SENNEBOGEN EXPANDS CRAWLER RANGE

THE DEDICATED RESOURCE FOR THE CRANE INDUSTRY Official Media Partner

FEATURES CICA launch Diversity NetworkMcMahon Services choose TIDDEmpire Cranes opt for new Maeda

With

over

The UAA Group has the knowledge, ability and capacity to insure a wide variety of plant and machinery spanning numerous industries.

Our insurance products are tailored to produce a hand crafted solution to meet your business needs

EXPERTS IN MOBILE PLANT INSURANCE For more information on UAA’s Industrial Special Plant and Procon products,

contact your Insurance Broker or visit www.uaa.com Industrial Special Plant and ProCon underwritten by QBE Insurance (Australia) Limited. ABN 78 003 191 035, AFSL 239545. Underwriting Agencies of Australia Pty Ltd. ABN 86 003 565 302 AFS Licence 238517. Underwriting Agencies of New Zealand Limited (UAA). 4758199, NZBN: 9429040999678. J6663

please

Our experienced claims team has access to a network of the very best expert industry repairers, assessors and suppliers. 30

years’

experience, UAA is the largest and most reputable specialist mobile plant and machinery insurer in Australia, New Zealand and globally.

IN THIS ISSUE

6 Industry News

News from Mammoet and Boom Logistics.

10 Pace Cranes

Sennebogen expands its telecrawler range.

14 CICA President’s Report

16 CICA Diversity Network Launch

19 CICA Member Profile Buchanan Mobile Crane Hire.

22 CICA Business Essentials

Wet and dry hire agreements in the crane industry.

24 National Precast Concrete Association of Australia

Sarah Bachmann elaborates on what to expect from the NPCAA in Cranes and Lifting.

29 Tadano

GM Crane Hire has purchased a new AC 4.080-1.

33 Inside Construction Expo

CICA board member Karli

Sutherland discusses her upcoming appearance on the event’s diversity panel.

EWP Section

36 MCT Equipment

MCT Equipment has partnered with Italian manufacturer Cimolai.

38 AlmaCrawler

AlmaCrawler continues to assert its lof ty position in the industry.

41 Haulotte

Clennett Hire’s Saar Alfasi discusses Haulotte’s products and service.

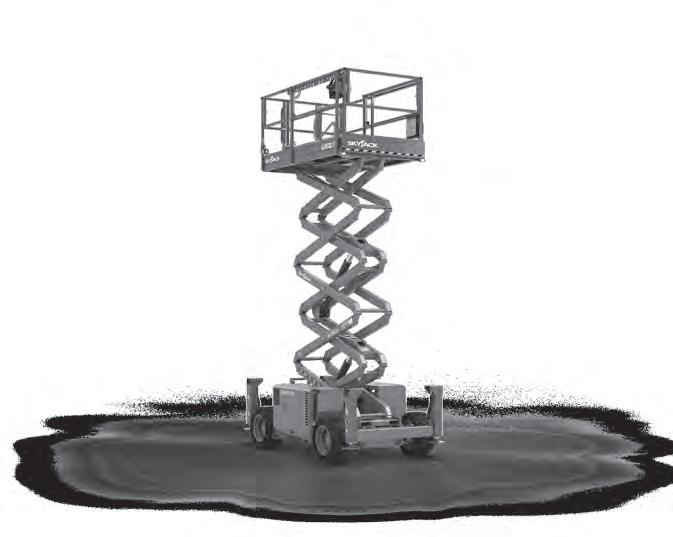

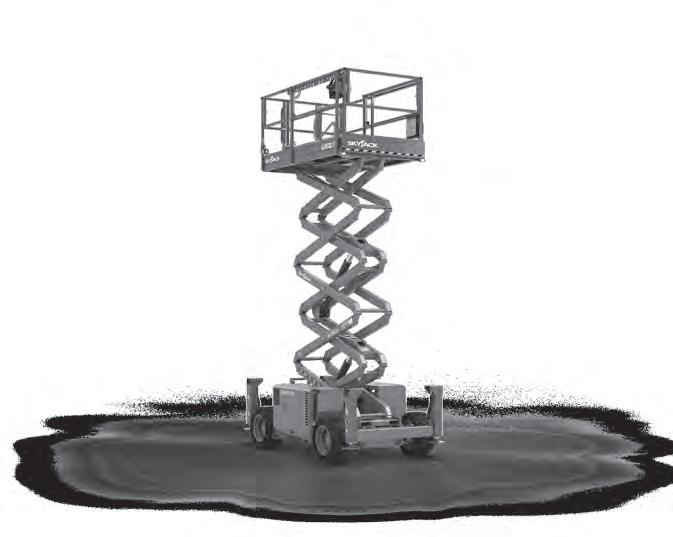

44 Skyjack

The UK-based access equipment manufacturer has released a new telematics system.

47 LiuGong

LiuGong has a new Australian PDC to solidify its relationship with customers down under.

50 Sinoboom

Uphire’s Nigel McKinley discusses all things Sinoboom and East-Asian manufacturing.

53 Empire Cranes

Pace Cranes has sold a new Maeda mini crawler to Empire Cranes.

56 Marr Contracting

Marr Contracting is using innovation to improve its services.

58 Gleason Cranes

Sales Director Chris Logan discusses what stock is soon to be available at Gleason Cranes.

62 UA A

Michelle Morrissey and George Grasso provide an insight into insurance claims processes.

66 McMahon Ser vices

The Adelaide-based company has a new TIDD P&C.

68 Grove

Manitowoc reveal who has replaced Andrew Gray as Sales Manager.

72 Verton Founder Stan Thomson discusses his company’s point of difference in lifting technologies.

75 Sany

Sany recently introduced the new C6 Crawler Crane Cab for its telescopic crawler range.

78 Comansa

The Spanish manufacturers reveal a new range of tower cranes.

80 Manitowoc

A recap of the Manitowoc dealers’ ‘meet and greet’ in Singapore.

83 Kobelco

Sydney’s Australian Piling Group recently took delivery of a 100t capacity Kobelco CKE 900G-3.

87 Franna Engineer Jamie Monaghan elaborates on the Franna crane’s efficacy in the mining industry.

4 Editor’s

Letter

Cranes and Lifting Magazine cranes_and_lifting Cranes and Lifting SCAN THE QR CODE TO SUBSCRIBE TO OUR NEWSLETTER 78 September 2023 CAL / 3 www.cranesandlifting.com.au

FROM THE EDITORIAL TEAM

WELCOME TO THE SEPTEMBER ISSUE OF CRANESANDLIFTING

INTEREST RATES ON HOLD

The Reserve Bank of Australia (RBA) recently made the decision to again hold the cash rate at the current level of 4.10%. A better-than-expected inflation rate over the June quarter, as well as slowing retail sales growth points to cooling economic conditions. And while the unemployment rate is still at record low levels, the forward indicators of employment conditions all point to a much tighter jobs market going forward.

These forward indicators include SEEK jobs vacancy data for June 2023, which are down 22.1% compared to the year prior. In addition, NAB’s Monthly Business survey shows capacity utilisation is down to 83.5%, which is the lowest read since April 2022. Capacity utilisation is a very good leading indicator of the unemployment rate, and falling utilisation typically means a higher unemployment rate in three to six months’ time.

Looking forward, it is likely we will see upwards movement in the unemployment rate over the second half of the year, which will further reduce inflationary and wages pressure.

Kennards Hire’s second annual ‘Construction Confidence Check’, surveyed over 500 of Australia’s business leaders in the construction industry with 20+ employees. This year’s results found that:

At the C-suite level, almost 9 in 10 (87%) agree that the industry is ‘stable’ and able to withstand pressures to continue growing. 56% of business leaders say rising costs of materials is their top issue impacting confidence in the industry, followed by skilled labour shortages (51%) and supply chain issues (45%).

Compared to last year, while overall confidence in Australia’s construction industry has improved, this year’s

survey results indicate a sentiment shift based on business size and location:

In smaller businesses (20-99 employees), confidence increased (86% in 2023 vs. 74% in 2022).

In larger businesses (100+ employees), confidence declined (80% in 2023 vs. 92% in 2022).

Cranes and Lifting attended the Crane Association of New Zealand’s Annual Conference and Exhibition in Christchurch. It was great to see so many industry leaders attend and the response to our regular NZ features was extremely positive.

The deadlines for the CICA Lift of the Year and Photograph of the year are fast approaching, so please jump onto the CICA website and complete your submissions.

As always, the team at Cranes and Lifting has worked hard to bring you a strong mix of content and we hope you enjoy the read.

