37 minute read

NEWS

Correction

In the New Products section of the April 2022 print issue, the images for Orbex’s ultrasmall gimbal motors and Leuze’s mutlisensor were swapped. The correct information with image for Orbex’s new gimbal motors can be viewed at http://awgo.to/1429 and the correct information and image for Leuze’s new multisensor can be viewed at http://awgo.to/1430.

ABB Showcases Its ASTI Mobile Robotics

By David Greenfield

Editor-in-Chief/Director of Content

Following ABB’s acquisition of ASTI Mobile Robotics in July 2021, the company showcased ASTI’s autonomous mobile robots (AMRs) as part of its exhibit at Modex 2022 in Atlanta. In its exhibit, ABB focused on the new EBot 350, an AMR designed for use in e-commerce, warehouse logistics, and manufacturing applications.

The EBot 350 features 360 degrees of protection to ensure against collisions with people or objects. ABB says two safety lasers on the Ebot 350 provide “full coverage of the vehicle’s perimeter.” The AMR also uses a safety PLC to further ensure safe operation.

According to ABB, ASTI robotics technologies allow users to replace linear production lines with flexible networks, where intelligent AMRs autonomously navigate materials, parts, and finished products between smart connected workstations in factories and logistics centers.

Real-time communications on the EBot 350 enables AMR monitoring for alerts and diagnostics, as well as remote software updates and customizable dashboards. Connectivity can be established using direct machine-to-machine protocol communications as well as Wi-Fi and 4G LTE.

The EBot 350’s navigation can be achieved via QR codes or SLAM (simultaneous localization and mapping)-Natural navigation. SLAM algorithms allow users to build a map and localize AMRs in that map. ABB says users can manage hundreds of locations with the EBot 350’s multiorigin and multi-destination capabilities with its Smart QR code/RFID reader system.

Sami Atiya, president of ABB’s Robotics & Discrete Automation business, said, “With this acquisition (of ASTI), ABB will be the only company to offer a full automation portfolio of AMRs, robots, and machine automation solutions, from production to logistics to point of consumption.”

See the Ebot 350 in action at Modex 2022.

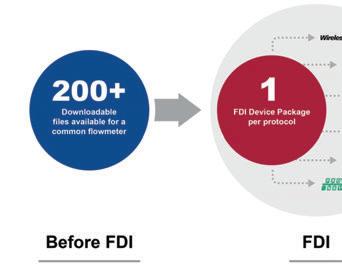

By David Miller Senior Technical Writer

As more intelligent sensors, smart instruments, and other connected devices make their way into the field, collecting and synthesizing the large amount of data they produce can become a challenge. Although these devices have the onboard capacity to extract a broad array of data, making it actionable can be complex. And with manufacturers of all sizes using devices and software from various vendors, end users are often forced to navigate an unwieldly patchwork environment wherein some data types are supported by their systems and others are not.

To solve this problem, industry organizations including the FieldComm Group, FDT Group, Profibus and Profinet International, and the OPC Foundation have jointly developed the Field Device Integration (FDI) standard with support from several major technology vendors, such as ABB, Emerson Process Management, Endress+Hauser, Honeywell, Schneider, Siemens, and Yokogawa.

Recently, Emerson reported that its AMS Device Manager, which provides real-time online access to intelligent instruments, became the first software of its kind to be fully registered under the new FDI standard.

By using FDI technology, the newest release of AMS Device Manager allows end users to forego the use of Electronic Device Description Language (EDDL) and Field Device Tool/Device Type Manager (FDT/DTM), which are currently the most common technologies for configuring and installing devices. This will simplify the process of setting up new field devices, allowing companies to save time and effort, Emerson said.

The ability to use the FDI standard requires two criteria to be met. First, the host systems or software packages receiving data from field devices must support FDI. Secondly, the field devices themselves must have onboard support for FDI packages.

To meet the first criteria, software and host systems must have: • The EDD Engine, which is a multiprotocol

EDDL (electronic device description language) interpreter; • The UI Engine, which provides rendering and hosting services for instrumentation user interfaces; and • A PA-DIM server, which enables access to a standardized set of device information.

The FieldComm Group supplies these components along with training workshops to automation suppliers to accelerate the development of FDIcompatible software and host systems.

According to Emerson, AMS Device Manager’s compatibility with the FDI standard is a further step in the company’s ongoing efforts to reduce the time and effort spent installing and configuring the field devices plants rely on to achieve their digital transformation goals.

“FDI integration technology takes the best features of EDDL and FDT/DTM and combines them into a single common standard, making it far easier to select, install, configure, and support new devices,” said Erik Lindhjem, vice president of Emerson’s Reliability Solutions business.

Why FDT 3.0 is a secure data exchange standard for IIoT applications.

Honeywell Expands Its Forge Software Capabilities

By David Greenfield

Editor-in-Chief/Director of Content

The trend toward cloud-based industrial software-as-a-service (SaaS) continues with Honeywell’s enhancements of its Honeywell Forge software, including the release of the Honeywell Forge Connected Warehouse.

