ANTIMONY SPOTLIGHT

VOLUME 116/10 | NOVEMBER 2024

MINING EDUCATION

ANTIMONY SPOTLIGHT

VOLUME 116/10 | NOVEMBER 2024

MINING EDUCATION

SAFE AND SUSTAINABLE MINE WASTE MANAGEMENT

United. Inspired.

Built for demanding underground operations, the battery-electric, automation-ready Scooptram ST18 SG gives you the ability to work in the toughest conditions without exposure to diesel particulates and toxic gases. This underground loader boasts a strong electrical drivetrain that is unmatched by any diesel engine, and when coupled with the traction control function, offers power and agility when entering the pile. Why compromise productivity for sustainability when the ST 18 SG offers it all?

WITH THE HELP OF THE METS SECTOR, AUSTRALIAN MINING COMPANIES HAVE AN OPPORTUNITY TO EVOLVE THE WAY THEY MANAGE THEIR WASTE.

There are many avenues for mining companies to improve their environmental performance.

This could involve decarbonising operations, whereby various technologies and methodologies can be implemented to drive down a miner’s carbon footprint.

The management of mine waste also offers opportunities to not only adhere to environmental regulations but also unlock operational efficiencies.

As more and more legislation is introduced to govern the way mine sites manage their waste, mining companies need to be increasingly vigilant about how they conduct themselves and how they manage leftover material from the mining process.

The Global Industry Standard on Tailings Management is one such type of reform, empowering greater proactivity to ensure the safe management of tailings facilities and avoid catastrophic dam collapses such as Brumadinho and Samarco.

To support miners on their mine waste management journey, the mining equipment, technology and services (METS) sector has been hard at work developing novel solutions for waste management applications.

The November edition of Australian Mining takes the opportunity to celebrate some of these METS companies and their innovations.

This includes Surfcleaner, which has developed patented surface separator technology to enable the capture of hydraulic oil from water.

This technology has been advantageous in underground mines, where volatile organic compounds (VOC) emissions can pose risks to

KELSIE TIBBEN

CHIEF EXECUTIVE OFFICER

JOHN MURPHY

CHIEF OPERATING OFFICER CHRISTINE CLANCY

MANAGING EDITOR PAUL HAYES

EDITOR

TOM PARKER

Email: tom.parker@primecreative.com.au

ASSISTANT EDITOR

ALEXANDRA EASTWOOD

Email: alexandra.eastwood@primecreative.com.au

JOURNALISTS

OLIVIA THOMSON

Email: olivia.thomson@primecreative.com.au

worker health and overall productivity. Surfcleaner technology collects hydrocarbons before they are emitted into the air, or find their way into water.

Mandalay Resources is seeing the benefits of the Surfcleaner technology in its water management at a Swedish gold mine. In just five days, the company was able to recover 400 litres of oil from the pumping area where it was situated.

An Australian company made up of a consortium of international businesses, Circular Mine has partnered with Amira Global to oversee the P1342 project, which is dedicated to fast-tracking the full re-use of mine tailings and refinery residue on a commercial scale.

We chat to Circular Mine about the project scope, which includes the development of a support tool for miners to make sustainable mine waste decisions, as well as a repository of practical guidelines that can be applied to any mining operation.

Complementing the industry’s mine waste management innovations, the November edition also takes the opportunity to celebrate MINExpo 2024, while we also profile Ramelius Resources –one of the fastest growing Australian gold miners.

We also wrap up the latest WA Mining Conference & Exhibition and celebrate the 2024 Prospect Awards winners.

Established in Perth in 2000, Acu-Tech Piping Systems is an Australian privately owned and operated company with a vision to be a market leader in pipeline solutions.

Acu-Tech places the utmost importance on meeting the needs of its customers, from technical assistance during design stage, through to constantly evolving the company’s extensive product portfolio to meet the needs of the market. Additionally, Acu-Tech recognises the importance of investing in the pipe-fitting industry by providing comprehensive product training.

Acu-Tech manufactures HDPE pipe and fittings at its state-of-the-art 40,000-square-metre facilities, in addition to importing and stocking a large range of products from some of the largest international pipefitting manufacturers.

Tom Parker Editor

Email: kelsie.tibben@primecreative.com.au

DYLAN BROWN

Email: dylan.brown@primecreative.com.au

CLIENT SUCCESS MANAGER

JANINE CLEMENTS

Tel: (02) 9439 7227

Email: janine.clements@primecreative.com.au

SALES MANAGER

JONATHAN DUCKETT

Tel: (02) 9439 7227 Mob: 0498 091 027

Email: jonathan.duckett@primecreative.com.au

ART DIRECTOR MICHELLE WESTON

michelle.weston@primecreative.com.au

SUBSCRIPTION RATES Australia (surface mail) $120.00

9690

Cover image: Acu-Tech Piping Systems

Jamie Spilsby - Manager at Litchfield Green Waste Recyclers (LGWR)

A

New technology from the University of Queensland is

Combining industry heavyweights

Hexagon, Scania and Fidens brought Brazil’s first remotely operated 8x4 mining truck online. Australian Mining looks at how the companies made it happen.

Fuelling the critical minerals revolution Aurelia Metals’ Federation critical minerals mine is

Partnerships

44 SURFACE MINING

The evolution of the Cat hydraulic shovel C aterpillar’s 6040 hydraulic mining shovel has taken the Australian resources industry by storm.

50 GOLD

A gold Greatland

Australian Mining takes a deep dive into Greatland Gold’s acquisition of two Newmont gold assets.

56 EQUIPMENT

Top-tier customer service

National Plastics and Rubber has expanded with a new supply centre in WA.

64 PROSPECT AWARDS

70 INDUSTRY EVENTS

A premier mining showcase

The 2024 WA Mining Conference and Exhibition was a must-see event for anyone in the mining industry.

The winners of the 2024 Prospect Awards

The 2024 Australian Mining Prospect Awards was a night of celebration, recognition and connection.

KEEP UP WITH THE LATEST EXECUTIVE MOVEMENTS ACROSS THE MINING SECTOR, FEATURING BOSS ENERGY, ALBEMARLE, THE ICMM, AND MORE.

Boss Energy has welcomed former IGO acting chief executive officer (CEO) Matt Dusci as its new chief operating officer (COO).

Dusci has more than 25 years of experience in all facets of the mining industry, including technical studies, project development, operations, business development, strategy and executive leadership.

His experience spans a diverse range of commodities, including battery metals.

For the past 10 years, Dusci has held several executive positions at IGO, which in addition to acting chief executive officer include chief operating officer and chief growth officer.

Boss chief executive officer Duncan Craib said Dusci has played a major role in the growth, development and transformation of IGO.

“With the ramp up at Honeymoon proceeding so well, we are advancing our strategy to grow the project’s inventory, production rate and mine life,” Craib said.

“As part of this strategy, we are committed to building a worldclass team of highly skilled and experienced people who can help ensure we maximise our huge opportunities.”

Albemarle has revealed several executive changes as part of its company wide structural change, most of which take effect on November 1.

Specialties business president Netha Johnson will become COO, where she will lead the company’s global manufacturing, research and technology, capital projects and process chemistry execution.

Energy storage business president Eric Norris will also move into the chief commercial officer role, where he will oversee enterprise product management, sales and commercial excellence.

Executive vice president and chief people officer Melissa Anderson will become chief transformation officer, a role that reflects Anderson’s current oversight of people, strategy and transformation.

Senior vice president of capital projects and integrated supply chain Mark Mummert will move into the chief capital, resources and integrated supply chain officer role, including expanded responsibilities for resources, joint venture management, customer service and operational excellence.

Other executive changes announced includes Stacy Grant moving from vice president and deputy general counsel, global corporate affairs to general counsel, corporate secretary and chief compliance officer.

The International Council on Mining and Metals (ICMM) has announced Tom Palmer, president and CEO of Newmont, as its new chair.

Palmer succeeds Iván Arriagada, CEO of Antofagasta Minerals, who has led the ICMM for the past two years.

ICMM is governed by a council made up of the CEOs from its 24 member companies, with the chair appointed from within the group and their term lasts for approximately two years.

“I am delighted to welcome Tom as our new chair as we embark on our new strategy to drive responsible mining practices under a consolidated Standard while enhancing dialogue and engagement with our stakeholders,” ICMM president and CEO Rohitesh Dhawan said.

“Tom has led by example in this regard, having chaired ICMM’s Social Performance Advisory Group and through his genuine sustainability leadership within our industry.”

Palmer said he is excited to be working with ICMM.

“Newmont is a founding member of ICMM, sharing its vision for a safe, just and sustainable mining industry,” he said.

“I look forward to working closely with ICMM leadership, council

members, and the wider mining industry. My focus will be on building support across the sector for a consolidated mining standard.”

