Plymouth Church

TYPE: Exterior / Interior restoration

COLLABORATE:

Architect: Thomas A. Fenniman, Architect

Architect: Christopher Rome

Address: 57 Orange Street / 75 Hicks Street Brooklyn, NY 11201

Project Type: Interior / Exterior Restoration

Project Responsibility: MasterPlanning, SD \ DD \ CD \ Bidding \ CA(w.i.p.)

Historically, Plymouth Church was a leader in the abolitionist movement, the underground “railroad” still exist till this day as part of tours available from the Church. The building went through series of changes and modifications due to fire, spatial expansion, and general maintenance. We were invited for a masterplan proposal to help analysing the existing spaces, as well as accommodating for any future expansions. Due to the lack of money, phasing of the masterplan was introduced to meet the Church’s timeline of the fundraiser. Furthermore, due to the age of the building and the LPC involvement, a thorough research through historic photos, data, and documents were needed in order to satisfy the needs of the LPC.

PAGE 4

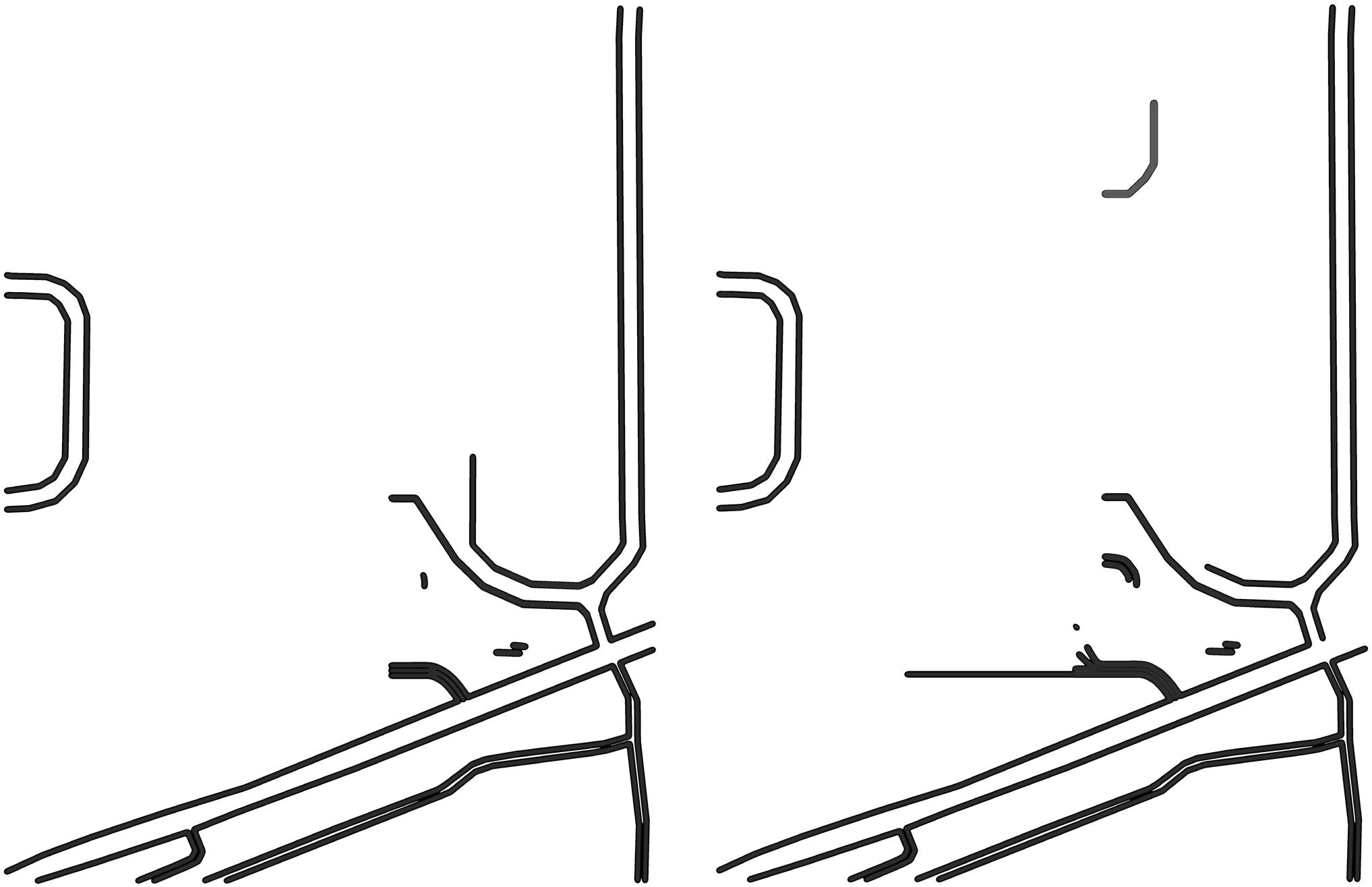

8 8 1 2 1 1 585 SF. 1 3 7 0 0 S F 1 8 0 0 S F 3 9 0 0 S F WW WW W W W PLAYGROUND EQUIPMENT 24" 24" 16" 24" 16" 16" 16" CURB LINE POLE SIGN G SIGN SIGN SIGN SIGN SIGN SIGN SIGN LIGHT LIGHT SIGN HYDRANT SIGN LIGHT FENCE LINE 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 275 DOWN TO CELLAR R U N W A Y UPTOCHOIR LOT LINE 82.25' LOT LINE 150.33' LOT LINE 150.17' LOT LINE 201.42' LOT LINE 30.50' LOT LINE LOT LINE 100.67' LOT LINE 201.42' BEECHER MEMORIAL PARK EXHAUST VENT TO ROOF. LINE OF MEZZ. ABOVE. LINE OF MEZZ. ABOVE. DN KNEE WALL & FENCE. STAIR UP FROM LIBRARY STEPS DOWN FROM GYM DN SPRAY GROUND (LOWER CEILING) (SLOPE ≤ 1:20) UP DN UP TO MEZZ. ( SLOPE ≤ 1:20 ) DN. TO CELLAR PLANTER PLANTER MECH. LOGGIA RESTROOMRESTROOM S T O R A G E STORAGE MECH. SLOPE ≤ 1:20 STORAGE GATE GATE GATE GATE FENCE CHAIR STORAGE D E S K MECH. TABLE STORAGE (SLOPE ≤ 1:20) OUTDOOR STORAGE GATE GATE GATE OUTDOOR STORAGE OUTDOOR STORAGE (SLOPE 1:20) WATER PLAY 4565 SF 1350 SF DOUBLEHEIGHT LINE OF TRACK ABOVE SANCTUARY PLANTER RECEPTION GATE FIRST FLOOR PLAN Scale: 3/32" = 1'-0" 1 GYMNASIUM UP UP DN UP UP KITCHEN KITCHEN SERVICE ENTRY POTENTIAL S.G. TABLE STORAGE EGRESS FROM MEZZANINE DN GATE ARCADE SG W W HILLIS HALL 1'4' 16' 2' 8' 32' 0 N ORANGE STREET HICKS STREET CRANBERRY STREET PANTRY MECH. RAMP ≤ 1:12 PLAYGROUND RAMP 1:12 23'-6" 4 0 0 0 S F ( 3 2 5 0 s f D H ) 6 5 4 3 2 1 12 11 10 9 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 45 46 47 48 49 44 43 42 41 40 39 38 37 36 35 34 33 32 31 30 71 70 69 68 67 66 65 64 63 62 61 60 59 58 57 56 55 54 53 52 92 91 90 89 88 87 86 85 84 83 82 81 80 79 78 77 76 75 74 183 184 185 186 187 188 177 178 179 176 175 174 173 172 171 170 169 168 167 166 165 164 163 162 144 143 142 141 140 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 LINCOLN (CONDENSING UNITS BEHIND SCREEN WALL) (MECH SPACE IN CELLAR) MEMORIAL GARDEN CRANBERRY STREET ELEVATION Scale: 3/32" = 1'-0" 2 SECTION THROUGH ARCADE LOOKING EAST Scale: 3/32" = 1'-0" 1 ELEV 41'-1" ELEV 21'-0" SG SG SG SG SG SG SG SG SG SG B B B B B B B GYMNASIUM HILLIS HALL HILLIS HALL SANCTUARY CRANBERRY STREET C.U. MECH. SPACE STORAGE RESTROOMS LIGHTWELL PAGE 5

TYPE: Exterior restoration

COLLABORATE:

Architect: Thomas A. Fenniman, Architect

Architect: Christopher Rome

Address: One Astor Place New York, NY 10003

Project Type: Exterior Restoration

Project Responsibility: SD \ DD \ CD \ Bidding \ CA(w.i.p.)

One Astor Place located at the corner of Astor Place and Broadway. Part of the NoHo historic district on Landmark Preservation Commission. As both Facade Inspection Safety Program and LPC project, several restrictions presented along the progress; a paint analyst was invited as part of investigation to satisfied the requirement of the landmark’s permit requirement. Unfortunately, we were not able to find any existing paint due to the scraping from previous work. Finally, using the neighboring historic photographs and written reports, we were able to puzzle the possible design of the painting on the cast-iron window heads and sills to satisfies the needs of the LPC. Work scope include brick masonry replacement, terracotta patching, terracotta replacement with cast-stone units, sheet-metal patching and replacement.