David Trice, chief product officer at Honeywell Connected Enterprise, says Honeywell started focusing on true SaaS, not containerized legacy solutions, in 2018. He explains Honeywell’s shift toward SaaS as a response to every manufacturing, processing, and warehouse facility being built “as a snowflake” to address specific needs and demands. The unique requirements of these facilities create complexity for running operations at the executive level and with the operations technology (OT) systems used to run the plant—which are largely still deployed as on-premises implementations. Honeywell Forge virtualizes OT systems in the cloud to lower the cost of ownership and increase speed of operations [through a focus] on personas and industry use cases. There’s a huge need to solve specific operations issues today, and that’s what we’re focusing on first.”

According to Honeywell, its newly launched Forge Connected Warehouse software “provides organizations with two modules that provide realtime visibility across their warehouse site operations and advanced analytics to reduce unplanned downtime, address recurring challenges, and automate legacy processes. The Site Operations module features a dashboard that indicates how sites are performing against plan and helps managers identify repetitive bottlenecks and proactively address issues that may impact performance. The interface, which is optimized for tablets, enables enterprise benchmarking, monitors areas such as picking and shipping, and makes recommendations to achieve daily targets. Users can use the Honeywell Forge Connect edge solution to connect devices and integrate with standard warehouse systems.”

“We’re attacking the on-premises systems approach,” says Trice, “by building everything on an extensible model. Forge Connect talks to assets to make setpoint adjustments and prepare the data [from those assets] for delivery to the Honeywell Forge cloud.” He stresses the importance of normalizing asset data at the edge before delivery to the cloud as a key aspect of Honeywell’s Forge Connect technology.

Asset data is collected by Forge Connect via OPC UA, MQTT, APIs (application programming interfaces), and Modbus connections with plant floor devices, as well as IT interfaces to ERP systems.

In a preview of the Honeywell Forge Connected Warehouse at the Honeywell Connected Enterprise headquarters in Atlanta, Honeywell’s Asset Performance Management (APM) technology was also highlighted. The APM for Warehouse module enables maintenance teams to collaborate on equipment issues that impact performance with remediation recommendations. Operations managers and maintenance managers can use rules-based analytics and asset modeling to identify and analyze trends.

APM’s Operations Manager dashboards can be configured to highlight metrics such as order quote KPIs (key performance indicators), percent of tasks completed, locations of issues in picking and shipping, and what needs to be done to address those issues to achieve specific goals.

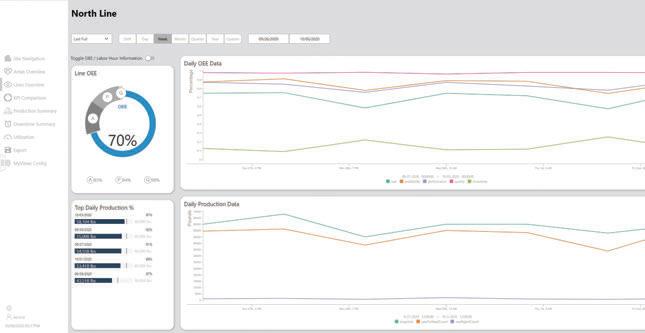

The Maintenance Manager dashboard in the APM for Warehouse module showcased in the preview focused on OEE (overall equipment effectiveness) and broke this metric out into its constituent parts—availability, performance, and quality. The dashboard also highlighted an asset summary status and how these factors can be sorted into a risk matrix by fault severity and asset criticality. This dashboard can also be configured to aggregate frequent faults and highlight key KPIs.

Trice says the Honeywell Force Connected Warehouse software can save 20-30% of an operations manager time simply by not requiring them to collect data for uploading into spreadsheets—a still-common practice in warehouse operations today. “Plus everyone is seeing the same information,” he adds.

Other technology enhancements highlighted by Honeywell include: • UniSim Design, which now provides a common simulation platform for upstream oil and gas, downstream processing, and sustainability. It contains new features for modeling Green H2,

CO2 capture, transportation and storage. • Honeywell Forge Inspection Rounds offers new features for industrial customers that allow the capture of images and videos during task execution and the creation of reusable checklists to drive standardization across an organization. Other additions include GPSenabled monitoring of worker proximity, enhanced capabilities for gaining insights from historical data trends, and improved asset identification through NFC tagging. • New Cyber Care services supplement Honeywell’s Process Control Network (PCN) Hardening Service. After completion of the initial

PCN hardening services to help industrial companies reduce their OT attack vectors,

Cyber Care provides an option to purchase biannual onsite Cyber Care visits by Honeywell consultants for maintaining previously implemented networking hardening benefits and identifying additional PCN hardening settings for enhanced protection.

Synthetic Data and Artificial Intelligence Combine to Improve Machine Vision

By David Miller Senior Technical Writer

With its ability to help automate quality control, guide flexible pick-andplace systems, and simplify inventory tracking procedures, machine vision is of growing importance to industrial automation technology. For some time now, artificial Intelligence (AI) has played a significant role in helping manufacturers make use of machine vision and these advances show no sign of slowing down in the near term. One example of this continuing advance of AI and machine vision is Siemens Digital Industries Software's SynthAI service, which uses AI and machine learning to train machine vision systems more effectively.