Published by:

Simon Gould Editor, Cranes and Lifting

379 Docklands Drive, Docklands VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

CEO

John Murphy

E: john.murphy@primecreative.com.au

Chief Operating Officer Christine Clancy

E: christine.clancy@primecreative.com.au

Managing Editor Andrew Hobbs

E: andrew.hobbs@primecreative.com.au

Editor Simon Gould

E: simon.gould@primecreative.com.au

T: 0404 865 109

Journalist

Jack Alfonso

E: jack.alfonso@primecreative.com.au

Business Development Manager Emily Schlegel

E: emily.schlegel@primecreative.com.au

T: 0466 317 555

Client Success Manager

Glenn Delaney

E: glenn.delaney@primecreative.com.au

Art Director Bea Barthelson

Imaging Assistant Paul Breen

Subscriptions Frank Rapone

T: 03 9690 8766

E: frank.rapone@primecreative.com.au

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published.

© Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

4 / CAL September 2023 www.cranesandlifting.com.au

Precise Swing Operation

“The quality of the HSC crane is evident everywhere you look. It provides comfort that the crane will provide many years of reliable, trouble free service”

Aaron Brimfield Managing Director Bridgepro Engineering

Aaron Brimfield Managing Director Bridgepro Engineering

brisbane | sydney | melbourne

Peter Lawgall0411 256 388Peter.Lawgall@tuttbryant.com.au Philip Chadwick0457 510 097Philip.Chadwick@tuttbryant.com.au

adelaide

perth

|

tuttbryant.com.au1300 658 888

TIER 4f Follow us on:

CUMMINS QSL9 TIER 4f

SCX2800A-3 STAGE IV /

Engine -

Capacity at Full Reach - 1.5t x 78.3m Max Lift Capacity - 275t x 4.3m Max Boom Length - 91.45m

MAX LIFT CAPACITY “100T x 3.8M” MAX LIFT CAPACITY “150T x 4.5M” MAX LIFT CAPACITY “175T x 4.1M” SCX1000A-3SCX1500A-3SCX1800A-3

Ben Pieyre

BOOM

INTERIM CEO BEN PIEYRE AS CEO AND MANAGING DIRECTOR

Boom Logistics Limited has announced the appointment of its Interim CEO Ben Pieyre as CEO and Managing Director effective immediately.

Pieyre’s performance as Interim CEO since his appointment to the position on February 14, 2023, has resulted in him being awarded the position after a wide internal and external search.

Chair of the ASX-listed company Melanie Allibon said she was pleased with the appointment, pointing to his skills being “invaluable” as they look to “grow the company”.

“We are delighted to appoint Ben to the CEO and Managing Director role. Ben joined Boom in 2019 and was most recently the Company’s COO prior to being appointed Interim CEO,” said Allibon. “The Board has been particularly impressed with Ben’s leadership through this period in which he has demonstrated excellent management skills, future planning capabilities,

effective decision making, adaptability, and most importantly, a clear vision for our business.”

Joining Boom Logistics in September 2019 and with a career in the crane hire industry dating back to 2006, Pieyre holds extensive operational experience in civil construction, industrial services, maintenance sectors, human resources, industrial relations, and engineering.

Currently holding the position of President of the CICA Board, Pieyre spoke about how “proud” he was to add the position as Boom’s CEO and Managing Director to his portfolio.

“During my time at Boom, I have been working with an extremely

talented and dedicated group of people and look forward to continuing working with them as we shape the Company’s future progress and development,” he said.

“Our recent tender wins, coupled with strong activity across our core markets, a healthy balance sheet and optimised assets, means we are in a strong position to drive growth as well as enhanced and sustained returns for our shareholders.”

Other role changes at Boom include Non-Executive Director Kieran Pryke’s increased involvement at the company revert back to what it was before the transition period commencing on 14 February 2023.

INDUSTRY NEWS 6 / CAL September 2023 www.cranesandlifting.com.au

APPOINTS

“Our recent tender wins, coupled with strong activity across our core markets, a healthy balance sheet and optimised assets, means we are in a strong position to drive growth as well as enhanced and sustained returns for our shareholders.”

EXPERIENCE THE VERSATILITY, DURABILITY AND COST EFFICIENCY OF A TEREX ROUGH TERRAIN CRANE BACKED BY FRANNA’S DEDICATED AUSTRALIA WIDE SERVICE AND PRODUCT SUPPORT TEAM

FRANNA IS THE EXCLUSIVE PROVIDER AND AFTERSALES SUPPORT VENDOR FOR TEREX ROUGH TERRAIN CRANES IN AUSTRALIA

To learn how a Franna or Rough Terrain Crane can assist you on site or to request a quote, scan the QR Code

For more information contact the Franna team today: T: 1800 837 395 E: franna@terex.com

www.terex.com/franna

OF A

DAWN

NEW AGE

THE

ENGINEERING EXPERTISE SHORTENS METRO TUNNEL PROJECT

The Cross River Rail project aimed to alleviate congestion in Brisbane’s metro transport system and improve transportation for the growing population. However, the project faced numerous obstacles due to limited space - the site is incredibly confined and congested and the construction sequencing was complex with the need for precision, efficiency, and safety.

Civil engineering contractor Kenny Constructions needed to install 59 concrete trusses, weighing up to 70 tonnes each, deep within the underground station cavern. Overcoming challenges such as restricted headroom and having a few millimetres of clearance on either side of the trusses was critical, not to mention doing so while completing the process in the shortest possible time and with minimum disruptions for the wider site.

The use of cranes at the project site was not feasible, so Mammoet embraced the challenge by devising an ingenious solution with precision and efficiency. The company proposed a custom packing structure positioned on Selfpropelled Modular Trailers (SPMTs), which enabled the transportation and installation of up to four trusses simultaneously, significantly accelerating the overall process.

To validate the solution, the team assembled the packing structure and transport configuration in its nearby yard, conducting a series of dry runs. After thorough preparation and onsite rehearsals, the actual operations commenced.

The customer’s tower crane lowered the trusses onto the packing structure, before they were delicately manoeuvred through the confined cavern. The hydraulic suspension and electrical multi-steering system of the SPMTs enabled them to carefully position the trusses on their designated positions.

The operation’s most challenging aspect was the limited clearance available. Each of the trusses had a span

of 17.6m, leaving just 100mm on either side – a little more than the width of a credit card.

Yet the first set of trusses, with a combined weight of 193t, had to travel to the very far end of the station cavern, a distance of 150m – the length of three Olympic sized swimming pools.

In the first phase, 55 trusses, weighing 48.3t each, were installed, followed by

went according to plan. Working with the Mammoet team was a pleasure. We made the right choice.”

The safe and efficient completion of the scope has made a significant contribution to the A$5.4 billion Cross River Rail project.

The addition of four new underground stations, more than 10km of new rail line and 5.9km of twin

four extra-large trusses weighing 70t each in the second phase. Yet, as part of operation pre-planning Mammoet ensured that the same configuration could be used for both phases, bringing further time savings – ultimately totalling 15 iterations, with each journey transporting and installing up to four trusses.

Thanks to the meticulous planning, specialised equipment and expert execution, the entire operation proceeded smoothly. Fergus McHugh, Project Manager at Kenny Constructions, praised Mammoet, stating, “This was a challenging scope of works, yet everything

tunnels beneath the Brisbane River and the central business district will reduce peak hour travel times by 24 per cent and accommodate 9,000 additional passengers daily.

By employing its expertise and innovative solutions, Mammoet helped unlock a bottleneck in the city’s transport network and contributed to the region’s economic growth.

This infrastructure development supports the projected 40 per cent population growth in South East Queensland, providing a substantial boost to the regional economy.

INDUSTRY NEWS 8 / CAL September 2023 www.cranesandlifting.com.au

Custom packing structure positioned on SPMTs, that enabled the transportation and installation of up to four trusses simultaneously

“This was a challenging scope of works, yet everything went according to plan. Working with the Mammoet team was a pleasure. We made the right choice.”

69m Boom!*

MAXbase Equipped

LEVEL ACCESS THE BENCMARK 150t HAS MORE REACH

The New GMK5150XL is the latest sibling of the GMK5150L-1, with longest boom (69m) and most versatile road weights in class

• Reach further with 69m boom and 30m hydraulic luffing fly

• 50t GVM with outriggers in situ for reduced cost legal travel in all Australian states and territories

• 10.2t counterweight in situ at 12t per axle

• Increased safety and flexibility with MAXbase variable outrigger positioning

• Faster, intuitive set-up with CCS (Crane Control System)

• Grove Connect Telematics

• Capacity: 150t

• Main boom: 68.7m pinned*

• Maximum Jib: 30.2m (40O hyd luff)

• Maximum tip height: 99m

New GMK5150XL

New GMK5150XL

SENNEBOGEN EXPANDS CRAWLER RANGE

Sennebogen continues to expand its range of telescopic crawlers with the release of the new 683 E. The 683 E series replaces the 683 D Series model and has a lifting capacity of 80t. Also, new to the range is the 6103 E with 100t lifting capacity. Both models fit into the manufacturer’s medium-size class.

