Iadmit to a real sense of shared joy in welcoming Arboriculture Australia to the fraternity which gathers around this magazine.

I’ve personally been very fortunate in the support and friendships which have formed with various association representatives across the country since I started on this title. The knowledge all the professional tree carers and arborists are happy to share with someone keen to learn is quite humbling.

And while all the associations are doing excellent work in stabilising the industry and putting in place the regulation it needs and deserves, there’s no denying Arboriculture Australia – ‘Arb Aus’ in everyday conversation – is the heavy hitter in arbor associations in our region.

To be invited to a board meeting to discuss how the alliance would progress was very gratifying indeed, and to see

the breadth of skills available from the various board members was an eye opener.

We can look forward to input from Arb Aus starting in the October/November 2024 issue.

Meanwhile, thinking of associations and recent eye openers, it’s difficult not to feel alarmed and concerned at Dave Crispin’s excellent piece from Arb West. Climate change is undeniable and a concern for everyone, but Dave’s thoughts and observations bring the matter to a real and relevant local focus.

As for an eye opener, Dave’s revelation of the 300m blast radius for a hazard zone around a lightning-struck tree had me sitting up straight in my plush office chair and taking notice, I can tell you!

Dave’s thoughts are just part of another great issue, of course. As always, Jim McArdle and the TCAA have their collective fingers on the pulse of the arbor world and are fighting

See the Arb West feature on page 34 for more information and how to assess and deal with lightning-struck trees. Image: Ken Griffiths/Stock.adobe.com

hard for muchneeded industry recognition, the QAA continues to lead the charge with excellent competition and training opportunities,

Brian Beecroft at the TTIA offers his usual insightful demystifying of some legal matters relating to those working with timber, Cass Humphreys has more thought-provoking ideas and suggestions, and there’s a wealth of great equipment and machinery featured.

Meanwhile, next time there’s a storm brewing, stay at least 300m away from tall trees.

In fact, it’d be a good time to stay inside and read this magazine.

Tom Foster Editor

The Australian Arbor Age bimonthly by Prime Creative Media Pty Ltd.

CEO

John Murphy

COO

Christine Clancy

Sales Director

Bradley Buchanan

Editor

Tom Foster tom.foster@primecreative.com.au

National Advertising Manager

Arron Reed arron.reed@primecreative.com.au

Phone: 0466 923 194

Client Success Manager

Arianna Lucini

arianna.lucini@primecreative.com.au

Design

Cat Zappia, Danielle Harris, Jacqueline Buckmaster

Subscriptions

P. +61 3 9690 8766 subscriptions@primecreative.com.au Website arborage.com.au

Copyright

The Australian Arbor Age magazine is owned by Prime Creative Media and published by John Murphy. All material in The Australian Arbor Age magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical, including information and retrieval systems) without written permission of the publisher. The editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions, or for any consequences arising from reliance on information published.

The opinions expressed in The Australian Arbor Age magazine are not necessarily the opinions of, or endorsed by, the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2024

Articles All articles submitted for publication become the property of the publisher. The editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Dr, Docklands VIC 3008

P: +61 3 9690 8766 enquiries@primecreative.com.au www.primecreative.com.au

Sydney Office

Cassian Humphreys

Cassian is an exMerristwoodian (NCH-arb 1991, bridged into the UK Diploma ’92), Qualified to the AQF L5 (AUS Dip) in ’09, upgraded in currency in 2017. He commenced his career after graduating in Horticulture (’85), transitioning into Arb (’89). Experienced in all aspects of arboriculture, having worked in Germany, Australia, Britain, PNG and Vanuatu, Cassian has been writing for AAA since 1999, with over 40 articles to his name. His core specialisation involves conservation arboriculture, education and tree-health-care.

Jim McArdle

B.Ed. Sc (Sydney), Dip. Arb. (Ryde), VTRA@QTRA qualifications. Director at McArdle Arboricultural Consultancy and TCAA President, Jim’s career spans across almost 40 years and focuses on consulting and reporting in tree risk protection and management plans, and tree impact assessments.

06. SIGNIFICANT TREES

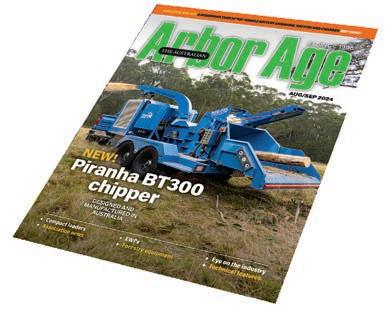

08. ON THE COVER

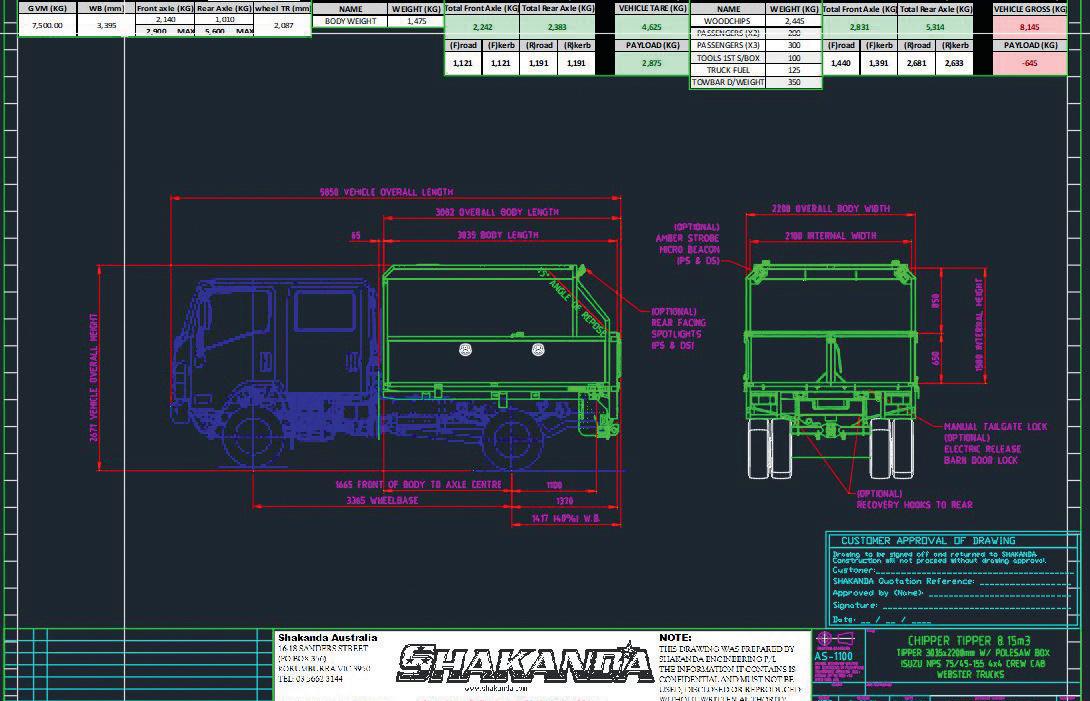

A new chipper has hit the Australian market! Piranha Chippers’ BT300 is ready to tackle the toughest timbers and conditions Australia can throw at it.

68. TECHNICAL FEATURE

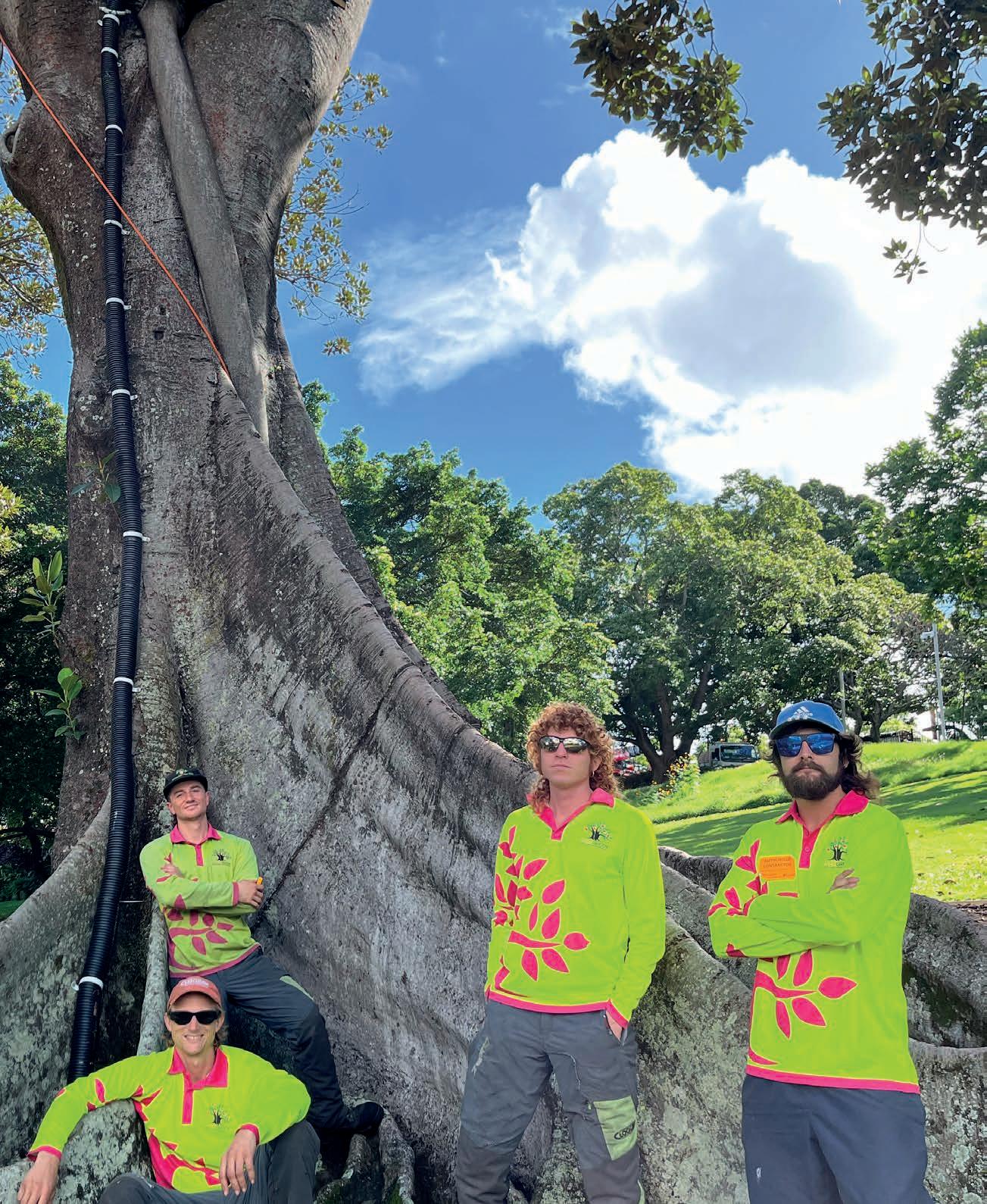

Cass Humphreys follows up on Ficus offering a unique opportunity for land care.