While the images captured by a machine vision system cannot be analyzed without some type software algorithm, most machine vision software uses fixed-rules determined by a human programmer. In these cases, data is extracted from images in the form of various criteria such as measurement or object type and then compared against preestablished target values to make a decision. This requires many images of an object to be taken.

The application of synthetic data for machine vision training can dramatically speed up the training process. However, using synthetic data for machine vision applications requires expertise in synthetic image generation, which is complex, labor intensive, and costly. To broaden the use of synthetic data beyond the realm of experts, SynthAI allows 3D CAD (computer-aided design) data to be used for machine vision system training instead. By ingesting the CAD data for a given item, SynthAI can generate thousands of randomized synthetic images and annotate them within minutes without specialized expertise.

SynthAI’s capabilities enable it to train a machine learning model from CAD data that can then be used to detect products in real life. Once the training is complete, the model can be downloaded, tested, and deployed in machine vision systems offline. Industrial applications for Siemens SynthAI include quality inspections, flexible robotic assembly, robotic picking and sorting and kitting.

“We were looking for a quick and easy solution that would enable us to detect wire terminals in a robotic electric cabinet assembly station. With SynthAI our control engineers were able to achieve great results within just a few hours,” said Omer Einav, CEO at Polygon Technologies, a supplier of robotics technologies. “The tedious task of annotating a large set of training images to train the model was shortened significantly. The results show great promise for many additional use cases we plan to handle with SynthAI."

Read more about smart sensors for machine vision.

Time-Sensitive Networking Plugfest Focuses on Interoperability

By David Miller Senior Technical Writer

Time-Sensitive Networking (TSN) is a deterministic Ethernet communication method developed as part of the IEC/ IEEE 60802 standard that enables the prioritization of certain data types over others with the goal of enabling the rapid transfer of control system data in applications that cannot tolerate even a small amount of latency, such as high-speed motion control.

Amid all the advances made with TSN over the past several years, interoperability has emerged as a challenge for some TSN implementations. To address this, Avnu Alliance, an industry forum focused on pushing deterministic capabilities

into open, standards-based networking, recently hosted an international “plugfest” in Boston. The event allowed Avnu members to come together and test their respective platforms and products.

The plugfest gave participants a chance to test new TSN developments, such as the recent revision to 802.1AS, which governs timing and synchronization for TSN applications. According to Avnu Alliance, the results of the event will inform future test plans.

“Plugfests are an invaluable opportunity to validate TSN features on our silicon and how our lowlevel software interoperates with others. [Doing this testing] remote is not a practical option when nanoseconds matter,” says Pekka Varis, senior member technical staff, Texas Instruments.

According to Avnu Alliance, “The unique mix of devices and testing equipment [at the plugfest] enabled insights to be gathered in real world scenarios, such as various implementations of 802.1AS on a single network. The range of perspectives and experience provided for constructive and lively discussions between suppliers and users of TSN components to take place on real world usages and needs.”

Plugfest follows from the formation of the Silicon Validation Task Group by Avnu in March 2020. The group has been working to create alignment on TSN interoperability by developing base test plans, the first of which are now available to members. In October 2021, Avnu also announced its Advanced Certificate Program to provide faster and less expensive testing and certification of endpoint devices.

Companies with end devices that use TSN were also present at the plugfest, including Adamson Systems Engineering, L-Acoustics, Meyer Sound, and Keysight. While many participants represented audio-video companies, which is not surprising considering that the TSN standard emerged from this industry, their use of TSN will have repercussions across other industries where TSN is used.

The Avnu Alliance plans to host more plugfests this year at various locations around the world.

Learn more about TSN.

Read about Belden/Hirschmann’s “TimeSensitive Networking for Dummies.”

| | EK11-20USA

Compact drive technology in a robust metal housing

The ultra-compact ELM72xx EtherCAT Terminals: full-fledged servo drives in an I/O terminal with robust metal housing increased output current of up to 16 A at 48 V DC metal housing for optimum heat dissipation at high outputs directly integrated in the standard EtherCAT I/O system increased performance and added functionality optimal shielding in case of electrical interference convenient connector front end and One Cable Technology (OCT) selectable safety range: STO or comprehensive Safe Motion function package

Scan and begin your migration to compact drive technology

Beckhoff Showcases Compact Motion Control for Mobile Applications

By David Greenfield

Editor-in-Chief/Director of Content

The rise in direct-to-consumer delivery requires increasingly flexible manufacturing and packaging operations. Supporting this shift are low-voltage compact motion control technologies that can be used in autonomous mobile robots and automated guided vehicles used on the factory floor as well as automated storage and retrieval system in warehouses.

At Modex 2022, Beckhoff displayed several compact motion control technologies suited for such applications. Key aspects of the products highlighted by Beckhoff are their safety features. Doug Schuchart, global intralogistics industry manager at Beckhoff, noted that the compact motion control products highlighted at the event can meet up to a Category 4 PLe safety.

