For pros that demand intelligent charging solutions, tools they can trust, and one system for every challenge, proven STIHL quality makes the difference. Driven by over 98 years of German engineering excellence, AP system power and performance is designed by professionals for professionals.

Constant power at hand, day in day out. Get it done. With battery power by STIHL.

IPX 4

For working in wet or adverse weather conditions

CONSTANT POWER

Constant battery performance regardless of the charge level

POWER BOOST

NEW ELECTRONICS SYSTEM ENABLING HIGHER PERFORMANCE WHEN REQUIRED

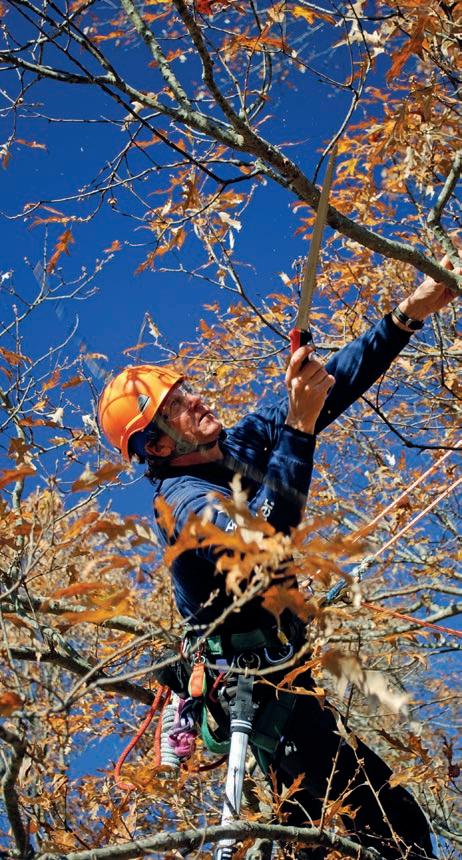

ballet-standard showing of balance and precision

The Queensland Tree Climbing Championship was an eye-opener for me.

I climbed out of my swag at the Mount Tambourine showground to be greeted by a glorious sunny day, mild temperatures, and a rapidly increasing crowd.

The crowd, admittedly, was due to the venue hosting the community market that day as well, and as far as I could see that was a master stroke by the organisers. As the surprisingly large throng made its way around the stalls picking up snack treats, hot drinks and various craftworks, most, at some time or another, stopped to watch the tree climbing.

I’d missed the first day, but it worked in my favour, because after meeting some of the great people involved in running the competition, I was able to watch Barton Allen-Hall, the multitime Australian and world champ, do a demonstration climb.

It was a ballet-standard showing of balance and precision, and I felt

privileged to have been there to see it.

But one unexpected aspect of the day made a big impression on me.

As Allen-Hall ascended the tree to its very highest and most tenuous handholds, a singularly rapacious magpie went the dive-bomb attack, complete with clearly audible beak snapping and some spectacular helmet contact.

As I watched Allen-Hall maintain his composure and not acknowledge the avian assault, I heard a child’s voice behind me say, “Mummy, is he hurting the bird?” and another adult voice comment, “She must have a nest in this tree. Poor thing.”

I had a quiet smile to myself. As far as I could see, the ‘poor thing’ had every intention of nabbing an ear or an eye as a trophy. And not only was AllenHall tolerating a quite determined and undeserved bollocking from the avifauna, he clearly wasn’t creating a great impression with some of the local people either.

The organisers were aware of the magpie and knew its nest to be quite some distance away.

Allen-Hall drew his saw, tapped the bell and, with some elegant swooping of his own, made off in the direction of the next target. The magpie retired to await another victim, and I was left pondering what I’d seen.

Next time things aren’t going well I’ll think about Barton Allen-Hall and the magpie. I’ll try and draw inspiration from his professionalism in a tough situation, and at the very least, the memory will make me smile. Sometimes a smile is all it takes to turn things around.

A huge thanks to the QAA for inviting me to the competition, to all the great people I met while I was there, and especially to all the volunteers who gave their time to make the event possible. I hope to see you all again soon.

If I do, that’ll make me smile, too.

Tom Foster Editor

The Australian Arbor Age is published bimonthly by Prime Creative Media Pty Ltd.

CEO

John Murphy

COO

Christine Clancy

Sales Director

Bradley Buchanan

Editor

Tom Foster tom.foster@primecreative.com.au

National Advertising Manager

Arron Reed arron.reed@primecreative.com.au

Phone: 0466 923 194

Client Success Manager

Arianna Lucini

arianna.lucini@primecreative.com.au

Design

Jacqueline Buckmaster, Danielle Harris

Subscriptions

P. +61 3 9690 8766 subscriptions@primecreative.com.au

Website arborage.com.au

Copyright

The Australian Arbor Age magazine is owned by Prime Creative Media and published by John Murphy. All material in The Australian Arbor Age magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical, including information and retrieval systems) without written permission of the publisher. The editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions, or for any consequences arising from reliance on information published. The opinions expressed in The Australian Arbor Age magazine are not necessarily the opinions of, or endorsed by, the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2024

Articles

All articles submitted for publication become the property of the publisher. The editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Dr, Docklands VIC 3008

P: +61 3 9690 8766

enquiries@primecreative.com.au www.primecreative.com.au

Sydney Office Suite 11.01, 201 Miller Street North Sydney, NSW. 2060. Australia

A potent proprietary technology from Germany has brought a whole range of new opportunities to tackle soil compaction.

08. SIGNIFICANT TREES

10. ON THE COVER

Soil compaction can have a negative impact on tree growth. The VOGT Geo Injector uses compressed air to alleviate the problem.

66. WOMEN IN ARBORICULTURE CLIMBING WORKSHOP

68. TECHNICAL FEATURE Ascension and the analogy of the tree to illustrate the human condition: Part 2.

Cassian Humphreys

Cassian is an exMerristwoodian (NCH-arb 1991, bridged into the UK Diploma ’92), Qualified to the AQF L5 (AUS Dip) in ’09, upgraded in currency in 2017. He commenced his career after graduating in Horticulture (’85), transitioning into Arb (’89). Experienced in all aspects of arboriculture, having worked in Germany, Australia, Britain, PNG and Vanuatu, Cassian has been writing for AAA since 1999, with over 40 articles to his name. His core specialisation involves conservation arboriculture, education and tree-health-care.

Jim McArdle

B.Ed. Sc (Sydney), Dip. Arb. (Ryde), VTRA@QTRA qualifications. Director at McArdle Arboricultural Consultancy and TCAA President, Jim’s career spans across almost 40 years and focuses on consulting and reporting in tree risk protection and management plans, and tree impact assessments.

Dave Crispin

A professional consulting arborist at Treeswest Australia, certified to AQF level 5 (Diploma), international coach, speaker and presenter.

At just under 84 metres tall and estimated to be around 2200 years old –give or take a century – this Sequoiadendron giganteum is a major tourist attraction in the United States.

While not the largest or tallest tree in recorded history, giant sequoia ‘General Sherman’ is the world’s the largest living tree by volume.

With neighbouring giant sequoias ‘General Grant’, ‘Lincoln’, and ‘Stagg’, General Sherman stands stately in the Giant Forest in Sequoia National Park, California. Sequoia roots are shallow but spread wide, and entangle with the roots of other sequoias to form a network that helps all the trees maintain balance and stability.

One quirky fact relating to this particular sequoia is, in 2021, the trunk was wrapped in aluminium foil to prevent an approaching fire from reigniting vulnerable fire scars.

At 84m tall and with a trunk circumference of 31m at ground level, giant sequoia ‘General Sherman’ is the world’s the largest living tree by volume. Image: Marek Poplawski/stock.adobe.com