STUDY: Morbark Beever 1821

Dave Crispin

A professional consulting arborist at Treeswest Australia, certified to AQF level 5 (Diploma), international coach, speaker and presenter.

The Socotra Dragon tree – or Dragon’s Blood tree –(Dracaena cinnabari), is thought to be named for the blood-like colour of its red sap.

Endemic to the mountaintops of the Socotra Archipelago, a group of four remote islands located in the Indian Ocean south of the Arabian Peninsula, the Dragon’s Blood tree exudes a red sap which forms a resin prized as a medicine and as a red dye in ancient times.

Dragon’s Blood resin is still used as a varnish.

A variety of the Dragon’s Blood tree, Dracaena draco, is popular as a landscaping feature plant in the NSW south coast and Sydney regions.

The species has been successfully propagated in Australia from seed, but can take up to a century to grow to a large specimen. Such large examples will often command prices ranging from $5000 to $100,000.

The Dragon’s Blood tree is popular as a landscaping feature plant in parts of southern NSW. Image: Janos/Stock.adobe.com

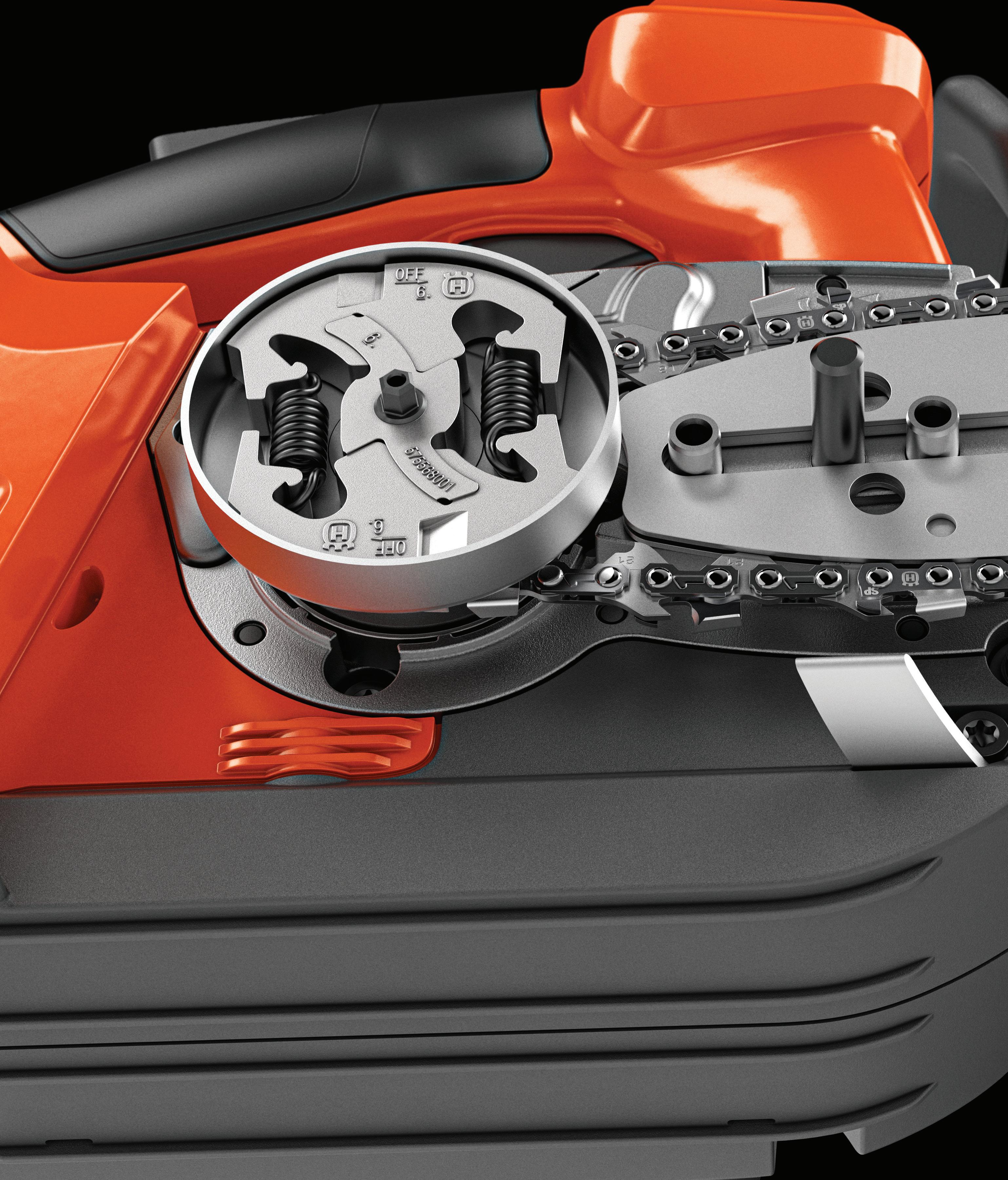

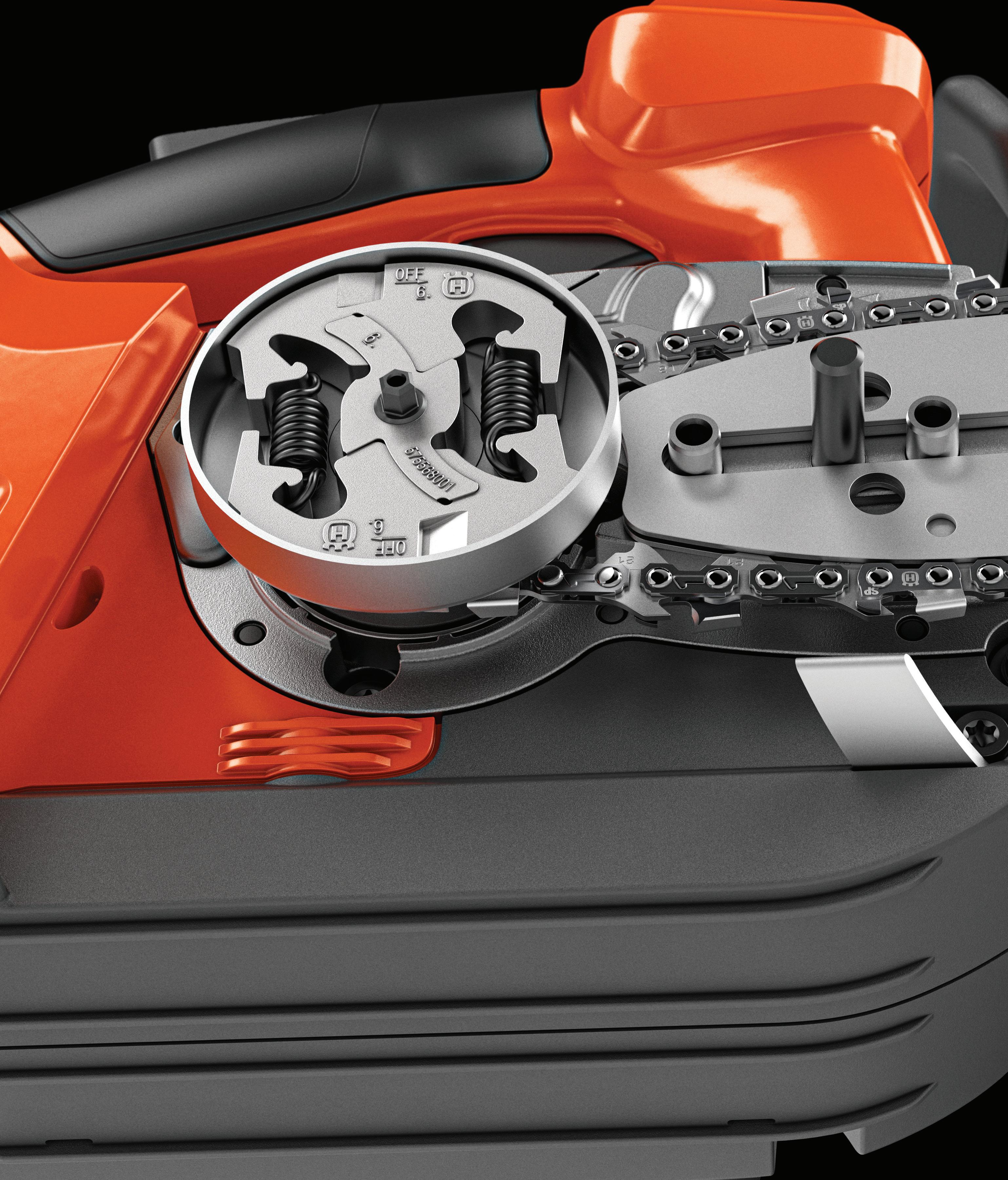

The Piranha Chippers’ BT300 is Australian designed and built, and all manufactured sheet-metal steel parts are individually primed and painted before assembly. Image: Piranha Woodchippers.

A new chipper has hit the Australian market. Piranha Chippers’ BT300 is Australian designed and built, and ready to tackle the toughest timbers and conditions the Wide Brown Land can throw at it.

The Piranha Chippers BT300 is powered by the 4HK Isuzu turbodiesel engine which produces a classleading 197hp. This power is sent to the 650mm diameter cutter drum which weighs 400kg with four staggered cutter knives and with a 390mmH X 500mmW (16" X 20") direct opening into the cutterdrum housing (no step downs).

The BT300 will outperform any other 12" chipper available in today’s market, and indeed has more horsepower than most other 18" chippers currently sold. Being a state-of-the-art, electronically controlled common-rail direct-injection diesel motor, the 4HK provides amazing fuel economy and is also very quiet when running. Dual horizontal infeed wheels offer incredible pulling power, and, with the assistance of the hydraulic

winch (which quickly folds up out of the way when loading), difficult trees and branches are quickly dealt with, using minimal physical effort from the operators. Other features that ensure ease-of-use include the hydraulic autoengage clutch, hydraulic dischargechute swivel and the hydraulic tailgateraise-and-lower functions.

