11 minute read

MINEXPO

CATERPILLAR CONSIDERS ALL WITH SPACIOUS MINEXPO SHOW

IT WILL BE HARD TO MISS CATERPILLAR’S EXHIBITION AT MINEXPO 2021, NOT ONLY FOR ITS SIZE BUT ALSO FOR THE FUTUREFOCUSED LESSONS AND EQUIPMENT THE OEM NOW OFFERS THE INDUSTRY.

Covering an expansive 5124 square metres – one twelfth of the event’s exhibition floor – Caterpillar’s display will be themed, ‘Together, we’re mining better.’

This title encompasses ideas of sustainability as well as overall productivity, both of which can be controlled by the quality of equipment and technology in an operation.

Through Caterpillar’s expanding portfolio, the original equipment manufacturer (OEM) is hoping to do most of the heavy lifting around any one mine site, while sticking to these pillars of smart and sustainable practices.

To this end, the massive exhibit at the Central Hall of the Las Vegas Convention Centre on September 13-15 will advocate three key themes: environmental, social, and corporate governance (ESG) and sustainability; technology and automation; and equipment lifecycle management solutions.

Caterpillar Resource Industries Group president Denise Johnson says the company has plenty to show off after the industry missed out on MINExpo in 2020.

“After waiting an extra year, the mining industry is ready to reconnect at MINExpo,” Johnson says.

“We are excited to show our customers and the industry the advancements Caterpillar has made not only in equipment, technology and services, but also in how we are helping customers mine more sustainably.”

The OEM has gone a step further at MINExpo this year, understanding that not everyone from such a large industry can make it to the United States in 2021.

“While we are eager to exhibit in Las Vegas, we recognise that many of our dealers and customers will not be able to travel to the show. Therefore, we are also creating a digital Caterpillar experience at cat.com/mining, where we will place MINExpo specific content,” Johnson says.

The equipment on show will include Cat’s latest in load and haul – the R1700 XE LHD.

As a fully electric mining vehicle producing less noise, the R1700 XE is just one move Cat has made to improve customers’ commitment to ESG goals and sustainability.

The loader has a 15-tonne payload and a 24.19-tonne lift and tilt breakout, ensuring that no operation is made to choose between electrification and productivity.

In conjunction with the new loader, the OEM will also showcase the capabilities of its new portable Cat MEC500 Mobile equipment charger, furthering that productivity angle.

The MEC500 can charge the R1700 XE in around half an hour with just one charger.

Next in show will be the R2900 XE LHD diesel-electric drivetrain for reduced maintenance costs; the D11 XE dozer for “the lowest cost of bank cubic meters (BCM) ever”; and Cat’s 992 wheel loader, which improves productivity by 32 per cent.

And while some companies might be content with that line up, Cat has also extended its range in the technology space.

Caterpillar Resource Industries vice president Marc Cameron emphasises the need to offer both equipment and technology solutions.

“Technology and automation are critical components for substantially improving machine uptime availability and productivity,” Cameron says.

One such piece of technology has been Cat’s autonomous MineStar Command, which has been proven around the world.

The automated technology this year hit three billion tonnes hauled around the world, while at Rio Tinto’s Gudai-Darri operation in the Pilbara – touted as the world’s most advanced mine – MineStar Command has been implemented on a 777G Water truck.

Further to the MineStar Command, Cat released MineStar Edge in 2020 to complement its existing MineStar technology suite.

Edge allows business to assess their operations, big and small, remotely and from a distance. This introduces aspects of safety and productivity by allowing those at management level to gauge their strengths and weaknesses at any one time.

Cameron says MINExpo will provide many customers with their first chance to witness and experience MineStar Edge.

“Through Cat MineStar Solutions, Caterpillar offers customers scalable technologies to fit the mine’s specific needs. The exhibit’s technology and automation stage will focus on the real value that Caterpillar technology options provide customers,” Cameron says.

A raft of complementary technological advantages will be on show at the Caterpillar exhibit. No mining business will want to miss out, either in-person or online. AM

The International Mining and Resources Conference (IMARC) is where global mining leaders connect with technology, finance and the future. As Australia's most influential mining event, IMARC creates a global conversation, mobilises the industry for collaboration and attracts some of the greatest leaders in the mining, investment, and technology industries for three days of learning, deal-making and unparalleled networking.

