23 minute read

NEWS

THE LATEST MINING AND SAFETY NEWS

AUSTRALIAN MINING PRESENTS THE LATEST NEWS FROM THE BOARDROOM TO THE MINE AND EVERYWHERE IN BETWEEN. VISIT WWW.AUSTRALIANMINING.COM.AU TO KEEP UP TO DATE WITH WHAT IS HAPPENING.

HYDROGEN RAIL ON THE AURIZON FOR ANGLO

Aurizon and Anglo American are investigating hydrogen-powered bulk freight trains to create more sustainable supply chains in mining.

As Australia’s largest rail freight company and one of the country’s largest miners, respectively, the two companies saw mutual benefits in the agreement to reach their decarbonisation goals.

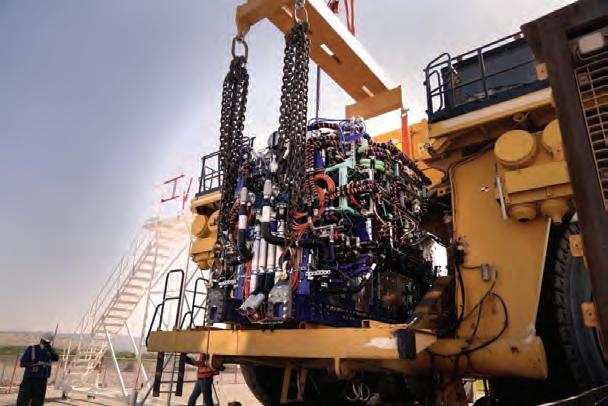

A feasibility study will consider using Anglo American’s hydrogen power technology – already in use for its ultra-class 290 tonne haul truck fleet – on Aurizon’s Moura (180 kilometres) and Mount Isa (977 kilometres) rail corridors in Queensland. This technology includes hydrogen fuel cell and battery hybrid power units.

The Moura and Mount Isa lines run from Anglo’s Dawson metallurgical coal mine and the Gladstone Port, and the North West Minerals Province to Townsville Port, respectively.

Aurizon managing director and chief executive officer Andrew Harding said this was the next step in rail freight technology.

“Hydrogen offers enormous opportunity in decarbonising and continuing to improve the competitiveness of Australia’s export supply chains,” Harding said.

“This is especially true for bulk products underpinning the Australian economy including minerals, agricultural products and fertilisers, industrials, and general freight.”

Rail freight already produces up to 16 times less carbon emissions per tonne per kilometre than road, according to Harding, but Aurizon wants more.

“Aurizon is excited to be teaming up with Anglo American on this project, particularly given their success to date in developing unique technology solutions for use in mine haul fleets,” Harding said.

Anglo American has publicly stated its goal of making its mining operations carbon neutral by 2040, with Scope 3 emissions to be halved by then.

Anglo American chief executive officer in Australia Tyler Mitchelson said working together with other industry leaders would be key to achieving these goals.

“We know that we cannot achieve all of this alone, so we are working with partners along our value chains and outside our industry to find technical solutions to decarbonise,” Mitchelson said.

“This collaboration with Aurizon is a great example of the power of partnerships to help address the urgent issue of climate change, while we also look to catalyse new markets to support the development and growth of the hydrogen economy,” he said.

WORKING WITH OTHER COMPANIES IS KEY TO ACHIEVING DECARBONISATION GOALS. AUSTRALIAN MINING GETS THE LATEST NEWS EVERY DAY, PROVIDING MINING PROFESSIONALS WITH UP-TOTHE-MINUTE INFORMATION ON SAFETY, NEWS AND TECHNOLOGY FOR THE AUSTRALIAN MINING AND RESOURCES INDUSTRY.

COAL PRICES FACE STARK FORECASTS TO 2024: KPMG

KPMG has predicted the decline of coal prices towards 2024 with a fall of more than 20 per cent on the horizon for hard coking coal.

The multinational advisory released its quarterly coal price and FX market forecasts report for September/October 2021, the first release since the beginning of 2020 to predict a decline in coal prices.

The report took a current average price for hard coking coal in the mid-$US180s per tonne.

It showed this average price to remain steady in 2022 before diving to $150 in 2023 and into the mid-$140s by 2024.