ESTABLISHED IN 1952, SENNEBOGEN HAS been manufacturing telescopic crawler cranes for more than 30 years, and it has successfully established this flexible crane concept in international markets.

With its load capacity of 80t and 42m of main boom, the Sennebogen 683 E is the ninth model in the series and fits perfectly into the gap between the existing 673 E and the 6103 E. It boasts impressive flexibility and a robust design that qualifies it for a wide range of applications and uses.

According to National Sales Manager Michael Cawston of Pace Cranes, the National Distributor for Sennebogen, the 683 E is well suited for a wide range of applications – with its heavy-duty Full Power boom and its powerful travel and winch motors. Sennebogen has updated the operating systems, assembly and disassembly process and transport configurations, in addition to the improved capacities and capabilities from the original D series crane.

“The 683 E is well-suited for building and below ground construction, bridge construction, pile driving during sheet pile installation, and as an agile auxiliary service

crane,” Michael said.

“With its particularly robust design, it demonstrates its strength during heavy-duty use on rough construction sites, where it easily handles pick-and-carry tasks as well as lifting operations on a 4-degree incline.

“We have a large population of Sennebogens locally and customers always comment on how strong and wellengineered they are, and with the amount of infrastructure projects planned for the next decade or so, we are seeing increased demand for these larger capacity machines,” he said.

The 80t tele crane is powered by a 186 kW Cummins engine with Stage V exhaust gas treatment. The main and auxiliary winches are driven by a high-pressure piston engine, which provides a considerable tractive force of 72 kN each and cable speeds of up to 120m/min. The individually configurable equipment can be supplemented by a wide range of attachments, options and additional features such as a programmable working range limiter and safety and low-temperature packages, thus appealing to users in specialised civil engineering and hydraulic engineering sectors, among others.

10 / CAL September 2023 www.cranesandlifting.com.au UP FRONT / SENNEBOGEN AND PACE CRANES

Flexible on the ground and at heights:

The 4-section Full Power-Boom, which can telescope to a length of 42m in the standard configuration, offers a decisive time advantage, especially in complex operations with changing boom lengths. Thanks to multi-cylinder technology, the maintenancefree boom control system provides variable telescoping and is always force-locking. This

means that any desired boom length can be reached quickly and easily, and the best payloads are always achieved automatically. As an option, the reach can be further extended to up to 57m with a double folding jib that can be angled, making it particularly attractive for structural engineering. Operation is simple and intuitive via joystick movement.

September 2023 CAL / 11 www.cranesandlifting.com.au

The 683 E is well-suited for building and below ground construction, bridge construction, pile driving during sheet pile installation, and as an agile auxiliary service crane.

Sennebogen has been manufacturing telescopic crawler cranes for more than 30 years, and it has successfully established this flexible crane concept in international markets.

The telescopic crawler undercarriage of the 683 E has a maximum track width of 4.2m. Depending on requirements, this can be reduced symmetrically or asymmetrically to as little as 2.68m, with the load charts being automatically adapted to the respective track width. Timeconsuming positioning of the machine can be eliminated thanks to the robust design of the undercarriage, which is particularly beneficial when working on inclines and for pick-andcarry tasks. The 80-tonner not only boasts impressive load values at inclinations of up to 4 degrees but can even travel with 100 per cent of the specified load on the hook. The standard 800mm triple grouser shoes installed provide a high degree of stability while reducing floor pressure to a minimum.

The 683 E can unload itself from a truck and with the aid of the radio remote control it is completely self-assembling. With crawler tracks attached, it has a transport width of only 3.5m. After simple disassembly of the crawler, not only is the transport weight reduced by almost 20t: the transport width also contracts to 3m.

In the comfortable Maxcab cabin, machine operators appreciate the ergonomic advantages of what Sennenbogen says is a particularly spacious cab. For a comfortable view of even distant loads, the cab has a possible standard tilt of 20 degrees.

Optionally, the crane can also be equipped with a hydraulically elevating cab that can be tilted 30 degrees at an eye level of 5.55m. Largearea window elements provide an optimal view of the entire safety and work area. In addition, the machine can be operated from outside the cabin via a radio remote control. Cameras and a large monitor extend the operator’s field of vision to the rear and right side and can also be used to monitor the winches.

The electric dual-axis control system features joystick control buttons for optional attachments and the graphically displayed load moment limiter. The system provides an audio-visual warning and locks the control lever when the load limits are reached or exceeded. The intuitive Sencon control system provides important diagnostics as well as valuable data on payloads, boom angle, boom length and radius, thus supporting the operator in his work with the machine - for maximum availability.

The Sennebogen 683 E also proves to be highly advantageous in terms of service friendliness. A central lubrication point for the

UP FRONT / SENNEBOGEN AND PACE CRANES 12 / CAL September 2023 www.cranesandlifting.com.au

boom base axle, luffing cylinder and slewing ring greatly reduces operator maintenance. Optimum access to the service points and clear identification of the components also saves valuable time in daily operation.

The Sennebogen 6103 E, 100t capacity telescopic crawler, is the ‘top of the range’ model and impresses with 100t capacity, long reach and flexibility.

With its current product portfolio of telescopic cranes from 16t to 130t load capacity, Sennebogen covers a wide range of applications, where the telescopic crawler cranes in particular offer many advantages when lifting, moving and positioning large loads. The Sennebogen 6103 E is a telescopic crawler with a load capacity of 100t and a maximum boom length of up to 62m, specially designed for demanding Pick and Carry applications.

The 6103 E is equipped with a 186 kW diesel engine of emissions stage V, which also hydraulically drives the powerful crawler drive of the 100t machine as well

The Sennebogen 6103 E has a load capacity of 100t, a maximum boom length of up to 62m, and is specially designed for demanding Pick and Carry applications.

as main and auxiliary winches with 100 kN tractive force each – while also allowing cable speeds of 125m/min. Thanks to a wide range of equipment solutions, the machine can also be configured to meet a variety of customer-specific requirements in special civil engineering or hydraulic engineering, for example with working area limitation, safety and low-temperature packages or for operation with organic oils.

The 5-section pin boom of the new 6103 E has a maximum length of 46.8m for the driver in standard configuration. The reach can be optionally optimised up to 62m with the fly jib and extension. The boom system thus enables comfortable working heights of up to 50m. Operation is carried out simply and intuitively via joystick movement.

Like all Sennebogen telescopic crawler cranes, the 100t machine also allows you to work on rough terrain. Thanks to the robust, telescoping crawler undercarriage with a

maximum track width of 4.2m, there is no need for time-consuming positioning or supporting the machine.

The crawler undercarriage is also stable and secure during crane operation. The extremely robust design of the entire machine, as well as the boom, is particularly noticeable when working at inclines of up to four degrees and with high load capacities. The 6103 E sets an impressive standard in its performance class here. As a Pick and Carry crane, the telescopic crawler crane can also be moved with up to 100 per cent load on the hook and thus offers a wide range of applications, particularly in prefabricated part and component assembly and on large construction sites.

In addition to the tried-and-tested equipment features, the spacious Maxcab offers operators even more options for making every-day work particularly comfortable and safe. The telescopic crane

has a cab that can tilt 20 degrees as standard. As an option, the cab can be hydraulically elevated to an eye level of 5.6m. Large-scale window elements and the tried-and-tested access area with sliding door leave nothing to be desired and provide an optimal workplace for the driver. There is also the option of operating the crane from outside the cab via radio remote control, which offers added precision and safety for operators and crew in many applications.

For contractors and rental companies alike, transport costs and set-up times are key criteria for efficient crane use. The new Sennebogen 6103 E telescopic crawler crane offers two major advantages here.

Additionally, the machine can be transported completely in one piece. For this, only the ballast must be removed to achieve a transport weight of around 61t and a width of 3.48m.

The crane weighs less than 40t and is therefore even easier to transport by low loader, when the crawler tracks are removed beforehand. The highlight with the 6103 E telescopic crawler crane is that all assembly steps can be carried out by the machine itself. Auxiliary cranes are not required thanks to the Sennebogen self-assembly system.

