Newsletter of the APRIL 2023

PORT ELIZABETH MODEL RAILROAD CLUB

Associated member of PEMLS (Port Elizabeth Model Locomotive Society)

Every Gauge Welcome!

IN THIS ISSUE:

Committee - Diary - Club News, PEMLS, Members, Last of Tyneside - Latest on Ohio

derailment ² - Brake Tenders - Horst Fleischmann † - Climax Class A Logging Locomotive

Locus Heights & Western RR - Tempi Train Crash - Trains in movies - Market Place

3D Printing + Special Offer - Trainz acquires Dwarvin - Club digital library

Sandstone extends line - Gallery

Bachmann HO East Broad and original

Bachmann HO East Broad and original

Our 2022 paid-up members as well as those who have already renewed their 2023 membership, are now associate members of the PEMLS. In that capacity we have the right of access to build our club house on the identified and agreed to site; we do not have any voting rights at any PEMLS meeting but we may observe proceedings. We may also volunteer to assist with the running of the monthly PEMLS Open Day; their rules and protocols will apply and we will have to abide by them. A part of your paid subscription to PEMRC has been paid across to PEMLS to achieve the above’ i.e. R100 annual 2023 subscription plus R50 once off joining fee.

Once the legalities of the lease have been finalised, we can start to build.

Please assist the planning team with an update of your skills set and available time so that we can roster the members as efficient as possible and taking their availability and skills into account.

I am available to spend up to ……hours on the Londt park site, but only on these days………

I am skilled in…….

Our Group as associated PEMLS members needs a name.

Do we continue as is with PEMRC? That might not be possible…

Or do we become Model Railroaders PE? Or Railway Modellers P E?

Or the Small Scale Model Rail Group Or………..

Our Club House needs a name too………………………………….

Please voice your opinion on these matters via Email to pemrailroadclub@gmail.com

Or WhatsApp to the PEMRC group (now Model Railroaders P E)

Or SMS to 0827397679 if you don’t have access to email or WA.

Please remember to add your name to your post or update your profile to include your real name.

James Kruger is recovering after a stroke.

We all need to use our hobby to relax and pass stress to someone else! Our “youngest member”, Albert Brown, is making good progress after facial surgery to remove a melanoma and as long as his third leg is there for support, he gets around although he no longer drives his car.

Hylary Smith is also doubting whether to renew his driving license and except for the meetings in Newton Park, may also have to forego on the member layout visits due to his failing eyesight.

We are grateful to the camaraderie amongst our members to share rides whenever possible.

No shipping costs for combined orders of R2000 or more. Shop online and fill your cart, even if less than R2000, then contact PEMRC Mike van Zyl, to combine your order with fellow club members and all will save.

THE END of “TYNESIDE”?!

On 18 March members visited Mike Smout’s current 00 layout “Tyneside” probably for the last time. After more than a decade of enjoyment, Mike wants to build something smaller but ‘bigger’ than a shelf layout and it could become a multilevel ‘shelf’ layout with a switchback… During the next month or so he will tackle the ‘demolition’ of “Tyneside” and where items could be repurposed on the new layout, they would be retained, if not, they will be disposed of. Therefore, be sure to attend the ‘salvage’ meeting at Mike Parsons’ in April. A final glimpse of Mike’s workmanship:

The third batch of Key Publishing’s popular ‘OO’ gauge Diesel Brake Tender ready-to-run models are now available with three new running numbers being applied to the Dapol produced model. The models are available to purchase exclusively through Key Publishing. Diesel Brake Tenders were introduced in the early 1960s to increase the brake force available to unfitted goods trains hauled by new diesel locomotives. There were several versions of the Brake Tender with Key Publishing’s model representing the Diagram 1/555 vehicles built at York in 1962-1965 and fitted with Gresley bogies. In total 122 Diesel Brake Tenders were built, numbered B964000B964121, with the last being withdrawn in the early 1980s. All were scrapped, but a replica has been built by the Railway Vehicle Preservations at the Great Central Railway. The new batch of Diesel Brake Tender models from Hornby Magazine and Key Publishing are ideal for pairing with classes 17, 24, 25, 37, 40 and 44 and they could be positioned in front or behind the locomotive when operating with unfitted coal trains. Identities chosen for the three models are B964040E in plain BR green with original body side markings (Cat No. HMDBT-017), B964066E in BR green with small yellow warning panels and original body side markings (HM-DBT018) and B963113 in BR green with small yellow warning panels, later body side markings and a weathered finish (HM-DBT-019), pictured above. Product highlights include removable lamps at each end of the brake tender, NEM coupling pockets fitted with small tension lock couplings, turned metal wheels and two designs of handbrake wheel to match the real vehicle.