Newly named Patronus Resources has promoted experienced mining executive John Ingram from COO to CEO.

Graham Ascough also joined the board as a non-executive director, bringing more than 30 years of experience in mining, while Rowan Johnston has transitioned to nonexecutive chair.

“With the merger between Patronus and PNX Metals having been successfully completed and our corporate rebranding finalised, the company has well and truly embarked on its next exciting growth chapter –underpinned by a strong balance sheet and an exceptional asset portfolio,” Johnston said.

“With drilling completed recently, a new MRE (mineral resource estimate) is being prepared for the Mertondale project and exploration drilling continues in Leonora.

“Further multiple exploration and drill programs are about to begin targeting uranium, gold and base metals in the NT. With all these programs going on, Patronus is set for a very exciting period of activity and newsflow ahead.”

AUSTRALIAN MINING PRESENTS THE LATEST NEWS FROM THE BOARDROOM TO THE MINE AND EVERYWHERE IN BETWEEN. VISIT WWW.AUSTRALIANMINING.COM.AU TO KEEP UP TO DATE WITH WHAT IS HAPPENING.

BHP IS TEAMING UP WITH COBRE TO EXPLORE TIER 1 COPPER-SILVER DEPOSITS IN BOTSWANA.

an earn-in joint venture over Cobre’s Kitlanya West and East copper projects, located on the northern and southern basin margins of the Kalahari copper belt.

The proposed transaction follows on from Cobre’s participation in the BHP Xplor program, which also

expertise to maximise Cobre’s chances of making significant new discoveries on its basin margin exploration ground while retaining 100 per cent ownership of its Ngami and Okavango copper projects, which are excluded from the potential deal.

“Successful negotiation and completion of this significant transaction with BHP ... will be a major moment in time for Cobre as a company,” Wooldridge said.

“Participating in the BHP 2024 Xplor cohort has provided the opportunity to do a belt-scale

AUSTRALIAN MINING GETS THE LATEST NEWS EVERY DAY, PROVIDING MINING PROFESSIONALS WITH UP-TO-THE-MINUTE INFORMATION ON SAFETY, NEWS AND TECHNOLOGY FOR THE AUSTRALIAN MINING AND RESOURCES INDUSTRY.

review of the Kalahari copper belt, culminating in the collection of seismic data over the prospective northern margin of the belt.

“The proposed transaction with BHP would allow us to fully fund our follow-on exploration programs and focus on discovering the Tier 1 deposits we believe may be hosted in our Kitlanya West and East projects.”

Independently, Cobre will continue advancing its in-situ copper recovery development at Ngami –with a scoping study due in early October – along with further drilling at Okavango.

In September, geoscientists had the opportunity to get up close to drill core examples from three of Victoria’s most promising mineral deposits.

The trip was organised as part of the Discoveries in the Tasmanides conference, providing attendees with the chance to examine drill core from the Fosterville and Costerfield mines, as well as the Sunday Creek gold-antimony project.

Co-led by Ross Caley, senior geologist from the Geological Survey of Victoria, the field trip took participants from Melbourne to Albury.

Along the route, key geological structures such as the Heathcote Fault and Moormbool Fault, critical features of the Costerfield goldantimony deposit, were examined.

Costerfield is known as Australia’s only antimony-producing mine, highlighting its importance in the country’s critical minerals strategy.

More than 50 geoscientists participated in the trip, with new technical data from various Victorian gold and critical minerals operations shared with attendees.

This was seen as a unique opportunity to gain fresh insights

into Victoria’s geological landscape, with a focus on enhancing exploration techniques for critical minerals and gold, key commodities for the region’s future.

Caley’s keynote presentation at the Discoveries in the Tasmanides conference provided further depth, covering the geology of Victoria and eastern Australia.

His speech emphasised the potential for new discoveries in under-explored areas of the Tasmanides region, which stretches across eastern Australia and is known for its mineral richness.

Some key information to come out of the conference is that the Lachlan orocline plays a crucial role in shaping the mineral systems in eastern Australia.

The orocline’s formation, driven by subduction and the collision of the microcontinent Vandieland, created ideal conditions for mineralisation particularly in the Ordovician-Silurian Lachlan Fold Belt.

This process led to the formation of deposits such as the Cadia and Ridgeway porphyry systems which underpin gold and copper production in New South Wales.

Lincoln Minerals uncovered highgrade uranium mineralisation at its Eridani deposit situated within the eastern Eyre Peninsula in South Australia in September.

As part of its uranium portfolio prospectivity review, Lincoln commenced a first-pass reconnaissance sampling program at Eridani earlier this year to determine the attractiveness of the Eyre Peninsula’s geological setting and assess uranium mineralisation potential within the region.

The company undertook a review of historic data from Eridani, which indicated accounts of carnotite

uranium mineralisation at the abandoned Minbrie West quarry, which previously mined for marble and talc.

To confirm the historic carnotite uranium mineralisation, Lincoln gathered 12 outcrop samples from Minbrie West and, by using portable x-ray fluorescence (pXRF) analysers, targeted the yellow mineralisation coating on the rock chips. This coating has been confirmed to be carnotite.

Some of the pXRF results included hits of 9250 parts per million (ppm) uranium at MQ12, 6219ppm uranium at UMQ11 and 6890ppm uranium at UMQ10.

The Queensland Government approved 10 projects to support almost 500 local jobs in Mount Isa ahead of planned mine closures by resources giant Glencore.

Glencore announced in October 2023 that it will close its underground copper mine and copper concentrator in Mount Isa in 2025, along with the nearby Lady Loretta zinc mine.

via the $20-million Mount Isa Transition Fund, as part of a broader $50-million structural adjustment package which also includes $30

ALMOST 500 LOCAL JOBS IN MOUNT ISA HAVE BEEN SUPPORTED AHEAD OF PLANNED MINE CLOSURES BY GLENCORE.

million to accelerate resources projects in the North West Minerals Province.

The Mount Isa Transition Fund includes $14.7 million for 10 projects including associated program delivery costs and $5.3 million for Mount Isa City Council to implement projects identified through its own economic transition strategy.

Historic drill core logs at Eridani also identified potential targets for uranium mineralisation, with the samples associated with extensive hydrothermal alteration of Donington Suite granites.

“The alteration occurs along fault and shear zones 2km southeast of the quarry and is proximal to Hiltaba Suite granite intrusions,” Lincoln Minerals said.

“The drill holes, initially part of Centrex Metals’ 2007–2011 iron ore exploration program, were not previously assayed for uranium, however, recent discoveries of uranium mineralisation by Alligator Energy, northeast of the Eridani

project area, have prompted further investigation.”

Lincoln has submitted pXRF analyses of the samples collected, with the results anticipated to be completed and released in the fourth quarter of 2024. The results will include additional mapping and sampling along the identified fault zone and will be used to aid future exploration.

Succeeding phases of the exploration program will involve reassaying historic drill core such as Centrex Metals’ drillholes to further understand the extent and grade of the uranium mineralisation in order to assist with target generation.

receive $2 million for the continued expansion of the project as it ramps up to production.

“We are thrilled to receive this approval from the State of Queensland, which underscores the significant economic impact that Ardmore is poised to have on the Mount Isa region,” Centrex managing director

Queensland Minister for Resources and Critical Minerals Scott Stewart said the almost 500 jobs are just the start of the state’s mining job creation.

“Mount Isa has been the backbone of Queensland’s resources industry for over a century and the Miles Government firmly believes the city will continue to play that role for the next

Certified Rebuild programs help you benefit from the multiple lives designed into Cat® machines, power trains and major components. They are “built to be rebuilt” for maximum value and longer life. Maximise the investment in your asset with full utilisation of a second life, at a fraction of the cost of buying new.

Access to advanced condition monitoring service with HDAdvantage™ program

Sustainability – reducing waste by reusing and recycling quality material

Finance options available

Call Hastings Deering on 131 228 or scan here to find out more

*Terms & Conditions apply.

**Offer ends 31 December 2024

THE NEW CAT DYNAMIC ENERGY TRANSFER SYSTEM ALLOWS FOR ENERGY TRANSFER TO BOTH DIESELELECTRIC AND BATTERY-ELECTRIC MINING TRUCKS.

Caterpillar introduced an innovative solution designed to address a major challenge in the mining industry’s shift to renewable energy: energy management.

The new Cat Dynamic Energy Transfer (DET) system allows for energy transfer to both diesel-electric and battery-electric mining trucks, increasing operational efficiency and reducing downtime.

The fully Caterpillar-developed Cat DET system not only supports the transfer of energy while trucks are in operation but also enhances

performance by charging machine batteries during use.