Schuchart also detailed Beckhoff’s EP7402 EtherCAT Box compact controller. In the demo at Modex 2022, Beckhoff used this controller to control motor-driven rollers from different manufacturers on a conveyor system. He underscored the importance of the real-time EtherCAT communications of this controller, noting compliance with NFPA 79, which provides safeguards for industrial machinery to protect operators, equipment, and facilities from fire and electrical hazards.

The EP7402 controller is a two-channel motor output stage for brushless DC motors used in motor-driven rollers. Beckhoff says the controller offers “optimal conveyor control through zeropressure accumulation logic in its firmware, programming in the TwinCAT 3 engineering environment, and high-performance EtherCAT industrial Ethernet communication.”

Designed with conveying tasks in intralogistics, packaging, food and beverage, and assembly in mind, the EP7402 is IP67 rated, does not require a protective enclosure, and features Beckhoff’s One Cable Automation, which allows for one cable to deliver communications and power via two B23 ENP hybrid connectors. The hybrid B23 cables can carry 28A to distribute power to up to 16 motordriven rollers. Built-in motor protection features of the EP7402 include voltage monitoring, thermal overload protection, and overcurrent protection. Watch this video explaining Beckho Automation’s hypervisor technology for virtual machine control applications.

Listen to this podcast with Beckho Automation about how OEMs can improve their machines’ material handling capabilities.

By Sean Riley

Senior Director, Media and Industry Communications, PMMI

Emerson will continue their more than a decade long sponsorship of The Amazing Packaging Race at PACK EXPO International (Oct. 23-26; McCormick Place, Chicago), according to show producer, PMMI, The Association for Packaging and Processing Technologies. “Education and workforce development is a main priority for PMMI and we are always looking for more ways to engage students to get them excited about our industry,” says Laura Thompson, vice president, trade shows, PMMI. “The Amazing Packaging Race is one of the most popular student programs during the show and we are excited to bring it back to Chicago this year.” The Amazing Packaging Race brings together students and exhibitors with student teams completing tasks assigned by exhibitors throughout all four halls of the show floor. The race will take place on the last day of the show, Oct. 26, and will conclude with the awarding of prizes to the top three teams in the competition at the Emerson Booth (N-4736). Each student on the winning team will receive $1,000. Second and third place team members will receive $500 and $250 each, respectively.

“Emerson’s dedicated support over the years enables us to offer this popular program at our shows year after year and invest in the industry in a big way through the contributions made to the PMMI Foundation,” says Jim Pittas, president and CEO, PMMI. “We are very proud of this partnership and the difference that we are able to make together in the future of this industry.”

Exhibitors who wish to participate in the race can sign up here. The cost to participate is $600 and all proceeds go to the PMMI Foundation. For more information, contact Kate Fiorianti, senior manager, workforce development, PMMI at 571287-4406 or kfiorianti@pmmi.org.

The PMMI Foundation provides financial support for packaging and processing education throughout the U.S and Canada. Since its inception in 1998, the PMMI Foundation has given more than $2.3 million to strengthen the workforce within the packaging and processing industry.

Registration is also officially open for PACK EXPO International’s return to McCormick Place, Oct. 23-26, 2022, in Chicago. Registration for the show is $30 until Sept. 30, after which it increases to $130. For more information and to register, visit packexpointernational.com.

Though they don’t often receive the attention given to other automation technologies, cables and connectors are critical to the power and data transmission needs of industry’s digital transformation.

By Lauren Gibbons Paul, contributing writer

A Single Pair Ethernet shielded copper cable. Source: Panduit

Considering their importance to the industrial world—delivering electrical power, transferring data, and providing reliable connectivity among end points—cables and connectors don’t often receive the attention they’re due. As much attention is spent on Industry 4.0, digital twins, and other advanced automation technologies, it’s important to recognize that cables and connectors are the transactional backbone of digital transformation. Nothing could be done without them—and that includes the wireless activities that depend on wired infrastructures to seamlessly transfer data to gateways for wireless transmission.

This reality is why the selection of cables and connectors should be treated as critically as the more advanced technologies that often capture more of our attention.

Underscoring the importance of cables and connectors to the digital transformation of industry is the health of this market. Allied Market Research projects the compound annual growth of the global cable and connector market will hit 8.3% between 2020 to 2027.

Paying more attention to cabling and connector choices is possibly more important now than ever, as many companies are in the position of needing to upgrade cabling, says Mike Berg, senior business development manager at Panduit. “Many of the plant fl oors put in Cat5 cabling for Ethernet. But that was a long time ago. The quality of the connection is not up to current standards,” he says. Now, the need to connect controls networks to the enterprise is driving the need for high-performance cabling.

Physical considerations

“When you’ve got 10 or 20 Ethernet-connected devices within a control panel, you need a comprehensive design and blueprint around Ethernet cabling” that accounts for security and safety, says Berg.

Control panel builders are very diligent about complying with safety requirements, but as connections have grown, “they have all struggled a little bit on how to handle this increase in communications cabling going into the control panel. So, there has defi nitely been a learning curve,” he adds.

End users and panel builders also need to look at long-term reliability and the ability to “future proof” their cable and connector selections to avoid having to upgrade just a year or two later.