The BT300 was designed and built for pro use: economics and ergonomics were both included in the design brief, and the result is a chipper ready to not only work hard, but with fast, easy access for essential servicing.

The tried and proven Isuzu 4HK diesel has 500-hour service intervals allowing longer between scheduled oil and filter

changes, and with Isuzu trucks being a popular choice in the arbor industry, shared filters makes for efficiency of stockholdings. Many essential engine service parts can be shared between the BT300 and the tow vehicle.

The front door of the BT300’s engine compartment gives access to all filters and service points, and the remote oil-drain hose makes draining the engine oil quick, easy, and mess-free. The access door at the top of the engine cover means replacing oil is just as swift and trouble-free an operation, and a work light mounted inside the engine bay makes checking and servicing an efficient, minimum-time operation.

The knives, an essential service item on any chipper, are accessed via the side walk-way ramp. With the chipper

housing hood open, the top part of the cutter drum is completely exposed. Servicing the knives is extremely easy and safe.

Piranha is quality

To ensure the highest quality workmanship, Piranha’s professional welder tradespeople are independently tested and NATA certified to AS/NZS 1554.1 welding standards. Australianmade structural-grade steel is used in

all components of Piranha’s chippers, and some of the leading features that set apart the BT300 include:

• Twin-axle trailer design gives double the braking power and flotation over soft surfaces compared to single-axle units

• Load-sharing ‘Soft-Glide’ leaf-spring suspension provides a superior ride compared to a single-axle trailer and doesn’t send violent feedback through the drawbar into the tow vehicle, and

• Heavy-duty all-terrain tyres on tough, steel rims.

Piranha’s ‘Posi-Arc’ infeed-arm pivot design means the large top infeed wheel aggressively climbs towards the incoming timber, up and on top of the trunks and brush, through the natural, positively inclined arc the unique feedarm design provides. This makes for a strong feeding action, allowing the Piranha to pull in difficult branches, twisty timber and whole trees with ease.

The unique staggered four-knife

with a 650mm diameter and integrated highvelocity fans give a superior chipping action and a very strong chip discharge.

With the housug hood open the top part of the cutter drum is completely exposed. Access is excellent. Image: Piranha Woodchippers

The hydraulic lift and crush also aides in feeding difficult timber sections into the chipping drum, and the 350mm high x 500mm wide in-feed opening directly into the chipper-drum housing makes for fast, positive feeding.

The unique staggered four-knife

chipper drum with a 650mm diameter –designed in-house by the Piranha team –with integrated high-velocity fans, gives a superior chipping action and a very strong chip discharge.

Replaceable blade-bolt blocks ensure the drum does not suffer integrity

Piranha

are 100 per cent Australian made and owned “ ”

damage if the blades encounter foreign material fed into the machine and they can be easily replaced if ever required.

All manufactured sheet-metal steel parts are individually primed and painted before assembly for superior, long-lasting corrosion protection, ensuring the Piranha will continue to look good and perform flawlessly for decades.

Piranha chippers come standard with many features that work together to reduce the operator’s fatigue and stress, including:

• Hydraulic auto clutch

• Hydraulic winch

• Hydraulic tailgate raise and lower

• Hydraulic 360° discharge chute (continuous swivel)

• Twin (top and bottom) horizontal infeed wheels

• Central grease-station hub

• Full-sized spare wheel, and

• Bulletproof one-touch capacitive switches for quick and easy operation of all functions.

They’re all standard on the Piranha Chippers BT300.

Piranha Chippers are 100 per cent Australian made and owned, and with a class-leading five-year/3000-hour warranty. They’re your first choice if you are serious about chipping wood.

Contact the Piranha team today. They’d love to show you just how good the BT300 is in real life. Call 1300 406 171, or log on to piranhachippers.com.au.

In a fleet of hardworking machines, the Morbark Beever 1821 turned out to be a crew’s favourite.

The Morbark Beever 1821 18" capacity wood chipper is a high-capacity, high-production chipper which includes more standard features than any other chipper in its class. Image: Monitor

Features include a live hydraulic system with ball valve, pump, motor, and valve bank, with an additional pre-plumbed valve section for installation of an aftermarket winch package. Image: Monitor

Based in Young, NSW, Tony Pullen went into business for himself in 2017. Seven years later his company, Hilltops Vegetation Services, has grown considerably.

“We kicked off with just myself and a trailer and a 12m cherry picker,” Tony recalled.

“Now we’ve got 10 employees and a heap of gear.”

Those employees and equipment aren’t only involved in tree work. Hilltops Vegetation Services offers a wide range of forestry and propertymaintenance expertise, including vegetation management, largearea mowing and work for councils, Transport NSW and residential and private work.

The equipment required to offer good service in those areas is varied, and Tony listed a few of the main machines in the company’s fleet.

“We have a brushcutter, a positrack and an excavator with a slasher head…” he searched through his mental files, “and an 1821 Morbark.”

The Morbark Beever 1821 18" capacity wood chipper is ideal for residential tree services, utility line clearing, vegetation management, maintenance contractors and municipalities. It’s a high-capacity, high-production chipper which includes more standard features than any other chipper in its class.

The Beever 1821 is also available tracked for right-of-way clearing, highway clean-ups and hard-toreach areas requiring a self-propelled unit for material access. The powerful TorqMax™ dual feed-wheel compression system generates more than 6600lb/ft (9822kg/m) of material pulling force, and many customerinspired innovations are featured, increasing efficiency and safety while reducing operating and maintenance costs. The unit is pre-plumbed and outfitted for the easy installation of most aftermarket components, and an ergonomic infeed design provides consistent feed control bar activation.

Like all Morbark equipment, the 1821 is a long-lasting, durable machine backed by a world-class parts-andservice support team.

Tony and the Hilltops Vegetation Services crew have more than one chipper in the fleet, but the Morbark 1821 has been the go-to machine for quite a while.

“We got it in 2019,” Tony explained.

“We haven’t had much downtime with it – just the odd little bits and pieces that go with a machine that works so hard. It’s been awesome.”

After the years of hard work Tony did think about upgrading the 1821, but he ran into a small difficulty.

“All my guys love it,” he chuckled. “I was actually going to trade it in earlier, but the boys on the crew talked me out of it. They told me to hold off because they really like it, so I’m holding back a bit.”

What is it they like so much, we wondered?

Tony supplied the answer: “I think it’s just the ease of use and how well it performs.”

Morbark Beever 1821 features

• Dual horizontal feed wheels with TorqMax top-feed wheelcompression system, hydraulic lift assist, variable-force constant hydraulic downpressure system with additional manually applied hydraulic down pressure at the valve handle and direct-drive bottomfeed wheel with torque-arm coupler

• Live hydraulic system, including: ball valve, pump, motor, and valve bank with additional pre-plumbed valve section for installation of an aftermarket winch package

• 3" (7.62cm) x 5" (12.7cm) tubularsteel telescoping drawbar with two 12" (30.48cm) extensions

• Morthane paint system – a chemically cured, electrostatically applied urethane coating with high-gloss finish, built-in UV protection, chip and chemical resistance and corrosion protection.

The 1821 will eventually have to be replaced, and Tony is considering his options. A big point in the favour of staying with Morbark is the service Hilltops Vegetation Services has enjoyed from Monitor.

“They’re a bit far away from where

we are, but we’ve got Monitor guys that work on the Morbark and we have no issues. Our contact, Stuart Samson, is great.”

After a little careful thought Tony summed up his position.

“I’m happy to go with Morbark again. I’d definitely buy one.”

Like all Morbark equipment, the 1821 is a longlasting, durable machine backed by a world-class parts-and-service support team. Image: Monitor

Morbark Beever 1821 specifications

weight (approximate):

Infeed opening: 56" (142.24cm) wide x 37" (93.98cm) high

Throat opening: 20.5" (52.07cm) wide x 18" (45.72cm) high Drum: 23.75" (60.3cm) wide x 30" (76.2cm) diameter Engine: Cummins diesel

LinCon now owns Australia’s largest fleet of close to 150 trucks, alongside a team of dedicated and talented staff and a growing footprint which has expanded across six Australian states.

LinCon is the Australian market leader in providing high-standard truck-mounted access-equipment hire, sales, repairs and servicing.

Established in 2001 in Brisbane, LinCon provides advanced truckmounted elevated work platforms and access hire equipment, and pioneered the introduction of global standards to the Australian market.

The company prides itself in its relentless pursuit of innovation, forging

partnerships with internationally renowned brands like Palfinger, Barin, and Bronto. These alliances allow bringing world-class technologies and superior access solutions to LinCon’s Australian customer base, setting new benchmarks in safety and efficiency.

LinCon also demonstrates its

commitment to excellence through every project, guaranteeing clients receive the most advanced and reliable hire equipment, establishing LinCon as a go-to provider of quality-driven access solutions, and marking the LinCon name as synonymous with trust and excellence in the industry.

Exceptional manoeuvrability, userfriendly controls, and the ability to precisely position the

LinCon Hire and Sales was founded by Director Colleen Lindores, and from the beginning LinCon had a mission –to supply the Australian safe-access market’s unmet need for practices and technologies of a global standard, which were yet to enter Australia’s safe-access industry.

With safety standards becoming more specialised, stringent, and regulated, LinCon took a deep dive into leading global brands able to meet and exceed Australia’s rising standards in for safe access, and it was the beginning of the enduring partnerships developed with global standard European suppliers, including Palfinger from Germany, Barin from Italy, and Bronto from Finland. It was the first step in what has become LinCon’s wide network of partnerships with world-standard international companies.

Today, LinCon’s Palfinger-trained expert technicians continue to seek new trends, technologies, and innovations to deliver on customers’ projects countrywide to the highest global standards.

LinCon’s truck-mounted Elevated Work Platforms (EWPs) are designed to excel in any project, large or small.

With working heights ranging from 13 metres to a remarkable 103 metres, LinCon’s truck-mounted EWPs provide unmatched access, even to the most challenging locations. Their exceptional

LinCon also demonstrates its commitment to excellence through every project “ ”

manoeuvrability, user-friendly controls, and ability to precisely position the basket make them ideal for any at-height task in arbor and other industries.

