7 minute read

Link Belt down under Strong currency is not helping US-based crane manufacturers

Manufactured to cope with rugged and remote conditions, Link-Belt Cranes are ideally suited for the Australian market. However, the strength of the US dollar is proving to be still a challenge. Cranes and Lifting explains. LINK-BELT CRANES DOWN UNDER

DURING LAST YEAR’S CICA Conference and Exhibition, Cranes and Lifting magazine discussed various topics with two of the global leaders from Link-Belt Cranes; Roy Burger managerinternational sales and Bill Stramer, senior vice president marketing sales and customer support.

According to Burger, Link-Belt Cranes have been well received locally and excel in the varied and rugged conditions.

“Link-Belt Cranes have been operating in Australia for about 10 years now. We started out by bringing in truck cranes, rough terrain and telescopic crawler cranes. They’ve been purchased by various

customers in different areas of the country and all seem to be working well. The Link-Belt truck crane is probably one of the better ones on the market and the telescopic crawlers and the larger rough terrain cranes seem to fit the Australian conditions very well,” he said.

“From a global perspective, we’ve certainly noticed a slow down with the global economy in the last 18 months and with our products being US dollarbased, our competitive position based on currency has deteriorated. This has made our task a little more difficult outside of North America. As far as the Australian market is concerned, we’ve seen New South Wales come back nicely in the past five years, and it’s still very active, but the US currency has been an issue.

“Telecrawlers have been a competitive product for us, and we can see plenty of opportunity in Australia with the resources sector coming back strongly. There’s a major pipeline of infrastructure projects across most of the states, so there’s plenty of opportunity for the placement of cranes. But we have to be realistic about the currency and it is going to continue to be a challenge. We can only try to make the most of opportunities as they come up,” Burger said.

According to Stramer, Link-Belt has plenty of new products relevant to the local market; there just hasn’t been the opportunity to bring them in to Australia.

“At this year’s bauma, we introduced a few new products but, again, we haven’t had an opportunity to bring any of the newly introduced products to the Australian market due to the currency situation. But I think we’ve positioned ourselves well with a 150t all-terrain (175|AT) and a 230t telescopic crawler (TCC-2500), along with improvements on our larger rough terrains, which now

Bill Stramer, International Sales Link-Belt, Anthony Davis, Baden Davis Crane Connection, Roy Burger, marketing sales and customer support manager, Link Belt and Ben Baden.

feature longer booms.

“The operator has been one of the consistent focuses with our product development. We focus on operator and personnel safety and try to mitigate any issues with working at height on all of our new products. We have utilised our patented interlock on our fly mechanism for one man fly erections, again to minimise working at height and to eliminate the number of climbs in and out of the operator’s cab. The fly mechanism eliminates the use of a second person. That’s been a major focus on our new products,” Stramer said.

“A year ago, we introduced three new models at a crane event in our factory, and at Bauma we introduced a fourth machine. We’re very proud that all four models are now in production. As a manufacturer you sometimes introduce a new product which takes a while to get into production, but these products are in full production and doing very well,” he said.

Link-Belt’s new 90t rough terrain the 100|RT was first unveiled in late 2018. It comes with the longest full-power boom available in its tonnage class and delivers outstanding reach with a five-section 12.3-47.2m full-power formed boom. An available two-piece on-board off-settable fly provides greater flexibility and range, and manually offsets at 0, 15, 30 and 45 degrees. A 4.9m lattice insert extension provides a maximum tip height of 72.2m.

The 100|RT is the first Link-Belt rough terrain crane to utilise the new fly erection technology from Link-Belt’s telescopic truck and telescopic crawler cranes. A fly assist cylinder makes erecting and stowing the fly a one-person operation and minimises work at height. Boom head speed screws and numbered spring-loaded latches provide intuitive assembly. Given the natural elevation of a rough terrain crane boom, Link-Belt has simplified fly assembly with new ground level carrier controls. One control raises and lowers boom angle from 10 to -3 degrees, and another control is used for the fly assist cylinder.

The 100|RT’s six-speed transmission is powered by a dual compliant Cummins Stage V/Tier IV QSB 6.7L 173 kW (232hp), and also available is a Cummins Tier III QSB 6.7L 179 kW (240 hp) diesel engine. Four 29.5x25 tires mounted on axles affixed to the carrier via greaseless 4-link suspension, thereby eliminating 10 previous grease points. Centralised electrical locations, remote mounted filters, and easy-access fluid checks make routine service a breeze. The 100|RT also features Link-Belt’s V-CALC (Variable Confined Area Lifting Capacities) system features 81 different outrigger configurations with real time 360° charts.

Stramer explains how telematics help with monitoring Link-Belt Cranes operating in remote areas.

“Australia is a large continent and Link-Belt Cranes are operating in remote and difficult terrains particularly in the mining and resources sectors. For this reason, we have telematics on all our cranes which helps our distributors with long distance diagnostics and troubleshooting.

“With telematics, a lot of data is being captured for our customers. The data is live and can be accessed by the owner and the distributor, even the Link-Belt factory, wherever the machine is operating. On our Pulse System, our operating system for our cranes, we’ve evolved to a Pulse 2.0 system with telematics which not only allows you to understand what the crane is doing, but we have the ability to send software updates to the crane remotely. We can send an update to a crane working in Western Australia from Lexington, Kentucky, US,” he said.