This capability allows for increased speed on grade, providing significant operational improvements and contributing to long-term sustainability goals.

“We believe Cat DET provides a technological leap for the mining industry,” Caterpillar resource industries group president Denise Johnson said.

“Our team of innovators designed this system to provide immediate benefit to miners who want to lower

Southern Cross Gold discovered a new and large gold-antimony below the historic Golden Dyke mine in Victoria in September.

The discovery was made at Southern Cross’ 100 per cent owned Sunday Creek gold-antimony project, with the mineralised zone hosting both metals and measuring at 135m.

The zone is also located 260m and 600m west, respectively, of the Rising Sun and Apollo prospects.

“The expanding Sunday Creek system coupled with the 60 kilometres of diamond drilling planned over the next year means we are well on our way to meet our aim to double the size of the Sunday Creek exploration target,” Southern Cross

their operating costs and greenhouse gas emissions today while also creating flexibility for the future.”

The Cat DET system is made up of several integrated components, including a power module, an electrified rail system, and a machine system.

This customisable rail system is adaptable to various mine layouts and can be easily moved or expanded to maximise mine site coverage.

The system’s flexibility extends to compatibility with different truck models, allowing for installation on either side of the truck.

It also integrates with Caterpillar’s MineStar Command for hauling, combining electrification and automation technologies to optimise site operations.

“We believe mine sites will benefit from enhanced efficiency with the integration of electrification and automation,”

Caterpillar senior vice president Marc Cameron said.

“When combined, these technologies will help miners achieve production targets while simultaneously managing energy demands.”

Gold managing director Michael Hudson said.

“Golden Dyke now joins Rising Sun and Apollo as the third highgrade mineralised domain in this exciting project.”

Hudson credited Southern Cross’ systemic drill approach for the find.

“Given this discovery, the company has already planned a significant

number of further holes under Golden Dyke,” he said.

Located 60km north of Melbourne, the Sunday Creek project has seen 131 drill holes completed since late 2020.

Southern Cross owns 133 hectares of freehold land at Sunday Creek that form the key portion in and around the main drilled area of the project.

MINING PROFILES RAMELIUS RESOURCES AND THE EXPANSION OF ITS GOLD PORTFOLIO ACROSS WESTERN AUSTRALIA.

In a year full of fluctuating prices for various commodities, gold has been a fairly consistent player for the Australian mining industry, with prices consistently on the up.

A company that has reaped the benefits from the sustained gold price is Ramelius Resources, a Western Australian gold miner that’s been in production since 2006.

Backed by a plethora of operating mines and a $2.49 billion market cap, Ramelius is focused on growing its portfolio through targeted exploration and value-accretive acquisitions.

An example of the latter is when Ramelius acquired Apollo Consolidated in 2021, which saw it take ownership of the Rebecca gold project, situated 150km east of the beloved mining town of Kalgoorlie.

“The company’s approach to inorganic growth – or growth through acquisition – is that it shouldn’t simply be growth for growth’s sake,” Ramelius managing director Mark Zeptner told Australian Mining. “If we are adding ounces to our production profile, they

need to be profitable ounces and that is what we have focused on with our acquisition strategy.

“Some of the acquisitions we have completed in recent years, including Musgrave Minerals, Explaurum and Spectrum Metals, have been adding resources within trucking distance of our two processing hubs at Mt Magnet and Edna May.

“Apollo and Breaker Resources differed slightly in that together they give us a resource of a sufficient scale (more than three million ounces) to support potentially building a new processing hub east of Kalgoorlie in the West Australian Goldfields.”

When Ramelius acquired Rebecca, it gave the company a project that covers a greenstone belt at the southern end of the 22-million-ounce (Moz) Laverton tectonic zone, a regionally significant structural corridor hosting multiple gold camps.

Backed by a mineral resource of 33 million tonnes (Mt) at 1.3 grams per tonne (g/t) gold for 1.4Moz, Rebecca is located 50km from the Roe gold project, which Ramelius acquired from

Breaker in 2023. Roe currently has a mineral resource of 32Mt at 1.6g/t gold for 1.8Moz.

In recognising the synergies between both projects, Ramelius viewed its Roe acquisition as a chance to consolidate its landholding in the Kalgoorlie region.

“Ramelius is due to complete a pre-feasibility study on a combined Rebecca–Roe development in the December quarter of this year,” Zeptner said.

North-west of Kalgoorlie is the Murchison region, which hosts the Mt Magnet gold mine and the Cue gold project.

To aid Mt Magnet in sustaining a long production life, Ramelius has a 10year mine plan that anticipates a total gold production exceeding 1.5Moz.

The plan includes mineral resources and production from Ramelius’ Penny, Cue, Eridanus and Bartus deposits.

“(The Mt Magnet plan) is the result of our investment in exploration on our tenements in the region and in the acquisitions of Musgrave Minerals and Spectrum Metals, which have delivered us ownership of the high-grade Cue

and Penny gold projects respectively,” Zeptner said. “Ore from these projects is being, or will be, processed through the Mt Magnet mill.

“The plan details production of 1.5Moz over 10 years at an average of 150,000oz a year and sets Mt Magnet up to be Ramelius’ flagship operation over that period.

“All-in sustaining costs are forecast to be $1700/oz over the 10 years and should average a very competitive $1350/oz for the first three years of the plan.”

Zeptner said Cue will begin being processed through the Mt Magnet mill in the December 2024 quarter, with development at the site already progressing to plan.

“Pre-strip and development activities began in June, with the first blast taking place in July,” he said.

“Ore mining has also started with high-grade ore being stockpiled ahead of road intersection work being completed and ore haulage to Mt Magnet commencing.”

Alongside its compelling gold acquisitions, Ramelius has made

a strategic investment in Spartan Resources, the owner of the Dalgaranga gold project 65km northwest of Mt Magnet.

After first acquiring an 8.9 per cent stake in Spartan in June, Ramelius gradually increased that stake to 18.35 per cent in October.

“Ramelius continually evaluates gold assets in Western Australia and will make investments in the sector where it believes there is strategic rationale, which is what happened with Spartan,” Zeptner said.

“Acquired for $180.4 million at around the end of the (2023–24) financial year, our stake in Spartan had appreciated in value by almost $100 million in the three months to the end of September. In that sense alone, it is proving to be a shrewd investment.”

Despite 2024 nearly coming to a close, Zeptner believes the recent strength in gold means the bull market will continue for at least the short-term.

“The US’ recent move to cut interest rates is broadly expected to be positive for gold as fixed rate investments become less attractive,” he said.

competitive as it has been in recent years.

“Combined with the strong gold price, the easing in input cost inflation means that most Australian miners have seen their profit margins expand, which has certainly been the case for Ramelius.

“We are also benefiting from the investments we have made in prior years, which have helped to lower our cost base significantly.”

Building off the record 293,033oz it produced during the 2023–24 financial year, Ramelius plans to close the 2024 calendar year on a high.

“Our key objectives for the rest of the year are continuing to focus on operational excellence and growing the resource base through smart, targeted exploration, as well as delivering the Eridanus and Rebecca–Roe studies,” Zeptner said.

“In terms of the Australian gold industry, we have started to see an easing in those inflationary pressures that grew quite acute during the (COVID-19) pandemic.

“In Western Australia at least, the labour market is no longer as

“We will keep an eye out for attractive acquisition opportunities should they arise, noting that we retain significant financial flexibility and a business development team that is match-fit and ready to move quickly.

“More broadly, we want to ensure we adhere to our mission statement of being a sustainable gold producer that focuses on delivering superior returns for stakeholders.” AM

NEW TECHNOLOGY FROM THE UNIVERSITY OF QUEENSLAND HAS THE POTENTIAL TO REVOLUTIONISE MINE WASTE MANAGEMENT.

NEW TECHNOLOGY FROM THE UNIVERSITY OF QUEENSLAND IS PROVING TO BE A GAME-CHANGER FOR MINE

The mining process can often lend itself to waste creation.

While the industry is essential for economic advancement and the energy transition, it almost inevitably generates mine waste or tailings. But the way miners are dealing with tailings is changing.

It’s estimated that the global mining industry produces around 10–12 billion tonnes of tailings per annum, a number that seen the industry rallying to move towards more sustainable practices in tailings management.

Monitoring and managing this waste has become increasingly complex and essential for the mining industry, particularly as environmental regulations tighten and sustainability takes centre stage.

University of Queensland Sustainable Minerals Institute associate professor Mansour Edraki spoke to Australian Mining about the new developments in drone and sensor technology that are transforming how mine waste is monitored and managed.

“Traditional methods of waste management involve drilling into the mine waste,” Edraki said. “In many cases, especially with mine tailings that are partially saturated, it’s not safe to drill.