Photo credit: Mulchtech.com.au and Vinetech.com.au

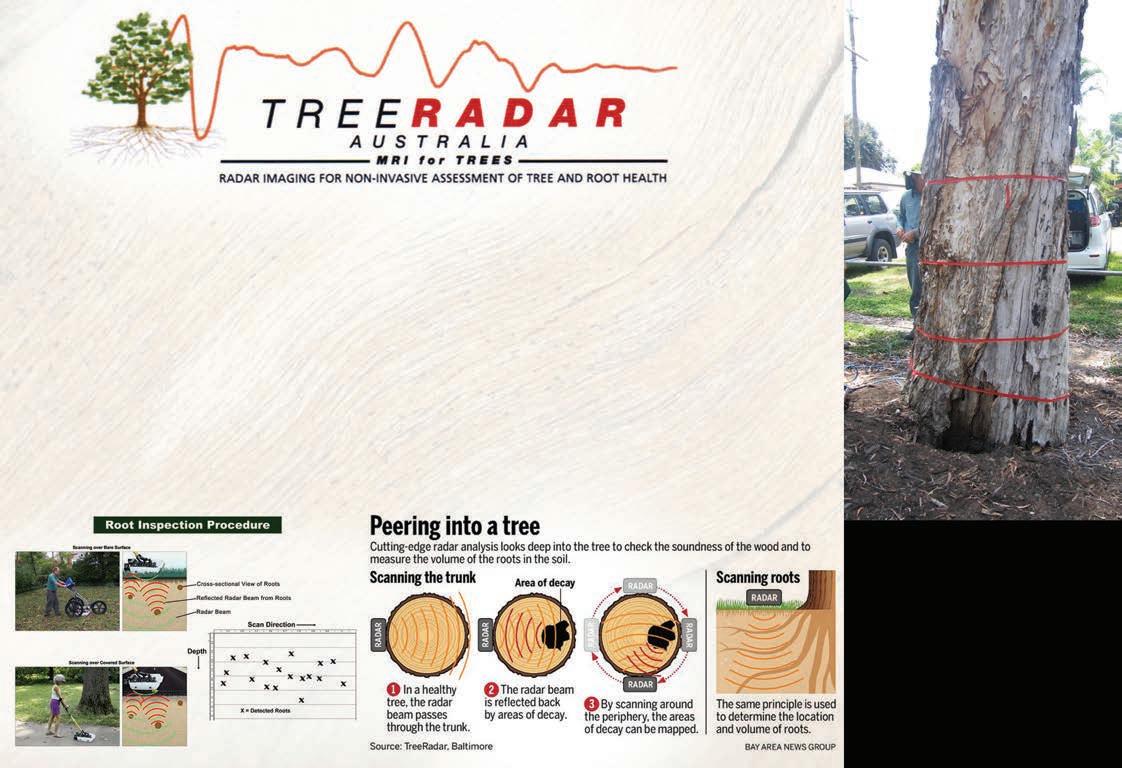

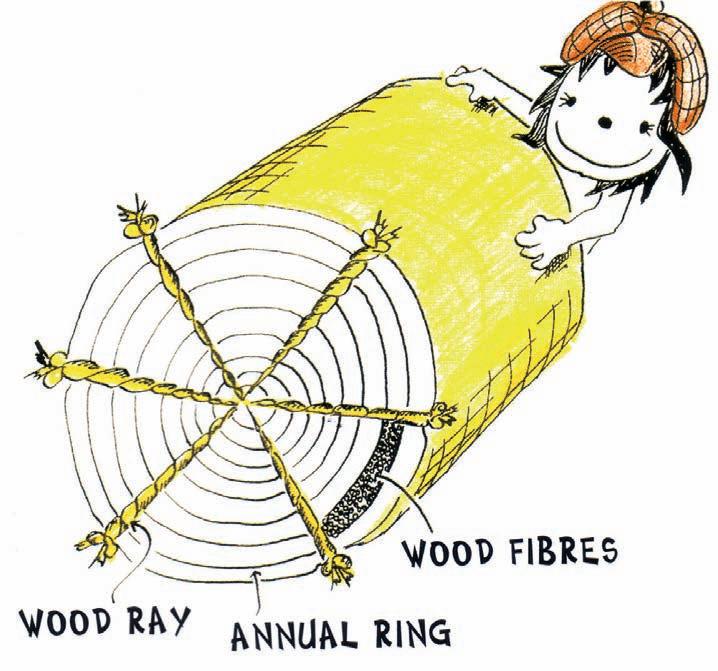

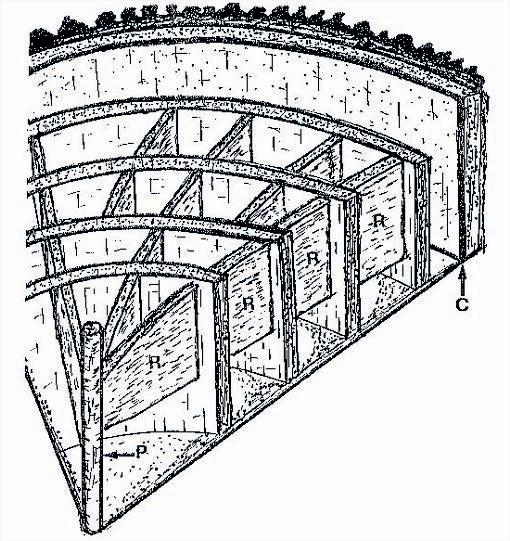

Soil compaction is a widespread problem that affects the health of various ecosystems and can have negative impacts on plant growth and overall soil health. Previously the best tool to combat this issue was the AirSpade. But a potent new proprietary technology from Germany has brought a whole range of new opportunities to tackle the problem.

Trees and shrubs get their sustenance from the area surrounding their roots, known as the rhizosphere. Their roots absorb water and nutrients through the root–soil interface structures, and even their ‘breathing’ is done through pores in the soil. However, this natural cycle can be disrupted by compacted soil, leading to a decline in vitality and the formation of deadwood. The VOGT Geo Injector can remedy this by using compressed air to loosen soil through a punctual aeration process. The injection tube applies adjustable pressure ranging from five to eight bar (72psi-116psi) and creates free spaces for soil additives, allowing

infusing it with essential elements like granulated fertilisers, adsorbents, soil conditioners and air, offering

soil structure and promotes nutrient cycling at a faster rate. Best of all?

The VOGT Geo Injector brings all of this to bear in a single pass. The operator can simply inject and go.

When soil becomes compacted, a tree’s natural cycle is disrupted, often leading to a decline in vitality, the formation of deadwood (and dormant soil microorganisms) and the start of the spiral of decline and loss of resilience.

The VOGT Geo Injector can help remedy these issues by using compressed air to loosen compacted soil through a targeted aeration process, allowing the operator to aerate the soil and inject a bespoke nutrient blend in a single application.

The device is mounted on a Plant Health Care (PHC) utility vehicle, which includes a 400-litre water tank, a fertiliser tank, and a Dosatron for adjusting mixes.

The VOGT aerator reaches deepseated, compacted soil layers, releasing compressed air to open sealed capillaries, while aeration holes are filled with a supporting dry-soil conditioner mix, removing stagnant moisture and allowing oxygen to reach the roots.

Valve-controlled trigger technology releases air suddenly, breaking up soil efficiently without physical exertion.

The technology used by the VOGT Geo Injector is recommended by Heritage Tree Care, the Australian company which has used the VOGT Geo Injector for five years and has begun distribution of the German innovation around Australia.

Heritage Tree Care’s plant-health research division is continuously working to improve arboriculture solutions, collaborating with credible agencies like Griffith University to conduct research trials assessing the beneficial effects of soil injections on trees in a variety of landscapes. Helmed by a microbiologist, an agronomist and arborists, the Heritage plant-health division believes the VOGT Geo Injector could change the game.

The VOGT Geo Injector has proven its effectiveness through real-world applications, having been extensively used by Heritage Tree Care in treating over 60,000 trees across major council projects throughout Queensland. Its success is evident in large-scale projects for councils such as the City of Gold Coast, Brisbane City Council,

Valve-controlled trigger technology releases air suddenly, breaking up soil efficiently without physical exertion.

and Toowoomba Regional Council. These case studies demonstrate the technology’s ability to address soil compaction and improve tree health on a significant scale, making it a reliable solution for urban and regional landscapes alike.

To experience the system’s capabilities or learn more about the plant-health applications, Heritage Tree Care is currently running workshops and demonstrations.

Learn more at heritagetreecare.com.au, or give the staff a call on 1800 353 053.

The device is mounted on a Plant Health Care (PHC) utility vehicle, which includes a 400-litre water tank, a fertiliser tank, and a Dosatron for adjusting mixes.

Established in 1994 and based in Queensland, Heritage Tree Care provides a comprehensive and professional arboricultural service that has its foundation in sound arboricultural practices and techniques.

The company strives to be the provider of choice for the arboriculture industry through reliability, delivery of high-quality outcomes and safe work practices.

Focused on sustainability and preservation, Heritage Tree Care works hard to maintain the highest standards of arboriculture and offer the utmost in tree care and land management, with Level 3 to Level 5 arborists fully trained to ensure quality workmanship.

Heritage Tree Care is committed to caring for the environment and dedicated to:

• Setting environmental strategies for areas that could have any kind of environmental impact within the operation of the company

• Minimising the emission of polluted runoff, dust and noise from site offices, facilities and equipment by use of maintenance and protective measures

• Setting specific documented procedures for the company’s objectives and targets for environmental impact, and

• Supporting ecologically sustainable development on all projects.

The VOGT Geo Injector allows for immediate enrichment of the soil to depth, fast tracking the transition of nutrients and making it ideal for urban tree management, landscaping and agriculture.

Socage Raptor spiders and truck-mounted EWPs are now available in Australia through trusted distributor, Altequip.

As highly experienced travel-tower and spider operators, Altequip knows firsthand the importance of quality and reliability when working at heights and is happy to bring Socage’s cutting-edge products to the eager Australian market.

Included in the Italian company’s innovative range are Raptor spider machines, delivering exceptional lifting capacity and versatility in a range of models, right up to the impressive truckmounted TJJ100 100m.

With advanced safety features and intelligent control systems, Socage sets the global standard for performance and precision.

The Raptors are spider boom lifts in a range of sizes, two of which especially suit the Australian arb market: the 18 S and the 21 S.

With a maximum working height of 18m and 20.80m respectively, the

18 S offers a maximum lateral outreach of 8.20m, while the 21 S reaches out to 10.3m.

The basket payload of both is 230kg (two operators + material) in the whole working area without any limitation, and both lifts are fitted with automatic stabilisation and automatic closing for easy and safe use.