Our constant adherence to the mantra ‘If you’re going to do something, do it right’ has seen LinCon innovate and grow, now owning Australia’s largest fleet of close to 150 trucks, alongside a team of dedicated and talented staff and a growing footprint which has expanded across six Australian states.

From providing the highest quality service delivery across every area of its business to a reputation for excellence, LinCon’s choice to never take shortcuts to save time or money has seen the company grow to become a true market leader and trusted authority in the safeaccess industry.

To find out more about LinCon and see the machinery and services on offer, log on to lincon.com.au.

LinCon’s truck-mounted EWPs provide unmatched access, even to the most challenging locations.

The SD170 offers a working height of up to 17 metres (56 feet) and an outreach of 8.7 metres (28 feet), making it ideal for a variety of arbor-care tasks.

Images: Niftylift

In the cold months of August and September, the Australian arbor care industry faces unique challenges. Safety, efficiency, and sustainability are at the forefront of every arborist’s mind. As the industry gravitates away from traditional climbing methods, the demand for reliable, innovative, and environmentally friendly elevating work platforms has never been higher. Niftylift’s self-drive range, specifically the SD170 and SD210 models, is set to revolutionise the way arborists approach their work, providing unparalleled benefits that meet the evolving needs of the industry.

The Australian arbor-care industry is experiencing a significant shift, driven by stringent Workplace Health and Safety (WHS) regulations and the rising costs of using traditional climbing methods.

Insurance premiums for climbers are increasing, and the complexity of ensuring climber safety is becoming more burdensome. In this context, Niftylift’s self-drive range offers a practical and efficient alternative.

The SD170 and SD210 models are designed with safety and efficiency in mind. These self-drive platforms provide stable and secure access to high and hard-to-reach areas, significantly reducing the risks associated with manual climbing. The SD170 offers a working height of up to 17 metres (56 feet) and an outreach of 8.7 metres (28 feet), making it ideal for a variety of arbor-care tasks. The SD210 takes it a step further with a working height of up to 21 metres (69 feet) and an outreach of 12.8 metres (42 feet), allowing for even greater reach and versatility.

Both models are equipped with advanced safety features, including hydraulic outriggers with safety

SD170 Specifications:

Working height: 17.1m (56ft)

Platform height: 15.1m (49ft)

Working outreach: 8.7m (28ft 6in)

Safe working load: 200kg (440lbs)

Width: 1.6m (5ft 3in)

Length: 5.6m (18ft 4in)

Height: 2.2m (7ft 3in)

Weight: 2750kg (6060lbs)

Power options: Diesel only or BiEnergy (battery and diesel)

interlocks for quick and easy stabilisation on uneven terrain. The platforms’ robust design ensures stability even in challenging conditions, providing arborists with the confidence to perform their tasks efficiently and safely.

Sustainability is a core value within the arbor-care community, and Niftylift is committed to supporting this ethos. The SD170 and SD210 models are designed with environmental responsibility in mind.

The SD170 features a Bi-Energy power option, which combines battery and diesel power. This combination allows arborists to operate the platform with zero emissions in electric-only mode, making it perfect for urban areas and environmentally sensitive sites. The battery power ensures a quieter operation, reducing noise pollution

Niftylift’s SD210 is a costeffective choice for arborists, balancing power and environmental responsibility.

SD210 Specifications:

Working height: 21.3m (70ft)

Platform height: 19.3m (63ft 6in)

Working outreach: 12.8m (42ft)

Safe working load: 225kg (500lbs)

Cage rotation: 100º

Width: 2.05m (6ft 9in)

Length: 6.15m (20ft 2in)

Height: 2.25m (7ft 5in)

Weight: 3,950kg (8,700lbs)

Power options: EU Stage V (Tier 4 Final) diesel 32Hp

Additional features: Turf tyres and four-wheel steer

and further supporting the arbor-care community’s sustainability goals.

The SD210, powered by an efficient yet powerful EU Stage V (Tier 4 Final) diesel engine, ensures compliance with the latest emissions standards. This engine not only delivers the power needed for demanding tasks but also minimises environmental impact by reducing emissions. The diesel engine’s fuel efficiency makes the SD210 a costeffective choice for arborists, balancing power and environmental responsibility. Both models boast easy-to-use control systems that enhance operator efficiency and safety. The

telescopic booms and fly-jib (SD210 only) provide precise positioning, while the 4WD capabilities ensure excellent manoeuvrability across varied terrains. These features make the SD170 and SD210 not only suitable but also indispensable for arbor-care professionals working in diverse Australian landscapes.

As the arbor-care industry continues to evolve, Niftylift’s self-drive range stands out as a beacon of innovation, safety, and sustainability. The SD170 and SD210 models are perfectly tailored to meet the demands of modern arborists, offering solutions that enhance productivity while prioritising safety and environmental responsibility. With these platforms, arborists can tackle their tasks with greater confidence and efficiency, making them invaluable assets during the colder months of August and September and beyond.

For more information on Niftylift’s selfdrive range and to explore how these platforms can benefit your arbor care operations, visit niftylift.com.au.

Four-wheel-drive and steer capabilities ensure excellent manoeuvrability across varied terrains.

Agile, robust, versatile and safe, CMC spider platforms meet every need of tree-care professionals.

First among CMC’s distinctive features is the ability to access areas otherwise impossible to reach.

Born from the most advanced lifting technology, CMC aerial platforms perform in all conditions, offering solutions and overcoming obstacles difficult for a truck-mounted platform.

First among CMC’s distinctive features is the ability to access areas otherwise impossible to reach as they can reduce their dimensions to the point of passing through a simple door, slipping under an awning, or traversing a narrow corridor to access a residential yard.

All this while moving autonomously on their tracks controlled by the operator via wire or radio control (depending on the model).

Not even a small operating space poses a problem. CMC aerial platforms are designed to adapt to the available space, achieving the best possible stabilisation, both in open fields and in the tightest and narrowest places.

As for levelling, it is difficult to find perfectly flat terrain in nature, and this can often be a major obstacle to the safe use of truck-mounted platforms.

However, the hydraulic stabilisers of CMC aerial platforms can perform the operation simply and quickly, especially with the Self Control System by CMC, an autopilot for MEWPs, forming the base to work perfectly on any terrain.

With working heights ranging from 13 metres to 41 metres, and an aboveaverage lateral reach, CMC spider platforms prove to be up to any task, allowing for easy pruning of any tall tree.

This is also thanks to an excellent manoeuvrability and easy and intuitive control features, both in full hydraulic versions and in those equipped with technologically advanced guidance systems that include automatic closure of the aerial part.

Thanks to their low weight and the availability of non-marking tracks, along with special support plates at the base of the stabilisers, CMC aerial platforms prove to be the perfect choice in even the most delicate missions, such as public and private gardens, courtyards, or golf courses.

Last, but certainly not least among CMC’s advantages, is their great ease of transport. CMC aerial platforms are self- loading and easily transportable on trailers, thanks to the excellent balance between robustness and low weight.

“For us, this means being The Specialifts, the specialists in spider aerial platforms,” declared Alessandro Mastrogiacomo, CEO of CMC. “We are able to design and manufacture efficient work tools that respond perfectly to the controls and meet the specific professional needs of our customers.”

See the CMC range of lifts at cmclift.com. CMC spider lifts are available through Monitor:

* Vic: 24 Williams Road, Dandenong, 3175

* NSW: 49 Cassola Place, Penrith, 2750

* Qld: 191 Magnesium Dr, Crestmead, 4132

* Qld: 2 Alta Dve, Caboolture, 4132

* WA: 11 Reihill Rd, Maddington, 6109

Phone: 1800 025 024

Email: Sales @monitor.net.au

CMCs can reduce their dimensions to the point of passing through a simple door, slipping under an awning, or traversing a narrow corridor to access a residential yard. Images: CMC

Safe and reliable for countless applications, Cingo tracked carriers are manageable and easy to drive, and include models with capacities from 700kg to 1200kg. Images: Merlo

Cingo multi-purpose transporters are compact and highly manageable machines designed to work in tight spaces. A low centre of gravity guarantees maximum transverse stability on slopes, while tracks allow for lower ground pressure and a better grip on deformed and irregular terrain.

The wide range available includes models with capacities of 700kg to 1200kg, and consists of two types of machines:

• Transporters – mini operating machines for the transport and loading of materials, and

• Multifunction machines – mini operating machines equipped with Merlo’s patented quick-coupling device, capable of being paired with countless attachments.

Cingo machines are tireless, versatile, and are specifically designed for

the maintenance of green areas, road and forest clearing, winter road maintenance, agricultural and livestock activities and construction work.

Safe and reliable for countless applications, the Cingo models are manageable and easy to drive thanks to hydraulic controls and hydraulic or hydrostatic transmissions. They’re even capable of operating in confined spaces. In fact, all the various models have a compact width and can turn in place, thanks to the counter-rotation of the tracks.

All the EVO series machines driven by hydrostatic transmissions are now equipped with hydraulic, servo-assisted transmission controls. A 70% reduction of the force needed to operate the levers greatly improves driving comfort and precision, and there are major advantages for maintenance as the system no longer requires periodical adjustments.

The versatility and multi-purpose qualities of the Cingo attachment system are unique.

A patented quick-attachmentcoupling device equips the sturdy tracked truck with two strong steel booms, and the hydraulically controlled coupling system allows rapid and simple replacement.

With the multiple attachments available, the Cingo becomes a highly efficient and productive machine that’s capable of significantly reducing costs for numerous different activities where specific machines are normally utilised. The excellent features and performance of Cingo attachments, and their total compatibility, are derived from an integrated design and an exclusive production process.

See the entire Cingo range and the full catalogue of attachments at merlo.com/ aus/en/.

This compact transporter is equipped with hydraulic transmission with gear pumps and hydraulic gear motors with the possibility of moving at double speed. Excellent performance and maximum safety are also guaranteed by the overcentre valve for controlling speed on slopes. Replacing the attachments available for his transporter model is facilitated by the possibility of placing the attachment on the ground with four support feet.

The hydrostatic system, with hydraulic servo-assisted controls, manages the speed from a few metres per hour up to a maximum of four kilometres per hour. It also allows easy control of the steering with micrometric precision for work accuracy and driving safety.

