15 minute read

NEWS

THE LATEST MINING AND SAFETY NEWS

AUSTRALIAN MINING PRESENTS THE LATEST NEWS FROM THE BOARDROOM TO THE MINE AND EVERYWHERE IN BETWEEN. VISIT WWW.AUSTRALIANMINING.COM.AU TO KEEP UP TO DATE WITH WHAT IS HAPPENING.

HITACHI LAUNCHES FLAGSHIP EX8000-7 EXCAVATOR

Hitachi has revealed the EX80007 excavator, which is designed to deliver the utmost power and force in the most challenging mining conditions.

Weighing more than 830 tonnes and with the ability to move 75 tonnes of dirt per bucket load, the EX8000-7 is Hitachi’s largest standard backhoe excavator.

The excavator can generate 2×1450 kilowatts of power at 1800 revolutions per minute and comes with the option of a Cummins QSKTA60 or MTU 12V 4000 C33 diesel-charged engine.

The EX8000-7 has been designed to perform across different mining profiles and comes with a front attachment design that prioritises performance.

The most significant update on the EX8000-7 is the excavator’s onboard sensors, diagnostic tools and advanced software, which deliver the insights to provide operators with the safest and most productive experience.

Further intelligence comes via the EX8000-7’s new electronic cylinder stroke controls that enable the signalling from angle sensors to the main frame, boom and arm.

Ensuring product durability and user visibility, operators can monitor the pump flow rate and cylinder speed in real time.

Hitachi has implemented the most advanced fuel optimisation technologies and cutting-edge safety features for the new excavator, while also ensuring easy maintenance and operational comfort.

The EX8000-7 features electronic joysticks, an intelligent multifunctional display, advanced air suspension seating and improved climate control.

Other attributes include an on-board inclinometer, improved machine access and ease of maintenance, a dual isolator switch as standard, an emergency escape chute, engine stop switching and optional perimeter monitoring cameras.

The EX8000-7 excavator joins Hitachi’s EX-7 series, which also includes EX1200-7, EX2600-7, EX3600-7, EX5600-7 and its new EX2000-7 excavator, recently revealed at MINExpo 2021.

The EX2000-7’s main pump electronic regulators, high hydraulic efficiency regeneration and cooling package work together to reduce fuel consumption by up to 20 per cent, offering mining companies a lower-emission option for their operations.

THE EX8000-7 BUILDS UPON ITS PREDECESSORS IN A BIG WAY. AUSTRALIAN MINING GETS THE LATEST NEWS EVERY DAY, PROVIDING MINING PROFESSIONALS WITH UP-TOTHE-MINUTE INFORMATION ON SAFETY, NEWS AND TECHNOLOGY FOR THE AUSTRALIAN MINING AND RESOURCES INDUSTRY.

FORTESCUE SETS RECORD MINING SERVICES CONTRACT

Fortescue Metals Group and members of the Wintawari Guruma Aboriginal Corporation are partnering to develop new mines at the Solomon Hub operations in Western Australia.

The 10-year mining services contract awarded to the joint venture is estimated to be worth more than $500 million, making it the largest ever contract Fortescue has awarded to an Aboriginal business.

Under the co-management framework, Fortescue and members of Wintawari – the prescribed body corporate for the Eastern Guruma People – will establish a culturally safe mining joint venture to mine the East and West Queens deposits.

The agreement builds on the decade long relationship between the parties, which was formalised in a Land Access Agreement in December 2009.

Wintawari chair Glen Camille said the establishment of the joint venture represents the next step in the journey with Fortescue.

“We are glad to work with Andrew Forrest and Fortescue to improve the economic outcomes for Aboriginal people and thank Andrew for his demonstrated commitment,” he said.

“Working collaboratively, we will ensure that Eastern Guruma people are active participants in the future development of mines on our country, enabling deeper consultation around the protection of culturally significant sites, while building a better future for our people.”

Fortescue chief executive officer Elizabeth Gaines said the company was proud of its longstanding relationship with Wintawari Guruma Aboriginal Corporation.

“We are confident that this new collaborative framework will strengthen our ties with the Eastern Guruma people, through the unique opportunity to have a seat at the table to share cultural knowledge and guide the growth of Fortescue’s operations on their country.”

Fortescue chairman and founder Andrew Forrest said the framework would shape a new shared direction for Fortescue and the Eastern Guruma people.