Contact your Märklin dealer or favourite model shop for this Shuco Unimog HO 1:87 #452663400

Railroads urged to improve the way they handle data from wayside detectors in wake of NS derailment

in East Palestine, Ohio

Smoke rises during a controlled release of chemicals at the East Palestine, Ohio, derailment earlier this month. Bazetta, Ohio, Fire Department, via Trains.com

WASHINGTON – The Federal Railroad Administration on 28 Feb 2023 encouraged railroads to improve the way they collect and use data from wayside hotbox detectors in order to prevent catastrophic derailments like the Feb. 3 Norfolk Southern hazardous materials wreck in East Palestine, Ohio.

“Preliminary investigation of recent train derailments indicates the cause of, or contributing factor to, the incidents was a mechanical failure, specifically burnt journal bearings. Accordingly, FRA is issuing this Safety Advisory to make recommendations to enhance the mechanical reliability of rolling stock and the safety of railroad operations,” the agency says.

Specifically, the FRA safety advisory recommends that railroads:

Evaluate the temperature thresholds for inspections based on hot bearing detector data.

Consider real-time use of trend analysis of detector data for stopping a train for inspection.

Ensure proper training of crews responsible for calibrating, inspecting, and maintaining hot bearing detectors.

Ensure proper inspection of rolling stock that trigger hot bearing detector alerts.

And improve safety culture, particularly regarding operational decisions that are based on hot bearing detector data.

The advisory notes that since 2021 the FRA has investigated five derailments that were suspected of being caused by burnt journal bearings. Three of those derailments occurred on Norfolk Southern, while the other two were on Kansas City Southern.

Two of the NS wrecks – in Warner Robins, Ga., and Sandusky, Ohio – occurred after hot bearing detectors warned of overheated journal bearings. In both instances, the train crews stopped and inspected the problem axles. But they then were instructed to continue on their way without setting out the problematic car in Georgia or the locomotive in Ohio. Both trains later derailed.

In the East Palestine wreck, a pair of hotbox detectors recorded increasing bearing temperatures on the car suspected of causing the derailment. But the temperature readings never reached the critical threshold that would have tripped an alarm and required the crew to stop the train – until moments before the derailment, when train 32N passed the detector at milepost 49.81 in East Palestine.

“Detecting overheated journal bearings before they fail is critical to accident prevention. Journal bearings are sealed components, and, as such, often do not display ‘tell-tale signs’ of overheating (e.g., leaking lubrication), making defects in journal bearings difficult to identify through visual inspections,” the FRA said. “HBDs can serve an important role in early detection of bearing defects, but the effectiveness of any HBD system maintenance standards and procedures; (2) the establishment of safe thresholds at which to act on HBD alerts; and (3) strict adherence to procedures that prescribe actions to be taken.”

The FRA noted that it does not regulate wayside detection systems and that its safety advisory does not carry the weight of law. But FRA said it is “likely not appropriate” to allow a train transporting hazardous materials to continue to operate without restrictions after it triggers a hot bearing detector alert. FRA said railroads should consider expanding the Association of American Railroads’ recommended operating practices for the transportation of hazardous materials to other trains. If a defect in a key train – one carrying one tank car load of poison inhalation hazards, or 20 loads of hazardous material, or one or more loads of spent nuclear fuel or high level radioactive waste – is reported by a wayside detector, but a visual inspection fails to find the problem, the train must not exceed 30 mph until it passed the next wayside detector or stops at a terminal for an inspection.

Greg Regan, president of the AFL-CIO Transportation Trades Department, praised the FRA recommendations.

“We welcome this action from the Federal Railroad Administration to improve safety in the freight rail industry. Currently, there are no federal regulations guiding wayside detectors, including their

placement along tracks or temperature thresholds,” he said. “There’s not even a federal definition of wayside detection technologies. Rail workers are eager to see a complete set of federal regulations on the installation, operation, testing, repairs, and maintenance of all wayside detection technologies, including defect detectors.”