Sustainability of the platforms was incorporated in the design and manufacture, and both offer

• Zero emissions

• Bi-energy as standard (an additional diesel engine incorporates a 230V electric motor that allows working without emissions, essential in some enclosed spaces)

• Three different travel speeds, and

• Exceptional manoeuvrability, thanks to 380º rotation and the hydraulic jib with double articulated arm.

Both lifts are lightweight and equipped with extendable, white, nonmarking tracks for better stability when

The 18 S and 21 S are among the best performing and most compact tracked lifting platforms of their size available. Images: Altequip

moving the machine, and the pair are among the best-performing and most compact tracked lifting platforms of their sizes available.

Altequip will soon have available the Raptor 35 S Socage tracked spider in addition to the 18 S and 21 S, and currently has in stock both the 37DJ Speed and 32DJ Speed truck-mounted platforms.

And as far as after-sales service and maintenance goes, Altequip utilises the experienced Access Service Australia team across Australia and New Zealand to meet its service and maintenance requirements, and has direct factory support from Socage in Italy.

Customers can rely on the strength of the three companies to support Socage machine requirements throughout Australia and New Zealand.

See the Socage range at altequip.au.

Altequip utilises the experienced Access Service Australia team across Australia and New Zealand, and has direct factory support from Socage in Italy.

Altequip was formed with the primary focus of bringing the Socage product to the Australian market. Committed to bringing a high-level of sales experience, with industry knowledge and understanding of a wide variety of users’ requirements, Altequip ensures the client is always the centre of operations.

Customers of Altequip can be confident when choosing the Socage product thanks to full-factory warranties and service support from Access Service Australia. Altequip also carries a high level of consumables, spare parts and sensors for all machines in the country, but also utilises express global drop shipping from the Socage Factory to ensure the absolute minimal time from order to delivery.

Altequip is excited to be bringing the Socage products to Australia and welcomes enquiries.

Socage Raptor 18 S and 21 S features

Hydraulically expandable undercarriage

White non-marking tracks

Electric hour counter

Manual hand pump

230V electric socket in the basket

Multifunction remote control

Auxiliary electric pump 230V-50Hz

Flanged holding valves

Diesel engine

Automatic closing

Automatic stabilisation

Outrigger plates

The 21 S has a maximum working height of 20.80m, and both lifts offer exceptional manoeuvrability, thanks to 380º rotation and the hydraulic jib with double articulated arm.

Working at height is a daily reality for Australian arborists. This article explores some key methods for improving safety when working at height, with a focus on the benefits of using Mobile Elevating Work Platforms (MEWPs) equipped with advanced safety features like Niftylift’s ClipOn and SiOPS systems.

Ensuring operator safety is a critical priority when working at heights. Images: Niftylift

Whether pruning, performing maintenance or clearing hazards, arborists face inherent risks working at heights. Ensuring operator safety is a critical priority, and modern equipment, safety protocols, and innovations have made significant advancements in mitigating these risks. Here are a few important factors affecting operator safety.

The foundation of any safe work environment is operator training. In the arbor industry, training isn’t just about knowing how to cut branches safely, but also about how to use tools and equipment effectively. Arborists must complete working-at-height certifications to ensure they are aware of the risks and are trained in both rescue and emergency procedures. Additionally, they need specific training on the safe operation of MEWPs. Understanding how to manoeuvre the machines, position them correctly, and assess the work environment is vital for reducing risk.

While PPE is the last line of defence, it’s a crucial part of any comprehensive safety approach.

PPE plays a significant role in protecting arborists from injury. Arborists should always wear helmets with visors or face shields, hearing protection, gloves, chainsaw protective clothing, and safety boots with reinforced toe caps. High-visibility clothing is also essential, especially in environments where other vehicles or equipment are in operation. While PPE is the last line of defence, it is a crucial part of any comprehensive safety approach.

In traditional tree climbing, arborists use harnesses, ropes, and pulleys to access high branches. However, as the industry increasingly adopts modern equipment, harness systems are also used in conjunction with MEWPs. This provides an extra layer of fall protection. Niftylift’s ClipOn Harness Attachment Detection System takes this one step further by ensuring operators are securely attached before operating the MEWP. ClipOn detects whether the operator is correctly harnessed and restricts the platform’s movement if a proper connection isn’t detected. This feature is essential in ensuring compliance with safety standards and minimising the risk of operator error.

MEWPs have transformed the way arborists work at height. Not only do they provide stable platforms, but they also allow operators to work in difficultto-reach areas with enhanced safety and efficiency. MEWPs reduce the need for climbing trees or using ladders, both of which present greater risks of falls and injuries. For arborists, the ability to position themselves safely and precisely while operating heavy-duty cutting tools is invaluable.

Niftylift’s range of MEWPs is particularly suited for the arbor industry due to its lightweight design and advanced safety features. The SD170 and SD210 self-drive platforms are ideal for tree-care professionals. These versatile machines offer excellent manoeuvrability, even on rough terrain, while providing the reach and stability needed for working at height. Their compact design allows easy access to confined spaces, while outriggers ensure a stable working platform, even on uneven ground. This makes the SD170 and SD210 perfect for the diverse challenges encountered in the arbor industry, where both height and terrain can vary greatly.

One of the key risks when using MEWPs is operator entrapment, where the operator could become trapped between the machine and another structure, leading to serious injury.

Niftylift’s SiOPS (Sustained Involuntary Operation Prevention System) is designed to prevent injury if an operator should become trapped between the machine and another structure.

Niftylift’s SiOPS (Sustained Involuntary Operation Prevention System) is designed to prevent this. SiOPS instantly stops all machine functions if it detects the operator has been pushed against the controls. This feature offers an essential layer of protection, particularly when working in dense environments, such as near tree trunks, branches, or other obstacles commonly encountered in arbor work.

Safe working at height in the Australian arbor industry relies on a combination of training, protective equipment, modern technology, and comprehensive planning. MEWPs, with innovations like Niftylift’s ClipOn and SiOPS systems, provide arborists with the tools they need to work more safely and efficiently. By adopting these advanced solutions and continuing to prioritise safety in every aspect of their work, arborists can minimise risk and focus on maintaining Australia’s urban forests and natural environments.

For more on Niftylift’s MEWPs, visit niftylift.com.au.

The new machine was presented at the European trade shows during September.

The platform is equipped with advanced automatic-stabilisation technology that ensures safety and precision. The S20 is shown here working at the Bari-Karol Wojtyla International Airport. Images: CMC

A global leader in the design and production of tracked spider aerial platforms, CMC was founded with the goal of offering innovative and highly specialised solutions for aerial lifting. CMC has quickly established itself as a reference in the industry, thanks to its ability to combine cutting-edge technology, safety, and reliability.

See the CMC range at cmclift.com/en/.

SA maximum outreach of 10.4 metres at full load in the basket makes the S20 ideal for a wide range of applications, like this task at the

eptember was packed with events for work-at-height professionals across Europe, and CMC was proud to launch its latest innovation, the CMC S20 platform, during the major trade shows:

• Platformers’ Days - Karlsruhe Trade Fair Centre (Germany)

• Vertikal Days – Newark Showground (UK)

• GaLaBau – Nuremberg (Germany), and

• APF 2024 – Ragley Estate –Warwickshire (UK).

The events offered the perfect opportunity to showcase a machine that combines superior performance, versatility, and advanced safety, occupying a unique spot in the 20-metre platform segment.

The CMC S20 stands out for its compact design without compromising on strength and functionality.

With a total weight of 2980kg and small dimensions, it is ideal for working in complex work environments, such as congested urban areas and construction sites with limited space. Also, because the S20 can run electrically, it can operate safely and quietly in indoor and enclosed sites. The platform is equipped with a 90°+90° rotating two-man basket with a quick-release system, enabling fast installation and removal, ensuring safety and convenience for two operators and their tools, with a maximum load capacity of 230kg.

Despite its compactness, the CMC S20 offers exceptional performance thanks to its geometric design, and with a maximum working height of 19.9 metres and a maximum outreach of 10.4 metres at full load in the basket, it is ideal for a wide range of applications, including arbor and tree work, building, electrical installations, pruning, and it can comfortably and safely perform all these functions both indoors and outdoors. The platform is equipped with advanced automaticstabilisation technology that ensures safety and precision even on uneven terrain, allowing the outreach to be fully utilised regardless of the basket load.

Alessandro Mastrogiacomo, CEO of CMC, stated: “A new era begins for tracked spider aerial platforms, since with the launch of the S20, CMC marks a significant evolution in the field of geometric double-pantograph platforms. The combination of advanced technology, compact design, and attention to safety makes the S20 an ideal choice for professionals looking for a versatile, reliable, and durable solution. Whether it’s maintenance, construction, or specialised interventions, the S20 is ready to meet the most demanding challenges, offering high-level performance without compromise.”

CMC S20 features

• Honda iGX390 petrol engine

• Hydraulically width-adjustable black rubber tracks

• Two-man basket equipped with quick-release system and wheels

• 200 Bar air/water hose in the basket

• 230V/120V/110V and 12V electrical socket in the basket

• Protective covers for outrigger cylinders

• Display with error-code detection

• Proportional hydraulic controls

• Proportional travel mode by radio remote control

• Lifting hooks

• Fixing points for transport

• Triple travel speed

• Automatic outrigger levelling

• Standard painting (RAL 3000)

• 24-months warranty

• Max working height: 19.9m

• Max outreach: 10.4m

• Height at floor level: 17.9m

• Max weight in the basket: 230kg

• Basket dimensions: 1.4m x 0.7m x 1.1m

• Basket rotation: +/-90°

• Turret rotation: +/- 180°

• Total weight: 2980kg

Rayco stump grinders are engineered to deliver superior performance, reliability, and ease of use. Images: Monitor Group

In the demanding world of arboriculture, efficiency and reliability are non-negotiable. That’s where Rayco’s range of stump grinders steps in to set a new standard, delivering innovative solutions that cater to the diverse needs of Australian arborists.