Burger explains a bit more about LinkBelt’s engineering philosophy.

“For Link-Belt, telematics isn’t just tracking information and helping with the predictive maintenance, it is also being used for trouble shooting and even helping with repairs remotely. Robustness is engineered into Link-Belt products. The telecrawler is a good example of a product that wants to work.

“We design and engineer them with the customer in mind. In many instances, they are bought for rental work and probably won’t be maintained very well so we try to eliminate the requirement for daily maintenance. To minimise that, we build all our products for the long term. We build with strong high-level componentry which means durability and performance is built into every machine,” he said.

“Prior to our engagement with Baden Davis Crane Connection, Link-Belt hadn’t been in Australia for a very long time. The last new crane sold would have been back in the early 80s. So, our cranes hadn’t been here for a very long time and we feel fortunate to have an agreement to work with this company which is well respected for its technical abilities and service capabilities, and Ben and Anthony represent our business extremely well,” Burger said.

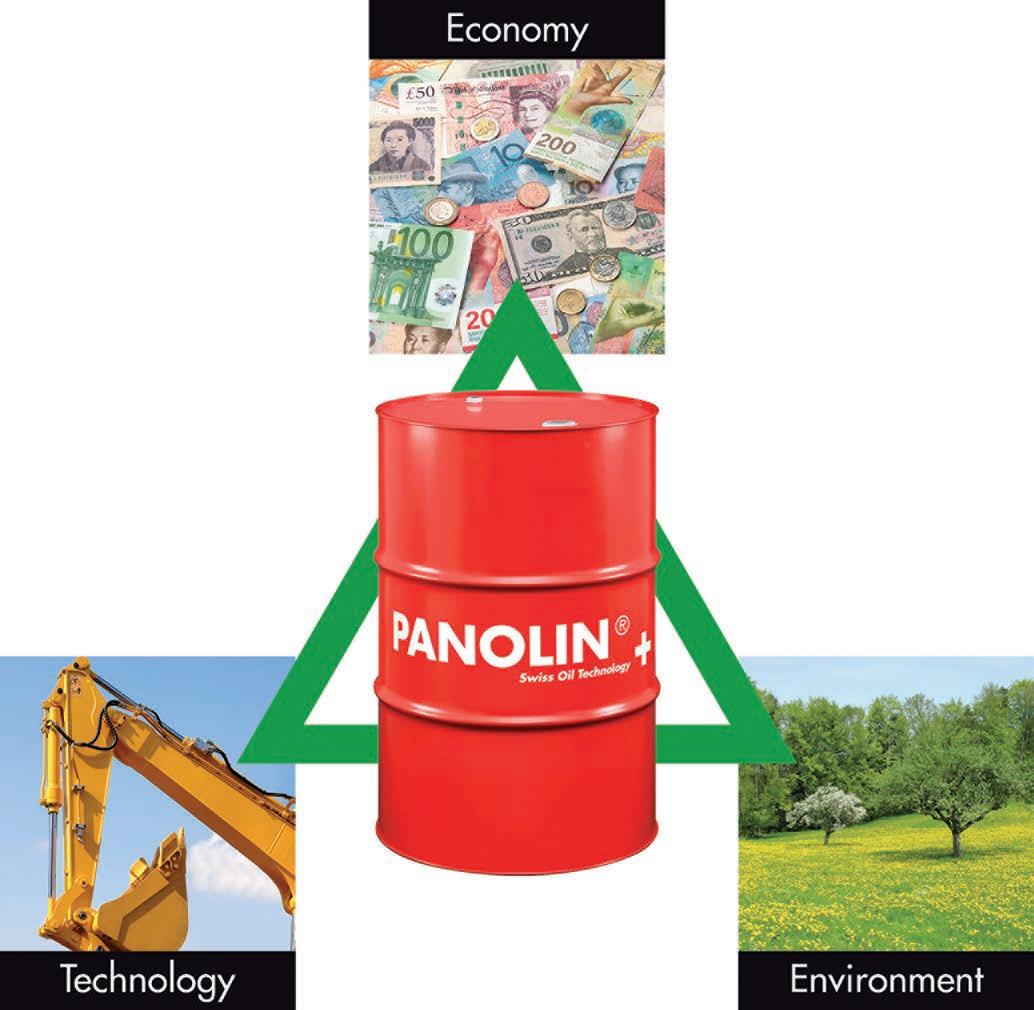

Imperial Oil is proud to introduce PANOLIN SPRINT as part of their Shuttle Boom Grease range of products. PANOLIN SPRINT is a superior, synthetic and longer lasting hydraulic fluid with up to 4000+ working hours. PANOLIN SPRINT is a technologically advanced, high-performance, biodegradable and non-toxic hydraulic oil, at the right price. PANOLIN SPRINT a cost effective, and environmentally friendly fluid with a longer life than a mineral fluid. It provides peace of mind when your crane is working in environmentally sensitive areas. PANOLIN SPRINT is a Game Changer

PROUDLY MADE

www.terex.com/franna For more information about our products or services contact: T: +61 7 3868 9600 E: franna@terex.com