According to the report, 2025 showed a slight rebound to about $150, however, fewer contributors hazarded a guess at these longerterm forecasts.

KPMG fielded the forecasts of 23 separate contributors, each from various research databases and broker reports on the price of hard coking, PCI, semi-soft coking and Newcastle benchmark thermal coal.

The latter three coal prices also received negative forecasts.

The last time hard coking coal was forecast to decline was in the December 2019/January 2020 report, when the 2020 price of about $154 per tonne was expected to drop marginally down to $150.

The report came in the wake of several major deals surrounding the future of coal.

The first being BHP’s sale of its stake in BHP Mitsui Coal (BMC) for $1.8 billion to Stanmore Resources, releasing the mining major of the Poitrel and South Walker Creek metallurgical coal mines.

Rio Tinto was already doing the same back in 2013, offloading the Clermont, Blair Athol and Coal & Allied assets, before later selling the Kestrel coal mine in 2018 for more than $US2 billion.

A joint statement from more than 50 countries and organisations was signed at the United Nations’ COP26 in Glasgow earlier in November, in an agreement to transition from coal power to clean power.

While Australia was not one of the dozens of parties to sign the Global coal to clean power transition statement, intentions have been made clear by the likes of BHP, Rio Tinto and Anglo American to sell out of coal mining while prices remain feasible.

MINRES HAULS IN AUTONOMOUS ROAD TRAINS

Mineral Resources (MinRes) has announced a partnership with automation specialist Hexagon to develop an autonomous road train solution for its haulage fleet in Western Australia’s Pilbara region.

The solution integrates driveby-wire technology with an autonomous management system to orchestrate vehicle movement in road-train haulage, as part of the Mineral Resources mining services infrastructure supply chain solution.

“In recent years, we have implemented a number of new technologies which have enhanced the safety and operational efficiency of our long-distance road train haulage fleet, reducing the risks of driver fatigue and increasing fleet availability,” Mineral Resources’ mining services chief executive officer Mike Grey said.

“The autonomous road trains will take us to the next level again. They provide a safe, cost-efficient solution for hauling ore, which is key to unlocking stranded tonnes in the Pilbara.”

An autonomous road train configuration of this scale is a worldfirst and reflects MinRes’ approach to continuous improvement and innovation. MinRes will initially adopt the technology for its own operations, with a view to offering the solution to its large tier-one customer base, further growing its mining services business.

MinRes is renowned for providing innovative and low-cost solutions across the mining infrastructure supply chain, and the autonomous road trains will form an essential part of the Ashburton Hub iron ore project.

Mineral Resources is planning to run a fleet of 425-tonne gross combination mass triple-trailer road trains operating across multiple convoys, with each road train convoy consisting of up to five prime-mover trucks, with three trailers each, hauling the ore from the mine site to the Port of Ashburton.

“Autonomous vehicles are revolutionising the way we work today and into the future, and Hexagon is very proud to be part of this revolution,” Hexagon president and chief executive officer Ola Rollén said.

The automated road-train solution focuses on safety, productivity and sustainability for Mineral Resources operations and will be phased in over the next two years.

AN AUTONOMOUS ROAD TRAIN CONFIGURATION OF THIS SCALE IS A WORLD-FIRST.

CHALICE MAKES AUSTRALIAN HISTORY AT GONNEVILLE

Chalice Mining has confirmed an historic mineral resource at the Gonneville nickel-copper-platinum deposit in Western Australia, becoming the largest nickel sulphide discovery in more than 20 years.

Gonneville is part of Chalice’s Julimar project, 70 kilometres north-east of Perth, and contains 10 million ounces of palladium, platinum and gold – collectively called 3E, one of several platinum group elements (PGE).

These figures make the project the largest PGE discovery in Australian history.

The 330 million tonne resource also holds 530,000 tonnes of nickel, 330,000 tonnes of copper and 53,000 tonnes of cobalt.

Chalice managing director and chief executive officer Alex Dorsch said it had been a strong effort by the team to develop Gonneville at such pace.

“This is a major milestone for Chalice, coming just 18 months after our stunning first hole discovery at Julimar,” Dorsch said.

“Since then, we have completed more than 175,000 metres of diamond and RC (reverse circulation) drilling and now defined a genuine Tier 1 scale deposit of critical minerals with exceptional growth potential.”