September 2023 CAL / 13 www.cranesandlifting.com.au

“The Sennebogen 6103 E, 100t capacity telescopic crawler, is the ‘top of the range’ model and impresses with 100t capacity, long reach and flexibility.”

NSW BRANCH CHAIR UPDATE

THE CRANE INDUSTRY IN NEW SOUTH WALES continues to thrive, playing a crucial role in supporting various sectors, including construction, infrastructure, logistics, and manufacturing. Our region’s strong economic performance, coupled with increased government investments in major projects, has created a steady demand for crane services.

Our branch continues to grow and look for new ways to cater for our members. Most recently, a river cruise on Sydney Harbour saw CICA N.S.W. members celebrate ‘Christmas in July’ in a very memorable way. The river cruise provided the perfect setting for networking in a relaxed setting, away from the usual work environment. As the cruise continued into the evening, a sumptuous dinner was served, featuring a delectable array of gourmet delights. Thank you, Justina and Paul, for your help in organising this enjoyable night for our members.

The Canberra regional meeting was another great event held this year. We honoured John Farrier and Anthony Davis with an award for their hard work and dedication to the Crane Industry. Simon Gould, editor of Cranes and Lifting magazine hosted the manufacturer’s panel and the representatives provided us with some useful insights.

There is a growing emphasis on sustainable practices within the crane industry in New South Wales. Companies are exploring eco-friendly options, such as electric and hybrid cranes, to reduce carbon footprints and comply with environmental regulations. As our cities grow, the limited availability of space for crane setups in dense urban areas poses logistical challenges, so we’re working closely with local authorities to find innovative solutions that ensure seamless crane operations without compromising on public safety.

Amidst the challenges, there are several opportunities that we can harness to further strengthen our industry’s position.

Diversity Network Breakfast Launch: Held in early August, the CICA Diversity

“As our cities grow, the limited availability of space for crane setups in dense urban areas poses logistical challenges, so we’re working closely with local authorities to find innovative solutions that ensure seamless crane operations without compromising on public safety.”

sharing their experiences, insights, and knowledge on how, in an increasingly interconnected world, diversity can foster innovation and thinking ‘outside the square’. They challenged the audience to see diversity as not just a buzzword but as an opportunity.

Collaboration with Government: Engaging with government bodies allows us to influence policies, regulations, and

represented effectively.

Road Manager Engagement: By collaborating with road managers CICA has been working to improve road access across the state. TfNSW is working on the delivery of a new Heavy Vehicle Access Management System (HVAMS) for cranes which will result in far more efficient and flexible road access across NSW.

Managing regulatory change: As of the first of July, all crane manufacturers are now

14 / CAL September 2023 www.cranesandlifting.com.au

CICA NEW SOUTH WALES REPORT

Anthony Heeks

required to comply with a number Federal ADR requirements, with full compliance to all relevant ADR’s needed by 1st July 2024. CICA has been collaborating with the Federal department and all crane manufacturers to ensure that the transition to the new ROVER system is seamless for companies in the market for a new crane.

Education and Awareness: By actively promoting the benefits and opportunities within the crane industry, we can attract young talent and diversify our workforce. Emphasising the rewarding and lucrative career paths available will help address the labour shortage. As our industry evolves, the need for a skilled and qualified workforce becomes paramount. Training and development are essential to ensure that operators possess the necessary expertise to handle modern crane technologies safely.

TAFE started the year with an intake of 25 trainees and we are expecting another 12 to start late in August 2023. We will be holding a traineeship information evening in early September for prospective employers and trainees to learn more about the benefits of the traineeship.

I would like to take this opportunity to thank former chair Jeff Wilson. Jeff has continued to provide me with ongoing support and guidance over the past 12 months which is greatly appreciated.

I would also like to thank the Vice Chair Stefan Becherand for his support and acknowledge our steering committee, Paul Churchill, Anthony Davis, Ari Debner, John Farrier, Kane Fuller, Grant Gjessing, Jay Gower, Neil Hollingshead, Adam Little and Emma Makinson who have volunteered their valuable time working to develop and implement initiatives with the hope to improve and raise the standards of our industry.

Thank you to all our members for your ongoing dedication and commitment to our industry’s growth, and I look forward to working together to overcome challenges and embrace opportunities in the year ahead.

Anthony Heeks

NSW / ACT Branch Chair

CICA BOARD

Ben Pieyre – President

Marcus Ferrari – Vice President

Tom Smith – Director

Danny Adair – Director

Danny Black – Director

Andrew Esquilant – Director

David Solomon – Director

Karli Sutherland– Director

CICA OFFICE

Brandon Hitch Chief Executive Officer 03 8320 0444 0428 228 048 ceo@cica.com.au

Paul Arztenhofer Membership Engagement/ Business Development Specialist 04 9093 9274 paul@cica.com.au

Alice Edwards Road Technical Engineer 03 8320 0440 alice@cica.com.au

Patrick Cran CraneSafe and CrewSafe Technical Advisor 0488 004 274 pat@cranesafe.com.au

Damien Hense CICA Road Policy Advisor 03 8320 0460 0488 007 575 damien@cica.com.au

Julie Turner

CICA Executive Assistant / Office Manager 03 8320 0411 julie@cica.com.au

Kate Galloway

Traineeship Coordinator 0491 047 118 Kate@cica.com.au

Ashleigh Gould

Cranesafe and Crewsafe Administration Officer

Phone: 03 8320 0466

Email: ashleigh@cica.com.au

Michelle Verkerk

Marketing Communications Officer 0404 938 714 michelle@cica.com.au

Justina Blackman

Member Events and Engagement 0403 717 626 justina@cica.com.au

Unit 10, 18–22 Lexia Place, Mulgrave Vic 3170

Phone: 03 9501 0078

Fax: 03 9501 0083

Email: admin@cica.com.au

Website: www.cica.com.au

For information, please visit our website or call the CICA office.

September 2023 CAL / 15 www.cranesandlifting.com.au

CICA OFFICIALLY LAUNCHES

IN A BOLD AND FORWARD-THINKING

move, the crane industry is breaking down barriers and embracing the power of diversity with the launch of the CICA Diversity Network a ground-breaking initiative aimed at promoting inclusivity and driving positive change.

To address what is probably the most pressing issue in the industry, the aging demographic, the CICA Diversity Network has been tasked with ensuring the crane sector is seen as the industry of choice for diverse groups, especially young women.

With Karli Sutherland from Quicklift Crane Hire in the Chair, the Diversity Network Committee Members are mainly women representing various areas of the industry, including crane owners and engineers.

The launch included a panel of industry leaders who emphasised how diversity and inclusivity in the

workplace should be a priority for every company. Building teams from varying backgrounds not only improves the employee experience, but how it also enhances productivity and the decisionmaking process, was the overall theme of the launch.

The panel included Sarah Toase, CEO of Crane Association of New Zealand, Colleen Lindores, Owner/Director Lincoln Hire and Sales, Danny Black, General Manager Terex Australia, Melissa Barry, Director Border Crane Consultants, Kate Halpin, Director Employ for Ability and Ben Pieyre, Chief Executive Officer, Boom Logistics and National President of CICA.

The panel agreed it’s not enough to just talk about change, action needs to be taken to effect change. The crane industry needs to build inclusive organisations by design, not default. Recruitment was a key theme with all

agreeing that decisions should be based on data and facts, not long-held bias. The crane sector and the construction industry in general, need to hire and nurture inclusive leaders who can bring together diverse knowledge, perspectives, and experiences.

Uniting the strengths of diversity and inclusion will help build performance and can help unite everyone behind the one vision and with the right team mindset and behaviours, combined with the right structure and processes, change will happen. Embedding diversity, equity and inclusion (DE&I) in the workplace is a journey and the panel agreed this journey can only start with an organisation understanding what they want to achieve in terms of DE&I.

Tadano was a major sponsor of the launch and Tadano Oceania’s and Marketing Manager, Genevieve

16 / CAL September 2023 www.cranesandlifting.com.au

CICA’S DIVERSITY NETWORK

The panel included Danny Black, Terex Australia, Melissa Barry, Border Crane Consultants, Sarah Toase, CANZ , Kate Halpin, Employ for Ability, Ben Pieyre, Boom Logistics and National President of CICA and Colleen Lindores, Lincoln Hire and Sales.

Mustafa spoke of her experience as a young, Asian female and the barriers to entry she has faced during her career.

Kate Halpin, Director, Neurodiversity spoke about Employ for Ability, an innovative social business focused on helping organisations understand the benefits of hiring neurodivergent people as part of their social inclusion and diversity programs.