“Together, we will provide enduring benefit for future generations, while preserving their unique culture and heritage,” he said.

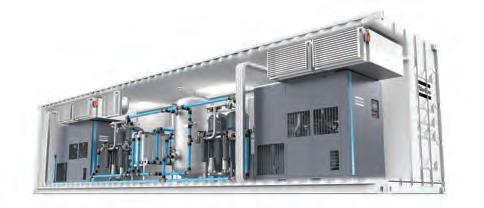

Containerised compressor room; the perfect mining plug-and-play solution

The AIRCUBE allows companies that don’t have the time or space, to add an indoor compressor room to quickly add compressed air capacity. It also solves a challenge many resource sector operations face: How do you get a dependable, high-quality air supply to some of our most remote places in Australia?

Great flexibility to meet your needs

The applications for containerised compressor rooms are so diverse that a onesize-fits-all approach simply won’t work. That is why the AIRCUBE offers a modular solution that lets you choose from many products and options.

The choices are yours!

First you pick one or two of our industry leading compressors to form the heart of your air system. You can choose between fixed-speed or energy-efficient variable speed drive compressors with sizes ranging from our GA 11+ to GA 90 models (for fixedspeed compressors) and GA 7 VSD+ to GA 110 VSD+ models (for variable speed drive compressors). Then you can mix and match many of the other Atlas Copco compressed air equipment that you already know, use and trust, such as dryers, air receivers, filters and any special add-ons you might need. We will assemble all of these products for you in a 20 or 40-foot ISO sea container.

By getting all of your components from a single source, you guarantee that there are no compatibility problems and you only have to deal with a single point of contact.

Proven quality

This modular approach offers you the best of both worlds: You get a containerised compressor room that is tailored to your needs. And, because we use only existing Atlas Copco products that have already been thoroughly tested, your plug-and-play compressor container will be ready in no time at all.

Built tough for any environment!

Each of the containers are built tough to withstand any weather conditions. They include many standard features, such as ventilation, internal power distribution and lighting. Optionally, we can add a wide array of options ranging from Smart Connectivity and controls, ISO8573 Filtration Class, Safety, etc., . In addition, the containers can be equipped with special insulation, automatic ventilation system and be outfitted so that they can operate in temperatures as low as -50°C and as high as 50°C, upon demand.

Want to find out how the AIRCUBE will help solve your compressed air challenges?

Chat with one of our team members right across Australia. We can’t wait to show you how this will work for your site. The perfect mining plug-and-play compressed air solution!

Scan below

PILBARA PORTS EXPLORES IRON ORE OPTIONS AT ASHBURTON

The Pilbara Ports Authority (PPA) has begun investigating the trade of iron ore at the Port of Ashburton in Western Australia in response to increased exports.

PPA chief executive officer Roger Johnston revealed to Australian Mining that the Port of Ashburton – 450 kilometres southwest of Port Hedland – was the subject of expansionary investigations.

“Pilbara Ports Authority is exploring export and import opportunities at the Port of Ashburton. This includes diversifying trade through the Port of Ashburton’s general cargo facilities,” Johnston said.

“Pilbara Ports Authority is working with a number of resources companies to support smaller transhipping operations and unlock stranded iron ore assets in the West Pilbara.”

The Port of Ashburton is currently a strategic industrial area for the processing of LNG and natural gas for the state’s domestic gas supply.

The port also handles project cargo, break bulk and general cargo. However, Johnston indicated that nearby businesses were calling for a change to the current set-up at Ashburton.

“Any development of infrastructure will be driven by individual proponents,” Johnston said.

“Potential export timelines are dependent on a proponent’s development and operational model.”

The Ashburton announcement came less than two weeks after BHP announced it was approved for 40 million more tonnes of annual throughput at Port Hedland.

In July, PPA reported a 29 per cent jump in full-year throughput, setting a record for the second time in two years.

The 724.7 million tonnes (Mt) in the 2020-21 financial year beat out the previous 12 month’s 700Mt record, indicating the growth occurring in the Western Australian resources industry.

THE PORT OF ASHBURTON. IMAGE: PILBARA PORTS AUTHORITY.

BHP CLOSES IN ON EV MARKET WITH FIRST NICKEL SULPHATE

BHP has produced the first nickel sulphate crystals from its Kwinana nickel sulphate plant south of Perth in Western Australia.