Norfolk Southern noted that the crew of train 32N was operating the train within company rules, began to stop the train after it triggered the wayside detector alarm, and that its detectors were operating as designed. The railroad also has inspected all of the nearly 1,000 detectors on its system, in addition to the regular inspections of the detectors every 30 days.

HORST FLEISCHMANN †

Horst Fleischmann, long-time owner of the former Nuremberg model railway manufacturer, passed away on December 18, 2022. He was born on February 14, 1936. The business graduate joined the management of the family business in 1969, which he later managed as the sole managing director. In the same year, after 20 years of HO production, Fleischmann expanded its range to include size N.

Horst Fleischmann paid attention to the smallest details for both sizes. Employees tell us that he ran his own test facility in his office with all sorts of chicanes in the track layout, on which new designs had to prove themselves before they went into production - a production that, of course, did not take place abroad. The slogans were correspondingly appropriate: "Quality, quality, quality" and "The model railway for professionals".

The increasing cost pressure and the Far East production of competitors made Fleischmann more and more difficult. In 2008 the company was sold to the Austrian Modelleisenbahn Holding GmbH, which for its part could not avoid Fleischmann's insolvency in 2015. Since then, Fleischmann has only been a product line that has focused on the production of N models since 2019.

With Horst Fleischmann, the industry loses one of the last business leaders from a time when it was not a question for little boys whether they owned a model railway, only which one - Märklin, Trix or the Fleischmann DC railway.

© Model Eisenbahner 3/2023

Home-grown logging railroad: step back into the past with the locust heights & western railroad, based in Clarksburg, W.VA. The railroad is powered by a replica of a climax type a logging locomotive, a design dating back to about 1890. Kevin Gilliam

As steam locomotives go, logging engines aren’t the most attractive specimens out there. They’re the railroad version of the long-standing joke that a camel is a horse designed by a committee. But let’s not get hung up on appearances. These engines carved out their own niche in the very lucrative timber industry, and they have an enormous fan base.

There were three main makers of logging locomotives Shay, Heisler, and Climax. The Climax Manufacturing Co., (later renamed Climax Locomotive Works), was based out of Corry, Pa., and eventually built about a thousand locomotives. Most of them had cylinders set at about a 45-degree angle connected to a line shaft running along the underside of the boiler.

Some of the earliest Climaxes had vertical boilers resembling tents on wheels to the entire world. Very few examples survive. One example is actually a replica class a, and it operates near Clarksburg, W.VA.

A man buys a caboose for the kids to play on. Then he decides the caboose needs some track to sit on. Then he decides he needs something to pull the caboose around with. So he goes hunting for blueprints and builds his own steam locomotive. Strange but true. This is the back story of the Mason Family.

Keith Mason owned a blacksmith shop, and his Locust Heights & Western soon expanded to fill the family’s property in the mountains. The rails are three-foot gauge and there’s just about three quarters of a mile of trunk with grades in excess of 4%. In the early 1970s,

Mason constructed a replica class A Climax. The closest real Climax of that type would have dated to about 1890 very early in the company’s history.

It may look strange, but its coal fired and it operates on steam – and that is all that matters!

https://youtu.be/0_jt5wqnwxu

https://www.facebook.com/LHWRR/photos/?ref=page_internal

LATEST FILM

A blend of historicrailroadattractionshelpsrecreatea1970s commutertrainfor “AManCalledOtto,” thelatestfeaturefilm starringTomHanks.

Emboldened by new state tax credits and a strong filmmaking community, Pennsylvania has seen a steady increase in film and television productions – and with them have come a special set of creative challenges. In late 2021, producers for AManCalledOttoknew they needed to solve one problem very early on: they needed trains. While trains had played a different role in the original Swedish book and subsequent film Man CalledOve(2015),the new American adaptation featured only vestiges of the railroad element, but in a more romantic backdrop.

“The train work in this picture helps form the narrative heart of the movie, but we knew it would be very challenging to serve our specific creative ambitions while remaining both on budget and on schedule,” explains John Adkins, locations manager for the movie. “We told our local contacts in Pittsburgh that we needed a ‘train guru’ and they knew just the right person to make it work.”

Linked by the technical expertise of railroad consulting firm FMW Solutions and its movie train coordinator Kelly Lynch, the equipment and locations of the Potomac Eagle Scenic Railway, Cuyahoga Valley Scenic Railroad, and Washington DC Chapter of the National Railway Historical Society were sourced to appear in two flashback sequences.