Rayco stump grinders embody a commitment to innovation and excellence. Each model is engineered to deliver superior performance, reliability, and ease of use, and the integration of advanced technology with practical features ensures arborists can work smarter, not harder.

Monitor is passionate about importing machines to provide the world’s best equipment and local backup service and parts support. In turn, this is supporting arborists in their quest to increase efficiency and excellence in their businesses.

Whether you’re dealing with tight urban sites or extensive land clearing, Rayco’s stump grinders provide the power and precision needed to get the job done right.

Here’s a quick rundown on three great Rayco models available for purchase or hire through Monitor.

To see more of the Monitor range of machinery and equipment, log on to monitor.net.au.

RG55T-R petrol stump grinder

Fuel tank: 32.0 litres

Cutter wheel: 51cm x 4.0cm

Cutting depth: 36.0cm

Cutting height: 62.0cm

Cutting width: 152.0cm

Power: 53.4hp Kubota engine

Weight: 1524kg

Width: 89cm

RG37T Trac petrol stump grinder

Fuel tank: 37.8 litres

Cutter wheel: 43.8cm x 2.5cm

Cutting depth: 44.5cm

Cutting height: 62.2cm

Power: 37hp Vanguard

Weight: 839kg

Width: 89cm

Rayco RG37T: compact powerhouse

For those navigating tight spaces and urban environments, the Rayco RG37T is a game-changer.

This compact yet powerful stump grinder is designed for manoeuvrability without sacrificing performance.

Equipped with a robust 37-horsepower engine, it combines agility with strength, allowing arborists to tackle stumps in confined areas with ease. The RG37T’s advanced hydraulic system ensures precise control, making it an indispensable tool for projects where precision is key.

Rayco RG55T-R: versatile workhorse

When versatility and durability are required, the Rayco RG55T-R stands out. Featuring a 55-horsepower engine and a user-friendly design, this model is ideal for both small and mediumsized stumps. Its innovative cutting technology offers a blend of speed and efficiency, significantly reducing grinding time. The RG55T-R’s reinforced frame and high-torque performance make it a reliable choice for demanding tasks, ensuring arborists can handle a variety of stump sizes and soil conditions with confidence.

Rayco RG80-R: the heavyweight champion

For the most challenging jobs, the Rayco RG80-R is the ultimate solution. With a formidable 80-horsepower engine, this stump grinder is built to handle large and stubborn stumps with remarkable ease. Its heavy-duty construction and advanced cutting system provide unparalleled power and durability, making it the go-to choice for professional arborists dealing with large-scale stump removal. The RG80-R’s efficiency is matched by its operator comfort, thanks to its ergonomic design and intuitive controls.

RG80-R petrol stump grinder

Fuel tank: 39.0 litres

Cutter wheel: 58.4cm x 3.8cm

Cutting depth: 53.3cm

Cutting height: 50.8cm

Cutting width: 165.1cm

Power: 85hp Ford engine

Weight: 1465kg

Width: 91.5cm

Exceptional after-sales support elevated Charlie Milone’s experience with Bandit.

W

hen it comes to running a successful tree-chipping business, having reliable machinery is just one piece of the puzzle. For Milone’s Tree and Lawn Solutions, trustworthy after-sales support has been a major reason in choosing Bandit and the national dealer, Tree Care Machinery.

The family run business in Melbourne purchased its first Bandit machine in 2022 – a 12X chipper – and since then has taken delivery of a variety of Bandit chippers and Bandit stump grinders. Today, Milone’s has expanded its fleet to

five Bandit machines, with a new SG-75 stump grinder and Bandit 15XPC arriving this month. Milone’s owner Charlie Milone said Tree Care Machinery’s commitment to quality and customer care resonated with his business values as soon as he walked through the door.

“From our first inquiry to the final purchase, the team at Tree Care Machinery demonstrated unparalleled professionalism and knowledge,” said Charlie. “They went above and beyond to ensure we had all the information we needed to make an informed decision.

“From their unwavering commitment to quality and their dedicated customer

service, to the exceptional performance of their products, we can confidently say Tree Care Machinery has set a high standard in the industry.

“When we purchased a wood chipper from Tree Care Machinery, we were not only impressed by the quality of the product, but also by the level of support we received after the sale.”

Charlie had previously dealt with other woodchipper brands in Melbourne, but said his experience with Tree Care Machinery has been nothing short of exemplary, highlighting the critical role

after-sales support plays in the longevity and efficiency of his business operations.

Charlie recalled a particular incident that stood out as a testament to TCM’s commitment to its customers.

“We reached out to TCM’s after-sales support people, and they promptly sent out a mechanic to diagnose and resolve the problem. The professionalism and efficiency with which they handled the situation were commendable. Not only did they fix the issue promptly, but they also provided us with valuable maintenance tips to prevent similar problems in the future.”

It’s this kind of comprehensive support Charlie believes sets Tree Care Machinery apart in the industry.

“TCM’s after-sales support didn’t end with just issue resolution. The company followed up to ensure everything was still running smoothly and offered additional resources for maintenance and care.

“The after-sales support from TCM has been instrumental in ensuring the optimal performance and longevity of the machinery we have purchased.”

The five Bandit machines in the Milone’s fleet have proven to be reliable and efficient performers. All Bandit machines are built in America, which

a top-quality product.

“The lift-and-crush features within the Bandit chippers ensure premium performance when processing large materials,” he pointed out, “and Bandit is an employee-owned model which aligns with our core values.”

Other impressive features of the 18XP chippers include:

• Forestry discharge

• A 142HP CAT engine and heavy-duty feed system, and

• A throat opening of 19.75"h x 20.5"w.

Charlie started his business after returning from service in the Australian Defence Force and has turned a humble idea into a thriving family run business

based in Melbourne’s western suburbs.

“Milone’s specialises in tree removal in the commercial, government and private sectors. We also specialise in residential pruning as well as cyclic and reactive pruning for local councils, as well as stump grinding,” said Charlie.

“Customers can expect Milone’s to stand apart from the competition because of our expertise in tree removal and commitment to customer service. We are dedicated to, and pride ourselves on, providing our customers with quality, professionalism and customer care, and this is what really sets us apart from our competitors.”

For more, visit treecaremach.com.au and milonestreesolutions.com.au.

Tree contractors should be aware that the Fair Work Legislation Amendment (Closing Loopholes No. 2) Act 2024 (Cth) (‘Closing Loopholes No 2 Act’) received Royal Assent on February 26, 2024. The Closing Loopholes No 2 Act significantly amends the Fair Work Act 2009 (Cth) (‘FWA’) and includes the following changes with respect to casual employment:

• It repeals the existing definition of ‘casual employee’ in s.15A FWA and introduces a new definition that includes a ‘general rule’ and ‘indicia’ in assessing whether

the employment relationship is characterised by an ‘absence of a firm advance commitment to continuing and indefinite work’, and takes into account the totality of the employment relationship;

• It clarifies that an employee engaged as a casual employee will remain a casual employee until the occurrence of a ‘specified event’;

• It replaces casual conversion arrangements with a new pathway for employees to change from casual employment to full-time or part-time employment through ‘employee choice’. Casual employees may provide their employer with written notification if they believe they no longer meet the requirements to be a casual employee, and such notification can be provided after six months (if the employer is not a small business) or 12 months (for smallbusiness employers) of employment;

• It replaces the process currently set out in s.66M (Disputes about the operation of this Division) with a new

process for resolving disputes about changes to casual employment; and

• It outlines additional obligations for employers in relation to the Casual Employment Information Statement, establishing an anti-avoidance framework in relation to sham contracting of casual employees to deter employers from engaging in tactics to avoid the new provisions.

The above changes take effect from the full first period on or after August 26, 2024.

The Fair Work Commission (‘FWC’) is currently reviewing the interaction between the changes to the FWA concerning casual employees and modern award terms. The FWC has expressed provisional views in relation to variations to modern award casual terms that variations are necessary to resolve potential uncertainty and difficulty in interactions between existing modern award provisions and the amended FWA.

Although the FWC published a sample of draft determinations reflecting its provisional views, final determinations varying modern awards have not yet been published. Any variations made by the FWC will commence on the date specified in the determination (which may be a day before the determination is made).

A new Casual Information Statement has been issued and is available from TTIA. Further information expanding the changes was discussed during TTIA’s Member IR briefings recently held in various states.

If you are not a TTIA Member and need assistance in developing policy in relation to these issues, or require further information, TTIA is ready to assist. Phone the TTIA office on (02) 9264 0011, or email ttia@ttia.asn.au, for information on becoming a member.

Available to demo and buy! Powered by a 365 HP QSL9 Cummins, the Bandit 20XPHD has landed in Australia. A huge 22-inch feed capacity makes any large-scale job a breeze. Enquire today!