B -BRICK TC -TERRACOTTA CI -CAST-IRON SM -SHEET METAL LS -LIMESTONE SP REPOINTING SPALL PATCH REPAIR CRACK REPAIR LEGEND C REPAINT SHEET-METAL REPAINT CAST-IRON SILL REPLACEMENT REPAIR KEY MATERIAL KEY RECONSTRUCTION MATCH LINE WEST ELEVATION - BROADWAY Scale: 1/8" = 1'-0" 1 1 KEY PLAN A-501 1 A-500 7 A-500 6 A-500 4 A-500 2ND 3RD 4TH 5TH 6TH 7TH 8TH 9TH 10TH 11TH 12TH ROOF 2ND 3RD 4TH 5TH 6TH 7TH ROOF N.I.C. N.I.C. N. I. C. REPAIR SPALLED TERRACOTTA. A-1 REPOINT BRICK MASONRY. B-2 REPAIR SPALLED LIMESTONE. B-2 REPAINT CAST IRON WINDOW SURROUND. B-2 PATCH HOLE IN SHEET-METAL IN-KIND AND PAINT TO MATCH ADJACENT. B-2 NO WORK AT STOREFRONT AS PART OF THIS APPLICATION N. I. C. N. I. C. A-1 REPAIR CRACK AT TERRACOTTA B-2 B-2 REPAINT CAST-IRON LINTELS & WINDOWSILLS (TYP.). REPAINT SHEET METAL CORNICE AND LEDGE. A-1 NO WORK AT STOREFRONT AS PART OF THIS APPLICATION C-1 NEW SHEET-METAL END PANEL AT EDGE. A-1 PATCH HOLE IN SHEET-METAL CORNICE IN-KIND. B-2 A-1 CUT JOINT AT TOP EDGE & ENDS OF WINDOWSILLS AND APPLY SEALANT (TYP.). REPOINT FACE BRICK RETURN. PINNING AT FACE BRICK RETURN. PATCH HOLE IN SHEET-METAL IN-KIND AND PAINT TO MATCH ADJACENT. A-1 REPAINT SHEET-METAL CORNICE. ADD / ALT #2: MISSING SHEET-METAL ELEMENTS. (REFER TO DETAIL 1,2/A-501) NEW FLUID-APPLIED FLASHING WITH CUSTOM COLOUR AT STOREFRONT SHEET-METAL CAPPING. TERMINATE IN SAW-CUT REGLET AT TOP EDGE. A-1 ADD ALT #4: REPAINT CAST-IRON STOREFRONT SURROUND. BROADWAY ASTOR & CORNER TOTAL LEMONS DIAMONDS BRACKETS 22 44 66 1 5 6 - 1 1 ADD ALT #2: RECREATE MISSING SHEET-METAL ELEMENTS. FABRICATE & INSTALL MISSING ELEMENTS FOR BROADWAY AS PER TABLE B-2 NEW PAINTED SHEET-METAL END PANEL AT CORNICE. C TC SP CI SP C CI LS C TC C B C CI C B C B C CI C CI C CI C CI C CI C B SP WEST ELEVATION 04/13/20 1 OF TITLE: SEAL: PROJECT: 32202 ONE ASTOR PLACE New York NY 10003 EXTERIOR RESTORATION PAGE NUMBER: BID SET 04/13/20 THOMAS A. FENNIMAN ARCHITECT ONE UNION SQUARE WEST NEW YORK, NY 10003 FAX: 212.414.0249 BIDONLY ADDENDUM 11/23/20 04 A-201.00 PH AS NOTED PAGE 6

One Astor Place

B -BRICK TC -TERRACOTTA CI -CAST-IRON SM -SHEET METAL LS -LIMESTONE SP REPOINTING SPALL PATCH REPAIR CRACK REPAIR LEGEND C REPAINT SHEET-METAL REPAINT CAST-IRON SILL REPLACEMENT REPAIR KEY MATERIAL KEY RECONSTRUCTION ONE ASTOR PLACE MATCH LINE MATCH LINE MATCH LINE SOUTH ELEVATION - ASTOR PLACE Scale: 1/8" = 1'-0" 2 SOUTHWEST CORNER ELEVATION Scale: 1/8" = 1'-0" 1 ENTRY 11-STOREY ADJACENT BUILDING 21 ASTOR PLACE KEY PLAN KEY PLAN A-501 1 A-501 A-500 6 A-500 1 A-500 3 A-500 2ND 3RD 4TH 5TH 6TH 7TH ROOF REPAINT SHEET-METAL CORNICE. B-1 REPAINT CAST IRON WINDOW SURROUND. B-1 N. I. C. N. I. C. N. I. C. N. I. C. N. I. C. NO WORK AT STOREFRONT AS PART OF THIS APPLICATION REPAINT SHEET METAL CORNICE AND LEDGE. A-1 REPAINT CAST-IRON LINTELS & WINDOWSILLS (TYP.). A-1 CORNER RECONSTRUCTION. B-1 REPOINT RETURN WALL ABOVE NEIGHBOR. B-1 NO WORK AT STOREFRONT AS PART OF THIS APPLICATION N. I. C. NEW PAINTED SHEET-METAL END PANEL AT LEDGE TO MATCH EXISTING. A-1 NEW FLUID-APPLIED MEMBRANE AND SHEATING AT TOP SIDE OF LEDGE. A-1 ADD ALT #2: RECREATE MISSING SHEET-METAL BRACKET AS PER TABLE ADD ALT #3: RECREATE MISSING SECTION OF LEDGE. NEW FLUID-APPLIED FLASHING WITH CUSTOM COLOUR AT STOREFRONT SHEET-METAL CAPPING. TERMINATE IN SAW-CUT REGLET AT TOP EDGE. A-1 ADD ALT #4: REPAINT CAST-IRON STOREFRONT SURROUND. ADD ALT #2: MISSING SHEET-METAL ELEMENTS. (REFER TO DETAIL 1,2/A-501) BROADWAY ASTOR & CORNER TOTAL LEMONS DIAMONDS BRACKETS 22 44 66 1 5 6 - 1 1 ADD ALT #2: RECREATE MISSING SHEET-METAL ELEMENTS. FABRICATE & INSTALL MISSING ELEMENTS FOR ASTOR PLACE & CORNER EXPOSURES AS PER TABLE A-1 CUT JOINT AT TOP EDGE & ENDS OF WINDOWSILLS AND APPLY SEALANT (TYP.). TC SP TC SP C B C B C B B SP C TC C TC C TC C CI C CI C CI C TC C CI B SP C TC SP B SP TC SP TC SP B SP SOUTH ELEVATION 04/13/20 1 TITLE: SEAL: 32202 ONE ASTOR PLACE New York NY 10003 EXTERIOR RESTORATION PAGE NUMBER: BID SET 04/13/20 THOMAS A. FENNIMAN ARCHITECT ONE UNION SQUARE WEST NEW YORK, NY 10003 FAX: 212.414.0249 BIDONLY ADDENDUM 11/23/20 03 A-200.00 PH AS NOTED PAGE 7

