8 minute read

Diagnostics

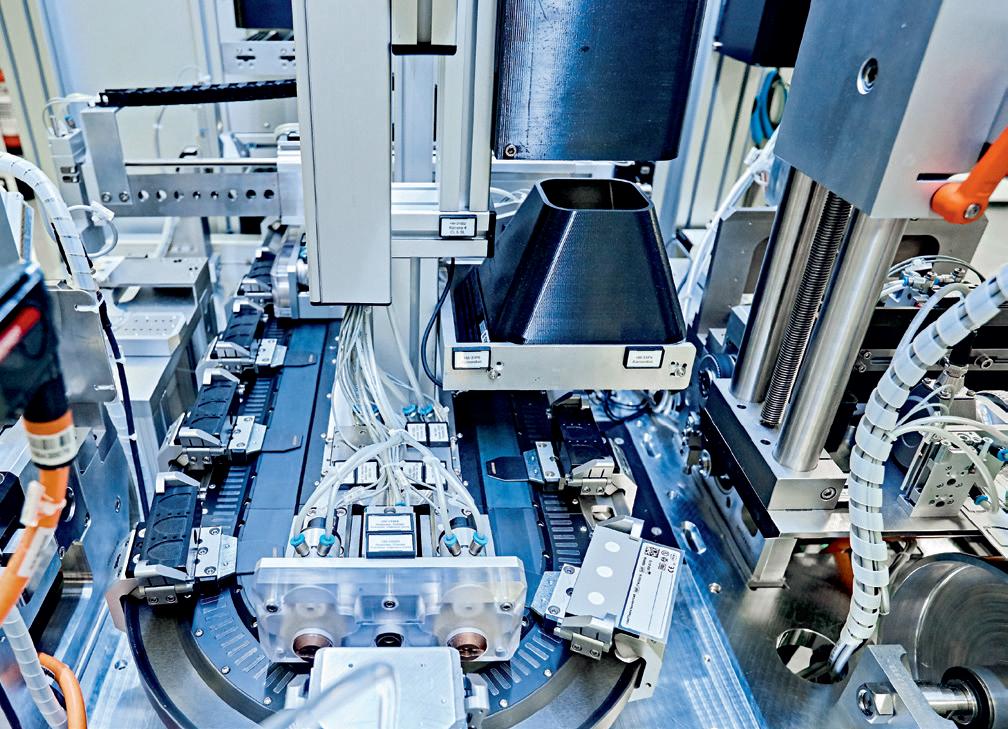

↖ The PSC layers are placed in the workpiece carrier of the XTS mover using vacuum grippers and dynamically transported to the production and testing stations. Credit: Beckhoff Automation.

Flexible Production Makes Roche’s HIV Test Innovation a Success

AARON HAND, EDITOR AT LARGE

TOP THREE TAKEAWAYS

1. Roche designed a plasma separation card 2. Production was cost-effective due to Beck3. The card features a carrier layer with a that greatly simplifies blood sampling and hoff Automation’s flexible, compact eXtended bonded nonwoven fabric and an upper layer for transport. Transport System. protection and labeling.

Close to 38 million people in the world were living with HIV— in environments with extreme heat and humidity. Roughly a credit the virus that causes AIDS—by the end of 2018, and some card in size, the stable and easy-to-use blood plasma sampling card 8 million of those people did not know they were living was achievable through Beckhoff’s eXtended Transport System with the virus, according to UNAIDS. Roche, a leader in personal(XTS), a flexible, compact and dynamic production technology that ized medicine, aims to help curb the public health threat through allows it to be made cost-effectively. improved examination and monitoring of HIV patients. The The Beckhoff XTS is central to the compact (3.5 x 3 m) machine company has developed a novel test device to make this possible. that makes the cobas PSC. The mechanical engineering specialIn turn, that breakthrough was made possible through advances in ists in Roche’s Manufacturing Service & Technology department production technologies from Beckhoff Automation. had just two years to get the project ready for production. As a

At its site in Mannheim, Germany, Roche developed a new plasma highly flexible transport system, the XTS helped the production unit separation card (PSC) that not only requires just a small amount of adapt to changing requirements during the development process. blood from a patient’s fingertip, but it also greatly simplifies sample Its software-based functionality, which is easy to modify, means that transport. For the first time, blood plasma samples no longer need process optimizations can be implemented quickly. to be cooled during transport to the laboratory. This is particularly The complex structure of the PSC makes this particularly importimportant given that more than two-thirds of the people infected ant. “A carrier layer is used for mechanical fixation,” describes Lukas with HIV live in sub-Saharan Africa. Nagel, specialist engineer at Roche’s Mannheim site. “Next, a thin

The cobas PSC significantly changes the way plasma samples are adhesive layer attaches to the plasma-separating membrane. Undertaken and prepared and facilitates reliable quantitative testing even neath is a non-woven material separated with a chemical stabilizer

to preserve the human plasma for up to six weeks during transport. A label is provided on which the patient information can be recorded by hand. Finally, there is a protective layer.”