“This new technology is nonintrusive, combining geophysics with geochemistry to monitor mine waste more effectively and accurately.”

This fusion of geophysics and geochemistry allows for a more comprehensive understanding of the properties of mine waste, offering several advantages over conventional methods.

Edraki said this integration not only improves accuracy but is also more costeffective, as it eliminates the need for extensive sampling and lab analysis.

“There are significant advantages to using geophysics and geochemistry together,” Edraki said.

“The geophysical methods, like electrical resistivity and induced polarisation, have been used in exploration, and now we are applying them to mine waste monitoring.”

One of the most exciting aspects of this new technology is its ability to address acid mine drainage, a persistent environmental issue in the industry.

Acid mine drainage occurs when exposed rocks interact with air and rainfall, resulting in contaminated water.

Edraki said that by using this innovative blend of techniques, researchers can better predict and monitor the generation of acid mine drainage from mine waste facilities.

“It’s really about the long-term stability of these facilities, both from a chemical and physical perspective, which involves safety and erosion concerns,” Edraki said.

The introduction of 4D monitoring has enabled mining companies to track changes in mine waste facilities over extended periods.

This feature is especially beneficial for monitoring the rehabilitation of tailings storage facilities after a mine’s closure.

“Drilling provides a snapshot in time,” Edraki said. “But with

this system, you can go back and monitor changes, ensuring the facility remains safe, stable, and nonpolluting for the next 100, 200, or even 500 years.”

The technology has already garnered attention from major mining companies, including Rio Tinto, which selected Edraki’s proposal after initiating an open call for sensor technologies that could monitor waste storage facilities across its global operations.

Edraki’s team has since been working closely with the company to implement these advanced monitoring systems at a prominent copper mine.

Beyond addressing current challenges, Edraki believes that this technology could play a vital role in the future of mining, particularly in the context of the growing demand for critical minerals.

According to the International Energy Agency, demand for these minerals is expected to increase by three and a half times by 2030 to meet netzero targets by 2050.

“We are going to produce a lot more minerals, which means more mining and, consequently, a lot more waste,” Edraki said.

“In copper mining, for example, more than 90 per cent of the mined material becomes waste. So, the business-asusual approach won’t work.

“We need much more intelligent, advanced ways of monitoring and predicting risks from these waste storage facilities.”

In addition to waste monitoring, this technology also has significant implications for land rehabilitation and mine closure.

Rehabilitation and closure costs are often underestimated, and the lack of appropriate tools for monitoring these processes makes it difficult to measure success accurately.

However, this new approach provides mining companies with the data needed to ensure rehabilitation efforts are effective and sustainable in the long term.

“Mine closure is a significant cost for the industry, and having enough data to meet closure criteria is crucial,” Edraki said.

“This technology can help monitor the performance of waste storage facilities, engineered covers, vegetation, and water balance, ensuring that we’re on the right trajectory for rehabilitation.”

As the mining industry continues to navigate the challenges of waste management, Edraki’s work offers a promising solution.

By combining geophysics, geochemistry, and advanced mathematical models, this approach not only improves the accuracy of mine waste monitoring but also enhances the industry’s ability to predict and mitigate environmental risks.

With major companies like Rio Tinto already on board, this technology has the potential to become a game-changer for the future of mining.

The Sustainable Minerals Institute is also working on a variety of different initiatives to tackle mining waste, including superpowered microbes.

The unidentified microbes are able to reduce the extreme alkalinity of bauxite residue (also known as red mud), and are a valuable technology that transforms toxic waste into functional soil.

Researchers say that while working on red mud, the microbes were noticed to be not only surviving in the extreme pH and salinity, but neutralising the hazardous alkaline wastes.

The Sustainable Minerals Institute said many mine sites may contain concentrations of new economy metals – metals and mineral elements essential to the development of emerging renewable, medical and consumer technologies.

Pyrite is one example of these metals. A sulphide mineral commonly found in mine waste, pyrite contains significant concentrations of cobalt, a critical mineral used for manufacturing electric vehicles. Pyrite is commonly known as “fool’s gold” for its brass-yellow colour. Other sulphides such as sphalerite and molybdenite contain indium and rhenium, used for touchscreens and high strength alloys.

IT’S ESTIMATED THAT THE GLOBAL MINING INDUSTRY PRODUCES AROUND 10–12 BILLION TONNES OF TAILINGS PER ANNUM.

As technology companies increasingly look to alternative resources for their metals, a case for reprocessing mine waste is starting to gain traction in the industry.

The UQ team is working on a four-year, $1 million project with the Queensland Government’s Department of Natural Resources, Mines and Energy (DNRME) examining new economy

metal concentrations in Queensland’s mine wastes.

There are approximately 120 abandoned ‘priority’ mines in Queensland, with many containing mine waste features.

With researchers finding innovative ways to deal with tailings and mining companies working to create more ecofriendly mines, the future is bright for a more sustainable mining industry.

MONITORING AND MANAGING WASTE HAS BECOME INCREASINGLY COMPLEX AND ESSENTIAL FOR THE MINING INDUSTRY.

ACU-TECH PIPING SYSTEMS IS RENOWNED FOR ITS COMMITMENT TO MANUFACTURING AND SUPPLYING BESPOKE POLYETHYLENE PIPE SOLUTIONS.

Waste management is critical to all mining operations. If waste material such as tailings and slurry are not handled safely and responsibly, there can be ramifications for not only the environment but also a mine’s social license to operate.

This is where Acu-Tech Piping Systems can help.

Acu-Tech manufactures and supplies comprehensive polyethylene (PE) pipe systems for a range of industries such as mining.

“We’re an Australian manufacturer that supplies directly to the mining company or contractor, providing all the necessary pipeline solutions and fittings,” Acu-Tech chief executive officer Ivan Morren told Australian Mining.

For years, PE pipes have been the preferred choice for various mining applications due to their proven performance in harsh terrains and extreme climates. Unique advantages include chemical resistance and fully

“PE is also the most economical pipe system available as it’s durable, making it suitable for the harsh environments that are seen in mine waste and tailings.”

PE pipe is also renowned for its flexibility, enabling easy installation and transportation across uneven landscapes with no special preparation needed.

Unlike single-use plastic material, PE pipes are built to last, reducing the need for frequent costly replacements and minimising environmental impacts.

“PE pipe is built to have a long design life and is 100 per cent recyclable,”

Acu-Tech general manager Donovan Morren told Australian Mining

“Our PE100 pipe product, AcuTherm, is specifically manufactured to be used above ground. Because it’s white and not the standard black colour, it doesn’t absorb heat, keeping the material cool and the external layers UV (ultraviolet) stabilised.”

tailored to the unique needs of the mining industry.

Since the company’s foundation in 2000, Acu-Tech’s piping systems and solutions have been used for mining applications such as slurry and tailings lines, above-ground pipelines,

The company has supplied PE piping solutions to a number of Australian mining projects, one being the Iron Bridge iron ore mine in Western Australia.

“As far as we are aware, it was Western Australia’s largest PE pipe project,” Ivan said.

“It required the manufacturing and delivery of a 270km-sized PE liner pipe, which was used as a corrosion liner within a high-pressure steel pipeline.”

Acu-Tech delivered the PE pipes to the project site through over 900 21m

ACU-THERM WHITE PE PIPES ARE DESIGNED TO KEEP WATER OR SLURRY COOLER, LEADING TO LONGER SERVICE

extendable truck and trailer movements within a compressed timeframe. The project scope was completed on-time, demonstrating Acu-Tech’s versatility and ability to deliver a range of projects.

“We do a lot of large and small projects,” Donovan said. “For the large projects, we specifically have a project manager assigned to them to ensure the

The company maintains its competitive edge through its modern production and distribution facilities – one of which was recently opened in Brisbane.

The expansion also helps AcuTech meet the increasing demand for large-diameter pipes, and offers mining contractors in the eastern states

with quicker delivery times and more efficient service.

Above all, Acu-Tech always works towards continuous improvement.

“We’re the only pipe manufacturer with a registered training organisation and a NATA (National Association of Testing Authorities) accredited laboratory for weld testing and our

own transport fleet to get pipes to site,” Ivan said. “We also have an equipment hire division that provides equipment to contractors and asset owners … allowing us to be in full control of our service to the installation contractor.