Another trend causing ripple e ects in cabling and connector decisions is that mechanical packaging is getting smaller. This creates specifi c issues for OEMs, says Daniel Koch, senior product manager for the signal division of Molex. “This means the area we have to work with is getting smaller. We can’t just grab things and plug them together as much anymore. The need for smaller components is a big driver in our industry,” says Koch.

Most end users need design assistance and advice on materials selection from a trusted partner such as a systems integrator before they buy. “The value of that collaboration is not having that ‘oh, boy’ moment when you realize something doesn’t work,” says Koch. “With prices soaring on copper and other cabling materials, a trusted advisor can also help you keep costs down, especially when it comes to distinguishing between a choice that saves money in the near term but might lead to prematurely having to replace the cable or connector.”

Selection parameters

The number of factors that fi gure into cable and connector selections are numerous. Here are four key issues to help ensure you select the right cables and connectors for your applications: 1. Examine your component media. Start with the basics, such as: What devices do you need to connect? Berg recommends asking: Which switches will be used? How many devices will be connected? Are IoT (Internet of Things) devices in play? What about cameras? What network protocols, such as EtherNet/IP, Profi net or CC-Link IE are used? Also, make sure your cabling and connector choices match up with existing terminations. Other issues to consider include use of cop-

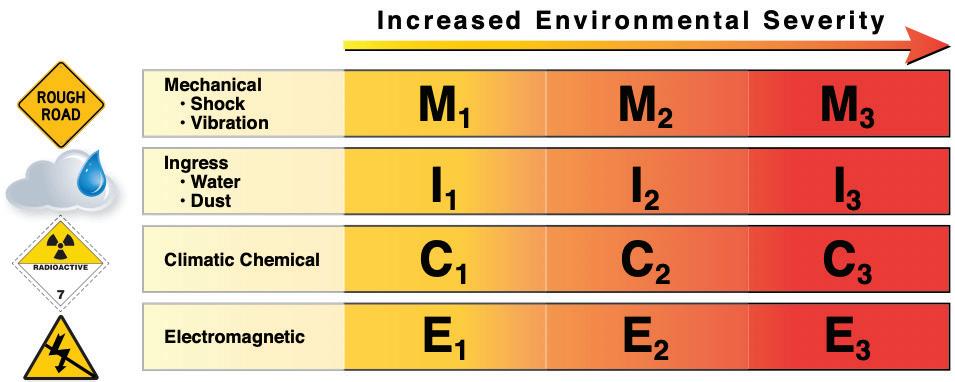

Environmental classifi cations and ratings based on mechanical, ingress, climatic/chemical, and electro magnetic (MICE) attributes provide a method of categorizing the environmental classes required for each of the industrial areas and are rated as 1 = low, 2 = medium, and 3 = high. Source: Panduit.

HOW SINGLE-PAIR ETHERNET IMPACTS CABLING OPTIONS

As most Ethernet-connected devices on plant fl oors incorporate Ethernet managed switches and use multi-layer segmented networks, Ethernet programmable controllers and smart I/O distribution devices are now common elements of control systems. But when you look at the edge of the network, “the majority of connections are to non-processor devices, such as analog devices, simple I/O, and sensors,” Berg says. “The Single Pair Ethernet (SPE) format has been designed for both IT and OT standards to provide communication, power, and extended distance cable runs for these type devices.”

Classic Ethernet works with a four-pair Cat 5 cable within a frequency range of up 100 MHz. The individual pairs send/receive interchangeably, and up to 1 Gbit can be transmitted. “In the case of SPE, only one pair is available. To transmit 1 Gbit, chip sets with a range of up to 600 MHz are used. Some frequencies in the wide spectrum receive, while other frequencies send,” says Horst Messner, product manager at Helukabel. “This is how SPE works.” SPE enables consistent data transmission up to the fi eld level, meaning that only one pair is required to transmit the signals instead of the previous two or four pairs. Messner says, in this way, SPE matches the industrial requirement profi le exactly, and o ers the following advantages (compared to the classical industrial Ethernet): • Thinner cables; • Lower cost of assembly; • Less space requirements, lower weight; • Smaller bending radii and smaller drag chains in the case of continuously moving applications; • Lower caloric load, less smoke development; and • Less materials like copper or plastic protects resources.

SPE is already being used in the process industries because it allows them to bring Ethernet to intrinsically safe areas and simplify the network and power design, says Mike Vermeer, engineering strategy manager, at Panduit. One signifi cant advantage to SPE seen by process industry users is “the ability for a single device to simultaneously support multiple protocols over SPE, for example OPCUA, Profi net, and Foundation Fieldbus,” he says.

per and two-pair or four-pair Ethernet cabling (see sidebar on Single Pair Ethernet). 2. Location. When you're shopping for cables, think about the spaces they’re going in. Are you routing from an office environment?

Are you going through any riser spaces between floors? You don't want to put cabling in and then find out later you ran through a plenum or a riser space requiring it to be ripped out. Fire safety factors are also key here. If the cabling and connectors will be in an IT cabinet, it is sufficient to use the commercial-grade Ethernet cable that is commonly available. But as you start to get closer and closer to the machine level, you’ll need to consider things like the location of the power source, what separations you might need, and whether you’ll use a cable tray. Berg suggests ensuring you select cabling with the proper jacketing or insulation to fit the application. Then look at the grounding and bonding requirements for the network system. 3. Termination performance level. This factor is key to noise susceptibility, says Berg.