Neurodiversity is the concept, that neurological differences like Autism Spectrum Disorder are part of the normal variation of the human population. It is a component of the social model of disability in comparison

to a medical model where we need to find a cure.

Autism is characterised by difficulty in social communication, social interaction and restricted or repetitive behaviours and interests. Neurodivergent people are also hard working, loyal, direct, problem solvers, unique thinkers and honest to name a few qualities. Hiring people who can solve problems and think differently provides advantages to organisations. Cranes and Lifting will actively work with the CICA Diversity Network Committee and provide updates as they happen.

September 2023 CAL / 17 www.cranesandlifting.com.au

“The crane sector and the construction industry in general, need to hire and nurture inclusive leaders who can bring together diverse knowledge, perspectives, and experiences.”

The Diversity Network Committee.

Tadano Oceania’s Gen Mustafa spoke about her expereince as a young Asian woman and the entry barriers she has experienced during her career

Engineered for the future, built on experience

LTM 1110-5.2 with LICCON3

The LTM 1110-5.2 with 3 new core features: the crane control system, the driver’s cab and the gearbox. The new LICCON3 crane control system comes with large touch displays and is prepared for fleet management and telematics. The ZF TraXon gearbox with DynamicPerform offers wear-free manoeuvring. Plus a modern crane design – the future of the all-terrain series. www.liebherr.com

Mobile and crawler cranes

Mobile and crawler cranes

RISING TO THE CHALLENGE

GREG BUCHANAN, THE FOUNDER OF Buchanan Mobile Cranes, has a boilermaking background and the crane side of the business evolved out of the need to install or erect the steelwork that he fabricated. While the crane work is now a significant business in its own right, steel fabrication and engineering complement the crane business and there are many niche projects that require both areas of expertise.

Buchanan Crane Hire started as Buchanan Welding, with a highly skilled team of boilermaker/welders and fitter and turners. It had its beginnings in a factory in Mornington primarily fabricating steel for small factories and select home builders. The business initially purchased a second

hand 9-tonne Coles crane, then a 13-17T Coles truck crane and then progressed to a 40T capacity P&H truck crane. After that, the business added a 12T capacity Franna. Steel fabrication, installation and crane hire were very complementary, and the multiskilled team grew quickly. They enjoyed the crane work, maintaining the crane fleet and taking on more general crane hire work across the Mornington Peninsula.

Greg’s son James Buchanan developed an early interest in cranes, from around the age of eight as he recalls. With the business and family home co-located on acreage at Moorooduc, it was easy for James to help out after school and on weekends. It was a great learning environment: nothing was forced but neither was anything sugar-

coated. As James says: “Every day was a school day.”

James’ learning covered both sides of the business and, when he left school, he took on an apprenticeship to become a fitter and turner with Jack Thompson Engineering in Hastings, Victoria. After spending four years in the mining industry in WA as a FIFO worker, James decided that it was time to return home and come back to the family business. Greg and Melanie happily embraced this decision.

James takes up the story.

“As the has business grown, so has the number of team members and we are proud that many of the team have been with us for over 20 years. They have adapted as changes and challenges have emerged and upskilled

September 2023 CAL / 19 www.cranesandlifting.com.au

With a carefully selected fleet of cranes, Buchanan Mobile Crane Hire has been servicing Victoria’s Mornington Peninsula, and surrounds, for over 30 years.

Buchanan Mobile Crane’s fleet is consistent with the businesses position in the market, and that’s being diverse and capable.

CICA MEMBER PROFILE

and grown with the business,” he says.

“As demand for our skilled services has increased, we have extended the fleet which now includes crawler cranes, crane trucks and larger capacity Franna pick and carry cranes and our most recent addition, our new Grove GMK 3060L 2023 model.

“The progression and continued renewal of our crane fleet has been driven by the diverse requirements of our clients,” says James.

James goes on to examine the evolution of the Buchanan Mobile Crane Hire fleet.

“We have predominately built our business on pick and carry cranes and small slewing cranes,” he says.

“With the Peninsula growing rapidly and with work sites getting smaller and harder to access I could see there was going to be a growing demand for this type of crane, and we would need to pitch our services at this market. I realised we needed a crane that would set up in a 6 metre by 6.5 metre square.

“In 2019 the business purchased an

older Kato 22H so we could utilise the versatility of an all-terrain crane and provide our clients with better outcomes on site and get a feel for the prospective market share of the larger capacity cranes,” James says.

“Today, our 20 tonne Franna and 25 tonne Franna are the bread and butter of our business. They are heavily utilised because they are suited to so many applications.”

“The Kato proved the point that a greater capacity crane with a small footprint was needed in the marketplace, and this led to the purchase of the Grove GMK 3060L this year. The Grove complements the cranes already in the fleet and we can now use the Frannas to set up the larger jobs that require the Grove,” he adds.

James says the new purchase is a key part of meeting client needs within Buchanan’s own fleet, rather than relying on other crane companies to supply a larger capacity crane.

“We now mitigate the frustration of

involving another business that doesn’t have the same level of attention to our clients as we have,” he says.

“We now run a small crane truck and a Maeda 355C. We have Frannas, an AT 20 and MAC 25SL and of course our star performer the Grove GMK 3060L. Our fleet is consistent with our position in the market, and that’s being diverse and capable. This is where our passion lies, we love a challenge and we have lift solutions for every problem.”

Buchanan’s is also a proactive member of the Crane Industry Council of Australia (CICA) – the accredited body representing the industry, and which provides the CraneSafe certification process which all its cranes undergo on an annual basis, James says.

“We then provide our clients with this accreditation which gives them the confidence that Buchanan Mobile Crane Hire complies with the National Standards of safety in our industry,” he says.

“CICA also is our first point of contact

20 / CAL September 2023 www.cranesandlifting.com.au CICA MEMBER PROFILE

The new Grove GMK 3060L complements the cranes already in the Buchanan Mobile Crane Hire fleet.

for advice and the annual conferences and workshops CICA provides gives us the opportunity to stay abreast of new technologies, information and network opportunities in our industry.”

BUCHANAN MOBILE CRANE HIRE PHILOSOPHY

The family business has thrived despite having to navigate some very uncertain economic times. This has been due largely to the family’s love and commitment to the industry and the dedication and expertise of the team.

“Our operators, our operational crew and backroom staff have a strong commitment to each other, and they are focused on the success of the company,” James says.

“Our business philosophy is one of commitment to the highest levels of service in the industry and this commitment is evident in the feedback we receive from our clients.

“We strive to meet the needs and requirements of all our clients, and we are focused on achieving excellence in everything we do. This benefits our clients, our business and the community.”

James adds that Buchanan’s mobile crane operators regularly provide a service that goes above and beyond client expectations.

“Our current operators come from a very extensive and skilled mechanical background with a wide knowledge base,” he says.

“Mitch ‘The Crane Doctor’ has years of experience in the crane industry and is passionate about cranes. We also have eager young operators and riggers keen to have the opportunity to grow their knowledge base through the guidance of our experienced team.”

James adds that the company’s larger client base means Buchanan’s Mobile Crane Hire often finds itself conducting specialised and diverse lifts requiring a high level of problem solving and lateral thinking.

“Our clients have high expectations, and our team approaches every job with the same level of enthusiasm and care providing the extra 1 percenters,” James says.

“This approach has given us our point of

difference in the crane hire market, which has led to many of our clients remaining loyal to our Buchanan Mobile Crane Hire for the 30 plus years we have been in business.

“Many clients have become personal friends and we are proud to have such a long association with many of them.”

Buchanan’s also works to serve the Mornington Peninsula community, actively

they are dealing with a considered and professional business,” James says.

“Our processes are focused on the safety and care when our operational staff are on site, and we are committed to providing the latest model machinery and technologies. Through the dedication of our team members, we have built a reputation for providing a reliable and high-quality service.

supporting local organisations, sporting clubs and local facilities, he says.

“Our commitment to serving our community has led to the company being held in high regard and our expertise and business ethics are readily acknowledged. We value our relationship with the local community greatly,” James says.

That said, James adds that establishing and maintaining client confidence in company processes and services is crucial.

“From the initial phone call clients know

“Our team is crucial to the success of the business, and we listen to their feedback relating to recent lifts and projects,” James adds.

“We then initiate staff participation in safety and quality improvement processes which continually drive improvements throughout the business. Transparent communication with our clients helps generate mutual respect and integrity with all our actions contributes to a healthy and happy workplace for all.”

September 2023 CAL / 21 www.cranesandlifting.com.au

“Buchanan’s is also a proactive member of the Crane Industry Council of Australia (CICA) – the accredited body representing the industry, and which provides the CraneSafe certification process which all its cranes undergo on an annual basis.”