Hear Hear from more than 250 mining leaders and resource experts with a conference program that covers all aspects of the mining supply chain. From exploration, to investment, production to optimisation through to new technologies and global opportunities. Alongside discussions on health and safety, renewable energy, critical minerals, and sustainability.

Furthermore, the exhibition will feature over 200 leading companies across the 10,000m2 expo floor showcasing the latest mining projects, equipment, and innovations the industry has on offer.

W With the world’s borders still locked down, IMARC will be a hybrid event in 2021, welcoming international attendees from more than 100 countries via our online platform. Attendees will be able to log in online to stream live and on demand conference presentations, participate in virtual meetings and interactive networking.

VISIT IMARCGLOBAL.COM TO REGISTER FOR AUSTRALIA'S MOST INFLUENTIAL MINING EVENT AND RECEIVE 10% OFF WITH THE DISCOUNT CODE AUSMINING

IN-PERSON & ONLINE 25 – 27 October 2021 Melbourne Showgrounds

BIGGER IS ALWAYS BETTER

Australian made, Australian owned, globally distributed. As the original equipment manufacturer of Allight towers and Sykes pumps and the Australian authorised distributor of Perkins engines and FG Wilson generators, we’ve got products to meet your every need - but we still reckon bigger is always better.

SUPERSKID RANGE

Robust, durable and heavy duty, the SuperSkid lighting tower is powered by a Perkins 403D-11 engine, built to withstand the most challenging and rigorous mining conditions in Australia. The SuperSkid range boasts a mast high wall capacity of 10.7m (35’), up to eighteen LED lights, hydraulic light tilt, mast rotation and extension. Optional add ons include a 1,000L base fuel tank and telemetry, meaning the SuperSkid range has all the features needed to make a big lighting impact.