Thanks to its compact size, the Cingo M8.3EVO is a multifunction machine ideal for working in particularly confined spaces. The 17HP diesel engine and the tracks’ high angle of contact allow the machine to overcome obstacles, guaranteeing maximum versatility and functionality in all work situations. As with all Cingo models equipped with hydrostatic transmission with gear motors, the integrated parking brake gives excellent dynamic braking, guaranteeing a lower stopping distance, and therefore greater safety. The hydraulic servo-assisted controls also allow the speed to be regulated from a few metres per hour up to a maximum of four kilometres per hour, and the steering to be controlled with ease and micrometric precision.

Designed to work in tight spaces “ ”

The Cingo M12.3 EVO, equipped with gear motors and integrated parking brake, is the largest and most versatile multifunction machine.

It’s equipped with a powerful 21HP diesel engine and suitable tracks that allow it to operate on any terrain, thanks to excellent ground contact. It’s ideal for work in hilly and mountain areas where the compact size, low centre of gravity and remarkable traction allow working effectively and safely.

The hydrostatic system, with hydraulic servo-assisted controls, also allows speed management from a few metres per hour up to a maximum of five kilometres per hour. It also allows the steering to be controlled with ease and micrometric precision for work accuracy and driving safety.

While the case in this article deals with a forklift, it could just as easily apply to equipment and machinery used by tree contractors. Image: ungvar/stock.adobe.com

Brian Beecroft of the Timber Trade Industrial Association underlines the importance of understanding and compliance with new legislation.

An ill-judged decision that caused the death of a young employee has resulted in a small business ending up with a $1.3m fine. A court found the sole director must pay $120,000 compensation to the family and complete two years’ unpaid community work.

The accident occurred when the director of the Melbourne stonemasonry was using a forklift to move an empty A-frame rack. He was driving the forklift across a sloping driveway with the load raised when it tipped over and crushed the 25-year-old, who had been trying to steady the swinging load.

The young worker was working with his father in a business using the same warehouse as the stonemasonry, and over the previous decade the

two businesses had regularly worked together.

Security cameras in the company’s warehouse and across the street captured footage, described in court as ‘harrowing’, as the forklift tilted and fell, pinning the 25-year-old under it.

The director of the stonemasonry called for help and the young man’s father rushed over to find his son crushed under the machine. When it was lifted, the director and others tried to unsuccessfully to revive him.

The company was prosecuted under section 39G(1) of Victoria’s Occupational Health and Safety Act 2004, which provides that a person must not engage

in conduct that is negligent, constitutes a breach of duty owed to a person and causes the death of that person.

The new provision, introduced in July 2020, carries a maximum penalty of 25 years imprisonment for a person, or 100,000 penalty units (almost $18.2 million at the time of the offence) for a body corporate.

The director was initially charged with workplace manslaughter, but the charge was subsequently transferred to the company. In Victoria’s Supreme Court, the director pleaded guilty as an officer of the company to a less serious offence, admitting liability for the failure to take reasonable care which resulted in the breach of the workplace manslaughter provision.

Directors, not just machinery operators, must understand and ensure compliance with new legislation. Image: earthstudiotomo/stock.adobe.com

Failure to ensure machinery is operated correctly and in a safe manner can leave business owners open to fines and disciplinary action. Image: NURA ALAM/stock.adobe.com

In court WorkSafe’s investigators submitted it had been reasonably practicable for the stonemasonry company to reduce the risk of serious injury or death by ensuring the forklift was driven with the load as low to the ground as possible, only driven in reverse down slopes or inclines, not driven across, or turned on, slopes or

inclines, and only operated when other people were at a safe distance.

The failure to ensure the forklift was operated properly was negligent because it fell well short of the standard of care that would have been taken by a reasonable person in the circumstances.

The director admitted he had not followed safety guidelines around

operating forklifts on a slope.

The director had told WorkSafe investigators he ‘never thought it’d be that dangerous’. He said he didn’t understand how the accident had happened, as he had told the young man to stay clear of the forklift.

He also said he’d shouted at him to ‘get back’ as the forklift began to tilt,

and that ‘maybe he thought he could hold it’. This indicated that the director realised the young man was close to the forklift, which is another departure from safety guidelines – forklifts should only be operated in an exclusion zone with people kept at a safe distance.

In Victoria’s Supreme Court, Justice Michael Croucher said the negligent conduct itself was very brief, occurring over a number of seconds.

Justice Croucher noted the director had cooperated with authorities, entered an early guilty plea and showed remorse for what had happened. He had ‘deep feelings of sadness and guilt’ and had provided significant financial assistance to the young man’s family, including paying almost $17,000 for the funeral.

Justice Croucher fined the company

$1.3 million – a sum significantly greater than the company’s assets – and ordered the director to pay the young man’s family $120,000 in compensation, as well as completing a forklift operation course and a two-year community corrections order, under which he will have to do 200 hours of community service.

While this case deals with a forklift, it could just as easily apply to equipment and machinery used by tree contractors. Duty holders face serious personal and financial consequences if they do things that put the workers’ health and safety at risk of death. TTIA Members in other states are also increasingly affected by industrial manslaughter legislation.

The TTIA WHS unit Manager, Ken Hocking, is able to assist in safe-work policies and procedures regarding the operation of forklifts.

TTIA has a fully functioning in-house WHS unit which is there to support TTIA members nationally, and the association has long-term experience in the treecontracting industry. TTIA also has a proven record in safety management, documentation, training and legal resources. Should you require a WHS audit of your workplace, please contact Ken Hocking on 0418 280 335 or the TTIA Office on (02) 9264 0011.

TCAA regular Jim McArdle updates the arbor industry with some news and points of discussion after the latest TCAA AGM.

After the 2024 AGM’s success the TCAA has a new vision: ‘Top of the Trees leaders in arboricultural excellence’. The committee now serving includes Dan McArdle, Bruce Smith, Carson Smith, Jeff Hunt, Murray Bolan, Greg Major and myself, Jim McArdle, as the new incoming president, and that committee is considering the following points as urgent matters for attention:

* The issues with the Code of Practice and SRT are noteworthy where the construction industry and managers of second-tier contract firms try to classify our industry with construction COP;

This is not the suitable. Arborists are not construction workers, but a breed of our own. We have specialised SWMs, specialised training, specialised knowledge and we are a specific industry;

• The discussion around apprenticeships is open again and we need a new award to bring apprenticeships online. This should be a big boost for the whole industry as, being short on staff, we can guarantee job security. We can also guarantee good mentors and training through TAFE and our other partners.

• Apparently the arbor industry has been removed from the list of critical skills shortages by the Labor government. How is this possible when our training numbers and totals of completed enrolments are pitiful? It also means practitioners through the industry will have to get on the same page over this common theme;

• It would be wise for the other industry partners to also review this information and be active over the detrimental issue of unlicensed and untrained people in the arbor industry. They are still going to job sites, still going to schools, and still going to utility companies. This is why our injury stats are high across the arbor industry and why bad press is news, including featuring ‘tree loppers’ on the ABC in Killers in the Suburbs on July 6, 2024.

Historically, thinking of the arborist taught and mentored me, it was my dad. He made me stay on the ground for three years before doing AQF 1 with Bruce Mcleod at Ryde TAFE, completing the Hort certificate. I felt like it was an apprenticeship with this additional training, and I was confident in my work thanks to the training I’d received.

But as I was learning there were some real characters who showed me many methods and philosophies in climbing, and some of the more high points make great memories for me now. I still remember Jim McArdle (senior) scampering up a huge blackbutt, and one of the lead climbers climbing with a small hessian rope and, while getting their balance on a limb, walk, then flip their beltloop around twice to stand on a spot on the limb while cutting the same limb.

That’s Adrenaline 101! It takes seriously good balance.

There was a climber who utilised ladders in a tree, which still puzzles me.

Of course there was Joe, barefoot and in jeans, who climbed a tree, and Carl who pioneered the team-leader role and was somewhat talkative and let

everyone know their exact job. Rick, who was very methodical in takedowns but had unusually short sentences.

All these people put in a good effort as contract climbers, and all before formal training started at TAFE.

When spikeless climbing was introduced, we found that the energy required to scale the tree was much greater. With new methods and new forms of safety we began to ask questions like, “Where’s the high point and is it load bearing?”

Along the journey

Fast forward to the day when we ask, “What skills does a good arborist have?”

The most-needed skill is clear thinking – resolving a problem in reducing weight and bringing down loads, including the arborist. safely to the ground.

What experiences have I had which I wish I didn’t?

* Getting caught up a tree in a storm which was blowing fiercely

* Hearing my brother’s story about climbing a moving tree which was tied down the day before his birthday, and

* Hearing the pain in several mates who lost someone from a tree dive.

With the exposure to the new training platforms there is discussion that apprenticeships will be created to endorse training for the trade level. With this in mind the programme AQF level 3 is recognised as a good profile for the trade arborist. TCAA is currently in discussions with ITAB, and its odd how other associations have limited participation on this discussion.

Some of the old methods, just like some of the trusted old machinery, need to be admired, but set aside.

So what does make an arborist a good arborist?

Experience and being knowledgeable, for sure, and doing the job efficiently and productively, reviewing practices for improvements. Making others follow instructions is important, including a regime of taking vegetation away to be disposed in the chipper, clearing spaces with the drop zone or building up debris which could be used to cushion larger pieces without damaging the hard surfaces.

My brother, Matthew, states a good arborist is “…one that doesn’t get hurt”. What’s the price for a good arborist when quoting industry rates per hour?

A fair price for a contract climber was established within the TCAA. Some climbers expect to be around the high pay range, but most would be earning well above the average wage per day. It’s dirty, dusty, dangerous work. For the lead arborist, the groundies’ lives, client’s property and lives of all on the site are in their hands.

So, what makes a good arborist?

Reliability, safety, honesty, being drugfree, being alcohol-free, experienced, having tools in working order with sharp chains, and having the correct PPE that is effective and light carry. The arborist must be able to envision the way the job is going to go and be able to estimate the time to remove the tree, and if they need the job safety reviewed, work method adjusted, additional help or equipment. The arborist must keep up to date with current trends be aware of legislative changes that affect tree preservation. The arborist must ensure their gear’s

When spikeless climbing was introduced the energy needed to scale a tree was much greater.

stored correctly and has no damage and that it is tagged and in time stamped for compliancy.

The arborist makes available the contact details of another nearby backup arborist to call in case of an incident.