“They are able to get everything from one source, making it easy for the project to be a success.” AM

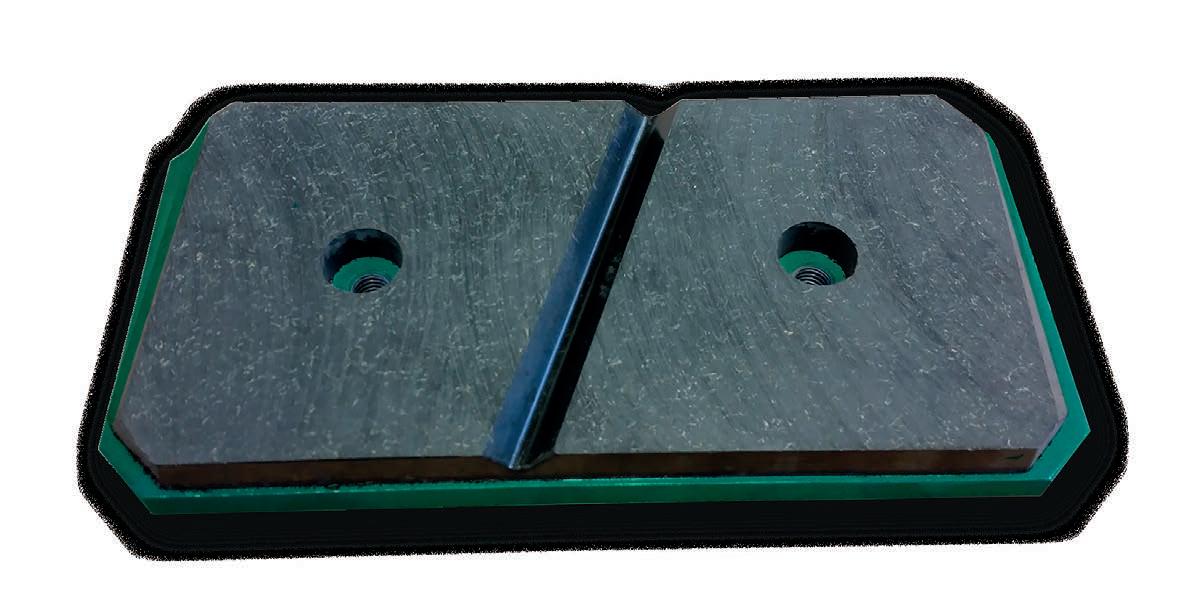

REGAL REXNORD’S GREEN BRAKE PADS CAN BE FOUND IN CONVEYORS, MINE WINDERS AND HOISTS.

One could be forgiven for only considering tailings when thinking about mine waste, but there are numerous points throughout the mining value chain where waste can be found.

Luckily, modern mines have a myriad of options when it comes to these sources of waste, with manufacturers working to help miners step into a new era of sustainability.

One well-known source of waste in any industry are brake pads. While essential to safety, traditional brake pads are designed to wear down through friction that can release harmful materials and particulates into the environment.

That’s why Regal Rexnord, through its brake solutions arm Svendborg Brakes, developed an organic green brake pad, which aims to ensure not only functionality but overall sustainability.

Regal Rexnord national product manager Rex Sinclair said the innovation was born out of the company’s ‘green principles’.

“By focusing on energy-efficient products and systems, we aim to reduce the power required to deliver motion, thereby enhancing productivity while minimising environmental impact,” Sinclair told Australian Mining

“This commitment not only addresses the growing demand for sustainable practices but also aligns with Regal Rexnord’s dedication to innovation and customer satisfaction.

“Through these efforts, Regal Rexnord strives to contribute to a more sustainable future, benefiting both its customers and the planet.”

The green brake pads were originally designed to meet the stringent environmental and performance requirements of wind turbines with a diverse range of friction qualities.

Once Regal Rexnord saw the benefits the green brake pads were able to achieve in turbines, they were developed for other technologies like mining conveyors.

Today, the green brake pads can be found in not only conveyors but mine winders, winches and hoists, as well as ball and sag mills.

“The development of Svendborg Brakes’ green brake pads was driven by the need to address environmental concerns associated with traditional brake pads, originally starting with wind turbines,” Sinclair said.

“Traditional brake pads often produce dust that can contaminate the environment and pose health risks to maintenance personnel.

“By creating brake pads made from non-asbestos organic materials, Svendborg Brakes aimed to reduce the environmental impact and enhance safety.”

Sinclair said the innovation was thanks to the company’s extensive research and development (R&D) capabilities, which includes an engineering team based in Newcastle, New South Wales.

“As a result of significant investment and accumulated knowledge, our

HEXAGON, SCANIA AND FIDENS BROUGHT BRAZIL’S FIRST REMOTELY OPERATED 8X4 MINING TRUCK ONLINE. AUSTRALIAN MINING LOOKS AT HOW THE COMPANIES MADE IT HAPPEN.

When the Samarco and Brumadinho dam disasters took place in 2015 and 2019, respectively, it signalled a need for change in the management of tailings dams.

In response to the incidents, the Brazilian Government elected to ban tailings dams built using the upstream method.

The construction of upstream tailings dams involves a dyke that continually expands upwards with the installation of raising lifts to accommodate waste as the tailings level rises.

On the other hand, downstream tailings dams are built on the dam wall away from the tailings pond, with the dykes built vertically on top of each other.

In light of the Brumadinho incident, the Brazilian Government mandated the decommissioning of all existing tailings dams by August 2021, which was later extended to February 2022.

The decision has led Brazilian mining companies to consider remotely operated vehicles that can access highrisk areas such as tailings dams without having a negative effect on the safety of workers and local communities.

Listening to this market need, Hexagon partnered with Scania and Fidens to create Brazil’s first ever remotely operated 8x4 mining truck.

The trailblazing partnership saw each company combine their technology, equipment and expertise.

Hexagon – a global leader in digital reality and autonomous mining solutions – brought its HARD-LINE TeleOp solution to the partnership.

TeleOp remotely operates any heavy machinery from a control station both on the surface and underground. This enhances safety by eliminating operator exposure to common mining hazards such as dust, flying rock, falls, diesel fumes, and noise, allowing the operator to comfortably control the equipment from a distance.

THE REMOTELY OPERATED SCANIA G 500 XT 8X4 MINING TRUCK HAS A TOTAL GROSS WEIGHT CAPACITY OF 60 TONNES.

The system also minimises travel risks and increases traffic control, keeping workers safe and operations moving.

TeleOp can keep machines working even during shift changes and blasting cycles, increasing productivity.

Supported by a user-friendly and customisable interface that can be applied to any machine, TeleOp provides ease of use across all equipment brands, one being Scania, a transport solutions provider.

“Just over a year ago, our partners Hexagon and Fidens came with a proposal,” Scania business development director Marcelo Gallao said.

“We have developed a lot of trucks for decommissioning dams. It was then that we came to drafting the first idea of a tele-operated Scania truck.

THE HARD-LINE TELEOP SYSTEM ENABLES THE SAFE TELE-REMOTE OPERATION OF HEAVY MACHINERY FROM A CONTROL STATION.

“With a total gross weight capacity of 60 tonnes, the largest capacity in tele-operated mining trucks, the eight-by-four truck has two drive axles and a dual-front steering system.”

THE HARD-LINE TELEOP SYSTEM WAS APPLIED TO A SCANIA G 500 XT 8X4 MINING TRUCK IN JULY 2024.

TeleOp was applied to a Scania G 500 XT 8x4 mining truck in July 2024, with the Fidens team sharing their mining expertise with Hexagon and Scania along the way.

“The new truck allows you to carry 50 per cent more cargo with the same investment in technology, the same operator and with practically the same operating costs, bringing around 30 per cent more productivity and more safety when performing services,” Fidens commercial director Thiago Frauches said.

Hexagon autonomous solutions – mining president Latin America Rodrigo Couto described the partnership as “a watershed moment for Brazilian mines”.

“We are shaping a new reality, demonstrating with our partners how technology can help mines be more productive and address the critical need for tailings dam decommissioning,” Couto said.

“Because TeleOp is adaptable to other truck models, this is just the beginning of what we know will be a highly impactful and positive transformation for the industry.” AM

Upgraded 800i crushers with new ACS-c 5

Even the best can always get better. Upgraded 800i crushers with new ACS-c 5 are our smartest, safest and most productive yet – designed around the needs of the people who work with them to raise the bar of what a crusher can be. Combining simple yet robust mechanical design with powerful user-friendly automation, 800i crushers are true workhorses that improve your ability to process more material, more accurately and more sustainably. Discover the upgraded 800i crusher series with new ACS-c 5 today, and see what’s possible when a crusher is designed with you in mind.

Underground mines can be prone to poor air quality, with diesel particulates and volatile organic compounds (VOCs) posing risks to worker health and overall productivity.

Both surface and underground mines can also face problems of water being polluted by oil and diesel, potentially polluting rivers or groundwater as a result.

But what if VOCs could be mitigated and underground mines could be freed of the air pollution to which they are commonly exposed, and there would be an efficient way to address water contaminated with oil and diesel?

Enter Surfcleaner, which has developed patented surface separator technology to support the collection of hydrocarbons before they enter the air or end up in water.