The resource will position Chalice to become a major player in the production of “green metals,” according to Dorsch, with reasonable proximity to key infrastructure and port facilities. Dorsch highlighted the sheer potential of this undeveloped deposit.

“It is also important to emphasise that the current resource covers just 7 per cent of the Julimar Intrusive Complex, which has been interpreted to cover a strike length of more than 26 kilometres,” Dorsch said.

“We know that the deposit remains open along strike to the north, and we are very much looking forward to receiving the final clearances to commence our initial low impact drilling program in the Julimar State Forest.”

A scoping study remains ongoing for Gonneville, which will be complete before mid2022 to clarify the initial mine development options.

BHP SELLS QLD COAL MINES TO STANMORE FOR $1.8BN

BHP has agreed to sell its 80 per cent share in BHP Mitsui Coal (BMC) to Stanmore Resources, offloading two Queensland coal mines and associated infrastructure.

BMC owns the Poitrel and South Walker Creek metallurgical coal mines, plus Red Mountain Infrastructure, and the Wards Well development.

The sale will see up to $US1.35 billion ($1.82 billion) change hands, with $1.1 billion to occur upon completion of the share sale and purchase agreement.

BHP Minerals Australia president Edgar Basto said the deal continued the company’s transition from large carbon emitting operations.

“This transaction is consistent with BHP’s strategy, delivers value for our company and shareholders and provides certainty for BMC’s workforce and the local community,” Basto said.

“South Walker Creek and Poitrel are well-run assets that have been an important part of our portfolio for many years, and we are grateful for their contribution to BHP.”

Poitrel and South Walker Creek have a combined metallurgical coal production of about 10 million tonnes per annum and marketable reserves of more than 135 million tonnes, according to Stanmore.

“This is an exciting and transformative acquisition for Stanmore, and we are fortunate to be able to rely on the full support received from our controlling shareholders, Golden Energy and Resources as well as the Sinar Mas Group, to successfully execute this deal,” Stanmore chief executive officer Marcelo Matos said.

“This transaction will see the company become one of the leading metallurgical coal producers globally and provide Stanmore with a portfolio of Tier 1 assets.

“(It brings) significantly increased reserves and resources base and assets with an expected mine life exceeding 25 years production, positioning the company for substantial cashflow generation and future growth opportunities.”

The deal will increase Stanmore’s metallurgical coal production by a multiple of 5.6, while its coal reserves will increase by a multiple of 4.2.

THE DEAL WILL INCREASE STANMORE’S METALLURGICAL COAL PRODUCTION.

DOWNER AND OUT: LEADING CONTRACTOR NO LONGER

Downer has officially divested its mining portfolio, completing its sale of the Open Cut Mining East business to BUMA Australia for about $150 million.

The Mining East business was the last piece of the puzzle for Downer to divest, with proceeds from the divestment program totalling $778 million.

As the sale was announced, Downer chief executive officer Grant Fenn said the company could focus all its energy on its new strategy.

“An important part of our urban services strategy was the exit from our capital-intensive mining businesses,” Fenn said.

“The sale of Open Cut Mining East is the last step of this process and follows the divestments of Open Cut Mining West, Downer Blasting Services, Underground Mining, Otraco, the Snowden consulting business and our share in the RTL Mining and Earthworks joint venture.”

Downer was previously one of Australia’s leading diversified mining contractors, serving more than 60 sites in Australia, Papua New Guinea, South America and Southern Africa.

The various businesses were sold to several high-profile buyers over the past 13 months, including MACA, Byrnecut, Bridgestone Mining Solutions, BUMA and Sigdo Koppers Group.

The divestment program was first announced as a possibility in Downer’s 2019 annual report. In March 2020, the advent of the volatility caused by COVID-19 put a temporary halt to proceedings before the annual report in July 2020 said the search for buyers was back on.

The first major sale in the divestment program came in November 2020, with the sale of Downer Blasting Services for $62 million to Enaex S.A, a subsidiary of Chilean company Sigdo Koppers Group.

This was closely followed by the sale of Open Cut Mining West to MACA in December 2020, for a total value of $200 million.