The best arborists now are the ones who can take more care, are very aware of their surroundings and spend less time at heights within a tree, and ultimately being a good arborist means honing the skills learned as an AQF 3 arborist without the pressure.

What’s in a name?

An ‘arborist climber’ means someone with strong limbs and useful muscles, a level of fitness and who has a resilient mental capacity to complete a difficult task.

‘Technology’ in arbor means utilising climbing mechanical ascenders to reduce fatigue, and utilising an EWP when the job requires pruning or reduction without having to out climber at risk.

‘Communication’ is allowing CB radios, walkie talkies, and mobile phones to communicate clearly and effectively so the experience of taking down or pruning is unhindered by a fault of mistake. Flashing a mirror to get the arborist attention in a high climb is not acceptable. Throwing a stick at the arborist is also not acceptable – even though it was used effectively in the past.

The use of the laser to assist in referencing what is essential to prune and material to be retained by the supervisor is also an excellent communication tool.

What ‘mistakes’ can an arborist afford to make?

None.

It’s a bit like a submarine captain. If the captain goes down then the whole team suffers.

What about the toolbox meeting in the morning, the lunch break and the afternoon tea/smoko? These are all enshrined in arborist’s sacred time to reflect on the job and get sorted over current issues or difficult parts of the job. Nobody wants a branch through their roof or window, and nobody wants to have hospital time.

Both views

‘Scars’ on arborists hint at something that got too personal. It tried to take a piece of the arborist with it. Or there may

Associations need to educate councils on hiring qualified arborists.

be the scars from laughing about the day you don’t know how it was done but you did it?

We used to take massive pieces down moving large limbs across buildings to be laid gently in a landscaped yard, and it would always get an accolade from the residents. Calculations were very rigid, with having a second experienced arborist comment on weights, knots and loadings was essential.

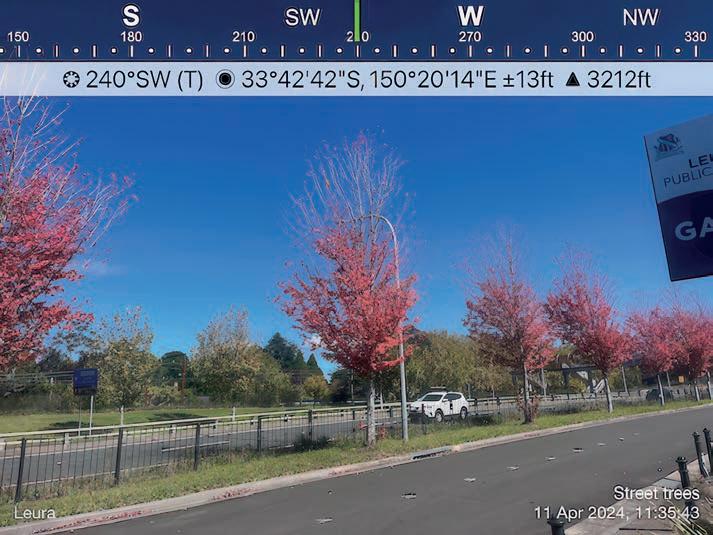

Looking up into the Darling Scarp. There are large patches of brown and huge stands of dead trees. Image: Arb West

Dave Crispin, senior arborist at Treeswest Australia and Arboricultural Association of Western Australia (Arb West) committee member, has observed the trend in climate change showing in trees.

Perth recorded just under 22 millimetres of rain between October 2023 and March 2024, the city’s driest period since rainfall records began almost 150 years ago.

Comments like, “Have you seen all the trees that are dying up in the hills?” or “Why are all our trees turning brown and losing their leaves?” have been common topics of conversation over the past several months. Perth has a Mediterranean climate: hot dry summers and wet, cool, winters. Or it used to be.

Now that is definitely not the case.

Over recent years the ‘wet’ has become less and less, with minimal recharge into the natural groundwater. ‘Recharge’

refers to the recharging of groundwater that supplies up to 40% of Perth’s water, which is mainly used for drinking and commercial use.

The fact is, it’s been declining since the 1960s, with fewer significant storms carrying any decent amount of rainfall. This decline has been studied by Dr Simone Gelsinari and his team at UWA (University of Western Australia), revealing a drop of nearly 70% in the past 50 years.

“Our findings suggest groundwater aquifers in climates like Perth’s are particularly vulnerable to climate change, and may see larger recharge declines as soil needs to be saturated with rain before water trickles down to aquifer level,” Dr Gelsinari said.

It’s a sobering thought.

Looking up into the Darling Scarp, named after the Governor of New South Wales, Lieutenant-General Ralph Darling, you would typically see a blanket of green, even in the height of summer. Now there are large patches of brown wherever you look, and huge stands of dead trees.

The scarp is part of the jarrah forest region, consisting of mainly Eucalyptus marginata, Corymbia calophylla, Eucalyptus megacarpa, Eucalyptus patens and Eucalyptus wandoo. The concentration of a species depends on which side of the slope, or whether in a high or low area.

In conversations with other arborists, it seems the juvenile and semi-mature trees have been hardest hit, not having

enough time to develop a deep enough root system to tap into the belowground water source. All these trees are vital for the local ecosystem, whether a food source, habitat, or roosting trees for local fauna. The ubiquitous Lophostemon confertus, so prized for its hardiness as an amenity tree, its ability to withstand harsh pruning, and being drought tolerant, seems to have fared the worst. I’ve lost count of how many I’ve seen dead or in a state of rapid decline. I say ‘rapid decline’ because it looks like they’ve been poisoned.

Towards the end of March I was asked to look at three Brush Box trees on a road verge. As I arrived, my first thoughts were that they looked like a typical case of Glyphosate poisoning. All the leaves were still intact, but all necrotic, with not one green healthy leaf remaining.

Unfortunately, this was not an isolated case. All over Perth numerous Queensland box trees were falling victim to the drought. Maybe it’s time to reconsider the long-term future for our Lophostemon confertus?

Another consequence of our changing climate is the increase in lightning and the strikes on trees.

Global warming influences the frequency of lightning strikes. For every one-degree increase in global warming

We need to partner with local and state governments to offer our expertise and guidance on sustainable tree management policies and urban greening strategies “

there is a rise in strikes of approximately 12%. In a recent study by the University of California, Berkeley, researchers found if conditions continue to warm at the rate they are, by the year 2100 we could see a rise in strikes by a staggering, 50%.

How many of our tall trees would we lose?

Australia has been identified as one of the countries that will be most affected by this phenomenon.

Recently, an Arb West member attended a remote mine site to carry out a routine assessment on the health and structural condition of several trees around the accommodation block. At this remote location a huge corridor of trees had been cleared, except for a few token trees dotted here and there. The trees were mainly Corymbia

The ubiquitous Lophostemon confertus, so prized for its hardiness as an amenity tree, its ability to withstand harsh pruning, and being drought tolerant, seems to have fared the worst in the warming, drying climate.

Image: Arb West

calophylla or Eucalyptus marginata, and each stood like a sentinel, their prominence in the landscape obvious by their size and height. Each tree was in excess of 100–150 years of age. Almost 50% of the 90 trees had been struck by lightning at some stage. Black scarring was evident on the trunks and branches to varying degrees. Recently, a large, 25m, Corymbia calophylla, with a canopy spread to match, was struck by lightning. The tree exploded, sending tree parts 300m away and damaging the accommodation block with pieces of wood embedded in the roof sheeting. A total of 10 cars were written off, with many others considerably damaged. One dual-cab utility had a piece of wood the thickness of a human thigh and two metres long spear through the rearwindow panel and embed in the front dash. Fortunately, no one was around

at the time as the workers were still on their shift.

A blast radius of some 300m! Imagine if anybody was close by. They were extremely lucky.

When lightning strikes a tree it’s not always game over. The species, the type of lightning (forked or sheet), and whether the tree is dry or wet, can greatly affect the outcome. According to Dr Gregory Moore, a University of Melbourne researcher, if the conditions are against the tree and it gets struck directly, potentially, up to one-million volts can flow through the tree, instantly raising the temperature to 20,0000ºC. The tree is a sealed system, with the flow of sap (mainly water) passing underneath bark near the surface, so when the lightning strikes the sap, it

instantly turns into steam, the tree acts like a huge pressure cooker and literally explodes.

It’s not a good place to be when lightning is close by.

Not all trees struck by lightning die instantly, some may take a couple of months, or even a year. If the tree’s natural defence system has been compromised, the potential for harm caused by pest or disease attack is greatly increased. If the lightning went to ground via the roots, it is quite possible they were burnt, which could eventually lead to tree death. The number and size of the roots has a direct influence on how quickly the tree declines.

Here are a few guidelines with managing a tree recently struck by lightning:

• Has the tree split, causing it to separate partially or totally? If structural integrity has been compromised, then removal may be the only option

• Is there a deep crack in the main stem? Longitudinal cracks up the main stem, deeper than one third of the tree’s diameter, probably mean the lightning has entered the woody xylem tissue and caused extensive damage. Structural defects are highly likely. Assess targets and the consequences, remove the tree if high-value targets will be impacted.

• Is there a deep crack or cracks on sizeable branches?

If the cracks are one third or more the diameter of the branch, then carry out reduction pruning or remove the whole limb if possible

• More than one third of the tree’s bark was removed around the circumference of the trunk at any one point by the strike.

Bark has been stripped from around the trunk exposing the tree to potential decay. Monitor the tree for decline. Assess targets and consequences, remove if high-value targets will be impacted, and

• Less than one third of the tree’s bark is removed around the circumference of the trunk at any one point.

Monitor the tree for several weeks to assess the extent of the damage. Recommend follow-up maintenance treatments if required.

The above comes from Arnold Brodbeck, Jack Rowe, and Jim Jacobi at the Alabama extension website (aces. edu/blog/topics/forestry/caring-forlightning-struck-trees).

Expertise is needed

We are facing challenging times in managing our green canopy cover, especially in our harsh urban environment. Now, more than ever, we need to partner with local and state governments to offer our expertise and guidance on sustainable tree management policies and urban greening strategies.

