COMPANY PROFILE 2023

MAKING LIFE ON BIKES BETTER

MAKING LIFE ON BIKES BETTER

Established in 1973, OXFORD is now one of the world’s leading suppliers of products in the two-wheeler industry. From its base in Oxfordshire, the company distributes to around 100 partners worldwide and around 2,000 domestically.

Its huge range of products encompasses everything which makes life on bikes better: from clothing and helmets to accessories, hard parts, locks, luggage and more! Following unprecedented investment in staff, product development and infrastructure, the company now employs around 170 people.

Having established an impressive growth curve, which has seen turnover doubling every 5 years, the company has further ambitious expansion plans both at home and abroad.

OXFORD products are designed in-house by a combined team of active enthusiasts and skilled technicians. They use the latest CAD technology and 3D printing techniques to innovate, analyse, test and develop the range in pursuit of the best product experience for their customers.

In addition to OXFORD branded products, the company uses its expertise to design and produce for many other labels around the world. Like many of its products, which have wider appeal in other leisure and outdoor-based markets, this activity is not restricted to the two-wheeled industry.

Making life on bikes better since 1973.

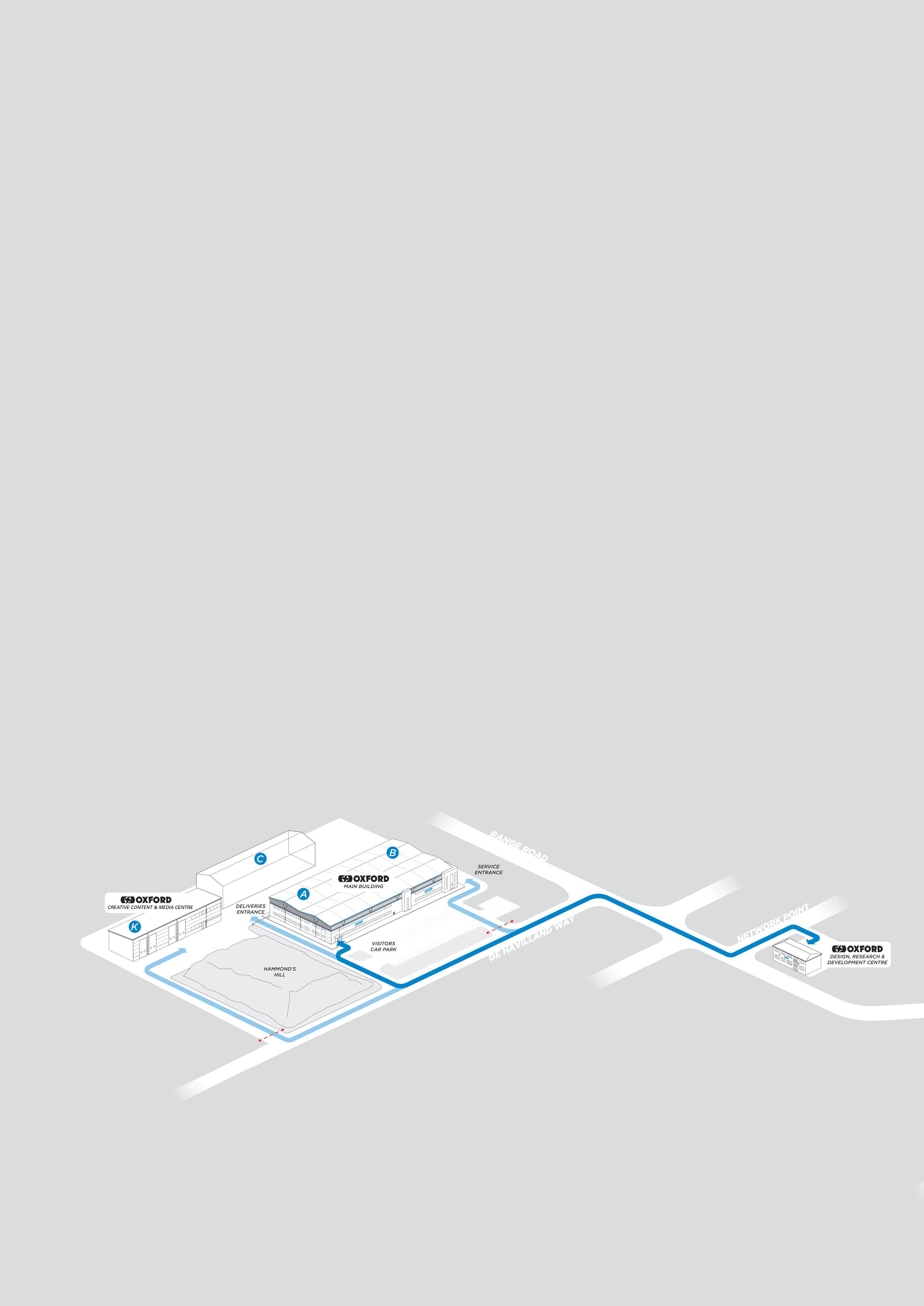

In 2021, this new facility opened, containing 2 large purpose-built photography & videography studios (fully equipped with the latest cameras, lighting and recording technologies) and an editing suite.

This and the team who run it are an essential investment in the development of our products and brands, in an increasingly audio-visual world.

Opened in 2022, this is where Oxford’s vast range of products is designed, tested and developed before being put to market.

A state-of-the-art laboratory allows all products to be tested on-site. 3D Printing capability allows rapid CAD design and prototyping to enhance product development.

OXFORD HEADQUARTERS

OXFORD HQ

A bespoke facility opened by Prime Minister David Cameron in 2014 has recently been expanded with additional warehousing to 150,000 sq ft / 14,000 m2

WHERE IT ALL STARTED

OXFORD HEADQUARTERS

OXFORD HQ

A bespoke facility opened by Prime Minister David Cameron in 2014 has recently been expanded with additional warehousing to 150,000 sq ft / 14,000 m2

WHERE IT ALL STARTED

Oxford Essential Rider Equipment is distributed in the UK by a network of retail partners.

Telephone: 01993 862 300