Today, Buchanan Mobile Crane Hire’s 20 tonne Franna and 25 tonne Franna are the bread and butter of the business.

LIFTING SUCCESS: THE SIGNIFICANCE OF RELEVANT AND CURRENT WET/DRY HIRE AGREEMENTS IN THE CRANE INDUSTRY

CICA UNDERSTANDS THE CHALLENGES faced by small/medium business owners, which is why Paul and Justina CICA’s Membership Engagement Team have curated a series of interactive and comprehensive workshops to cover a range of vital topics, empowering small/medium businesses to navigate the dynamic business landscape with confidence.

These workshops will delve into various aspects critical to small/medium business growth, such as business strategies, financial management, customer relationship management, and effective leadership. Each workshop is designed to be highly engaging and incorporate group discussions, case studies, and real-life scenarios.

On 11 July 2023, CICA hosted its first ‘CICA Business Essentials’ (CBE) event at the Quest in Preston, Victoria - this was also live-streamed, so that members could gain from the content. Ping Gangur from Level Playing Field Lawyers delivered a presentation on the importance of relevant and current wet/ dry hire agreements. Ping highlighted that the risk and responsibility for cranes and equipment come down to the specific terms of the contract, so it is important to review these contracts carefully.

Ambiguity and misunderstandings can lead to disputes that can be both costly and time-consuming. A comprehensive wet/dry hire agreement serves as a roadmap, clearly defining the terms and conditions of the contract, such as payment terms, duration of hire, equipment specifications, and termination clauses. Clarity on these aspects fosters trust and prevents potential conflicts.

A well-drafted agreement can protect all parties from financial risks. For crane owners, it ensures that they receive

timely and fair compensation for their equipment and services. On the other hand, clients can rest assured that they will not be held liable for unforeseen damages or accidents if the crane and personnel are hired under the right terms and conditions.

Mutually beneficial relationships are the cornerstone of success in any industry. By having relevant and current wet/dry hire agreements, all parties demonstrate their commitment to professionalism and accountability. This

fosters trust and strengthens business relationships, encouraging repeat collaborations and positive word-ofmouth referrals.

CICA has developed wet and dry hire documents with a contract lawyer, and these have been customised for each State. CICA is currently working on a cross-hire agreement. CICA members can access these through the CICA Member Portal. If you have any queries, reach out to Paul Arztenhofer (paul@cica.com.au).

22 / CAL September 2023 www.cranesandlifting.com.au

CICA’s Membership Engagement Team have curated a series of interactive and comprehensive workshops to cover a range of vital topics.

CICA WORKSHOPS

pacecranes.com.au +61 2 9533 5411 sales@pacecranes.com.au

CRANES AND LIFTING PARTNERS WITH THE NATIONAL PRECAST ASSOCIATION

In an exciting development, Cranes and Lifting magazine and the National Precast Association

“The crane industry has an integral role to play in precast installation and it’s important we work together to raise the bar through appropriate standards and work practices. We are delighted to partner with Cranes and Lifting magazine as a way of sharing information with the crane industry.”

Cranes and Lifting magazine recognises the important role the National Precast Association holds within the construction sector, with almost every precast concrete construction project involving cranes in one way or another.

“We are thrilled to be partnering with the precast industry. The crane industry works very closely with precast concrete manufacturers, especially on major infrastructure projects and it makes total sense to reflect the activities of the association and its members in the magazine,” said business development manager, Emily Schlegel.

With the relationship, members of the association will receive a copy of Cranes and Lifting and the weekly newsletter, with regular editorial contributions featuring association news and member

projects in both

“The overarching aim of the relationship is to create more awareness of the challenges facing both the precast industry and the crane sector and help develop more communication and understanding between the two industry groups,” said Emily.

24 / CAL September 2023 www.cranesandlifting.com.au

“The crane industry has an integral role to play in precast installation and it’s important we work together to raise the bar through appropriate standards and work practices.”

Core Concrete was engaged by project builder Kapitol Group to supply a set of long-span load-bearing beams to make the $85 million project a reality. The innovative long span precast concrete beams reduce the requirements of vertical structure, and in turn frees the data center’s floorplates. A carefully designed system of super tee beams maximises server rack density by relocating vertical members to the building’s edges. Each load-bearing beam was designed to withstand a 15kPa (1.5 tonne/m2) load over a 20-metre clear-span.

As precast concrete is manufactured offsite in a factory-controlled environment, Hollow Core Concrete, like all National Precast Master Precasters, was able to deliver a consistently high-quality finish throughout all precast elements across the project. Furthermore, the offsite manufacturing process greatly reduces congestion of trades and materials’ delivers on the construction site.

The $85 million Next DC M2 project has been predicted to provide 300 new employment opportunities in both the Melbourne region and throughout the broader supply chain, this achievement has been driven by an innovative use of precast concrete.

PROJECT: NextDC M2 Tier IV Datacentre

LOCATION: Tullamarine, Victoria

MASTER PRECASTER: Hollow Core Concrete

CLIENT: NextDC

BUILDER: Kapitol Group

September 2023 CAL / 25 www.cranesandlifting.com.au

INNOVATING TO IMPROVE SAFETY

One National Precast Industry Partner is bringing innovation to the table. It’s a new panel connection system and it promises

safety while making precast installation even more cost effective and speedy.

ACCORDING TO NATIONAL PRECAST’S CEO

Sarah Bachmann, Partner Hagane Systems set out to overcome not only workingfrom-heights challenges during precast installation, but to also reduce the need for patching, hiring time for plant and props, and site welding traditional cast-in plateswhich are commonly used in the industry.

Traditional panel connections using cast-in plates require plates to be castin during the manufacturing process, at precise locations, so that when erected on site, the two plates marry. Threaded bolts are then used to connect the ‘stitch plate’ to the two cast-in plates, connections are welded and voids are patched. The panel joint is then able to be caulked.

Precast already offers construction a massive opportunity to improve productivity and efficiency, and Bachmann says this new system could be a game changer.

“Awareness is key and anything that can improve safety and speed of construction is something we need to help promote.”

WHAT IS THE NEW SYSTEM?

As with traditional cast-in plates, Hagane panel connectors are also cast-in during manufactrure. The difference is that these connectors are always located in the top corner of panels, which minimises installation difficulties.

During installation, grout tubes are filled with specified non-shrink grout, then pins are aligned as the connector is dropped into place. According to the company, the connection takes two minutes instead of the traditional forty-five to ninety minutes needed for

traditional connectors. No welding or patching are needed.

IMPRESSIVE RESULTS

Sarah says Hagane’s new system has the potential to increase the number of connections an installer can install up to one hundred in a day!

“That’s an impressive productivity improvement,” she said.

Extensively tested – with test results readily available - the new system provides engineers with client solutions that are structurally sound, cost effective and efficient.

HAPPY CUSTOMERS

Director at Matrix Consulting Engineers

Ray Buttigieg, says the system offers clients a way to save money and reduce construction time.

“After grasping the engineering concepts behind the system, which closely resemble our current design methods, it becomes relatively easy to present our clients the benefits and then impact it can have on their panel projects. Our team will be introducing and implementing Hagane panel connectors to all of our clients as ‘the new normal’ when it comes to future projects,” he remarks.

Meanwhile, Sebastian Canzoneri, Director at C3 Construction Group, says that the system has allowed his company to save money on plant and labour, with installers connecting panels in minutes, while eliminating welding and patching.

“And now our finished panels look cleaner than ever before,” he comments.

The Hagane Systems team will be travelling the country over the next couple of months to meet with builders, engineers and precasters to further discuss the systems, and offering complimentary re-designs for those who are interested in using the system on their next panel project.

For more information on when they are in your state, email Steven Adamic directly on steve@hagane.com.au.

to improve

26 / CAL September 2023 www.cranesandlifting.com.au

“Awareness is key and anything that can improve safety and speed of construction is something we need to help promote.”

ENGINES/ GEARBOXES DIFFERENTIALS/ TRANSFER CASES BARE/GLAZED CABS UPPER AND LOWER SERVICE EXCHANGE HYDRAULIC CYLINDERS BOOM SECTIONS/ FLYJIBS BEN BADEN SERVICES PTY LTD | PH (02) 9679 8333 | 43 HOLBECHE ROAD ARNDELL PARK 2148 MECHANICAL STRUCTURAL PAINTING MACHINING AND LINE BORING ENGINE AND TRANSMISSION OVERHAULS CASAR WIRE ROPE DISTRIBUTOR BEN BADEN SERVICES NO DOWNTIME! MOBILE CRANE REPAIRS COMPONENTS EXCHANGE PROGRAM DRY HIRE AVAILABLE WHILE YOUR CRANE IS BEING REPAIRED!

