SPRING/SUMMER

SPRING/SUMMER

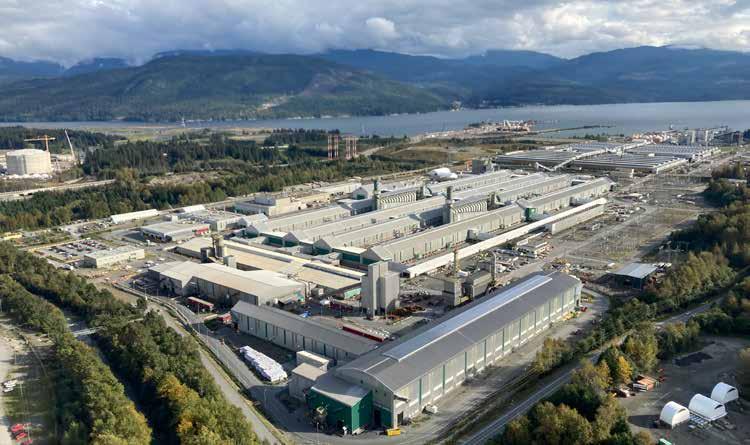

This aerial shot taken this month shows the progress of construction of the Blackwater Gold mine 160 km southwest of Prince George. Construction is now 73 per cent complete

The mild winter of 2024 was less than ideal for replenishing moisture in the forests or topping up water levels in rivers and lakes.

But the weather was great for building a gold mine, 160 kilometres southwest of Prince George.

As of March 31st, construction of the new Blackwater Gold mine being built by Artemis Gold Inc., of Vancouver was 73 per cent complete.

The project is fully funded and remains on schedule to produce its first pour in the second half of this year.

About $530 million has been spent, well within the parameters of the guided initial capital expenditure of $730-$750 million. That spending is expected to rise to $682 million by the end of June.

“We have an exceptional team managing the development of the Blackwater Mine,” said Steven Dean, chairman and CEO of Artemis Gold.

“Execution is critical in all projects, and managing the day-to-day challenges that arise in building a mine of this scale and complexity is key to being successful,” he said. “We have an experienced group of people who are first-class problem solvers, ensuring we advance toward operational readiness and remain on track for first gold pour.

“The remainder of 2024 will be transformational for Artemis Gold as we make progress on the Blackwater Mine, a Tier 1 asset in a Tier 1 jurisdiction, into production.”

By the start of April, 1.7 million hours of labour had been put into major works construction, with no longterm injury incidents and an all-injuries frequency rate of 87.68 per one million hours.

Most of the concrete work has been done, including the primary crusher runof-mine slab, crusher vault and ore stockpile reclaim tunnel. Construction of the reagents and mill buildings has begun, with installation of an

overhead crane in place, and the main electrical room has been built.

Key to the $2.5 billion project will be a new 133-kilometre BC Hydro transmission line which will allow Blackwater to build one of the mining sector’s first fully-electric ore processing plants. The carbonneutral setup will replace traditional diesel/propane fuelled processing and adds to the cost of construction but it will reduce the carbon footprint of the mine.

The transmission line right of way has been cleared and laydown areas for the power poles and camp facilities are ready. Poles and hardware deliveries will be sequenced to support the construction schedule.

The line will be built in two sections divided by the Nechako River. North of the river the new line will run for approximately 50 km, while the south segment is about 80 km long.

Assembly and commissioning

of the owner’s mining fleet continues to advance. Two 400-tonne hydraulic backhoe excavators have been assembled at the site, along with six 240-tonne rigid-frame haul trucks and two large mining front-end loaders. The remaining pieces of heavy equipment needed to support initial operations are on-site, nearing completion.

The mine’s workforce remained constant through the first three months of 2024 at 320 employees, of which 20 per cent are women, 30 per cent identify as Indigenous, 50 per cent are from the North Central Interior and 80 per cent are B.C. residents.

Artemis has borrowed an additional $130 million under the project loan facility, bringing the loan total to $280 million, with an additional $5 million in interest costs through March 31.