3crs 3crs 6" min. 6" min. EQ. EQ. 3crs 3crs EQ. EQ. STAGGER 4" to 12" ~16"o.c. 3"min. ~4" (N) SST HELICAL TIE SET INTO BACKUP MASONRY AND BENT 90deg AS INDICATED. STITCH IN (N) FACE BRICK TO MATCH EXISTING COLOUR, TEXTURE & DIMENSION, LAID TO MATCH EXISTING BOND, COURSING & JOINTING. REMOVE DAMAGED BRICK, SUPPORT ADJACENT TO REMAIN. (N) SST HELICAL ROD SET IN MORTAR; EXTEND PAST REPAIR AS INDICATED. STITCH IN (N) FACE BRICK TO MATCH EXISTING COLOUR, TEXTURE & DIMENSION, LAID TO MATCH EXISTING BOND, COURSING & JOINTING. REPLACE INIDIVIDUAL CRACKED BRICKS AT BACKUP WHERE PRESENT; NOTIFY ARHCITECT FOR INSPECTION. REMOVE CRACKED BRICKS AND BRICK EITHER SIDE OF CRACKED JOINT AS INIDCATED. STEEL LINTEL REPLACEMENT Scale: 1 1/2" = 1'-0" 1 TERMINATE TOP EDGE OF FLASHING WITH TERMINATION OF BAR & MASTIC. (N) SST HELICAL TIE BENT 90deg AT EVERY 16" O.C. (N) BITUMINOUS FLASHING MEMBRANE. HOLD BACK 1"MIN. FROM FACE. FORM END DAMS. REPLACE DAMAGED DETERIORATED BRICK @ BEARING. TEMPORARY SUPPORT FOR (E) BRICK AS REQ'D. (N) 4 x 3 x 5/16 GALV. LINTELS L.L.V. PRIMED & PAINTED. (E) ANGLE TO REMAIN. LINE OF LINTELS. 8" MIN. BRICK MASONRY SPALL REPAIR Scale: 1 1/2" = 1'-0" 3 BRICK MASONRY CRACK REPAIR Scale: 1 1/2" = 1'-0" 2 ASSUMED (E) STRUCTURE. (N) WINDOW BY OTHERS. UNDER SEPARATE APPLICATION. (E) BACKUP MASONRY TO REMAIN. 1" MIN. LAP R-30 AT LOW POINT 8" min. 4" min. TREAT SEAMS AND PREPARE, MIXTURE LEVELLING COMPOUND PRIOR TO APPLICATION OF PRIMER & MEMBRANE (TYP.). FLUID-APPLIED REINFORCED FLASHING MEMBRANE. FLUID-APPLIED FIELD MEMBRANE. REFER TO TYPICAL ROOF DETAILS FINISH SURFACE; REFER TO TYPICAL ROOF DETAILS FOR 8" min. FLUID-APPLIED REINFORCED FLASHING HANDCUT FROM REINFORCING FLEECE. FORM TO PROVIDE 2" FIELD MEMBRANE. FIELD MEMBRANE. FLUID-APPLIED REINFORCED FLASHING 'L'-SHAPED OUTSIDE CORNER HANDCUT FROM REINFORCING FLEECE. FORM INSIDE EDGE TO 8" min. 4"min. 8" min. PREPARE SUBSTRATE AS APPLICATION OF PRIMER & MEMBRANE (TYP.). FLUID-APPLIED REINFORCED FLASHING FILL VOIDS AT TRANSITIONS & TO APPLICATION OF FLASHING MEMBRANE (TYP.). TYPICAL ROOF DETAILS FOR REINFORCEMENT INFORMATION. OUTSIDE CORNER INSIDE CORNER BASE FLASHING PENETRATION 1" PER FOOT. SKYLIGHT Scale: 3" = 1'-0" 5 DRAIN FLASHING Scale: 3" = 1'-0" 7 (N) FLUID APPLIED REINF. MEMBRANE FLASHING. (N) ROOFING ASSEMBLY (E) CONCRETE DECK. (N) CAST IRON DRAIN, STRAINER & SEDIMENT BUCKET. EXPOSED MEMBRANE ROOF Scale: NTS 8 (N) MULTIPLE LAYERS INSULATION. OFFSET LAYERS, STAGGER SEAMS. (N) VAPOR BARRIER. REMOVE & DISPOSE OF (E) ROOFING & (E) MEMBRANE DOWN TO (E) CONCRETE SLAB. (N) CEMENT BOARD COVERBOARD. STAGGER SEAMS. (N) REINFORCED FLUID-APPLIED MEMBRANE ROOFING SYSTEM. PROVIDE 20yr NDL WARRANTY. PREPARE SUBSTRATE, INCLUDING MINOR PATCH REPAIRS UP TO ONE-INCH (1") IN DEPTH FOR TEN-PERCENT (10%) OF ROOFING AREA (N) ROOF ASSEMBLY FORM & POUR (N) RAISED SKYLIGHT CURB. ROUGHEN FOR KEY. (N) FLUID-APPLIED FLASHING. FLUID-APPLIED MEMBRANE TYPICAL DETAILS Scale: NTS 9 SKYLIGHT REFER TO SCHEDULE. 8" MIN. A.F.R. 4" MIN. (N) 1/2" DIA. SST THREADED ROD. SKYLIGHT Scale: 3" = 1'-0" 6 BEVELLED SEALANT JOINT. FORM & POUR (N) RAISED SKYLIGHT CURB. ROUGHEN FOR KEY. (N) FLUID-APPLIED FLASHING. SKYLIGHT REFER TO SCHEDULE. 2" COVER 4" EMBED (N) 1/2" Ø SST THREADED ROD @24" O.C. 4" MIN. 4" EMBED 2" COVER ASSUMED (E) ROOF COVER ASSEMBLY SEALANT JOINT. 8" MIN. 12" MIN. (N) 2" THK BLUESTONE FOUR FEET MIN. LENGTHS; NB: SEALANT JOINT @ CROSS JOINTS. F5 F4 F3 USE WOOD PLANK FORMWORK SIZE TO MATCH PATTERN AT EXISTING CURB INTERIOR FACE. R1 (N) OVER-DRIED AGGREGATED & RESIN PASTE SLOPED WASH. USE WOOD PLANK FORMWORK SIZE TO MATCH PATTERN AT EXISTING CURB INTERIOR FACE. REPAIR KEY 1. REMOVE (E) MORTAR TO SUFFICIENT UNIFORM DEPTH (2 TO 2-1/2 JOINT WIDTH) approx. ONE INCH (1") min. REMOVE LOOSE OR DISINTEGRATED MORTAR BEYOND CUT DEPTH TO SOUND SUBSTRATE. 2. HORIZONTAL/ BED JOINTS: REMOVE (E) MORTAR BY CUTTING CENTER OF JOINT w/ THIN BLADE GRINDER. REMOVE REMAINING MORTAR w/ HAND TOOLS VERTICAL/ HEAD JOINTS: REMOVE MORTAR w/ HAND TOOLS 3. CLEAN OUT JOINTS w/ CLEAN COMPRESSED AIR AND FLUSH w/ CLEAN WATER TO REMOVE ALL LOOSE PARTICLES & DUST. 4. THOROUGHLY WET MASONRY & (E) MORTAR BEFORE PLACING (N) MORTAR. ALLOW SUFFICIENT TIME FOR JOINTS TO BE DAMP, BUT w/ NO FREESTANDING WATER PRESENT. 5. PROVIDE (N) MORTAR, TYPE AS PER SPECS, TO MATCH EXISTING COLOUR, TEXTURE & PROFILE. FILL JOINTS BY APPLYING SUCCESSIVE appx. 1/4" LIFTS OF WELL-PACKED MORTAR. ALLOW EACH LAYER OF MORTAR TO BECOME THUMBPRINT HARD BEFORE APPLYING NEXT LIFT. 6. TOOL FINAL LAYER OF MORTAR TO MATCH EXISTING. RECESS MORTAR SLIGHTLY FROM FACE OF MASONRY; DO NOT CREATE FEATHERED EDGE. 7. DURING CURING PROCESS, KEEP MASONRY UNITS & (N) MORTAR DAMP BY MISTING PERIODICALLY SHADING FOR SEVERAL DAYS AFTER INSTALLATION, ACCORDING TO LOCAL CONDITIONS. CLEAN REPOINTED MASONRY w/ NATURAL BRISTLE OR NYLON BRUSH. 8. AFTER FULL CURE, WASH DOWN REPOINTED MASONRY w/ CLEAN WATER AND CONSTRUCTION CLEANER AS PER SPECS. NB: PROVIDE appx. 2'-0"x 2'-0" MOCK-UP PANEL IN PLACE FOR REVIEW. NOTE #1, 2 SECTION HORIZONTAL BED JOINT #1, 2 SECTION B-B VERTICAL HEAD JOINT #3, 4 #5, 6, 7, 8 ONE INCH (1") min REPOINTING DEPTH. REMOVED (TYP.). (E) MORTAR SOUND (TYP.). LINE OF (E) BRICK UNIT BEYOND. (E) MORTAR TO SOUND (TYP.). REMOVE MORTAR w/ HAND TOOLS PATH OF THIN BLADE GRINDER; HAND TOOLS ONE INCH (1") SATURATED SURFACE DRY PLACE (N) MORTAR IN LIFTS. MORTAR TO BE REPOINTING Scale: Half Actual Size 4 MASONRY & ROOFING DETAILS 06/20/19 03 Fax: 212.414.0249 Thomas A. Fenniman Architect New York, New York 10003 SEAL: 57001 245 WEST 18 th STREET New York , NY 10021 EXTERIOR RESTORATION D.O.B. NUMBER: BID SET 7/12/19 CONSTRUCTION SET 9/10/19 03 A-500.00 PH AS NOTED GRAPHIC LEGEND LOWER ROOF UPPER ROOF 1ST ROOF 2ND FLOOR 6'-0" MAX. 42" MIN. 3 A-200 STREET FACADE Scale: 1/4" = 1'-0" 1 REAR FACADE AT ROOF LEVEL Scale: 1/4" = 1'-0" 2 BRICK RECONSTRUCTION LINTEL RECONSTRUCTION LINTEL MAINTENANCE REPAINT (E) BEAM. REPAINT (N) & (E) MASONRY. REPAINT (E) METAL FENCING (TYP.). 6" 1" 1" 1" 2" 12" 3/8" BLADE BASEPLATE OFFSET LINE OF INTERIOR FINISHES 3 A-200 3 A-200 1 A-500 PARAPET RECONSTRUCTION Scale: 3" = 1'-0" 4 4" 1'-4" min. less than overlap (N) GALV. PIPE FENCE & GUARD RAIL. NEW SST THOUGH BOLTS w/ LOCK WASHERS AND ACORN NUTS. NEW SST CUSTOM FABRICATED BLADE BASE WITH VERTICAL BLADE WELDED TO HORIZONTAL BASEPLATE. ANCHOR BASEPLATE w/ SST THREADED RODS & NUTS. SET IN EPOXY. EMBED 4"min. RECESSED POCKET IN UNDERSIDE OF COPINGSTONE TO ACCOMODATE BASEPLATE & ANCHORS PREFABRICATE; DO NOT FIELD CUT. NEW CAST STONE COPINGSTONE REINFORCED WITH SST OR FIBREGLASS ROD LONGITUDINALLY AND LATERALLY. COORDINATE w/ POST LOCATIONS. FLASH BASEPLATE & ANCHORS AFTER INSTALLATION w/ FLUID-APPLIED MEMBRANE. SST THREADED ROD DOWEL AT EACH COPING JOINT. SET IN SEALANT. EMBED 2"min. ea. COPINGSTONE. PROVIDE FACTORY FORMED CORNERS; NO MITERS OR CUTTING PERMITTED. PROVIDE COLOUR FROM FABRICATORS FULL RANGE w/ SANDBLAST TEXTURE (N) BOTTOM RAIL. (N) S.S.T. HELICAL WALLTIE BENT TO 90deg. PARAPET @ LOT LINE Scale: 3" = 1'-0" 5 PARAPET FENCE REPLACEMENT Scale: 3" = 1'-0" 3 TEMPORARY SUPPORT FOR (E) BRICK AS REQ'D. (N) WINDOWS BY OTHERS UNDER SEPARATE APPLICATION (N) FINISHES BY OTHERS. UNDER SEPARATE APPLICATION (E) CONCRETE ROOF DECK TO REMAIN. LINTEL REPLACEMENT; REFER TO 1/A-500 EXPOSE BEAM TO ATTACH REINFORCEMENT AND PATCH AS REQ'D. (N) BITUMINOUS EMBEDDED WATERPROOFING MEMBRANE. (N) DRAINAGE MAT CAVITY MESH. (N) 1/2" dia S.S.T. THREADED ROD VERTICAL REINFORCEMENT @ 24" O.C. MAX. WELD TO SPANDREL. BACKFILLED C.M.U. COPING STONE NOTES; REFER TO 3/A-200. (N) ROOF ASSEMBLY; REFER TO 8/A-500. (N) 20oz. COPPER REGLET FLASHING. 4" MIN. 4" (N) FACE BRICK t.m.e. (N) S.S.T. LADDER TYPE HORIZONTAL REINFORCEMENT. FOR COPING STONE, RAILING & BASEPLATE NOTES. REFER TO 3/A-200 (N) FLUID-APPLIED BASE FLASHING. (N) 20oz. COPPER TWOPIECES COUNTER FLASHING. LAP WATERPROOFING MEMBRANE ONTO FLASHING. (N) BONDED BACK-UP MASONRY. COMPRESSIBLE FILLER BACKER ROD & SEALANT JOINT. BENT S.S.T. STRAP & DOWEL ANCHOR AT COPING JOINTS. SEAL PENETRATION. SIM. F1 F2 F1 ADD ALT #1: PARAPET RECONSTRUCTION AT WEST & EAST LOT-LINE WALLS. PAGE 8 MISC DETAILS

