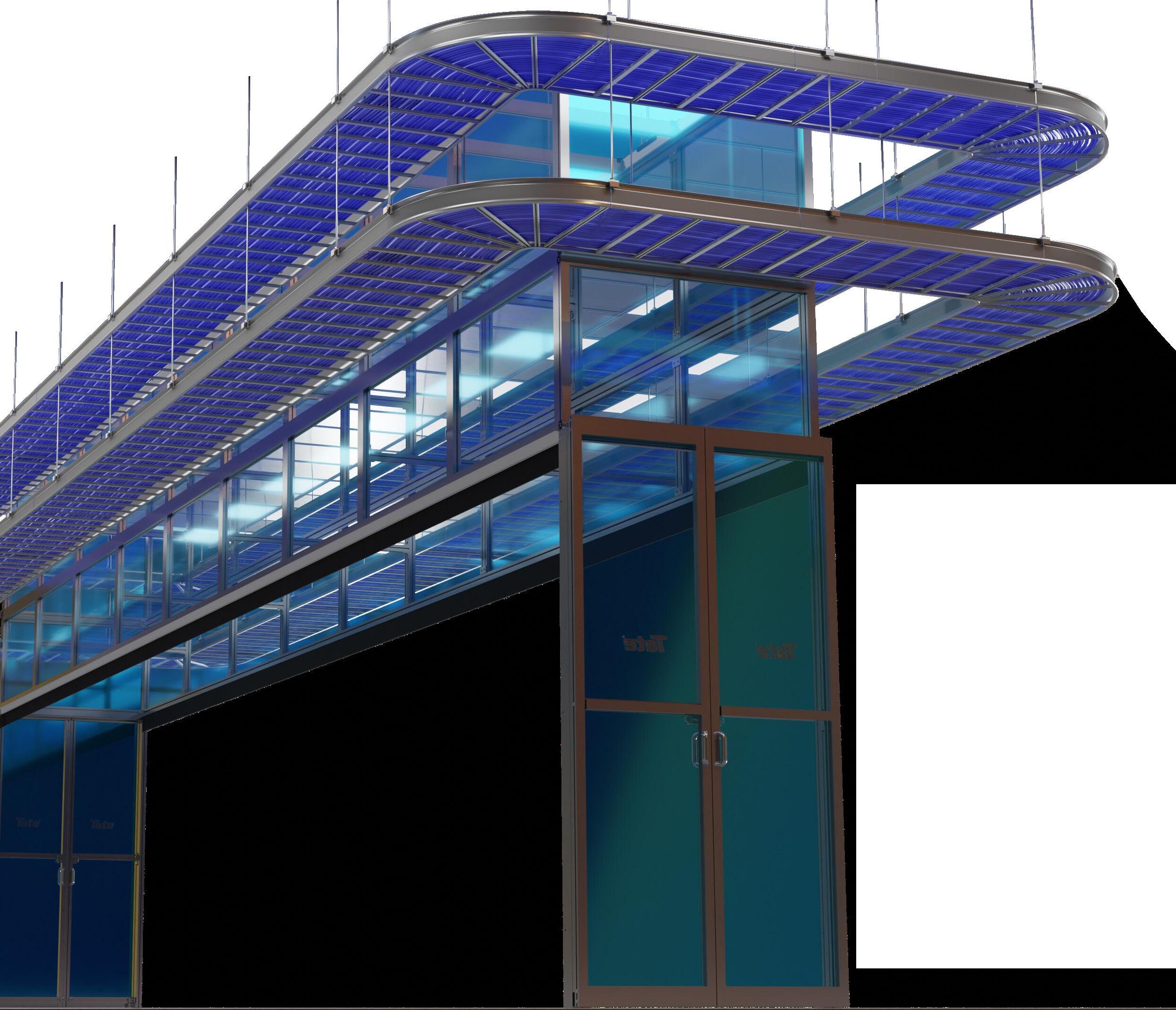

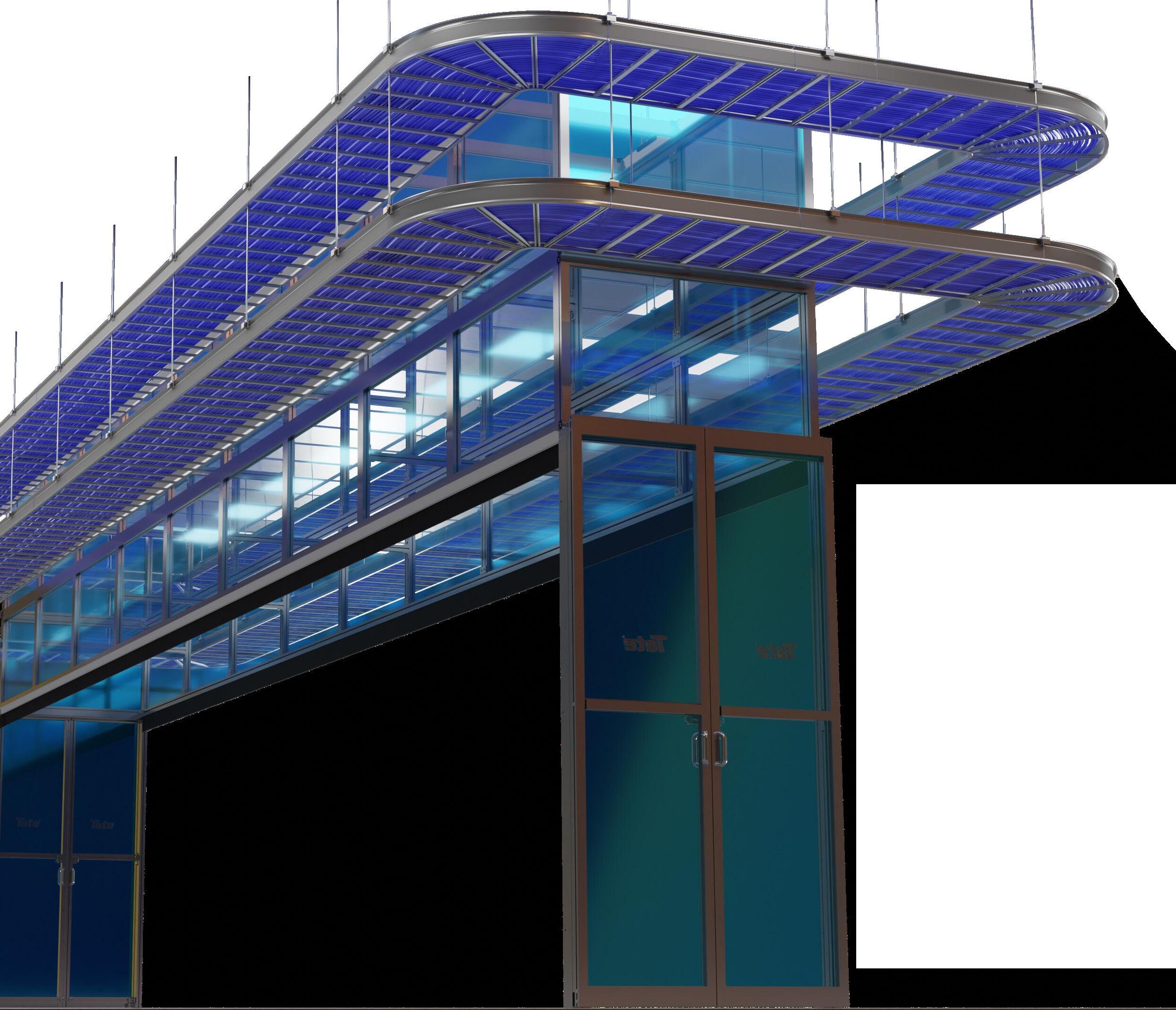

Elsewhere, the company is fortunate enough to be highly active in the data center and life sciences markets, showcased by a plethora of amazing, recently completed projects.

For example, Turner completed the conversion of a commercial space into a Level 2 biomedical lab in collaboration with the University of Toronto and Canderel, one of Canada’s largest commercial and residential developers.

This particular venture proved to be a leading-edge project, as the company innovatively transformed a space so that it could be efficiently used by a renowned teaching institution.

Additionally, Turner continues to pursue different strategies to expertly utilize mass timber to support the affordable housing market, whilst also creating a sustainable environment and giving back to the community.

Demonstrated by its most recent projects, Turner is devoted to transforming the industry whilst also

actively caring for its people and sustaining the planet.

These values continue to be equally as important as the company’s founding ethos of teamwork, integrity, and commitment.

“If we can make a positive difference to the lives of people in the local communities where we work, and marry that with our industry, we will continue to create generations of construction workers who will support growth and become leaders for the next generation,” emphasizes Smith.

This is most aptly shown by the company’s community engagement projects across Toronto, its work with a local dog guide organization being a particular standout.

“An opportunity was presented to us to be a part of the construction of a national dog guide training facility for the Lions Foundation of Canada Dog Guides. As a result of the project, the organization will be able to deliver over 300 support dogs a year,” explains Smith.

