5 minute read

CICA Tech Corner

MULTI-CRANE LIFT LOAD SHARE

In this article, The Technical Committee of CICA takes a look at the issues relating to multi-crane lift load share.

MULTI-CRANE AND MULTI-HOOK LIFTING

arrangements or methods are sometimes used on lifting jobs when environmental restrictions; lifted object physical dimensions, characteristics, mass; or other factors - prevent the lifting operation from being performed by a single crane or single hoist.

When should you consider multiple crane lifts? In general, some of these considerations may determine when you would choose a dual crane lift (but not a blanket fixed set of rules): • where the load would be too heavy for a single crane to lift in the setup area available, or • where there is a large distance between lift point locations relative to boom length, which would impact on retaining pins, localised stress distribution and other elements of the crane.

Lifting operations using two or more cranes should be carried out in accordance with AS 2550.1:2011 and AS2550.5:2016. Due to the complicity of these types of lifts, a comprehensive documented lift procedure (AS2550.5:2016 Section 1.4.5) should be prepared for all multiple crane lifts, and if there is any doubt as to the capabilities of the crane or conformity of the lift planning in relation to applicable standards, then the lift should be considered as a designed lift.

Many factors need to be considered or assessed when planning multiple crane lifts. Risk assessment should be done considering the crane model, position of the crane, ground preparation, weather and environment conditions.

As well as the factors mentioned above, understanding the mass of the load, load center of gravity (CoG) and load share/distribution between the different cranes are the most important part of multiple crane lift planning. One aspect in the load share/distribution calculation that needs to be noted when lifting a load with multiple cranes – is that it is impossible to achieve perfectly synchronised motion between the different cranes when operated independently. The example below explains why.

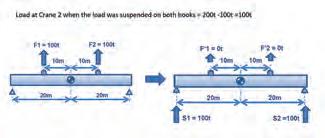

Two cranes are used to lift a long beam and place it on 2 support points. The weight of the load is 200t, the lifting lugs and support points are symmetrical on each side of the CoG of the load. Load share between the two cranes when the load was suspended on both cranes before setting down on ground is 100 t on each hook. If the load was lowered by both cranes simultaneously touching both support points, then load share for each crane went down from 100t to 0t at the same time.

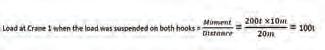

If the load was lowered by both cranes not simultaneously and one side set on support point first, then using load moment calculation method, load share will be:

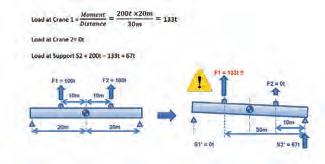

Compare with the scenario before, crane 1 is now taking 33 per cent more load. If crane 1 was selected based on the assumption that it only needs to take 100t of load, then the extra load on crane 1 could be greater than its rated capacity. This overload could occur due to a small variance in the multiple crane lift operation.

An interesting point here is in AS2550.1, other than a designed lift, the minimum capacity requirements for each crane shall apply by a safety margin, for two cranes, 20 per cent greater than the calculated share of the load, which is not adequate in this case. This is why each

multiple crane lift using mobile cranes requires a documented lift procedure that involves detailed engineering study.

One way to counteract the impact of landing the load, is to move the lifting points outward or moving the landing points inward. If the lifting points are moved outward the increase in Crane 1 loading is 14 per cent. This is within the 20 per cent margin for the calculated share of the load.

In the example above, the position of the CoG of the load is at the same distance from both cranes, if for example, the CoG is actually not in the middle, it is 5m from crane 1 and 15m from crane 2, then load share on crane 1 (when the load was suspended on both hooks) increases from 100t to 150t. It is important to establish an accurate location of the CoG for load share calculation, otherwise the load share can change dramatically.

Some years ago, tests were done to show that using load equalisation equipment (i.e., a snatch block) could optimise load sharing among multilegged sling arrangements. The use of devices such as equaliser beams or balancer plates can also help to reduce the risk of unintended load distribution of the cranes due to uncoordinated vertical movements by equalising the loads on several hoist lines when making multiple lifts. The selection or design of the equaliser beams or balancer plates should be included in the engineering/ planning of the lift. The dimension and the geometry of the equipment should be considered in the design.

Multiple crane lifts are complicated lifting operations, it is important to have proper planning in place prior to the lift. The International Crane Stakeholders Assembly (ICSA) published a guidance note on “Lifting A Load with Several Mobile Cranes (Multiple Crane or Tandem Lifting)”, which provides guidance in the assessment of risks and contains information related to the use of mobile cranes for multiple crane lifting where the cranes are operated separately under control of more than one operator. CICA is an active member of ICSA and the CICA technical committee contributes to the development of ICSA technical documents. ICSA guidance notes can be accessed from CICA website.

Lifting operations using two or more cranes should be carrie out in accordance with the recommended procedures.