TCAA regular Jim McArdle delves into a topic which deserves far more attention from arboriculturalists.

Infrastructure must, over time, affect tree health. Images: TCAA

The best type of soil for trees? Loam is probably a reasonable guess, and soil with a large humus content.

With suitable environmental conditions this type of soil hosts a thriving mass of beneficial microbes and macro-organisms suitable for root colonisation and stabilisation.

While reviewing literature on new products that can assist the beneficial role microbes play within the rhizosphere, the TCAA came across a few golden ones. Nutrogs Popul8, Bushtucker, Osmocote Native, Biodynamic 500 and other natural conditioners for native trees with low phosphorus requirements have taken the remedial world by storm and help create the best conditions within the root zone for growth and development of the tree’s root systems.

Humus content assists soil moisture capacity and increases soluble-nutrient

uptake. It’s ideal when clearing or compaction is limited or non-existent, and will, in turn, lead to growth of fungal hyphae and so on, allowing an increase in nutrient supply and improved soil structure.

Fungi are the heavy lifters in soil. All trees have relationships with fungi, and use of glyphosates destroys the soil biota which contain the hyphae mycelium. Bacteria evolved with us, and the only issue with bacteria is that it should be in the right place. Some bacteria from the garden are good for human immune systems, while common bacteria like M.vaccae acts as an antidepressant, increasing hormones like serotonin and norepinephrine in the prefrontal cortex. Maybe this will bring a new rush of sustainability arborists who want to feel good about their job?

There was also a saying: ‘Anything that’s

biological does eventually kill you’, but that’s no surprise. Everything in Australia can kill you, so prioritise your risk.

Nematodes – or ‘microscopic eel worms’ – colonise pests like slugs, weevils, leather jackets, grubs, and codlin moths. After a lightning strike and rain they release a chemical which can be bad for attacking roots, allowing entry to disease and decay.

Hyphae are the superglue which holds the soil together. Glomalin (from fungi) can last over 40 years in soil, but was invisible to science until around 25 years ago. That was partly as it was treated as a stable component and thought inert. But the slow depletion that stores carbon does most of the bonding in soil.

Excavation in soil can change the soil biome as hyphae strands are cut, and exposure to air can kill a lot of microbes beneficial to the soil.

We know nitrogen is replenished though lightning and legumes (the Fabaceae and bean family). Mimosa, Alder, Redbud, Autumn Olive, Kentucky Coffee Tree, Golden Chain Tree, Acacia and Mesquite are examples of trees that support nitrogen in soil with the help of bacteria. The Azolla tree fern fixes nitrogen with cynobacterium and is used for remediation sites where it’s shown excellent results removing metals like zinc, cadmium, copper and lead. Allocasuarina sp. and Casuarina sp. also fix nitrogen and so can Alnus sp (Alder) and Betula sp (Birch). Cynobacteria can be utilised in conifers, ginko and cycads. Nitrogen is generally an expansive – if not explosive – gas that can increase soil fertility as it’s utilised to create proteins, nucleic acids and other compounds.

Leaching can occur where the soil has been excavated.

We all understand working the soil continuously will reduce fertility and eventually damage the soil. Losing

carbon, losing structure and erosion are troublesome issues.

The moron principle applies to spraying trees with glyphosates, especially natives that thrive on low phosphate soils and affect soil fertility. Glyphosates actively compromise the fungal colonies of soil and reduce soil microbes and the amino acids synthesised by them. Glyphosate also interferes with the shikimate pathway found in all plants, some fungi and bacteria, but not in animals. Thus, glyphosate has a non-selective, broadspectrum herbicidal activity.

After application to plant foliage and subsequent uptake by leaves, glyphosate is transported through the phloem to actively growing tissues like roots and storage organs. Glyphosate may be an additional nutrient source, stimulator of enzyme activity, and promoter of growth for certain fungi species, but negative effects on soil microbiota include reduced root mycorrhization and increased colonisation of Fusarium species. Ecotoxicological effects include

severe growth reduction, chlorosis and phytotoxicity, especially during the early stages of plant development.

A study suggested a limit on the drift dose of glyphosate to five per cent based on a species sensitivity distribution performed to avoid biodiversity loss. We can gauge the education level of the outdoor ground assistant or gardener at most sites we visit. For example, if there is a beautifully crafted ring of lawn cuttings around the base of trees which is increasing temperature around the stem and causing elevated levels of grass-type chemicals which ultimately cause damage and in some cases root rot or stem canker, we assess the groundskeeper’s horticultural training accordingly.

‘Nature positive’ is a term used to describe circumstances where nature – species and ecosystems – is being repaired and is regenerating, rather than being in decline as described by Tanya Plibersek, Minister for Environment

and Water. In her words, the current conservation strategy is ‘failing’. Offset arrangements are failing to prevent environmental decline as they don’t properly compensate for the loss of habitat values.

From a political viewpoint, naturepositive bills are creating two new agencies: the Environment Protection Australia (EPA), an environmental regulator and watchdog; and Environment Information Australia (EIA), an environmental bureau of statistics. Will the consultant eco-arborist be a tool for the new conservation laws?

It’s painful to imagine another level of policing, but maybe consulting in panels for local councils is a specific role where an eco-arborist with specialised knowledge can assist the ecologists and compliance roles in council.

Insecticides and herbicides also aim to interfere with biological functions, and unless it’s within a crisis like a psyllid plague or breaking of a cyclic attack, we should rarely issue a specification without considering the alternatives.

Where an old tree is cut down the subterranean soil microbe community gets attached to the previous tree and turns ‘deadly’ – a bit like when a pharaoh died and the subjects all died when buried with the king. So, replenishment is more difficult on an old stump space and should be avoided. Good results happen if we dig up volumes of soil around the tree or bring in new soil. The

chemicals released, exudates, are still a new area of science. Root tips exude phyto chemicals such as flavonoids, carotenoids and polyphenols, as well as sugars and amino acids. With this sort of action in the soil, trees farm microbes.

One of the unfortunate ways of reducing carbon is land or brush clearing. These are actions which decimate the soil microbial hierarchy so more solar gain is made and wind micro currents change, inducing moisture loss and, in turn, reducing tree and undergrowth capacity and growth. The agroforestry systems could be better at replacing nutrients exported and add nitrogen, inorganic and organic sources and soil conditioners.

There has been a growing disconnect between people and trees and vegetated spaces, particularly for those living in cities. “Many people have become so focused on urban survival they’ve become distanced from the essential and intimate dependence human beings have on plant life,” said Greg Moore on theconversation.com. My thought is urbanites are actively against all forms of space-taking plants and that a Lorax with teeth is needed in the compliance teams of several compliance-issuing bodies.

The programme of lecturing our urbanites is a constant education burden where the AQF3 and AQF5 wave the flag of tree health and growth in the natural environment.

How do we get genuine interaction of the natural environment and humans? Tree climbs, Earth Garden magazine, Saturday morning TV with Costa, Don’s Backyard, Graham Ross Garden Show, landscape shows which bring a new garden…all these things help. Within our design teams they require increasing input dialogue and specification for how we can ensure TPZ edging encroachments are not damaging the ground within the rhizosphere and roots’ zone of influence. Town-planner design teams are adamant that communal facilities within the cities are built. We should be making riparian connectivity adjacent to our roads. Not patches of forest, but rainforest hamlets, tree cities and forest infrastructure – more green, less sheen.

One of the wonders of the tree world is the mangrove tree. It lives in the saltiest, plant-intolerant location and thrives due to adaptions called pneumatophores or air breathers which are modified roots that exchange gasses.

Blue carbon is the sequestrian of biological driven carbon fluxes and storages in marine systems. The term most commonly refers to the role tidal mangroves, marshes and sea-meadows can play in carbon sequestration. When the blue-carbon ecosystems are lost, they release carbon back to the atmosphere, adding to greenhouse gas emissions.

When maintaining carbon discussion and credits we should remember our ‘Dojo of life’ which is the green carbon.

Green carbon is the carbon found in plants and soil of the natural ecosystem. The cross between these is cyan family colours which are the interaction of these two natural places. The blue-green (cyan) interfaces where algae, bacteria, fungi and microbes are the new sequesters of carbon.

Given that in his book SOILS, Matthew Evans stated, ‘…there is three times more carbon in soil than in air’, it makes you think soil is a better storer of carbon than trees. But that’s not the case. Trees are mostly carbon and water and are a product of the soil.

What can the urbanites learn from this?

They also are living in intolerant conditions, with low bacteria which makes it difficult for them to be happy, low oxygen so they’re half alive, and low sunlight so they have frail bones. The theory then should apply where there are healthy, abundant gardens and forest for habitat, where we are able to increase environmental conditions – green culture and green infrastructure – and reduce hard surfaces which reflect heat and reduce soil and the biome of activity that connects us with nature, we’ll be healthier. Hard surfaces and light reflective colours like white can increase heat affectation in nearby trees.

Let’s ponder: ‘how do we get learning institutions to be more appropriate to eco-arborist education?’

AIR-SPADES® are in use in arboriculture, utility, construction, and industrial applications worldwide. AIR-SPADE is the tool of choice due to its fast, non-destructive method of excavation.

Flows from 25cfm to 330cfm.