The Underground Mining services at OZ Minerals’ Carrapateena gold mine was handed to Byrnecut Australia in January 2021 for an undisclosed value.

The tyre management business Otraco was sold to Bridgestone Corporation in April 2021 for $79 million, before Open Cut Mining East became the last business to fall in line in December.

GLENCORE SHIFTING TO SEVEN-DAY ROSTER

Glencore’s Mount Isa mines has announced its Mount Isa copper operations (MICO) will be changing its primary rosters to a seven days on/seven days off roster.

From late February, workers on the primary roster at the MICO operations will move to the new roster in line with the George Fisher mine, which has been successfully operating on the schedule for several years.

The change will improve work/ life balance for the MICO employees in many ways including having every second weekend off to allow Glencore to more easily transfer workers between the two sites to improve productivity.

Glencore has been addressing any questions or concerns raised by affected workers, and will continue to monitor and seek feedback as it implements the roster changes.

“We are committed to maintaining a local workforce and the move is not about transferring to a fly-in/fly-out roster,” a Glencore spokesperson said.

“Our key focus will remain on the safety and wellbeing of our workforce, as we implement and embed the change.”

Mount Isa mines is one of the world’s largest mining complexes and is the hub of Glencore’s copper and zinc operations in Queensland.

Mount Isa mines comprises of underground mines, mineral processing and smelting operations, power generation, and support and administrative services, and operates two mining and processing streams, copper and zinc-lead-silver, to deliver natural resources of enduring value in modern society.

Glencore is capable of producing 300,000 tonnes of 99.995 per cent pure copper cathode a year at its Townsville refinery, and 99.7 per cent pure copper plates at the Mount Isa smelter.

THE CHANGE WILL IMPROVE WORK/LIFE BALANCE.

LYNAS RARE EARTHS BEGINS CONTRACTING FOR PROCESS PLANT

Lynas Rare Earths has kicked off construction of its Kalgoorlie processing facility in Western Australia, awarding a formative contract to a WestStar Industrial subsidiary for $12 million.

The rare earths processing facility will treat concentrate from the Mt Weld mine to produce rare earth carbonate for export to Lynas’ Malaysian facility for further processing.

WestStar’s engineering, construction and contracting business Alltype Engineering has been keen to ramp up its strategic plan to deliver major construction projects, and the Lynas contract will bolster this plan as works begin immediately.

Alltype managing director Kelvin Andrijich said the business had been building to this moment for some months.

“During our FY21 (financial year 2021) strategic planning in 2020, we identified a niche market opportunity in the rotary kiln and rotating equipment installation space,” Andrijich said.

“It is very pleasing to see that the subsequent business case and execution of this strategy 12 months later has resulted in securing our first rotary kiln erection contract as part of the landmark Lynas Rare Earths processing facility development in Kalgoorlie.”

The rotary kiln will be six metres wide and 110 metres long.

The contract will also encompass the fabrication and installation of the discharge end building, a dust chute, primary leach overflow hopper, and the installation of pumps, agitators, piping and electrical instrumentation.

Andrijich said it was rewarding to be acknowledged for Alltype’s expertise in a range of disciplines.

“We are pleased that Lynas has recognised the experience and capability of our delivery team, and the proven self-execution multidiscipline construction capability of Alltype Engineering in the gas, energy, petrochemical and minerals processing industries,” Andrijich said.

“Alltype Engineering has previously undertaken balance of plant scopes around rotary kilns on operational mineral sands and lithium processing sites in the past and we are excited to now be completing the entire turnkey package in addition to those works.”

The Kalgoorlie processing facility was recommended for construction by the Western Australian Environmental Protection Agency (EPA), granted a 30-metre native vegetation buffer was maintained around the site.

THIESS TO MAKE A MOUNTAIN FROM AN ANTHILL

Thiess has secured two mining services contracts worth a combined $200 million in Queensland, partnering with BHP Mitsubishi Alliance (BMA) and Austral Resources.

The BMA contract is worth around $105 million for the provision of mining and maintenance services at Caval Ridge coal mine in the Bowen Basin near Moranbah.

The multinational contractor was also notified in October of Austral’s intention to finalise a $95 million deal, with all signatures now confirmed for Thiess to begin works at Anthill copper mine from January 2022.

