The pewag engineering group is an independently operating group of companies within the pewag group.

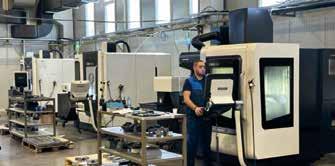

With their modern machinery, our specialised companies have many years of experience in the production of components (CNC turning/ milling, cutting, forming) and welded assemblies. Furthermore, we can offer our customers a wide range of services, from assistance with technical questions relating to their components and products to customised special machine construction and automation technology.

We see ourselves as a partner and one-stop shop for our customers, offering development and manufacturing expertise for individual components as well as turnkey system solutions.

The following pages provide you with an overview of our production and expertise portfolio.

Peter Hopfer Markus Scheibner Managing Director Managing Director

Peter Hopfer Markus Scheibner Managing Director Managing Director

Company purpose:

Special machine construction, product development

Core competence: Assembly and automation technology and selected welding technologies

Company purpose: CNC milling and turning, welded assemblies

Core competence: Production of complex geometries

Company purpose:

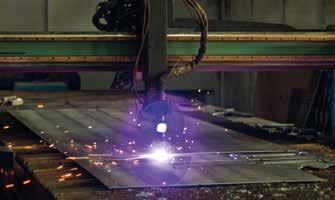

Laser/water jet cutting, forming, welded assemblies

Core competence: cutting processes and welding technologies for single part and small series production. Processing of a wide variety of materials.

Company purpose:

CNC milling and turning (3 and 4 axles)

Core competence:

Production with tight tolerances, processing of hardened steels

Company purpose:

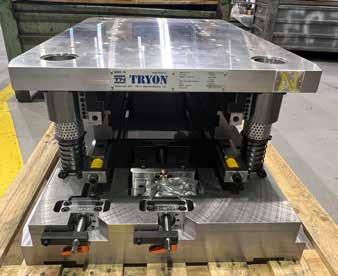

Development and production of pressing tools, stamped part production

Core competence: Progressive press tools, Single-purpose press lines, Maintenance and Repair of press tools

Stainless steel Soft metals Hardened steels Plastics available at

Stainless steel Soft metals Hardened steels Plastics available at

Podolí pfpsale@peform.com

agentur@tryon.cz

Podolí pfpsale@peform.com

info@hidraulikaflex.com

pwe@pewag.com

agentur@tryon.cz

pwe@pewag.com

Podolí pfpsale@peform.com

info@hidraulikaflex.com

info@hidraulikaflex.com

info@hidraulikaflex.com

agentur@tryon.cz

pwe@pewag.com

agentur@tryon.cz

info@hidraulikaflex.com

Stainless steel Soft metals Hardened steels Plastics available at

Podolí pfpsale@peform.com

agentur@tryon.cz

Stainless steel Soft metals Hardened steels Plastics available at

pwe@pewag.com

The automation of production and assembly processes is crucial for increasing efficiency. Especially in the context of digitalisation, there are many opportunities for you to generate a competitive advantage. In addition to cost savings, innovative assembly automation also improves ergonomics and the health of your employees.

Our innovative combination of camera systems and modern industrial robot technology enables, for example, the unmanned loading of machine tools using bin picking or various other customised robot applications. Your gain in flexibility and efficiency is our mission.

Our core expertise lies in the development and production of forming and punching tools, e.g such as progressive dies, transfer tools, punching and bending tools. We also manufacture single-purpose pressing lines. We manufacture these on customer’s request maximum dimensions 2000 x 800 x 600 mm and weight up to 3 tons. Our solutions come together cost efficiency and better working conditions - the next step towards modern production processes.

We process materials such as mild steel, stainless steel, hardening steel, aluminium and copper alloys and use tools manufactured in-house or manufacture these on a contract basis at the customer‘s request (the customer can provide the punching tools). Our punching presses (max. 160 tons) can process blanks with a wall thickness of up to 6 mm and punch individual components with dimensions of 500 x 300 mm and an individual component weight of 3 kg. The production capacity is up to 50,000 pieces per year. In addition, we offer the development and construction of customised stamped parts to meet your requirements.

Country: Austria

Address: Mariazeller Straße 143, 8605 Kapfenberg

Date of foundation: 1999

Manufacturing technologies & core competencies:

Engineering and manufacturing in the field of special machine construction product development

Production area: 2780 m2

Contact: www.pwe.at pwe@pewag.com

Country: Bosnia and Herzegovina

Address: Jovana Cvijića 3, 78250 Laktaši

Date of foundation: 2004

Manufacturing technologies & core competencies: CNC milling and turning of complex components, production of welded assemblies

Production area: 6000 m²

Contact: www.hidraulikaflex.com info@hidraulikaflex.com

Country: Czech Republic

Address: 43001 Chomutov, Pražská 585

Date of foundation: 1996

Manufacturing technologies & core competencies: In-depth expertise in cutting processes and welding technologies for single part and small series production. Processing of a wide variety of materials.

Production area: 4000 m2

Contact: www.peform-chomutov.cz info.fco@peform.com

Country: Czech Republic

Address:

č. ev. 73, 686 04 Podolí

Date of foundation: 2003

Manufacturing technologies & core competencies:

CNC milling and lathe turning (3 and 4 axles)

Production area: 1.800 m²

Contact:

www.peform-Podolí.cz

PFPsale@peform.com

Country: Czech Republic

Address: Kloboucká 866, Brumov-Bylnice 763 31

Date of foundation: 1995

Manufacturing technologies & core competencies:

Toolmaking/ Punching tools

Production area: 1650 m2

Contact: www.tryon.cz/en/ agentur@tryon.cz trade@tryon.cz

pewag engineering GmbH

pewag engineering GmbH Mariazeller Straße 143, 8605 Kapfenberg, Austria, office@pwe.at, www.pewag-engineering.at

Hidraulika Flex d.o.o., Jovana Cvijića 3, 78250 Laktaši, Bosnia and Herzegovina, info@hidraulikaflex.com, www.hidraulikaflex.com

peform Chomutov s.r.o., Pražská 585, 43001 Chomutov, Czech Republic, info@peform.com, www.peform-chomutov.cz

peform Podolí s.r.o., č. ev. 73, 686 04 Podolí, Czech Republic, info@poxon.cz, www.peform-Podolí.cz

TRYON s. r. o., Kloboucká 866, Brumov-Bylnice 763 31, Czech Republic, agentur@tryon.cz, trade@tryon.cz, www.tryon.cz/en/

TRYON s. r. o. Hidraulika Flex d.o.o. peform Podolí s.r.o. peform Chomutov s.r.o.