The surface separator has three operations built into one system –collection, separation and discharge.

“Based on gravimetric separation, the Surfcleaner technology supports the separation of fluids due to density difference,” Surfcleaner chief executive officer Johnny Sajland told Australian Mining. “A flow of water, oil and/or diesel is collected at the centre of the system. With negative pressure, created by a propeller at the bottom of the system, an inlet flow is created at the centre of the unit.”

When fluid reaches the deflection discs, the fluid velocity decreases, and the separation takes place.

Hydrocarbons rise inside the Surfcleaner unit, with clean water exiting from the bottom. When the machine becomes full of hydrocarbons, the pollutants are automatically discharged into an external tank or floating barge.

The Surfcleaner machines, made up of the SCO 8000 and SCO 1000 models, are fully automated systems, with the SCO 1000 unit able to be operated from a mobile phone or tablet.

Internet of Things (IoT) enables operators to monitor the separation process in real-time, and data can be downloaded to support further analysis or create reports.

Sajland said Surfcleaner technology stands apart from what is available elsewhere on the market.

“The Surfcleaner technology completes three operations all within a single system,” he said.

“This is achieved with high separation efficiency (up to 99.5 per cent) and extremely low power consumption, a combination we believe is unmatched by any other technology in the market.

Surfcleaner can significantly improve working environments in underground mines, improving water quality, enhancing a mining company’s environmental performance and its social license to operate.

“Surfcleaner’s system effectively removes surface pollution and significantly reduces VOC emissions, improving air quality and the working environment,” Sajland said.

“Additionally, our system is highly adaptable to demanding environments, proving less sensitive to sediment, sand particles and dust from drilling operations compared to alternatives like high-speed separators and filtration systems.”

Surfcleaner’s technology can remove oil layers as thin as 0.1 micrometre (μm), continuously ensuring a completely oil-free water surface. And with the SCO 1000 weighing in at less than 30kg, the machine is also

“In sites where the Surfcleaner technology has been installed, mine workers have noted a noticeable improvement in air quality, particularly in underground mines. This is due to the system continuously collecting and separating hydraulic oil and

The ability to generate data provides complete visibility of a Surfcleaner operation, with energy usage, the volume of oil collected, and the amount of water processed able to be monitored. This can support sustainability reporting and operators’ compliance with water regulations.

Mandalay Resources, which uses the system at a gold mine in northern Sweden, has been a key beneficiary of Surfcleaner’s technology. In just five days, the company was able to recover 400 litres of oil from the pumping area where it was situated.

“This is a massive difference and is making the entire process of managing wastewater much easier ensuring we operate well within national mining industry regulations,” the foreman of Mandalay Resources Sweden’s mining construction division said.

Surfcleaner not only sees a market for its technology in underground mines, but also in metal processing applications such as smelters, as well as in power generation.

And given the company’s technology is proven in all these applications, Surfcleaner is ready to make a mark in Australia. The company aims to establish direct partnerships with Australian mining companies and distributors to further the technology’s reach.

“Local distributors will be instrumental in communicating the sustainability benefits of our technology to stakeholders, helping Surfcleaner position itself as a leader in the green technology space and achieve long-term growth,” Sajland said. AM

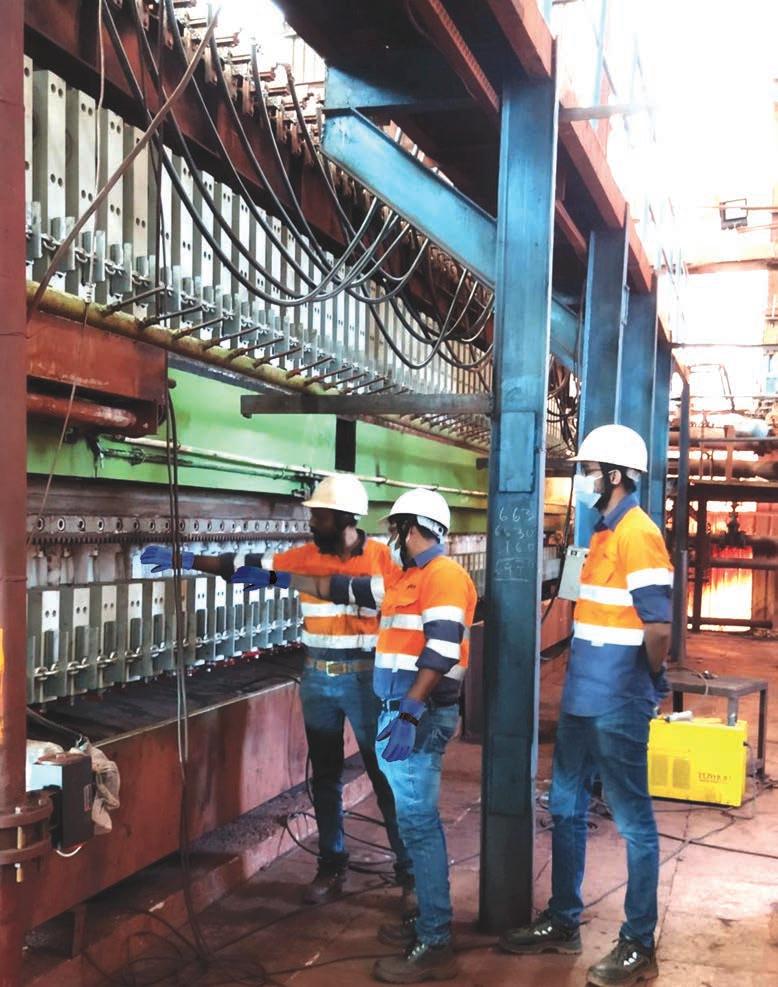

AUSTRALIAN MINING SAT DOWN WITH THEJO AUSTRALIA TO DISCUSS WASTE MANAGEMENT AND THE ROLE OF FILTRATION IN MINERAL PROCESSING.

Waste management is a crucial concern in the mining industry, especially when there is growing emphasis on environmental sustainability and stringent regulations.

Efficient disposal of waste, particularly in mineral processing plants, is more important than ever.

One major challenge in this sector is the effective separation of solids and liquids in slurry form, a core process in mineral processing.

Thejo Australia’s filtration division has a range of solutions to address this need, playing a key role in waste management across the industry.

Pressure filtration is essential for solid–liquid separation in mineral processing plants, particularly in the final stages where valuable minerals are extracted from slurry.

The process involves removing water to concentrate the mineral product and treat the tailings, leading to reduced waste and more sustainable operations.

Thejo Australia has made a name for itself in this space by providing highquality filtration products tailored to the specific needs of each application.

These solutions not only enhance operational efficiency but also contribute significantly to environmental compliance.

Thejo Australia specialises in concentrate filtration, a critical step that sees mineral slurry undergo filtration to remove water before further processing.

Using advanced materials and customised designs, Thejo Australia’s HIPO filtration products aim to ensure optimal performance while minimising product loss.

HIPO filtration parts, designed for pressure filter presses, are engineered to meet the specific requirements of each project, with efficiency and regulatory compliance a top priority.

The ability to remove water effectively from the concentrate improves the quality of the final product while reducing operational waste.

Tailings pose a significant environmental risk if not managed properly.

In the past, tailings were often disposed of in slurry form, a practice that has led to incidents of dam failures and water contamination.

These risks have driven countries such as Australia to introduce strict regulations mandating that tailings must be filtered before disposal.

Thejo Australia’s filtration solutions aim to ensure tailings are dewatered to a solid state, reducing the environmental footprint and allowing for the safe recycling of water back into the processing cycle.

a comprehensive range of retrofit filtration spares under its HIPO brand, designed to integrate seamlessly with existing systems.

These high-performance components aim to optimise filtration processes, enhancing concentrate filtration and tailings management.

The company also undertakes retrofitting and re-engineering of filter presses to increase operational efficiency and render operation and maintenance services to its clients.

Thejo Australia’s filtration parts include:

• r ubber diaphragms that are essential for maintaining pressure in the filter chamber, enabling effective liquid release and solid–liquid separation

• plate pack seals critical for preventing leaks, ensuring system integrity during the filtration process

• f illing shoes to facilitate uniform distribution of slurry across filter plates, ensuring efficient filtration

• pinch valve sleeves for ensuring precise control of slurry, filtrate and air flow, boosting system efficiency

reduce waste and meet the required environmental standards.

Stringent environmental regulations now mandate the filtration of tailings and the reuse of water in many regions. This shift aims to prevent environmental damage, conserve resources, and reduce the risk of catastrophic tailings dam failures.

Thejo Australia’s filtration solutions are designed to help mining companies meet these legal requirements while maintaining high levels of operational efficiency.