2 Heland Place Braeside VIC 3195 | 1300 686 626 | sales@gleason.com.au | www.gleason.com.au All terrain, crawler crane, tower crane, rough terrain and truck crane Dealer for: New Cranes Include: New Zoomlion ZCT900V 90 tonne Hydraulic Boom Crawler

HISTORY, TECHNOLOGY, SERVICE

WHILE TODAY GM CRANE HIRE HAS its feet firmly planted in the South Australian market, Yani Mihos admits to a few early doubts in 2016, when he was just venturing into the world of crane hire company ownership.

“When GM Crane Hire first started, we completed a host of projects on wind farms with our old 60-tonne Demag,” he reflects. “Initially it was a struggle; there wasn’t much work for us, and I really needed to think about the future of the business.”

Having started his career as an open ticket operator with Nick’s Crane Services in 2007, Yani had nearly 10 years of experience behind him, as well as a commitment to providing a standout service when he started the business. Fast forward seven years, and GM Crane Hire is now an established company undertaking services in residential and commercial construction as well as general crane hire services from its base in Adelaide, South Australia.

“We’ve now got five cranes in our fleet, and all our operations remain close to home,” says Yani. “I want to stay in the city because there’s so much work here, and I want to come home to my family at a reasonable time.”

A family-owned business –underlined by the ‘GM’ in the company’s name being a testimony to Yani’s late father George Mihos – the company is capable of completing big, heavy lifts, in tandem with small, dexterous lifts.

Today, with over 16 years of experience in the industry, Yani says he’s seen lots of changes over his time in and around cranes.

“Personally, the main thing that’s changed is the way technology has evolved in cranes,” he says. “Everything

is getting more and more advanced, and it’s all about enhancing safety and improving our ability to perform a lift.”

And, that’s never been more visible to Yani than in his company’s latest acquisition: a Tadano AC 3.060-1.

With the relationship between GM Crane Hire and Tadano inadvertently beginning when the Japanese manufacturers acquired the Demag brand back in 2019, the Adelaide-based crane hire company’s first experience with Tadano was back in 2022, when the company brought the first AC 4.080 to Australian shores. Having made the decision to purchase the crane in 2021, Yani’s 80-tonne all-terrain crane came

custom-painted in a two-tone grey livery and went straight to work in the local building and construction industries.

“Our first crane was a Demag, and all the old technicians there went to Tadano (after the acquisition),” says Yani. “I’m only a small operator in Adelaide, but every single one of them went out of their way to make sure I felt valued even though I was a nobody.”

“A crane is a crane, but what makes people feel valued is that post-product support service,” he continues. “I didn’t feel the need to look anywhere else because of that foundational relationship.”

When Yani’s original AC 60 tonne

IN FOCUS /TADANO September 2023 CAL / 29 www.cranesandlifting.com.au

Yani Mihos started Adelaide-based GM Crane Hire with one Demag Crane and a commitment to quality service. He talks his career, the evolution of the crane industry and his ongoing relationship with Tadano, seven years on.

Owner of family business GM Crane Hire Yani Mihos stands in front of his new Tadano AC 3.060 with his two children.

crane was decommissioned in late 2022, GM Crane Hire turned to Tadano for a replacement, a three-axle, 60-tonne capacity all-terrain crane delivered in early 2023. Yani highlighted the interchangeability of accessories between the two models as a key reason to stick with the Tadano brand.

“Extra accessories are expensive, and with a business like mine, we want to save money where we can,” he explains. “That’s one of the reasons we stayed with the Tadano brand; the fly extension, hooks, the lot really – it’s all just very interchangeable between machines, which helps us a lot.”

With a main boom length of up to 50 metres, with a further 16 metre extension on standby, the AC 3.060-1 thrives in high lifts in confined spaces. Due to its Flex Base system that allows less outrigger positioning, the all-terrain crane excels in spaces where versatility and manoeuvrability are required.

“Purchasing the 60-tonne crane

“We can place the outriggers wherever we want, which makes working in compact spaces so much easier – we’ve never worked with a crane that does that.”

allowed us to continue our work in general building lifts, formwork and steelwork,” says Yani. “It’s the area that we want to continue targeting, and our new all-terrain crane facilitates that.”

Powered by a Mercedes-Benz diesel engine, the crane complies with EU Stage V/Tier 4 emission restrictions and carries an AdBlue fuel tank –another option for reducing emissions through the treatment of exhaust gasses, catalysing the nitrous oxide and transforming it into nitrogen and water.

The AC 3.060-1 holds a maximum counterweight of 12.1 tonnes with the rigging system for the counterweights able to be set up outside of the cab via remote control. It can be operated by

just one person, with Yani labelling the crane as “very practical”.

“We can place the outriggers wherever we want, which makes working in compact spaces so much easier – we’ve never worked with a crane that does that,” he says. “Additionally, the computer system built within the Tadano ensures no matter where the outriggers are placed, we’ll be able to lift safely at maximum capacity.”

Yani is very complimentary of the Tadano’s capacity to enact lift plans onsite before operations begin, saying the data that it displays is “everything” he needs to know facilitate a safe lift.

“Back in the old days, nothing would stop us if something were to potentially

30 / CAL September 2023 www.cranesandlifting.com.au IN FOCUS / TADANO

One of the key selling points for Yani was the interchangeability between the features of his Tadano cranes.

go wrong,” he says. “With the new technology in these new ones, you can’t do that; there’s too many fail-safes, which is only a good thing.”

A key feature of operations at GM Crane Hire is safety. Underscoring its view that safety is paramount and something the company takes “very seriously”, the Adelaide company prepares Job Safety Analysis Reports and detailed lift studies prior to all its lifts, which it makes readily available to anyone engaging its services.

“We make sure we take everything into consideration,” says Yani. “Any potential hazard, anything that could potentially be unsafe – we want to make sure we’re covering all bases when we’re lifting something because we want everyone to go home safely.”

“Ultimately, our new Tadano helps us do exactly that.”

REGISTER NOW!

Platinum Sponsor:

The 60-tonne all-terrain crane’s counterweight system can be set up outside the superstructure via remote control.

The 60-tonne all-terrain crane’s counterweight system can be set up outside the superstructure via remote control.

DIVERSITY IN CONSTRUCTION AT INSIDE CONSTRUCTION EXPO

From September 20-21, Melbourne’s Convention and Exhibition Centre will be bustling with a range of key construction industry stakeholders.

INSIDE CONSTRUCTION EXPO, AN event dedicated to major commercial and civil projects in the Australian construction industry, aims to shine a spotlight on key industry issues such as skills shortages, automation and other digitisation, safety, and diversity in the industry.

Featuring a range of top-level speakers to address these issues, the event will tackle diversity in construction head on as it provides a platform for women who have made it in a traditionally male-dominated industry.

According to the Australian Government’s labour market insights published in June last year, 1,322,100 people were employed in the construction sector at that time. Of that total, only 13.3 per cent were

female, roughly totalling a miserly 176,000 workers. With a projected total of over 100,000 roles in construction currently going unfilled, according to a report from Arcadis Construction Costs, the time to address the gender diversity in the industry is now.“The crane industry’s average age is over 50 years old, and with that comes a lot of conservative attitudes on diversity and inclusivity in the workplace,” says co-owner and Business Manager of Quicklift Crane and Access Hire Karli Sutherland. “Women in the construction industry is one issue, but women in the crane industry is a topic in its own right; Inside Construction Expo will be a good forum to platform these ideas and challenge the preexisting norms.”

Set to speak on Inside Construction

Expo’s Women in Construction panel, Karli is a Board Director of The Crane Industry Council of Australia where she actively advocates for supporting women in non-traditional roles in the male-dominated industry.

“Inside Construction Expo will give us a chance to increase the visibility of diversity in the industry,” said Karli. “One part of the issue is for women to be supporting women, but it’s also up to our male counterparts to be champions for change in our industry. Everyone has a role to play in creating an inclusive culture.”

Her sentiments are echoed by the Australian Constructors Association’s CEO Jon Davies, who highlighted the need for change in cultural attitudes in the construction industry to attract a more gender-diverse workforce.

IN FOCUS / INSIDE CONSTRUCTION EXPO September 2023 CAL / 33 www.cranesandlifting.com.au

The National Association of Women in Construction (NAWIC) is also set to feature at the event. Formed in 1995, the not-for-profit organisation aims to help champion and empower women in the construction (and other adjacent) industries across a global network spanning the US, New Zealand, and Canada.