The remaining Phase 1 capital expenditures will be between $207 million and $227 million.

Like most forestry workers who have seen the decline of B.C.’s once-thriving pulp-producing industry, Jonathan Blacker was not surprised when he got the news May 1st that the company he works for, Canfor Pulp Products Inc., plans to curtail one of its two pulp lines at Northwood Pulp Mill.

The indefinite curtailment means as many 220 Northwood workers are about to lose their jobs and Blacker, president of Unifor Local 603 that represents the 361 active members who work at Northwood, feels their pain.

The 51-year-old machinist has worked at Northwood for 12 years and he’s hoping he has enough seniority to keep his job, but he’s not sure. That cloud of uncertainty will hang over the mill for the next few months until the job cuts take effect this summer.

“It’s ugly, it’s a pretty big hit for Prince George,” said Blacker. “It’s pretty bad, I’m concerned about the workforce and all the employees who are going to lose their jobs.”

Blacker said Northwood absorbed some of the job losses when Canfor shut down its Prince George Pulp and Paper pulp line in April 2023 and several workers who were closer to retirement age took buyouts to keep younger employees at the lower rung of the seniority ladder from losing their jobs. Now they face the reality once again they could be heading for the unemployment line.

“The average age is probably 25-40 now,” said Blacker. “Lots of the older people that started at the pulp mill are retired now, they took buyouts when PG (Pulp) was closing so I don’t know if the government is going to step in again to help these workers.”

Blacker says management jobs will also be lost, but he doesn’t know how many.

“They’re worried too, it’s going to affect everybody when you lose half a mill,” said Blacker. “You’ve got couriers, foresters, loggers, truckers, the first-line guys. I’m sure Canfor is looking at saving jobs and where they can amalgamate people and absorb them, be it at a sawmill out of town or whatever, then Prince George loses again because all that money’s gone.”

Combined with Canfor’s other announcements on May 1st that it will permanently close the Polar Sawmill at Bear Lake and that it‘s suspending its reinvestment in its sawmill in Houston, hundreds of direct jobs will be lost as well as hundreds of indirect jobs from support industries.

Blacker points the blame directly at the provincial government and its permitting process which he says creates too many barriers for harvesting companies which he says are shying away from investing in the province’s forest industry. Harvesting has declined sharply and in 2023 the actual cut was 43 per cent lower than the annual allowable cut set by the province.

“Just the state of the industry itself and how hard it is to get fibre now through caribou habitat and Indigenous rights, it’s a tough go,” said Blacker. “Stumpage fees are way up. We’re exporting raw logs. There's companies chipping whole logs (to support the wood pellet export industry), that’s not right.

“It’s hard to get cutting permits, it takes a year or two, whereas other places in the world it’s like a week or two and you can harvest wood. You have to go further out to get the wood. They cut too much wood too fast.”

He says forestry is looked upon as a dying industry by young

workers and skilled trades people, which compounds the problems foresters are facing.

Blacker attended the BC Forest Workers Summit in Victoria in March and two weeks later he said Unifor executives met with the provincial government officials to try to get them to reshape their forestry policies to save jobs. He says they’ve known the industry has been dying and have been too slow to react.

“They’ve seen this coming for years,” said Blacker.

“The bottom line is they’ve managed our plantation horribly. They let the harvesters manage the plantation and of course they’re going to cut. There’s wood, there’s lots of trees left, but it’s just harder to get now and more hoops to jump through to get it.

“Canfor’s getting ready to leave, it’s too hard to make money here now. They’ve harvested what they needed and got all the easy wood. They want out, these big harvesters have made their cash and it will be the smaller guys left, I think.”

Blacker says union management will be coming to the mill to discuss the future of the affected workers and he hopes to have more answers for workers when he returns from his holidays at the end of May.

“Everybody’s got truck payments, house payments, mortgage rates and interest rates through the roof, Blacker said. “Maybe we’ve got to leave British Columbia and go to Edmonton. You’ve got to chase work, you’ve got bills to pay. I’ve been there 12 years and I might just make the cut, but it’s hard to say and I don’t know.