Thiess chairman and chief executive officer Michael Wright said the deals gave the company yet another opportunity to display its expertise in an Australian context.

“These contracts reflect Thiess’ ability to deliver value for our clients, providing competitive and sustainable mining solutions across a diversified portfolio of projects,” Wright said.

Austral is aiming to produce 10,000 tonnes of copper cathode per annum for the four years from mid-2022. Austral chief executive officer Steve Tambanis said Thiess was a strong choice to get Anthill off the ground.

“Austral is pleased to be partnering with Thiess, a leading mining services provider with superb mining experience and capabilities,” Tambanis said.

“They bring a commitment to safe and innovative mining practices, providing certainty of delivery in the development of our new Anthill mine.”

Thiess is now mobilising its fleet to Anthill, 80 kilometres northwest of Mount Isa, with 70 people expected to be directly employed by the contract. The fleet includes a 225-tonne Liebherr R994B excavator and multiple Cat 789 haul trucks.

Tambanis added that Anthill would continue to grow elsewhere while Thiess began work on the existing copper asset.

“Exploration and development activities are currently being significantly expanded with the goal of fast-tracking discoveries,” he said.

“We look forward to further update shareholders as we prepare to commence maiden production at Anthill, and begin exploration and development activities.”

Thiess was in attendance when Austral performed its first blast at Anthill in mid-November, along with blast management company Orica and drill specialists Roc-Drill.

The blast was an impressive achievement, coming just three weeks after approval was received to commence mining.

A total 110,000 cubic metres of iron stone was broken in the blast at Anthill’s east pit, with the first ore to be mined by April 2022.

Copper cathode is expected to be produced in mid-2022 at the company’s Mount Kelly copper oxide heap leach and solvent extraction electrowinning (SXEW) plant.

THIESS IS MOBILISING ITS FLEET TO ANTHILL, NORTH-WEST OF MOUNT ISA.

BUILT TO CONNECT

Astec - Connecting People, Processes and Products

With unmatched strength from rock to road, connection is at the heart of everything we do. At Astec we design and manufacture products used to build the infrastructure that physically connects the world, but it’s the connections we make with people that drive us forward. Our company was founded on innovation and we’re committed to helping our customers succeed. Astec, we are Built to Connect.

astecaustralia.com.au

WAS GAINES’ TRANSITION THE RIGHT MOVE FOR FORTESCUE?

Analysts have suggested Fortescue Metals Group may be better served by diversifying into more reliable commodities like base metals, rather than renewable energy.

Adrian Prendergast of Australia’s largest wealth management network, Morgans, said the recent transition of Fortescue chief executive officer Elizabeth Gaines from the top job was a shock.

“Of some concern, our initial impression is that FMG appears to be prioritising getting a new CEO with experience outside iron ore,” Prendergast said.

Instead, the senior analyst suggested Fortescue would be better served by sticking to what it knows in these uncertain times.

“We see now as a critical time for FMG to be focusing on the iron ore market, particularly given its position as a mass-scale low-grade producer,” Prendergast said.

“Given the iron ore dynamics, we had expected FMG to diversify actively but had thought a safer option might have been to enter other mature markets (i.e. base metals) where cycles and economics are already well established and understood, allowing for a faster transition.”

Morgans expects Fortescue to remain financially dependent on iron ore until at least 2030, while the clean energy transition continues to build momentum.

Building on this, Prendergast gave three reasons why iron ore markets may remain uncertain for the next five years:

“One, the Chinese steel market has matured (less stimulus, environmental reforms, rising recycling) and unlikely to reclaim previous highs,” Prendergast said.

“Two, seaborne iron ore supply is recovering (Vale has mitigated risks while we expect Rio’s operational performance to eventually improve).

“Three, new supply is coming (most notably Simandou but other supply is also responding to the increased rents on offer).”

Gaines will transition into a role as non-executive director of Fortescue’s board and as the company’s global green hydrogen brand ambassador.

Fortescue’s Board of Directors has started an extensive global search, appointing Egon Zehnder, to identify a CEO and other leaders with exceptional skills and global experience across heavy industry, manufacturing, and renewable energy.

GAINES WILL TRANSITION INTO A NON-EXECUTIVE DIRECTOR OF FORTESCUE’S BOARD.