People tend to overlook the fact that a lot of the copper Ethernet cabling on industrial plant floors is susceptible to electromagnetic interference noise (EMI). The latest cabling—Cat6, Cat6A and Cat8, for example—is much less susceptible to EMI.

Going with the most up-to-date version will protect your investment. “That gives you the best possible lifespan on that cabling install,” says Berg. 4. Harsh conditions. Be sure to consider factors such as shock and vibration, resistance to dust, temperature thresholds, washdown areas, exposure to acids or oil mixtures, and electromagnetic noise. A commonly recommended approach to cable and connector selection is called a MICE analysis, which addresses the mechanical, ingress, climate/ chemical and EMI factors that can impact cabling and connector choices. We rate our cabling for use in di erent MICE environments, explains Berg. The MICE analysis helps users determine if a di erent cable or connector can better survive in their operating environment. It can also be helpful in evaluating the e ects on maintenance scheduling.

Harsh conditions can also dictate specific requirements for cables and connectors. For example, an RJ45 connection is susceptible to vibration, but an M12 connector prevents vibration from a ecting that Ethernet connection. Likewise, when connecting a high-flex device such as a robotic arm, you will need a high-flex cable. The most rugged cable type is rated as being able to handle more than 10 million cycles. “If you have some type of a moving device on a manufacturing floor that is making a new widget every 10 seconds, you can easily exceed 15,000 cycles very quickly. So, going with a cable that has a rating over 10 million cycles makes a lot of sense in that application,” says Berg.

Panduit’s SPE Shielded Copper Cable has 18/7 AWG stranded tinned copper conductors with foamed polyethylene insulation. The conductors are twisted in a pair and include two fillers. The pair is surrounded by an aluminum/ polyester foil shield, a tinned copper braid shield, and includes a 24/7 AWG stranded tinned copper ground wire. Source: Panduit

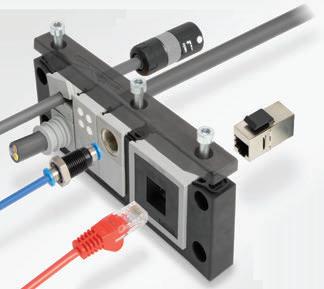

Cable Entry and Connectivity in One

With the IMAS-CONNECT™ adapter grommets create your individual interface for keystone modules, connectors and hose ttings. Con gure online now at www.icotek.com

IP66

www.icotek.com

OEE as a Tool for Continuous Improvement

Four real-world application stories show why OEE remains a bedrock manufacturing metric for real-time data collection to enhance companies’ ability to take corrective actions continuously.

By Beth Stackpole, contributing writer

Fueledby the proliferation of industrial data and push for data-driven business practices, OEE (overall equipment e ectiveness) remains a core manufacturing metric given its ability to boil complex production problems down to relatively simple terms and drive continuous improvement.

OEE, which can be used to evaluate a single machine, an entire line, or a complete factory, is a relatively simple equation based on three factors: Equipment availability—specifi cally run-time divided by planned production time for that specifi c asset, performance—the ideal cycle time multiplied by total product/part count divided by run time, and quality—established by the good count divided by total count. The goal of OEE is to improve e ciency, reduce downtime and operating expenses, and minimize waste.

Calculating OEE as an ongoing best practice gives manufacturers a reality check on production planning and business expectations based on what equipment is actually doing as opposed to presumptions about what it’s supposed to be doing. As a result, OEE remains a top-three metric for manufacturers, according to LNS Research’s 2020 Analytics That Matter survey conducted in partnership with MESA International. More than half (54%) of analytics leaders said they are tracking OEE, which puts it behind only net profi t margin tracking (63%) and on-time delivery tracking (68%), the survey found.

“OEE is an easy metric to start with as it doesn’t require downtime, it’s not mission critical, and it isn’t going to break your line,” says Chris McLaughlin, director of sales and marketing for Vertech, a systems integrator specializing in industrial automation. “It’s also easy to prove ROI (return on investment) as it creates a baseline for continuous improvement, highlighting how much production has improved and how much e ciency you’ve gained.”

Measuring OEE was once a manual exercise, but more recently OEE functionality has found its way into MES software as well as control systems, SCADA platforms, and edge computing devices. Advances in plant fl oor connectivity and increased availability of real-time data through Industrial Internet of Things (IIoT) platforms is putting a fresh face on OEE by expanding access to real-time and enterprise system data that can deliver additional context and insights to improve OEE scores.

“Companies are trying to take it further upstream and downstream and integrate with other systems to take more into account,” says McLaughlin. “The more information you can get from ERP and other systems, the more you improve an abil-

OEE is used to monitor performance on a tissue converting line at Cascades Tissue Group. Source: Cascades Holdings US Inc.

Vertech helps customers like Hunter Industries create OEE metrics to monitor line performance. Source: Vertech

ity to do continuous improvement because you understand what is really behind why something is unavailable or performing poorly.”