4 5 A-501 PREPARE, PRIME & PAINT (E) SPANDREL & FRAMING. NOTIFY ARCHITECT WHEN EXPOSED; DO NOT COVER UNTIL AFTER INSPECTION. (N) 6" x 4" x 3/8" ANGLE w/ SLOTTED CONNECTIONS. (N) CONTINUOUS BITUMINOUS MEMBRANE FLASHING. TURN ON TO DRIP EDGE AT BOTTOM. HOLD BACK FROM FACE OF MASONRY. PROVIDE END DAMS. (N) PLASTIC WEEP TUBES (N) 1/2" thk. COMPRESSIBLE FILLER OVER PROFILE OF SPANDREL. (N) STAINLESS- STEEL FLASHING w/ HEMMED DRIP EDGE. SEPARATE DISSIMILAR METALS. (N) 3/8" thk. GALV. STEEL BEARING PLATE. (N) MOVEMENT JOINT; REFER TO DTL. 6/D-1. PARGE SMOOTH (E) BACK-UP MASONRY. (N) BRICK MASONRY VENEER t.m.e. NB. STABILIZE (E) MASONRY TO REMAIN PRIOR TO REMOVAL AND THROUGHOUT RECONSTRUCTION. DETAIL SECTION AT SPANDREL DETAIL SECTION NEAR CORNER CORNER RECONSTRUCTION Scale: 1 1/2" = 1'-0" 6 SPANDREL RECONSTRUCTION Scale: 1 1/2" 1'-0" 7 6 A-501 7 A-501 7 D-2 (N) BRICK MASONRY t.m.e. PREPARE, PRIME & PAINT (E) SPANDREL & FRAMING. NOTIFY ARCHITECT WHEN EXPOSED; DO NOT COVER UNTIL AFTER INSPECTION. (N) 6" 4" x 3/8" ANGLE w/ SLOTTED CONNECTIONS. (N) CONTINUOUS BITUMINOUS MEMBRANE FLASHING. TURN OUT AT BOTTOM. HOLD BACK FROM FACE OF MASONRY. PROVIDE END DAMS. (N) 1/2" thk. COMPRESSIBLE FILLER OVER PROFILE OF SPANDREL. (N) STAINLESS- STEEL JOINT STABILIZING ANCHOR @ ea. 6crs OR 16" max. VERTICALLY. (N) MOVEMENT JOINT; REFER TO DTL. 6/D-1. (N) BACK-UP MASONRY AS REQ'D. (N) NON-CORROSIVE HELICAL WALL TIE; REFER TO DTL.1,2/D-1. (N) BRICK MASONRY t.m.e. (N) STAINLESS- STEEL JOINT STABILIZING ANCHOR @ ea. 6crs OR 16" max. VERTICALLY. (N) MOVEMENT JOINT; REFER TO DTL. 6/D-1. (N) NON-CORROSIVE HELICAL WALL TIE; REFER TO DTL.1,2/D-1. NB. STABILIZE (E) MASONRY TO REMAIN PRIOR TO REMOVAL AND THROUGHOUT RECONSTRUCTION. DETAIL PLAN SECTION AT SPANDREL DETAIL PLAN SECTION CORNER RECONSTRUCTION Scale: 1 1/2" 1'-0" 4 CORNER RECONSTRUCTION Scale: 1/2" = 1'-0" 5 4 A-501 5 A-501 PREPARE, PRIME & PAINT (E) SPANDREL & FRAMING. NOTIFY ARCHITECT WHEN EXPOSED; DO NOT COVER UNTIL AFTER INSPECTION. (N) 6" 4" 3/8" ANGLE w/ SLOTTED CONNECTIONS. (N) BRICK MASONRY t.m.e. (N) CONTINUOUS BITUMINOUS MEMBRANE FLASHING. TURN ON TO DRIP EDGE AT BOTTOM. HOLD BACK FROM FACE OF MASONRY. PROVIDE END DAMS. (N) PLASTIC WEEP TUBES (N) 1/2" thk. COMPRESSIBLE FILLER OVER PROFILE OF SPANDREL. (N) STAINLESS- STEEL FLASHING w/ HEMMED DRIP EDGE. SEPARATE DISSIMILAR METALS. (N) 3/8" thk. GALV. STEEL BEARING PLATE. (N) MOVEMENT JOINT; REFER TO DTL. 6/D-1. PARGE SMOOTH (E) BACK-UP MASONRY. FLUID-APPLIED MEMBRANE TYPICAL DETAILS Scale: 3" = 1'-0" 3 8" min. 4" min. TREAT SEAMS AND PREPARE, PATCH AND/OR LEVEL SUBSTRATE MIXTURE LEVELLING COMPOUND PRIOR TO APPLICATION OF PRIMER MEMBRANE (TYP.). FLUID-APPLIED REINFORCED REFER TO TYPICAL ROOF DETAILS FOR REINFORCEMENT INFORMATION. FINISH SURFACE; REFER TYPICAL ROOF DETAILS FOR SURFACING INFORMATION. 8" min. FLASHING MEMBRANE. INSIDE CORNER HANDCUT FROM FLEECE. FORM TO PROVIDE 2" min. UPTURN. MEMBRANE. MEMBRANE. FLUID-APPLIED FLASHING MEMBRANE. CORNER HANDCUT FROM REINFORCING FLEECE. FORM INSIDE EDGE TO 8" min. 4"min. OUTSIDE CORNER INSIDE CORNER BASE FLASHING CORNICE AND BRACKET RECONSTRUCTION Scale: 3" = 1'-0" 1 CORNICE AND BRACKET RECONSTRUCTION Scale: 3" = 1'-0" 2 DETAIL SECTION DETAIL ELEVATION 4'-0" 11 1/2" 3/4" 3" 3'-0" 6" 4 1/2" 1 1/2" 1/4" 1/4" 21/2" 21/2" 1/2" 3/4" 1 3/4" 1/2" 3/4" 4 1/2" 1" 2 1/2" 1/2" 1/2" 21/4" 3" 3" 2'-9" 2 1/2" 1'-2" 1'-8" 3" 3" 1" 2 1/2" 9" 6" 2 1/2" 1/2" 2 1/2" 1 1/2" 6" 5 1/2" 3" 5 1/2" 1'-2" 11/2" 11/2" 11/2" 1" 3" BRACKET LEMON 5 1/2" LEMON DIAMONDS 1 1/2" (N) FLUID-APPLIED MEMBRANE FLASHING w/ CUSTOM COLOR FINISH. (E) CAST-IRON SILL. PREPARE FOR MEMBRANE. REPAINT (E) SHEETMETAL THROUGHOUT LEDGE. REMOVE (E) DETERIORATED ROOFING MEMBRANE AND SHEETMETAL TO EXPOSE (E) WOOD SHEATHING. ADD/ALTERNATE #2. FABRICATE AND INSTALL MISSING ELEMENTS. REFER TO ELEVATIONS FOR QUANTITIES. ADD/ALTERNATE #3. FABRICATE AND INSTALL MISSING PORTION OF LEDGE AT ASTOR PLACE INCLUDING SHEETMETAL, FRAMING AND SHEATHING AS REQ'D. REFER TO ELEVATION. (N) CEMENT BOARD COVERBOARD SCREWED TO (E) WOOD SHEATHING. (N) NON-CORROSIVE SHEETMETAL CONTINUOUS EDGE FLASHING PAINTED TO MATCH ADJACENT NB. DIMENSIONS SHOWN ARE FOR GENERAL GUIDANCE ONLY. FABRICATE REPLICA ELEMENTS BASED ON ORIGINAL FABRIC. PROVIDE MOCK-UPS FOR REVIEW & APPROVAL. (E) FRAMING TO REMAIN. MASONRY DETAILS 04/13/20 09 REVISIONS: TITLE: PROJECT #: SEAL: PROJECT: 32202 ONE ASTOR PLACE New York , NY 10003 EXTERIOR RESTORATION D.O.B. NUMBER: BID SET 04/13/20 THOMAS A. FENNIMAN ARCHITECT ONE UNION SQUARE WEST TEL: 212.414.0250 BIDONLY 09 A-501.00 PH AS NOTED 4" min. REMOVE (E) SEALANT AND MORTAR AS INDICATED. REMOVE LOOSE PAINT AND ABRADE METAL TO REMOVE CORROSION. CLEAN METAL TO PREPARE FOR PAINTING. PRIME & PAINT FRESHLY PREPARED METAL PRIOR TO MORTAR AND SEALANT REPLACEMENT. PRIMER: ONE (1) COAT. INTERMEDIATE: ONE (1) COAT. FINISH: ONE (1) COAT. REPOINT WITH (N) MORTAR IN ACCORDANCE WITH PROJECT REPOINTING DETAILS. DO NOT OBSTRUCT WEEP HOLES. APPLY (N) SEALANT IN ACCORDANCE WITH PROJECT DETAILS. COLOR TO BE SELECTED BY ARCHITECT 1" min. EXISTING MASONRY; REFER TO PROJECT DRAWINGS FOR SCOPE OF WORK. REMOVE (E) SEALANT AT (E) WINDOWHEAD TO REMAIN. LINTEL MAINTENANCE Scale: 3" = 1'-0" 8 EQ. EQ. 3"min. 3crs 3crs 6" min. 6" min. EQ. EQ. EQ. EQ. 1/2" min. ~ 4" ~ 16" o.c. EQ. EQ. 16" o.c. ~ 16" o.c. SUPPORT ADJACENT MASONRY DURING WORK. TOOTH (N) BRICK INTO EXISTING. LINE OF RECONSTRUCTION. REPLACE ADJACENT LOOSE INDIVIDUAL BRICKS WHERE PRESENT. FILL COLLAR JOINT SOLID w/ MORTAR. (N) FACE BRICK TO MATCH EXISTING COLOUR, TEXTURE & DIMENSION, LAID TO MATCH EXISTING BOND, COURSING & JOINTING. (N) SST HELICAL TIE SET INTO BACKUP MASONRY AND BENT 90deg AS INDICATED. (N) SST HELICAL TIE SET INTO BACKUP MASONRY AND BENT 90deg AS INDICATED. STITCH IN (N) FACE BRICK TO MATCH EXISTING COLOUR, TEXTURE & DIMENSION, LAID TO MATCH EXISTING BOND, COURSING & JOINTING. REMOVE DAMAGED BRICK, SUPPORT ADJACENT TO (N) SST HELICAL ROD SET IN MORTAR; EXTEND PAST REPAIR AS INDICATED. STITCH IN (N) FACE BRICK TO MATCH EXISTING COLOUR, TEXTURE & DIMENSION, LAID TO MATCH EXISTING BOND, COURSING & JOINTING. REPLACE INIDIVIDUAL CRACKED