• Ideal for Bare Rooting

• Radial Trenching

Some of the iconic Moreton Bay figs (Ficus macrophylla) in Perth’s Hyde Park had become infested by the PSHB. ArbWest and the WA arbor community banded together to assess the infestation in the hope some or all of the trees could be saved. Images:

Dave Crispin, senior arborist at Treeswest Australia and Arboricultural Association of Western Australia (Arb West) committee member, was rapt to see the arborists of WA unite in time of need.

I have never been one for cliches, but in this case it is warranted: our industry is like one big family.

We all care for our trees. There’s no disputing that, and when it came down to a request for our local arborist community to volunteer their time on a Saturday, we were overwhelmed by the response.

PSHB action

Over the past year I’ve included various updates on a tiny borer that’s creating a great deal of concern and heartache disproportionate to its size. The Polyphagous Shot Hole Borer, or PSHB for short, is a beetle approximately 2.0mm in length. It’s tiny compared to the huge impact it’s having on our urban canopy.

An estimated 6000 trees have become infected – of which 3000 have now been removed – in only three years. Many historical and culturally significant trees have had to be removed, several in some of Perth’s most prominent locations, and it was at one of these high-profile locations, Hyde Park, we were asked to help. At least five

Custom build chippers from the Netherlands available on:

TRACKS

TRAILER

HOOK LIFT

PTO VERSIONS

FROM 12 TO 36 INCH

75 TO 900 HP

Ufkes Greentec Australia Victoria | +61 458 047 132

A sticky white latex was applied over the tiny hole or holes to see if the beetle would emerge.

Ficus macrophylla, the iconic Moreton Bay fig, had become infested by the borer and there was a slim chance that if assessment deemed the infestation level ‘low’, removal of the trees could be delayed, or they could even be saved.

The process was fairly simple, but labour intensive: we needed as many people as possible, including experienced climbers and ground staff to make the event work.

Our association, ArbWest, organised the event in conjunction with the City of Vincent (a local government area outside Perth) and the Department of Primary Industries and Regional Development (DPIRD). Like all our events, a sub-committee was formed, led by Joe Carriera from Beaver Tree Service, myself, and Matt Clark from the City of Canning.

As the DPIRD is still in the eradication phase of dealing with the borer the

strategy has been mainly one of removal, which is part of the mandate, but has meant a huge cost to Perth’s already dwindling urban canopy. With so many trees already gone, if we were able to assist in assessing some of the trees, and the infestation loads were deemed low, there may have been a chance to rethink the removal strategy.

Maybe this could be replicated on some of the other significant trees?

This was of course dependent on the DPIRD.

Working under the direction of the DPIRD and Ben Phillips, a researcher from Curtin University, the data collected would be used as part of a bigger initiative in predicting spread.

We set the date for 6.45am Saturday, August 10. By then the DPIRD had agreed to attend the event and as part of its public awareness campaign, to inform the local community about the borer, the City of Vincent to show it was being proactive in managing its canopy

and ArbWest was to bring everything together.

From the outset, the day attracted a considerable amount of interest from local and mainstream media. Nothing like it had been attempted before, and to my amazement we had 45 people turn up, a mixture of male and female, locals and people willing to lend a hand from out of town.

As usual, our industry has its diehards, the people you can count on time after time, and they did not disappoint this time either.

I have nothing but praise.

We decided to tackle three of the trees, dividing each one into quadrants using the cardinal points as reference markers. Each climber would work in one quadrant with a corresponding colour. This was consistent throughout the three trees.

For north we allocated green, red,

The process was simple, but labour intensive. Experienced climbers and ground staff were needed to make the event work.

yellow then blue. These were coloured surveyors’ flagging tapes. Once the climber had a positive identification of a hole, the tape was tied around the limb and logged by the ground crew. As the climbers worked methodically throughout their quadrant they would flag the hole or holes, write the distance from a central stem, and then the number of holes on the flagging tape in permanent marker. The climber then painted a sticky white latex over the tiny hole or holes to wait and see if the beetle would emerge.

These were checked by the rotating climber later that morning and the information made available to Ben Phillips (the Curtin University researcher).

I am pleased to say it worked a treat!

Pascal Oosterik

Although this was a serious business and extremely important, it was great fun. No personalities or egos surfaced and the veteran climbers helped out the less experienced (every climber had to have a minimum of Cert III in arboriculture to be allowed to climb), and there was even an opportunity to show off some of our new gear –after all, we’re attracted to the latest, shiniest, fastest and generally mostexpensive pieces of kit – aren’t we?

Several of Western Australia’s top climbers turned up, ones that regularly feature high up in the climbing

competitions. One in particular was Pascal Oosterik.

I’ve known Pascal for a number of years, and at 29 he’s worked in more countries and states than most people will ever visit in their lifetime. Originally from the Netherlands where he completed a degree in forestry, Pascal went on to work in the United Kingdom, United States, British Columbia, and a small country called Aruba. Having climbed countless species and being tasked with a variety of challenges, climbing in a large Ficus and painting white latex on borer holes was to be just another one.

I asked Pascal what sort of challenges or other interesting experiences he’d had while climbing trees. He smiled and recalled two occasions. One was when he was climbing in the rainforest in Queensland and became hooked up for ages by a climbing palm called Wait-awhile (Calamus Australia). The plant is covered in spikes that hook into skin and clothing, making it almost impossible to break free, hence you have to wait more than a while to become untangled.

The second (and a big smile came over his face when he related the story) was being bitten by green tree ants (Oecophylla smaragdina). “If you weren’t getting bitten at least 100 times you weren’t really trying,” he said. He recalled they would regularly drop out of the trees and bite him in every orifice.

Ouch!

As I write this in early September 2024, the DPIRD has removed the quarantine areas and has now named them zones. Perth and the surrounding suburbs are Zone A. Outside Zone A, is Zone B, an area currently with little or no infestation. This is looked at as a buffer to try and contain the borer, and my understanding is this zone is going to be heavily monitored and infestations dealt with as quickly as possible when they arise.

We don’t have a playbook for this, and it’s been extremely stressful and challenging for all stakeholders. We’ve had to make it up as we go along. One positive that has come out of this is the need to work together. Collaborations are a must, and the sharing of information is paramount. It’s the only way we will manage this pest.

Fortunately, for us, we have the benefit of hindsight. Fellow arborists, researchers and academics in Southern California are willingly sharing their experiences and knowledge so we may be better placed to lessen the impact.

Our industry is like one big arborist family!

The Queensland Arboricultural Association oversaw a blinder of an event with the 2024 Queensland Tree Climbing Championships at Mount Tambourine in Queensland in September.

Set against the stunning backdrop of Mount Tamborine, the Queensland Tree Climbing Championships (QTCC) 2024 took place on September 7th and 8th, and what an unforgettable weekend it was! Over the two days, 28 highly skilled competitors battled it out for the prestigious title of Queensland state champion, with their eyes on mastering both skill and precision.

Incredible efforts from all participants overcame a few technical hiccups which were quickly sorted thanks to the assistance of Lee from Arb Connect. After a thrilling first day, the finalists were announced for the Masters’ Event, with Jarrah Hamlin, Jamie Boston, Terry Boston, Rory Haydock, Jess Hamer, and Julia Steele earning their spots in the final showdown.

Sunday brought even more excitement as the world number-one climber, Barton Allen-Hall, performed a breathtaking demo climb. Spectators from the local Mount Tamborine Country Markets were captivated by his skill, while the top four male and top two female competitors from the Saturday rounds prepared to take on the Masters’ Event. As if the competition wasn’t intense enough, competitors were greeted by some feisty local magpies, adding an unexpected challenge to the day!

The QAA owes a special thanks to the Mount Tamborine showgrounds for hosting us in such a picturesque setting, and to the Country Market attendees for their enthusiasm in watching and supporting the talented, qualified arborists. It was an excellent opportunity to highlight the importance of using tradequalified professionals for tree care.

The final tally saw tight competition and razor-thin margins, with the places going to:

Males:

• 1st: Jamie Boston (210.33)

• 2nd: Jarrah Hamlin (211)

• 3rd: Rory Haydock (183)

• 4th: Terry Boston (115.67)

Females:

• 1st: Jess Hamer (115.67)

• 2nd: Julia Steele (40.33)

Major event sponsor, Husqvarna, was instrumental in making this event a success. We’re incredibly grateful for Husqvarna’s ongoing support, including its contribution to the female perpetual shield. Special thanks also go to Inspiration Trees (Nick Batson) for organising the beautifully crafted perpetual trophies, which truly added a touch of elegance to the event.

We extend our deepest gratitude to all our trade sponsors: Arb Connect, Arbor Industrial, Husqvarna, Inspiration Trees, Professional Tree Works, Reecoil, Shockload Bags, The Arbor Van, and Vermeer. Your generous donations, both in prizes and support, were invaluable and deeply appreciated by the competitors and the wider community.

Lastly, a heartfelt thankyou to our volunteers, the backbone of this event, braving the sun all day with stopwatches and clipboards in hand, some cooking the BBQ and never complaining, and always staying to help pack up. We couldn’t have done it without you, and we truly appreciate your dedication.

For more photos of the event, be sure to check out the QAA’s social media pages and website. Don’t forget to follow and support us — and our sponsors — so we can continue to grow this incredible community.