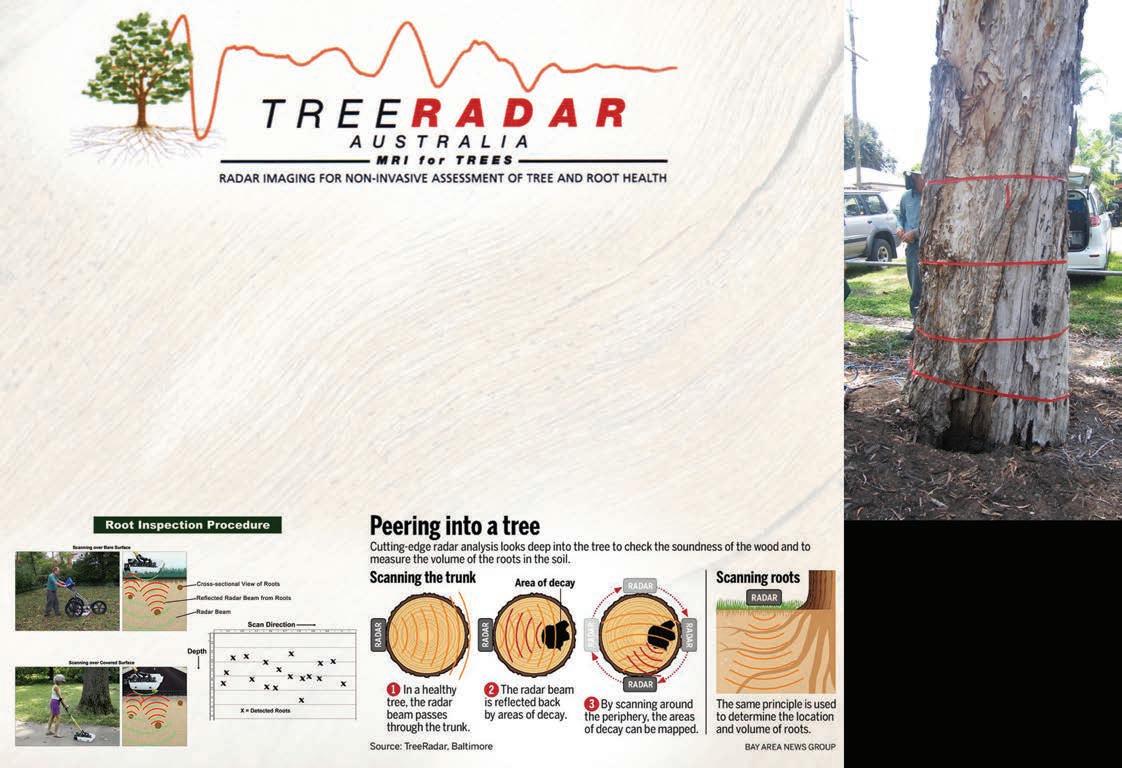

Tree Radar Australia uses a ground penetrating Radar Unit to provide the only, completely non-invasive method of tree decay detection and tree root detection available in Australia.

TREE RADAR UNIT™ DECAY DETECTION.

Tree Decay is a severe problem which can put all the structure around a tree at risk. With Tree Radar Units™ decay detection, Tree Radar can scan for decay in any tree regardless of its height. The Tree Radar unit can give an accurate read out of the severity of decay in a tree without having to penetrate the Tree’s surface.

TREE RADAR UNIT™ TREE ROOT DETECTION.

Tree Radar Unit™ can detect and establish the root proliferation of a tree, this allows the arborist to inform developers of any structural or instability issues without the need for drilling or digging.

The QAA’s 2024 Freestyle Competition turned out to be one of the biggest and most memorable events yet.

The Queensland Arboricultural Association wraps up its 2024 Freestyle Competition.

Despite some cold and wet weather at the Bangalow showgrounds, the 2024 Freestyle Competition turned out to be one of the QAA’s biggest and most memorable events yet. The enthusiasm of competitors and spectators was truly remarkable, and a special thanks goes out to major sponsor Vermeer for making the event possible.

The QAA is also grateful to its other generous sponsors: LRV8, for vouchers totalling $4500; Arb Supplies/Husqvarna for the T542i XP; Shockload Bags; The Arbor Van; Reecoil & Arbor Industrial; and Universal Cranes Ballina, for its efficiency in getting our competitors ready to compete. A big shout-out to Brad’s Butchery at Byron for keeping everyone well-fed with delicious meat donations.

A heartfelt thank you to the volunteers who braved the adverse weather to set up and score the event. Special mentions go to Terry Boston, Beaver

Kindred, Adam Lovering, and Jim Trouse. Geraldine and Mark Boston, as always, stepped up to cook the BBQ, ensuring everyone stayed nourished. Their dedication and hard work were invaluable.

Industry Meet & Mingle events have proven to be an outstanding success.

Honours

This year’s competition was fierce, with 39 competitors from across Australia vying for the top spot. Due to time and weather constraints, a single qualifier narrowed the field down to the top 20 for

the semi-finals. The top 10 then moved to the Pro Final, while the remaining 10 competed in the B-Class finals.

Here are the winners…

Pro class: Ryan Robinson (00:47.94), Jamie Boston (1:01.85), Chris Fahy (1:05.62)

B Class: Joe Astell (01:30.29), Nathan Skelton (01:36.30), Jorim Hutton (01:40.41)

Female: Alana Murray, Julia Steele, Laura Arbon

Special Awards: Spirit of the Comp –Adam Lovering and Beaver Kindred.

Video Prize: Joe Astell

Thanks go to everyone for their support, camaraderie, and professionalism throughout the event. The QAA couldn’t be prouder of our industry and look forward to more exciting competitions in the future!

Introduction to Fungi for Arborists: The QAA extends its thanks to Craig Reid and all participants for attending the Introduction to Fungi for Arborists workshop held at QAA head office in May.

engaging

provided participants with invaluable insights into the world of fungi. Attendees explored the evolutionary relationships between trees and fungi, learned to identify various fungi, and understood their impact on tree health and ecosystems.

The workshop was a resounding success, enhancing the knowledge and skills crucial for effective arboricultural practices.

TRAQ: Mark Roberts presented the ISA TRAQ courses again in Brisbane in June. Thanks to all who attended, who should

now all have their results. At this stage TRAQ will not return to Brisbane until 2026, so if you are due for a renewal prior to this, please keep an eye on Arb Australia’s website.

The QAA Industry Meet & Mingle events have proven to be an outstanding success, offering arborists and tree-care professionals invaluable opportunities to connect and stay updated on industry trends. The first event, held at Fitzys Loganholme, and the second at The Sports Globe, Chermside, both fostered a vibrant sense of community and collaboration. These gatherings have become a vital platform for sharing knowledge and enhancing connections within the arboriculture community.

Stay tuned for future events and continue to build your industry network!

The Queensland Arboricultural Association Inc. (QAA) extends a heartfelt ‘thank you’ to its 2023-24 sponsors. The unwavering support has been pivotal in the mission to preserve, protect, maintain, and enhance the recreational and environmental value of trees. Thanks to you the QAA has successfully hosted numerous events and workshops, fostering growth and knowledge within the arboricultural industry.

Your contributions have allowed provision of valuable resources, training, and networking opportunities to QAA members, ensuring they remain at the forefront of the industry. The success of initiatives like the Industry Meet & Mingle is a testament to your generosity and commitment to our shared goals.

As the QAA looks ahead to the 2024-25 period, potential sponsors are invited to join the QAA in supporting this vital industry. Don’t miss the chance to make a meaningful impact and be part of a community dedicated to the care and preservation of trees. Together, we can continue to lead by example, advancing arboriculture for the benefit of all.

The QAA thanks everyone once again for their indispensable support. Here’s to a thriving future for the QAA and the arboricultural industry!

Running a forestry business is a challenging and rewarding endeavour. Forestry business owners need to secure continual access to lucrative woodlots, and they also need to invest in heavy timber equipment that cuts back on labor costs and maximises productivity. This guide to forestry equipment introduces the top attachments forestry businesses can invest in for success. It outlines the different forestry attachments and provides tips for choosing the right forestry attachment for your business. It also explains why choosing Cat® forestry attachments ensures the best value for your investment.

Acrucial consideration is which types of work tools you’ll need. With the right work tools, any standard heavy equipment can be taken and turned into a highly functional and versatile machine that takes on specific duties. Here are five of the best equipment attachments for a forestry businesses to invest in:

Widely utilised for Cat wheel loaders in forestry applications, load and lumber forks attachments have been designed from the beginning to work exclusively with Cat machines.

Only Cat forks are built to precisely match the performance characteristics of Cat machines.

These forks come with a top clamp and with a pin-on or quickcoupler pick up. They offer the best productivity for loading and unloading logs or lumber on forestry sites and in processing plants.

Similar to log and lumber forks, Millyard forks also offer distinct quality and feature benefits which competitors can’t match –like a next-generation top-clamp design with superior strength and durability in mind. Cat top-clamp wrapper is made from a single, seamless piece of cut steel to minimise welding, increasing the strength and decreasing the likelihood of cracking.

As one of the most versatile attachments in heavy equipment, bucket attachments are necessary for site clearing and cleanup. Use a bucket attachment throughout operations to clean up debris and clear access ways. An excavator bucket can also be used to dig around tree stumps to extract them for removal. Or, put the bucket attachment to use in a final cleanup pass, loading and hauling away unwanted brush or trees.

There is an extensive range of buckets available to attach to your heavy equipment, whether it’s an excavator or a loader. Cat generalpurpose, severe-duty and excavator buckets with thumbs all help to clean up with precision and efficiency.

Grapples are attachments designed to fit on forestry machines and make quick work of transporting trees. Their unique curved design means multiple trees can be gripped at one time, making them very efficient at relocating trees after they’ve been processed. Additionally, grapple attachments are used to load and unload logging trucks before and after their journey, making them useful in the forest and at the lumber’s destination.

After trees have been harvested, their stumps may still remain. These can essentially make the land unusable. Luckily, forestry mulcher attachments are designed to tackle the problem of leftover tree stumps.

Forestry mulchers attach to forest machines and excavators and work by rotating a shaft containing many hardened steel teeth. With a combination of downward force from the forestry machine and the rotation of the mulcher shaft, the teeth are able to pulverise the remaining stump.

Forestry mulchers are so effective in destroying stumps that they can often remove the stump below the ground level. Afterward, the stump hole can be filled with dirt and smoothed over, leaving no trace of the stump.