BRICKS AT BACKUP WHERE PRESENT; NOTIFY ARHCITECT FOR INSPECTION. REMOVE CRACKED BRICKS AND BRICK EITHER SIDE OF CRACKED JOINT AS INIDCATED. BRICK MASONRY CRACK REPAIR Scale: NTS 1 BRICK MASONRY SPALL REPAIR Scale: NTS 2 BRICK MASONRY RECONSTRUCTION - FACE BRICK Scale: NTS 3 3crs 3crs STAGGER 4" to 12" ~16"o.c. EQ. EQ. 3"min. BRICK MASONRY RECONSTRUCTION FULL THICKNESS Scale: NTS 4 SUPPORT ADJACENT MASONRY DURING WORK. TOOTH (N) BRICK INTO EXISTING. LINE OF RECONSTRUCTION. (N) FACE BRICK TO MATCH EXISTING COLOUR, TEXTURE & DIMENSION, LAID TO MATCH EXISTING BOND, COURSING & JOINTING. (N) COMMON BRICK BACKUP MASONRY TO MATCH EXISTING DIMENSION AND LAID IN COMMON BOND, TO MATCH EXISTING COURSING & JOINTING. (N) SST LADDER REINFORCEMENT AT EVERY 6crs VERTICALLY. REPLACE ADJACENT LOOSE INDIVIDUAL BRICKS WHERE PRESENT. FILL COLLAR JOINTS SOLID w/ MORTAR. ~ 16" o.c. ~ 16" o.c. EQ. EQ. 16" o.c. ~ 16" o.c. 2 1/2" 2 1/2" 1/2" min. min. min. 1 PROVIDE STAINLESS STEEL HELICAL WALL TIES INSTALLED INTO PRE-DRILLED PILOT HOLES 2 LOCATE PINS IN 'T' JOINTS IN STAGGERED PATTERN 3 SET PIN SLIGHTLY RECESSED FROM FACE OF WALL 4 TUCK POINT RECESS WASH DOWN WALL WITH CONSTRUCTION CLEANER 5 REFER TO SPECIFICATIONS FOR PINNING INFORMATION BRICK MASONRY PINNING Scale: NTS 6 (N) REGLET FLASHING INTO JOINT IN BACK-UP MASONRY AS INDICATED OR PROVIDE SST TERMINATION BAR. (E) WINDOW; REFER TO DRAWINGS FOR SCOPE. REMOVE (E) MASONRY AS REQ'D. PARGE BACK-UP MASONRY SMOOTH. REPLACE w/ (N) BRICK MASONRY AS INDICATED. TOOTH INTO ADJACENT MASONRY. CUT HEADERS AS REQ'D. (N) BITUMINOUS WATERPROOFING MEMBRANE FLASHING ADHERED TO BACK-UP MASONRY. PRIME SUBSTRATE. HOLD BACK 1" FROM FACE OF BRICK. PROVIDE END DAMS. SEAL SEAMS & PENETRATIONS. (N) SST. HELICAL BENT WALL TIE @ 16" o.c. HORIZONTALLY. (N) GALV. STEEL LINTEL w/ 8" min. BEARING ea. END. PREPARE, PRIME & PAINT. PRIMER: ONE (1) COAT RUST INHIBITIVE METAL PRIMER. FINISH: TWO (2) COATS METAL ENAMEL. COLOR & SHEEN: t.b.d. 1/2" min. (N) SEALANT & BACKER ROD. (E) ADJACENT MASONRY TO REMAIN. PROVIDE TEMPORARY PROTECTION & SHORING AS REQ'D. (N) 100% COTTON ROPE WEEP @ 16" o.c. HORIZONTALLY AND CONTINUOUS ALONG BACK. 16" o.c. 8" min. NB. REPLACE DAMAGED (E) MASONRY BEARING AS REQ'D; ALLOW ONE (1) S.F. LINTEL REPLACEMENT Scale: 1 1/2" = 1'-0" 7 BRICK MASONRY REPOINTING Scale: NTS 5 REPAIR KEY 1. REMOVE (E) MORTAR TO SUFFICIENT UNIFORM DEPTH (2 TO 2-1/2 JOINT WIDTH) approx. ONE INCH (1") min. REMOVE LOOSE OR DISINTEGRATED MORTAR BEYOND CUT DEPTH TO SOUND SUBSTRATE. 2. HORIZONTAL/ BED JOINTS: REMOVE (E) MORTAR BY CUTTING CENTER OF JOINT w/ THIN BLADE GRINDER. REMOVE REMAINING MORTAR w/ HAND TOOLS VERTICAL/ HEAD JOINTS: REMOVE MORTAR w/ HAND TOOLS 3. CLEAN OUT JOINTS w/ CLEAN COMPRESSED AIR AND FLUSH w/ CLEAN WATER TO REMOVE ALL LOOSE PARTICLES & DUST. 4. THOROUGHLY WET MASONRY & (E) MORTAR BEFORE PLACING (N) MORTAR. ALLOW SUFFICIENT TIME FOR JOINTS TO BE DAMP, BUT w/ NO FREESTANDING WATER PRESENT. 5. PROVIDE (N) MORTAR, TYPE AS PER SPECS, TO MATCH EXISTING COLOUR, TEXTURE & PROFILE. FILL JOINTS BY APPLYING SUCCESSIVE appx. 1/4" LIFTS OF WELL-PACKED MORTAR. ALLOW EACH LAYER OF MORTAR TO BECOME THUMBPRINT HARD BEFORE APPLYING NEXT LIFT. 6. TOOL FINAL LAYER OF MORTAR TO MATCH EXISTING. RECESS MORTAR SLIGHTLY FROM FACE OF MASONRY; DO NOT CREATE FEATHERED EDGE. 7. DURING CURING PROCESS, KEEP MASONRY UNITS & (N) MORTAR DAMP BY MISTING PERIODICALLY AND SHADING FOR SEVERAL DAYS AFTER INSTALLATION, ACCORDING TO LOCAL CONDITIONS. CLEAN REPOINTED MASONRY w/ NATURAL BRISTLE OR NYLON BRUSH. 8. AFTER FULL CURE, WASH DOWN REPOINTED MASONRY w/ CLEAN WATER AND CONSTRUCTION CLEANER AS PER SPECS. NB: PROVIDE appx. 2'-0"x 2'-0" MOCK-UP PANEL IN PLACE FOR REVIEW. NOTE #1, SECTION A-A HORIZONTAL BED JOINT #1, #3, #5, 6, 7, 8 ONE INCH (1") min REPOINTING DEPTH. MORTAR TO BE REMOVED (TYP.). (E) MORTAR REMAIN WHERE SOUND (TYP.). LINE OF (E) BRICK (E) MORTAR SOUND (TYP.). REMOVE MORTAR w/ HAND TOOLS PATH OF THIN BLADE GRINDER; REMAINDER w/ HAND TOOLS ONE INCH (1") DEPTH. SATURATED SURFACE PLACE (N) MORTAR IN LIFTS. (N) BOND-BREAKER TAPE REMOVE (E) MORTAR DOWN TO REQ'D DEPTH OR TO SOUND SUBSTRATE, WHICHEVER IS GREATER. PROVIDE (N) MORTAR AS REQ'D TO ACHIEVE PROPER JOINT DEPTH. JOINT OR 1/4" min., WHICHEVER IS GREATER. NB. PROVIDE appx. 12" SAMPLE IN PLACE FOR ARCHITECT'S REVIEW MASK EDGE OF JOINT w/ TAPE PRIOR TO APPLICATION OF SEALANT. REMOVE TAPE AFTER SEALANT HAS BEEN APPLIED (N) SEALANT. PROVIDE FLAT SURFACE. MASK EDGE OF JOINT w/ TAPE PRIOR TO APPLICATION OF SEALANT. REMOVE TAPE AFTER SEALANT HAS BEEN APPLIED. (N) NON- SAG POLYURETHANE SEALANT. PROVIDE CONCAVE SURFACE. (N) CLOSED CELL FOAM BACKER ROD. ROD Ø TO BE 1/4" > WIDTH OF JOINT. (N) COMPRESSIBLE FILLER. JOINT OR 1/4" min., WHICHEVER IS GREATER. NB. PROVIDE appx. 12" SAMPLE IN PLACE FOR ARCHITECT'S REVIEW SEALANT - SKY FACING / WASH JOINT Scale: NTS 9B SEALANT - SOFT JOINT Scale: NTS 9A TOOLING Scale: NTS 10C TOOLING Scale: NTS 10B TOOLING Scale: NTS 10A TOOL MORTAR FLAT, VERTICAL AND SLIGHTLY RECESSED FROM SURFACE OF MASONRY. POINTING OR SETTING MORTAR. MASONRY UNITS. NB. TYPICAL FOR ALL MORTAR JOINTS. NB. DETAIL FOR JOINT PROFILE AND PLACEMENT ONLY; REFER TO DRAWINGS & DETAILS FOR SCOPE. MASONRY UNITS. UNACCEPTABLE MORTAR PLACEMENT. PLACE MORTAR AS INDICATED; TOOL FLAT & VERTICAL. DO NOT PLACE MORTAR AT CURVE OF LINTEL. CURVED 'TOE' OF LINTEL ANGLE. NB. DETAIL FOR JOINT PROFILE AND PLACEMENT ONLY; REFER TO DRAWINGS & DETAILS FOR SCOPE. LINTEL ANGLE SHEET METAL FLASHING. NB. DETAIL FOR JOINT PROFILE AND PLACEMENT ONLY; REFER TO DRAWINGS & DETAILS FOR SCOPE. ANGLED EDGE OF SHEET METAL FLASHING. PLACE MORTAR AS INDICATED; TOOL FLAT & VERTICAL. DO NOT PLACE MORTAR AT ANGLE OF FLASHING. COPINGSTONE OR MASONRY UNITS. UNACCEPTABLE MORTAR PLACEMENT. REVISIONS: ONE WELDING ROAD Brooklyn, NY 11205 EXTERIOR RESTORATION THOMAS A. FENNIMAN ARCHITECT NEW YORK, NY 10003 TITLE: PROJECT: 54503 08/17/2021 PAGE NUMBER: 20 FOR REVIEW 06/28/2021 ROOF SCOPE REVIEW 08/17/2021 W.I.P. UPDATES 08/31/2021 ROOFING & FACADE SCOPE 99% SET 9/30/2021 B00611325-I1 DoB FILING SET 2021/10/13 BID SET 2021/12/02 A-502.00 MASONRY DETAILS 16 PAGE 9