We are excited to announce the QAA AGM is coming up in November. Keep an eye on qaa.net.au and the QAA social-media channels for the exact date and details. We are calling for new committee members to help keep this association running smoothly and continue supporting the arboriculture community.

If you’re passionate about the industry, we would love for you to get involved!

Great support from sponsors.

The 952 Mega 22-inch, 400hp chipper in action chipping a dead gum. Images: Ufkes Greentec

Dutch company Ufkes Greentec specialises in the engineering and production of woodchippers, from 12 inch to 36 inch, 75hp to 900hp, PTO and excavator stump grinders, wood cranes and forest mulchers. The company’s machines are custom built for professional use and will meet the demands of even the hardest working contractors.

Ufkes Greentec’s production site boasts welding robots, a wellequipped testing area and a modern stock-management system, and the company works hard at sustainability in its careful use of both energy and personnel. The building is heated with wood chips obtained from machine testing, for instance, and the whole process from design to production is handled within the company itself.

Ufkes Greentec arrived in Australia when Dutch-born arborist Jor Boogaart started his own company, The Climbing Dutchman, here in 2010. After a couple of happy decades in the tree-care industry, Jor was surprised it was not a common sight to see chippers with cranes. His time as an arborist in Europe had taught him the rig made for efficient, safer and less-strenuous work,

and after three years of careful planning he set up Ufkes Greentec Australia, based in Somerville, Victoria.

In Jor’s own words, “A big dream comes true.”

Ufkes Greentec Australia offers all machines listed on the website, and all chippers are custom built to customers’ specs. But here’s s selection of models:

• 12-inch Cheetah disk 75hp Kubota or 140hp Doosan

• 16-inch Jaguar 140 Doosan with quickchange knives on the drum

• 22-inch 942 275hp John Deere

• 22-inch to 26-inch 952 MEGA 400hp John Deere

• 30-inch 962hp, 400hp, 600hp or 780hp, and

• 36-inch Panthera 900hp.

All these chippers are available in a PTO version, and some are electric PTO

with their own chip bin. The chippers also have wear plates under the knives on the drum, in the chute and behind the rollers – all the spots where the most wear happens. It’s a great feature and extends machine life.

There are two service locations. Ufkes Greentec works together with Chipstar Australia in Kilsyth and Ufkes Greentec Australia Somerville. Jor himself ensures there’s a good stock of parts and consumables available – that’s aside from the locally available parts like bearings.

To learn more of Ufkes Greentec Australia, go to ufkes.net and select the Australian flag on the right-hand side.

Also check out the 3D configurator where you can build your own chipper!

Ufkes Greentec – timeline

• 2004 – Ufkes Greentec was founded in 2004 by Jippe Ufkes. It started with selling and servicing forestry and landscaping machines. Woodchippers, stump grinders, wood cranes, tree shears and so on from renowned brands where sold. To meet the standards of the customers, a start was made at developing its own Greentec machines.

• 2009 – The company grew fast and soon there was the need for more space. In 2009 the first location in Drachten was opened: 2000m2 with a large workplace, warehouse, showroom and offices.

The development of Greentec machines went on and the range of Greentec machines grew: Wood chippers (compact hand- and crane-fed machines suitable for towing behind a car), wood-chipper combinations. stump grinders suited to a three-point hitch and excavators, and forestcutters.

• 2017 – Because the emphasis became more and more the production of new machines, in 2017 there was a new production location built near the existing facility. The site measuring 4400m2 and has all that might be expected of a modern machine factory: a nicely decorated area with lots of light and space, a new welding robot, a well-equipped testing area and optimal stock management, allowing the employees to do their job unobstructed and safe.

Fast forward to 2024 Ufkes has dealers in Australia, USA, New Zealand, UK, Madegascar and all over Europe

Piranha’s BT300 was designed to address two key challenges common in the current offering of woodchippers: performance and serviceability.

Design of the BT300 kicked off with performance in mind and started on a clean sheet of paper. From there, Piranha Chippers built a robust woodchipper that will chip 300mm-diameter (12") solid Australian hardwood. That’s what the ‘BT300’ model number signifies (300mm), and it can process tough timber up to that diameter with ease.

Powering the BT300 is the supertough Isuzu 4HK1 engine, producing a class-leading 197hp, which spins the 26" (650mm) diameter drum and its four staggered knives. The drum is fed the timber via two large horizontal feed wheels, with high torque capacity hydraulic motors, through a direct infeed opening at 500mm wide x 390mm high (20" x 15") to produce very impressive chipping performance.

The BT300 has a huge 170-litre fuel tank custom made to fit underneath the chassis and create a low centre of gravity. The large capacity ensures the

chipper will work for many days before needing to be refilled, saving valuable time at the start of every day as the crew heads out. Add in the comprehensive hydraulic-assisted features which include infeed hopper up and down, 360-degree discharge chute swivel, automatic clutch engagement, feed roller lift/crush and a powerful winch, and the BT300 is a serious performer designed from the ground up to excel at chipping wood and making life easy and safe for the operator.

All this is packaged into a modular chipper design which is hand made from Australian 350-grade structural steel to ensure the BT300 will perform as expected every day.

Does that mean that the Piranha is expensive or heavy?

It’s a good question.

The reality is that in 2024 the BT300 is, at 3800kg, currently the lightest

and sharpest-priced 190+hp chipper currently available anywhere in Australia. If horsepower equals productivity, then the BT300 is offering serious value for money. Backed by a comprehensive five-year/3000-hour warranty, it’s a true revelation in ground-breaking design. When you see the BT300 operating in person, you’ll truly appreciate the craftsmanship and value a Piranha chipper has to offer anyone serious about chipping timber.

Serviceability was another factor Piranha wanted to get right and could see the most practical solutions were not being offered in other chipper designs.

First is the resilience of the Isuzu engine itself, renowned as one of the world’s most reliable engine packages. The 500-hour service intervals of the 4HK1 mean you can concentrate on working for longer, while the chipper is earning its keep rather than being stuck

in the workshop being serviced.

Next is the front engine-cover access door which houses all engine and hydraulic filters in an easily accessible configuration, making servicing the BT300 stress free. When it comes time to change the engine oil, a remote drain sump hose makes the task easier than could ever be imagined. There is no more crawling underneath the chipper to remove a sump plug and watch the dirty oil spill all over the trailer chassis to make a time-consuming mess that needs to be cleaned up.

Next, the central greasing station: there’s no need to climb all over the chipper looking for every grease nipple that needs to be greased. The BT300 has a centralised grease station which ensures that this daily task is simple and straightforward, making life easier.

Then there’s the chipper drum housing – possibly the greatest feature of all Piranha chippers – which makes servicing the cutting knives as easy

and as safe as possible. The whole top of the drum enclosure opens, fully exposing the chipper drum, so knives can be changed out as quickly and easily as required. In addition, there is an accessway alongside the drum housing to ensure secure footing is available while maintaining the cutting knives.

Finally, all the running parts themselves.

The Piranha BT300 has been built with the highest quality parts available here in Australia, and all parts are widely available off-the-shelf from quality suppliers, meaning parts are readily available Australia-wide. With the factory support and backing from Isuzu Australia, the Piranha BT300 can easily be booked in for a service at any of the 42 factory Isuzu service agents Australia-wide.

To learn more of the BT300 and the Piranha company, log on to piranhachippers.com.au.

Merlo is a relatively new brand for South Australian-based companies Mulchtech Australia and Vinetech Machinery. For Director Ben Stephen, adding the brand to the company’s catalogue has been a good move.

Mulchtech and its sister company Vinetech were established in 2010 with branches in the Barossa Valley and Renmark, South Australia. Mulchtech deals with machinery relating primarily to forestry and agricultural work, while Vinetech specialises mostly in viticulture and orchard machinery.

The companies’ websites point out they both ‘…strive to have the finest equipment readily available, allowing you to make purchases without enduring months of delays’.

A year or two ago the companies began offering Merlo equipment, and as Director Ben Stephen pointed out, “They’re European machines, and generally European stuff’s very reliable.”

While Ben’s happy with the Merlo telehandlers on the Vinetech side of the business, the TReEmme is kicking some big goals with Mulchtech. Ben had just made a sale and was fairly confident of another in the not-too-distant future, and he was very clear about the reasons why.

“They have good engines,” he told The Australian Arbor Age. “They have a Deutz Tier 3 engine, which is a super-reliable motor, and they’re very fuel-efficient. That’s key these days while fuel costs are through the roof,” he pointed out, and before we could ask anything else he continued: “They’re easy to navigate for operators, and very easy to control. Maintenance is great, and everything’s in a good spot for servicing. We don’t get mechanics being frustrated.”

We jumped in while Ben was thinking and asked about the service from Merlo.

“We haven’t really done a lot of training with Merlo yet,” the South Aussie told us, “but so far the response has been good. Any time there’s an issue they’re onto it. They see us at every field day they go to, and they call in, so there’s good communication so far. Parts they haven’t had in stock have been airbagged quickly, which is good.

“No dramas there at all,” he concluded.

Ben has plenty of experience with heavy machinery of all kinds, and even with other brands and mulchers within his companies. We wondered what set the Merlo TreEmme apart.

“We’re importing and distributing Australia-wide,” the very busy Director explained, “and with the TreEmme we’re obviously trying to promote a tractor platform. We do have other options, but at moment, in certain situations, the TreEmme is a more suitable machine.