KALGOORLIE-BOULDER TO ASSESS FIFO POLICY

The City of Kalgoorlie-Boulder in Western Australia’s Goldfields region is seeking submissions on a policy which aims to provide guidance on potential accommodation development applications, including for a fly-in, fly-out (FIFO) workforce.

Mayor John Bowler said while the policy discourages construction of worker camps for FIFO employees and contractors, it provides a clear framework for assessing workforce accommodation proposals and will help build a more sustainable local community and economy.

The objective of the policy is to manage the development of workforce accommodation with a longer-term aim to maximise the residential workforce and ensure that, where workforce accommodation is provided, it is designed appropriately and contributes to Kalgoorlie-Boulder’s vision to be a place people call home.

The council will undertake a consultative process that will guide the policy measures including time limited approvals, need for accommodation, location, design and community integration.

The draft policy indicates proposed facilities would undergo a Social Impact Assessment and require a Social Impact Management Plan to identify and mitigate negative effects to the community.

“The city acknowledges there needs to be a base level of temporary accommodation available to address the upcoming large construction projects planned for the city,” Bowler said.

“However, with the need for workforce accommodation always changing, it is integral that the supply of such accommodation is managed properly.

“Local communities benefit from having workers and their families permanently located in the city and can suffer negative impacts from a large FIFO presence.

“Key objectives of this draft policy are to achieve reciprocal benefits for the local community and businesses and enable facility occupants to integrate with the community, local businesses and city services.”

The policy will ensure any new developments are fully evaluated and properly assessed within the approval process.

In addition, 12-months before the expiry of the approved timeframe, the landowner must provide Council with a site decommissioning program or a transition plan.

“We would obviously prefer longterm operational workers to be based in our town and contributing to the community,” Bowler said.

“Families should be able to tuck their kids into bed every night and spend quality time with their partners.

“The policy emphasises that, where long-term town-based FIFO operations are required by industry, council expects their accommodation to be of a high standard; suitably integrated with surrounding development and the community; and not of a camp design or layout appropriate to an isolated/remote camp.”

MONADELPHOUS SECURES RIO TINTO CONTRACTS

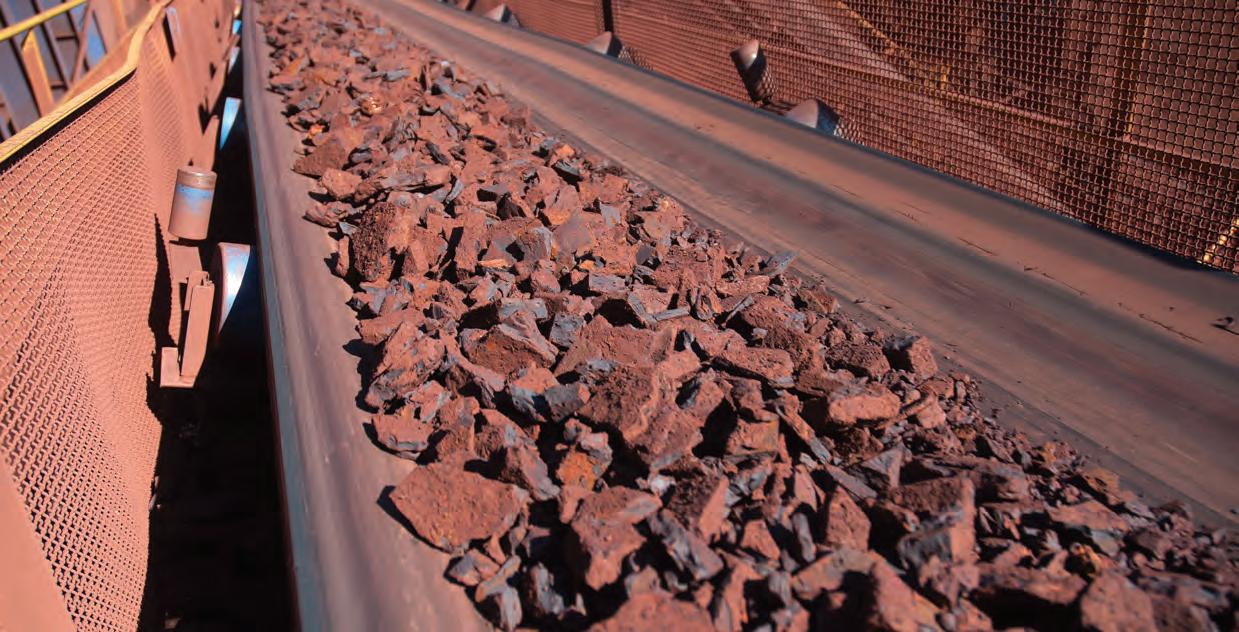

Monadelphous has secured new contracts and contract extensions with Rio Tinto and BHP in the Pilbara region of Western Australia (WA) worth approximately $110 million.