SENDA VERDE

TYPE: Architecture Competition

COLLABORATE:

Architect: Gonzalo Carbajo

Project Discription:

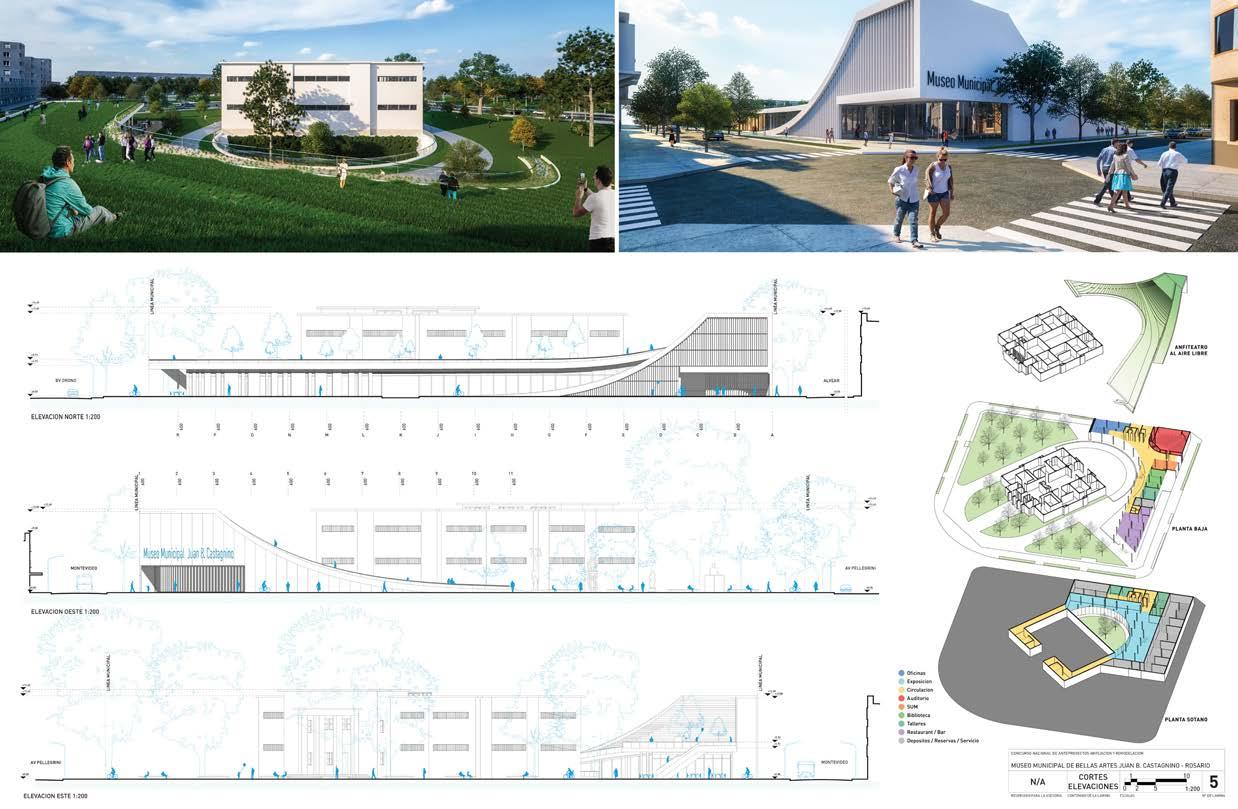

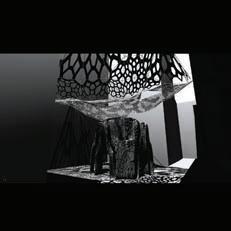

Address: Av. Pellegrini 2202, S2000QDN Rosario, Santa Fe, Argentina

Project Type: Museum Extension Competition

Project Responsibility: rendering schematics plans and sections

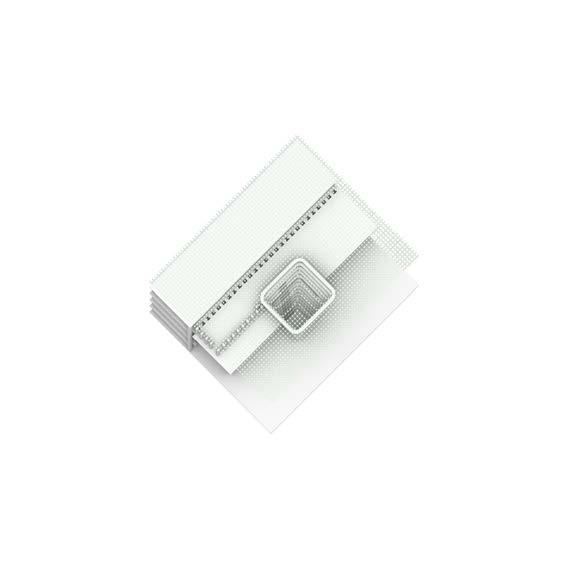

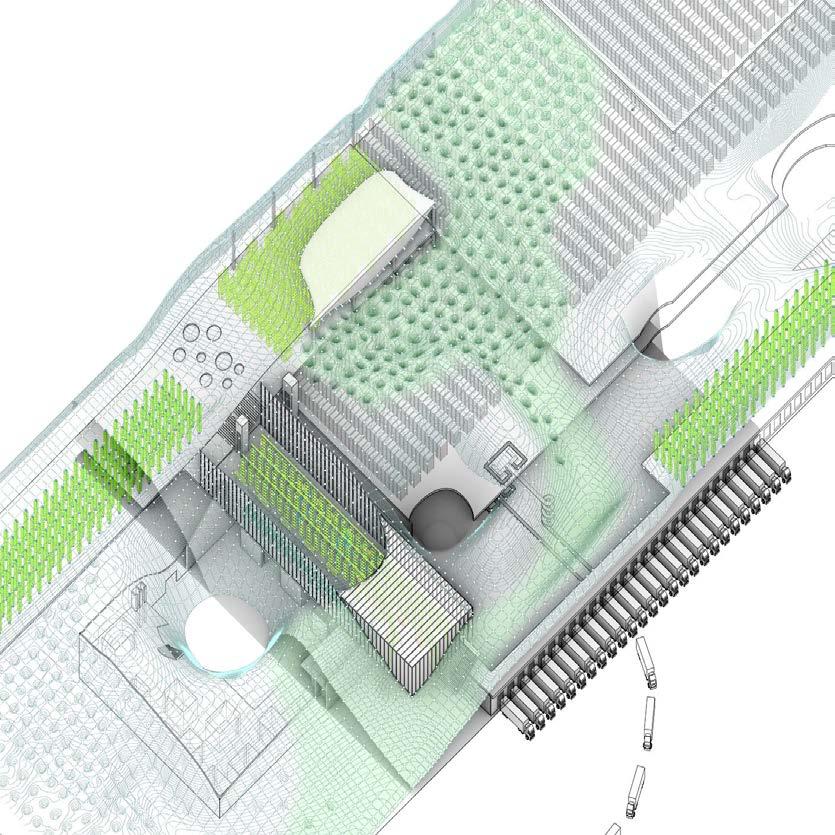

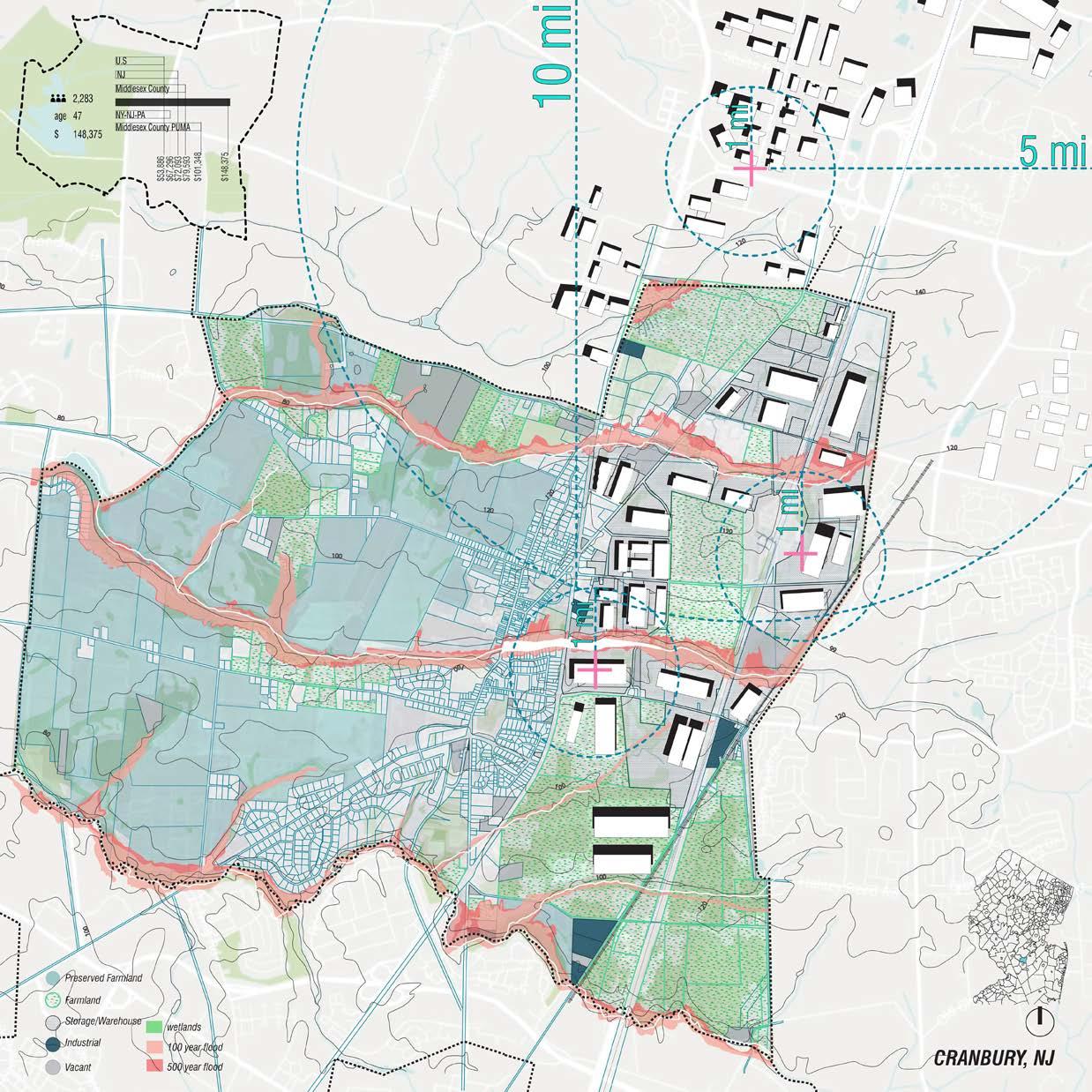

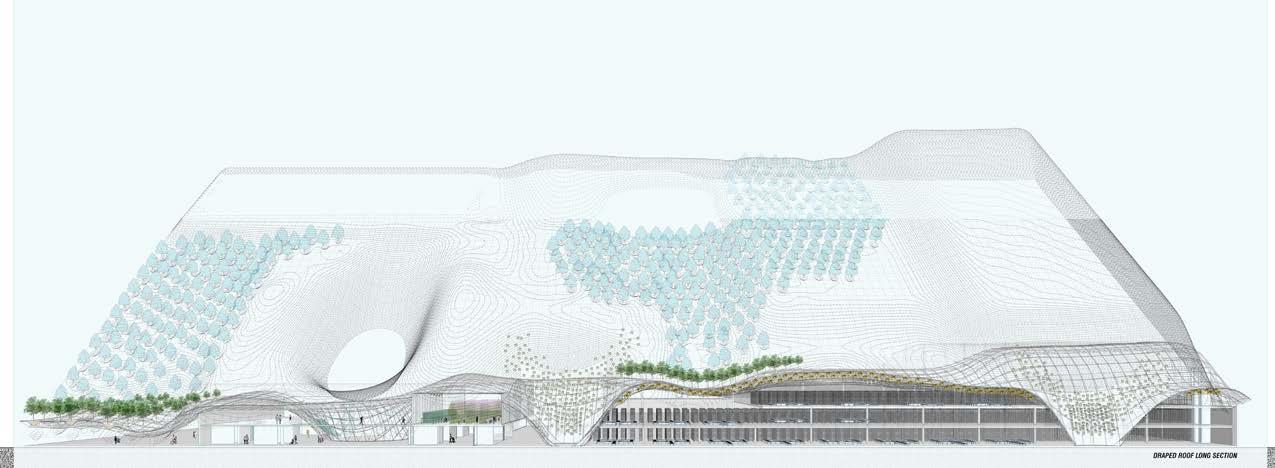

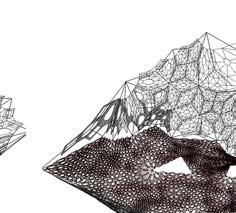

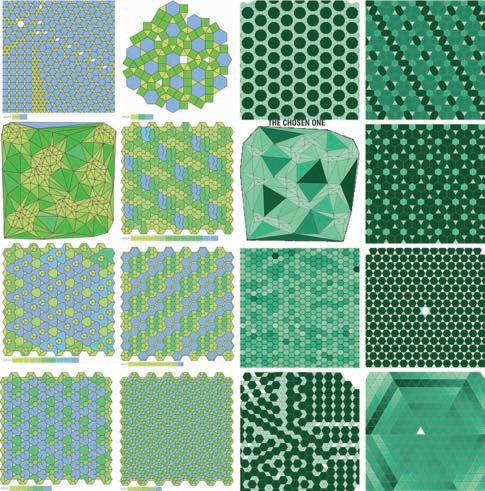

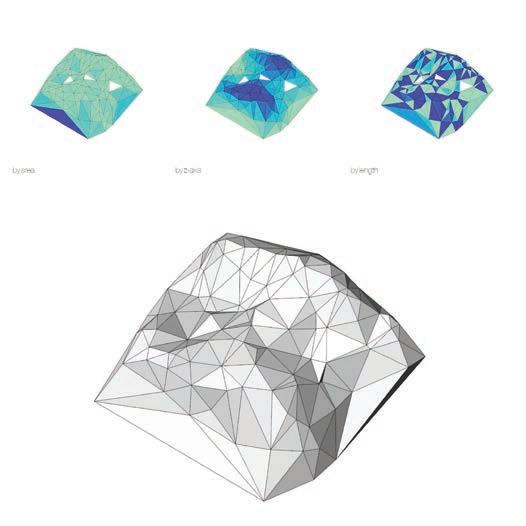

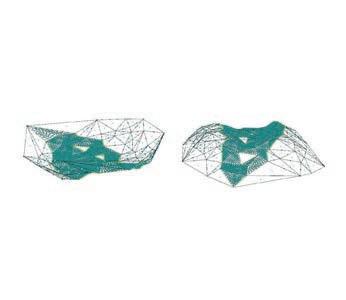

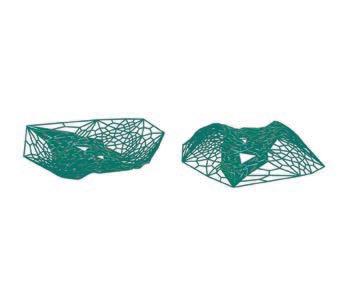

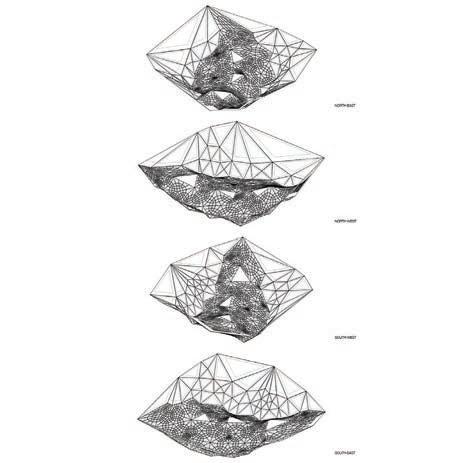

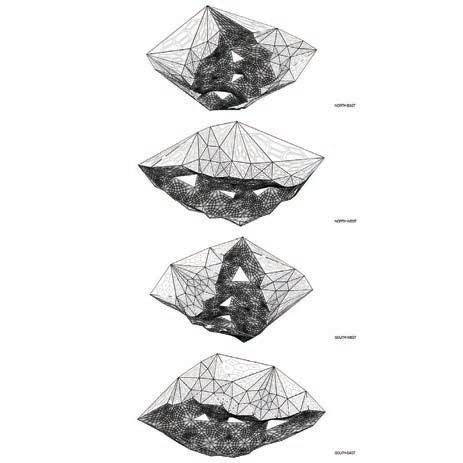