Email: info@oxprod.com

Web: www.oxfordproducts.com

Online store (trade-only): Retail partners can view stock availability, prices and place orders online via a secure log-in. Please contact trade@oxprod.com for more information.

OXFORD is a remarkable British success story! For five decades the company has waved the flag for British ingenuity and innovation and is proud to have distribution partners in all corners of the globe.

In return, foreign markets have provided many fresh ideas to OXFORD’s product range; the challenges of widely varying climates, customs and terrain have only served to enrich the company’s offering.

You will find a full distributor list at www.oxfordproducts.com. Please contact us for further information: Tel: +44 (0) 1993 862 300

For export trade enquiries email us at export@oxprod.com

FACEBOOK /OxfordProductsLtd

TWITTER @OxfordProducts

INSTAGRAM @oxfordproducts

YOUTUBE /OxfordProductsLtd

LINKEDIN /oxford-products-ltd

At its heart, Oxford is a products company – Oxford Products! The team develops its products in-house, increasingly through the use of Computer Aided Design. In order to maximise the benefits of CAD, the company has invested in the latest 3D print technology.

This means that a product or component designed today can be printed off overnight and tested tomorrow. The day after, our factory can be making the moulds and production can begin shortly after. In this way, product development time is dramatically reduced and the end result far more relevant and ambitious. Here is a typical design cycle for an Oxford product…

DESIGN ANALYSIS

TECHNICAL DRAWINGS

VISUALISATION

3D PRINTED PROTOTYPES

PRODUCT TESTING

FINISHED PRODUCT

Our products are rigorously tested for both real-world usability and relevant product standards in our test laboratory. Having this facility in-house enables us to develop products which are measurably better, faster. Some of our key testing equipment is outlined here.

Our Fuse 1+ printer produces high precision prototypes within 24 hours with a powerful 30W laser that prints at scan speeds of up to 12.5 meters per second.

A powder recovery system for the Fuse 1+, allows for the recycling of leftover particles from printed prototypes, and reuse in future prints.

Our Form 3+ printer produces functional, high-quality resin prototypes and end-use parts in short time frames.

Using the Form Wash, we remove residual resin from 3D printed parts. The Form Cure then exposes the part to multi-directional LEDs, curing and maximising the strength and performance of 3D printed prototypes.