A key aspect that sets the PSC apart from other testing solutions is that the human plasma only needs to dry a little for safe transport, and then can be liquefied again in the laboratory to be analyzed in the same way as blood plasma is normally analyzed, Nagel notes. The carrier layer—used mainly for sample transport—is just one part of the complex structure of the card, however. Two adhesive strips are applied to the carrier layer, followed by the nonwoven fabric for plasma absorption. The desired geometry is punched into a carrier tape and small adhesive dots are then applied to seal the plasma in. Finally, each card is laminated with an adhesive tape to form the underside and then it is bonded to the carrier layer. Those two layers form the first intermediate product.

The second intermediate product—the top side of the PSC—is formed in a similar way. The desired geometries are also punched and the card corners are rounded off for easier removal in a subsequent step. After several optical test steps, both intermediate products are bonded. The assembly and label placement then undergo a final check.

Exacting demands

The special fabric for the plasma-separating membrane is very sensitive and expensive, resulting in stringent demands in order to minimize waste, Nagel says. Forces must not exceed 7 N to avoid altering the structure of the nonwoven fabric—to guarantee this, a laser cuts out the membrane very gently. “When the unit starts up, the processing table from which the membrane is collected is

↑ The complex structure of Roche’s cobas plasma separation card consists of a carrier layer with a bonded nonwoven fabric and an upper layer for protection and labeling. Credit: Beckhoff Automation. measured. The system then checks the workpiece carriers on all 10 XTS movers,” Nagel explains. “In this way, all component tolerances are compensated. In order to exert as little process force as possible, the membrane is applied to the adhesive layer with vacuum grippers.”

One advantage of the XTS, Nagel notes, is that the component tolerances can be stored in software and then assigned to each mover individually for the entire production process. “In a conventional transport system, this would have to be implemented mechanically at each workstation and would therefore be much more complex,” he says. “In addition, XTS automatically provides traceability, which would otherwise have to be implemented using QR codes, for example.”

The XTS also provides high precision and software functionality in the motion axes of the workstations—such as cutting units, rotary tables, and transfer arms—implemented using EL7211 servo motor terminals and AX5000 servo drives. One example is the measuring probe function of the AX5000 servo drive, which can be used to store the actual position of the controller without time offset, depending on an event.

“This function comes into play when punching the geometry into the carrier tape and has been a great advantage during the development process,” Nagel says. “Initially, neither the exact card size nor the number of openings to be punched for subsequent application of the plasma were known. The lifting and punching sequences could be quite easily determined by software and adapted as required. For example, the card size could be optimized very efficiently, the number of application fields defined, and the card corners rounded off.”

Flexibility in a compact design

With limited space available in its production environment, Roche also relied on the XTS to provide high flexibility within a compact system. Roche is using an XTS with 10 movers and a 3 m track length, with individual workstations set up around it. “This results in a symmetrical machine layout in which the first preliminary product—the carrier layer—is processed on one side and the second preliminary layer—the upper layer—is processed and optically inspected on the other side,” Nagel explains. “The membrane is cut out in the center of the unit so that the complete card can be produced in a single XTS cycle. A system based on a rotary indexing table, which had been considered initially, would have been much larger.”

A key benefit of the XTS is its asynchronous motion between stations—providing the ability to synchronize fast workstations with slow process sequences. Rather than the speed of the line being dictated by the slowest process, the system flexibility lets workstations be better utilized by duplicating time-consuming work

processes. Beckhoff ’s conveyor automatically adjusts itself to the slowest process step and remembers the current processing status and missing input materials for each mover, Nagel adds.

In the case of the cobas PSC, the slowest processes are laser cutting of the nonwoven fabric and the associated pick-and-place,

↑ To produce the cobas PSC, Roche uses an XTS with 10 movers and a 3 m track length. Credit: Beckhoff Automation Nagel says. “With XTS, it is now very easy to prepare six cards at a time, transfer them to the laser cutting unit, and then glue them individually to the corresponding card tops,” he says. “Without this high fl exibility off ered by XTS, we would have had to process much larger membrane pieces or make provisions for multiple transfer stations.”

This capability also simplifi es early ejection of defective subcomponents. If a part is recognized as a reject, its mover disregards all other workstations, simply pushing the part through each step until it can be ejected from the process. Unlike a rotary indexing table, the XTS avoids further processing of reject parts.

Beckhoff ’s TwinCAT 3 XTS Extension software provides collision avoidance and synchronization functions to achieve this fl exibility. But the XTS also has the ability to limit the current or force available for each mover, increasing or decreasing the current as needed for each individual mover even if both movers are on the same motor. This gives Roche the ability to better control the interaction between tooling. “We use this function when the workpiece carriers for opening the holding clamps are mechanically fi xed,” Nagel explains. “Limiting the controller current simplifi es this mechanical referencing without losing the position control via the XTS encoder system that is advantageous elsewhere in the system.”

GROW with the

•Invest in the new 24-plate MV-11 Triple Knife Outsert System and fold up to 350 panels.

Fold drug information leaflets!

•Start with a system that folds outserts as small as 1 1 /8" x 1 1 /8" with up to 110 panels—or 150, 190, or even 294 panels.

The most accurate and dependable outsert systems by the company that invented outsert folding!

•Expand your services by adding a coding and serializing station. • Fold larger-size outserts or medication guides by specifying or adding the new GUK FA73 Folder to your outsert system and folding sheets up to 28 3 /4" wide.