Juan B. Castagnino museum extension has named numerous requirements in their program needs and their connectivity between these, however, they also wanted to preserve as much of the green area onsite. The location is in the middle of Rosario, Santa Fe, Argentina, it’s at the crossroads of their urban greenery. The design of the museum extension is to have more programs they required but also have the ability to preserve the existing urban greenery. We decided to lift the greenery and place the program underneath to simultaneously have both greenery and program as the museum required.

By lifting the site, we also created a framing towards to original museum as well as the center of the greenery park. By lifting the site, we also faced some opportunity to have this gradual slope to have different use of the site program, such as floor to seating to wall.

PAGE 10

PAGE 11

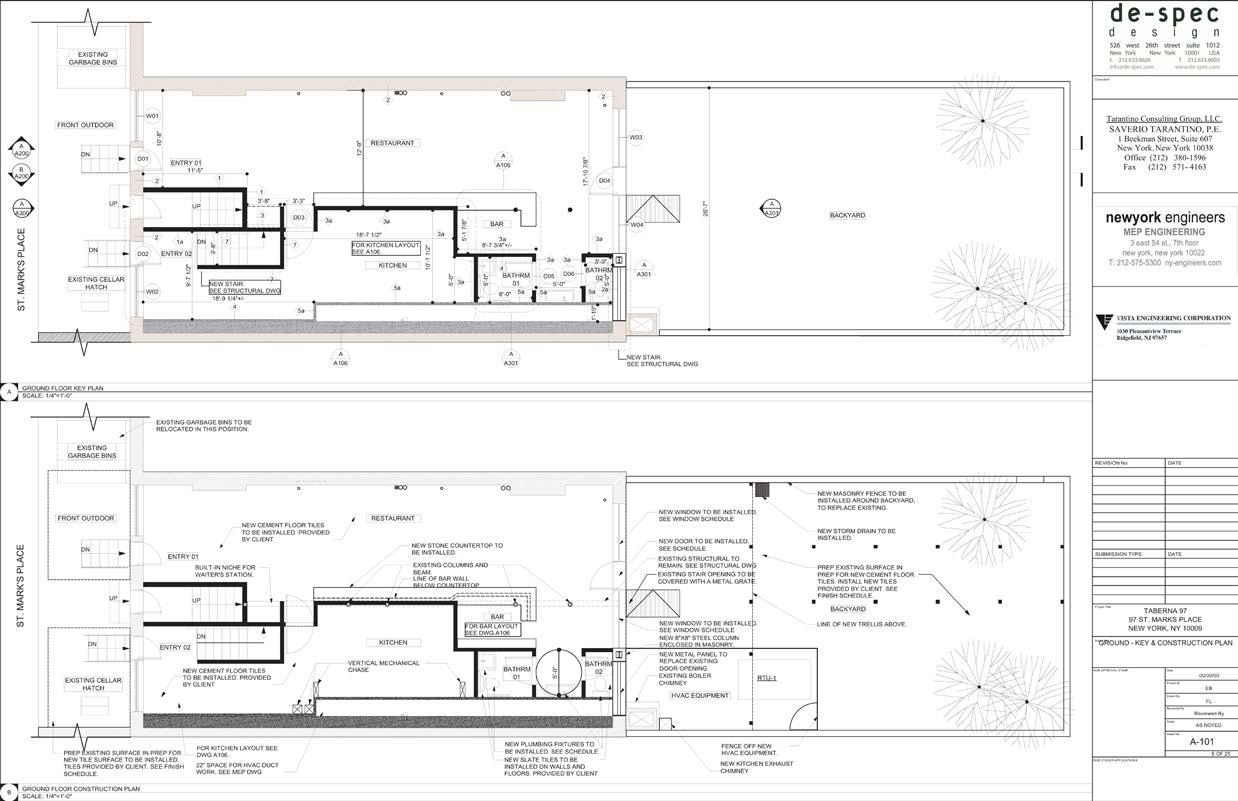

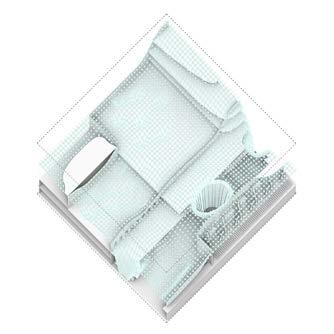