“It’s no good, the government better step in and do something.”

SHIRLEY BOND

INTERIM LEADER OF THE OFFICIAL OPPOSITION MLA|PRINCE GEORGE-VALEMOUNT 250-612-4181

Shirley.Bond.MLA@leg.bc.ca /ShirleyBondforBC

MLA|PRINCE GEORGE-MACKENZIE 250-612-4194

Mike.Morris.MLA@leg.bc.ca /MikeMorrisforBC

Nelson Bennett Mining has never been viewed as exactly environmentally friendly.

Mines and miners have often been the target of NGOs for the impacts mining can have on water, land and Indigenous communities.

But because mining plays such an important role in the energy transition needed to address climate change, there is increasing support for mining by governments, First Nations and the general public.

The need for critical minerals to supply the energy transition poses a huge opportunity for B.C., said Michael Goehring, president of the Mining Association of BC (MABC).

The International Energy Agency (IEA) has estimated a sixfold increase in demand for critical minerals will be needed by 2040, largely to supply the energy transition. Of the 31 minerals on the federal

government’s critical minerals list, 16 are found in B.C.

Copper is the most abundant critical mineral mined in B.C., but there are also proposals here for new nickel mines, and even a rare earth mine.

There are 17 critical mineral mines proposed for B.C., and a recent economic impact study on them found that, if all were built, their development and construction alone would generate an “eye-popping” $36 billion in near-term investment, Goehring said.

“That will result in a whopping economic output of $80 billion, labour income of $23 billion and $11 billion in tax revenues,” Goehring said.

The longer term impact of these mines, once in operation, could reach nearly $800 billion over the life of the mines, Goehring added.

Five proposed gold mines in B.C. would exceed $29 billion

“ If we’re to fully unlock B.C.’s critical mineral potential, we need competitive fiscal and regulatory policies to attract and retain investment to grow our sector

in economic activity over their lifespans.

But Goehring warned against complacency. Though support for critical minerals mining is generally growing, obstacles remain.

“Many countries are looking to Canada as a reliable and responsible producer of critical minerals, but we’re in a high stakes game with many competitors,” Goehring said.

“This is also taking place at a time when the pool of

capital for mining is shrinking, fragmented and more risk averse than in years past. And you have to face the fact, too, the new mines are large, high-risk capital projects, and like it or not, today’s investors are seeking faster and more certain returns.

“So that means that, while we’re very well positioned to be at the forefront of this energy transition, and to be a leading global supplier of responsibly produced critical minerals, our time is limited to capitalize on this generational opportunity.”

Mining is already a major economic pillar in B.C. More than 1,100 exploration and mining companies are headed quartered in B.C.

There are 17 operating mines in the province – seven of them metallurgical coal mines -- two smelters, and two new gold mines going into production this year: Premier and Blackwater.

In 2022, mining generated $18 billion in economic activity, accounted for nearly one-third of B.C.’s total exports – 30 per cent – and employed 35,000 British Columbians, Goehring said.

Mineral exploration expenditures reached $644 million last year, Josie Osborne, minister of energy, Mines and Low Carbon Innovation, said in a press release in observation of Mining Month. And over the past five years, exploration spending totalled $2.8 billion, she said, with mining production valued at $60 billion.

“The year ahead promises to be marked by milestones, as we welcome two major mines starting or resuming operations: Premier Gold, near Stewart, and Blackwater Gold, southwest of Prince George,” Osbourne said.

Mining is the largest employer

of aboriginal people in Canada, and in B.C. 45 First Nations share in the benefits of mining through participation or impact benefit agreements, and 49 have received $326 million in mineral tax payments, Goehring said.

Goehring said federal and provincial governments – both of which have adopted critical minerals strategies – have made strides in promoting mining. But more needs to be done, mainly on permitting.

“If we’re to fully unlock B.C.’s critical mineral potential, we need competitive fiscal and regulatory policies to attract and retain investment to grow our sector,” Goehring said.