Accelerated weathering testing reproduces damage caused by sunlight, rain and dew. In a few days or weeks, the QUV UV tester can reproduce the damage that normally occurs over months or years outdoors. This allows us to select materials and finishes which will offer impressive longevity.

Our Tensile Testing System allows us to test our samples with up to 5,000kg of controlled tension until the product fails. We can observe not only when failure occurs, but how it occurs and engineer the final product accordingly.

We have 2 industry-standard bench multimeters for electronic component design, programming and testing along with 2 portable multimeters for testing on the road. In addition, we use a multi-channel thermocouple and a thermal imaging FLIR camera to measure and record the heat distribution and pattern. This is critical equipment in the design and continuous development of the HotGrips ® and battery management ranges.

We use our Perspirometer and Incubator to test for colour fastness and phenolic yellowing.

Using the Hydrostatic Head Tester, we are able to determine the resistance to water penetration under pressure.

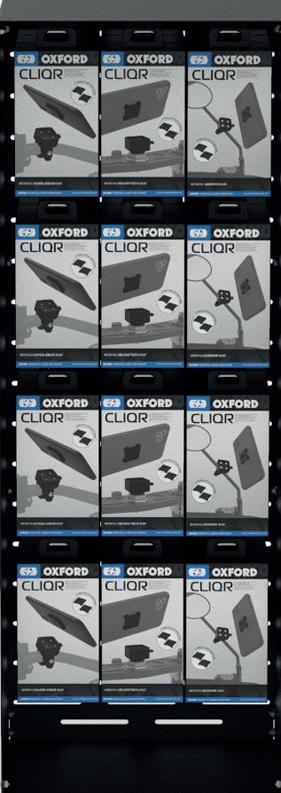

Oxford provides its partners with a huge choice of bespoke display systems, all designed to present its products efficiently, effectively and in the best possible light.

PC7000

‘HARDWARE’ REQUIRED:

PC7001 End uprights (black)

PC7003 Central upright (white)

PC7004 Base plinth & back panels

PC7005 Pair of header wings (black)

PC7006 Centre header (black)

‘SOFTWARE’ REQUIRED:

PC7007 A/C Acrylic header

PC7005 A/B/C Header wing vinyl

PC7006 A/C Centre header vinyl

PC7004 A/C Base plinth branding

OPTIONAL ACCESSORIES:

PC7008 Crossbar (white)

PC7009 Product arm (black)

PC7009A/C Product arm branding

PC7010 Product shelf

PC7011 Glove rack

PC7011A/C Glove rack branding

PC7012 D-bar

PC8020

COMPONENT CODES:

PC8020A Lower section

PC8020B Upper section

PC8022 Display Arm

PC8023 Shelf with hanging rail

PC8027 Shelf with Brand Ticket Strip

PC8025 Glove Rack

PC3020OXA Graphics packs

PC3020OXB Optional infill panels

PC8060 Stand

PC8061 Arm PC5062 Shelf

PC8010 Advanced flexible display frame set

PC8011 Panel set (Pack of 2)

PC8012 Short hanging arms

1400mm

1230mm

465mm

PC5001

FOR A SINGLE UNIT, YOU NEED:

1 x PC5001 - Stand panel set

1 x PC5002 - Stand base & header

1 x PC5003 - Stand uprights (2)

1 x PC5005L - Left hand decorative end

1 x PC5005R - Right hand decorative end

FOR EACH ADDITIONAL UNIT JOINED TOGETHER, YOU NEED:

1 x PC5001 - Stand panel set

1 x PC5002 - Stand base & header

1 x PC5004 - Upright (1)

MATCHING DISPLAY ACCESSORIES INCLUDE:

PCHOOKBL Black euro hooks (typically 30 per unit)

PC5006 Black half-width shelves

2290mm

PC8040

‘HARDWARE’ REQUIRED:

PC8040A Wall display base & header

PC8040B Wall display lower & upper panels

PC3016A & B

‘HARDWARE’ REQUIRED:

PC8015A Advanced double sided stand base

PC8015B Advanced double sided stand 2 x panel & header

PCHOOKLB Wall display replacement base stickers

PCHOOKSB Wall display replacement header stickers

PC5006 Accessory shelf

‘HARDWARE’ REQUIRED:

PCZEROA Zero-G Display Stand Base

PCZEROB Zero-G Display Stand Arm

PCZEROC Zero-G Display Stand Header

OPTIONAL ACCESSORIES:

PCZEROD Zero-G Signage (pack of 8) Use up to 4 arms

Still family-owned and family-run, the company has developed from the humblest of beginnings into the UK’s largest distributor of two-wheel aftermarket products and created an international brand to be reckoned with in all corners of the globe.