Production trend assessments

Hunter Industries depends on a varied automation landscape to produce its irrigation and outdoor lighting equipment. With regular OEE monitoring of machines, starting with spreadsheets before moving to the Inductive Automation Ignition software platform in 2013, Hunter Industries can stay on top of machine performance and keep production goals on track.

“There are a variety of reasons a machine isn’t producing the amount we need it to,” says Scott Corbett, Hunter Industries senior manager of operations technology and training. “OEE is the best method to figure that out and maximize machine output.”

Hunter Industries mostly conducts OEE at a machine or line level to advance both long-term and real-time performance goals. The company fuels its OEE calculations with real-time data from PLCs using a mix of automated and manual methods. The results are regularly served up to employees via visual dashboards on the plant floor, enabling them to monitor issues and make essential adjustments.

“You don’t know if a machine running tooling is a half a second slower than it’s supposed to be running without a real-time monitoring system,” Corbett explains. “Real-time OEE performance is extremely beneficial in a high-volume molding operation to produce the right amount of parts.”

OEE also delivers valuable trending data for Hunter Industries to evaluate subtle losses and gains over time while providing measurable performance targets that can be harnessed to drive progress. “It helps to have something that can compile data for short or long periods of time so engineers can stay on top of putting out fires as well as making long-term progress on process improvement projects,” Corbett says.

Informing operations and executives

With 30 plants all using standardized industrial assets, Saint Gobain Sekurit is a strong proponent of OEE as a way to measure and compare performance across its global factory footprint as well as for capacity planning.

As part of its core KPI (key performance indicator) portfolio for the last 15 years, OEE is reported per shift and once daily drawing from Saint Gobain Sekurit’s MES system along with some manual data entry. Sebastien Thuillier, Saint Gobain Sekurit’s digital transformation manager, says the company recently advanced its OEE reporting using Litmus’ edge data platform to automate data collection and allow anyone from any location to check in on the performance of key manufacturing lines. In fact, OEE metrics are not only used by plant floor personnel at Saint Gobain Sekurit; it also informs managers in logistics, supply chain, and maintenance operations to help them focus on continuous improvement, whether that involves adjustments to spare parts inventory or addressing reliability issues.

Automating OEE ensures data is collected in a standard way across equipment and made available to any system, which takes the burden o plant floor operators and reduces the potential for miscommunication.

Of course, the ability to apply live monitoring to production operations doesn’t necessarily advance OEE reporting, but it does mean Saint Gobain Sekurit personnel are alerted to problems quicker, enabling them to respond faster and even anticipate issues in some cases. In the end, corrective action translates into a better OEE score.

“The system enables us to more quickly react to decrease downtime and address issues if a line stopped because there are no more raw materials or it’s missing an operator,” Thuillier explains.

Avoiding the blame game

For Glidewell Dental, producing tens of thousands of patient-specifi c restorative dental devices cost e ectively requires major automation and e ective communication. As part of an end-to-end automation initiative to enable cloud-connected manufacturing, put in motion through a collaboration with Amazon Web Services (AWS) and the University of California, Berkeley, Glidewell has made OEE a best practice to ensure high-quality production with the support of Beckho Automation’s industrial PCs and TwinCAT3 automation platform. Glidewell calculates OEE every 15 minutes at the machine level to extrapolate the data for the entire production line.

The micro-level OEE calculation helps evaluate how many parts are rejected against whether a machine is down because it produced too many parts or it’s running at too high a calibration. Calculating OEE at this level is particularly important to ensure the automated production workfl ow runs smoothly on two lines pumping out 2,000 units daily without sacrifi cing quality of output.

“Our process is highly statistical and the parts we mill are very fragile,” says Kunal Patil, manager of automation engineering for Glidewell. “Any bit of wear on the tools can generate inconsistencies on the part and any tiny bit of calibration change alters the performance of the machines.”

Prior to calculating OEE, there would be a lot of fi nger pointing and blame games in the event of a problem or if target numbers were missed because there was no benchmark to measure against and no insight into why a specifi c machine was down. “Now that we have OEE, we know exactly which machine or part is not producing,” Patil says. “It’s a high-level metric that tells people whether they’re losing their time or opportunity because of unavailability, performance, or quality.”

OEE’s simple terms also make it clear which group is responsible for addressing an issue. “If we lost an opportunity because of performance, that’s something the engineering group has to work on, if it’s due to availability, that’s a di erent group,” he explains. “It provides a common language where everyone understands what to fi x.”

Plant performance comparisons

At Cascades Canada, an organization with more than 70 paper and pulp plants, OEE has been a long-standing metric that everyone in the company takes seriously.

OEE calculations are regularly performed at the individual machine and line level, but the metric is also used at the plant level to drive continuous improvement and keep its multiple sites striving toward the same business goals. To ensure the application of this focus, Cascades Canada has cultivated a culture of OEE by establishing a Center of Excellence (CoE) and indoctrinating employees at every level in the importance of a strong OEE score and how the metric and relevant data can inform action to drive continuous improvement.