Positive steps from the province include a First Nations equity financing plan that helps First Nations gain equity positions in resource projects. Goehring urged the government to provide more capacity funding for First Nations, since dealing

with resource development projects takes a huge amount of resources, which many First Nations do not have.

“First Nations governing bodies require governance, administrative and technical capacity to enable them to be on a level playing field and participate in governmentto-government processes and reviews of major mine projects on their terms,” Goehring said.

Goehring also said the industry needs to work on “perception” issues to attract more young people into mining.

But topping the list of urgent reforms is still permitting timelines. It simply takes too long to get new mines approved.

“Permitting is currently the major obstacle to critical minerals development,” Goehring said.

Mark Nielsen

Mark Nielsen

Going by the submissions made during a public comment period, a proposal to build a liquefied natural gas plant near Summit Lake has failed to impress. JX LNG Canada is seeking go-ahead from B.C. Environmental Assessment Office and the Impact Assessment Agency of Canada to build at a site known as the Hart Industrial about 11 kilometres south of the community and about 30 kilometres north of Prince George.

According to an initial project description, the plant would occupy about 250 hectares and produce up to 2.7 million tonnes per year of the product and have it shipped by rail to Prince Rupert in special ISO containers for export to Asia.

It would rely on the nearby Enbridge Westcoast Pipeline for feedstock via a twokilometre pipeline that would be constructed as part of the

project. A six-kilometre power line would also be put in place to connect to BC Hydro’s Salmon Valley substation.

JX LNG Canada, is an Alberta-based subsidiary of Changchun Jixing New Energy Ltd., which is involved in the LNG and compressed natural gas sector in northeastern China.

By the closing of the comment period 10 comments were posted on the agencies’ respective websites - six from private citizens, three from environmental advocacy groups and one from the Summit Lake Community Association (SLCA) which has taken a neutral stance on the proposal but raised several concerns. In submissions on the B.C. Environmental Assessment Office’s website, both David Suzuki Foundation and Stand Earth dispute the contention that LNG would reduce worldwide carbon emissions by displacing coal in the countries the product

is shipped to - a key argument put forward by the proponent.

“As our report Burning Bridge showed, and as other studies indicate, there is little evidence that LNG exports will displace coal. In fact, there is a considerable risk more LNG infrastructure will lock out investments in renewables and an oversupplied market could depress prices and lead to the stranding of assets,” David Suzuki Foundation energy transition strategist John Young writes. Similarly, in a submission on the Impact Assessment Agency of Canada website, Albertabased Citizen’s Oil and Gas Council maintains that while LNG may have lower burner tip emissions, once production and shipping are taken into account, the fuel produces significantly higher greenhouse gas emissions than locally-produced Asian coal.

Shipping by rail was also

raised as a concern.

Rail traffic between the site and Prince Rupert is projected to increase by 5,600 to 11,200 cars per month, according to Young.

“Canadian National Railways has a history of accidents and derailment along this stretch of track, bringing increased risk of negative impacts attributable to the Project. In addition to public safety concerns, much of the CN mainline between the Project site and Prince Rupert is immediately adjacent to key rivers that support culturally important and ecologically sensitive stocks of all five Pacific salmon species as well as Steelhead,” Young writes. In its submission, the SLCA maintains the viability of the site as a place for heavy industry is based on dated information noting the land use study is more than 20 years old.

“It is clear based on current environmental trends today that assessments made previously in regards to impacts of heavy industry were often underestimated, and overlooked, resulting in the overall negative environmental impacts we see currently. This is no different when considering the Hart North Industrial site as prior analysis and understanding of impacts in the past have vastly changed in today’s terms,” the group says.

“The overall lack of current analysis of the viability of the proposed location is extremely concerning due to its proximity to the Summit Lake community, the lake itself and water shed, farmland, the Salmon River and many other sensitive water bodies within close proximity.”

The SCLA goes on to suggest the old Winton Global mill site further north of Summit Lake could have been considered

“as the site has an already established footprint and would have access to power, rail and sits near the gas line the proponent would require.”