With his lifelong connection to the railroad world, Lynch’s film pursuits began at NBC/Universal in 2005 and have since led to a number of awards for his screenwriting, creative, and commercial work. After bringing his expertise to FMW Solutions in 2021, Lynch’s help on an Amazon television series in Pittsburgh led to the recommendation for Otto.

“Sourcing equipment that would fit the look and feel for Ottowas the easiest part, but threading the needle of getting the locomotive and passenger cars where they needed to be is why we were hired,” explained Lynch. “While the original desire was to film platform exteriors at Pittsburgh Union Station and moving train work on a nearby regional railroad, the short lead time, proximity to a busy freight and passenger mainline, and other logistical limitations meant we had to explore a number of alternatives.”

Loosely inspired by the Mon Valley Commuter Rail system that served the Pittsburgh region in the 1970s, an FP-9A locomotive from Potomac Eagle and former MARC and Pennsylvania Railroad commuter cars fit the bill.

After leading a series of technical and director scouts, filming took place over three days, at three different locations. The first was a day of exterior aerial work in Romney, West Virginia featuring the Potomac Eagle’s characteristic diesel locomotive and stainless steel passenger cars, which looked visually similar to the MARC cars. A few weeks later, filming resumed in May for interior scenes aboard the Cuyahoga Valley Scenic Railroad’s passenger train set in the Cuyahoga National Park.

“During the busy tourist season, hosting a film production can be a big task, but we’re grateful to the National Park Service for helping us welcome the production to the Valley,” said Joe Mazur, President of the Cuyahoga Valley Scenic Railroad. “Our crews really enjoyed it and it created a lot of buzz for us in the community.”

For the moving train work, the production modified a former Budd Rail Diesel Car, chosen for its spartan interior to reflect the state of passenger rail in the 1970s, and operated between Jaite and Rockside, Ohio.

“Every movie train is special, though generally, productions want either steam locomotives or modern freight or passenger trains,” added Lynch. “This is an era of passenger rail rarely seen on film. In some cases, car interiors were rejected because they were restored and looked too nice.”

In the interim, the Potomac Eagle locomotive ventured to Toledo where it would meet two former MARC commuter cars shipped in from the Cuyahoga Valley where they’d been leased for

seasonal events. Lynch escorted both shipments as they moved en route over CSX, and the equipment arrived a week before production began.

“For the Potomac Eagle, shipping one their primary locomotives out ahead of their regular season was not an easy decision, but we were fortunate to have CSX railroad crews in Cumberland, Maryland, Walbridge, Ohio, and at CSX Community Affairs to make sure this equipment would make it to and from its engagement in Toledo without issue, ” detailed Lynch.

Amid pre-production, Toledo’s art-deco Central Union Terminal had been an early favourite of director Marc Forster and production designer Barbara Ling.

“The station and period trains were a perfect match,” said Louise Rosner, executive producer. “Once we confirmed the Toledo Port Authority owned the platforms and actual trackage, we knew we had three tracks and 4,000 feet of the railroad to operate on without encumbering the nearby mainline or disrupting Amtrak’s passenger operations,” Lynch stated.

“The local Norfolk Southern crews were critical to ensuring the production could select Toledo as a location, as they worked with us to ship, switch, and position the equipment so that our teams could take over,” said Lynch. “Their level of responsive customer service was not only impressive but a great relief.”

In coordination with the Port Authority, Norfolk Southern, and Amtrak, Lynch isolated the platforms, imported station props from a nearby railroad museum, and conducted safety briefings with a cast of over 160 performers. The third day of railroad work on the production would also be the final day of principal photography.

“Even in a tightly controlled operating environment, this many people on a platform with a moving train represents safety concerns. During our production briefing, we taught everyone the signal to ‘stop,’ for instance if they saw someone trip, fall, or otherwise saw something that was unsafe. Everyone knew what our whistle signals meant in terms of train movement and direction and we had flagmen to protect performers,” explained Lynch.

Overall, the production brought a six-figure boost to the local economies in Brecksville and Toledo as a cast and crew of 300 descended on Ohio, and equipment returned without issue. “The train work went off perfectly,” added Rosner.

Ultimately, the movie train work makes up approximately five minutes of total screen time, but the additional layer of authenticity and practical sets are a departure from a trend towards artificial sets or digital imagery. Of course, it also means the railroad entities involved were compensated too.