1. What are the key benefits of using Tate's containment solutions for data center construction?

Tate's containment solutions offer enhanced cooling efficiency, improved energy savings, and optimized airflow management in data centers. These benefits help maintain consistent temperatures, reduce energy consumption, and ensure reliable operation of equipment. Additionally, their modular design allows for easy integration and scalability.

2. How do Tate's containment systems improve energy efficiency in data centers?

Tate's containment systems improve energy efficiency by preventing hot and cold air from mixing, which enhances the effectiveness of cooling systems. This targeted airflow management reduces the need for excessive cooling, leading to significant energy savings. By maintaining optimal operating conditions, these systems also extend the lifespan of equipment.

3. What types of containment solutions does Tate offer for data centers?

Tate offers various containment solutions, including hot aisle containment (HAC) and cold aisle containment (CAC). These solutions are designed to fit different data center configurations and cooling strategies. The company provides both standard and custom solutions to meet specific operational needs and enhance data center performance.

4. How do Tate's containment solutions contribute to the overall reliability of a data center?

By ensuring effective airflow management and maintaining consistent temperatures, Tate's containment solutions enhance the reliability of data centers. These systems prevent overheating, reduce the risk of equipment failure, and contribute to stable and continuous operation. Reliable cooling helps in protecting sensitive equipment and maintaining optimal performance.

5. Can Tate's containment solutions be customized to fit specific data center requirements?

Yes, Tate's containment solutions can be customized to meet specific data center requirements. They offer flexible designs that can be tailored to different room sizes, rack configurations, and cooling needs. This customization ensures optimal performance and integration with existing infrastructure.

For more information or to connect with one of our sales representatives, please visit www.tateinc.com or call us at 410-799-4200

6. What materials are used in Tate’s containment products, and how do they ensure durability and performance?

Tate’s containment products are made from highquality materials like aluminum and poly carbonate These materials ensure durability, and long-term performance. The robust construction of these products helps in maintaining structural integrity and effective containment under various operational conditions.

7. How does Tate’s raised floor system integrate with their containment solutions?

Tate’s raised floor systems are designed to seamlessly integrate with their containment solutions, providing a comprehensive approach to data center cooling. The raised floors facilitate efficient underfloor airflow distribution, while the containment systems manage hot and cold air separation. This integration ensures optimal cooling performance and energy efficiency.

8. What installation support and services does Tate provide for their containment solutions?

Tate provides comprehensive installation support and services for their containment solutions,including site assessments, design consultation,and professional installation. Their team of experts ensures that the solutions are correctly implemented and optimized for maximum efficiency and performance. Postinstallation support and maintenance services are also available.

9. Are Tate’s containment solutions compliant with industry standards and certifications?

Yes, Tate’s containment solutions comply with industry standards and certifications, ensuring they meet the highest quality and performance criteria. Their products are designed to adhere to regulations such as those set by ASHRAE and other relevant organizations. Compliance guarantees reliability, safety, and efficiency in data center operations.

10. How do Tate products address the growing need for planet sustainability?

Tate Inc. demonstrates a strong commitment to sustainability by aiming for zero waste to landfill and implementing significant solar power systems at their facilities. They actively manage energy consumption and continuously improve their products and processes to meet and exceed industry standards for environmental r esponsibility. This dedication to sustainable practices reflects their role as a leader in the industry, ensuring that their operations have a minimal climate impact. Tate’s ongoing efforts highlight their unwaivering commitment of adopting sustainable manufacturing processes

Turner is proud to have been featured on Forbes’ Best Employers for Women 2024 and America’s Best Employers for New Grads 2024 lists. Smith owes this achievement to the company’s ability to foster an open-minded and inclusive work environment.

“I think it all starts with our active caring philosophy and commitment to building a culture for our employees where everyone has a voice and feels comfortable enough to feel they can contribute and add value. We strive to create an industry where all people can be at their best, be authentic, and are treated with dignity and respect,” shares Smith.

Indeed, the two highly prestigious awards are a recognition of the leadership team’s ability to create an environment that sets ambitious but achievable goals.

“I believe that our employees should take advantage of these opportunities to lead and grow their careers through networking in the organization and make change across the industry.”

The new facility will contain a number of apartment units where the recipient of the support animal can participate in the training process and learn how to work with the dogs.

When completing the project, the company was asked whether it would ever consider taking onboard one of the dogs, and as a result, it adopted a black labrador named Turner, who has made a major positive difference on-site.

“She has increased the morale of our team members overwhelmingly. All our trade workers love to see

Turner in the site trailer area and really enjoy her presence, so it has been a great journey for us,” smiles Smith.