“All the KPIs are made available through the Microsoft Power BI platform to be accessible for everyone from the president of the company to the mill manager,” says Claude Bedard, project director/CoE Maintenance and Reliability. “If you have two consecutive days of bad OEE, you fully expect to get a call from the boss asking about what’s happening and what the action plan is to fi x it.”

Cascades manages OEE through mostly manual processes with individual operators using a homegrown system to capture data from a variety of legacy platforms and SAP ERP to calculate scores. More recently, its OEE e orts are being burnished by a project to holistically improve asset health across its 70 plants using Emerson condition monitoring technologies. While the detailed asset health data doesn’t directly change OEE calculations, it does provide a guide to target improvements.

“With its asset health information, Cascades can drill down and fi gure out what needs to be improved in order to have better OEE results,” says Alain Pellegrino, vice president of industrial reliability solutions for Laurentide Controls, an Emerson Impact Partner working as a system integrator on Cascades Canada’s asset health project.

Moving forward, standardization of terms and coding across the disparate mill sites will be a priority to squeeze more value out of OEE and use it as a tool to compare factory performance.

“We have to make sure when we’re comparing one paper mill with another and one has an OEE of 85 and the other an OEE of 84, that the 1% difference is real, not just because they’re doing OEE differently,” Bedard says. “We are working on governance—standard codes and ways of doing assessments to make sure data is compiled in the same way.”

The basic OEE calculation is performed by calculating three factors: availability, performance, and quality. Source: OEE.com

OEE Tools and Guidance

More information about OEE guidelines and benefi ts can be accessed via PMMI’s OpX Leadership Network at www.opxleadershipnetwork.org.

Sensors Help Increase Batch Capacity

Non-contact infrared sensors enabled global plastics and rubber processor Ilpea Industries Inc. to increase yields and reduce cycle times.

By Jeanne Schweder, contributing writer

Temperature is one of the most critical factors in managing plastics processing. In response, an entire industry has grown up around creating sensors and other devices to monitor and measure process temperatures. Yet even sophisticated thermal technologies sometimes need an upgrade, particularly when companies are trying the improve the productivity and quality of their processes.

That was the case for Ilpea Industries, founded in 1960 and long considered a global leader in the design and manufacture of plastic, magnetic, and rubber components. The company is headquartered in the town of Malgesso, in the Lombardy region of northern Italy, not far from Milan, the center of Italian industrial activity. Ilpea operates manufacturing facilities around the world near its customers’ facilities.

Examples of extruded under-windshield products produced by Ilpea Industries for the automotive industry. Source: Ilpea Industries

The Raytek Marathon MM infrared temperature sensor from Fluke Process Instruments.

Ilpea wanted to reduce batch cycle time and improve yields on a mixing process for plastic extrusions used to make gaskets, tubing, and other custom products. Prior to the extrusion process, polymers must be mixed in a hopper and heated to achieve specific material properties.

While thermocouples are frequently employed to measure temperature during this operation, the heated plastic tends to accumulate on the end of the device, where it acts as an insulator. This a ects measurement accuracy and delays determination of the process temperature setpoint. In addition, thermocouples can easily break due to the thick, viscous nature of the heated plastic material.

To address these issues, Ilpea Industries turned to Fluke Process Instruments, which installed a Raytek Marathon MM sensor on each blender at the plant. Unlike thermocouples, this non-contact sensor is una ected by product build-up and consequently provides a faster reading of temperature setpoint. The resulting improvement in measurement accuracy has helped the company optimize the performance of the extrusion process.

Rod Hackney, electrical engineering supervisor at Ilpea, says the faster, more accurate indication of the temperature setpoint enabled the company to save approximately 15 minutes of production time on every batch. This increased capacity for each blender by one batch per day. With six blenders in operation, each installed with the Raytek non-contact sensor, this means an extra six batches can be produced every day at the Ilpea plant.

The Raytek Marathon MM sensor has a wide process temperature measurement range (from 204-260oC/400-500oF) and can be used in both batch and continuous process applications. It features integrated through-the-lens video or laser sighting, along with fast and accurate focusing and a user-friendly interface.

Formed in 2015 after Fluke’s acquisitions of Raytek, Ircon and Datapaq, Fluke Process Instruments specializes in making products that measure temperatures in a variety of industrial applications. These products include noncontact infrared temperature measurement instruments and industrial process monitoring equipment such as thermal imagers, infrared line-scanners, and fixed infrared sensors; measurement and calibration tools, including thermal imaging cameras and software; and systems for analyzing and reporting on the e ectiveness of industrial heating processes.

“In developing products for the plastics industry, the goal of Fluke Process Instruments is to improve the productivity and e ciency of plastics processing by providing more accurate temperature data,” says Dr. Martin Budweg, senior product manager. “Our products also help the industry quickly detect potential problems to avoid scrap, waste, and energy loss, as well as control the temperature of fast-moving parts.”

Turn data into actionable insights

Increase availability, improve quality, and enhance energy management with easy to implement IIoT solutions from Emerson. From measuring critical parameters in your production process, to detecting leaks, to improving predictive maintenance, intelligent pneumatics – such as the AVENTICS™ AF2 series flow sensor – provide actionable insights that enhance decision-making and help optimize the performance of your manufacturing operations.