Waste management is an integral part of modern mining, and Thejo Australia is determined to be at the forefront of providing filtration solutions that enhance both efficiency and sustainability.

By minimising waste, conserving water, and ensuring compliance with strict regulations, Thejo Australia is helping its clients stay ahead in a competitive and increasingly ecoconscious industry. AM

The Schlam Hercules open-cut dump body continues to improve the payload capacity of all classes of haul trucks, across all commodities, the world over.

Engineered to meet the challenges of hard rock mining, the unique Hercules curved design offers a lighter body, with outstanding strength and durability.

Being lighter means your fleet can carry more payload every trip. With a payback period of as little as a few months, you’ll be rewarded with a solution that will keep delivering for longer.

Every Hercules is custom engineered to meet your unique site-specific requirements. We can also design and supply the right wear package, and even a wear maintenance program, to further extend the life of your Hercules body.

Maximise your payload productivity with the Schlam Hercules dump body.

schlam.com/hercules

Since its foundation over 30 years ago, Mechanix Wear has manufactured its gloves to protect the hands of heavy industry workers while withstanding tough environmental conditions.

But like any piece of personal protective equipment (PPE), when the gloves reach the end of their lifespan, they are replaced and the old material is discarded.

However, the correct disposal of such material isn’t always a clear process, meaning millions of tonnes of textiles end up in landfill each year, with PPE from all industries acting as a major contributor.

To help prevent its old gloves from ending up in landfill, Mechanix Wear has partnered with Melbourne-based garment recycling facility UPPAREL

to create RevUp, a recycling program that extends the lifecycle of the gloves.

The initiative is especially appealing to Mechanix Wear commercial account manager – western region Ashley Rozze, who has a background working in the waste industry.

“We have partnerships within the retail sector where our gloves have been a part of UPPAREL’s recycling process for over 12 months,” Rozze told Australian Mining

“RevUp is our exciting new initiative. Here, we’ve looked at consumption rates of our gloves to understand the impact we have on landfill.

“We anticipate for just one of our end users, in just one style of glove, we will save over four tonnes of waste from landfill based on their current consumption.”

Mechanix Wear conducted extensive research into various Australian

recycling programs to find its perfect match.

“Mechanix was adamant it needed a program that was transparent and easy to implement,” Rozze said. “This led us to UPPAREL, which has shown creativity and innovation in how it uses the waste.”

When Mechanix Wear gloves arrive at UPPAREL’s facility, they are sorted into two groups: gloves that can be reused and gloves that can be recycled.

The gloves that can be reused are circulated through UPPAREL’s 450 charity partners to find a new home, and the recyclable gloves are converted into various types of products.

“The gloves might be shredded to make FluffUP, which is used to fill things like soft toys, beds or cushions,” UPPAREL partnerships manager Riley Aickin told Australian Mining “They could also be used to make UPtex, a material from UPPAREL that is made entirely from recycled textiles. UPtex can be used to make slippers, desk mats, furniture – the possibilities are endless.”

UPPAREL also recycles material to create FillUP, a material that can be utilised to replace polyurethane foam commonly found in couch cushions and plush toys.

“Polyurethane foam can sometimes be recycled, but is quite difficult to recycle,” Aickin said. “FillUP is an easily recyclable replacement for that.”

The RevUp program follows a four-step, closed loop process. This begins with the user wearing Mechanix Wear gloves.

Prioritising durability and efficiency, Mechanix Wear gloves have been created to withstand the tough conditions of the mining industry, allowing the user to get the most out of every pair.

Once the gloves have reached the end of their life, Mechanix Wear utilises

an easy and accessible reverse logistics process to collect the used gloves so they can be recycled.

The gloves are then sorted and processed through UPPAREL’s advanced recycling and upcycling techniques.

The facility’s revitalisation process turns the waste material from the gloves into valuable new resources, giving the material a second life.

The revitalised materials are then turned into new products or raw materials for future use, reducing the need to create new resources, thus reducing environmental impact.

“RevUp stands out in the Australian mining sector by offering an innovative approach to PPE waste management alongside its trusted functional protection from Mechanix Wear gloves,” Rozze said.

“We have simplified the collection process, making it easy for mining operations to participate. Each site will have different challenges, which is why this program can be tailored to suit what the end user needs.

“The program acts as a single collection point for all Mechanix Wear gloves – even when covered in grime or oil.”

Since launching at the Queensland Mining Industry Health & Safety Conference in August, RevUp has set the mining industry abuzz.

“When we talk about the RevUp initiative, people genuinely seem really excited about it, indicating the need on site for an easy and sustainable recycling solution,” Rozze said.

Currently, RevUp upcycles all Mechanix Wear gloves, with the exception of disposables due to their thin nature. Excitingly, Mechanix Wear is actively exploring innovative solutions to make it possible for every glove, including disposables, to undergo the RevUp process.

RevUp is just one example of Mechanix Wear’s ongoing commitment to environmental, social and governance (ESG) initiatives.

“We are always looking for ways to increase recycled elements within our manufacturing process and ways to consider our impact on the world,” Rozze said.

“What has become evident is there will be times where the materials within our gloves cannot be altered with current technologies, and hence it’s important to ensure the end of life of our gloves is considered, regardless of the material used.

“Without compromising on glove quality, RevUp prevents our gloves from ending up in landfill, enabling us to genuinely work towards minimising the impact of waste within Australia.” AM

MINE TAILINGS CAN NOW BE REPURPOSED IN NEW, INNOVATIVE WAYS.

CIRCULAR MINE IS TAKING A HOLISTIC APPROACH TO AUSTRALIA’S MINE WASTE MANAGEMENT CHALLENGES.

Waste management may be an inevitable final step in the mining chain, but it doesn’t have to be an afterthought.

With so many of Australia’s mines hungry for greener practices, there are those who believe mine waste is the key to positioning the mining industry at the centre of a circular economy.

Circular Mine, an Australian company made up of a consortium of international businesses, is one such believer, with a mission to reduce mine waste to zero.

With the collaboration boasting an extensive team of engineers, technicians, researchers and laboratory facilities with experience in water, tailings and recycling, the company first got its start in the 2020 BHP tailings challenge when it beat out 170 companies to become one of nine successful businesses to launch into the mining sector.

Circular Mine managing director Michael Ingwersen said the company has been working hard to make the most out of the resources miners unearth in Australia and across the globe.

“Circular Mine is all about environmental, social and governance (ESG) responsibility to eliminate mine waste and make the most out of the resources we mine,” Ingwersen told Australian Mining

“We view mine waste such as tailings as a resource for other industries that can transform mine waste into sustainable resources such as clean soil, construction and industrial materials.

“We have global partners in a range of industries, including research and development institutions and organisations such as Amira Global who focus on improving the efficiency, productivity, and sustainability of mining operations by linking the industry with solution providers.”

Amira Global is an independent global not-for-profit organisation representing members from the resources industry that seeks to enhance, sustain and deliver transformational research and development across the mining value chain.

Circular Mine and Amira Global, together with mining and technology companies, are now aiming to lead the charge through the Amira P1342 project – dedicated to fast-tracking the

full re-use of mine tailings and refinery residue on a commercial scale.

The project scope includes the development of a support tool for miners to make sustainable mine waste decisions, as well as a repository of practical guidelines that can be applied to any mining operation.

The aim is to address the technical, collaborative, environmental, regulatory, community and legislative aspects of the mine waste management process.

Circular Mine recently explored this approach at one Australian mine where it discovered that, once decontaminated, approximately 40 per cent of the mine’s tailings could be used as a geopolymer construction material, with the rest able to be used as a topsoil dressing product.

Ingwersen said these kinds of findings have huge potential for the industry and the environment, as geopolymer construction materials take 70 per cent less carbon emissions to make than traditional construction materials.

“The question we ask ourselves is, ‘How do we make the most out of resources?’,” he said. “They’ve already been mined, they’ve been processed, now we want to turn what’s left into products that can benefit mankind.”

For mine waste that isn’t able to be re-purposed into a new product, Circular Mine can still help operators take a greener approach.

“While our mission is to re-use 100 per cent of mine waste, there are significant opportunities for carbon capture where offsite repurposing potential is limited,” Ingwersen said.

“On a recent project at a mine site, we were able to demonstrate at lab scale that we could capture 13 kilograms of CO2 from a tonne of mine waste, which is a significant amount of carbon.”

While many mine waste management approaches look at extracting certain re-sellable minerals from the rest, Ingwersen said Circular Mine differentiates itself by looking at the bigger picture.

“It’s important to look broadly and bring together different solutions from different industries to find innovative uses for mine waste, and focus on the bulk, not just the one-percenters,” he said.

“It’s a collaborative approach between Circular Mine, our global partners, organisations like Amira Global and Austmine and the mines themselves that will help us eliminate waste.

