2 minute read

Surface Grinding

Surface Grinding

Surface grinding process is generally the most common grinding techniques. The term surface grinding

Advertisement

assign that any process which accurately processes or grinds a surface. Surface grinding methods are

included horizontal spindle, vertical spindle, vertical spindle rotary grinding, vertical spindle single disk

and vertical head grinding. Parts or workpieces may require a grinding process if there is a need to

produce a flat surface with accurate thickness tolerance. Surface grinding also able to provide a part

with specified and very smooth surface roughness. Surface grinding can be used for cutting tool

sharpening. Surface grinding is used primarily for grinding and to obtain a desired flat surface finish or

smoothness, precise angularity, perpendicularity and flatness tolerances. Surface grinding machines and processes where first developed to manufacture and removed material from very hard metals.

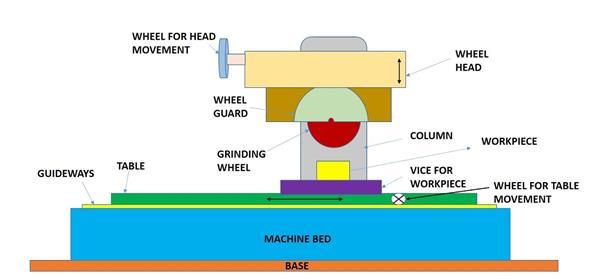

A surface grinding machine normally consists of a magnetic chuck, which resembles a table,

the grinding wheel that is attached to a rotating spindle, and a few handwheels for manually

operated. A straight wheel is mounted on the horizontal spindle of the grinder. Transverse grinding

occurs as the table reciprocates longitudinally and feeds laterally after each stroke. Surface grinding

machine and all parts includes is illustrates in a diagram of Figure 9. The grinding wheel used is

depends on the component being ground. Different grinding wheel compound for different type of

material to be ground.

Figure 9. Parts of surface grinding machine, 2020, Retrieved from https://www.youtube.com/watch?v=mGR7oszv9SE/

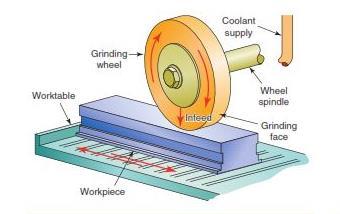

On the surface grinding machine, the workpiece is placed on a magnetic chuck attached to a worktable

of the grinder. The chuck is activated either by a switch or lever. When the chuck is activated, the part

will then hold firmly to the magnetic chuck. Non-magnetic workpieces are held by vices or fixtures.

The workpiece mounted on either a reciprocating or a rotary table is brought into contact with the

grinding wheel. The workpiece will be feed in horizontal direction, below the grinding wheel, with the

help of fed table. The abrasive grinding wheel rotates on a spindle and runs generally above the

workpiece. This produces the desired surface finish along with the ability to grind to extremely high tolerances, with typically + /-0 .0001” or + / – 0 .002 mm. Once the grinding wheel is touching the

workpiece surface, the worktable is set to move side to side and front to back until the entire surface

of the part is ground. The movement of worktable is repeat with the grinding wheel brought close to

touch the workpiece surface until the desired dimension is accomplished. The illustration of workpiece

attached on the worktable and how the grinding wheel is positioned above the workpiece is shown in

Figure 10 below. Figure 11 shows the actual setup of workpiece material on a surface grinding

machine with grinding wheel located above to workpiece to be ground. There are sparks generate just

after the grinding wheel rotated in high speed and touched surface of workpiece.

Figure 10.Position of workpiece on the worktable and grinding wheel is above the workpiece, 2015, Retrieved from https://cadcamengineering.net/types-of-grinding-machines/

Figure 11.Surface grinding operation produce sparks on the surface of workpiece, 2018, Retrieved from https://www.mech4study.com/2018/12/grinding-machining-process-complete-notes.html/