6 minute read

Liebherr Tower Cranes What to expect now that Liebherr is factory direct

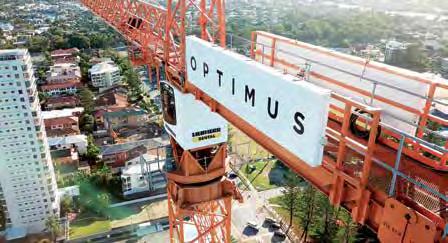

Liebherr has 100 tower cranes in the fleet.

LIEBHERR TOWER CRANES: A NEW BEGINNING

Liebherr Tower Cranes is transitioning from being represented by a local dealer to a factory direct business since taking over the business activities of Morrow Equipment.

IN JANUARY 2019, LIEBHERR TOWER Cranes division took over the Morrow Equipment Co business including facilities in Sydney, Brisbane and Wellington, New Zealand. Morrow Equipment had represented Liebherr Tower cranes for over 30 years. Thomas Schroeder, executive general manager Australia and New Zealand Liebherr Tower Cranes, is working with the former Morrow Equipment team on the transitioning period.

Schroeder started with Liebherr in 2007 and has worked within the tower crane business in various countries including Spain, Germany, India and Thailand. With a background in finance, he finds himself transitioning a business from a dealership to a factory direct sales environment.

For the last four years, he’s been working at the Liebherr-Werk Biberach GmbH Germany, looking after the tower crane strategy, including mergers and acquisitions.

Morrow Equipment had been the US dealer for 50 years and had been the Liebherr dealer in Australia for over 30 years, so both were extremely wellestablished businesses. According to Schroeder, there were always going to be challenges with the transition.

“The Australian tower crane market is predominantly focussed on rental. Morrow has been very successful in the rental market. This new collaboration will enable us to learn from their experience and with the joined forces, we’ll be able to support the Australian market even better,” he said.

“When we first took over the operations in Australia, we made the customer the first priority and we didn’t want them to feel there had been change. That was a major focus initially, and I think this has been a success.

“My job is to ensure customers continue to receive the same levels of service and support they are used to and gradually introduce the changes to the internal systems and the way we do things,” he said.

According to Schroeder, maintaining service and support is a key strategy and operating on a factory direct basis has obvious benefits.

“We haven’t changed any of the support strategies that were in place through Morrow, so there are crane crews that maintain erect and dismantle the cranes and we have a technical support and service team. The main difference is the support we are now able to call upon from the factory. Being so close to the factory does have substantial benefits.

“Being part of the Liebherr group gives us the chance to provide stronger sales and service support to our customers,” he said.

Liebherr Tower Cranes has a central office in Caringbah, Sydney and a yard in Unanderra, an office and yard in Brisbane, and an office in Wellington. The only difference with the New Zealand operation is that it is not

Thomas Schroeder is the divisional manager for Liebherr Tower Cranes in Australia and New Zealand.

focussed on rentals, that business is sales based.

“We have a crane fleet of 100 cranes plus 40 construction hoists. This is new development for Liebherr, it is the first time we have been involved with construction hoists. Once again, this development presents challenges, but we are very happy with the way it is going as it presents a huge business opportunity,” said Schroeder.

Typically, Liebherr tower cranes are being rented by tier-one and tier-two builders with customers including Multiplex, CPB and Probuild.

“In Australia, we are operating in a market where our competition has been manufacturing locally and is a recognised brand, it’s always difficult to come into a market where a crane company has been manufacturing,” said Schroeder. “However, our product range can provide good lifting solutions to the customer. Our electric cranes offer considerable advantages, such as noise reduction, and the outstanding in-house developed components permit us to offer a product that performs very well.

“The key USPs as to why customers come to Liebherr for their tower cranes, and it’s the same reason all over the world, they are safe, they work, and they last forever. The quality of the product is the biggest advantage Liebherr has as a brand, its traditional German engineering and manufacturing at its best,” he said.

Schroeder recognises there is plenty of competition in the Australian market.

“The Australian market is influenced by Chinese and other brands from Europe where the crane may be cheaper by comparison. But the one thing a builder wants from his tower crane is reliability. We have a good, reliable product and we have the back up and service to go with it. Morrow has long been recognised for the excellent service provided over many years. It has some very experienced people and our team from Germany has the highest respect for them. Most of them have been with Morrow for more than 20 years and that experience and knowledge is so important during this transitional period,” said Schroeder.

Regularly maintaining the tower crane fleet is key to its longevity says Schroeder.

“We service our machines regularly, making sure they can provide the best performance when on site. It is not unusual to see 20-year-old Liebherr tower cranes, when well serviced, these cranes can last for far longer than that,” he said.

In a crowded market with most of the global brands represented one way or another, Schroeder is realistic with his vision and expectations for the business.

“The first step is to focus on the integration process and we obviously plan to maintain, service and support the rental business. We also intend to develop the sales side of the business in both Australia and New Zealand,” he said.

“We are happy with where the business is at, but we do expect to expand it. As a manufacturer, we want to show the market what we can do, and this means further improving our service and support and introducing new models. It’s a bauma year and a lot of new technology was released at the show.

“We are looking forward to offering the newest products and technologies to our Australian customers and to show what we are capable of doing,” he said.

With construction forecasts mixed and areas like high-rise residential beginning to cool, Schroeder can see opportunities for the business, especially in the infrastructure space

“We benefit from the global Liebherr structure, which gives us direct access to the factory but also to the extensive support and know-how the group has. This will allow us to be more ambitious when expanding our operations in Australia and New Zealand. For example, we are now able to access the technical resources from the group when it comes to applications works. Simply put, we have brought the factory closer to our customers,” he said.

“Liebherr has proven, many times that challenging projects can be managed, for example the Lakhta Tower in Saint Petersburg. This project demonstrated the wide selection of possibilities Liebherr can offer. We realise that when we have the opportunity we have to deliver, that means having the right cranes available at the right time,” said Schroeder.