Nickel sulphate is a key material in the lithium-ion batteries that power electric vehicles (EVs), with more than 85 per cent of BHP’s current production sold to the future-battery supply chain.

The production followed an announcement in July that BHP will supply Tesla with nickel from its Nickel West assets in a collaboration which will aim to make the battery supply chain more sustainable.

According to BHP, the nickel sulphate plant is an Australian-first and will produce 100,000 tonnes of nickel sulphate per year when fully operational.

Nickel from BHP’s mines is processed at the Kalgoorlie nickel smelter, before it is transported to the Kwinana nickel refinery and refined into nickel metal in the form of powder or briquettes.

The powder is then processed through the new sulphate plant to make nickel sulphate and will be exported to global battery markets from Fremantle port.

BHP Nickel West asset president Jessica Farrell said the plant is expected to produce enough premium nickel sulphate to make 700,000 EV batteries each year.

“The plant will create 80 new direct jobs and support 400 new indirect jobs, in addition to the 200 construction jobs that were created during the construction phase,” Farrell said.

“High quality and sustainable nickel is essential for our customers, and we expect demand for nickel in batteries will increase by 500 per cent in the next decade.

“Our investment to upgrade the refinery to produce high purity nickel sulphate, along with nickel powder and briquettes, will enhance Nickel West’s position as a supplier of choice for the growing global electric battery market.”

Over half of the plant was fabricated in Western Australia using local skills and suppliers including the steel work, fibreglass leach vessels and stainless-steel tanks.

RIO TINTO TO TRIAL CATERPILLAR HAUL TRUCKS AT GUDAI-DARRI

Rio Tinto will be the first to deploy Caterpillar’s 793 zero-emission autonomous haul trucks once development is complete at the Gudai-Darri iron ore mine in Western Australia.

Under a memorandum of understanding (MoU), the two companies have agreed to a prototype pilot program for the 793 fleet, with testing and pre-production trials to come.

The 220-tonne trucks will form another piece of Rio Tinto’s most technically advanced iron ore mine, which will ramp up to first production over the coming few years.

Rio Tinto chief commercial officer Alf Barrios said agreements such as this were key to the company’s targets at Gudai-Darri.

“Our ambition to reach net zero emissions across our operations is a priority. Reaching this ambition will require new and innovative solutions, and partnerships with supplier partners like Caterpillar,” Barrios said.

“This collaboration represents a small but important step on that journey.”

The announcement came after the companies agreed to pioneer Caterpillar’s autonomous water trucks at the same mine, in a further step to lower emissions and increase productivity.

Caterpillar Group president Denise Johnson said Rio Tinto was a leader in commissioning these futurefocussed technologies.

“By leveraging these technologies across their sites, Rio Tinto can more safely increase productivity, efficiency and be more sustainable,” Johnson said.

“We are pleased to be part of Rio Tinto’s sustainability journey and look forward to building on our longstanding collaboration.”

Rio has continued to assess the scope of Gudai-Darri at peak production, with a $44 million prefeasibility study underway.

To cater for the raft of autonomous solutions to be implemented at the iron ore mine, Rio Tinto announced in June it would provide autonomous training solutions from Immersive Technologies.

Once trained, the mine’s workforce will be capable of operating the autonomous machinery with Caterpillar’s MineStar Command system.

CATERPILLAR HAS PARTNERED WITH SEVERAL MAJOR MINERS FOR AUTONOMOUS HAULAGE.

VITRINITE GETS GREEN LIGHT FOR VULCAN COAL MINE

Vitrinite has received approval for its Vulcan mine complex, paving the way for the development of a $160 million metallurgical coal mine in Queensland’s Bowen Basin.

The lease will unlock the first four years of an expected 15-yearplus mine life, opening the door for more than 150 full-time jobs while delivering a major economic boost to the region.

“Having the Vulcan mining lease approved for Vitrinite is a huge milestone for our company,” Vitrinite founder and managing director Nick Williams said of the approval.

“Going from a greenfield to a producing mine is a huge feat for any company, and to do it in the time we’ve done it is an amazing feat and we’re very excited.”

Vitrinite first acquired the asset in 2018, quickly accelerating the project into development soon thereafter.