Now into its 51st year, the Oxfordshire-based brand packs an impressive punch, boasting a range of around 12,000 motorcycle and bicycle products, each one designed, developed and tested in-house at the firm’s R&D centre, part of their 150,000 sq ft empire in Oxfordshire. In the UK, the company also distributes several thousand product lines from some key global brands. And it all started in 1973 with the humble top box…

“Motorcycling was somewhat different in those days,” begins Oxford founder and Chairman, Alec Hammond, who back in 1973 was a 28-year-old sales manager working in the pharmaceutical industry. “There were massive numbers of folk riding to work and luggage hardly existed.”

Around that time, Alec was introduced to a Nottinghamshire-based innovator who had created a range of high-quality top boxes but had no idea how to get them to market.

“I agreed to show some samples to a few motorcycle dealers whilst travelling in the course of my job,” continues Alec. “The top boxes got a massive thumbs up from several dealers who clamoured to buy them. I became convinced that I could build a business in the motorcycle world, so I left my comfortable, secure job and pushed David to go into full-time production of the boxes.”

From fibreglass top boxes, Alec quickly branched out into bodywork, and it wasn’t long before the fledgling Oxford Fairings got into the sportier side of motorcycling.

“We got involved with racing fairly early on,” says Alec, “sponsoring several riders with our fairings on Peckett-McNab Kawasakis. This evolved over time until I was running our own team in the equivalent of BSB and at the Isle of Man.”

Although still very much involved with racing through the title sponsorship of the Moto Rapido Ducati BSB team, the Oxford of today is a far cry from those early days marketing fibreglass fairings and top boxes. In the early 1980s, Alec started manufacturing motorcycle locks, then came accessories – including the now legendary HotGrips, which were born in 1983 and have remained a constantly evolving product in Oxford’s lineup ever since.

Oxford’s huge range of products now encompasses everything which makes life on bikes better: from clothing and helmets to accessories, hard parts, locks, luggage and more!

During the 1990s, the company diversified into cycle locks and then rapidly into helmets and other cycle

accessories during the 2000s. Following an acquisition in 2010, a new cycle division was established to focus on selling a complete range of parts and accessories into the wholesale market. This eventually expanded into independent bicycle dealers in 2016 and has not looked back since.

Following unprecedented investment in staff, product development and infrastructure, the company now employs around 170 people.

Having established an impressive growth curve, which has seen turnover doubling every 5 years, the company has further ambitious expansion plans both at home and abroad.

1973 Present owner and chairman Alec Hammond starts selling GRP motorcycle top boxes out of the back of his car.

1974 Oxford Fairings expand the product range and Alec starts recruiting staff to cope with business growth.

1975 Launch of complete seat & tank unit for FS1E.

1976 Track involvement begins with own race team: Les Burgan, Asa Moyce, Mike Hunt, Geoff Johnson all ride for Team Oxford.

1977 Based in Botley, on the edge of Oxford, now with warehouse and office complex. The company’s expands it’s range and introduces first security device: Bike Guard.

1978 Oxford produces carbon fibre bodywork for Mike Hailwood to use at the TT.

1981 Botley HQ wiped out by a fire. Phil Read rides the Oxford Yoshimura Suzuki at the TT.

1982 Relocation to Abingdon, business starts again almost from scratch.

1983 Oxford “HotGrips” are born, the start of a legend!

1984 Re-built business moves to new premises in Kidlington and sponsors Trevor Nation’s first ever TT win.

1985 International sourcing begins and range expands quickly. Over the next period, lock development moves on apace and Oxford quickly becomes market leader in bicycle security with the “Sentinel” range of U-locks.