“Tourist railroads and museums are great assets that can usually be very accommodating within reason,” Lynch furthered. “We filmed a drone scout for the aerial film crew on a Friday so the director could pick out locations, and less than a day later we were on board the passenger train to travel to the spots that had been selected, and then filmed until we ran out of daylight. Even for cost-conscious shows, there’s still a lot that’s very achievable and can be accomplished safely, quickly, and creatively.”

“With trains, you have all the complications of props, locations, safety, stunts, vintage vehicles, and more rolled up into one. FMW not only helped all of us wrap our heads around what was achievable, but they went out and made it possible,” explained Adkins.

FMW Solutions was also assisted by Mid America Railcar, Carload Express, Mad River & NKP Railroad Museum, Horizon Rail, Fort Wayne Railroad Historical Society, McRail Insurance, Brian Smith, and Chris Homco.

“It really means a lot to marry two remarkably complex industries,” said Lynch. “But it’s also immensely satisfying to call up our network of partners and connect the dots together for a project like this. Railroad magic and movie magic really aren’t that much different from one another.”

A MAN CALLED OTTO - Official Trailer https://youtu.be/eFYUX9l-m5I

Website: https://www.amancalledotto.movie

RAILWAY BOOKS - Model and more

I have reorganised the uploads to our various Google Drives and this will impact on some of the links in previous newsletetrs but that is unavoidale. Let me know when you can’t find what you are looking for and I will help you out!

PDFs of books are now orgainised under PEMRC E-BOOKS COLLECTION (99% full) as follows: E-Books and E-Magazines are now on separate drives (mostly) but some reference magazines had to be included on the E-Books drive due to lack of space. Digital

The E-Books folder has these sub-folders:

British railways publications; South African Railways Illustrated; VGB Traumanlagen

On the double page spread that follows you will find an example and the link to the Weathering books folder.

THE MAGAZINES ARE HERE and currently the following are on this 99% full drive:

Click on the two links above.

Please advise which titles you want to see there and which ones we can discard. Foreign language titles are worthwhile reads and there is always help at hand, just ask, but pictures mostly tell the story anyway.

A spread sheet with a more detailed list of what is on the drives is here I encourage you to download as much as possible to create space for the 2023 issues.

Please review our collection and download those you want and advise which ones can be discarded as obsolete: Our video collections are here:

Collection 1

97% full

Collection 2

86% full

Collection 3

97% full

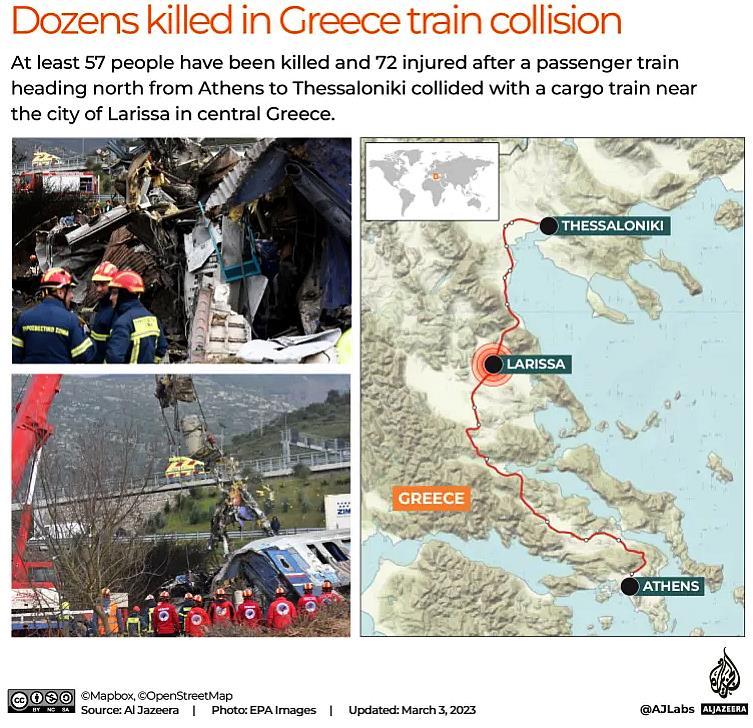

Siemens/Bombardier UIC-Z1 coaches of Hellenic Train that are used on InterCity services in Greece

