2 minute read

HOW SAFE ARE YOUR TEAM?

The waste and recycling sector is a critical part of our economy and plays a crucial role in ensuring a sustainably led future. However, it is also a sector that is fraught with danger and risks. From hazardous waste to workplace accidents, the waste and recycling sector presents a significant challenge for workers and businesses when it comes to safety.

As with any large-scale waste operation, the use of heavy plant machinery and vehicles alongside operatives and ground workers, will always present a safety risk. No site, even with the highest health and safety standards and best practices is 100% free from danger. In fact, between 2017 and 2021, the waste and recycling industry had the highest rate of fatal injuries per year – with 70% of all fatalities linked to workers being struck by vehicles or through contact with moving machinery.

In a report from the HSE in 2022, they highlighted the increased dangers associated with the waste and recycling sector - between 2017/18 and 2020/21, the waste sector recorded an average of five fatal injuries per year saying: “The waste and recycling sector has an elevated rate of fatal injury [between 2017/18 and 2020/21] compared to the average across all industries: 11 times as high.”

The most common cause of injury or fatality was being struck by a moving vehicle with 37% of all confirmed fatalities. Second was contact with moving machinery at 33%.

Although existing control methods such as physical barriers, warning signs and correct health and safety training for workers are already in place, they are never 100% effective due to human error, on-site distractions, and other mitigating circumstances.

So, what can be done to increase the control measures already in place to help make the industry even safer and reduce the number of injuries and fatalities?

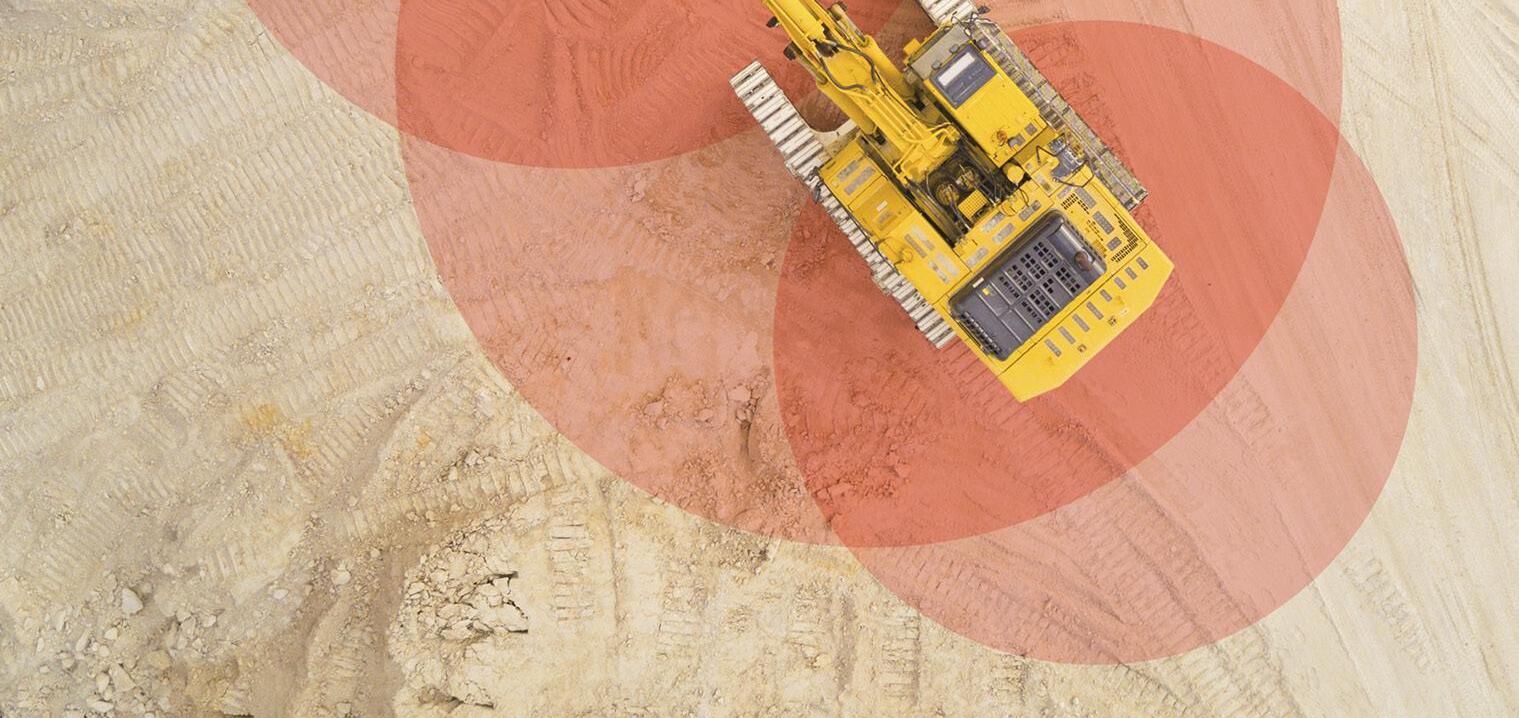

One way to that you can increase your safety measures is to implement a plant proximity solution. One of the best on the market is the Zonr Plant Proximity Solution. Zonr creates virtual safety exclusion zones that warn your workers when they are getting too close to dangerous or moving equipment. The Zonr system creates a virtual barrier around anything you attach a sensor to, using UWB technology (the same technology found in an Apple Tag). This allows workers and plant operators to have an extra layer of safety protection while on site.

A great unit for a greater business STAND

Clean

Remove DIRT & WATER in the same mobile application

Affordable and easy to change out replacement cartridges

Kind to the planet - as a natural, sustainable product

Save waste costs, replacement value and labour

Simple ‘plug and play’ application Site permantely on a problematic machine or on a rotational cleanse across your fleet.

Whether it be to tackle one off contamination issues, or as a permanent fix to heavy use equipment to protect pumps, valves & cylinders etc.. or as a rotational cleanse on off-hire equipment.

KLEENOIL offer a completely free trial at your site ; with before and after independent oil analysis.