The engineering company has secured two new contracts with Rio Tinto under its sustaining capital projects panel agreement.

The first Rio Tinto contract is for the construction of new hawser rails and upgrades to the existing dolphins at Cape Lambert A and B wharves, which includes design, fabrication, supply and installation which is expected to be completed by July 2023.

The second contract is for the upgrade of conveyor gravity take up systems at East Intercourse Island and Cape Lambert, with work expected to be completed in the third quarter of 2022.

Monadelphous has also secured a 12-month extension to its existing contract with BHP Iron Ore for the provision of general maintenance services for shutdowns, outages and minor capital works at the Mt Whaleback, Jimblebar, Eastern Ridge, Mining Area C and Yandi mine sites.

The company also won a 12-month extension to its existing mechanical and electrical maintenance, shutdown and project services contract across BHP’s Nickel West operations in WA.

These new contracts follow a string of sustaining capital work projects Monadelphous has won with both BHP and Rio Tinto this year, including providing smelter maintenance works at BHP’s Olympic Dam copper mine in South Australia, and for the provision of construction and support services at Rio Tinto’s Gudai-Darri iron ore project in WA.

Monadelphous is a leading Australian engineering group providing construction, maintenance and industrial services to the resources, energy and infrastructure sectors.

MONADELPHOUS HAS WON A STRING OF SUSTAINING CAPITAL WORK PROJECTS CONTRACTS.

PILBARA INDUSTRIAL HUBS TO GROW WITH LOTS OF LOTS

Industrial hubs in Port Hedland and Karratha have been opened to new tenants, as DevelopmentWA invests in the Pilbara mining industry of Western Australia.

Major engineering contractor Monadelphous is already one of many companies to have taken up residence at the Gap Ridge Industrial Estate in Karratha, as eight new lots are made available.

The eight lots in Gap Ridge’s fifth stage range in size from 6722 square metres to almost three hectares.

Near Port Hedland, the Wedgefield Industrial Estate has opened its third stage with five lots ranging from 1.5 to 2.4 hectares – suitable for a variety of industrial and transport related uses.

Lands Minister Tony Buti said the new lots were hoped to benefit the industries that best served the state.

“The McGowan Government has made a big investment to ensure the rapid development of industrial land across the state, with a focus on regional Western Australia and businesses supporting the resources industry,” Buti said.

“This commitment has resulted in an increasing supply of industrial land to meet growing demand.”

Stages one and two at Wedgefield have already sold out to more than 20 businesses including Komatsu, Bridgestone, Qube and Reece Plumbing, all taking advantage of the estate’s access to power, water, the national broadband network (NBN) and sewerage.

In October, DevelopmentWA chief executive Frank Marra discussed the benefits of strategic industrial areas (SIA) with Australian Mining.

The Kwinana and Rockingham SIAs in the state’s southwest – home to the likes of BHP and Tianqi Lithium – inspire similar synergies to those planned in the Pilbara.

“The Kwinana SIA and the neighbouring Rockingham SIA are part of the world’s largest integrated ecology industrial estates,” Marra said.

“They support growth among industrial businesses by facilitating access to extensive commonuse infrastructure, deep pools of skilled labour and proximity to other industrial businesses inputs and outputs that exhibit a high degree of complementarity.”

Pilbara Minister Kevin Michel said it was hoped a broad range of businesses would take up the call to join the Pilbara’s resources sectors.

“This strategic land release will attract new businesses to Port Hedland and Karratha, which will help diversify our local economy,” Michel said

“These industrial lots are another fantastic opportunity for new businesses to join our local business community, providing jobs and growth for the Pilbara.”