Located on the strip of Saint Marks Place along with several restaurants. The restaurant inspires to have Portuguese influence in the design to match the parallel of the cuisine. We started with color coordination and mood boards to find the basis of design. Follow by dealing the existing low ceiling height condition, we went through several design process to achieve a greater ceiling height. To incorporate the exposed wood beam, we took the opportunity to carry the linear element of the beam onto the wall as the bar shelving units.

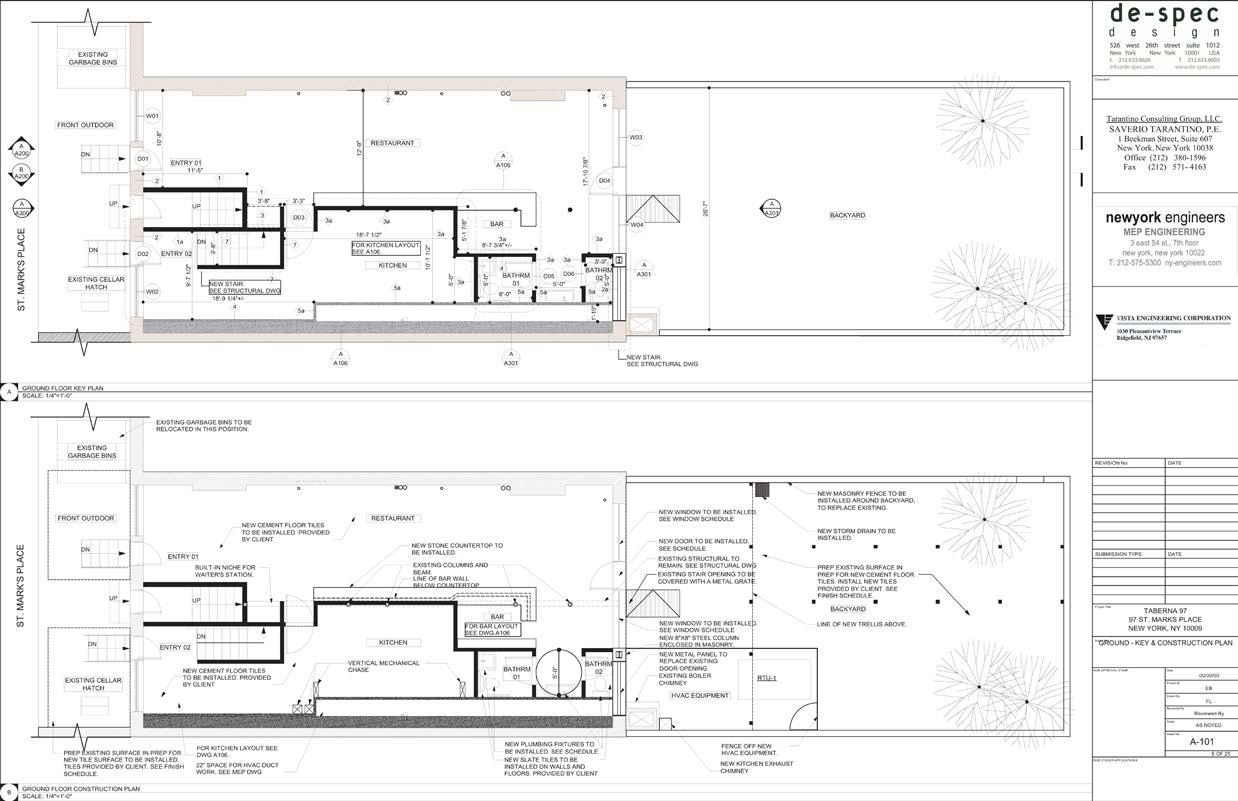

TABERNA 012015 SD PRESENATION-4 PAGE 16 INTERIOR d e-s p e c 526 west 26th street suite 1012 New York New York 10001 USA t. 212.633.6626 212.633.6603 info@de-spec.com www.de-spec.com PAGE 12 Project Discription: Address: 97 St. Marks Place New York, NY 10009 Project Type: interior renovation Project Responsibility: Rendering Schematics plan and section CD drawings TYPE: Interior Renovation COLLABORATE: Architect: Frederic Levrat TABERNA 97

PAGE 13