Elsewhere, the company also supported Youth Without Shelter (YWS), an Ontario-based organization that provides housing support and educational opportunities for young people who have made the decision to restart their lives and distance themselves from difficult situations.

The company has built a broad network of support with YWS and

continues to establish partnerships by offering programs in craft training and trade support, as well as educating younger generations about the construction industry.

“Our hope is that this will provide continuous opportunities for individuals who are transitioning their lives to the best they can be.”

On top of this, Turner has welcomed interns from a local women’s shelter, supporting many in re-energizing their lives and careers by starting on a new path with the company.

“WE WANT TO TRANSFORM THE INDUSTRY LANDSCAPE TO BE THE BEST POSSIBLE PLACE FOR PEOPLE WHO WANT TO BE A PART OF IT, BUILDING LONG-LASTING CAREERS”

– STUART SMITH JR., VICE PRESIDENT AND GENERAL MANAGER, TURNER CONSTRUCTION

Turner also recently partnered with The Riverwood Conservancy in Ontario as part of a clean-up initiative to help beautify a nature park located

west of Toronto, so that it continues to be a place of nature and relaxation for years to come.

“These initiatives that we’ve been a

“IF WE CAN MAKE A POSITIVE DIFFERENCE TO THE LIVES OF PEOPLE IN THE LOCAL COMMUNITIES WHERE WE WORK, AND MARRY THAT WITH OUR INDUSTRY, WE WILL CONTINUE TO CREATE GENERATIONS OF CONSTRUCTION WORKERS WHO WILL SUPPORT GROWTH AND BECOME LEADERS FOR THE NEXT GENERATION”

– STUART SMITH JR., VICE PRESIDENT AND GENERAL MANAGER, TURNER CONSTRUCTION

part of are all core to our mission as an organization to support growth and give back to the community,” Smith expresses.

Turner strongly believes in finding the best solutions to support its clients’ initiatives, primarily through its procurement entity, SourceBlue, which has rapidly expanded over the last year.

Indeed, the brand enables the company to work directly with manufacturers to help accelerate their schedules and cement production cycles, whilst also receiving prioritized pricing.

“All in all, this leads to significant benefits for our clients, who need to order mechanical or electrical equipment, for example, before the design is complete,” highlights Smith.

SourceBlue therefore brings the required expertise of its team members to the table, leveraging experience to create what the

business calls bridging documents. These support the transition of equipment to trade contractors who will eventually install it and work with the SourceBlue team to commission it for the client.

This reflects Turner’s commitment to overseeing and ensuring the success of its clients’ supply chain, as it hopes to continue to broaden SourceBlue’s scope going forward.

The company’s future goals also include organic and holistic growth across North America, with a particular focus on core markets

across Toronto.

“We see an opportunity in the Greater Toronto area to increase our market penetration and diversify into other sectors that we are not currently engaged in, including healthcare and aviation,” closes Smith.

www.turnerconstruction.com

G&P Millwork manufacture custom millwork for the business and corporate sector. Our skilled cabinet makers, estimators, and dedicated management team are committed to providing our customers with a high quality product. G&P Millwork is one of the leading custom millwork shops in the GTA, servicing General Contractors in the office interior sector for over 35 years.

Your trusted partner in Mechanical, Electrical, and High Voltage services.

Phone: (416) 298-4204

Fax: (416) 298-6084

info@gpmillwork.com www.gpmillwork.com

Building excellence for over 45 years, MultiTech Trades Corp (MultiTech) is your trusted partner in mechanical, electrical, and high voltage services. COR certified and with over 400 skilled professionals at our disposal, we ensure every project meets the highest standards.

Our clients know they can depend on us for emergency services and preventative maintenance, 24/7, 365 days a year, whilst our expertise in HVAC, refrigeration, critical cooling, and building automation systems enable us to provide cutting-edge solutions for every sector.

Having recently expanded our capabilities through a strategic collaboration with CEC Services Limited and CEC Mechanical Ltd, we are able to offer even broader expertise and resources. From new construction to retrofits, we handle plumbing, HVAC, electrical, and custom fabrication projects across virtually all construction sectors – truly a one-stop shop for all your contracting needs.

estimating@multitechcorp.ca multitechtradescorp.ca

In addition, our modern fleet and top-of-theline equipment allows us to ensure efficient, high-quality execution on every job, truly equipping us for success.

Our state-of-the-art facilities for custom sheet metal, piping, and electrical assemblies enable custom fabrication tailored to individual needs, and our comprehensive testing, maintenance, and repair services ensure your systems run smoothly.

As we continue this successful collaboration, we are well-positioned to continue to succeed in an increasingly competitive industry.