1990s Business continues to grow strongly, acquiring more premises in the same industrial estate and expanding its quality team of staff.

1994 Oxford launches its first Disc Lock, the “Quartz” and sales spiral internationally.

1997 Launch of revolutionary “Oxford Lifetime Luggage” enables company to become UK market leader in soft luggage almost overnight and globally recognised within two years.

1998 Oxford is appointed exclusive UK distributor for HJC helmets, First track signing is Steve Plater on the Sanyo Honda and HJC’s race involvement increases every year thereafter.

2004 Company moves to large, purpose-built premises in Witney, Oxfordshire. Local schoolboy Bradley Smith is sponsored to ride in HJC helmets.

2005 Launch of a specific cycle products division.

2006 Oxford creates new helmet brand: BOX helmets.

2009 Oxford sponsors 125cc GP race winner Bradley Smith.

2010 Company purchases cycle parts distributor Sprint CPA Appointed UK distributor for global brand Alpinestars.

2011 Title sponsorship of Oxford TAG Triumph British Supersport race team, to add to sponsorship of the Buildbase BMW BSB team, Bradley Smith in Moto 2 and many more.

2012 Company wins exclusive distribution for Muc-Off in the motorcycle market.

Oxford Products USA opens its doors.

Launch of B2B website.

Voted “BDN Wholesaler of the Year” and “MCN Wholesaler of the Year”.

Oxford-sponsored Bradley Smith finishes stint in Moto 2 and takes first steps into the Moto GP paddock.

2013 The company’s 40th Anniversary is celebrated with its biggest ever line-up of new products and brands.

Oxford Essential Rider Wear is launched.

Oxford wins “Large Business of the Year” in the Oxfordshire Business Awards.

2014 Prime Minister David Cameron officially opens the company’s 100,000 sq ft expanded warehouse and office complex.

Company wins Oxfordshire Business of the Year award. Andrew Hammond wins Businessman of the Year award!

2015 Voted as Distributor of the Year in British Dealer News and Motorcycle Trader, and second successive Motorcycle News Distributor of the Year award. Major race sponsorship deals with TYCO BMW, Buildbase BMW and Quattro Plant Kawasaki.

2016 Oxford passes the 100 staff milestone and a new sales team hits the road. Signs a 16-country distribution deal with Shimano Europe.

2017 Oxford celebrates 40 years of involvement in racing. In-house design capability increases with development of a Product Test Laboratory.

25th anniversary of Oxford Team Ducati’s last appearance at the Isle of Man TT Celebrated by recreating the team for the 2017 Classic TT with rider James Hillier.

2018 Launch of ‘Advanced Accessories’ range

Oxford launches its first range of cleaning and maintenance products under the name ‘MINT’,

2019 Launch of the Advanced Rider Series.

Establishment of a number of exclusive Oxford Group stores.

Oxford’s bicycle division enjoys significant growth, as continued product development is capitalised through a rapidly growing customer base. IBDs begin to catch onto Oxford’s displays systems as a way of increasing sales in-store.

Oxford Racing Ducati (and sponsored rider Tommy Bridewell) finishes the season in an amazing third place in the British Superbike Championship.

2020 As the UK and global economies are hit by intermittent lockdowns, Oxford keeps its doors open at all times and swivels its focus to support on-line, export and cycle business.

Oxford’s cycle business doubles almost overnight, as lockdown reminds the UK of the merits of pedal power!

On-line sales boom and export sales defy Brexit. The company breaks sales records.

In-house design capability increases with development of a Product Test Laboratory.

2021 Company records its biggest ever annual growth.

Race sponsorship continues at the highest level of BSB, with Tommy Bridewell finally bringing home Oxford Products Racing Ducati in second position and HJC rider Christian Iddon in fourth.

2022 Oxford purchases a new building a short walk from its existing HQ and opens a new Design, Research & Development Centre equipped with new 3D printers, test laboratory and an expanded product team.

An additional warehouse is built on the existing site, providing a further 3,500 pallet spaces to accommodate further significant expansion.

Race sponsorship continues at the highest level of BSB, with Tommy Bridewell battling for the championship all the way to the last round, finally bringing home Oxford Products Racing Ducati in third position.