Williams was buoyed by the opportunities that will come of the Vulcan mine once it begins producing two millions tonnes per annum.

“The Vitrinite family are looking forward to supplying 150 jobs to the local people,” he said. “We’re also excited about providing opportunities for local businesses.”

With the sustainability of producing coal always in question, Williams said Vitrinite is conscious of the role it needs to play to maintain the environment.

“We take our environmental responsibilities very seriously. We are adopting world-class, innovative technologies to progressively rehabilitate our pit beyond our statutory requirements,” he said.

Queensland Resources Council (QRC) chief executive Ian Macfarlane echoed Williams’ sentiments, highlighting the environmental considerations at play.

“Queensland is widely regarded as having the strictest environmental regulations in the world, which our industry is fully committed to complying with, along with our determination to lower carbon emissions and implement sustainable mining practices,” Macfarlane said.

“The Vulcan complex mine project is also the first resources project in Queensland to have its progressive rehabilitation and closure plan (PRCP) approved under new legislation introduced in 2019.”

Researchers from the University of Adelaide have discovered how a billion-year-old geological mystery could help locate the critical minerals of today.

Eclogites are known to have disappeared from geological records between 1.8 and 1.2 billion years ago, before reappearing.

Upon their resurgence, a concentration of trace elements found in igneous rocks has been recognised and these trace elements presented a link to critical minerals.

The paper, titled Mantle heating at ca. 2 Ga by continental insulation: Evidence from granites and eclogites, was written by lead author Renee Tamblyn and her associates.

Tamblyn explained the importance of her team’s discovery.

“We found evidence from the trace element chemistry of granites that suggests a large-scale heating of the continents around two billion years ago that corresponds with the assembly of Nuna, a supercontinent which completed its formation 1.6 billion years ago,” Tamblyn said.

“The Earth has generally been cooling since its formation, but Nuna had an insulating effect on the mantle, rather like a thick blanket, which caused temperatures to rise beneath the continents and prevent the preservation of eclogites and change the chemistry of granites.

“The changes in chemistry resulting from this unusual warming event during Earth’s geologic past could help to locate certain critical minerals by looking for rocks formed before or after this heating event – depending on which element is of being looked for.”

Australia presents a suitable sample for the research to continue, as the continent has regions both older and younger than the 1.8-billion-year mark when the eclogites disappeared.

“The rocks in the Northern Territory and northwest Queensland are a little older than the 1.8-billionyear mark so may be a place where we can continue our investigations into this mysterious geological case,” Hasterok said.

ECLOGITE FROM NORWAY. IMAGE: DR DERRICK HASTEROK, UNIVERSITY OF ADELAIDE.

AUSTRALIA AND INDIA TAKE NEXT STEP IN MINING PARTNERSHIP

Australia and India have discussed opportunities in coal technology, skills development and businessto-business collaboration at a Joint Working Group (JWG) meeting called Coal and Mines.

The forum was co-chaired by Australia’s head of resources division Paul Trotman and India additional secretary, Ministry of Coal, Vinod Kumar Tiwari.

The delegates also discussed issues relating to India’s coking coal imports from Australia.

Australia made presentations on its Global Resources Strategy, as well as ways of leveraging technologies and infrastructure to decarbonise energy and industry.

Tiwari provided an overview of the coal sector in India, outlining the country’s current and future coal resources, while forecasting India’s critical and strategic minerals demand and supply scenarios.

Tiwari also explained the coal and broader mining priority areas the two countries could capitalise on in the future.

Other specific conversations included India and Australia’s collaboration on clean coal technology, surface coal gasification, coal bed methane, sharing of technology deployed for fire quenching, coal-based hydrogen, and carbon capture, utilisation and storage (CCUS).

An open house discussion was also held.

The JWG meeting was a precursor to the India-Australia Energy Dialogue – an annual meeting which then took place on October 13.

The Energy Dialogue discussed the countries’ bilateral engagement on energy and resources.

Coal and Mines is one of four working groups established to support the forum, which also includes Oil and Gas, Renewable Energy and Smart Grids, and Power and Energy Efficiency units.

In June 2020, Australia and India announced a Memorandum of Understanding (MoU) on critical minerals.

The MoU has seen Australia take a significant step towards establishing itself as a reliable supplier of critical minerals for India’s growing manufacturing sector and its defence and space capabilities.