Also known as the early engagement stage, the public comment period closed on Thursday. Next steps include the agencies jointly preparing a summary outlining the key issues and concerns identified and list First Nations that will be participating in the assessment process.

The summary will help guide JX LNG Canada Ltd as they develop a detailed project description, the BC EAO says.

“Once submitted, the detailed project description informs the EAO’s decision on whether the project is ready to proceed to an environmental assessment,” the agency says.

Ascot Resource’s mine to employ up to 250 people, targets full production by July

An historic gold mine that has operated off and on in the Stewart area of British Columbia for more than a century is once again back in operation.

Ascot Resources Ltd. (TSX:AOT, OTCQX:AOTVF) recently marked a critical milestone for its Premier gold mine—first gold pour on April 20—and the mine is now in commissioning. The company expects full commercial production by the end of July.

“We’ll continue to make more gold pours and then we kind of get to a steady state and then we say we have a commissioned mill,” said Ascot Resources CEO Derek White.

With gold prices hitting a record high in mid-April, the timing is good for Ascot.

Ascot’s feasibility study projected a net present value of $516 million and internal rate of return of 62 per cent based on gold prices being at US$1,400 per ounce and silver at US$17 per ounce.

“Costs have also risen, but not to the same extent the gold price has risen, so the margin that we make on every ounce we produce has gone way up,” White said. “So it’s extremely favourable to us.”

The Premier mine, located 25 kilometres north of Stewart, will be the first gold mine to go into production in B.C. since the Brucejack mine in 2017.

The original Premier gold mine began operating more than a century ago, in 1918, and continued to operate off and on for decades.

“ We save a lot of money by having a lot of this stuff already there, but we have to still spend money to bring it up to today’s standard.

It stopped operating more than two decades ago.

Ascot acquired the property in 2018 and acquired other nearby deposits, including the Red Mountain deposit. There are four deposits that will be mined from underground in a spoke-andwheel design, with the four deposits feeding a central mill.

The mill had to be upgraded, as was a tailings pond and water treatment plant. But otherwise, much of the infrastructure that is needed for a mine was still in place, which brought the capital costs of restarting the mine down.

The total capital cost of bringing the mine back into production is estimated at $340 million.

“If we were going to do this on a greenfield basis … it would probably cost us a billion to a billion and a half dollars to build it,” White said.

up to today’s standard.”

The mine is within Nisga’a First Nation treaty territory and has the support of the First Nation.

The Big Missouri deposit is the first being mined. Ascot plans to start underground mining at the Premier Northern Lights deposit in September, followed by the Silver Coin deposit in the fall of 2025.

Around 2029, the company then plans to start mining the Red Mountain deposit, which is 44 kilometres from the mill.

During construction, the project employed about 250 people, White said. Once in full operation, it will employ 200 to 250 people, not counting contractors.

“We save a lot of money by having a lot of this stuff already there, but we have to still spend money to bring it

Written by: Submitted by Rio Tinto BC Works

Written by: Submitted by Rio Tinto BC Works

Rio Tinto BC Works’ story dates back to the 1920s when the Government of British Columbia conducted a survey that recognized the area now known as the Regional District of BulkleyNechako for its hydroelectric potential. Alcan was invited by the government to build an aluminium smelter in Kitimat, powered by hydroelectricity through the Kemano powerhouse. At the time, the Kitimat – Kemano project was the largest single investment by a private company in Canada.

It was a remarkable feat building BC Works which was commissioned in 1954 and was the only aluminium smelter in Canada outside Quebec. Our footprint spans more than 400 kms from the smelter and port facilities in Kitimat to our vast

hydroelectric assets in the Nechako Reservoir.

The completion of the Kenney Dam, Nechako Reservoir, Kemano tunnel, Kemano hydropower facility and the Aluminium smelter took five years to be completed, provided jobs to 35,000 workers and required 30 million man-hours. Our expansive operational footprint spans two regional districts and we are hosted within the traditional territories of 21 Indigenous communities.