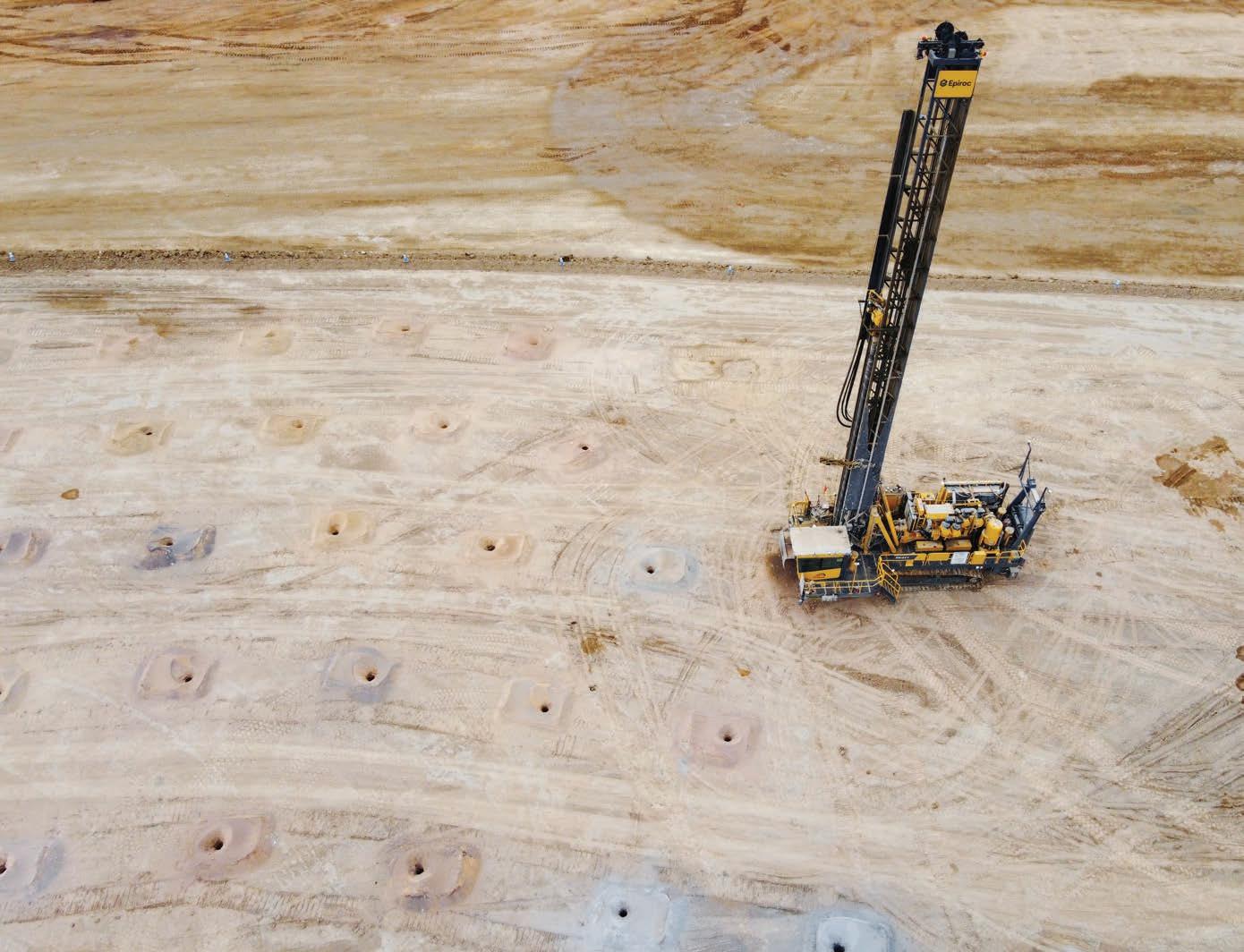

THE LATEST AND GREATEST IN MINING TECHNOLOGY

EPIROC’S PIT VIPER 291 IS DESIGNED TO TACKLE LARGER DIAMETER DRILLING.

AUSTRALIAN MINING LOOKS AT THE LATEST INNOVATIVE EQUIPMENT, TECHNOLOGY AND SERVICES FOR THE RESOURCES INDUSTRY BEING DISPLAYED BY LEADING ORIGINAL EQUIPMENT MANUFACTURERS AT THIS YEAR’S MINEXPO INTERNATIONAL IN LAS VEGAS.

As the countdown to this year’s MINExpo International draws closer, exhibitors are preparing to show the world their latest offerings for those involved in the resources and mining sector.

Considered the world’s largest mining event, the show covers the entire industry – exploration, mine development, open pit and underground mining, processing, safety, environmental improvement and more.

With the event to be held in Las Vegas from September 13 to 15, Australian Mining previews the latest products that will be on display from industry giants Liebherr, Sandvik, Epiroc and Komatsu. Liebherr Liebherr will introduce three new excavators at MINExpo with the R 9150 Generation 7, the R 9200 Generation 7, and the brand-new R 9600 Generation.

All three excavators are equipped with the latest innovations including Liebherr Power Efficiency (LPE), assistance systems and bucket filling assistant (BFA).

LPE is a specific engine and hydraulic management system which reduces fuel consumption by up to 20 per cent. Assistance systems are advanced on-board applications designed to support the operator to become more efficient through analytics and actionable insights.

BFA is the first automation product of the Liebherr hydraulic excavator portfolio and allows the operator to realise the bucket filling process automatically.

The T274 haul truck is a 305-tonne machine that provides fast cycle times, higher production rates, low fuel consumption and a low cost per tonne.

This new truck follows the same

SANDVIK WILL SHOWCASE ELECTRIFICATION, AUTOMATION AND MORE AT MINEXPO.

base design as the T284, benefitting from its decades of field experience.

Liebherr components for mining applications will also feature at MINExpo. Among the components is the D98 diesel engine series, which is available for both Liebherr and other mining equipment manufacturers, for new and repowered machines.

Also on display will be the LRT 1090-2.1 90-tonne rough terrain crane, which is designed to deliver the highest safety level. It is fitted as standard with an outrigger monitor which automatically detects the support status and includes the crane control system.

It is also delivered as standard with the VarioBase variable support base, which enhances flexibility on site and increases the crane’s lifting capacity.

Liebherr has also revealed that strategic partnerships with energy and infrastructure providers will be announced at MINExpo, alongside the roadmap for the company to provide these solutions to its customers.

Sandvik Sandvik will have several of its latest innovations on display for the first time anywhere in the world at MINExpo, including its AutoMine Concept vehicle.