“Together, we are making zero mine waste a reality.” AM

Only Enduron® HPGR comes with a 10-year bearing warranty. Not that you’ll need it. After all, there hasn’t been one premature bearing failure to date. Enduron® HPGR delivers unmatched grinding efficiency, even when processing the hardest rocks, boosting mineral recovery. Expect ≥95% equipment availability, so operators can rest assured production targets

will be achieved whilst using the lowest possible resources. With lowest energy consumption and no water or grinding media required, typical operating costs for HPGR based circuits are over 20% lower compared to conventional SABC circuits whilst reducing comminution CO2 emissions by 30%. It’s no wonder we say Enduron® on and on and on.

AGAINST A BACKDROP OF SURGING PRICES, AUSTRALIA IS REALISING ITS PLACE AS A FUTURE ANTIMONY EXPORT PARTNER.

Antimony has surged in interest across Australian investment portfolios, simultaneously driven by rising prices and the quality of local antimony exploration assets.

A key material for solar panels, antimony is also a central input for high-tech and defence applications. The critical mineral is also seen as a promising anode material for lithiumion batteries.

While China dominates antimony production, making up 48 per cent of global output according to the latest United States Geological Survey, the country recently placed export controls on six antimony products, including antimony ore and antimony oxide.

This sent prices above $US25,000 per tonne (t), which is sure to impact the US, one of the world’s key antimony buyers.

The US, which uses antimony in a variety of defence products such as ammunition, nuclear weapons and night-vision goggles, consumed 22,000t of the critical mineral in 2023. China accounted for 63 per cent of these imports.

The antimony market’s reliance on China highlights the importance of alternative supply pathways, an area in which Australia is looming as a potential partner.

So which companies are advancing antimony projects in Australia?

Southern Cross Gold (ASX: SXG)

Sunday Creek, one of Australia’s most significant gold discoveries in recent times, doubles as an antimony project.

Southern Cross Gold has completed more than 130 drill holes for 58,494m at Sunday Creek since late 2020, with three high-grade mineralised domains delineated at the project: Rising Sun, Apollo and Golden Dyke.

The company made a new discovery at the Victorian asset in early September, with a 135m-wide goldantimony zone identified below the Golden Dyke mine.

Drill hole SDDSC130 intersected seven high-grade veins over a 230m downhole interval, with visible gold discovered 10 times and nine assays returning more than 20 grams per tonne (g/t) gold, with up to 124g/t gold recorded.

The drill hole also returned 10 assays of more than five per cent

antimony, with a peak grade of 31.5 per cent antimony.

“The scale of the Sunday Creek goldantimony system continues to grow impressively,” Southern Cross Gold managing director Michael Hudson said. “This new discovery is located 260m and 600m west, respectively, of the Rising Sun and Apollo mineralised bodies.

“The expanding Sunday Creek system coupled with the 60km of diamond drilling planned over the next year means we are well on our way to meet our aim to double the size of the Sunday Creek exploration target.”

Larvotto Resources (ASX: LRV)

Larvotto’s Hillgrove antimony deposit is the largest in Australia and one of the 10 largest in the world.

The New South Wales project boasts a maiden ore reserve of 606,000 ounces of gold equivalent (AuEq) at six grams per tonne AuEq.

Larvotto has forecast $73 million of capital expenditure to develop an operation capable of producing 80,000 ounces (oz) AuEq per year, comprising 41,100oz of gold and 5400t of antimony.

A pre-feasibility study (PFS) demonstrated Hillgrove’s economics at spot and base gold and antimony prices, with the spot estimation highlighting the project’s profitability at current record gold and antimony prices.

Hillgrove has a post-tax net-present value (NPV) of $157 million at base prices ($US2000/oz for gold and $US15,000/t for antimony) and a posttax NPV of $383 million at spot prices ($US2350/oz for gold and $US23,000/t for antimony).

Following the completion of a definitive feasibility study and a positive final investment decision, Larvotto is targeting first ore by early 2026.

“All financial and technical objectives have been met and the capital cost of the development is low compared to a greenfields development, with much of the required surface and underground infrastructure already in place,” Larvotto managing director Ron Heeks said when the PFS was released.

“Larvotto will be bringing Australia’s largest antimony project online in a rising antimony market, driven by the increasing use of antimony in solar panel production whilst production from other global producers becomes stressed.”

system to deliver a high-grade resource and, amid the antimony price surge, there is not a better time to be doing this work,” Iltani managing director Donald Garner said.

“The antimony mineralisation sampled … to date contains exceptionally low arsenic. Arsenic is a key penalty element with regards to antimony concentrates, so this is another good sign.”

Kalamazoo Resources (ASX: KZR)

Kalamazoo holds a promising exploration portfolio in the Victorian Goldfields, where the South Muckleford project holds the potential to produce antimony in the coming years.

The explorer believes South Muckleford is analogous to Australia’s only antimony producer, the Costerfield mine, and the revered low-cost Fosterville gold mine.

Field programs in 2020–21 identified historic mine workings coincident with gold-antimony mineralisation. Gold production at Fentiman’s Reef in the late 1800s was associated with high-grade antimony lodes containing up to 42 per cent antimony.

After conducting a review of South Muckleford, Kalamazoo is carrying out a follow-up program of 3D structural geology modelling as it aims to identify extensional and potentially deeper targets along the project’s defined reef structures.

Kalamazoo chief executive officer Luke Mortimer detailed the opportunity at hand.

antimony geological province,” he said.

“This is a potentially significant development for Kalamazoo, which holds a substantial 2000-square-kilometre exploration package in the region.”

Trigg Minerals (ASX: TMG)

Trigg recently acquired a pair of highgrade antimony assets in NSW, one of which is located adjacent to Larvotto’s Hillgrove project.

The Taylors Arm project contains the Testers mine, which boasts massive stibnite veins of up to 63 per cent in antimony grade, which Trigg believes is Australia’s highest recorded antimony grade.

The Swallows Nest mine extracted antimony from 1940 to 1955 at 40 per cent antimony, with recent rock sampling identifying grades as high as 31.4 per cent antimony.

Overall, the Taylors Arm tenement includes 71 historical workings across six mineral camps with a widespread occurrence of stibnite, the primary ore for antimony. Trigg believes the project could host antimony mineralisation or a gold-antimony association similar to the Hillgrove project. There is also the potential for polymetallic deposits.

Trigg recently commenced a maiden exploration program at Taylors Arm, with the company engaging Dirt Exploration’s Neil Pendock to conduct remote and geophysical surveying.

The company also acquired the Spartan antimony project in its acquisition, which borders Larvotto’s Hillgrove project. Spartan covers part of the Hillgrove fault. AM

AURELIA METALS’ FEDERATION CRITICAL MINERALS MINE IS OFFICIALLY UP AND RUNNING IN NSW.

It’s not often that a new critical minerals mine opens its doors in Australia.

600,000 tonnes (t) of zinc, gold, copper and lead per year.

While the country has upwards of 80 projects in the development pipeline at any one time, the timeline from exploration to production is often a long one.

So, when mining starts at a project, it’s a cause for celebration.

Such was the case in September when Aurelia Metals’ Federation mine was officially opened by New South Wales Minister for Natural Resources Courtney Houssos.

Situated near the historic mining town of Cobar in central NSW, Federation is set to produce up to

THE FEDERATION PROJECT WAS FIRST DISCOVERED IN APRIL 2019.

Each of these commodities will be essential in the energy transition.

Copper will be used in new energy technologies and electrification, gold will find a home in circuitry components and solar panel wiring, zinc will be used to galvanise the steel in electric vehicles, and lead plays a key role in renewable batteries.

The Federation mine is also contributing directly to the NSW community, generating an estimated $74 million in royalties over its life and employing over 4000 people.

This contribution has been dubbed “remarkable” by Aurelia chief executive

officer (CEO) Bryan Quinn, especially considering the mine was first discovered in 2019.

“The short turnaround is testament to the excellent collaboration of NSW Government agencies, the Aurelia team and strong support from the community,” Quinn said.

“It puts in place a strong foundation for the future success of the Federation mine and high-quality jobs and opportunities in the region.”

Since its discovery in April 2019, the Federation deposit has developed at a rate rarely seen in the industry.

Aurelia moved swiftly to mobilise teams to explore and drill the site, while working hard behind the scenes

to evaluate the discovery and progress permit applications.

A mineral resource estimate was released in February 2021, totalling 3.5 million tonnes and a further estimate was released in July that same year detailing a 45 per cent growth in mineral tonnage.

Further drilling at the site confirmed early on that Aurelia had a winner on its hands, and, on June 30 2022, Federation’s mineral resource estimate hit five million tonnes.