Fast forward to today, we are celebrating our 70 years of operations, with 1,100 employees and 400 indirect contractors in Kitimat. This is a very exciting year for BC Works where we reflect on the past seven decades and think again about the next 70 years.

In Kitimat, we produce over

400,000 tonnes of aluminium in various formats including small form ingots, slabs and sows, for shipment via rail and ship to North American and European markets.

BC Works remains committed to ongoing improvements at our site to sustain our operations for many decades to come. BC Works remains committed to ongoing improvements at our site to sustain our operations for many decades to come. Some notable investments over the last decade are the $6 billion investment to modernize the smelter, completed in 2015; in 2022 the second tunnel to the Kemano hydropower facility was commissioned, an $850 million investment; and announced in 2024 is the $135 million investment to build a new alumina conveyor system at the smelter site, this is anticipated to be completed by June 2025.

These investments demonstrate Rio Tinto’s commitment to produce aluminium to the highest internationally recognized standard for responsible environmental, social and governance practices, driving decarbonization and enabling the energy transition.

Aluminium plays an important role on both sides of the energy transition. Surprising to many is the wide use of aluminium in transmission lines due to its light weight and conductive properties. It is also used in many of the products that are key to the energy transition like electric vehicles and solar panels.

There is an increased demand for aluminium across North American markets due to the increasing electrification needs of our society. The future is bright for aluminium, with the metal

being infinitely recyclable, making it a key component of our increasingly circular economy.

We have a complex history in BC. With the creation of the Kenney Dam, water was diverted to produce hydroelectric power at the Kemano powerhouse. This fundamentally changed ecosystems and impacted the people who lived there. While we hold great pride in the strides taken together with our First Nation hosts, we acknowledge the past injustices and impacts of our decisions and operations. We are working hard on our path to authentic partnerships, genuine twoway communication, and proactive co-design with our core values of care, courage, and curiosity at the forefront.

In 2010, we signed a historic 30-year agreement called the Haisla Legacy Agreement with the Haisla First Nation. Ten years later in 2020, we signed the New Day Agreement with the Cheslatta Carrier Nation. Both agreements promote the social and economic well-being of the Haisla First Nation and Cheslatta Carrier Nation through

engagement in the areas of training, employment and business opportunities and environmental stewardship. We are proud of both agreements and continue to build long-lasting relationships based on trust and transparency with other Nations.

Meanwhile, we continue to be a longstanding part of BC’s economy and are amongst the largest contributors to BC’s manufacturing GDP. In the past five years, we have contributed an estimated $142 million towards municipal and provincial tax base, $1.1 billion in salaries, benefits and pension payments, $1.85 billion in supply chain investments and $11.4 million in community donations and sponsorships.

Rio Tinto has a long and proud history at BC Works. Four generations of women and men producing lowcarbon aluminium in Northern British Columbia is no small feat. The passion and dedication of our employees is remarkable – they are steadfast, unified, and inspiring – qualities that will drive our future for another successful 70 years.

rates suppress new housing construction.

B.C. lumber production down a ‘whopping’ 26.5 per cent in 2023.

Canadian lumber output was down more than 20 per cent for the better part of 2023, compared to 2022, and even lower in B.C. -- a reflection of higher interest rates and muted global economic growth, according to a Global Consulting Alliance forest sector outlook.

And the first half of 2024 may not be much better for the forest sector.

Forest sector analyst Russ Taylor, whose consulting firm is part of the Global Consulting Alliance, noted that lumber prices have recently fallen below US$400 per thousand board feet -- the break-even point for many producers in B.C., as well as the U.S.

“We’re sort of treading water,” Taylor said.

“The U.S. south is losing money,” he added. “They’re below break-even. They’re in worse shape right now than B.C. mills are.”

Lumber demand has not come back yet in 2024 the way he expected, Taylor said. High interest rates have a lot to do with the muted demand for lumber, since high interest

“Housing starts, I think, are going to be lower this year than last year,” Taylor said. “It’s not what I would have thought a few months ago.”