Siemens/Bombardier UIC-Z1 coaches of Hellenic Train that are used on InterCity services in Greece

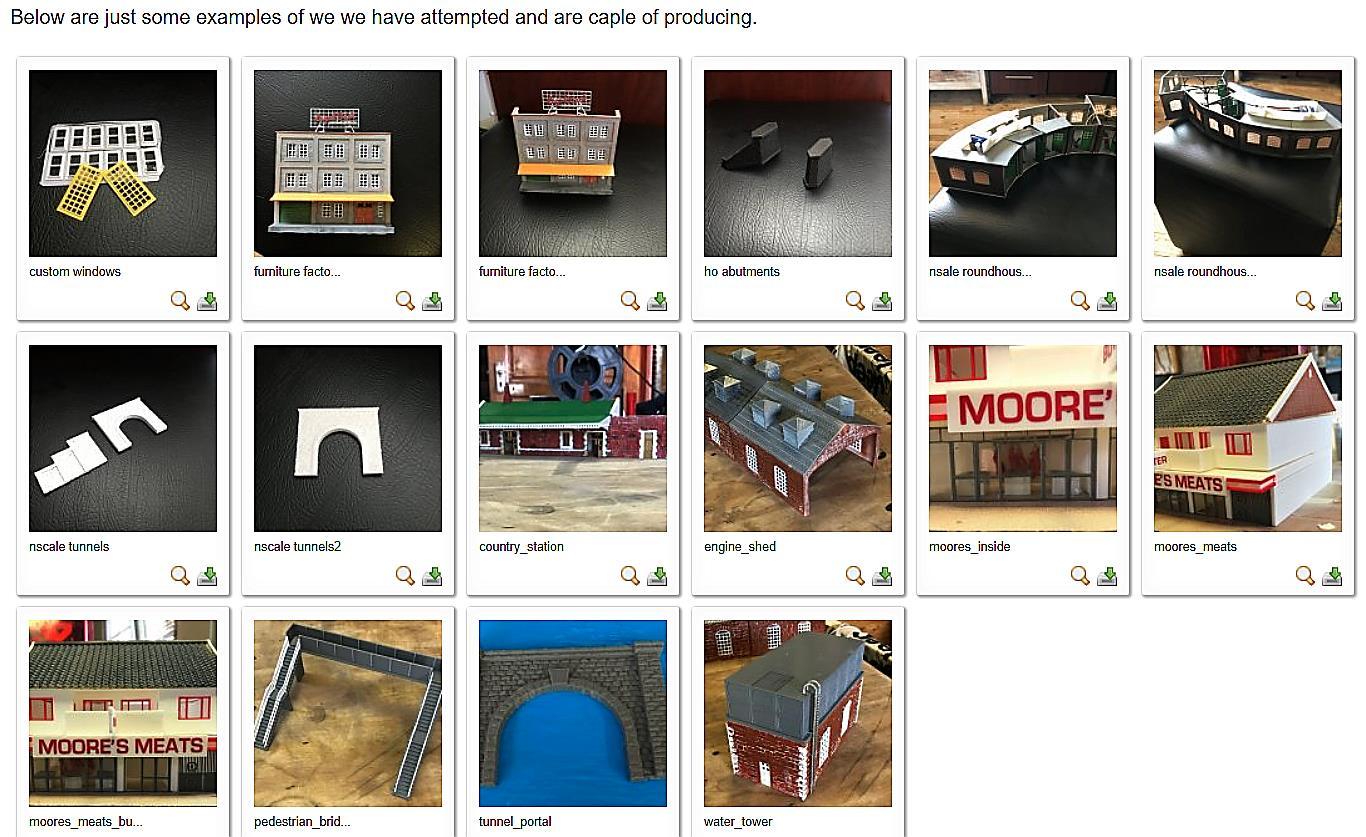

Robbie Deacon 082 852 5119 is selling these HO buildings:

Henk Grootendorst 071 851 4661 is selling a vast collection of HO rolling stock

Robbie Deacon 082 852 5119 is selling these HO buildings:

Henk Grootendorst 071 851 4661 is selling a vast collection of HO rolling stock

View Dwarvin’s YouTube Channel videos:

View Dwarvin’s YouTube Channel videos:

© David Benn.

© David Benn.

© Eugene Armer

© Eugene Armer