The first fully autonomous battery-electric vehicle (BEV) for underground mining is equipped with new sensing capabilities and artificial intelligence to help the cabinless technology demonstrator perceive its surroundings and environment in 3D and react in real time, enabling it to adapt and plan its own route and to find the most suitable paths even in continuously changing environments.

In addition, Sandvik will unveil its latest battery-electric underground truck, together with a virtual introduction to new loader technology with AutoMine readiness.

Sandvik will also launch the DS412iE, its first battery-powered rock bolter that rounds out the company’s first full zero-emissions offering for all underground drilling applications.

Sandvik Mining and Rock Solutions president Henrik Ager says the company was proud to launch the industry’s first batterydriven underground jumbo five years ago at MINExpo 2016, as well as its ongoing progress in electric equipment innovation since then.

In addition to displaying its latest rock tools offering at MINExpo, Sandvik will launch a new DTH hammer with class-leading fuel efficiency.

The company will also present a new rotary bit, new heavy-duty drill bits, a new drill bit for autonomous drilling and its latest digital rock tools solutions, all developed to increase sustainability and productivity.

Sandvik will use a simulation game to introduce its new digital offering, Remote Monitoring Service, and will also showcase its smart inspection tools through interactive demonstrations.

“Nothing beats meeting customers face-to-face and being able to showcase all of our latest developments in person,” Ager says.

“However, we also understand that not everyone will be able to travel to Las Vegas, so that’s why we will also be providing a rich digital MINExpo experience.”

Epiroc Epiroc’s Pit Viper 291 makes its debut at MINExpo 2021. The rig is designed to tackle larger diameter drilling in soft to medium ground conditions in both rotary and DTH drilling.

The Pit Viper 291 offers more than 100 different options to configure the perfect drill rig for your specific application. With Epiroc’s Rig Control System (RCS), the Pit Viper 291 can be configured with scalable automation features, including fully autonomous drilling.

With protected hydraulics, sensors and cables, Epiroc’s new Boomer M20 is the next generation in underground mining. The world’s first face drill rig with internal hydraulics, the Boomer M20 is designed to minimise unplanned stops and maximise uptime and performance even in the toughest conditions.

High precision and performance are ensured with on-board automation features, tele-remote capabilities and digital drill plans which give higher reliability and quality of the full drill cycle. Through tele-remote capabilities, operators can drill from a safe distance and keep production going over shift changes.

The Boomer M20 comes with a battery-electric driveline option. With the on-board charger, charging automatically happens while connected to the grid for drilling.

Epiroc will also showcase its automation and information management solutions as part of the 6th Sense capabilities. The 6th Sense is Epiroc’s answer to the mining and construction industries need for digitalisation as an enabler for safety and productivity gains.

Komatsu Komatsu’s latest haulage concepts, designed to prioritise customers’ desire to reduce emissions and for autonomous haulage solutions, will be on display; revealing its future vision for power agnostic dump trucks and autonomous haulage retrofits for existing equipment.

The OEM will also preview future

THE BOLTEC M10 COMES WITH A BATTERY DRIVELINE OPTION.

capabilities for remote operation of equipment featuring hydraulic excavators and autonomous haulage.

Other new Komatsu solutions designed to advance more sustainable mining methods that will be on display include the WE1850 Gen 3 surface wheel loader with proven SR (switched reluctance) hybrid drive technology and the ZR122 surface blasthole drill with automated features.

Komatsu, to assist its customers’ sustainability needs, will also display its battery hauler for underground mining powered by lithium-ion battery technology, as well as its battery-tram powered ZJ32Bi jumbo drill for underground hard rock mining.

Created with input from customers around the world, the company’s latest equipment, service and technology solutions are designed to simplify tasks, streamline processes and – ultimately – help optimise customers’ productivity.

Komatsu mining president and chief executive officer, as well as MINExpo chairman, Jeff Dawes says the show provides the perfect opportunity for industry leaders to collaborate on new ways to extract essential minerals at this critical time.

“Supporting our customers’ path forward with new solutions that leverage digitalisation, electrification and automation is crucial to our role as an essential provider to the industry, and we look forward to sharing these innovations developed in partnership with today’s mines,” Dawes says. AM