“The TreEmme offers more diversity for operators who want to multifunction and use that tractor for more throughout the year. There’s a section of owners who’d buy, for instance, an $800,000 or $900,000, purpose-built mulching-tractor package they can only use for three months. They can only do one job with it: mulch material.

“With the TreEmme we already have three different mulching heads for one machine we sold, and we have stone crushers and bigger flails – out to six metres – on the way. So by this time next year we’ll have at least five different mulching heads for the one tractor platform.

“For corporates it means when they’re going to spend $800,000, they’ll be able to use the machine for nine months of the year, not three months.”

Another facet of the TreEmme which Ben highlighted is the unit’s transport capability.

“In forestry the road speed’s a big thing,” Ben underlined. “The TreEmme’s not tracked machine which has to go on a truck trailer. It can travel from one site to another on its own, ready to work”.

As we listened and contemplated how this story might look, Ben did a great deal of the work for us.

“It’s more just key features,” he said, proceeding to list them:

• Fuel consumption

• Quality motor

• Ease of operator use

• Comfort

• Quiet in the cab, and

• Good vision.

“I mean,” he said, “It’s pretty much just dot-point stuff. But those dot points are what sells the machine.”

We couldn’t agree more.

See more of the TreEmme and Merlo machinery at merlo.com, and Mulchtech at mulchtech.com.au.

Forestry business owners need to secure continual access to lucrative woodlots and invest in heavy equipment. This guide introduces some Cat® forestry equipment which helps cut back on labor costs and maximise productivity.

The forestry industry thrives on dynamic and streamlined work. Each critical step in the timber-harvesting process needs to be highly efficient, using high-quality heavy equipment that optimises output and completes essential tasks. From felling and extracting to loading and transporting, forestry workers depend on specialised machines that get more done in less time. Additional machines are required to prep logging sites by building and maintaining service roads that give easy access to loggers and their equipment.

Here’s a helpful overview of the common types of heavy equipment for forestry work and the applications for which they’re best suited…

With sheer brute strength, dozers move at a slow speed and plough the earth, trees, boulders and everything else, creating a clear path in their wake.

Images: Caterpillar

Long before logging crews can enter a woodlot to begin processing trees, access roads need to be built, and a dozer is the go-to machine for the task. With sheer brute strength, dozers move at a slow speed and plough the earth, trees, boulders and everything else, creating a clear path in their wake.

Dozers are often used during and after forest fires to create a fire break – a long line cut into the forest to disrupt the path of a fire so it can’t continue burning in that direction.

Dozers come equipped with tracks instead of tyres, which gives them more traction and allows them to work on steeper grades.

In addition to creating roads, dozers are also excellent at leveling ground with their large, heavy blade.

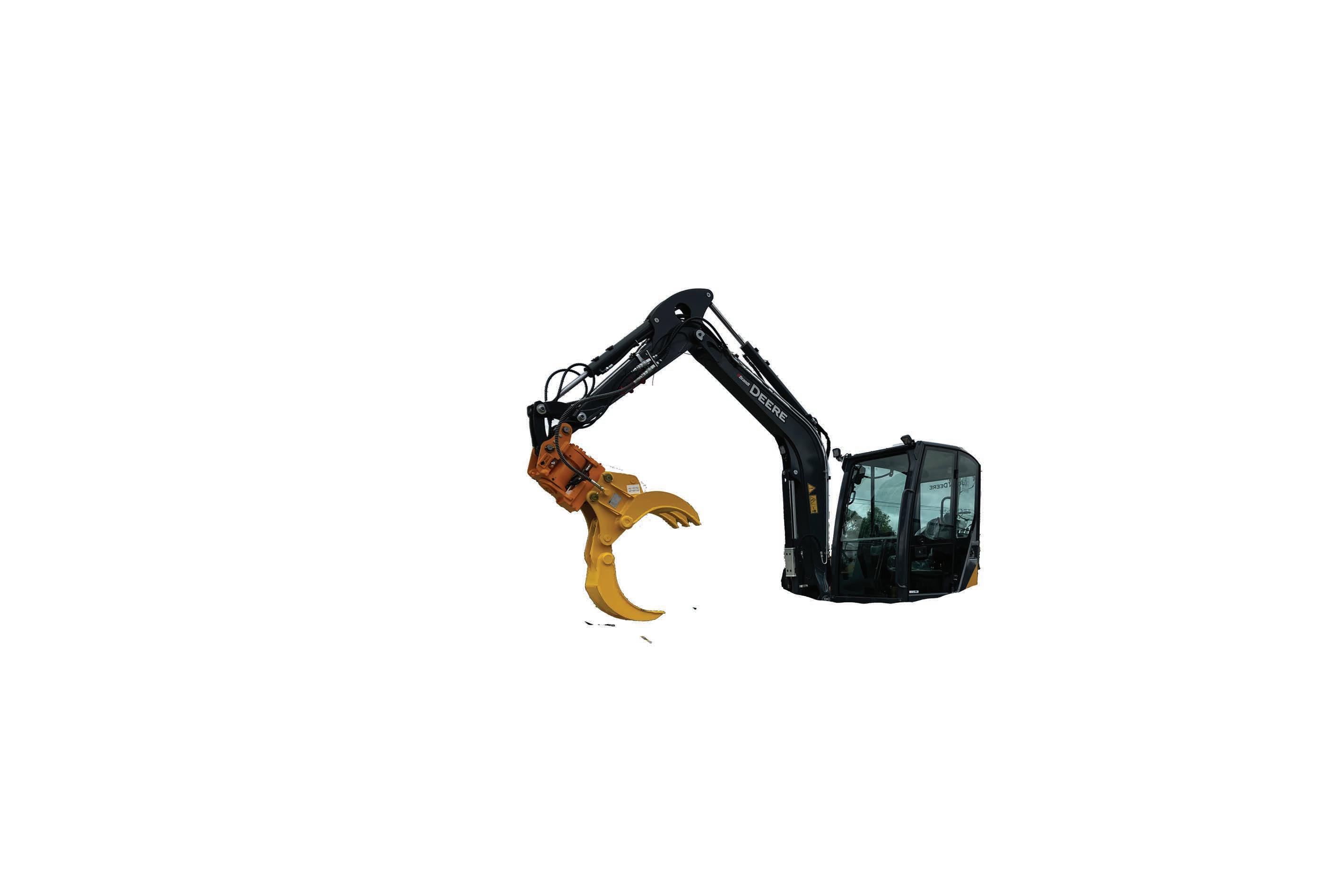

The excavator is an extremely versatile machine featuring a large arm that can be equipped with a wide range of attachments. Most commonly in forestry work, a bucket attachment with an opposable thumb is fitted to give the excavator the ability to dig holes and trenches and move around heavy objects like trees, boulders and other equipment.

Excavators are also frequently used to dig out tree stumps after a tree has been felled. The bucket attachment allows the excavator to make precision digging movements ideal for digging around stumps and unearthing them to be transported.

Usually, excavators come equipped with a blade that can be lowered and used to push earth, giving the excavator the capability to level soil and create pathways free of debris.

Forest machines are designed specifically to meet the demands of tree processing in the field.

Similar to an excavator in their design and operation, forest machines can come equipped with a few different attachments to perform common tasks required during a tree-harvesting operation. These attachments include:

The excavator is an extremely versatile machine featuring a large arm that can be equipped with a wide range of attachments.

• Felling heads: designed to grip a tree and cut it at a low level. After the sawing is complete, the forest machine can reorient the tree horizontally and stack it to the side

Businesses looking to invest in new forestry equipment need a reliable supplier. For more information about Cat forestry equipment, visit your local Cat dealer.

NSW/ACT: WesTrac 1300 881 064

Victoria/Tasmania: William Adams 1300 923 267

Western Australia: WesTrac 1300 881 064

Queensland/NT: Hastings Deering 131 228

South Australia: Cavpower 08 8343 1600

New Zealand: TERRA 0800 93 39 39

• Harvest heads: specialised equipment for cleaning the fallen trees of branches and stems by feeding the tree through the attachment with feed rollers as delimbing knives remove any branches, and

• Grapples: specifically designed to grab bunches of delimbed trees, grapples have a distinct advantage over using a generic excavator bucket-and-thumb attachment because of their curved design that can cradle many trees at once.

The grader is heavy equipment used to create smooth, flat road surfaces. Equipped with a large blade, the grader runs along the road surface and breaks down larger chunks of rock and debris while using those pieces of debris to fill shallow holes. The result is a flatter and smoother road, free of potholes, uneven slopes and other debris.

Graders are frequently used on established forest service roads to reestablish the smooth surface that existed when the road was first constructed. Over time, logging trucks and other traffic begin to create imperfections in the road, such as potholes, cracks and other obstacles, giving the road a washboard surface and making it almost undrivable.

Depending on the frequency of road traffic, a motor grader might be required to service a forest road multiple times each month to keep the surface smooth and ideal for logging-truck traffic.

Skidders are an essential piece of equipment used to transport a large number of trees to another location where they can be loaded onto a logging truck.

After the forest machines cut down and delimb trees, the raw timber is

Similar to an excavator in their design and operation, forest machines can come equipped with a few different attachments to perform common tasks required during a tree-harvesting operation.