The outlook notes that Canadian lumber output was 21.2 per cent lower in the first nine months of 2023 than the same period of 2022.

“B.C. production was down by a whopping 26.5 per cent,” the report observes.

“Canadian softwood lumber exports through November were 12.35 billion (board feet), down 7.7 per cent compared to last year, with most of the reduction attributed to declining output in B.C.”

The report notes that B.C.’s Crown timber harvest has “plunged” from 65 million cubic metres in mid-2016 to just 32.5 million cubic metres at the end of 2023.

“The outlook for the Crown timber harvest in 2024 is for a level below 30 million (cubic metres).”

The report acknowledges the role forest fires and beetle infestations have played in reducing B.C.’s fibre basket, but also blames government policies like old growth

logging moratoria, landscape planning, “and other initiatives that play to the government’s base of urban voters.”

“Forest stewardship and incentives for the industry are sadly lacking,” the report says.

The biggest market for B.C. lumber is the U.S, followed by Japan and China.

Total U.S. housing starts in 2023 were 1.414 million units – nine per cent lower than in 2022.

The lower demand for lumber in the U.S. drove North American lumber prices down – low enough to cause some higher cost mills to take curtailments, including in the U.S.

The average price for Western SPF (spruce-pine-fir) was around US$400 per thousand board feet.

Canadian lumber exports to the U.S. through November were 7.9 per cent lower than the same 11-month period of 2022. Canadian exports to Japan were also down 21 per cent, and 12.6 per cent higher in China.

B.C. lumber exports for the first 11 months of 2023 were 16 per cent lower than the same period of 2022.

B.C. pulp exports were also 11

per cent lower in the first 11 months of 2023 compared to the same period of 2022.

“B.C. lumber exports to the U.S.A. were 19 per cent lower than a year earlier, partly due to weak prices that were below break-even levels for much of the year,” the Global Consulting Alliance report observes.

Going forward, economic growth is expected to be somewhat muted this year and next, compared to previous periods.

The outlook cites the World Bank, which forecasts global economic growth to be 2.4 per cent in 2024 and 2.5 per cent in 2025.

It forecasts U.S. real GDP growth be 1.6 per cent in 2024 an 1.7 per cent in 2025. China’s growth is expected to slide from 5.3 per cent in 2023 to 4.5 per cent in 2025.

“I think it’s going to be a tough first half of the year,” Taylor predicted.

He expects more North American sawmill curtailments this year.

“That will put supply and demand back into balance,” he said. “I think the second half of the year should be better.”

B.C. Forests Minister Bruce Ralston is applauding a NAFTA panel’s recent decision to order the U.S. Department of Commerce to correct errors in its setting of countervailing duties on Canadian softwood lumber.

Ever since the last softwood lumber agreement ended in 2015, Canadian lumber producers exporting to the U.S. have faced countervailing and anti dumping duties, which are subject to legal challenges revisions. As a major lumber producer and exporter, B.C. is disproportionately affected by the duties.

The North American Free Trade Agreement (NAFTA) – which was renegotiated to become the US-MexicoCanada Agreement (USMCA) – has a trade resolution section, chapter 19.

A bi-national NAFTA chapter 19 panel recently ruled that the U.S. Department of Congress needs to correct errors it made in its most recent determination on duties.

B.C. Forests

Minister

Bruce Ralston applauds NAFTA panel ruling. | BC Government Flickr

“Today, a NAFTA panel has taken an important step in the right direction to correcting this by directing the U.S. Department of Commerce to review certain aspects of its determination,” Ralston said in a press release.

“This decision is good news to communities and the tens of thousands of forestry workers throughout B.C., as well as American and Canadian families. The panel decision supports what the province of British Columbia and Government of Canada have said from the start: These duties are unfair and unwarranted.

“Despite the good news that NAFTA has directed the U.S. Department of Commerce to correct errors that it made in its countervailing decision, this decision does not immediately put an end to U.S. countervailing duties on softwood lumber. The province of British Columbia will continue to take action alongside the Government of Canada and our forestry industry to vigorously fight for the removal of U.S. duties.”