Businesses looking to invest in new forestry attachments need to source them from a reliable dealer. For more information about Cat forestry attachments, visit your local Cat dealer:

• NSW/ACT, WesTrac: phone 1300 881 064

• VIC/TAS, William Adams: phone 1300 923 267

• Western Australia, WesTrac: phone 1300 881 064

• QLD/NT, Hastings Deering: phone 131 228

• South Australia, Cavpower: phone 08 8343 1600

• NZ, TERRA: phone 0800 93 39 39.

To see the range of Cat attachments, log on to cat.com.

EFI (electric free installation) heads operate without electricity. Just attach the head to the excavators’ quick coupler and attach two hoses. Recommended pressure and flow for the head are 200250 bar and 100-120l/min.

Images: Waratah Forestry Equipment

Waratah Forestry Equipment and Moisio Forest Oy, a Finland-based forest attachment and accessory manufacturer, are proud to offer Moipu products to Australian arborists and the forestry industry.

Moipu attachments are not only adaptable and simple to install to any carrier type, but are a safe and efficient solution for pruning and removal of trees.

Super versatile

Moipu energy wood heads were first built in the 1990s and have proven to serve customers in many applications, including energy wood harvesting, early thinning, roadside cleaning, rail-side cleaning and riverbank cleaning.

The new Moipu attachments come in a range of shear or saw-bar options and are designed to be installed on practically any carrier with ease. Electric-free installation makes the Moipu product a universal tool not bound to any specific base machine.

Fast and efficient

As the installation is so quick, heads can be changed to another attachment and back, even while keeping pace with a busy working site. Compatible carriers include telehandlers, excavators, crane trucks, forwarders, harvesters, or any carrier with a crane and suitable hydraulic oil flow.

Waratah Forestry Equipment

Moipu products will be sold and supported in Australia by the dedicated Waratah Forestry Equipment parts and product support teams – teams with a wealth of experience in aftersales service and support from being the preferred customers’ choice in forestry attachments.

Contractors can rely on Waratah Forestry Equipment attachments for optimal performance.

To see the Moipu range, log on to moipu.com, and for more information, chat to the local folks at Waratah Forestry Equipment on (03) 9747 4200.

Waratah Forestry Equipment offers an extensive range of parts and services designed to support the durability and performance of its New Zealand and Finnish manufactured forestry and arbor attachments. With over 50 years of experience in the forestry industry, the company has a strong emphasis on customer satisfaction and support, ensuring contractors can rely on their attachments for optimal performance, making them the market-leading attachment of choice.

Forest Centre is the equipment supplier which not only meets the high standards and embraces the environmental aims of Granite Group Services, but gets actively involved in helping the company achieve its goals.

Granite Group Services encompasses several divisions, one of which is Granite Tree Works, and Director Jon Rogash is strong on the company’s aims.

“Everything we remove, we recycle,” the Mornington Peninsula-based director told The Australian Arbor Age “Absolutely everything we can.”

“We don’t believe in waste, he continued. “We work very closely with a mill called The Wood Project and recycle as much timber as we possibly can.”

That’s saying something, because Jon and his team run a sizable collection of machinery which is kept steadily at work.

“It’s a pretty large fleet,” Jon outlined. “We have a Westtech Woodcracker CS750 smart grapple saw – the first Westttech grapple saw retro-fitted to a Magni telehandler in Australia – and we also have a Westtech Woodcracker W1350 log-splitting grapple that partners up with our Morbark 22x30inch chipper, so we don’t get stuck with log wood. We can break it down and we can feed it all through the chipper.”

Filling out this particular set, but by no means completing the fleet inventory, is a Hultdins SuperSaw 555 grapple saw unit retro-fitted to an existing rotating grapple, operating on a 14T excavator.

All three attachments came from Forest Centre.

The work of Granite Tree Works is heavily based in land clearing and large-scale tree removal, although the company also offers earthworks, driveway packages, and complete packages to builders. A division of the company is also focussed on its environmental aims, and includes

I don’t deal with anyone else for attachments. Everything goes through Forest Centre “ ”

The Magni with the Woodcracker CS750 has incredible grab power. Image: Granite Tree Works

I wanted to set up the 25-metre so it was actually light enough to transport on our tri-axle float, being 18.1 ton instead of 23 ton “ ”

a horizontal grinder, forestry mulching and similar machinery to ensure the product of the company’s activities can be reused and recycled.

Despite a considerable commitment to a sizable fleet of machinery, Granite Tree Works’ doesn’t include any LGAs or councils.

“We’re solely concentrated on the private sector,” said Jon, “and we’re booked out for the rest of the year.”

We asked which machine was the most popular with the Granite Tree Works team.

“They’ve all got their different purposes,” Jon explained thoughtfully.

“I like the Magni for the control it has over the lifts. When we’re working in tight spaces, over structures and things like that, it’s very smooth, and the Woodcracker CS750 has incredible grab power, so it doesn’t feel like a load is going to go astray.

“That gets everything down to the height of 10 metres, and then the 14-tonner with the Hultdins takes over. It’s just so quick and efficient.”

Why retro fit the attachments in the first place?

“I wanted to set up the 25-metre so it was actually light enough to transport ourselves on our tri-axle float, being 18.1 ton instead of 23 ton,” Jon told us, quietly gliding over what a daunting task that could possibly be.

As it turned out, Westtech grapples are designed to fit and work seamlessly with a wide range of machinery, and the fitting of the grapples wasn’t too much trouble. And that’s helped along by Granite Tree Works’ association with Rey Kell at Forest Centre in Tumut, NSW.

“100 per cent!” agreed the Victorian. “I don’t deal with anyone else for attachments. Everything goes through Rey at Forest Centre.”

We asked why that was.

“We think a lot alike,” said Jon. “Mechanically, I tell him an idea and he’ll go, ‘If we do it a bit different…’ or he’ll throw a couple of other ideas out there, and it makes the whole retro-fitting scenario so much easier. There’s never an issue. It’s always a result when it’s Rey and Forest Centre.

“I probably end up on the phone too long with him,” chuckled Jon, who clearly wasn’t complaining. It seems like sessions of problem solving with Rey at Forest Centre are one of the enjoyable parts of purchasing and fitting equipment.

And after speaking to Jon, it looks as though those conversations will be continuing for some time to come.

Check out Forest Centre attachment solutions at forestcentre.com.au or visit Forest Centre’s social-media channels.

Dominic Osborne of TreeWorks Canberra, in Queanbeyan East, NSW, was over the moon when he heard he’d won the Climbing Harness and six mini carabiners with a total value of $1030.90 in The Australian Arbor Age’s subscription draw. It all happened just as we were going to print, so we’ll have a pic and more for you next issue.

Isuzu’s legendary reliability and power allow the Piranha BT300 to make short work of even the toughest job.

The Japanese engine giant gives factory backing to a new Australian arbor sensation.

Piranha chippers continually give high-performance and yield the highest return-on-investment figures, ultimately increasing bottom-line dollars. One of Piranha’s foremost suppliers is a leader in the world of diesel engines: Isuzu.

In 2016 Isuzu brought the 4HK1 –arguably the cleanest Japanese diesel engine – to the Australian market, and nearly a decade later there’s still nothing quite like it for advanced Japanese engine technology. It meets emission-control requirements for commercial vehicles laid out by the current Australian Design Rules (ADR) 80/03, exceeds Euro V, and complies with Japan’s Post New Long-Term (PNLT) emissions standard.

But being environmentally conscious doesn’t mean the Isuzu can’t still pack a serious punch. The 4HK1 engine is a low-displacement, high-torque, fourcylinder, turbocharged and intercooled diesel engine which produces a classleading 197hp. A hydraulic autoengaging clutch on the BT300 ensures the easiest start-up and operating procedure of any hand-fed chipper unit currently available, and Isuzu’s legendary reliability and power allow the Piranha BT300 to make short work of even the toughest job.

With Isuzu being such a popular brand in commercial vehicles, especially among arborists, it makes a lot of economic sense to run an Isuzu diesel in an Australian designed and built chipper. It means a single set of service items like filters and belts can be kept on hand to cover both the work vehicle and the Piranha.

Isuzu’s reputation for reliability, superb engineering and after-sales support is legendary and undeniable. When a company the stature Isuzu Australia gives its support to the Piranha Chippers brand, it makes a big statement about the performance and durability of the Australian chipper.

Piranha Chippers’ BT300 is powered by the 4HK Isuzu turbo-diesel, a low-displacement, high-torque, fourcylinder, two-stage turbocharged and intercooled diesel engine.

Contact the Piranha team today. They’re very keen to show just how good the BT300and its Isuzu diesel are. Call 1300 406 171, or log on to piranhachippers.com.au. It makes a lot of economic sense to run an Isuzu diesel in an Australian designed and built chipper

Through its Certificate III in Conservation and Ecosystem Management, TAFE NSW is arming students with the practical experience and specialist skills to give them an advantage in the booming ‘green’ jobs market.

Tomas Pool chose TAFE to gain more hands-on skills and is now focussed on regenerating land to its natural state.

Image: TAFE NSW

Current TAFE NSW Taree student, Tomas Pool, is already working in the field, employed as a bush regenerator for Natural Resources Group.

“I’ve always had a passion for the environment and outdoors,” he said. “I grew up in the bush as part of a very green family in a house that was completely solar powered, and my mum worked in horticulture. I got to know plants and see how they grow. Plants are the primary producers, and they can be overwhelming, but there’s so much to learn.

“I studied ecology at university and have experience in botany, zoology, and even avocado farming, but I wanted to add to my passion, so I chose TAFE NSW to get more hands-on skills. This added to my knowledge and skillset which really helped with finding local work.

“My current role is focused on regenerating the land to its natural state by encouraging regrowth of the native habitat through removal of threatening weeds like lantana. We aim to limit

chemical usage and do most of this by hand, so the practical skills I gained at TAFE NSW really helped.

“Through TAFE NSW, I learned about cultural methods around land management, and at Natural Resources Group we work hand in hand with the Local Aboriginal Land Council and Tide Rangers. This is an area where I’d like to get even more experience, as well as focus on the scientific side of ecosystem management,” Tomas said.

Group Coordinator of Manning Landcare Group, Lyn Booth, has encouraged more local students to undertake Conservation and Ecosystem Management studies with TAFE NSW.

“The Manning region is facing issues including landscape degradation, soil erosion, soil health issues, and changing climate, which brings greater risks and more extremes that affect animal health, among other things. Manning Landcare is focussed on planting