With a core policy of achieving a minimum of 25% per cent female participation across all construction by the end of 2025, NAWIC is attempting to achieve this by addressing pay disparities and improving workplace inclusion and safety to arrive at its ultimate objective: equity in female participation.

However, as Karli notes, gender disparity is only one part of the equation when it comes to tackling diversity in the construction industry. With other facets including

multiculturalism, accessibility and general inclusivity, Karli believes the more diverse a business’ profile is, the more chance it holds of bucking the norm and incorporating new ideas toward progress. According to a recent report by report by global management consultants McKinsey, companies are likely to be more profitable if they display a diverse, equitable, and inclusive workforce.

“Inside Construction Expo will give us a chance to send that message that everyone in the industry holds the capacity to make construction and the crane industry a more welcoming place,” she said.

“Every worker, manager, business owner can contribute toward diversifying the workforce and fostering new ideas of progress, and that’s what we want to discuss on the Women in Industry panel.”

FINALISTS OF THE AWARDS: Prime Creative Media, in partnership with a range of titles, will be hosting the inaugural Inside Construction Foundation Awards on September 20.

Set to take place at the Melbourne at Showtime Events Centre, at South Wharf in Docklands, the cocktailthemed evening will run from 7pm until late at night. The event will recognise and celebrate the construction industry, and the individuals working in the sector.

The awards will promote major construction and civil infrastructure contributions, with innovative major and local projects promoting standards pertaining to safety and environmental sustainability to be honoured.

34 / CAL September 2023 www.cranesandlifting.com.au IN FOCUS / INSIDE CONSTRUCTION EXPO

THE IMPORTANCE OF ELEVATED WORK PLATFORMS IN THE LIFTING SECTOR

CUTTING-EDGE LIFTING SOLUTIONS WITH MCT AND CIMOLAI

With a new facility in Henderson, WA, and a new partnership with Italian manufacturers Cimolai, MCT Equipment is ready to tackle the lifting industry head on.

AS THE AUSTRALIAN SUPPLIER OF Italian based Cimolai Technology, MCT Equipment proudly offers an extensive range of alternative lifting solutions that is set to redefine the local market.

With its expertise in providing solutions for large-scale construction, mining and infrastructure projects, it is committed to delivering equipment that prioritises safety, efficiency, and reliability.

“Partnering with Cimolai Technology has been a game-changer for MCT Equipment,” says Anthony Grosser, Managing Director at MCT Equipment. “With Cimolai’s expertise and our unwavering commitment to customer satisfaction, we can tailor solutions that suit the unique needs of our clients. We are changing the way heavy materials are handled and transported, empowering our clients to achieve unparalleled success.”

Cimolai Technology’s Rubber Tyre/Rail Gantry Crane range has become an industry

staple in large-scale construction projects. These cranes feature suspended beams and play a crucial role in handling existing structures and precisely placing new beams during in-situ construction. With an unwavering focus on safety and accuracy, these gantries provide the necessary lifting capabilities for demanding projects.

The Flat Bed Trolleys are designed for the convenient transportation of steel and concrete beams within and between construction sites. With a strong emphasis on reliability and efficiency, these flatbed trolleys offer an optimal solution for moving heavy materials, ensuring smooth operations and increased productivity.

The Self-Propelled Transporters are specifically designed for handling and transporting precast or reinforced blocks and beams. These transporters provide flexibility and manoeuvrability, enabling efficient movement of heavy materials within construction sites. With their

state-of-the-art design, these transporters streamline operations and contribute to overall project efficiency.

“We are thrilled to venture into the dynamic Australian market, hand in hand with our valued partner, MCT Equipment,” says Alberto Rosin, Sales Engineer at Cimolai Technology. “Bringing our state-of-the-art cranes, gantries, and lifting solutions to Australia represents a significant milestone for us.

“We are confident that our advanced technologies, combined with MCT Equipment’s deep understanding of the local industry, will empower Australian businesses to take on ambitious projects,” he adds.

“Together, we are eagerly embracing this new chapter, where innovation and collaboration will undoubtedly shape the future of market sectors in Australia.”

Visit mctequip.com.au to find out more.

IN FOCUS / MCT EQUIPMENT 36 / CAL September 2023 www.cranesandlifting.com.au

Rubber Tyre Gantry Crane utilised on prominent project in Western Australia.

DESIGNED FOR RENTAL

Skyjack’s vertical mast lifts with AC electric drive offer a quiet and versatile package with zero emissions.

www.skyjack.com

PRIME POSITION

AlmaCrawler continues to push the boundaries of what is possible, with its JIBBI 1890 PRiMO now recognised as the Hire and Rental Industry Association’s (HRIA) HIRE23Best New Product for Access Equipment.

THE AWARD, PRESENTED TO GENERAL Manager Bob Mules and CEO Andrea Artoni earlier this year, recognises true excellence and innovation. It focuses on new offerings across the industry with regards to modernising and enhancing technology, safety and performance.

Judged by an expert panel and voted on by HRIA members attending HIRE23, this accolade highlights the strengths of Almac’s strategic approach to research and development in order to lead the advancement of access equipment.

“Our customer-centric approach ensures that our equipment is engineered based on real-world scenarios. Our customers provide us with invaluable knowledge for product and design innovation and it is their feedback that ensures our machines are exceptional in functionality, reliability and

durability across diverse environments”, said Bob Mules, general manager, Almac Pacific.

Using 100 per cent Italian materials and technology, Almac stands true to its reputation for producing world-class access equipment that exceeds the required Australian and New Zealand standards. All machines are produced using Italian materials, in Italy, at Almac’s Viadana facilities in the province of Mantua. Constant research into new technologies and functions allows Almac to surge forward with exclusively unique and highperformance machines for the industry.

The JIBBI 1890 PRiMO (PRiMO) is a significant milestone for Almac as it introduces its first fully electric, selflevelling, tracked telescopic boom with electric drive. This innovative addition to

IN FOCUS / ALMACRAWLER 38 / CAL September 2023 www.cranesandlifting.com.au

AlmaCrawler’s JIBBI 1890 PRiMO was recently recognised as the Hire and Rental Industry Association’s (HRIA) HIRE23 - Best New Product for Access Equipment.

its product range was unveiled at the Hire and Rental Industry Association’s HIRE23 event in Sydney in May and represents the evolution of its renowned JT-Line.

Crafted to meet the demanding requirements of complex worksites, the PRiMO showcases an impressive 18-metre working height, enabling safe driving and automatic levelling at 14m on 15 degree lateral and longitudinal inclinations. What sets this telescopic boom apart is its exceptional versatility, allowing it to operate effectively on heavy, sloping and slippery terrains. With a total weight of 5,900kg, it holds the distinction of being the lightest 18m telescopic boom in the market. This remarkable feat is made possible by its design, which allows levelling of the chassis up to 15 degrees laterally and longitudinally without the use of outriggers. Moreover, the PRiMO features a generous 38cm ground clearance and low ground pressure, further enhancing its adaptability. The track width of 2.20m allows the machine to navigate with ease in narrow workspaces, providing flexibility in diverse work environments.

The PRiMO comes equipped with a 1.8m wide basket as a standard feature, which can rotate plus or minus 70 degrees, offering a maximum capacity of 250 kg. It presents two reach options: 9.9m in the 140kg working diagram and 8.3m in the 250kg working diagram. These capabilities enable

efficient and precise execution of tasks at varying heights and weight requirements.

Safety is a paramount concern at any worksite, and the PRiMO addresses this with its advanced safety features. The AntiEntrapment System is designed to prevent serious injuries by automatically stopping the machine and initiating a reverse trajectory for 3-5 seconds when a crushing injury is imminent. This system acts as a crucial safeguard, providing vital protection for operators and other personnel. In addition, Ultrasonic Anti-Collision Sensors are strategically placed to monitor the area above and below the basket, as well as the front and back of the tracks and the tail swing. This comprehensive sensor system ensures collisions are prevented, significantly reducing the risk of accidents.

The PRiMO offers three battery pack options, which are entirely removable and replaceable. These options include the ELC (Lead Acid 420Ah 48V), LTH 330 (Lithium 330Ah 48V), and LTH 440 (Lithium 440Ah 48V). This flexibility allows users to select the battery pack that best suits their specific needs and operational requirements.

To cater to evolving industry demands, the PRiMO features a redesigned controller with an Anti-Entrapment bar and comfortable joysticks, enhancing the user experience. This controller streamlines operations and ensures ease of use, making

the PRiMO a user-friendly machine for operators of all levels of expertise.